fuel filter location MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 10 of 408

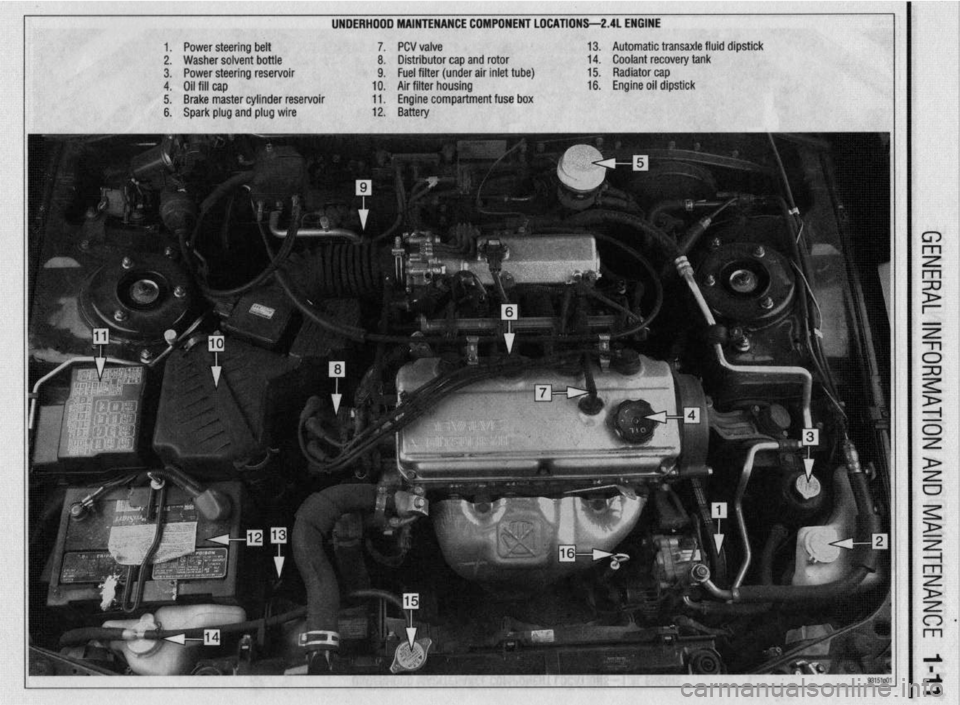

UNDERHDDD MAINTENANCE COMPONENT LOCATIONS-2AL ENGINE

II

1. Power steering belt 7. PCV valve

2. Washer solvent bottle 8. Distributor cap and rotor

3. Power steering reservoir 9. Fuel filter (under air inlet tube)

4. Oil fill cap 10. Air filter housing

5. Brake master cylinder reservoir 11. Engine compartment fuse box

6. Spark plug and plug wire 12. Battery 13. Automatic transaxle fluid dipstick

14. Coolant recovery tank

15. Radiator cap

16. Engine oil dipstick

Page 11 of 408

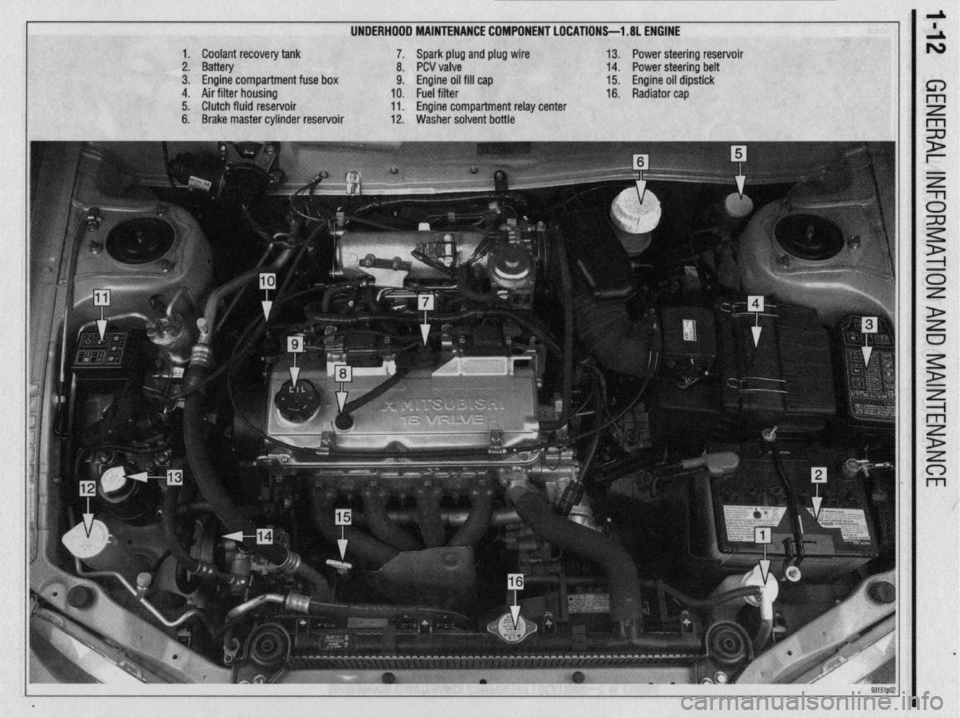

UNDERHOOD MAINTENANCE COMPONENT LOCATIONS-l .8L ENGINE

1. Coolant recovery tank

2. Battery

3. Engine compartment fuse box

4. Air filter housing

5. Clutch fluid reservoir

6. Brake master cylinder reservoir 7. Spark plug and plug wire

8. PCV valve

9. Engine oil fill cap

10. Fuel filter

11. Engine compartment relay center

12. Washer solvent bottle 13. Power steering reservoir

14. Power steering belt

15. Engine oil dipstick

16. Radiator cap

Page 87 of 408

3-26 ENGINEANDENGINEOVERHAUL

18. Remove the self-locking nuts and the small

retaining bolt holding the exhaust pipe to the bottom

of the exhaust manifold. Separate the pipe from the

manifold and remove the gasket.

19. Remove the bolts holding the support brace

to the bottom of the intake manifold.

20. Use the special hex wrench (MB 998051-01)

and loosen the head bolts in the order shown in 2 or

3 passes. When all are finger loose, remove the bolts.

21. Rock the head gently to break it loose; if tap-

ping is necessary, do so with a rubber or wooden

mallet at the corners of the head. DO NOT pry the

head up by wedging tools between the head and the

block.

22. Lift the head free of the engine. It is coming

off with both manifolds and the intake plenum at-

tached; the help of an assistant is recommended for

lifting. Support the head assembly on wooden blocks

on a suitable workbench. Refer to Cleaning and In-

spection in this section for work to be done before in-

stalling the head. If the head has been removed for

work other than gasket replacement, the rocker as-

sembly and camshaft or other components may be

removed.

Before reinstallation, the head should be com-

pletely assembled on the bench. This allows proper

location and tightening of all the external items.

To install: 23. Place a new gasket on the engine so that the

identifying mark faces up (towards the head) and is at

the timing belt end of the block. Install a new gasket

on the exhaust pipe.

Do not apply sealant to the head gasket or

mating surfaces.

24. Install the head straight down onto the block.

Try to eliminate most of the side-to-side adjust-

ments as this may move the gasket out of position.

Install the bolts by hand and just start each bolt 1 or

2 turns on the threads.

25. The head bolt torque specification is 68 ft.

Ibs. (92 Nm) for a cold engine. The bolts must be

tightened in the order shown in 3 steps. On the first

pass, tighten all the bolts to about 22 ft. Ibs. (30 Nm),

then proceed through the order tightening each bolt

to about 45 ft. Ibs. (61 Nm). The final torque is

achieved on the third pass.

26. Install the intake manifold support brace to

the manifold and tighten the bolts to 16 ft. Ibs. (22

Nm). 27. Making sure the gasket is still in place, con-

nect the exhaust pipe to the base of the exhaust man-

ifold. Use new self-locking nuts; tighten the nuts and

the small bracket bolt to 26 ft. Ibs. (35 Nm).

28. Make sure the camshaft has not changed po-

sition during repalrs. Carefully install the camshaft

sprocket and belt onto the camshaft. Tighten the re-

taining bolt to 66 ft. Ibs. (91 Nm).

29. Install the upper timing belt cover, then

tighten the bolts to 8 ft. Ibs. (11 Nm).

30. Apply sealant to the contact surfaces of the

half-circle plug and install the plug in the head In-

stall the valve cover and gasket.

31. Install the engine mount bracket to the en-

gine. Tighten the mounting nuts and bolts to 42 ft.

Ibs. (57 Nm).

32. Adjust the jack (if necessary) so that the en-

gine mount bushing aligns with the bodywork

bracket. Install the through-bolt and tighten the nuts

snug.

33. Slowly release tension on the floor jack so

that the weight of the engine bears fully on the

mount. Tighten the through-bolt to 52 ft. Ibs. (71

Nm) and the small safety nut to 26 ft. tbs. (36 Nm).

34. Install the bracket holding the power steering

hose and air conditioning hose to the top of the en-

gine mount.

35. Position the control wiring harness and in-

stall the retaining bolts. Attach each electrical con-

nector to its proper location, making sure the wires

are properly routed and firmly connected.

36. Install the spark plug wires in the distributor

cap.

37. Connect the PCV hose and the vacuum

hose(s).

38. Connect the fuel return line. Connect the

brake booster vacuum hose.

39. Install the heater hose, the coolant by-pass

hose and.the upper radiator hose. Pay close attention

to the position and routing of these hoses and insure

that they are not crimped or constricted. Install the

clamps in the same location as before removal.

40. Install a new O-ring on the high pressure fuel

line and lubricate it with a coating of gasoline. Care-

fully connect the high pressure fuel line to the fuel

rail, taking care not to damage the O-ring. Tighten the

bolts only to 4 ft. Ibs. (6 Nm).

41. Connect the accelerator cable and adjust it as

necessary.

42. Install the air intake hose.

43. Fill the cooling system with coolant.

44. Changing the oil and filter is recommended

to eliminate pollutants in the oil.

Intake side

I Front of

engine

Exhaust side

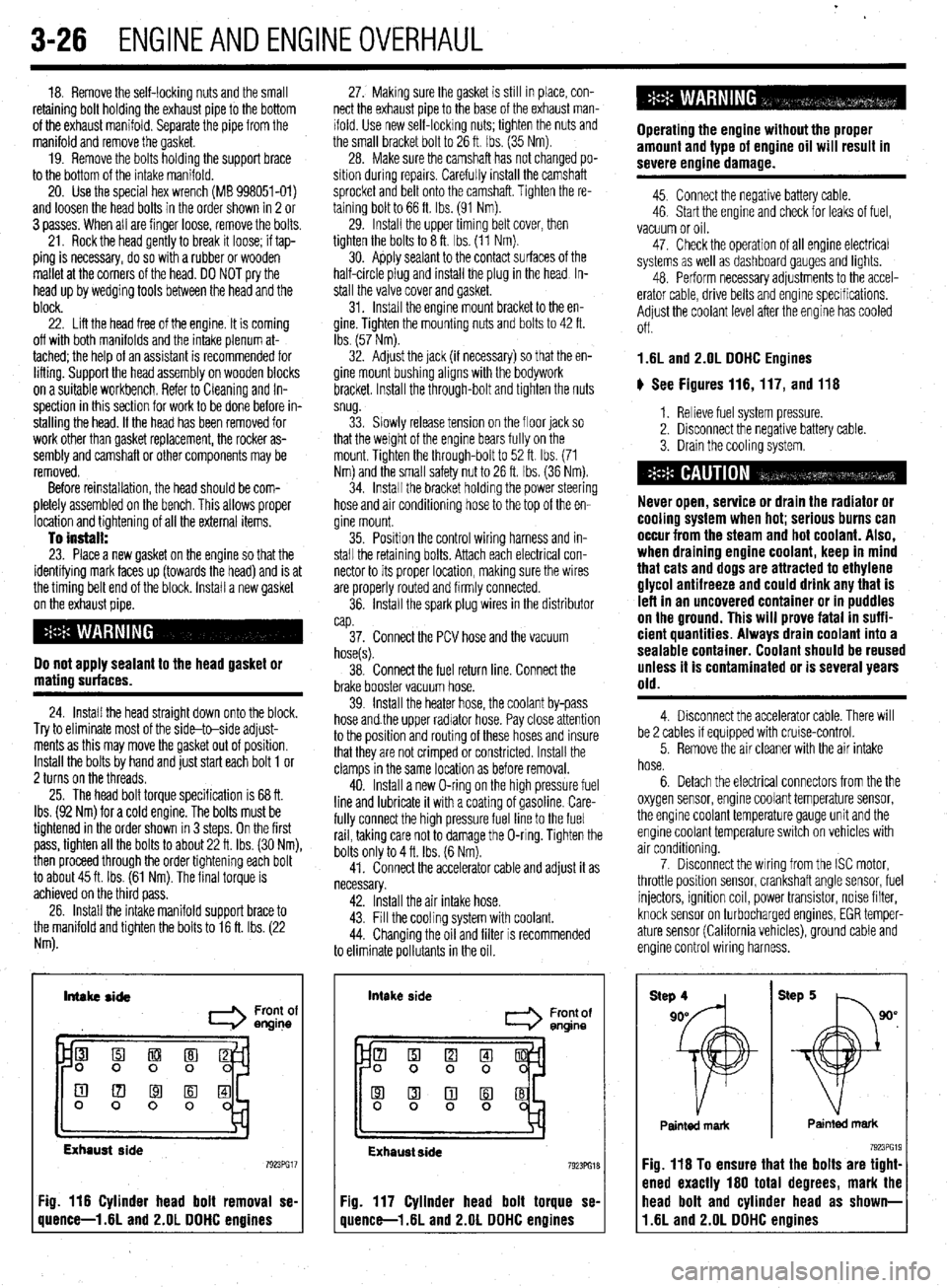

Fig. 116 Cylinder head bolt removal se-

quence-l .6L and 2.OL DDHC engines intake

side

Front of

entine

Exhaust side 7923PG18

Fig. 117 Cylinder head bolt torque se-

quence-l .6L and 2.OL DDHC engines Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

45. Connect the negative battery cable.

46. Start the engine and check for leaks of fuel,

vacuum or oil.

47. Check the operation of all engine electrical

systems as well as dashboard gauges and lights.

48. Perform necessary adjustments to the accel-

erator cable, drive belts and engine specifications.

Adjust the coolant level after the engine has cooled

Off.

1.6L and 2.OL DDHC Engines

ti See Figures 116,117, and 116

1. Relieve fuel system pressure.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Disconnect the accelerator cable. There will

be 2 cables if equipped with cruise-control.

5. Remove the air cleaner with the air intake

hose.

6. Detach the electrical connectors from the the

oxygen sensor, engine coolant temperature sensor,

the engine coolant temperature gauge unit and the

engine coolant temperature switch on vehicles with

air conditioning.

7. Disconnect the wiring from the ISC motor,

throttle position sensor, crankshaft angle sensor, fuel

injectors, ignition coil, power transistor, noise filter,

knock sensor on turbocharged engines, EGR temper-

ature sensor (California vehicles), ground cable and

engine control wiring harness.

Painted mark Painted mark

Fig. 116 To ensure that the bolts are tight-

ened exactly 160 total degrees, mark the

11.6L and 2.OL DDHC engines head bolt and cylinder head as shown-

Page 396 of 408

II-14 TROUBLESHOOTING

b. Check for low voltage at the bulb socket positive terminal or a poor ground. If voltage

is low, or the ground marginal, trace the wiring to, and check for loose, damaged or

corroded wires and electrical terminals; repair as necessary.

c. Check the light switch operation and replace if necessary.

1. Interior light inoperative

a. Verify the interior light switch location and position(s), and set the switch in the cor-

rect position.

b. Check for battery voltage and ground at the interior light bulb socket. If battery voltage

and ground are present, replace the bulb. If voltage is not present, check the interior

light fuse for battery voltage. If the fuse is missing, replace the fuse. If the fuse has

blown, or if battery voltage is present, refer to the wiring diagram to troubleshoot the

cause for an open or shorted circuit. If ground is not present, check the door switch

contacts and clean or repair as necessary.

2. Interior light works intermittent/y

a. Check the bulb for a damaged filament, and replace if damaged.

b. Check the bulb and bulb socket for corrosion, and clean or replace the bulb and

socket.

c. Check for loose, damaged or corroded wires and electrical terminals; repair as neces-

sary.

d. Check the door and light switch operation, and replace if necessary.

3. Interior light very dim

a. Check the bulb and bulb socket for corrosion, and clean or replace the bulb and

socket.

b. Check for low voltage at the bulb socket positive terminal or a poor ground. If voltage

is low, or the ground marginal, trace the wiring to, and check for loose, damaged or

corroded wires and electrical terminals; repair as necessary.

c. Check the door and light switch operation, and replace if necessary.

1. One brake light inoperative

a. PressPress the brake pedal and check for battery voltage and ground at the brake light

bulb socket. If present, replace the bulb. If either battery voltage or ground is not pre-

sent, refer to the wiring diagram to troubleshoot.

2. Both brake lights inoperative

a. Press the brake pedal and check for battery voltage and grou’nd at the brake light bulb

socket. If present, replace both bulbs. If battery voltage is not present, check the brake

light switch adjustment and adjust as necessary. If the brake light switch is properly

adjusted, and battery voltage or the ground is not present at the bulb sockets, or at the

bulb electrical connector with the brake pedal pressed, refer to the wiring diagram to

troubleshoot the cause of an open circuit.

3. One or both brake lights very dim

a. Press the brake pedal and measure the voltage at the brake light bulb socket. If the

measured voltage is close to the battery voltage, check for a poor ground caused by a

loose, damaged, or corroded wire, terminal, bulb or bulb socket. If the ground is

bolted to a painted surface, it may be necessary to remove the electrical connector and

clean the mounting surface, so the connector mounts on bare metal. If battery voltage

is low, check for a poor connection caused by either a faulty brake light switch, a

loose, damaged, or corroded wire, terminal or electrical connector. Refer to the wiring

diagram to troubleshoot the cause of a voltage drop.

1. Warning light(s) stay on when the engine is started

Ignition, Battery or Alternator Warning light a. Check the alternator output and voltage regulator operation, and replace as necessary.

b. Check the warning light wiring for a shorted wire.

Check Engine Light a. Check the engine for routine maintenance and tune-up status. Note the engine tune-up

specifications and verify the spark plug, air filter and engine oil condition; replace

and/or adjust items as necessary.

b. Check the fuel tank for low fuel level, causing an intermittent lean fuel mixtur

e. Top off fuel tank and reset check engine light.

c. Check for a failed or disconnected engine fuel or ignition component, sensor or con-

trol unit and repair or replace as necessary.

d. Check the intake manifold and vacuum hoses for air leaks and repair as

necessary.

e. Check the engine’s mechanical condition for excessive oil consumption.

Anti-Lock Braking System (ABS) Light a. Check the wheel sensors and sensor rings for debris, and clean as necessary.

b. Check the brake master cylinder for fluid leakage or seal failure and replace as neces-

sary.

c, Check the ABS control unit, pump and proportioning valves for proper operation; re-

place as necessary.

d. Check the sensor wiring at the wheel sensors and the ABS control unit for a loose or

shorted wire, and repair as necessary.

brake Warning Light a. Check the brake fluid level and check for possible leakage from the hydraulic lines and

seals. Top off brake fluid and repair leakage as necessary.

b. Check the brake linings for wear and replace as necessary.

c. Check for a loose or shot-ted brake warning light sensor or wire, and replace or repair

as necessary.

Oil Pressure Warning Light a. Stop the engine immediately. Check the engine oil level and oil filter condition, and

top off or change the oil as necessary.

b. Check the oil pressure sensor wire for being shorted to ground. Disconnect the wire

from the oil pressure sensor and with the ignition in the ON position, but not running,

the oil pressure light should not be working. If the light works with the wire discon-

nected, check the sensor wire for being shorted to ground. Check the wire routing to

make sure the wire is not pinched and check for insulation damage. Repair or replace

the wire as necessary and recheck before starting the engine.

c. Remove the oil pan and check for a clogged oil pick-up tube screen.

d. Check the oil pressure sensor operation by substituting a known good sensor.

e. Check the oil filter for internal restrictions or leaks, and replace as necessary.

WARNING: If the engine is operated with oil pressure below the manufac-

turer’s specification, severe (and costly) engine damage could occur. Low

oil pressure can be caused by excessive internal wear or damage to the en-

gine bearings, oil pressure relief valve, oil pump or oil pump drive mecha-

nism.

Before starting the engine, check for possible causes of rapid oil loss, such as leaking

oil lines or a loose, damaged, restricted, or leaking oil filter or oil pressure sensor. If the

engine oil level and condition are acceptable, measure the engine’s oil pressure using a

pressure gauge, or determine the cause for the oil pressure warning light to function

when the engine is running, before operating the engine for an extended period of time.

Another symptom of operating an engine with low oil pressure is the presence of severe

knocking and tapping noises.

Parking Brake Warning Light a. Check the brake release mechanism and verify the parking brake has been fully re-

leased.

b. CheckCheck the parking brake light switch for looseness or misalignment.

c. CheckCheck for a damaged switch or a loose or shorted brake light switch wire, and

replace or repair as necessary.

2. Warning light(s) flickers on and off when driving

Ignition, Battery or Alternator Warning Light a. Check the alternator output and voltage regulator operation. An intermittent condition

may indicate worn brushes, an internal short, or a defective voltage regulator. Replace

the alternator or failed component.

b. Check the warning light wiring for a shorted, pinched or damaged wire and repair as

necessary.

Check Engine Light a. Check the engine for required maintenance and tune-up status. Verify engine tune-up

specifications, as well as spark plug, air filter and engine oil condition; replace and/or

adjust items as necessary.

b. Check the fuel tank for low fuel level causing an intermittent lean fuel mixture. Top off

fuel tank and reset check engine light.

c. Check for an intermittent failure or partially disconnected engine fuel and ignition

component, sensor or control unit; repair or replace as necessary.

d. Check the intake manifold and vacuum hoses for air leaks, and repair as necessary.

e. Check the warning light wiring for a shorted, pinched or damaged wire and repair as

necessary.

Anti-Lock Braking System (ABS) Light a. Check the wheel sensors and sensor rings for debris, and clean as necessary.

b. Check the brake master cylinder for fluid leakage or seal failure and replace as neces-

sary.

c. Check the ABS control unit, pump and proportioning valves for proper operation, and

replace as necessary.