drain bolt MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 1 of 408

HOW TO USE THIS BOOK 1-2

WHERE TOBEGIN l-2

AVOIDINGTROUBLE 1-2

MAINTENANCEORREPAIR? 1-2

AVOIDINGTHEMOSTCOMMONMISTAKES l-2

TOOLS AND EQUIPMENT 1-2

SPECIALTOOLS l-4

YOUR VEHICLE SAFELY 1-4

DON'TS l-6

FASTENERS, MEASUREMENTS AND

CONVERSIONS l-6

BOLTS,NUTSANDOTHERTHREADED

RETAINERS 1-6

TORQUE l-7

TORQUEWRENCHES l-7

TORQUEANGLEMETERS 1-9

STANDARDANDMETRIC MEASUREMENTS l-9

SERIAL NUMBER IDENTIFICATION l-10

VEHICLE IDENTIFICATION NUMBER l-10

ENGINE IDENTIFICATION NUMBER I-10

TRANSAXLEIDENTIFICATION I-10

DRlVEAXLE(AWDGALANTONLY) l-10

TRANSFERCASE(AWDGALANTONLY) l-10

ROUTINE MAINTENANCE AND TUNE-UP l-14

AIRCLEANER(ELEMENT) 1-14

REMOVAL&INSTALLATION 1-14

FUELFILTER 1-15

REMOVAL &INSTALLATION l-15

PCVVALVE l-15

REMOVAL&INSTALLATION l-15

EVAPORATIVECANISTER l-16

SERVICING 1-16

BATTERY 1-16

PRECAUTIONS I-16

GENERALMAINTENANCE 1-16

BEL BATTERYFLUID 1-16

CABLES I-17

CHARGING I-18

REPLACEMENT 1-18

TS 1-18

INSPECTiON l-18

ADJUSTMENT 1-18

REMOVAL&INSTALLATION 1-18

TIMINGBELTS l-20

INSPECTION l-20

HOSES I-20

INSPECTION l-20

REMOVAL&INSTALLATION

CV-BOOTS 1-21

INSPECTION l-21

SPARKPLUGS l-22

SPARKPLUGHEATRANGE

REMOVAL&INSTALLATION

INSPECTION &GAPPING 1.

SPARKPLUG WIRES 1-24

TESTING 1-24

REMOVAL&INSTALLATION

DISTRIBUTORCAPANDROTOR

REMOVAL&INSTALLATION

INSPECTION 1-25

IGNITIONTIMING 1-25

. GENERALINFORAMTION l-

lNSPECTlON&ADJUSTMENl

VALVE LASH l-27

ADJUSTMENT l-27

IDLESPEED 1-28 1-21

l-22

l-22

-23

1-24

l-25

l-25

.25

1-26

AIR CONDITIONING SYSTEM 1-28

SYSTEMSERVlCEiiREPAlR l-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION l-29

WINDSHIELD WIPERS l-29

ELEMENT(REFILL)CARE&

REPLACEMENT l-29

TIRESANDWHEELS l-30

TIRE ROTATION I-30

TIRE DESIGN 1-31

TIRESTORAGE l-31

INFLATION &INSPECTION l-31

CARE OFSPECIALWHEELS l-32 OPERATION INFOREIGNCOUNTRIES l-33

ENGINE l-33

OILLEVELCHECK 1-33

OIL& FILTER CHANGE l-34

MANUALTRANSAXLE l-35

FLUIDRECOMMENDATIONS l-35

LEVELCHECK l-35

DRAIN&REFILL l-36

AUTOMATICTRANSAXLE l-36

FLUIDRECOMMENDATIONS l-36

LEVELCHECK 1-36

DRAIN&REFILL l-36

PAN & FILTERSERVICE 1-36

TRANSFERCASE(AWDGAlANT ONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

REARDRlVEAXLE(AWDGALANTONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

COOLINGSYSTEM l-39

FLUIDRECOMMENDATIONS l-39

iM-41

FLUIDS AND LUBRICANTS 1-33

FLUID DISPOSAL 1-33

FlJELANDENGlNEOILRECOMMENDATlONS

ENGINE OIL l-33

FUEL l-33

Page 2 of 408

.

1-2 GENERALINFORMATIONAND MAINTENANCE

Chitton’s Total Car Care manual for the 199M10

Mitsubishi Mirage, Galant and Diamante is intended

to help you learn more about the inner workings of

your vehicle while saving you money on its upkeep

and operation.

The beginning of the book will likely be referred to

the most, since that is where you will find information

for maintenance and tune-up. The other sections deal

with the more complex systems of your vehicle. Oper-

ating systems from engine through brakes are cov-

ered to the extent that the average do-it-yourselfer be-

comes mechanically involved. This book will not

explain such things as rebuilding a differential for the

simple reason that the expertise required and the in-

vestment in special tools make this task uneconomi-

cal. It will, however, give you detailed instructions to

help you change your own brake pads and shoes, re-

place spark plugs, and perform many more jobs that

can save you money, give you personal satisfaction

and help you avoid expensive problems.

A secondary purpose of this book is a reference for

owners who want to understand their vehicle and/or

their mechanics better. In this case, no tools at all are

required.

Before removing any bolts, read through the entire

procedure. This will give you the overall view of what

tools and supplies will be required. There is nothing

more frustrating than having to walk to the bus stop

on Monday morning because you were short one bolt

on Sunday afternoon. So read ahead and plan ahead.

Each operation should be approached logically and

all procedures thoroughly understood before attempt-

ing any work.

All sections contain adjustments, maintenance, re-

moval and installation procedures, and in some cases,

repair or overhaul procedures. When repair is not con-

sidered practical, we tell you how to remove the part

and then how to install the new or rebuilt replacement.

In this way, you at least save labor costs. “Backyard”

repair of some components is just not practical.

Many procedures in this book require you to “label

and disconnect. . ” a group of lines, hoses or wires.

Don’t be lulled into thinking you can remember where

everything goes-you won’t. If you hook up vacuum

or fuel lines incorrectly, the vehicle may run poorly, if

at all. If you hook up electrical wiring incorrectly, you

may instantly learn a very expensive lesson.

You don’t need to know the official or engineering

name for each hose or line. A piece of masking tape

on the hose and a piece on its fitting will allow you to

assign your own label such as the letter A or a short name. As long as you remember your own code, the

lines can be reconnected by matching similar letters

or names. Do remember that tape will dissolve in

gasolrne or other fluids; if a component is to be

washed or cleaned, use another method of identifica-

tion. A permanent felt-tipped marker or a metal scribe

can be very handy for marking metal parts. Remove

any tape or paper labels after assembly.

It’s necessary to mention the difference between

maintenance and repair Maintenance includes rou-

tine inspections, adjustments, and replacement of

parts which show signs of normal wear Maintenance

compensates for wear or deterioration. Repair implies

that something has broken or is not working. A need

for repair is often caused by lack of maintenance. Ex-

ample, draining and refilling the automatic transaxle

fluid is maintenance recommended by the manufac-

turer at specific mileage intervals. Failure to do this

can shorten the life of the transmission/transaxle, re-

quiring very expensive repairs. While no maintenance

program can prevent items from breaking or wearing

out, a general rule can be stated: MAINTENANCE IS

CHEAPER THAN REPAIR.

Two basic mechanrc’s rules should be mentioned

here. First, whenever the left side of the vehicle or en-

gine is referred to, it is meant to specify the drivers

side. Conversely, the right side of the vehicle means

the passengers side. Second, screws and bolts are

removed by turning counterclockwise, and tightened

by turning clockwrse unless specifically noted.

Safety is always the most important rule. Con-

stantly be aware of the dangers involved in working

on an automobile and take the proper precautions.

See the informatron in this section regarding SER-

VICING YOUR VEHICLE SAFELY and the SAFETY

NOTICE on the acknowledgment page.

Pay attention to the instructions provided. There

are 3 common mistakes in mechanical work:

1. Incorrect order of assembly, disassembly or

adjustment. When taking something apart or putting

it together, performing steps in the wrong order usu-

ally just costs you extra time; however, it CAN break

something. Read the entire procedure before begin-

ning disassembly. Perform everything in the order in

which the instructions say you should, even if you

can’t immedrately see a reason for it. When you’re

taking apart something that is very intricate, you

might want to draw a picture of how it looks when as-

sembled at one point in order to make sure you get everything back in its proper position. We will supply

exploded views whenever possible. When making

adjustments, perform them in the proper order. One

adjustment possibly will affect another.

2. Overtorquing (or undertorquing). While it is

more common for overtorquing to cause damage,

undertorquing may allow a fastener to vibrate loose

causing serious damage. Especially when dealing

with aluminum parts, pay attention to torque specifi-

cations and utilize a torque wrench in assembly. If a

torque figure is not available, remember that if you

are using the right tool to perform the job, you will

probably not have to strain yourself to get a fastener

tight enough. The pitch of most threads is so slight

that the tension you put on the wrench will be multi-

plied many times in actual force on what you are

tightening. A good example of how critical torque is

can be seen in the case of spark plug installation, es-

pecially where you are putting the plug into an alu-

minum cylinder head. Too little torque can fail to

crush the gasket, causing leakage of combustion

gases and consequent overheating of the plug and

engine parts. Too much torque can damage the

threads or distort the plug, changing the spark gap.

There are many commercial products available for

ensuring that fasteners won’t come loose, even if they

are not torqued just right (a very common brand is

Loctite? If you’re worried

about getting something

together tight enough to hold, but loose enough to

avoid mechanical damage during assembly, one of

these products might offer substantial insurance. Be-

fore choosing a threadlocking compound, read the

label on the package and make sure the product is

compatible with the materials, fluids, etc. involved.

3. Crossthreading. This occurs when a part such

as a bolt is screwed into a nut or casting at the wrong

angle and forced. Crossthreading is more likely to

occur if access is difficult. It helps to clean and lubri-

cate fasteners, then to start threading the bolt, spark

plug, etc. with your fingers If you encounter resis-

tance, unscrew the part and start over again at a dif-

ferent angle until it can be inserted and turned several

times without much effort. Keep in mind that many

parts, especially spark plugs, have tapered threads,

so that gentle turning will automatically bring the part

you’re threading to the proper angle. Don’t put a

wrench on the part until its been tightened a couple

of turns by hand. If you suddenly encounter resis-

tance, and the part has not seated fully, don’t force it.

Pull it back out to make sure it’s clean and threading

properly.

Be sure to take your time and be patient, and al-

ways plan ahead. Allow yourself ample time to per-

form repairs and maintenance You may find main-

taining your car a satisfying and enjoyable

experience.

b See Figures 1 thru 15

Naturally, without the proper tools and equipment

it is impossible to properly service your vehicle. It

would also be virtually impossible

to catalog every

tool that you would need to perform all of the opera-

tions in this book. Of course, It would be unwise for

the amateur to rush out and buy an expensive set of

tools on the theory that he/she may need one or more

of them at some time, The best approach is to proceed slowly, gathering savings will

be far outweighed by frustration and

a good quality set of those tools that are used most mangled knuckles.

frequently Don’t be misled by the low cost of bargain Begin accumulating those tools that are used most

tools. It is far better to spend a little more for better frequently: those associated with routine maintenance

quality. Forged wrenches, 6 or 12-point sockets and and tune-up. In addition to the normal assortment of

fine tooth ratchets are by far preferable to their less screwdrivers and pliers, you should have the follow-

expensive counterparts. As any good mechanic can ing tools:

tell you, there are few worse experiences than trying

l Wrenches/sockets and combination open

to work on a vehicle with bad tools. Your monetary end/box end wrenches in sizes from %-% in. or

Page 36 of 408

_. .I ..-.

-._.

GENERALINFORMATIONAND MAINTENANCE l-37

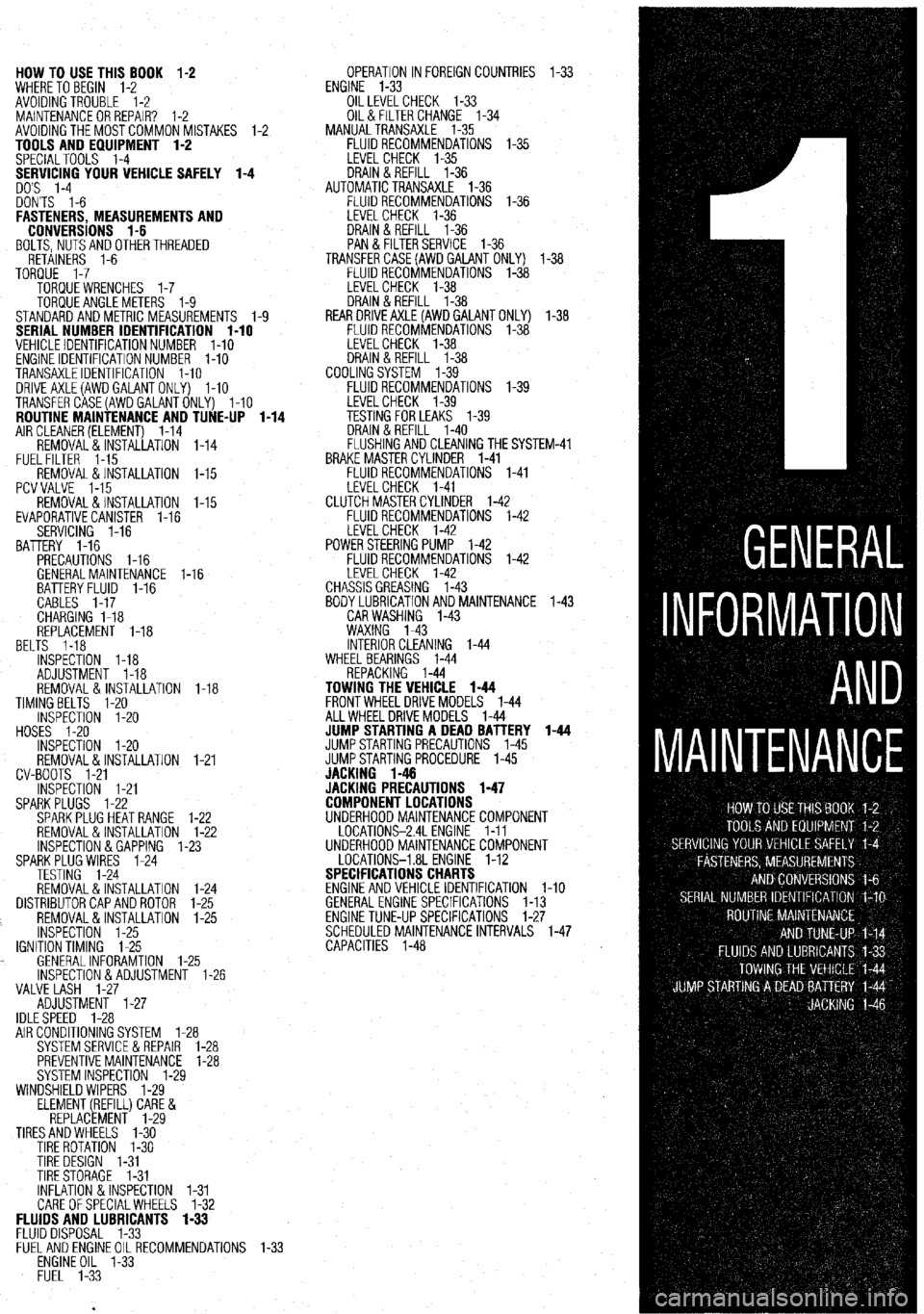

Fig. 172 Carefully pull the transaxie drain

plug out and to the side, out of the way oi

flowing transaxie oil Fig. 173 The differential drain plug is lo-

cated at the bottom of the transaxie, to the

left of the fluid pan. Typically the drain plug

reauires a 17mm wrench

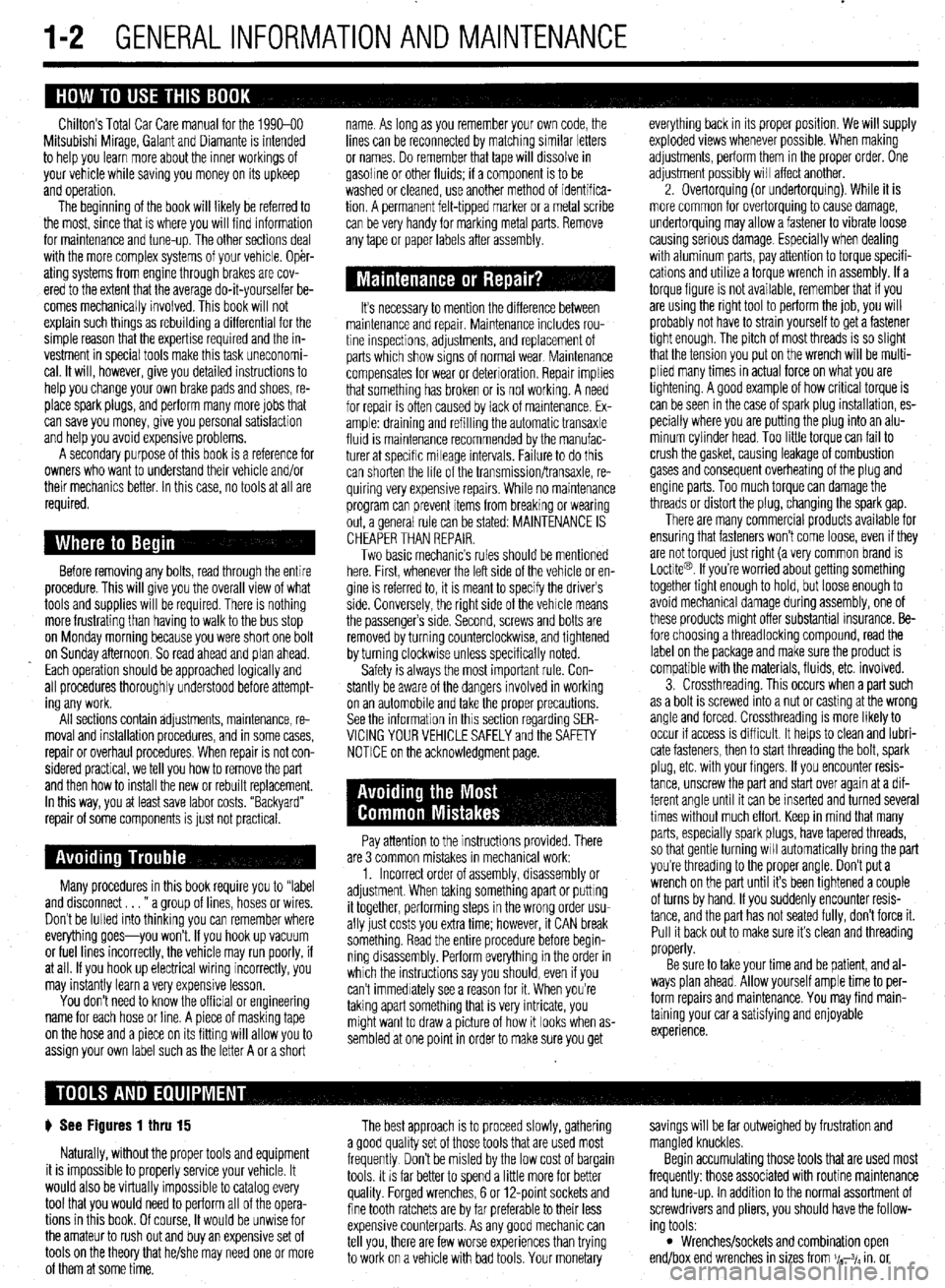

periodically checking the fluid level to

make sure you do not overfill the transaxle pan mounting

bolts, a 1Omm wrench is re-

Fig. 179 . . , then carefully lower the fluid

quired. Remove the pan retaining bolts . . . pan from the transaxle

Fig, 181 . , . then remove the transaxie film

ter from the valve body Fig. 182 Remove the transaxie pan

gasket from the pan

Page 37 of 408

t

1-38 GENERALINFORMATIONAND MAINTENANCE

11 I Add the recommended automatic transaxle

fluid to the transaxle through the dipstick tube. You

will need a long necked funnel, or a funnel and tube

to do this. A quick check of the capacities chart later

in this Section will reveal the capacity of the transaxle

in your vehicle. On a first fill after removing the pan

and filter, this number should be cut into a ‘hand

checked on the dipstick before refilling.

12. With the transaxle in P, put on the parking

brake, block the front wheels, start the engine and let

it idle. DO NOT RACE THE ENGINE. DO NOT MOVE

THE LEVER THROUGH ITS RANGES.

13. With the lever in Park, check the fluid level. If

it’s OK, take the car out for a short drive, park on a

level surface, and check the level again, as outlined

earlier in this section. Add more fluid if necessary. Be

careful not to overfill, which will cause foaming and

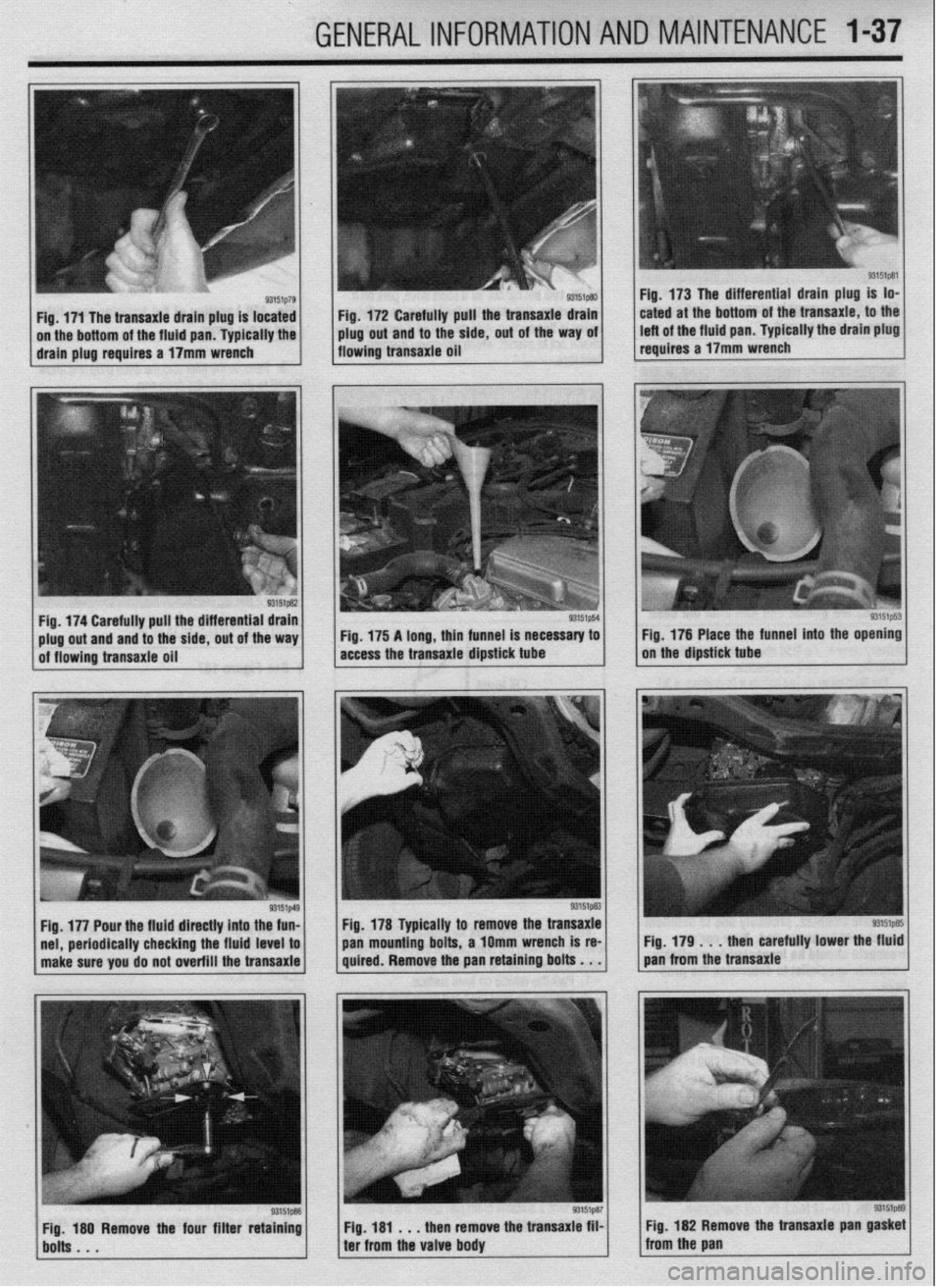

w fluid loss. n of the transfer case filler

3. Remove the filler and the drain plug and allow

the oil to drain into the drain pan.

4. After the fluid has drained completely, install

the drain plug and tighten to 24 ft. Ibs. (32 Nm).

5. Refill the transfer case to the proper level with

Fig. 184 . . .

the transaxle case before in-

stalling the gasket

and pan onto the case FLUID RECOMMENDATIONS Hypoid gear oil SAE 75W-85W/75W-9OW conform-

ing to API specifications GL-4 or higher. The oil level

-‘-,*I’ -nnnh +‘* “%om edge of the oil filler hole.

nxfer raw filler nlm and tinhtm When adding fluid or refilling the transfer case,

use Hypoid gear oil SAE 75W-85W or 75W-9OW

conforming to API specifications 61-4 or higher.

LEVELCHECK 6. Install the tra .._._. ____ .._. T.-J _.._ .lJ . .._..

to 24 ft. lbs. (32 Nm).

7. Carefully lower the vehicle.

u See Figure 185

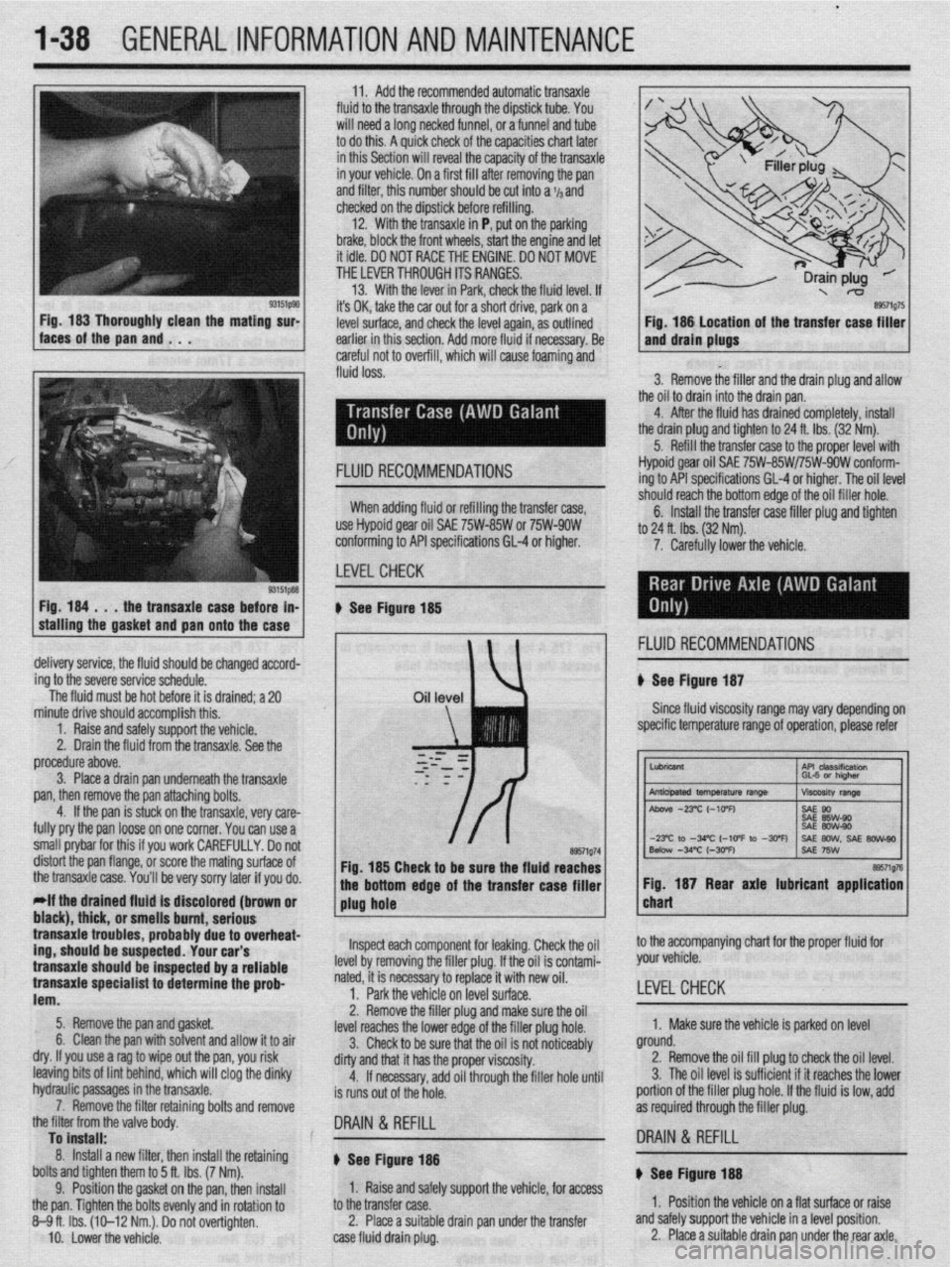

, 1 FLUID RECOMMENDATIONS

delivery service, the fluid should be changed accord-

ing to the severe service schedule.

The fluid must be hot before it is drained; a 20 u See Figure 187

Since fluid viscosity range may

vary depending on

specific temperature range of operation, please refer

~~

tne transaxle case.

You’ll be very sorry later if you do. bottom edge of the transfer case filler 1 1 Fig. 187 Rear axle lubricant application I

*If the drained fluld is discolored (brown or

1 plug hole chart black), thick, or pmmll~ hmmt nnrinmm I transaxle trouble .llln3llU ““III., url,““P s, probably due to overheat-

,r..rr,rA “#.a.- rrdr

trig, should be susp~~lr;u. lvUl vLlr J

transaxle should be inspected by a reliable

transaxle specialist to determine the prob-

lem.

5. Remove the pan and gasket.

6. Clean the pan with solvent and allow it to air

dry. If you use a rag to wipe out the pan, you risk

leaving bits of lint behind, which will clog the dinky

hydraulic passages in the bansaxle.

7. Remove the filter retaining bolts and remove

the filter from the valve bodv. lnsoect each component for leaking. Check the oil

he filler plug. If the oil is contami-

ry to replace it with new oil.

if% nn IPVPI z11rf2r~

level by removing t

nated, it is necessa

1. Park the vehi,., -.. ,-.“, __. ,“-_.

2. Remove the filler plug and make sure the oil

level reaches the lower edge of the filler plug hole.

3. Check to be sure that the oil is not noticeably

dirty and that it has the proper viscosity.

4. If necessary, add oil through the filler hole until

is runs out of the hole. to the accompanying chart for the proper fluid for

your vehicle.

LEVEL CHECK

1. Make sure the vehicle is parked on level

ground.

2. Remove the oil fill plug to check the oil level.

3. The oil level is sufficient if it reaches the lower

portion of the filler plug hole. If the fluid is low, add

as required through the filler plug.

To install: .

8. Install a new filter, then install the retaining

bolts and tighten them to 5 ft. Ibs. (7 Nm).

9. Position the gasket on the pan, then install

the pan. Tighten the bolts evenly and in rotation to

8-9ft. Ibs. (10-12 Nm.). Do not overtighten.

IO. Lower the vehicle. DRAIN & REFILL

I8 DRAIN & REFILL

u See Figure 188 ) See Figure- 14

1. Raise and safely support the vehicle, for access

to the transfer case.

2. Place a suitable drain pan under the transfer

case fluid drain plug. 1. Position the vehicle on a flat surface or raise

and safely support the vehicle in a level position.

2. Place a suitable drain pan under the rear axle.

Page 63 of 408

3-2 ENGINEANDENGINEOVERHAUL

REMOVAL &INSTALLATION

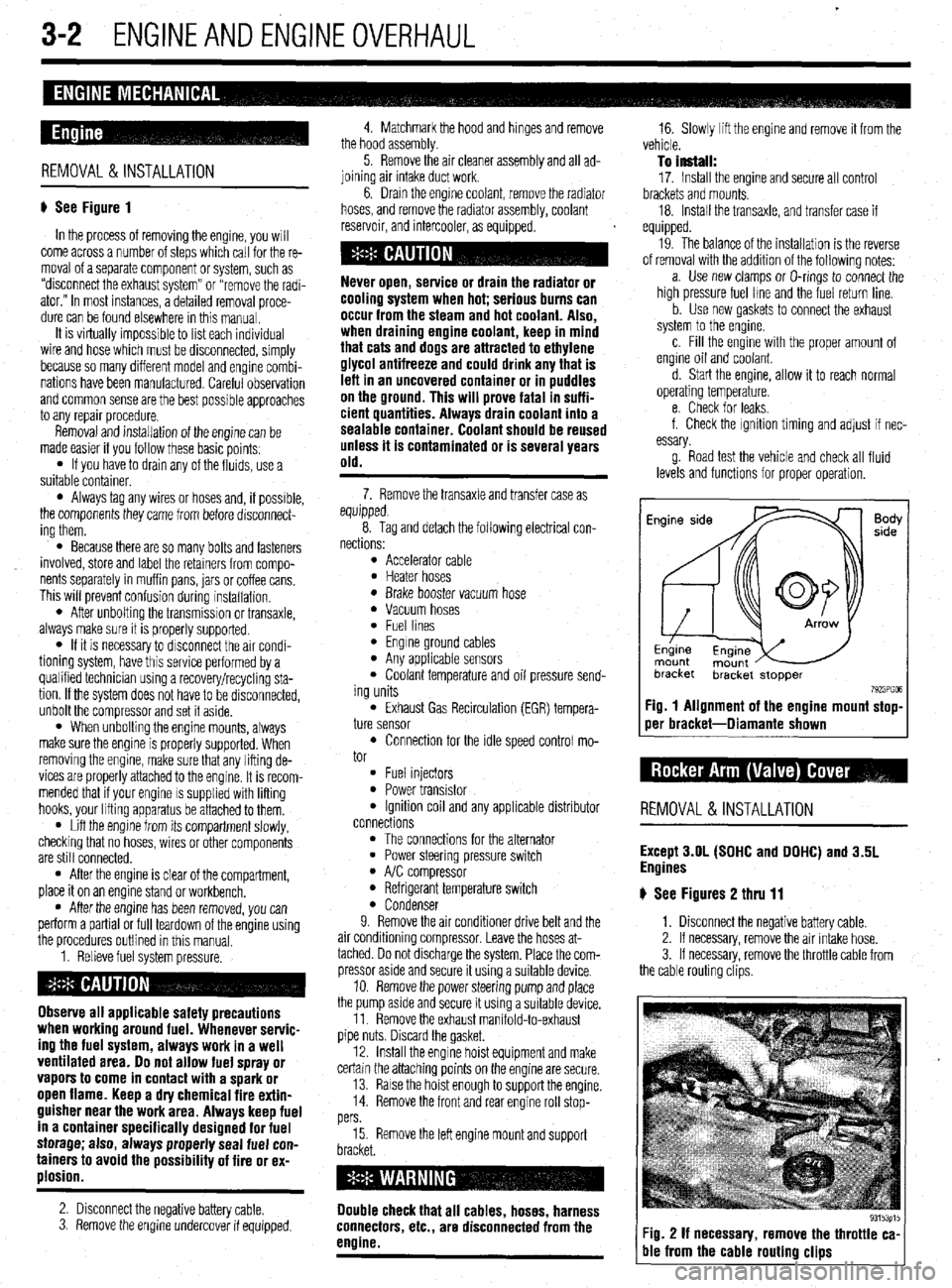

# See Figure 1

In the process of removing the engine, you will

come across a number of steps which call for the re-

moval of a separate component or system, such as

“disconnect the exhaust system” or “remove the radi-

ator.” In most instances, a detailed removal proce-

dure can be found elsewhere in this manual.

It is virtually impossible to list each individual

wire and hose which must be disconnected, simply

because so many different model and engrne combi-

nations have been manufactured Careful observation

and common sense are the best possible approaches

to any repair procedure.

Removal and installation of the engine can be

made easier if you follow these basic points:

l If you have to drain any of the fluids, use a

suitable container.

l Always tag any wires or hoses and, if possrble,

the components they came from before disconnect-

ing them.

l Because there are so many bolts and fasteners

involved, store and label the retainers from compo-

nents separately in muffin pans, jars or coffee cans.

This will prevent confusion during installatron.

l After unbolting the transmisston or transaxle,

always make sure it is properly supported.

l If it is necessary to disconnect the air condi-

tioning system, have this service performed by a

qualified technician using a recovery/recycling sta-

tion If the system does not have to be disconnected,

unbolt the compressor and set it aside.

l When unbolting the engine mounts, always

make sure the engine is properly supported. When

removing the engine, make sure that any lifting de-

vices are properly attached to the engine. It is recom-

mended that if your engine IS supplied with lifting

hooks, your lifting apparatus be attached to them.

l Lift the engine from its compartment slowly,

checking that no hoses, wires or other components

are still connected.

l After the engine is clear of the compartment,

place it on an engine stand or workbench.

l After the engine has been removed, you can

perform a partial or full teardown of the engine using

the procedures outlined in this manual.

1. Relieve fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect the negative battery cable.

3. Remove the engine undercover if equipped. 4. Matchmark the hood and hinges and remove

the hood assembly.

5. Remove the air cleaner assembly and all ad-

joining air intake duct work.

6. Drain the engine coolant, remove the radiator

hoses, and remove the radiator assembly, coolant

reservoir, and intercooler, as equipped.

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

7. Remove the transaxle and transfer case as

equipped.

8. Tag and detach the following electrical con-

nections:

l Accelerator cable l Heater hoses l Brake booster vacuum hose l Vacuum hoses l Fuel lines l Engine ground cables l Any applicable sensors l Coolant temperature and oil pressure send-

ing units

l Exhaust Gas Recirculation (EGR) tempera-

ture sensor

l Connection for the idle speed control mo-

tor

l Fuel injectors l Power transistor l Ignition coil and any applicable distributor

connections

l The connections for the alternator l Power steering pressure switch l A/C compressor l Refrigerant temperature switch l Condenser

9. Remove the air conditioner drive belt and the

air conditioning compressor. Leave the hoses at-

tached. Do not discharge the system. Place the com-

pressor aside and secure it using a suitable device.

10. Remove the power steering pump and place

the pump asrde and secure it using a surtable device.

11. Remove the exhaust manifold-to-exhaust

pipe nuts. Discard the gasket.

12. Install the engine hoist equipment and make

certain the attaching points on the engine are secure.

13. Raise the hoist enough to support the engine.

14. Remove the front and rear engine roll stop-

pers

15. Remove the left engine mount and support

Double check that all cables, hoses, harness

connectors, etc., are disconnected from the

engine.

16. Slowly lift the engine and remove it from the

vehicle.

To install:

17. Install the engine and secure all control

brackets and mounts.

18. Install the transaxle, and transfer case if

equipped.

19. The balance of the installation is the reverse

of removal with the addition of the following notes:

a. Use new clamps or O-rings to connect the

high pressure fuel lme and the fuel return line.

b. Use new gaskets to connect the exhaust

system to the engine.

c. Fill the engine with the proper amount of

engine oil and coolant.

d. Start the engine, allow it to reach normal

operating temperature.

e. Check for leaks.

f. Check the ignition timing and adjust if nec-

essary.

g. Road test the vehicle and check all fluid

levels and functions for proper operation.

Fig. 1 Alignment of the engine mount stop-

oer bracket-Diamante shown

REMOVAL &INSTALLATION

Except 3.OL (SOHC and DOHC) and 3.5L

Engines

# See Figures 2 thru 11

1. Disconnect the negative battery cable.

2. If necessary, remove the air intake hose.

3. If necessary, remove the throttle cable from

the cable routing clips.

Fig. 2 If necessary, remove the throttle ca-

ble from the cable routing clips

Page 68 of 408

ENGINEANDENGINEOVERHAUL 3-7

4. Remove the center cover, breather and PCV

hoses, and spark plug cables.

5. Remove the rocker cover.

6. Remove the throttle body stay, both camshaft

sprockets, and oil seals.

7. Remove the Camshaft Position fCMP) sensor 3. install the lash adjuster clips on the rocker

arms, then loosen the bearing cap bolts. Do not re-

move the bolts from the bearing caps.

4. Remove the rocker arms, shafts and bearing

caps as an assembly.

lo hlstall: unless it is contaminated or is several years old.

3. Remove any necessary components to access

the thermostat.

4. Remove the thermostat housinq retaininq

nd adapter from the rear of the camshah. ’

8. Remove the intake and exhaust camshafts.

9. Remove rocker arms and lash adjusters from

he head. It is recommended that all lash adjusters

md rockers be replaced as a complete set.

To Install:

10. Immerse the lash adjusters in clean diesel

uel. Using a small wire, move the plunger of the lash

tdjuster up and down four or five times while push-

ng down lightly on the check ball in order to bleed

jut the air. Lubricate and install the lash adjusters in

he cylinder head.

11. Lubricate the camshafts with clean enqine oil

nd position the camshafts on the cylinder head.

12. Install the bearing caps. Tighten the caps in

sequence, in 2 or 3 steps. Caps 2,3 and 4 have a

ront mark. Install with the mark aligned with the front

nark on the cylinder head. Intake caps have I

stamped on the cap and exhaust caps have E. Also,

)e sure the rocker arm is correctly mounted on the

ash adjuster and the valve stem end. Torque the front

md rear retaining cap bolts to 14 ft. Ibs. (20 Nm) and

ighten the center 3 retaining cap bolts to 8 ft. Ibs.

11 Nm).

13. Apply a coating of engine oil to the oil seals

md install.

14. Install the timing belt, valve cover and all re-

ated parts. Refer to the timing belt procedure in this

;ection. 5. Install the bearing caps/rocker arm assem-

blies. Tighten the bolts to 23 ft. Ibs. (31 Nm).

6. Remove the lash adjuster clips.

7. Install the rocker arm cover using a new gas-

ket.

8. Connect the negative battery cable.

REMOVAL &INSTALLATION

b See Figures 24, 25, 26, and 27

1. Disconnect the negative battery cable.

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious bums can

occur from the

steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused bolts.

5. Lift the housing from the engine.

6. Remove the thermostat taking note of its

original position in the housing.

To Install:

*In order to prevent leakage, make sure

both mating

surfaces are clean and free of

any old gasket material.

7. Install the thermostat so its flange seats

tightly in the machined groove in the intake manifold

or thermostat case. Refer to its location prior to re-

moval. Aliqn the relief valve with the alignment mark

on the thermostat housing.

8. Use a new gasket or D-ring and reinstall the

thermostat housing. Torque the housing mounting

bolts to the following specifications:

l 1.8L engine: 16 ft. Ibs. (22 Nm) l 1.5L, 1.61, 2.OL DOHC, and 1990-92 2.OL

SOHC engines: 12-14 ft. Ibs. (17-20 Nm)

l 1993 2.01 SOHC engine: 7-10 ft. Ibs.

(10-15 Nm)

l 2.4L engine: IO ft. Ibs. (14 Nm) l 3.OL and 3.5L engines: 12-14 ft. Ibs.

(17-20 Nm)

9. Fill the system with coolant.

10. Install the removed air intake plumbing.

15. Connect the negative battery cable and check

or leaks.

3.51 Engine

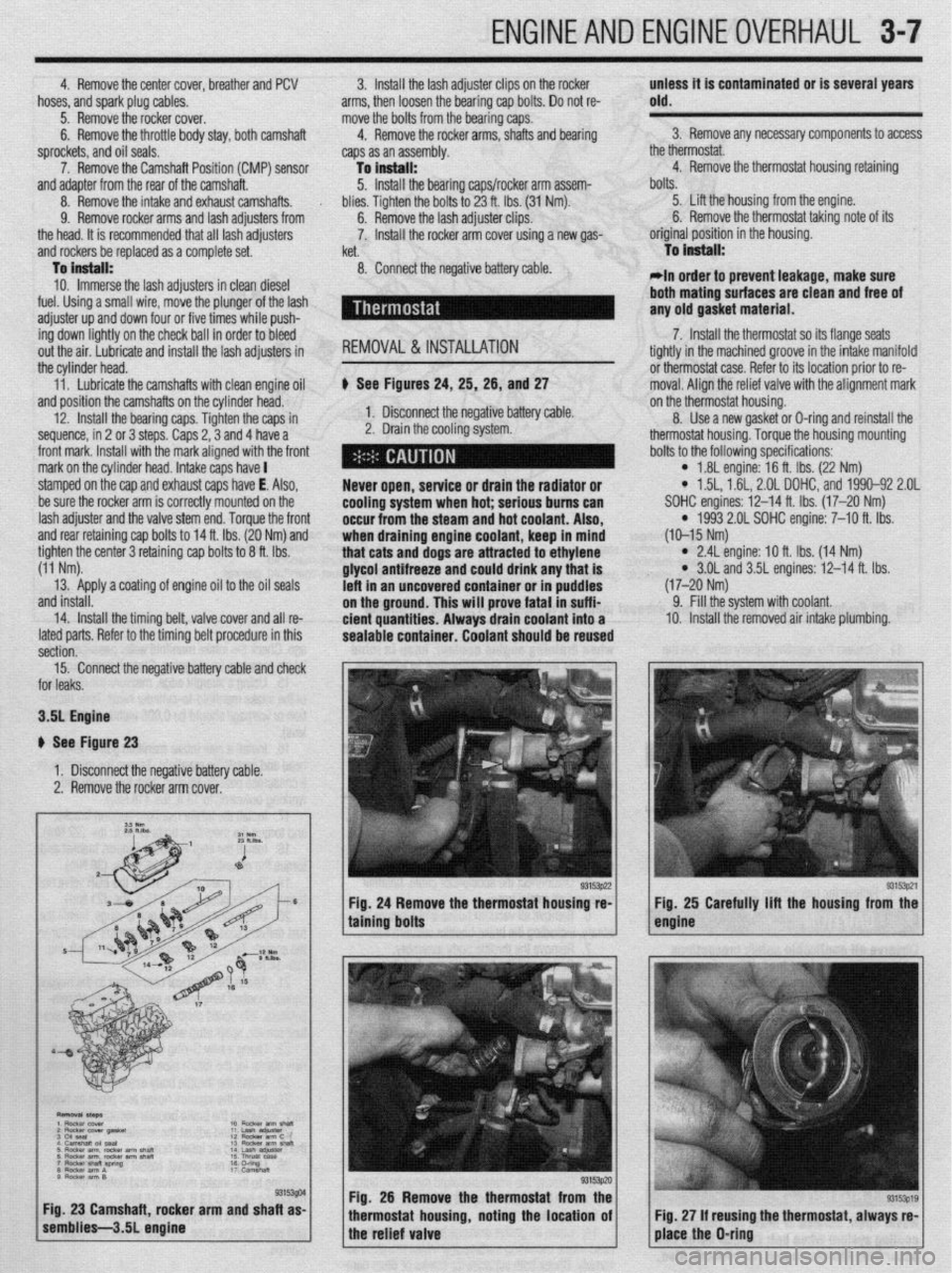

I See Figure 23

1. Disconnect the negative battery cable.

2. Remove the rocker arm cover.

g. 26 Remove the thermostat from the

ousing, noting the location of using the thermostat, always re-

Page 69 of 408

3-8' ENGINEANDENGINEOVERHAUL

Nm ft.lbs.

1. Engine hanger 5. Engine hanger

2. Intake manifold stay 6. Exhaust manifold cover

3. intake manifold 7. Exhaust manifold

4. Intake manifold gasket 8. Exhaust manifold gasket

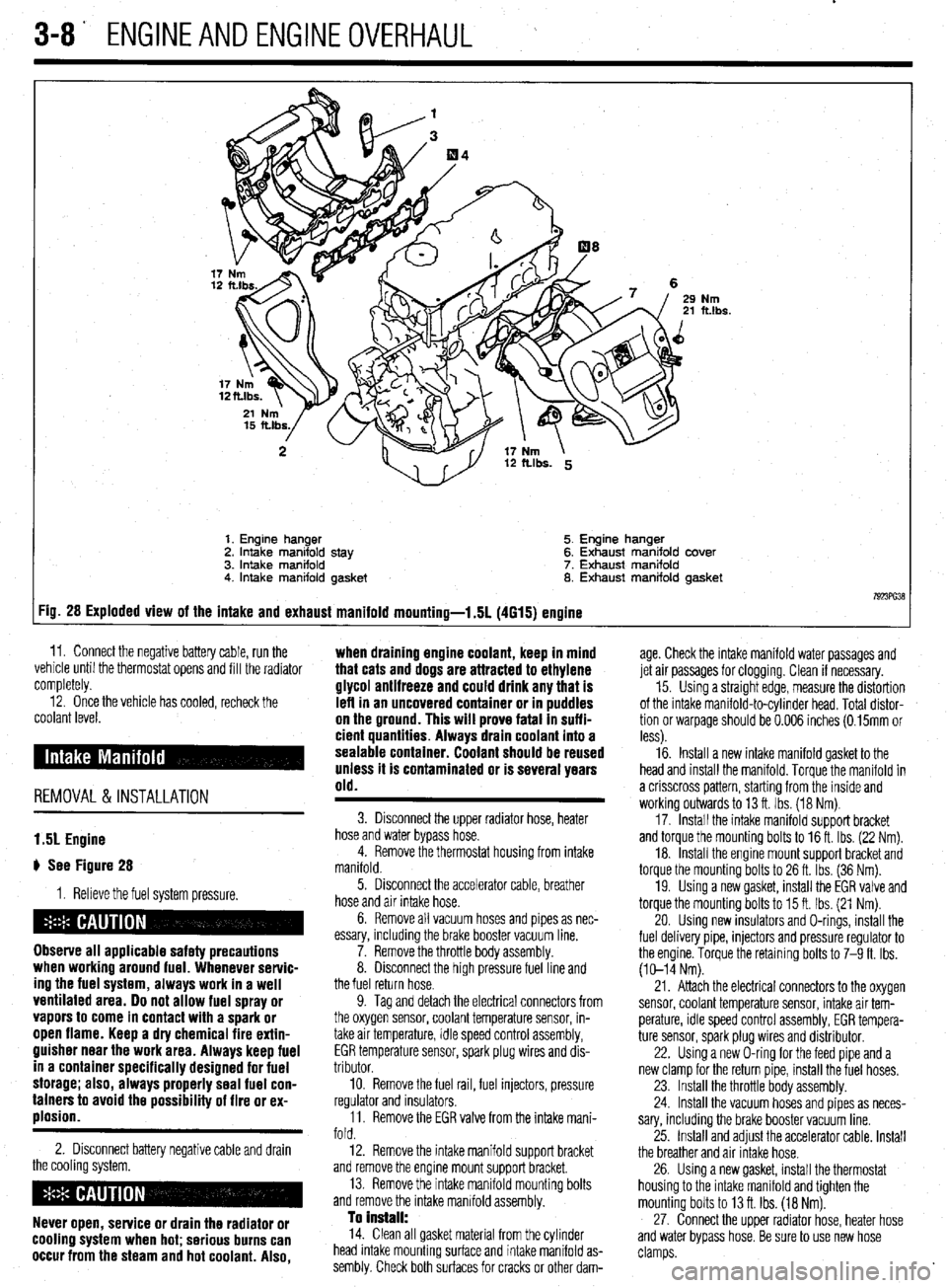

7923ffi38 :ig. 28 Exploded view of the intake and exhaust manifold mounting-l .5L (4615) engine

11. Connect the negative battery cable, run the ,. . . .

vemcie unnl me tnermostat opens ano till the radiator

completely. age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

12. Once the vehicle has cooled, recheck the

coolant level.

REMOVAL &INSTALLATION when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal In suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

15. Using a straight edge, measure the distortion

of the intake manifold-to-cylinder head. Total distor-

tion or warpage should be 0.006 inches (0.15mm or

less).

16. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crisscross pattern, starting from the inside and

working outwards to 13 ft. Ibs. (18 Nm).

17. Install the intake manifold support bracket

and torque the mounting bolts to 16 ft. Ibs. (22 Nm).

18. Install the engine mount support bracket and

torque the mounting bolts to 26 ft. Ibs. (36 Nm).

19. Using a new gasket, install the EGR valve and

torque the mounting bolts to 15 ft. Ibs. (21 Nm).

20. Using new insulators and O-rings, install the

fuel delivery pipe, injectors and pressure regulator to

the engine. Torque the retaining bolts to 7-9 ft. Ibs.

(10-14 Nm).

1.51 Engine

# See Figure 28

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drain

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

3. Disconnect the upper radiator hose, heater

hose and water bypass hose.

4. Remove the thermostat housing from intake

manifold.

5. Disconnect the accelerator cable, breather

hose and air intake hose.

6. Remove all vacuum hoses and pipes as nec-

essary, including the brake booster vacuum line.

7. Remove the throttle body assembly.

8. Disconnect the high pressure fuel line and

the fuel return hose.

9. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor, in-

take air temperature, idle speed control assembly,

EGR temperature sensor, spark plug wires and dis-

tributor.

10. Remove the fuel rail, fuel injectors, pressure

regulator and insulators.

11. Remove the EGR valve from the intake mani-

fold.

12. Remove the intake manifold support bracket

and remove the engine mount support bracket.

13. Remove the intake manifold mounting bolts

and remove the intake manifold assembly.

To Install: 14. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly. Check both surfaces for cracks or other dam- 21. Attach the electrical connectors to the oxygen

sensor, coolant temperature sensor, intake air tem-

perature, idle speed control assembly, EGR tempera-

ture sensor, spark plug wires and distributor.

22. Using a new O-ring for the feed pipe and a

new clamp for the return pipe, install the fuel hoses.

23. Install the throttle body assembly.

24. Install the vacuum hoses and pipes as neces-

sary, including the brake booster vacuum line.

25. Install and adjust the accelerator cable. Install

the breather and air Intake hose.

26. Using a new gasket, install the thermostat

housing to the intake manifold and tighten the

mounting bolts to 13 ft. Ibs. (18 Nm).

27. Connect the upper radiator hose, heater hose

and water bypass hose. Be sure to use new hose

clamps.

Page 70 of 408

ENGINEANDENGINEOVERHAUL 3-9

28. Fill the system with coolant.

29. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

30. Check and adjust the idle speed and ignition

timing.

31. Once the vehicle has cooled, recheck the

coolant level.

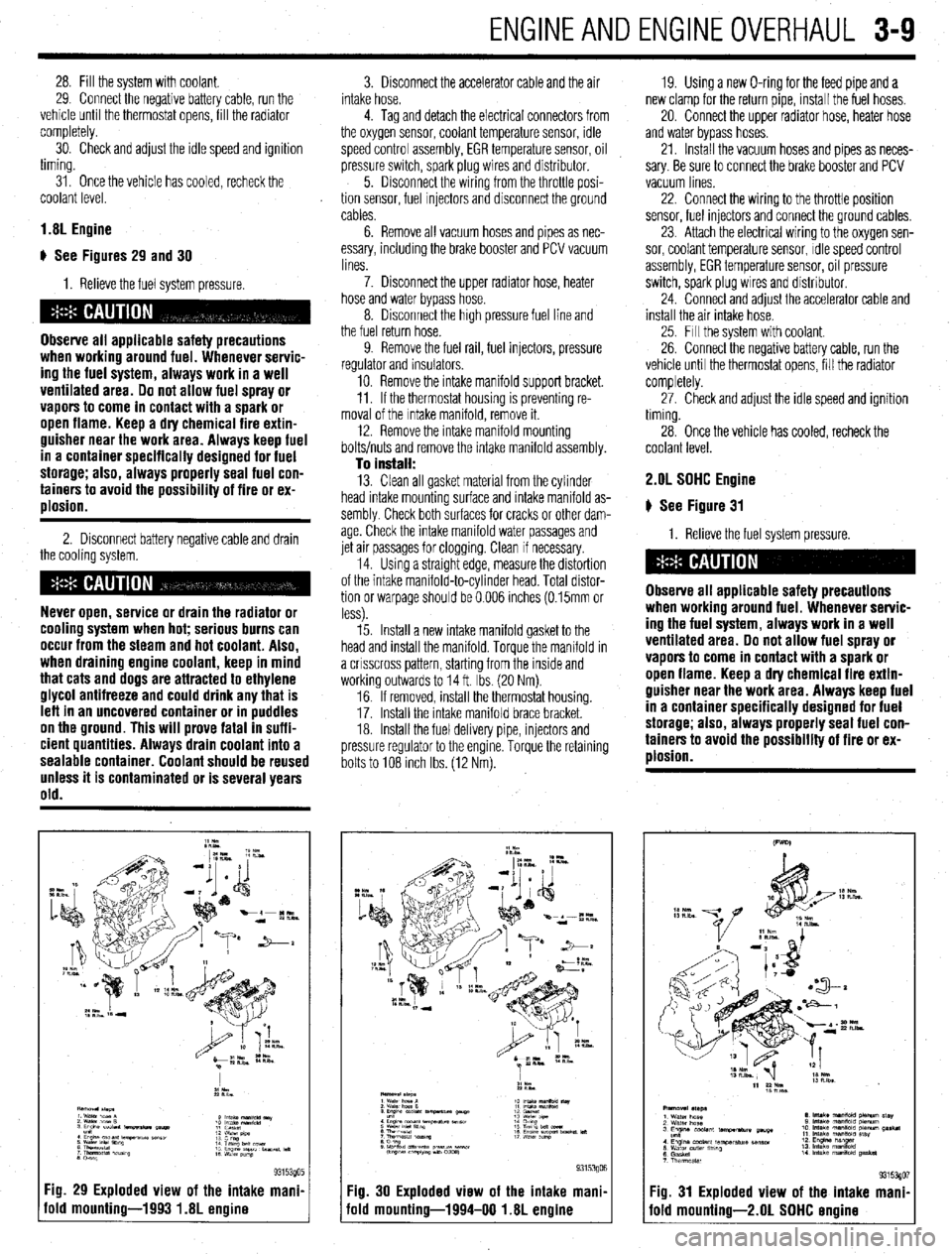

1.8L Engine

) See Figures 29 and 30

I. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drain

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

leff in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

Fig. 29 Exploded view of the intake mani.

old mounting-1993 1.8L engine

3. Disconnect the accelerator cable and the air

intake hose.

4. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor, idle

speed control assembly, EGR temperature sensor, oil

pressure switch, spark plug wires and distributor.

5. Disconnect the wiring from the throttle posi-

tion sensor, fuel Injectors and disconnect the ground

cables.

6. Remove all vacuum hoses and pipes as nec-

essary, including the brake booster and PCV vacuum

lines.

7. Disconnect the upper radiator hose, heater

hose and water bypass hose.

8. Disconnect the high pressure fuel line and

the fuel return hose.

9. Remove the fuel rail, fuel injectors, pressure

regulator and insulators.

10. Remove the intake manifold support bracket.

11. If the thermostat housing is preventing re-

moval of the Intake manifold, remove it.

12. Remove the intake manifold mounting

bolts/nuts and remove the intake manifold assembly.

To install: 13. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

14. Using a straight edge, measure the distortion

of the intake manifold-to-cylinder head. Total distor-

tion or warpage should be 0.006 inches (0.15mm or

less).

15. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crrsscross pattern, starting from the inside and

working outwards to 14 ft. Ibs. (20 Nm).

16. If removed, install the thermostat housing.

17. Install the Intake manifold brace bracket.

18. Install the fuel delivery pipe, injectors and

pressure regulator to the engine. Torque the retaining

bolts to 108 Inch Ibs. (12 Nm). 19. Using a new O-ring for the feed pipe and a

new clamp for the return pipe, install the fuel hoses,

20. Connect the upper radiator hose, heater hose

and water bypass hoses.

21. Install the vacuum hoses and pipes as neces-

sary. Be sure to connect the brake booster and PCV

vacuum lines

22. Connect the wiring to the throttle position

sensor, fuel injectors and connect the ground cables,

23. Attach the electrical wiring to the oxygen sen-

sor, coolant temperature sensor, Idle speed control

assembly, EGR temperature sensor, oil pressure

switch, spark plug wires and distributor.

24. Connect and adjust the accelerator cable and

install the air intake hose.

25. Fill the system with coolant.

26. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

27. Check and adjust the idle speed and ignition

timing.

28. Once the vehicle has cooled, recheck the

coolant level. 2.OL SOHC Engine

# See Figure 31

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

Fig. 30 Exploded view of the intake mani,

iold mounting-1994-00 1.8L engine Fig. 31 Exploded view of the intake mani

fold mounting-2.01 SOHC ermine

Page 71 of 408

3-10 ENGINEANDENGINEOVERHAUL

2. Disconnect the battery negative cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4 Disconnect the accelerator cable and air in-

take hose.

5. Disconnect the upper radiator hose, heater

hose and water bypass hose.

6. Unplug the vacuum connection at the power

brake booster and the PCV valve if still connected.

Disconnect all remaining vacuum hoses and pipes as

necessary.

7. Disconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack-

ets

8. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor,

therm0 switch, idle speed control assembly, EGR

temperature sensor, distributor, fuel injectors and

spark plug wires. Position the engine wiring harness

aside.

9. Matchmark the distributor housing to the in-

take manifold, and remove the distributor.

10. Remove the intake manifold bracket and the

engine hanger.

11. If the thermostat housing is preventing re-

moval of the intake manifold, remove it.

12. Remove the intake manifold mounting bolts

and remove the intake manifold assembly. Drsassem-

ble manifold from the Intake plenum on a work bench

as required

To install: 13. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

14 Assemble the intake manifold assembly using

all new gaskets. Torque air intake plenum bolts to

11-14ff. Ibs. (15-19 Nm).

15. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crrsscross pattern, starting from the inside and

working outwards to 11-14 ff. Ibs. (15-19 Nm).

16. Install the fuel delivery pipe, injectors and

pressure regulator to the engine. Torque the retaining

bolts to 4 ft. Ibs (6 Nm).

17. install the thermostat housing, intake mani-

fold brace bracket, and engine hanger bracket.

18 Connect or install all hoses, cables and elec-

trical connectors that were removed or disconnected

during the removal procedure.

19. Align the distributor matchmarks and install

the distributor.

20. Fill the system with coolant,

21. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely. 22. Adjust the accelerator cable. Check and ad-

just the idle speed and ignition timing.

23. Once the vehicle has cooled, recheck the

coolant level.

1.6L and 2.OL DDHC Engines

# See Figure 32

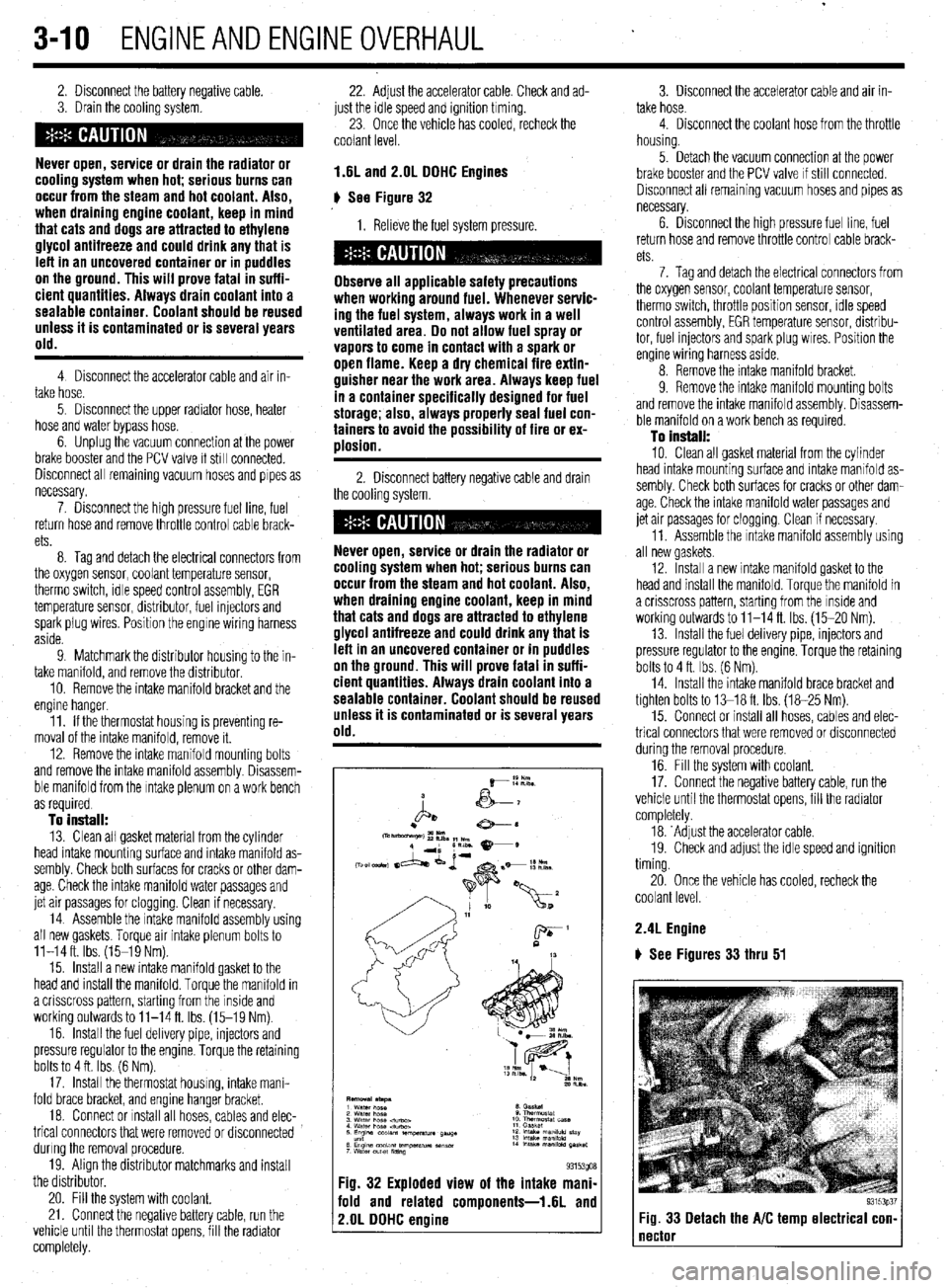

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

ulosion.

2. Disconnect battery negative cable and drain

the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

Fig. 32 Exploded view of the intake mani-

fold and related components-1.6L and

2.OL DDHC engine

3. Disconnect the accelerator cable and air in-

take hose.

4. Disconnect the coolant hose from the throttle

housing.

5. Detach the vacuum connection at the power

brake booster and the PCV valve If still connected.

Disconnect all remaining vacuum hoses and pipes as

necessary.

6. Drsconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack-

ets

7. Tag and detach the electrical connectors from

the oxygen sensor, coolant temperature sensor,

therm0 switch, throttle position sensor, rdle speed

control assembly, EGR temperature sensor, distribu-

tor, fuel injectors and spark plug wires. Position the

engine wiring harness aside.

8. Remove the intake manifold bracket.

9. Remove the intake mamfold mounting bolts

and remove the intake manifold assembly. Disassem-

ble manifold on a work bench as required.

To install:

10. Clean all gasket material from the cylinder

head intake mounting surface and intake manifold as-

sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and

jet air passages for clogging. Clean if necessary.

11. Assemble the Intake manifold assembly using

all new gaskets.

12. Install a new intake manifold gasket to the

head and install the manifold. Torque the manifold in

a crisscross pattern, starting from the inside and

working outwards to 11-14 ft. Ibs. (15-20 Nm).

13. Install the fuel delivery pipe, injectors and

pressure regulator to the engine. Torque the retaining

bolts to 4 ft. Ibs. (6 Nm).

14. Install the intake manifold brace bracket and

tighten bolts to 13-18 ft. Ibs. (18-25 Nm).

15. Connect or install all hoses, cables and elec-

trical connectors that were removed or disconnected

during the removal procedure.

16. Fill the system with coolant.

17. Connect the negative battery cable, run the

vehicle until the thermostat opens, fill the radiator

completely.

18. ‘Adjust the accelerator cable.

19. Check and adjust the idle speed and ignition

timing.

20. Once the vehicle has cooled, recheck the

coolant level.

2.4L Engine

) See Figures 33 thru 51

93153p37 Fig. 33 Detach the A/C temp electrical con- 1

Page 73 of 408

.

3-12 ENGINEANDENGINEOVERHAUL

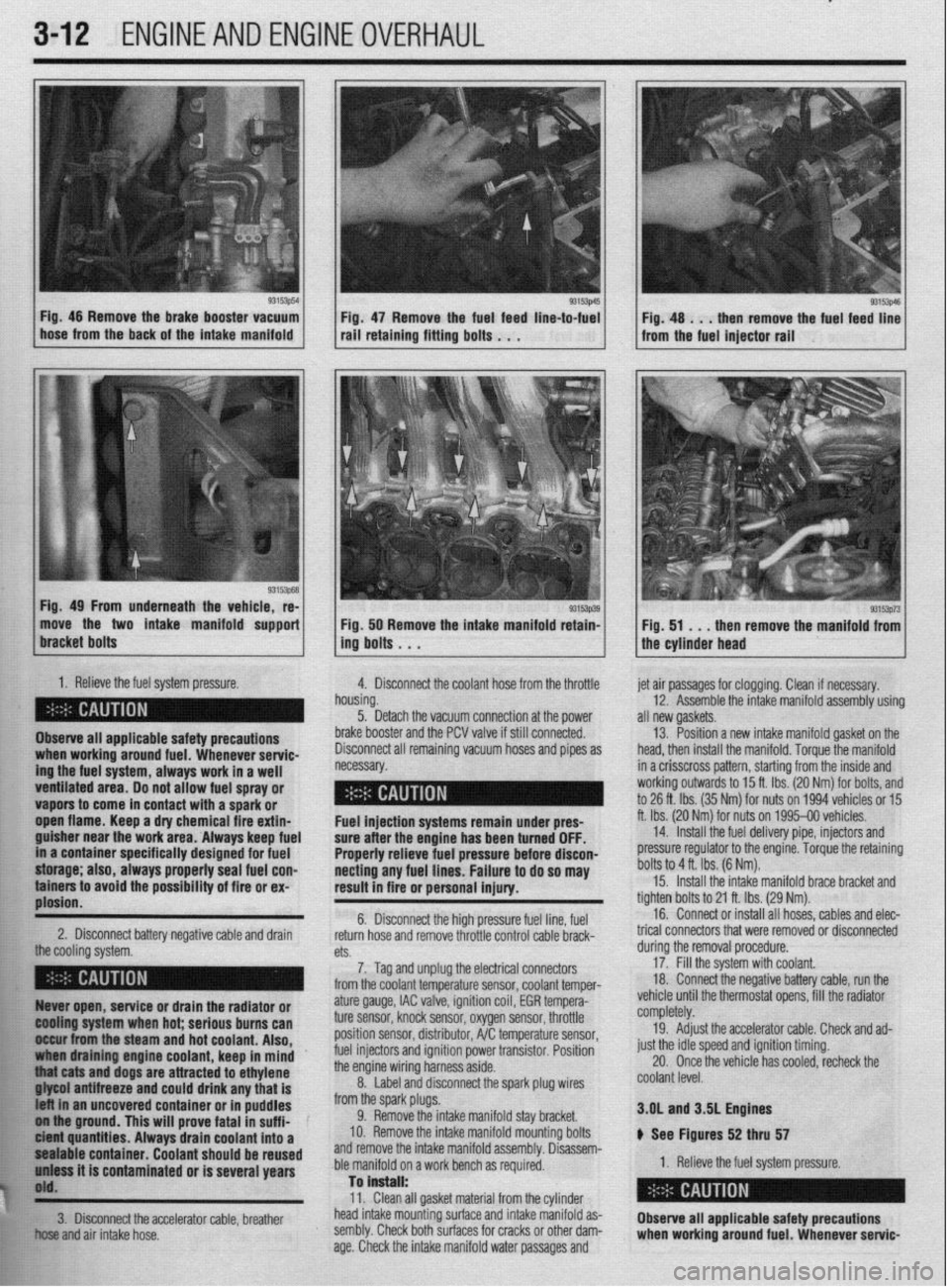

93153p54

1

L Fig. 46 Remove the brake booster vacuum

hose from the back of the intake manifold Fig 47 Remove the fuel feed line-to-fuel rail’retaini”g fitti”g bo,ts . . .

Fig. 49 From underneath the vehicle, re-

move the two intake manifold support

1. Relieve the fuel system pressure.

4. Disconnect the coolant hose from the throttle

Observe all applicable safety precautions

ing the fuel system, always work in a well when working around fuel. Whenever servic-

ventilated area. Do not allow fuel spray or - __.

vapors to come in contact with a spark or

._

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable and drain

the cooling rtfctnm 93153p39 Fig. 50 Remove the intake manifold retain-

ing bolts . . .

h

n ousing.

5. Detach the vacuum connection at the power

b

rake booster and the PCV valve if still connected.

C lisconnect all remaining vacuum hoses and pipes as

ecessary. et air passages for clogging. Clean if necessary.

12. Assemble the intake manifold assembly using

III new gaskets.

13. Position a new intake manifold gasket on the

lead, then install the manifold. Torque the manifold

n a crisscross pattern, starting from the inside and

vorking outwards to 15 ft. Ibs. (20 Nm) for bolts, and

o 26 ft. Ibs. (35 Nm) for nuts on 1994 vehicles or 15

t. Ibs. (20 Nr$ for nuts on 1995-00 vehicles.

14. Install the fuel delivery pipe, injectors and

xessure regulator to the engine. Torque the retaining

)olts to 4 ft. Ibs. (6 Nm). Fuel injection systems remain under pres- f

sure after the engine has been turned OFF.

Properly relieve fuel pressure before discon-

necting any fuel lines. Failure to do so may [

result in fire or personal injury.

t 6. Disconnect the high pressure fuel line, fuel

return hose and remove throttle control cable brack- t

n+C.

cm. durino the removal orocedure. 15. Install the intake manifold brace bracket and

ighten bolts to 21 ft. Ibs. (29 Nm).

16. Connect or install all hoses, cables and elec-

rical connectors that were removed or disconnected

7. Tag and unplug the electrical connectors

from the coolant temperature sensor, coolant temper- 17: Fill the system with coolant.

18 Connect the negative battery cable, run the

, . : .., ,, ., , ,

,,,, ,. ,.

93153p73 Fig. 51 . . .

then remove the manifold from

the cylinder head

Ruver open, service or drain the radiator or

@Ming system when hot; serious burns can

II&ur from the steam and hot coolant. Also,

draining engine coolant, keep in mind ’

j “thiat cats and dogs are attracted to ethylene

. . . ..____ “..” 11_,1 -...... any that is

t uncovered container or in puddles

FE ol iha ground. This will prove fatal in suff i-

k ici?M quantities. Always drain coolant into a

$1 pealable container. Coolant should be reused

h’ uniass it is contaminated or is several years

j$O'd.

**w

ature gauge, IAC valve, ignition coil, EGR tempera-

ture sensor, knock sensor, oxygen sensor, throttle

position sensor, distributor, A/C temperature sensor,

fuel injectors and ignition power transistor. Position

the engine wiring harness aside.

8. Label and disconnect the spark plug wires

from the spark plugs.

9. Remove the intake manifold stay bracket.

IO. Remove the intake manifold mounting bolts

and remove the intake manifold assembly. Disassem-

ble manifold on a work bench as required.

Tan is”.+..ll. vemcle unrn me mermosrar opens, ml tne raalaror

completely.

19. Adjust the accelerator cable. Check and ad-

just the idle speed and ignition timing.

20. Once the vehicle has cooled, recheck the

coolant level.

3.OL and 3SL Engines

ti See Figures 52 thru 57

1. Relieve the fuel system pressure.

W.>. Clean all gasket material from the cylinder

!&S head intake mounting surface and intake manifold as-

fir!: 3. Disconnect the accelerator cable, breather

Observe all applicable safety precautions

El .;,

+w..” and air intake hose. sembly. Check both surfaces for cracks or other dam-

age. Check the intake manifold water passages and when working around fuel. Whenever servic-