hood release MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 214 of 408

CHASSIS ELECTRICAL 6-11

45. Install the heater hoses under the hood.

46. Install the mstrument panel by reversing its

removal procedure.

47. Install the center console.

48. install the upper and lower steering column

covers.

49. Install the center panel undercover.

50. Install the small column panel.

51. Install the steering wheel.

52. Fill the cooling system.

53. Connect the negative battery cable and check

the entire climate control system for proper operation

and leaks.

Mirage

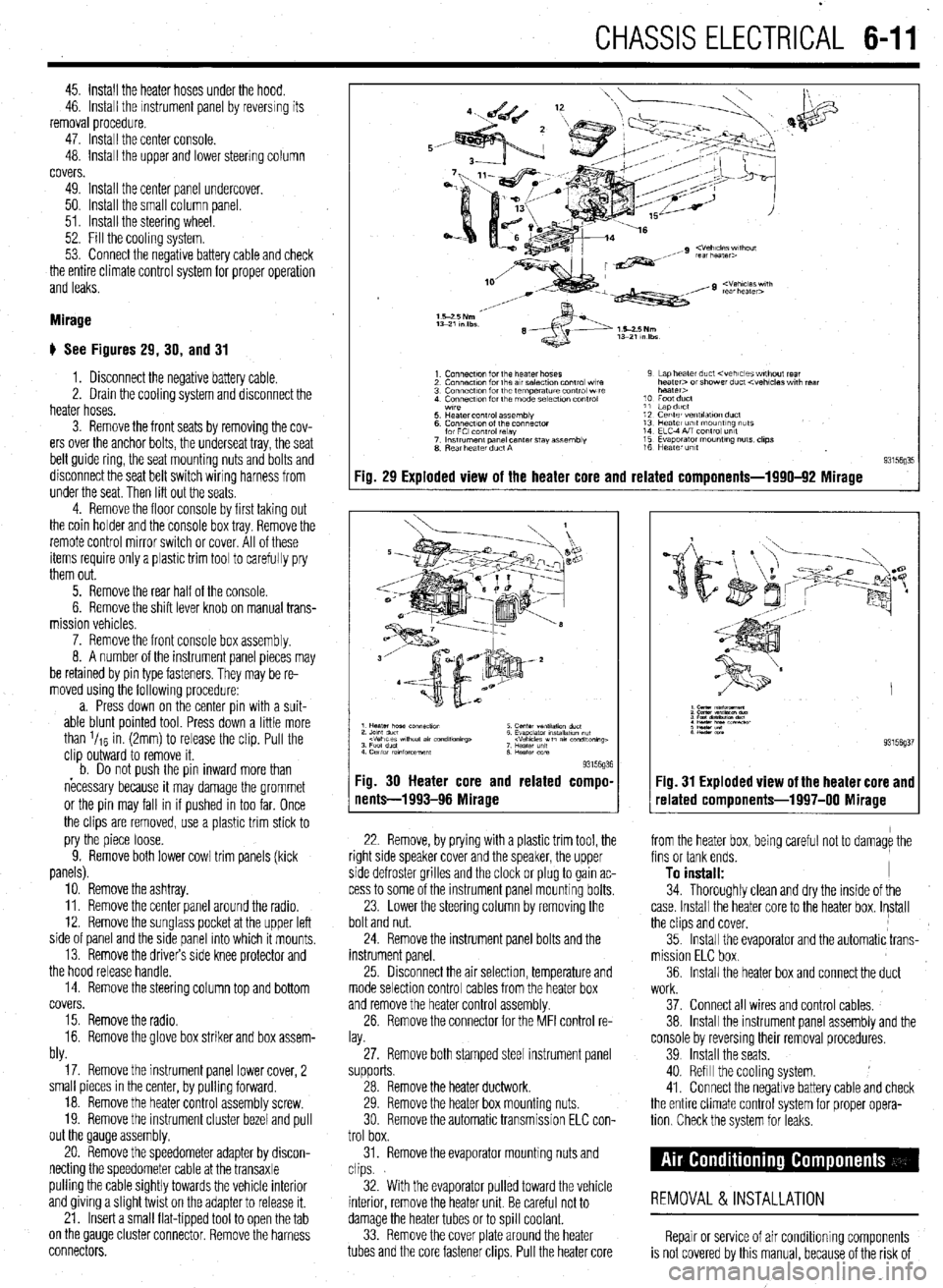

# See Figures 29, 30, and 31

1. Disconnect the negative battery cable.

2. Drain the cooling system and disconnect the

heater hoses.

3. Remove the front seats by removing the cov-

ers over the anchor bolts, the underseat tray, the seat

belt guide ring, the seat mounting nuts and bolts and

disconnect the seat belt switch wiring harness from

under the seat. Then lift out the seats

4. Remove the floor console by first taking out

the coin holder and the console box tray. Remove the

remote control mirror switch or cover. All of these

items require only a plastic trim tool to carefully pry

them out.

5. Remove the rear half of the console.

6. Remove the shift lever knob on manual trans-

mission vehicles.

7. Remove the front console box assembly.

8. A number of the instrument panel pieces may

be retamed by pin type fasteners. They may be re-

moved using the following procedure:

a. Press down on the center pin with a suit-

able blunt pointed tool. Press down a little more

than l/re in. (2mm) to release the clip. Pull the

clip outward to remove it.

b. Do not oush the oin inward more than

necessary because it may damage the grommet

or the pin may fall in if pushed in too far. Once

the clips are removed, use a plastic trim stick to

pry the piece loose.

9. Remove both lower cowl trim panels (kick

panels).

10. Remove the ashtray.

11. Remove the center panel around the radio.

12. Remove the sunglass pocket at the upper left

side of panel and the side panel into which it mounts,

13. Remove the drivers side knee protector and

the hood release handle.

14. Remove the steering column top and bottom

covers.

15. Remove the radio.

16. Remove the glove box striker and box assem-

bly.

17. Remove the instrument panel lower cover, 2

small pieces in the center, by pulling forward.

18. Remove the heater control assembly screw.

19. Remove the instrument cluster bezel and pull

out the Qauge assembly.

20. Remove the speedometer adapter by discon-

necting the speedometer cable at the transaxle

pulling the cable Sightly towards the vehicle interior

and giving a Slight twist on the adapter to release it.

21. Insert a small flat-tipped tool to open the tab

on the QauQe cluster connector. Remove the harness

connectors.

Fig. 29 Exploded view of the heater core and related components-1990-92 Mirage

93l%Q% Fig. 30 Heater core and related compo-

nents-1993-96 Mirage

22. Remove, by prying with a plastic trim tool, the

right side speaker cover and the speaker, the upper

side defroster grilles and the clock or plug to gain ac-

cess to some of the instrument panel mounting bolts.

23. Lower the steering column by removing the

bolt and nut.

24. Remove the instrument panel bolts and the

instrument panel.

25 Drsconnect the air selection, temperature and

mode selection control cables from the heater box

and remove the heater control assembly.

26. Remove the connector for the MFI control re-

lay.

27. Remove both stamped steel instrument panel

supports.

28. Remove the heater ductwork.

29. Remove the heater box mounting nuts.

30 Remove the automatic transmission ELC con-

trol box.

31. Remove the evaporator mounting nuts and

clips.

32. With the evaporator pulled toward the vehicle

interior, remove the heater unit. Be careful not to

damage the heater tubes or to spill coolant.

33. Remove the cover plate around the heater

tubes and the core fastener clips. Pull the heater core 34. Thoroughly clean and dry the inside of the

case. Install the heater core to the heater box. Install

the clips and cover,

35. Install the evaporator and the automatic trans-

mission ELC box.

36. Install the heater box and connect the duct

Fig. 31 Exploded view of the heater core and

related components-1997-00 Mirage

from the heater box, being careful not to damage the

fins or tank ends.

To install: I

work.

37. Connect all wires and control cables,

38. Install the instrument panel assembly and the

console by reversmg their removal procedures.

39 Install the seats.

40. Refill the cooling system.

41. Connect the negative battery cable and check

the entire climate control system for proper opera-

tion Check the system for leaks.

REMOVAL &INSTALLATION

Repair or service of air Conditioning components

is not covered by this manual, because of the risk of

Page 220 of 408

CHASSIS ELECTRICAL 647

3. Remove the windshield wiper arms by un-

screwing the cap nuts and lifting the arms from the

linkage posts.

4. Remove the front deck garnish assembly.

Iver.

xl harness plug from

,I6 #-n\,LIr 5. Remove the air inlet c(

6. Disconnect the electric

the wiper motor.

7. Remove the access ho,, LIVIGil. To install:

5. Install the motor and install the retaining bolts.

6. Install the wiper arm so that the arm is 3.35

inches (85mm) between the measurement points,

when parked. Secure the wiper arm with the retaining

nut.

*Before proceeding, connect the battery and

8. Remove the wiper motor mounting bolts.

9. Detach the motor crank arm from the wiper

linkane and remnve the mntnr

motor has been factory set. Do not remove

them unless necessary. if they must be re-

moved, remove them only after marking their

mounting positions. check the operation of the motor. if satisfae-

tory, disconnect the cable and complete the

installation.

o. WIIIIW LIE Il~&WVt: vatreryoable and recheck

the system for proper operation.

..-

a- - ‘- _ _ _ . _ _ _

*The installation angle of the crank arm and 7. Install the interior trim piece

n II ^_^^^ IAL- -^I-I:..- L-AL--

To install:

10. Install the windshield wiper motor and con-

REMOVAL&INSTALLATION nect the linkage.

I 14. Install the front deck garnish assembly. I. YIV”“I1IIYVL VI” “UyuL’.” “UL’“‘, UUUIU. 2. Remove the windshield washer fluid resarvnir

’ 11. Attach the electrical harness plug.

12. Install the access hole cover.

13. Install the air inlet cover.

15. Reinstall the wiper arm and tighten the

mounting nuts to 14 ft. Ibs. (19 Nm). Install the arms

so the blades are parallel to the garnish molding -

Front and Rear

1 nivnnnprt the nonatiua haltorv rahlo

3. Drain any washer fluid in the reservoir into an

appropriate container.

4.

I when parked. Remove the pump from the reservoir by either

16. Connect the neaative batterv cable and check removing the retaining hardware or twisting gently

tlntil it is frpp frnm thP rosorvnir the wiper system for proper operation.

lo Install:

5. Inspect the pump seal on the reservoir, replace

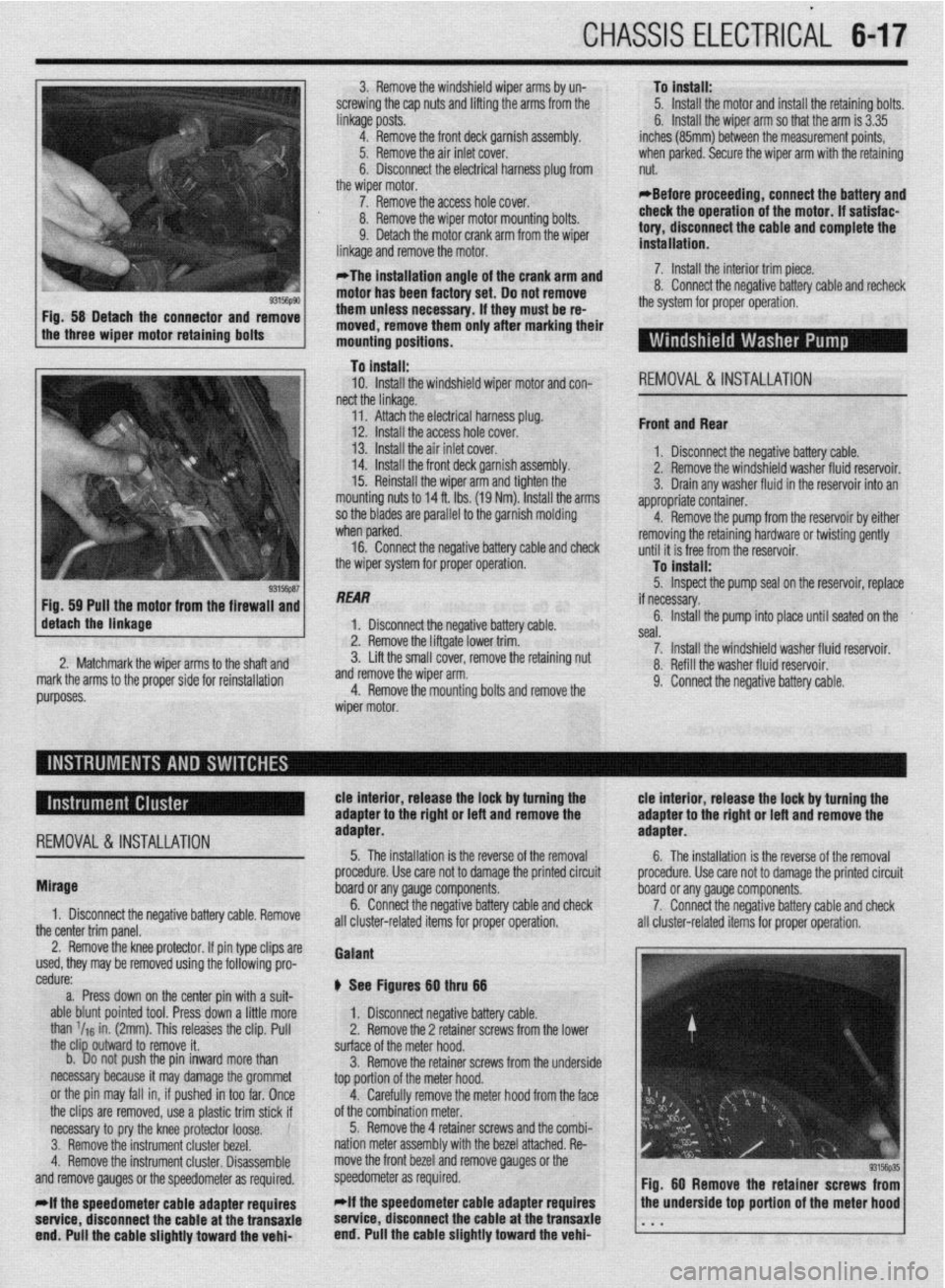

/ de&h the linkage Fig 59 Pull the motor from the firewaii and

“‘%‘y 1 ““I”“,,,,,, the if necessary.

1 1 Disconn& thP rwnativo hatton/ rahlm 6. Install the pump into place until seated on the .I,” ~‘“p.L’,” YULL”‘, -YI”. liftgate lower trim. seal.

3: Lift the smatr CUVBI, I~IIIUV~ tilt: lfAdllllll~ IIUL II --. .-- -^- ^..^ .L^ -_,_:..:-- -.A 7. Install the windshield washer fluid reservoir. 2. Matchmark the wirier arms tn the shaft and A Refill thp wxhpr fllk-l rpqprvnir markthe arms to the proper side for reinstallation and remove the wiper arm.

4. Remove the mountina bolts and remove the “. .,“...S .V.” ....“III. ,*..*” IYUY..“m,.

9. Connect the negative battery cable.

REMOVAL&INSTALLATION

tie interior, release the lock by turning the tie interior, release the lock by turning the

adapter to the right or left and remove the adapter to the rigM or left and remove the

adapter. adapter.

5. The installation is the reverse of the removal

6. The installation is the reverse of the removal

Mirage

1. Disconnect the negative battery cable. Remove

the center trim panel. procedure. Use care not to damage the printed circuit procedure. Use care not to damage the printed circuit

board or any gauge components.

board or any gauge components.

6. Connect the negative battery cable and check

7. Connect the negative battery cable and check

all cluster-related items for proper operation. i III cluster-related items for proper operation.

2. Remove the knee protector. If pin type clips are

used, they may be removed using the following pro-

cedure:

a. Press down on the center pin with a suit-

able blunt pointed tool. Press down a little more

than ‘IIS in. (2mm). This releases the clip. Pull

the clip outward to remove it.

b. Do not push the pin inward more than

necessary because it may damage the grommet

or the pin may fall in, if pushed in too far. Once

the clips are removed, use a plastic trim stick if

necessary to pry the knee protector loose.

3. Remove the instrument cluster bezel.

4. Remove the instrument cluster. Disassemble

and remove gauges or the speedometer as required.

*if the speedometer cable adapter requires

setvice, disconnect the cable at the transaxie

end. Pull the cable slightly toward the vehi- Gaiant

@ See Figures Bg thru 66

1. Disconnect negative battery cable.

2. Remove the 2 retainer screws from the lower

surface of the meter hood.

3. Remove the retainer screws from the underside

top portion of the meter hood.

4. Carefully remove the meter hood from the face

of the combination meter.

5. Remove the 4 retainer screws and the combi-

nation meter assembly with the bezel attached. Re-

move the front bezel and remove gauges or the

speedometer as required.

*if the speedometer cable adapter requires

service, disconnect the cable at the transaxie

end. Pull the cable slightly toward the vehi-

Page 221 of 408

.

6-18 CHASSIS ELECTRICAL

Fig. 64 Grasp the instrument cluster and

carefully pull it out of the instrument panel tached; the cluster has sockets on the back Fig. 66 . , .

these sockets engage connec-

tors solidly mounted behind the cluster

Diamante

1. Disconnect the negative battery cable.

*If equipped with an air bag, be sure to dis-

arm it before entering the vehicle.

2. Remove the hood lock release handle and

switches from the knee protector below the steering

column. Then remove the exposed retaining screws

and remove the knee protector.

3. Remove the upper and the lower steering col-

umn covers.

4. Remove the instrument cluster bezel.

5. Remove the instrument cluster. Disassemble

and remove gauges or the speedometer as required.

*If the speedometer cable adapter must be

serviced. disconnect the cable at the

transaxle end. Pull the cable slightly toward

the vehicle interior, release the lock by turn-

ing the adapter to the right or left and remove

the adapter.

6. The installation is the reverse of the removal

procedure. Use care not to damage the printed circuit

board or any gauge components,

7. Connect the negative battery cable and check

all cluster-related items for proper operation.

REMOVAL &INSTALLATION

I

b See Figures 67, 66, 69, and 70

83156pD6 Fig. 69 Remove the gauge retaining screws Fig. 70 . . . then carefully lift the gauges

from the instrument cluster to remove them

Page 281 of 408

7-2 'DRIVETRAIN

Because of the way an internal combustron engine

breathes, it can produce torque, or twisting force,

only within a narrow speed range. Most modern,

overhead valve pushrod engines must turn at about

2500 rpm to produce their peak torque By 4500 rpm

they are producrng so lrttle torque that contrnued in-

creases in engine speed produce no power increases.

The torque peak on overhead camshaft engines IS

generally much higher, but much narrower.

The manual transaxle and clutch are employed to

vary the relationship between engine speed and the

speed of the wheels so that adequate engine power can

be produced under all crrcumstances. The clutch al-

lows engine torque to be applied to the transaxle input

shaft gradually, due to mechanical slippage. Conse-

quently, the vehicle may be started smoothly from a

full stop The transaxle changes the ratio between the

rotating speeds of the engine and the wheels by the

use of gears. The gear ratios allow full engine power to

be applied to the wheels during acceleration at low

speeds and at highway/passing speeds.

In a front wheel drive transaxle, power is usually

transmitted from the input shaft to a mainshaft or out-

put shaft located slightly beneath and to the side of

the input shaft. The gears of the mainshaft mesh with

gears on the input shaft, allowing power to be carried

from one to the other. All forward gears are in con-

stant mesh and are free from rotating with the shaft

unless the synchronizer and clutch IS engaged. Shaft-

ing from one gear to the next causes one of the gears

to be freed from rotating with the shaft and locks an-

other to it. Gears are locked and unlocked by internal

dog clutches which slide between the center of the

gear and the shaft. The forward gears employ syn-

chronizers; friction members which smoothly bring

gear and shaft to the same speed before the toothed

dog clutches are engaged.

SHIFT LINKAGE

1. Disconnect the shift linkage from the transaxle.

2. On the transaxle, put select lever in N and

move the shift lever in

4th gear. Depress the clutch,

if necessary, to shift.

3. Move the shift lever in the vehicle to the

4th gear position until it contacts the stop.

4. Turn the adjuster turnbuckle so the shift cable

eye aligns with the eye in the gear shift lever. When

installing the cable eye, make sure the flange side of

the plastic bushing at the shift cable end is on the

cotter pin side.

5 The cables should be adjusted so the clear-

ance between the shift lever and the 2 stoppers are

equal when the shift lever IS moved to 3rd and 4th

gear. Move the shift lever to each positron and check i

that the shifting is smooth

REMOVAL &INSTALLATION

1, Disconnect the negative battery cable 2. Remove any components necessary to access

the back-up light switch.

3. Unplug the back-up light switch connector.

4. Remove the switch from the case using the ap-

propriate size socket and drive tool.

To install: 5. Install the switch and tighten it to 22-25 ft. Ibs.

(30-35 Nm).

6. Attach the back-up light switch connector

7. Install any components removed to access the

back-up light switch

8. Connect the negative battery cable.

REMOVAL & INSTALLATION

Mirage

*If the vehicle is going to be roiled while the

halfshafts are out of the vehicle, obtain 2 outer

CV-joints or proper equivalent tools and install

to the hubs. If the vehicle is rolled without the

proper torque applied to the front wheel bear-

ings, the bearings will no longer be usable.

*The suspension components should not be

tightened until the vehicles weight is resting

on the ground.

1. Remove the battery and battery tray.

2. Remove the air cleaner assembly and vacuum

hoses.

3. Note the locations and disconnect the shifter

cables.

4. If equipped with 1.61 engine, remove the ten-

sion rod.

5. Detach the backup lamp switch connector,

speedometer cable connection and remove the starter

motor.

6. Raise the vehicle and support safely.

7. Remove the front wheels and the inner wheel

panels.

8. Remove the undercover and splash pan.

9. Drain the transaxle oil into a suitable con-

tainer

10. Support the engine and remove the cross-

member.

11. Remove the upper transaxle mounting bolt

and bracket.

12 Disconnect the stabilizer bar, tie rod ends and

the lower ball joint connections.

13 Remove the clutch release cylinder and clutch

oil line bracket. Do not disconnect the fluid lines and

secure the slave cylinder with wire.

14 Disconnect the clutch cable, if equipped with

cable controlled clutch system.

15. Remove the halfshafts by inserting a prybar

between the transaxle case and the driveshaft and

prying the shaft from the transaxle. Do not pull on the

driveshaft Doing so damages the inboard joint. Do

not insert the prybar so far the oil seal in the case is

damaged.

*It is not necessary to disconnect the half-

shafts from the steering knuckle. Remove the

shaft with the hub and knuckle as an assem-

bly. Tie the shafts aside. Note the circle clip

on the end of the inboard shafts should not

be reused.

16. Remove the bellhousing lower cover.

17 Remove the transaxle to engine bolts and

lower the transaxle from the vehrcle.

To install:

*When installing the transaxle, be sure to

align the splines of the transaxle with the

clutch disc.

18 Install the transaxle to the engine and install

the mounting bolts. Tighten the bolts to 31-40 ft. Ibs.

(43-55 Nm) on 1990-92 models and 35 ft. Ibs. (48

Nm) on 1993-00 models.

19 Install the bellhousing cover.

*When installing the halfshafts, use new

circlips on the axle ends. Care must be taken

to ensure that the oil seal lip of the transaxle

is not damaged by the serrated part of the

driveshaft.

20. Install and fully seat the halfshafts into the

transaxle.

21. Install the slave cylinder.

22. Connect the ball joints, tie rod ends and the

stabilizer bar connections.

23. Install the upper transaxle mounting bracket

and bolt.

24. Install the crossmember.

25. Install the undercover.

26. Install the upper transaxle-to-engine mount-

ing bolts, Tighten the bolts to 31-40 ft. Ibs. (43-55

Nm) on 199C-92 models and 35 ff. Ibs. (48 Nm) on

1993-00 models.

27. Install the starter motor.

28 Connect the backup light switch connector

and speedometer cable.

29 Connect and adjust the shifter cables.

30 Install the air cleaner assembly.

31. Install the front wheels.

32 Make sure the vehicle is level when refilling

the transaxle Use Hypoid gear oil or equivalent, GL-

4 or higher.

33. Connect the negative battery cable and check

the transaxle for proper operation. Make sure the re-

verse lights operate when in reverse.

Galant

1999-93 MODELS

rlf the vehicle is going to be rolled on its

wheels while the halfshafts are out of the ve-

hicle, obtain two outer CV-joints or proper

equivalent tools and install to the hubs. If the

vehicle is rolled without the proper torque

applied to the front wheel bearings, the bear-

ings will no longer be usable.

1. Remove the battery and the air intake hoses.

2. If equipped with Active-ECS, unplug the

compressor wiring.

3. Remove the auto-cruise actuator and under-

hood bracket, located on the passenger side inner

fender well.

4. Drain the transaxle and transfer case fluid, if

equipped, into a suitable waste container.

5. Remove the retainer bolt and pull the

speedometer cable from the transaxle assembly.

6. Remove the cotter pin securing the select and

shift cables and remove the cable ends from the

transaxle.

Page 288 of 408

DRIVETRAIN 7-9

*When adjusting the clutch pedal height or

the clutch pedal clevis pin play, be careful

not to push the pushrod toward the master

cylinder.

d. Check that when the clutch pedal is de-

pressed all the way, the interlock switch switches

over from ON to OFF.

ADJUSTMENT

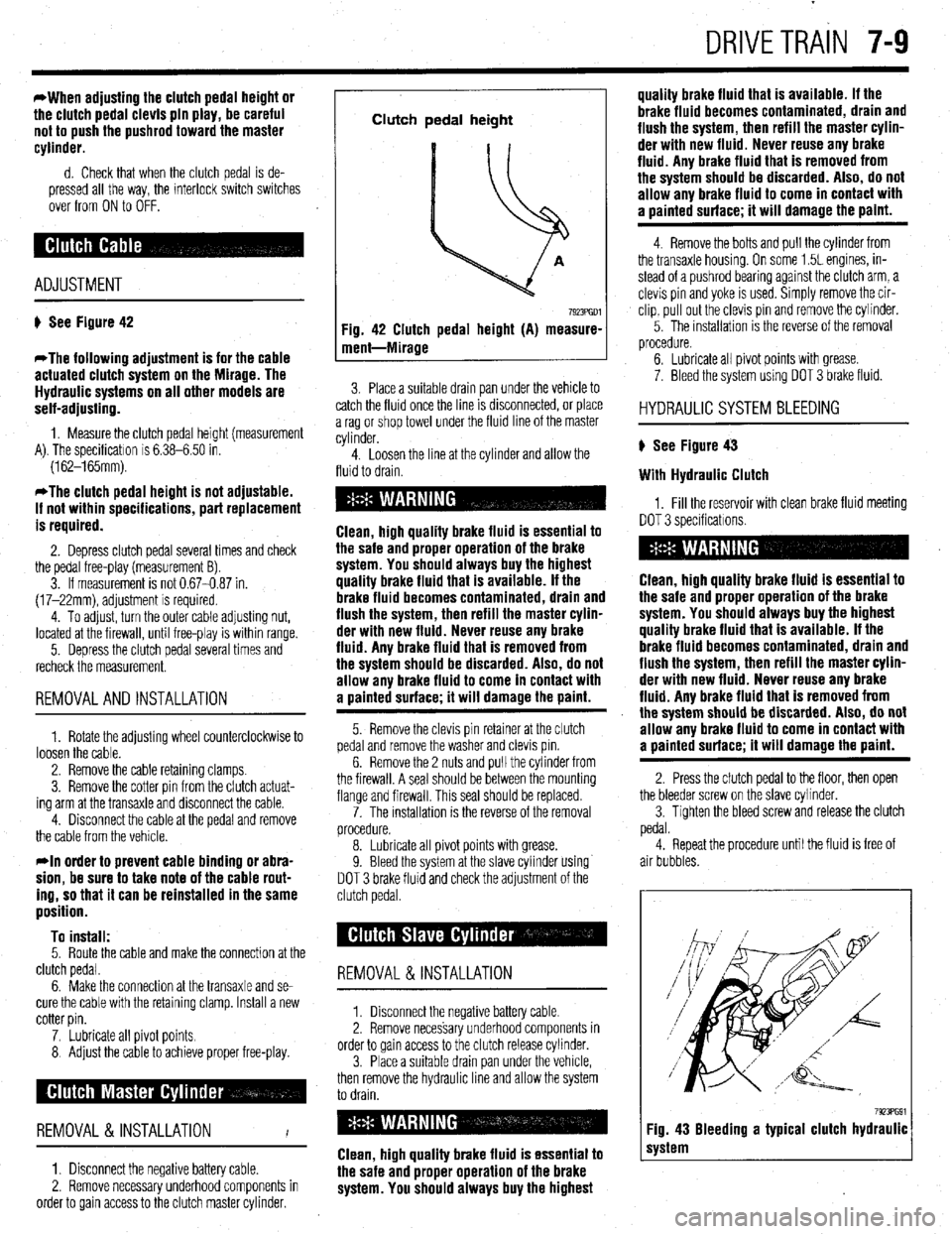

# See Figure 42

*The following adjustment is for the cable

actuated clutch system on the Mirage. The

Hydraulic systems on all other models are

self-adjusting.

1. Measure the clutch pedal height (measurement

A). The specificatron is 6.38-6.50 in.

(162-165mm).

*The clutch pedal height is not adjustable.

If not within specifications, part replacement

is required.

2. Depress clutch pedal several times and check

the pedal free-play (measurement B).

3. If measurement is not 0.67-0.87 in.

(17-22mm), adjustment is required.

4. To adjust, turn the outer cable adjusting nut,

located at the firewall, until free-play is within range.

5. Depress the clutch pedal several times and

recheck the measurement.

REMOVALANDINSTALLATION

1. Rotate the adjusting wheel counterclockwise to

loosen the cable.

2. Remove the cable retaining clamps.

3. Remove the cotter pin from the clutch actuat-

ing arm at the transaxle and disconnect the cable.

4. Disconnect the cable at the pedal and remove

the cable from the vehicle.

rln order to prevent cable binding or abra-

sion, be sure to take note of the cable rout-

ing, so that it can be reinstalled in the same

position.

To install:

5. Route the cable and make the connection at the

clutch pedal.

6. Make the connection at the transaxle and se-

cure the cable with the retaining clamp. Install a new

cotter pin.

7. Lubricate all pivot points.

8 Adjust the cable to achieve proper free-play.

REMOVAL &INSTALLATION

I

1. Disconnect the negative battery cable.

2. Remove necessary underhood components in

order to gain access to the clutch master cylinder.

Clutch pedal height

Fig. 42 Clutch pedal height (A) measure-

ment-Mirage

7923PGDl

3. Place a suitable drain pan under the vehicle to

catch the fluid once the line IS drsconnected, or place

a rag or shop towel under the fluid line of the master

cylinder.

4. Loosen the line at the cylinder and allow the

fluid to drain.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a oainted surface; it will damage the paint.

5. Remove the clevis pin retainer at the clutch

pedal and remove the washer and clevis pm.

6. Remove the 2 nuts and pull the cylinder from

the firewall. A seal should be between the mounting

flange and firewall. This seal should be replaced.

7. The installation is the reverse of the removal

procedure.

8. Lubricate all pivot points with grease.

9. Bleed the system at the slave cylinder using

DOT 3 brake fluid and check the adjustment of the

clutch pedal.

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable

2. Remove necessary underhood components in

order to gain access to the clutch release cylinder.

3. Place a suitable drain pan under the vehicle,

then remove the hydraulic line and allow the system

to drain.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a uainted surface; it will damage the paint.

4. Remove the bolts and pull the cylinder from

the transaxle housing. On some 1.5L engines, in-

stead of a pushrod bearing against the clutch arm, a

clevis pin and yoke is used. Simply remove the cir-

clip, pull out the clevis pin and remove the cylinder.

5. The installation IS the reverse of the removal

procedure.

6. Lubricate all pivot points with grease.

7. Bleed the system using DOT 3 brake fluid.

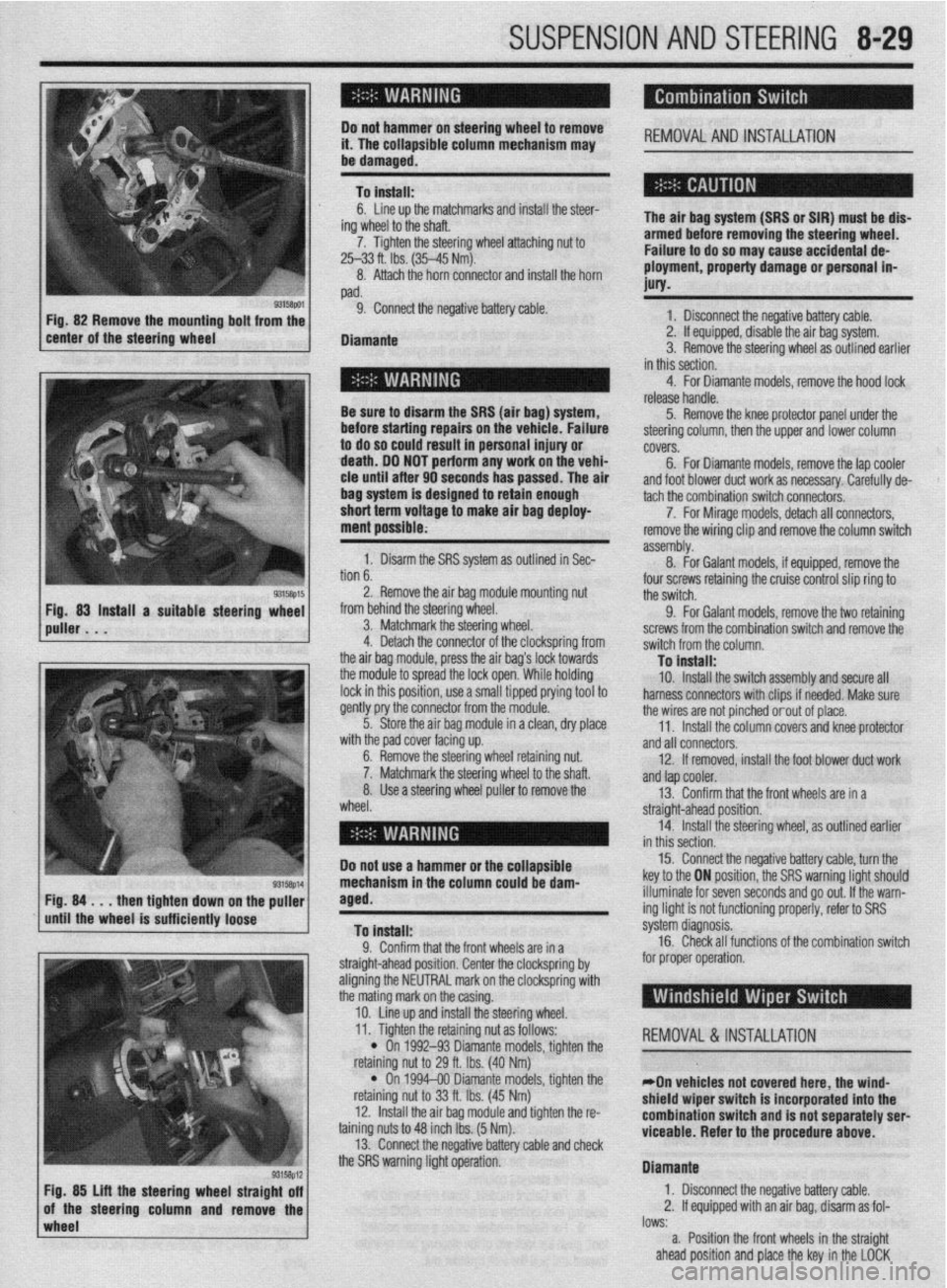

HYDRAULIC SYSTEM BLEEDING

) See Figure 43

With Hydraulic Clutch

1, Fill the reservoir with clean brake fluid meeting

DOT 3 specificatrons.

Clean, high quality brake fluid is essential to

the safe and proper operation of the brake

system. You should always buy the highest

quality brake fluid that is available. If the

brake fluid becomes contaminated, drain and

flush the system, then refill the master cylin-

der with new fluid. Never reuse any brake

fluid. Any brake fluid that is removed from

the system should be discarded. Also, do not

allow any brake fluid to come in contact with

a painted surface; it will damage the paint.

2. Press the clutch pedal to the floor, then open

the bleeder screw on the slave cvlinder.

3. Tighten the bleed screw and release the clutch

pedal.

4. Repeat the procedure until the fluid is free of

air bubbles.

7923PG91 Fig. 43 Bleeding a typical clutch hydraulic

system

Page 325 of 408

SUSPENSION AND STEERING 8-29

i ’

Do not hamme i4 l-ha nnlhnr !r on steering wheel to remove

,,. , II= ,,,,,,Jfble column mechanism may REMOVALANDINSTALLATION

I

be damaged.

To install:

ing

7.

6. Line up the matchmarks and install the steer-

/heel to the shaft.

Tighten the steering wheel attaching nut to

25-33 ft. Ibs. (35-45 Mm).

8. Attach the horn connector and install the horn

pad.

9. Connect the negative battery cable.

Diamante The air bag system (SRS or SIR) must be dis-

armed before removing the steering wheel.

Failure to do so may cause accidental de-

ployment, property damage or personal in-

MY.

1 Rscnnnnd the nnmtivn hattm rJhle . I._“” . ..I_. . ..I *.-~ _...” ““.‘“‘, _““._. 2. If equipped, disable the air bag system.

3. Remove the steering wheel as outlined earlier

in this section.

Be sure to disarm the SRS (air bag

before starting repairs OI

to do so could result in p

death. DO NOT perform ;

cle until after 90 seconds has passed. The ai

bag system is designed to retain enough

short term voltage to make air bag deploy-

ment possible; I) system,

n the vehicle. Failure

lersonal injury or

any work on the vehi-

ir 4. For Diamante models, remove the hood lock

release handle.

5. Remove the knee protector panel under the

steering column, then the upper and lower column

covers.

6. For Diamante models, remove the lap cooler

and foot blower duct work as necessary. Carefully de-

non

b. 1. Disarm the SRS system as outlined in Sec-

. . ^ I assembly. tach the combination switch connecto&.

8. -

7. For Mirage models, detach all connectors,

For Galant models, if equipped, remove the remove the wiring clip and remove the column switch

2. Remove the air bag module mounting nut

from behind the steering wheel.

3. Matchmark the steering wheel.

4. Detach the connector of the clockspring from

the air baq module, press the air baa’s lock towards four screws retaining the cruise control slip ring to

the switch.

9. For Galant models, remove the two retaining

screws from the combination switch and remove the

switch from the column.

Tn install: the modub to spread the lock open:While holding

lock in this position, use a small tipped prying tool to

gently pry the connector from the module.

5. Store the air bag module in a clean, dry place

..# ,I I I .

ut.

Iaft. wlrn me paa cover racmg up.

6. Remove the steering wheel retaining nl

7. Matchmark the steering wheel to the sl

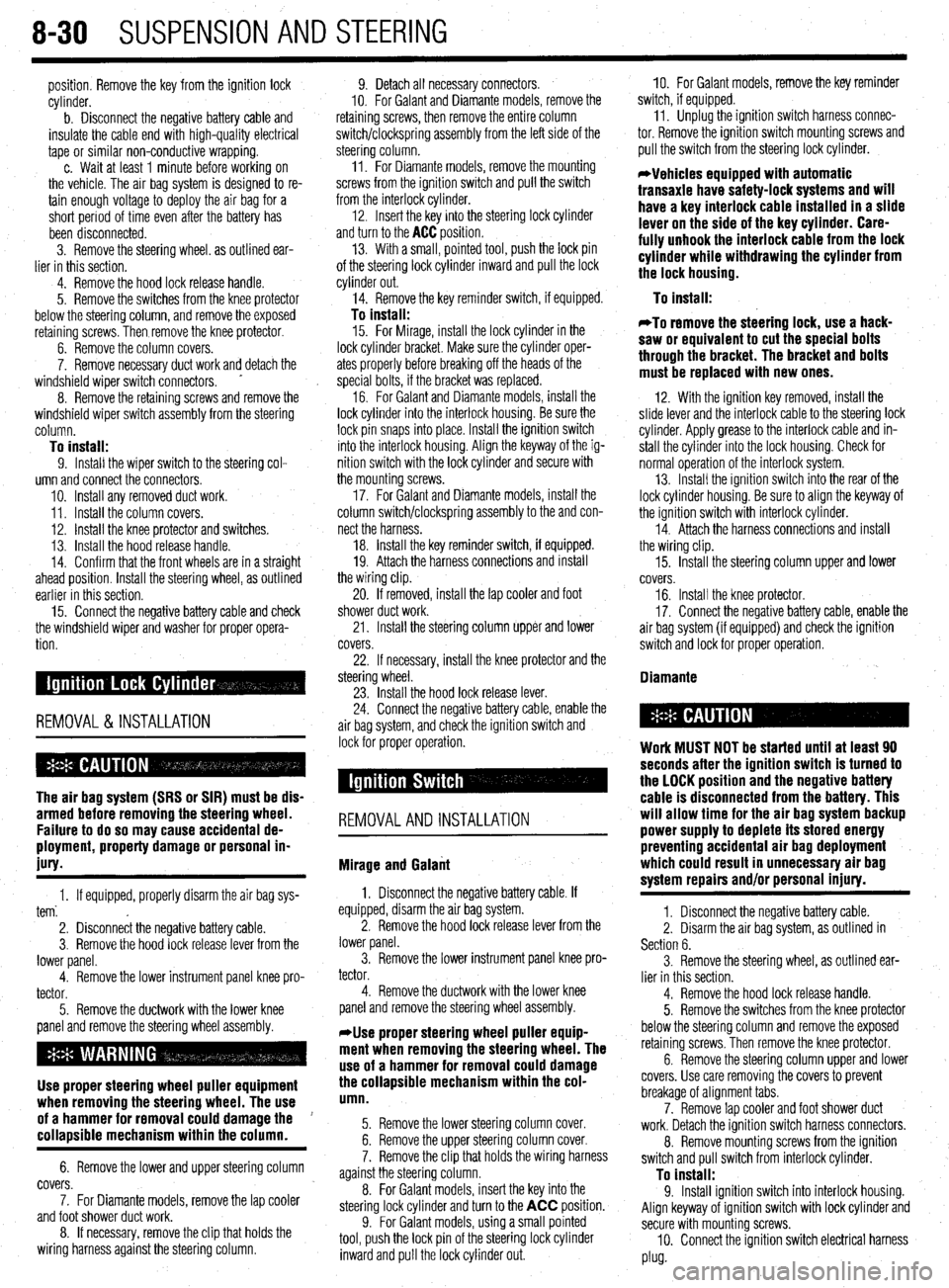

8. Use a steering wheel puller to remove the

wheel. - . . - _-. . _

10. Install the switch assembly and secure all

harness connectors with clips if needed. Make sure

the wires are not pinched orout of place.

11. Install the column covers and knee protector

and all connectors.

12. If removed, install the foot blower duct work

anfl tan cnnler -..- .-

r --- ”

13. Confirm that the front wheels are in a

straight-ahead position.

14. Install the steering wheel, as outlined earlier

in thir

Do not use a hammer or the ~r”---‘~‘- 15. Connect the negative battery cable, turn the

key to the ON position, the SRS warning light should

NW down

rinntlv

wImpl* the puller

iem Fig. 84 . . . then tighte

until the wheel is suffL,,,,, lVvoV

To install:

0 Pnnfirm that thn frnnt whnalc ,?A in , .I. ““llllllll u,a, ,110 ll”lll I.ll~rJlJ CnIj 111 a

straight-ahead position. Center the clockspring by

aligning the NEUTRAL mark on the clockspring with

the mating mark on the casing.

10. Line up and install the steering wheel. illuminate for seven seconds and go out. If the warn-

ing light is not functioning properly, refer to SRS

s’ .’ ystem cllagnosls.

16. Check all functions of the combination switch

for proper operation.

wheel lows:

a. Position the front wheels in the straight

ahead position and place the key in the LOCK

93158p12 Fig. 85 Lift the steering wheel straight off

of the steering column and remove the 11. Tighten the retaining nut as follows:

REMOVAL &INSTALLATION

l On 1992-93 Diamante models, tighten the

nut to 29 ft. Ibs. (40 Nm) retammg I

l On

retaining I

12. lnstal

taining nuts 1

13. Conn

“... . ..” .‘“J...*.” ‘&.“WSJ Y..“.” . ..rn” VII”“..

the SRS warning light operation. 1994-00 Diamante models, tighten the

iut to 33 ft. Ibs. (45 Nm)

II the air bag module and tighten the r&

:o 48 inch Ibs. (5 Nm).

wt the rwnative hatim rahle ami rhwk

*On vehicles not covered here, the wind-

shield wiper switch is incorporated into the

combination switch and is not separately serl

viceable. Refer to the procedure

above.

Diamante

1. Disconnect the negative battery cable.

2. If equipped with an air bag, disarm as fol-

I” .L

Page 326 of 408

8-30 SUSPENSION AND STEERING

position. Remove the key from the ignition lock

cylinder.

b. Disconnect the negative battery cable and

insulate the cable end with high-quality electrical

tape or similar non-conductive wrapping.

c. Wait at least 1 minute before working on

the vehicle. The air bag system is designed to re-

tain enough voltage to deploy the air bag for a

short period of time even after the battery has

been disconnected.

3. Remove the steering wheel. as outlined ear-

lier in this section.

4. Remove the hood lock release handle.

5. Remove the switches from the knee protector

below the steering column, and remove the exposed

retaining screws. Then remove the knee protector.

6. Remove the column covers.

7. Remove necessary duct work and detach the

windshield wiper switch connectors. +

8. Remove the retaining screws and remove the

windshield wiper switch assembly from the steering

column.

To install: 9. Install the wiper switch to the steering col-

umn and connect the connectors.

IO. Install any removed duct work.

11. Install the column covers.

12. Install the knee protector and switches.

13. Install the hood release handle.

14. Confirm that the front wheels are in a straight

ahead position. Install the steering wheel, as outlined

earlier in this section.

15. Connect the negative battery cable and check

the windshield wiper and washer for proper opera-

tion

REMOVAL &INSTALLATION

The air bag system (SRS or SIR) must be dis-

armed before removing the steering wheel.

Failure to do so may cause accidental de-

ployment, property damage or personal in-

jury.

1. If equipped, properly disarm the air bag sys-

tern:

2. Disconnect the negative battery cable.

3. Remove the hood lock release lever from the

lower panel.

4. Remove the lower instrument panel knee pro-

tector.

5. Remove the ductwork with the lower knee

panel and remove the steering wheel assembly.

Use proper steering wheel puller equipment

when removing the steering wheel. The use

of a hammer for removal could damage the

collapsible mechanism within the column.

6. Remove the lower and upper steering column

covers.

7. For Diamante models, remove the lap cooler

and foot shower duct work.

8. If necessary, remove the clip that holds the

wiring harness against the steering column. 9. Detach all necessary connectors.

10. For Galant and Diamante models, remove the

retaining screws, then remove the entire column

switch/clockspring assembly from the left side of the

steering column.

11. For Diarnante models, remove the mounting

screws from the ignition switch and pull the switch

from the interlock cylinder.

12. Insert the key into the steering lock cylinder

and turn to the

ACC position.

13. With a small, pointed tool, push the lock pin

of the steering lock cylinder inward and pull the lock

cylinder out.

14. Remove the key reminder switch, if equipped.

To install: 15. For Mirage, install the lock cylinder in the

lock cylinder bracket. Make sure the cylinder oper-

ates properly before breaking off the heads of the

special bolts, if the bracket was replaced.

16. For Galant and Diarnante models, install the

lock cylinder into the interlock housing. Be sure the

lock pin snaps into place. Install the ignition switch

into the interlock housing. Align the keyway of the ig-

nition switch with the lock cylinder and secure with

the mounting screws.

17. For Galant and Diamante models, install the

column switch/clockspring assembly to the and con-

nect the harness.

18. install the key reminder switch, if equipped.

19. Attach the harness connections and install

the wiring clip.

20. If removed, install the lap cooler and foot

shower duct work.

21. Install the steering column upper and lower

covers.

22. If necessary, install the knee protector and the

steering wheel.

23. Install the hood lock release lever.

24. Connect the negative battery cable, enable the

air bag system, and check the ignition switch and

lock for proper operation.

REMOVALANDINSTALLATION

Mirage and Galant

I. Disconnect the negative battery cable. If

equipped, disarm the air bag system.

2. Remove the hood lock release lever from the

lower panel.

3. Remove the lower instrument panel knee pro-

tector.

4. Remove the ductwork with the lower knee

panel and remove the steering wheel assembly.

*Use proper steering wheel puller equip-

ment when removing the steering wheel. The

use of a hammer for removal could damage

the collapsible mechanism within the col-

umn.

5. Remove the lower steering column cover.

6. Remove the upper steering column cover.

7. Remove the clip that holds the wiring harness

against the steering column.

8. For Galant models, insert the key into the

steering lock cylinder and turn to the ACC position.

9. For Galant models, using a small pointed

tool, push the lock pin of the steering lock cylinder

inward and pull the lock cylinder out. IO. For Galant models, remove the key reminder

switch, if equipped.

11. Unplug the ignition switch harness connec-

tor. Remove the ignition switch mounting screws and

pull the switch from the steering lock cylinder.

*Vehicles equipped with automatic

transaxle have safety-lock systems and will

have a key interlock cable installed in a slide

lever on the side of the key cyfinder. Care-

fully unhook the interlock cable from the lock

cylinder while withdrawing the cylinder from

the lock housing.

To install:

*To remove the steerlng lock, use a hack-

saw or equivalent to cut the special bolts

through the bracket. The bracket and bolts

must be replaced with new ones.

12. With the ignition key removed, install the

slide lever and the interlock cable to the steering lock

cylinder. Apply grease to the interlock cable and in-

stall the cylinder into the lock housing. Check for

normal operation of the interlock system.

13. Install the ignition switch into the rear of the

lock cylinder housing. Be sure to align the keyway of

the ignition switch with interlock cylinder.

14. Attach the harness connections and install

the wiring clip.

15. Install the steering column upper and lower

covers.

16. Install the knee protector.

17. Connect the negative battery cable, enable the

air

bag system (if equipped) and check the ignition

switch and lock for proper operation.

Diamante

Work MUST NOT be started until at least 90

seconds after the ignition switch is turned to

the LOCK position and the negative battery

cable is disconnected from the battery. This

will allow time for the air bag system backup

power supply to deplete its stored energy

preventing accidental air bag deployment

which could result in unnecessary air bag

system repairs and/or personal injury.

I. Disconnect the negative battery cable.

2. Disarm the air bag system, as outlined in

Section 6.

3. Remove the steering wheel, as outlined ear-

lier in this section.

4. Remove the hood lock release handle.

5. Remove the switches from the knee protector

below the steering column and remove the exposed

retaining screws. Then remove the knee protector.

6. Remove the steering column upper and lower

covers. Use care removing the covers to prevent

breakage of alignment tabs.

7. Remove lap cooler and foot shower

duct work. Detach the ignition switch harness connectors.

8. Remove mounting screws from the ignition

switch and pull switch from interlock cylinder.

To install: 9. Install ignition switch into interlock housing.

Align keyway of ignition switch with lock cylinder and

secure with mounting screws.

IO. Connect the ignition switch electrical harness

Plug.

Page 327 of 408

I

SUSPENSION AND STEERING 8-31

11. Install lap cooler and foot shower duct work.

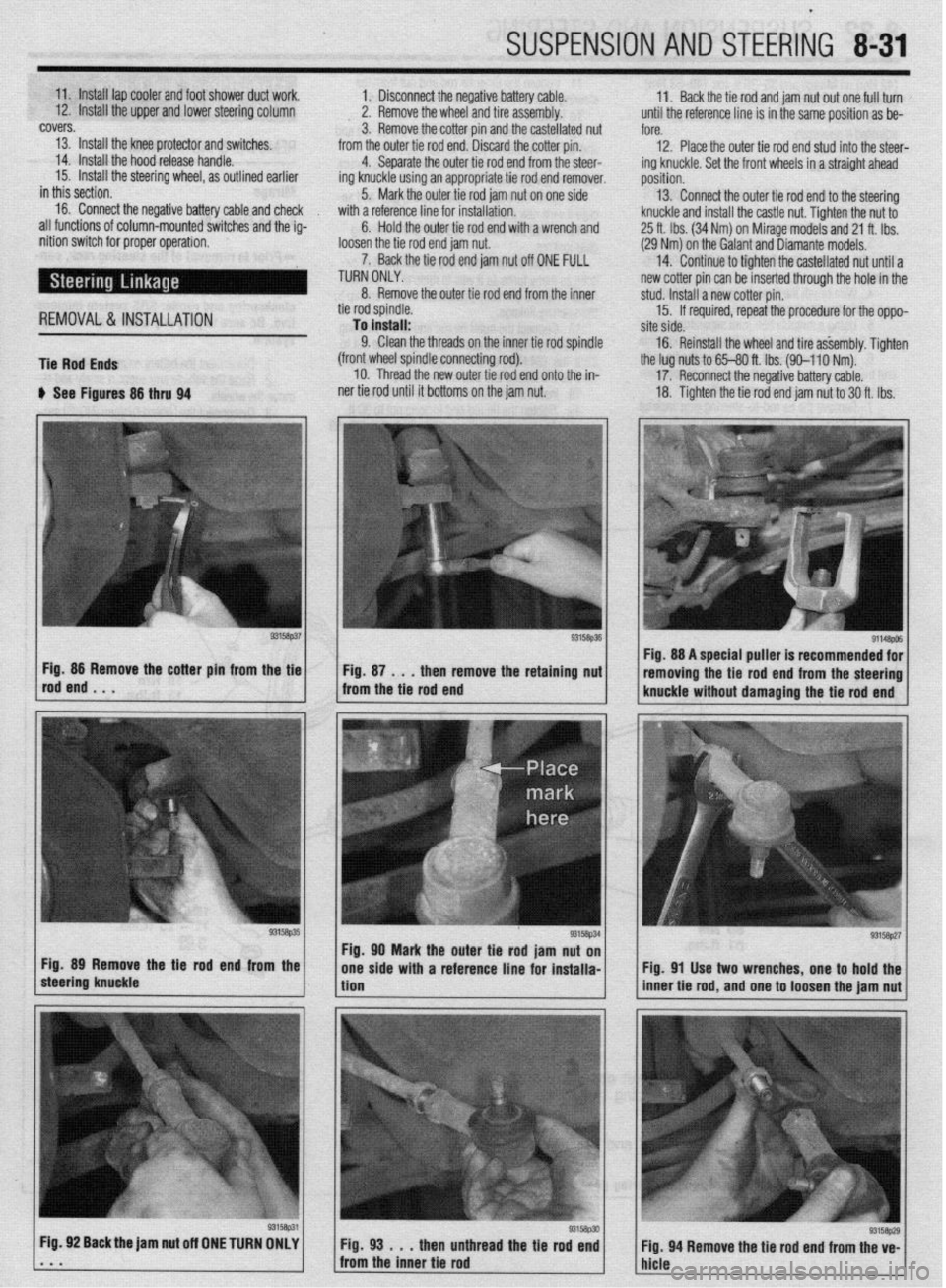

1.’ Disconnect the negative battery cable. 11.

12. Install the upper and lower steering column Back the tie rod and jam nut out one full turn

2. Remove the wheel and tire assembly. until the reference line is in the same position as be-

covers.

3. Remove the cotter pin and the castellated nut

fore.

13. Install the knee protector and switches.

12. Place the outer tie rod end stud into the steer-

14. Install the hood release handle. from the outer tie rod end. Discard the cotter pin.

4. Separate the outer tie rod end from the steer-

15. Install the steering wheel, as outlined earlier

ing knuckle using an appropriate tie rod end remover. ing knuckle. Set the front wheels in a straight ahead

in this section. position.

16. Connect the negative battery cable and check 5. Mark the outer tie rod jam nut on one side 13. Connect the outer tie rod end to the steering

with a reference line for installation.

all functions of column-mounted switches and the ig-

Hold the outer tie rod end with a wrench and knuckle and install the castle nut. Tighten the nut to

6.

nition switch for proper operation,

loosen the tie rod end jam nut. 25 ft. Ibs. (34 Nm) on Mirage models and 21 ft. Ibs.

(29 Nm) on the Galant and Diamante models.

7. Back the tie rod end jam nut off ONE FULL

TURN ONLY. 14. Continue to tighten the castellated nut until a

new cotter pin can be inserted through the hole in the

8. Remove the outer tie rod end from the inner

REMOVAL&INSTALLATION

Tie Rod Ends tie rod spindle.

To install:

9. Clean the threads on the inner tie rod spindle

(front wheel spindle connecting rod).

10. Thread the new outer tie rod end onto the in- stud. Install a new cotter pin.

15. If required, repeat the procedure for the oppo-

site side,

16. Reinstall the wheel and tire a&embly. Tighten

the lug nuts to 65-80 ft. Ibs. (90-l 10 Nm).

u See Figures 86 thru 94 ner tie rod until it bottoms on the jam nut. 17. Reconnect the negative battery cable.

18. Tighten the tie rod end jam nut to 30 ft. Ibs.

g3’5a~51 Fig. 89 Remove the Be rod end from the

steering knuckle *

Fig. 92 Back the jam nut off ONE TURN OMLY

. * m Fig. 98 . . .

then unthread the tie rod end

Fig. 94 Remove the tie rod end from the ve-

from the inner tie rod

hicle Fig. 88 A special puller is recommended for

removing the tie rod end from the steering

knuckle without damaging the tie rod end

Fig. 91 Use two wrenches, one to hold the

inner tie rod, and one to loosen the jam nut

93158p29

Page 371 of 408

BODYANDTRIM 10-3

3. Check the hood latch operation; it should en-

gage easily and smoothly. The latch should release

without the use of excessive force. The hood latch

mounting bolts may be loosened; the latch can be

adjusted left/right or up/down to compensate for the

hood striker position.

4. With the hood closed and latched, check the

height of the hood. It should sit even with the fender

tops; this dimension may be adjusted by turning the

hood stops to a higher or lower position. Note that

adjusting these stops may require readjustment of the

latch to position the hood correctly.

REMOVAL &INSTALLATION

1999-92 Mirage

1. Disconnect the liftgate support or strut. The

9315Ql10 struts are held by either a cross-point screw or a bolt.

2. Disconnect the washer tube running to the

glass.

3. Disconnect any necessary wiring harnesses.

4. Close the hatch. From the inside of the vehi-

cle, remove the nuts holding the lid to the hinge.

With an assistant. carefullv ooen the lid and remove it

from the car. ’

To install:

5. Fit the hatch into place and install the nuts

finger tight.

6. Reinstall the support.

7. Close the tailgate and align it by checking the

seam all around. Thegap must be equal and even.

Align the hatch by moving it on the hinges until cor-

rectly placed, then tighten the hinge nuts to 11 ft. Ibs.

(15 Nm).

8. Attach the electrical harnesses.

9. Connect the rear windshield washer tube.

Make sure it is pressed firmly onto the fitting.

10. Check the alignment of the hatch.

ALIGNMENT

Close the hatch and align it by checking the seam

all around. The gap must be equal and even. Align

the hatch by moving it on the hinges until correctly

placed, then tighten the hinge nuts. The final position

of the lid may be further adjusted by moving the latch

and/or striker on their mounts. When fully closed, the

hatch must be flush with the surrounding body pan-

els. Minor adjustments in this dimension may be

made by turning the rubber bumpers in or out as

needed.

REMOVAL &INSTALLATION

then remove the hose retaining

ALIGNMENT

1, Close the hood, at least engaging the first

latch, and check the hood-to-fender and hood-to-

cowl seams and alignment. Re-open the hood and Fig. 7 With an assistant supporting the

make adjustments as needed to give equal seams all

around. When the hood is in final alignment, tighten

the hinge bolts.

2. Reconnect the washer lines and any electrical

lines which were disconnected. Diamante Wagon

ti See Figure 8

1. Disconnect the tailgate support.

2. Disconnect the washer fluid tube.

3. Disconnect any necessary wiring harnesses.

4. Have an assistant support the tailgate.

5. Remove the nuts holding the tailgate to the

hinge.

Page 375 of 408

BODYANDTRIM IO-7

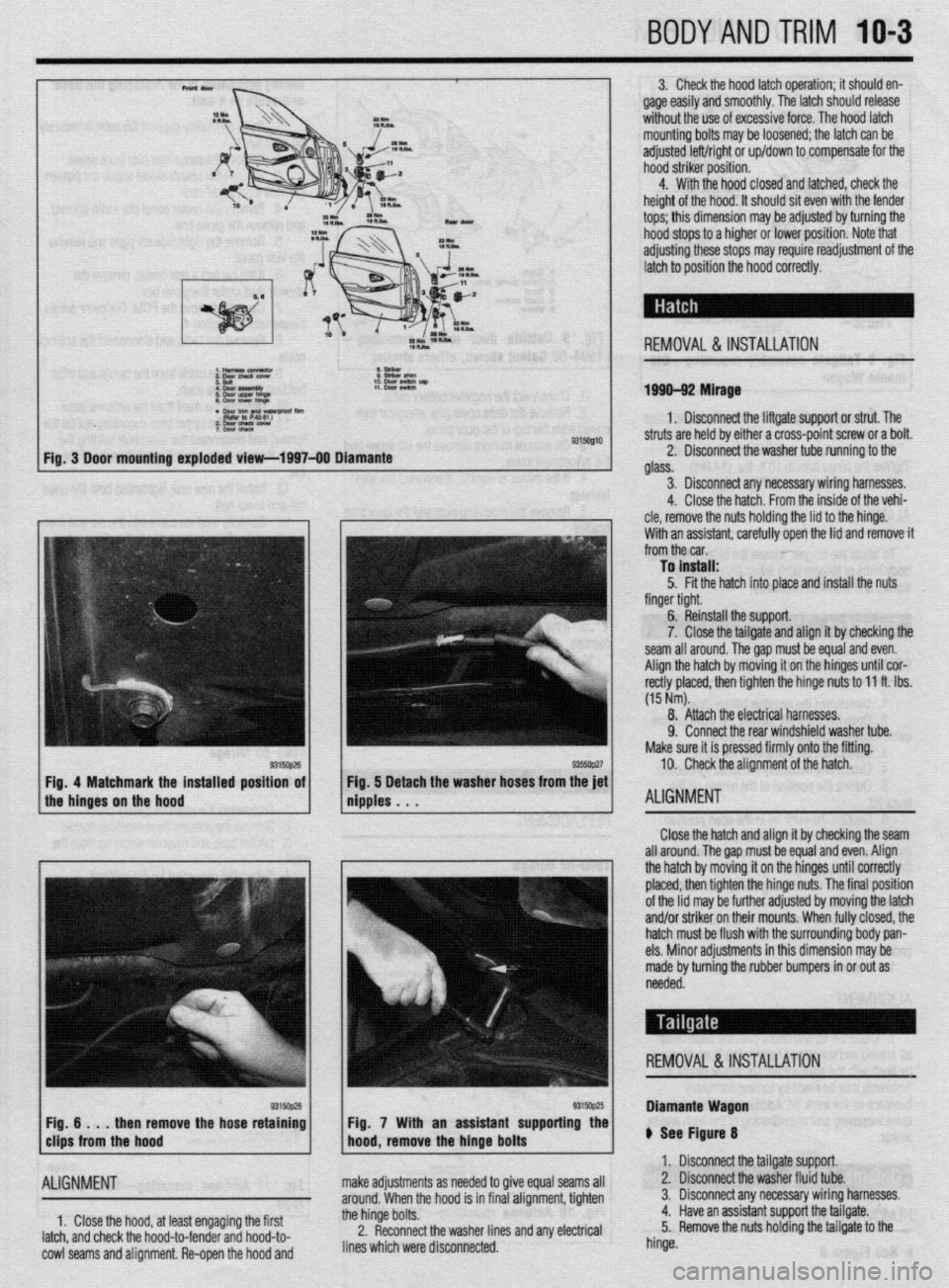

1. Ashtray

2 cenrer DaneI

3. Sunglass pocket

4 Side panel assembly

5 Knee protector assembly (L

6 Hood lock release handle

7 Column cover. lower

8 Column cover. upper

9 Radio

10 Striker

11. Glove box assembly

Fig. 21 Exploded view of the instrument panel (1 of 2)-1990-92 Mi-

rage

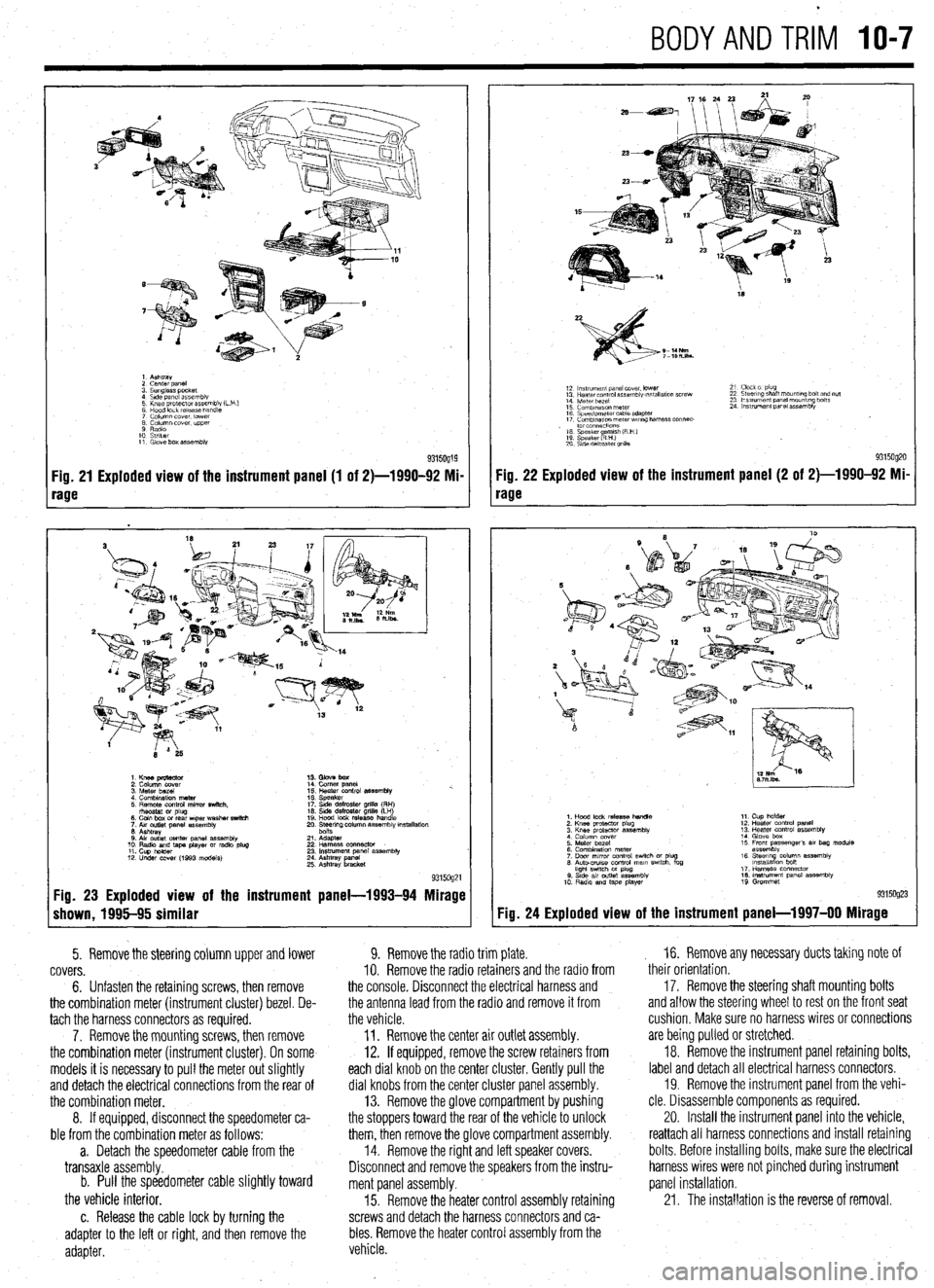

1. Knee pmtector

2. Column cover

3. Meter bezel

4. Combination meter

5. Remote control mirror switch.

rhsostat or plug

6. Coin box or rear wper washer switch

7. Aw outlet panel assembly

6. Ashtray

0. Air outlet center panel assembly

10. Radio and tape player or radio plug

11. Cup holder

12. Under COW (1993 models) 14. Comer panel

15. Heater control assembly %.

16. Speaker

17. Side defroster grille (RH)

16. Side defroster grille (LH)

19. Hood lock release handle

20. Ee$ng column assembly mstallation

21. Adapter

22 Harness oonnector

23. Instrument panel assembly

24. Ashtray panel

25. Ashtray bracket

9315og21 Fig. 23 Exploded view of the instrument panel-1993-94 Mirage

shown, 1995-95 similar

5. Remove the steering column upper and lower

covers.

6. Unfasten the retaining screws, then remove

the combination meter (instrument cluster) bezel. De-

tach the harness connectors as required.

7. Remove the mounting screws, then remove

the combination meter (instrument cluster). On some

models it is necessary to pull the meter out slightly

and detach the electrical connections from the rear of

the combination meter.

8. If equipped, disconnect the speedometer ca-

ble from the combination meter as follows:

a. Detach the speedometer cable from the

transaxle assembly.

b. Pull the speedometer cable slightly toward

the vehicle interior.

c. Release the cable lock by turning the

adapter to the left or right, and then remove the

adapter.

18

S-14Nm

7-lOh.lbs.

12 ln~v~rnent panel cover. lower

13 Hearer control assembly w,tallatlon screw

14 Meter bezel

15 Combination meter

16 Speedometer cable adapter

17 Comblnawn meterwr~ng harness connec-

. to1 co”“ectlo”s

16 Speaker amlsh (R H )

19 Speaker RHI e

20 S\de defroster grllla 21 Clock 01 plug

22 Steering shaft mount,ng bolt and nut

23 Ins!rument panel mounting bolts

24 Instrument panel assembly

9315og20 Fig. 22 Exploded view of the instrument panel (2 of 2)-1990-92 Mi-

rage

Fig. 24

1. Hood lock release handle

2. Knee protactor plug

3. Knee protector assembly

4 Column cover

5. Meter bezel

6. Combination meter

7. Door mrror control swich or plug

6. Auto-CNISO control mam swtch. fog

hght swtch M plug

0. Stde av outlet assembly

10 Radio and tape player 11. Cup holder

12. Heater control panel

13. Heater control assembly

14. Glove box

15 Front passenger’s 81, bag module

assembly

16. Steerq column assembly

lnstallatlon bon

17. Harness connector

16. Instrument panel assembly

19 Grommet

Exploded view of the instrument panel-l 997-00 Mirage

9. Remove the radio trim plate.

IO. Remove the radio retainers and the radio from

the console. Disconnect the electrical harness and

the antenna lead from the radio and remove it from

the vehicle.

11. Remove the center air outlet assembly.

12. If equipped, remove the screw retainers from

each dial knob on the center cluster. Gently pull the

dial knobs from the center cluster panel assembly.

13. Remove the glove compartment by pushing

the stoppers toward the rear of the vehicle to unlock

them, then remove the glove compartment assembly.

14. Remove the right and left speaker covers.

Disconnect and remove the speakers from the instru-

ment panel assembly.

15. Remove the heater control assembly retaining

screws and detach the harness connectors and ca-

bles. Remove the heater control assembly from the

vehicle. , 16. Remove any necessary ducts taking note of

their orientation,

17. Remove the steering shaft mounting bolts

and allow the steering wheel to rest on the front seat

cushion, Make sure no harness wires or connections

are being pulled or stretched.

18. Remove the instrument panel retaining bolts,

label and detach all electrical harness connectors.

19. Remove the instrument panel from the vehi-

cle. Disassemble components as required.

20. Install the instrument panel into the vehicle,

reattach all harness connections and install retaining

bolts. Before installing bolts, make sure the electrical

harness wires were not pinched during instrument

panel installation.

21. The installation is the reverse of removal.