timing belt MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 1 of 408

HOW TO USE THIS BOOK 1-2

WHERE TOBEGIN l-2

AVOIDINGTROUBLE 1-2

MAINTENANCEORREPAIR? 1-2

AVOIDINGTHEMOSTCOMMONMISTAKES l-2

TOOLS AND EQUIPMENT 1-2

SPECIALTOOLS l-4

YOUR VEHICLE SAFELY 1-4

DON'TS l-6

FASTENERS, MEASUREMENTS AND

CONVERSIONS l-6

BOLTS,NUTSANDOTHERTHREADED

RETAINERS 1-6

TORQUE l-7

TORQUEWRENCHES l-7

TORQUEANGLEMETERS 1-9

STANDARDANDMETRIC MEASUREMENTS l-9

SERIAL NUMBER IDENTIFICATION l-10

VEHICLE IDENTIFICATION NUMBER l-10

ENGINE IDENTIFICATION NUMBER I-10

TRANSAXLEIDENTIFICATION I-10

DRlVEAXLE(AWDGALANTONLY) l-10

TRANSFERCASE(AWDGALANTONLY) l-10

ROUTINE MAINTENANCE AND TUNE-UP l-14

AIRCLEANER(ELEMENT) 1-14

REMOVAL&INSTALLATION 1-14

FUELFILTER 1-15

REMOVAL &INSTALLATION l-15

PCVVALVE l-15

REMOVAL&INSTALLATION l-15

EVAPORATIVECANISTER l-16

SERVICING 1-16

BATTERY 1-16

PRECAUTIONS I-16

GENERALMAINTENANCE 1-16

BEL BATTERYFLUID 1-16

CABLES I-17

CHARGING I-18

REPLACEMENT 1-18

TS 1-18

INSPECTiON l-18

ADJUSTMENT 1-18

REMOVAL&INSTALLATION 1-18

TIMINGBELTS l-20

INSPECTION l-20

HOSES I-20

INSPECTION l-20

REMOVAL&INSTALLATION

CV-BOOTS 1-21

INSPECTION l-21

SPARKPLUGS l-22

SPARKPLUGHEATRANGE

REMOVAL&INSTALLATION

INSPECTION &GAPPING 1.

SPARKPLUG WIRES 1-24

TESTING 1-24

REMOVAL&INSTALLATION

DISTRIBUTORCAPANDROTOR

REMOVAL&INSTALLATION

INSPECTION 1-25

IGNITIONTIMING 1-25

. GENERALINFORAMTION l-

lNSPECTlON&ADJUSTMENl

VALVE LASH l-27

ADJUSTMENT l-27

IDLESPEED 1-28 1-21

l-22

l-22

-23

1-24

l-25

l-25

.25

1-26

AIR CONDITIONING SYSTEM 1-28

SYSTEMSERVlCEiiREPAlR l-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION l-29

WINDSHIELD WIPERS l-29

ELEMENT(REFILL)CARE&

REPLACEMENT l-29

TIRESANDWHEELS l-30

TIRE ROTATION I-30

TIRE DESIGN 1-31

TIRESTORAGE l-31

INFLATION &INSPECTION l-31

CARE OFSPECIALWHEELS l-32 OPERATION INFOREIGNCOUNTRIES l-33

ENGINE l-33

OILLEVELCHECK 1-33

OIL& FILTER CHANGE l-34

MANUALTRANSAXLE l-35

FLUIDRECOMMENDATIONS l-35

LEVELCHECK l-35

DRAIN&REFILL l-36

AUTOMATICTRANSAXLE l-36

FLUIDRECOMMENDATIONS l-36

LEVELCHECK 1-36

DRAIN&REFILL l-36

PAN & FILTERSERVICE 1-36

TRANSFERCASE(AWDGAlANT ONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

REARDRlVEAXLE(AWDGALANTONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

COOLINGSYSTEM l-39

FLUIDRECOMMENDATIONS l-39

iM-41

FLUIDS AND LUBRICANTS 1-33

FLUID DISPOSAL 1-33

FlJELANDENGlNEOILRECOMMENDATlONS

ENGINE OIL l-33

FUEL l-33

Page 19 of 408

.

l-20 GENERALINFORMATIONAND MAINTENANCE

INSPECTION

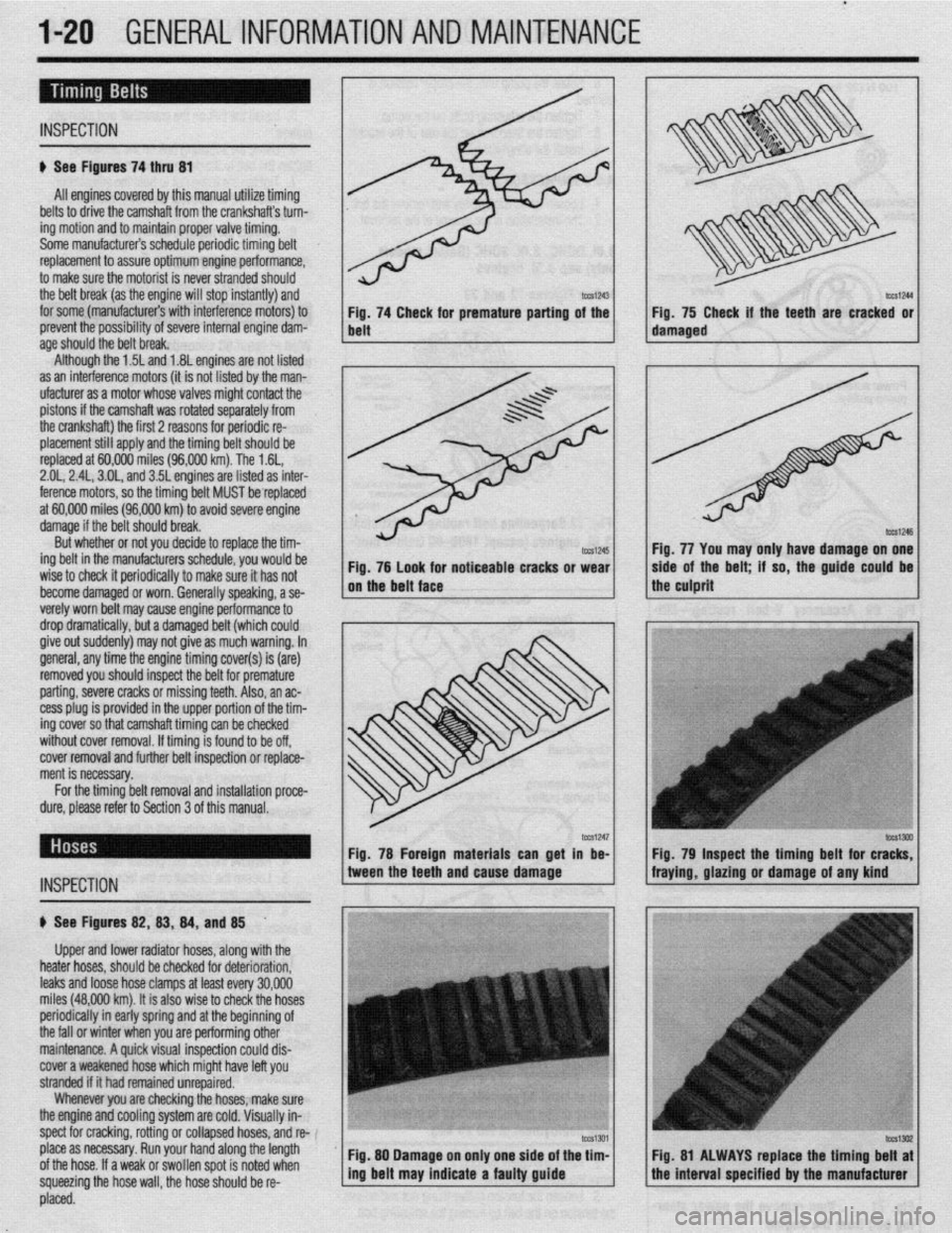

# See Figures 74 thru 81

All engines covered by this manual utilize timing

belts to drive the camshaft from the crankshafts turn-

ing motion and to maintain proper valve timing.

Some manufacturers schedule periodic timing belt

replacement to assure optimum engine performance,

to make sure the motorist is never stranded should

the belt break (as the engine will stop instantly) and

for some (manufacturers with interference motors) to

prevent the possibility of severe internal engine dam-

age

St10Ula the Delt break. Although the 1.5L and 1.8L engines are not listed

as an interference motors (it is not listed by the man-

ufacturer as a motor whose valves might contact the

pistons if the camshaft was rotated separately from

the crankshaft) the first 2 reasons for periodic re-

placement still apply and the timing belt should be

replaced at 60,000 miles (96,000 km). The 1.6L,

2.01,2.4L, 3.OL, and 35L engines are listed as inter-

ference motors, so the timing belt MUST be replaced

at 60,000 miles (96,000 km) to avoid severe engine

damage if the belt should break.

But whether or not you decide to replace the tim-

ing belt in the manufacturers schedule, you would be

wise to check it periodically to make sure it has not

become damaged or worn. Generally speaking, a se-

verelv worn belt mav cause enaine oerformance to

drop~dramatically, but a damaged belt (which could

give out suddenly) may not give as much warning. In

general, any time the engine timing cover(s) is (are)

removed you should inspect the belt for premature

parting, severe cracks or missing teeth. Also, an ac-

cess plug is provided in the upper portion of the tim-

ing cover so that camshaft timing can be checked

without cover removal. If timing is found to be off,

cover removal and further belt inspection or replace-

ment is necessary.

tml245 Fig. 76 look for noticeable cracks or wear

on the belt face

_

For the timing belt removal and installation proce-

dure, please refer to Section 3 of this manual. Fig. 74 Check for premature parting of the

belt

INSPECTION

. 75 Check if the teeth are cracked or

fig. 77 You may only have damage on one

side of the belt; if so, the guide could be

the culprit

b See Figures 82,8S, 84, and 85 .

Upper and lower radiator hoses, along with the

heater hoses, should be checked for deterioration,

leaks and loose hose clamps at least every 30,000

miles (48,000 km). It is also wise to check the hoses

periodically in early spring and at the beginning of

the fall or winter when you are performing other

maintenance. A quick visual inspection could dis-

cover a weakened hose which might have left you

stranded if it had remained unrepaired.

Whenever you are checking the hoses, make sure

the engine and cooling system are cold. Visually in-

spect for cracking, rotting or collapsed hoses, and w-

place as necessary. Run your hand along the length

of the hose. If a weak or swollen spot is noted when

squeezing the hose wall, the hose should be re- Fig. 78 Foreign materials can get in be- Fig. 79 Inspect the timing belt for c

tween the teeth and cause damage fraying, glazing or damage of any kind

Fig. 80 Damage on only one side of the tim-

I I Fig. 81 ALWAYS replace the timing belt at

ing belt may indicate a faulty guide

the interval specified by the manufacturer

, L placed.

Page 25 of 408

.

1-26 GENERALINFORMATIONAND MAINTENANCE

TDC of the compression stroke. If this happens, the

piston WIII be at the beginning of the power stroke

just as the compressed and ignited air/fuel mixture

forces the piston down and turns the crankshaft. Be-

cause it takes a fraction of a second for the spark

plug to ignite the mixture in the cylinder, the spark

plug must fire a little before the piston reaches TDC.

Otherwise, the mixture will not be completely ignited

as the piston passes TDC and the full power of the

explosion will not be used by the engine.

The timing measurement is given in degrees of

crankshaft rotation before the piston reaches TDC

(BTDC). If the setting for the ignition timing is 10”

BTDC, each spark plug must fire 10 degrees before

each piston reaches TDC. This only holds true, how-

ever, when the engine is at idle speed. The combus-

tion process must be complete by 23”ATDC to main-

tain proper engine performance, fuel mileage, and

low emissions.

As the engine speed increases, the pistons go

faster. The spark plugs have to ignite the fuel even

sooner if it IS to be completely ignited when the pis-

ton reaches TDC. If the ignition is set too far ad-

vanced (BTDC), the ignition and expansion of the fuel

in the cylinder wtll occur too soon and tend to force

the piston down while it is still traveling up. Thus

causes pre ignition or “knockmg and pinging”. If the

ignition spark is set too far retarded, or after TDC

(ATDC), the piston will have already started on its

way down when the fuel is ignited. The piston will be

forced down for only a portion of its travel, resulting

in poor engine performance and lack of power.

Timing marks or scales can be found on the rim of

the crankshaft pulley and the timing cover. The marks

on the pulley correspond to the posrtion of the piston

in the No. 1 cylinder. A stroboscopic (dynamic) tim-

ing light is hooked onto the No. 1 cylinder spark plug

wrre. Every time the spark plug fires, the timing light

flashes. By aiming the light at the timing marks while

the engine is running, the exact position of the piston

within the cylinder can be easily read (the flash of

light makes the mark on the pulley appear to be

standing still). Proper timing is indicated when the

mark and scale are in specified alignment.

When checking timing with the engine run-

ning, take care not to get the timing light

wires tangled in the tan blades and/or drive

belts.

INSPECTION &ADJUSTMENT

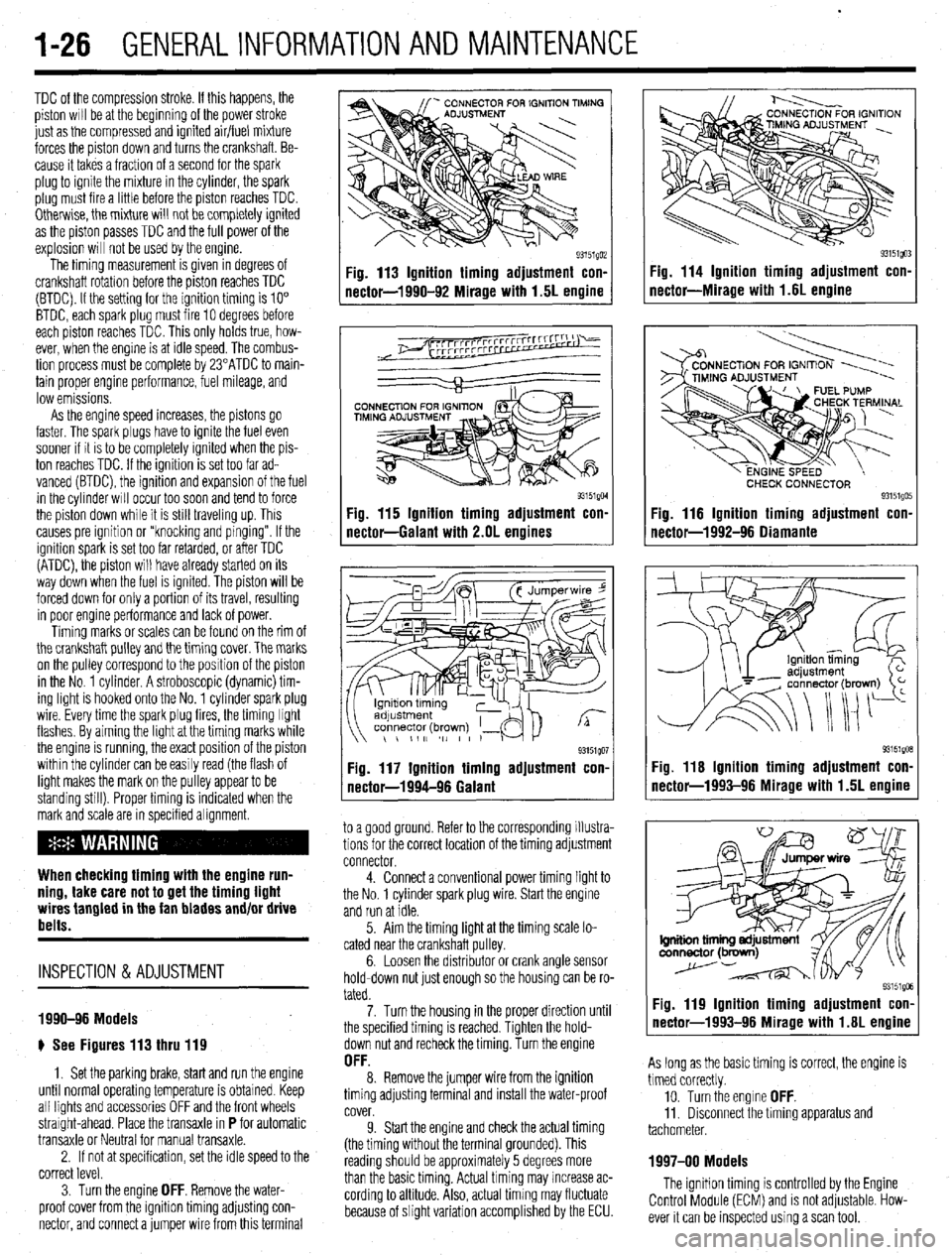

1990-96 Models

e See Figures 113 thru 119

1. Set the parking brake, start and run the engine

until normal operating temperature is obtained. Keep

all lights and accessories OFF and the front wheels

straight-ahead. Place the transaxle in

P for automatic

transaxle or Neutral for manual transaxle.

2. If not at specification, set the idle speed to the

correct level.

3. Turn the engine

OFF. Remove the water-

proof cover from the igmtion timing adjusting con-

nector, and connect a jumper wire from this terminal

Fig. 113 Ignition timing adjustment con-

nector-1990-92 Mirage with 1.5L engine

93151QM Fig. 115 Ignition timing adjustment con-

nectar-Galant with 2.OL engines

93151QO1 Fig. 117 Ignition timing adjustment con.

nectar-1994-96 Galant

to a good ground. Refer to the corresponding illustra-

tions for the correct location of the timing adjustment

connector.

4. Connect a conventional power timing light to

the No. 1 cylinder spark plug wire. Start the engine

and run at idle.

5. Aim the timing light at the timing scale lo-

cated near the crankshaft pulley.

6. Loosen the distributor or crank angle sensor

hold-down nut just enough so the housing can be ro-

tated.

7. Turn the housing in the proper direction until

the specified timing is reached. Tighten the hold-

down nut and recheck the timing. Turn the engine

OFF. 8. Remove the jumper wire from the ignition

timing adjusting terminal and install the water-proof

cover.

9. Start the engine and check the actual timing

(the timing without the terminal grounded). This

reading should be approximately 5 degrees more

than the basic timing. Actual timing may increase ac-

cording to altitude. Also, actual timing may fluctuate

because of slight variation accomplished by the ECU.

Fig. 114 Ignition timing adjustment con-

nectar-Miracle with 1.6L enaine

CHECK CONNECTOR 93151QO! Fig. 116 Ignition timing adjustment con.

nectar-1992-96 Oiamante

93151gOB Fig. 116 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.5L engine

Fig. 119 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.6L engine

As long as the basic timing is correct, the engine is

timed correctly.

10. Turn the engine

OFF. 11. Disconnect the timing apparatus and

tachometer.

1997-00 Models

The ignition timing is controlled by the Engine

Control Module (ECM) and is not adjustable. How-

ever it can be inspected using a scan tool.

Page 26 of 408

GENERALINFORMATIONAND MAlNTENANdE I-27

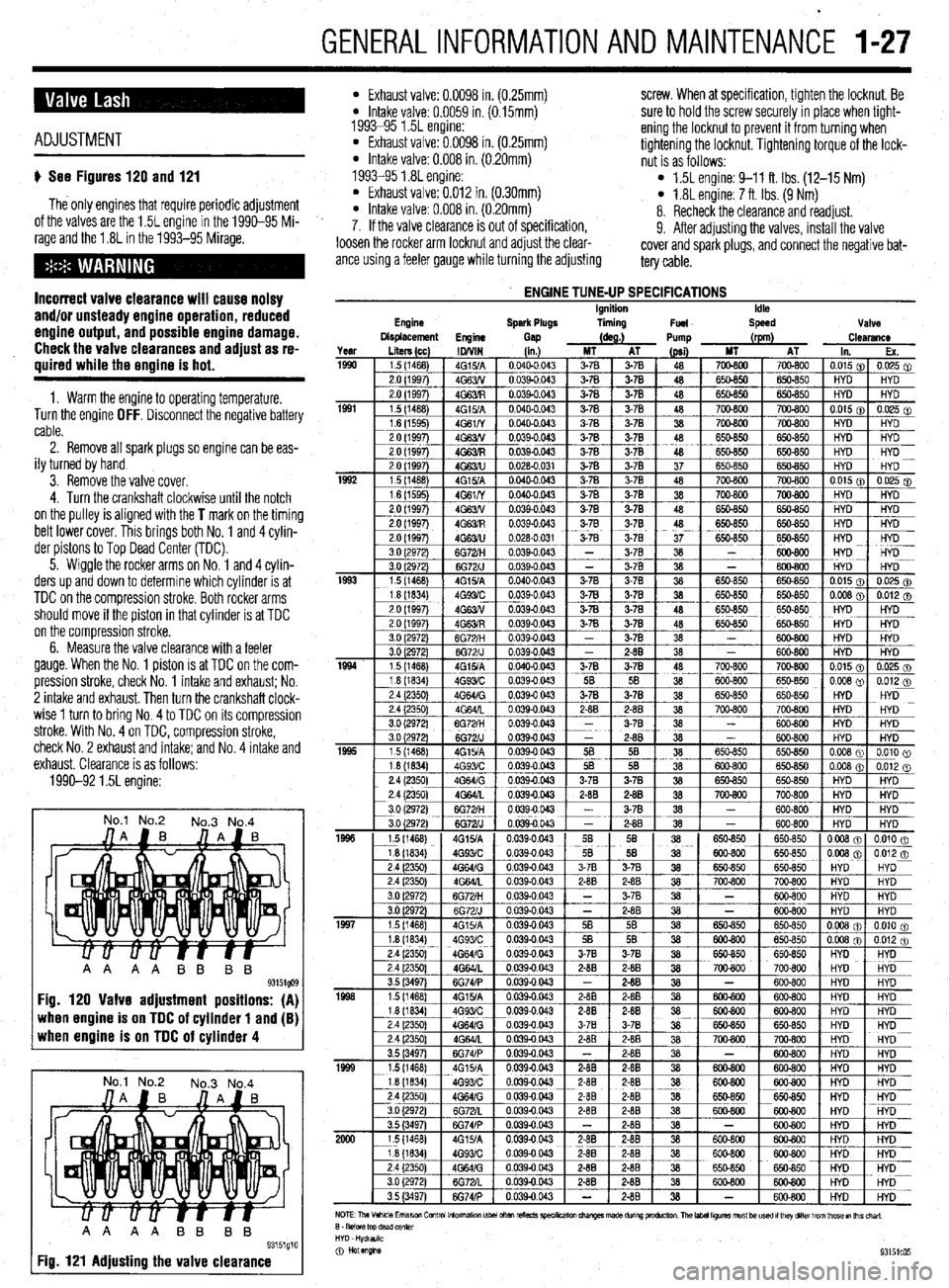

ADJUSTMENT

u See Figures 120 and 121

The only engines that require periodic adjustment

of the valves are the 1.5L engine in the 1990-95 Mi-

rage and the 1.8L in the 1993-95 Mirage.

Incorrect valve clearance will cause noisy

and/or unsteady engine operation, reduced

engine output, and possible engine damage.

Check the valve clearances and adjust as re-

quired while the engine is hot.

1. Warm the engine to operating temperature.

Turn the engine OFF. Disconnect the negative battery

cable.

2. Remove all spark plugs so engine can be eas-

ily turned by hand

3. Remove the valve cover.

4. Turn the crankshaft clockwise until the notch

on the pulley is aligned with the

T mark on the timing

belt lower cover. This brings both No. 1 and 4 cylin-

der pistons to Top Dead Center (TDC).

5. Wiggle the rocker arms on No. 1 and 4 cylin-

ders up and down to determine which cylinder is at

TDC on the compression stroke. Both rocker arms

should move if the piston in that cylinder is at TDC

on the compression stroke.

6. Measure the valve clearance with a feeler

gauge. When the No. 1 piston is at TDC on the com-

pression stroke, check No. 1 intake and

exhaust; No.

2 intake and exhaust. Then turn the crankshaft clock-

wise 1 turn to bring No. 4 to TDC on its compression

stroke. With No. 4 on TDC, compression stroke,

check No. 2 exhaust and intake; and No. 4 intake and

exhaust. Clearance is as follows:

1990-92 1.5L engine:

No.1 No.2

No.3 No.4

when engine is on TDC of cylinder 1 and (B) when engine is on TDC of cylinder 4

No.1 No.2

No.3 No.4

AA AA BB BB

93151g10 Fig. 121 Adjusting the valve clearance

l Exhaust valve: 0.0098 in. (0.25mm) screw. When at specification, tighten the locknut. Be l Intake valve: 0.0059 in. (0.15mm)

1993-95 1.5L engine: sure to hold the screw securely in place when tight-

l Exhaust valve: 0.0098 in. (0.25mm) ening the locknut to prevent it from turning when

* Intake valve: 0.008 in. (0.20mm) tightening the locknut. Tightening torque of the lock-

nut is as follows:

1993-95 1.8L engine:

l Exhaust valve: 0.012 in. (0.30mm) l 1.5L engine: 9-11 ft. Ibs. (12-15 Nm)

l Intake valve: 0.008 in. (0.20mm) l 1.8L engine: 7 ft. Ibs. (9 Nm)

8. Recheck the clearance and readjust.

7. If the valve clearance is out of specification,

9. After adjusting the valves, install the valve

loosen the rocker arm locknut and adjust the clear-

ante using a feeler gauge while turning the adjusting cover and spark plugs, and connect the negative bat-

tery cable.

Engine

ENGINE TUNE-UP SPECIFICATIONS Ignition

Spark Plugs liming

Fuel Idle

Speed Valve

Displacement

Engine

Gap (as.) Pump (rpm)

Clearance

Page 62 of 408

ENGINE MECHANICAL 3-1

ENGINE 3-1

REMOVAL &INSTALLATION 3-l

ROCKERARM(VALVE)COVER 3-l

REMOVAL &INSTALLATION 3-l

ROCKER ARM/SHAFTS 3-4

REMOVAL & INSTALLATION 3-4

THERMOSTAT 3-7

REMOVAL & INSTALLATION 3-7

INTAKE MANIFOLD 3-7

REMOVAL & INSTALLATION 3-7

EXHAUSTMANIFOLD 3-14

REMOVAL &INSTALLATION 3-14

TURBOCHARGER 3-17

REMOVAL & INSTALLATION 3-17

RADIATOR 3-18

REMOVAL & INSTALLATION 3-18

ENGINE FAN 3-19

REMOVAL &INSTALLATION 3-19

WATER PUMP 3-20

REMOVAL & INSTALLATION 3-20

CYLINDER HEAD 3-23

REMOVAL &INSTALLATION 3-23

OIL PAN 3-30

REMOVAL & INSTALLATION 3-30

OIL PUMP 3-33

REMOVAL &INSTALLATION 3-33

CRANKSHAFT DAMPER 3-36

REMOVAL &INSTALLATION 3-36

TIMING COVERAND BELT 3-36

REMOVAL & INSTALLATION 3-36

INSPECTION 3-48

FRONT CRANKSHAFTSEAL 3-48

REMOVAL & INSTALLATION 3-48

CAMSHAFT,BEARlNGSAND

LIFTERS 3-48

REMOVAL & INSTALLATION 3-48

INSPECTION 3-53

BALANCE SHAFT 3-54

REMOVAL &INSTALLATION 3-54

REAR MAIN SEAL 3-54

REMOVAL&INSTALLATION 3-54

FLYWHEEL/DRIVEPLATE 3-55

REMOVAL &INSTALLATION 3-55

EXHAUST SYSTEM 3-55

INSPECTION 3-55

REPLACEMENT 3-56

ENGINE RECONDITIONING 3-57

DETERMINIG ENGINE CONDITION 3-57

COMPRESSION TEST 3-57

OIL PRESSURETEST 3-57

BUYOR REBUILD? 3-57

ENGINE OVERHAULTIPS 3-58

TOOLS 3-58

OVERHAULTIPS 3-58

CLEANING 3-58

REPAIRING DAMAGEDTHREADS 3-59

ENGINE PREPARATION 3-59

CYLINDER HEAD 3-60

DISASSEMBLY 3-60

INSPECTION 3-

REFINISHING & REPAIRING 3-63 ASSEMBLY 3-64

ENGINE BLOCK 3-65

GENERALINFORMAITON 3-65

DISASSEMBLY 3-65

INSPECTION 3-65

REFINISHING 3-67

ASSEMBLY 3-67

ENGINE START-UP AND BREAK-IN 3-

STARTING THE ENGINE 3-69

BREAKING IT IN 3-69

KEEP IT MAINTAINED 3-69

SPECIFICATIONS CHARTS

ENGINE MECHANICAL

SPECIFICATIONS 3-70

TORQUE SPECIFICATIONS 3-81 .69

Page 63 of 408

3-2 ENGINEANDENGINEOVERHAUL

REMOVAL &INSTALLATION

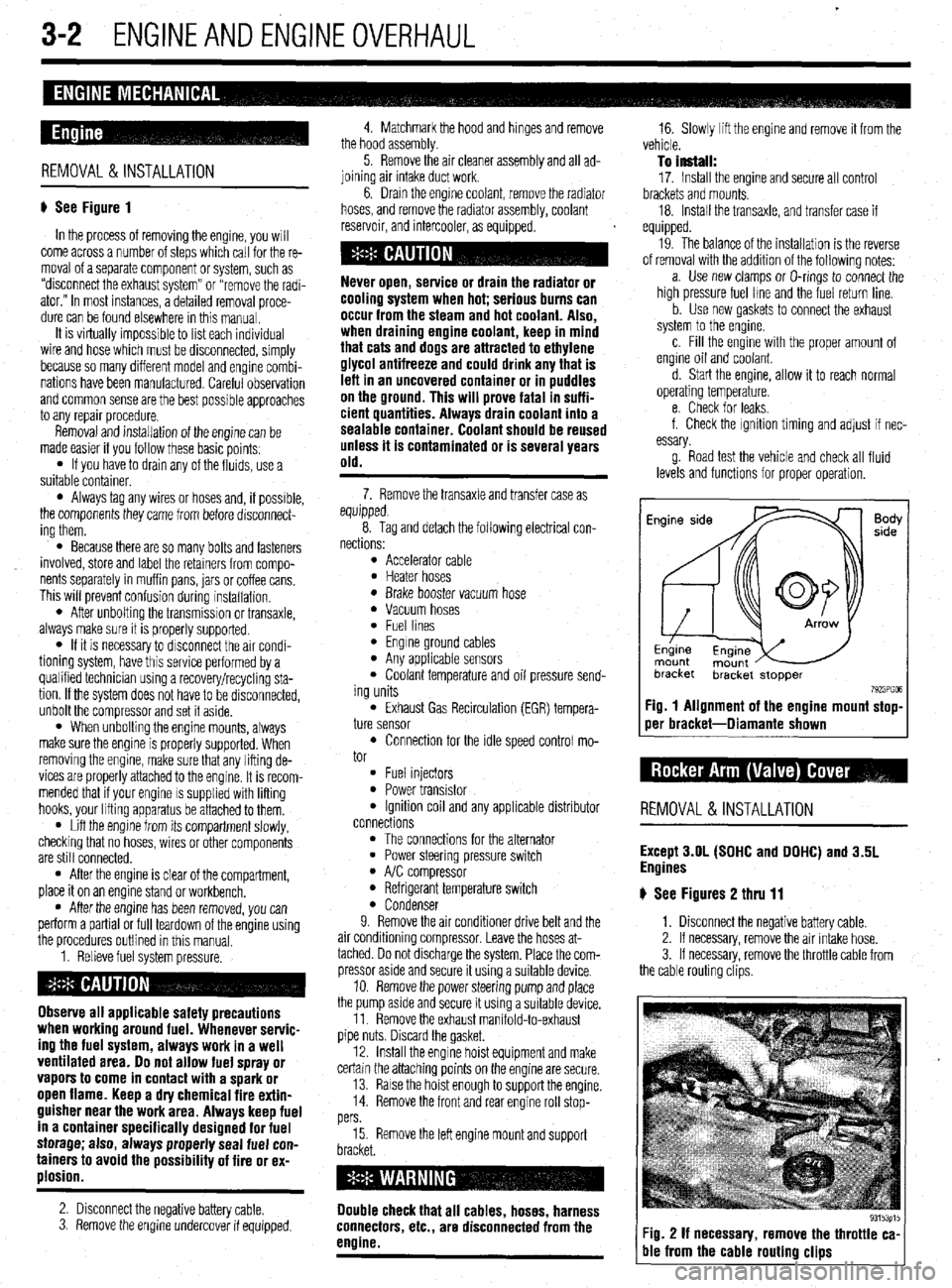

# See Figure 1

In the process of removing the engine, you will

come across a number of steps which call for the re-

moval of a separate component or system, such as

“disconnect the exhaust system” or “remove the radi-

ator.” In most instances, a detailed removal proce-

dure can be found elsewhere in this manual.

It is virtually impossible to list each individual

wire and hose which must be disconnected, simply

because so many different model and engrne combi-

nations have been manufactured Careful observation

and common sense are the best possible approaches

to any repair procedure.

Removal and installation of the engine can be

made easier if you follow these basic points:

l If you have to drain any of the fluids, use a

suitable container.

l Always tag any wires or hoses and, if possrble,

the components they came from before disconnect-

ing them.

l Because there are so many bolts and fasteners

involved, store and label the retainers from compo-

nents separately in muffin pans, jars or coffee cans.

This will prevent confusion during installatron.

l After unbolting the transmisston or transaxle,

always make sure it is properly supported.

l If it is necessary to disconnect the air condi-

tioning system, have this service performed by a

qualified technician using a recovery/recycling sta-

tion If the system does not have to be disconnected,

unbolt the compressor and set it aside.

l When unbolting the engine mounts, always

make sure the engine is properly supported. When

removing the engine, make sure that any lifting de-

vices are properly attached to the engine. It is recom-

mended that if your engine IS supplied with lifting

hooks, your lifting apparatus be attached to them.

l Lift the engine from its compartment slowly,

checking that no hoses, wires or other components

are still connected.

l After the engine is clear of the compartment,

place it on an engine stand or workbench.

l After the engine has been removed, you can

perform a partial or full teardown of the engine using

the procedures outlined in this manual.

1. Relieve fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect the negative battery cable.

3. Remove the engine undercover if equipped. 4. Matchmark the hood and hinges and remove

the hood assembly.

5. Remove the air cleaner assembly and all ad-

joining air intake duct work.

6. Drain the engine coolant, remove the radiator

hoses, and remove the radiator assembly, coolant

reservoir, and intercooler, as equipped.

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

7. Remove the transaxle and transfer case as

equipped.

8. Tag and detach the following electrical con-

nections:

l Accelerator cable l Heater hoses l Brake booster vacuum hose l Vacuum hoses l Fuel lines l Engine ground cables l Any applicable sensors l Coolant temperature and oil pressure send-

ing units

l Exhaust Gas Recirculation (EGR) tempera-

ture sensor

l Connection for the idle speed control mo-

tor

l Fuel injectors l Power transistor l Ignition coil and any applicable distributor

connections

l The connections for the alternator l Power steering pressure switch l A/C compressor l Refrigerant temperature switch l Condenser

9. Remove the air conditioner drive belt and the

air conditioning compressor. Leave the hoses at-

tached. Do not discharge the system. Place the com-

pressor aside and secure it using a suitable device.

10. Remove the power steering pump and place

the pump asrde and secure it using a surtable device.

11. Remove the exhaust manifold-to-exhaust

pipe nuts. Discard the gasket.

12. Install the engine hoist equipment and make

certain the attaching points on the engine are secure.

13. Raise the hoist enough to support the engine.

14. Remove the front and rear engine roll stop-

pers

15. Remove the left engine mount and support

Double check that all cables, hoses, harness

connectors, etc., are disconnected from the

engine.

16. Slowly lift the engine and remove it from the

vehicle.

To install:

17. Install the engine and secure all control

brackets and mounts.

18. Install the transaxle, and transfer case if

equipped.

19. The balance of the installation is the reverse

of removal with the addition of the following notes:

a. Use new clamps or O-rings to connect the

high pressure fuel lme and the fuel return line.

b. Use new gaskets to connect the exhaust

system to the engine.

c. Fill the engine with the proper amount of

engine oil and coolant.

d. Start the engine, allow it to reach normal

operating temperature.

e. Check for leaks.

f. Check the ignition timing and adjust if nec-

essary.

g. Road test the vehicle and check all fluid

levels and functions for proper operation.

Fig. 1 Alignment of the engine mount stop-

oer bracket-Diamante shown

REMOVAL &INSTALLATION

Except 3.OL (SOHC and DOHC) and 3.5L

Engines

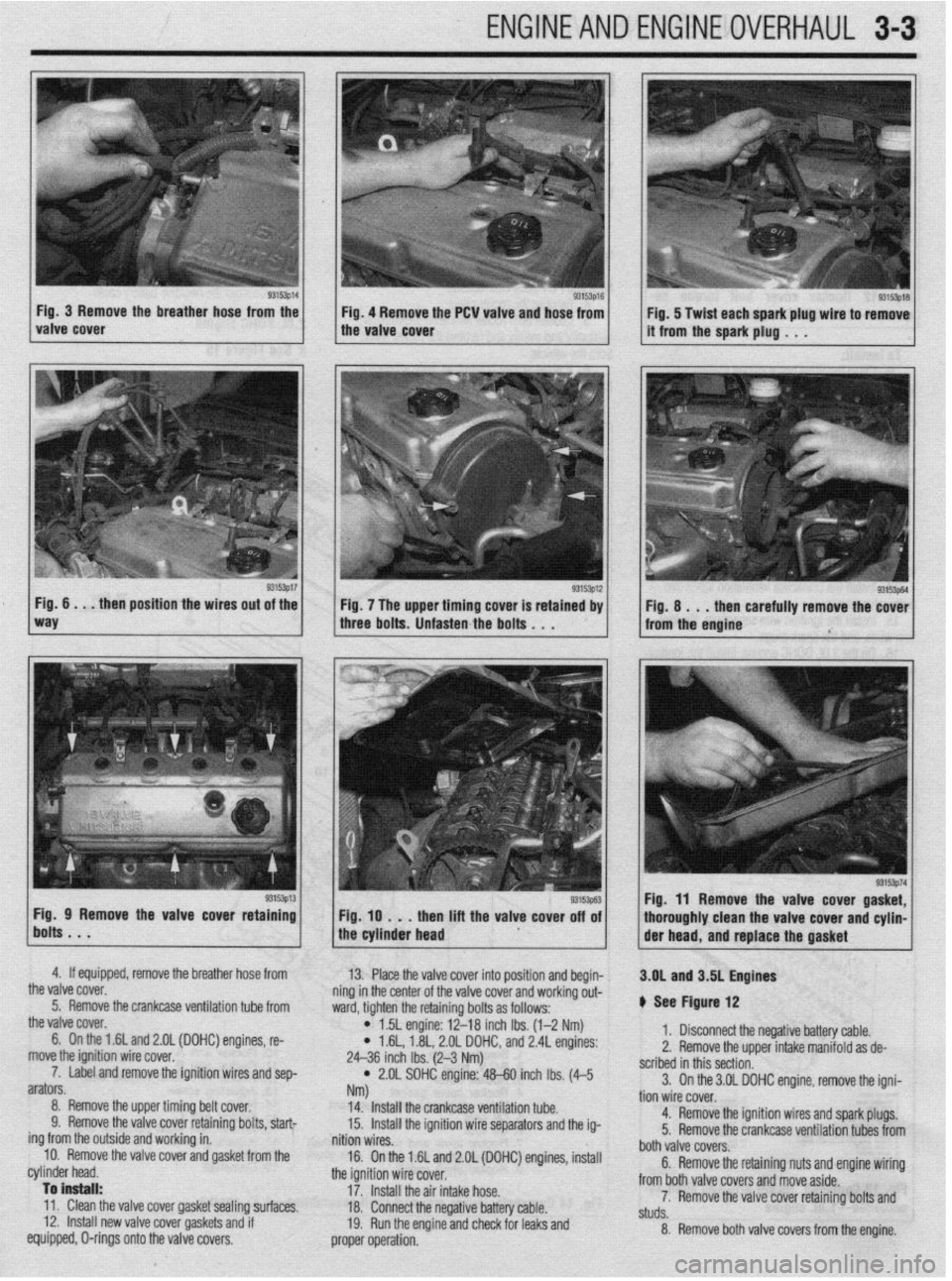

# See Figures 2 thru 11

1. Disconnect the negative battery cable.

2. If necessary, remove the air intake hose.

3. If necessary, remove the throttle cable from

the cable routing clips.

Fig. 2 If necessary, remove the throttle ca-

ble from the cable routing clips

Page 64 of 408

ENGINEANDENGINEOVERHAUL 3-3

Fig. 3 Remove the

breather hose from the Fig. 4 Remove the PCW valve

and hose from

93153p17 Fig. 6 . . . then position the wires out of the

Fig. 7 The upper timing cover is retained by

three bolts. Unfasten the bolts . . . Fig. 8 . . . then carefully remove the cover

from the engine

Fig. 9 Remove the valve cover retaini

then lift the valve cover

4. If equipped, remove the breather hose from

13.

the valve cover. Place the valve cover into position and begin-

5. Remove the crankcase ventilation tube from ning in the center of the valve cover and working out-

the valve cover. ward, tighten the retaining bolts as follows:

6. On the 1.6L and 2.gL (DOHC) engines, re-

l 15L engine: 12-18 inch Ibs. (l-2 Nm)

move the ignition wire cover. l 1.6L, 1.8L, 2.OL DOHC, and 2.4L engines:

7. Label and remove the ignition wires and sep- 24-36 inch Ibs. (2-3 Nm)

arators. * 2.OL SOHC engine: WO inch Ibs. (4-5

8. Remove the upper timing belt cover. Nm)

14. Install the crankcase ventilation tube.

9. Remove the valve cover retaining bolts, start

15.

ing from the outside and working in. Install the ignition wire separators and the ig-

nition wires.

10. Remove the valve cover and gasket from the

16.

cylinder head. On the 1.6L and 2.OL (DOHC) engines, install

the ignition wire cover.

To install:

17. Install the air intake hose.

11. Clean the valve cover gasket sealing surfaces,

12, Install new valve cover gaskets and if 18. Connect the negative battery cable.

equipped, O-rings onto the valve covers. 19. Run the engine and check for leaks and

proper operation. 3.OL and 3.5L Engines

b See Figure 12

1. Disconnect the negative battery cable.

2. Remove the upper intake manifold as de-

scribed in this section.

3. On the 3.OL DOHC engine, remove the igni-

tion wire cover.

4. Remove the ignition wires and spark plugs.

5. Remove the crankcase ventilation tubes from

both valve covers.

6. Remove the retaining nuts and engine wiring

from both valve covers and move aside.

7. Remove the valve cover retaining bolts and

studs.

8. Remove both valve covers from the engine.

Page 66 of 408

ENGINEANDENGINEOVERHALJL 3-5

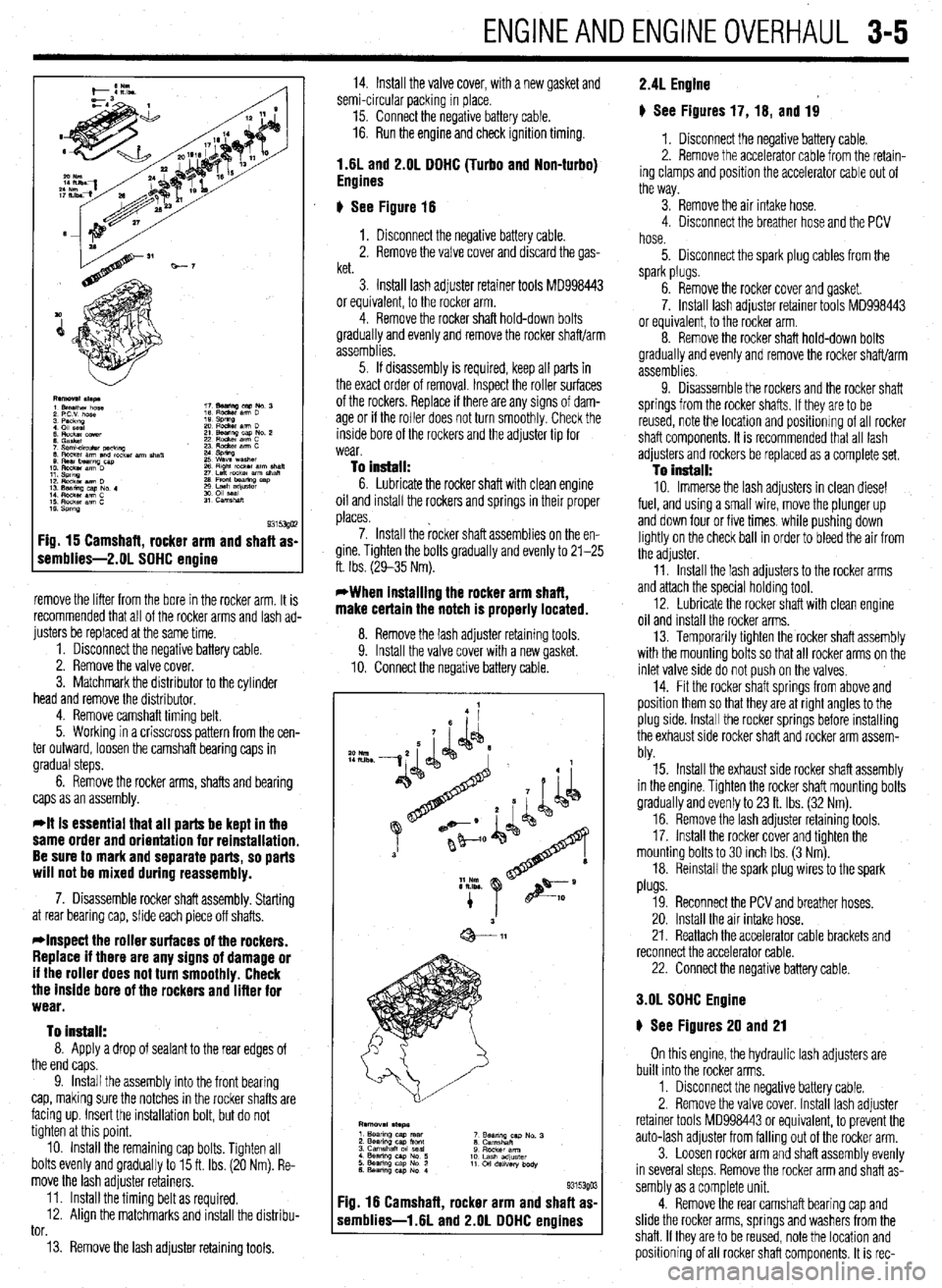

Fig. 15 Camshaft, rocker arm and shaft as-

remblies-2.01 SOHC engine

remove the lifter from the bore in the rocker arm. It is

recommended that all of the rocker arms and lash ad-

justers be replaced at the same time.

1. Disconnect the negative battery cable.

2. Remove the valve cover.

3. Matchmark the distributor to the cylinder

head and remove the distributor.

4. Remove camshaft timing belt.

5. Working in a crisscross pattern from the cen-

ter outward, loosen the camshaft bearing caps in

gradual steps.

6. Remove the rocker arms, shafts and bearing

caps as an assembly.

*It is essential that all parts be kept in the

same order and orientation for reinstallation.

Be sure to mark and separate parts, so parts

will not be mixed during reassembly.

7. Disassemble rocker shaft assembly. Starting

at rear bearing cap, slide each piece off shafts.

*Inspect the roller surfaces of the rockers.

Replace if there are any signs of damage or

if the roller does not turn smoothly. Check

the inside bore of the rockers and lifter for

wear.

To install:

8. Apply a drop of sealant to the rear edges of

the end caps.

9. Install the assembly into the front bearing

cap, making sure the notches in the rocker shafts are

facing up. Insert the installation bolt, but do not

tighten at this point.

10. Install the remaining cap bolts. Tighten all

bolts evenly and gradually to 15 ft. Ibs. (20 Nm). Re-

move the lash adjuster retainers.

11. Install the timing belt as required.

12. Align the matchmarks and install the distribu-

tor.

13. Remove the lash adjuster retaining tools. 14. Install the valve cover, with a new gasket and

semi-circular packing in place.

15. Connect the negative battery cable.

16. Run the engine and check ignition timing.

1.6L and 2.OL DOHC (Turbo and Non-turbo)

Engines

6 See Figure 16

1. Disconnect the negative battery cable.

2. Remove the valve cover and discard the gas-

ket.

3. Install lash adjuster retainer tools MD998443

or equivalent, to the rocker arm.

4. Remove the rocker shaft hold-down bolts

gradually and evenly and remove the rocker shaft/arm

assemblies.

5. If disassembly is required, keep all parts in

the exact order of removal. Inspect the roller surfaces

of the rockers. Replace if there are any signs of dam-

age or if the roller does not turn smoothly. Check the

inside bore of the rockers and the adjuster tip for

wear.

To install: 6. Lubricate the rocker shaft with clean engine

oil and install the rockers and springs in their proper

places.

7. Install the rocker shaft assemblies on the en-

gine. Tighten the bolts gradually and evenly to 21-25

ft. Ibs. (29-35 Nm).

*When installing the rocker arm shaft,

make certain the notch is properly located.

8. Remove the lash adiuster retainina tools

9. Install the valve cover with a new gasket.

10. Connect the negative battery cable.

F :ig. 16 Camshaft, rocker arm and shaft as

s iemblies-1.6L and 2.OL DOHC engines

*o Nm

IILlbs -

9315390 3

2.4L Engine

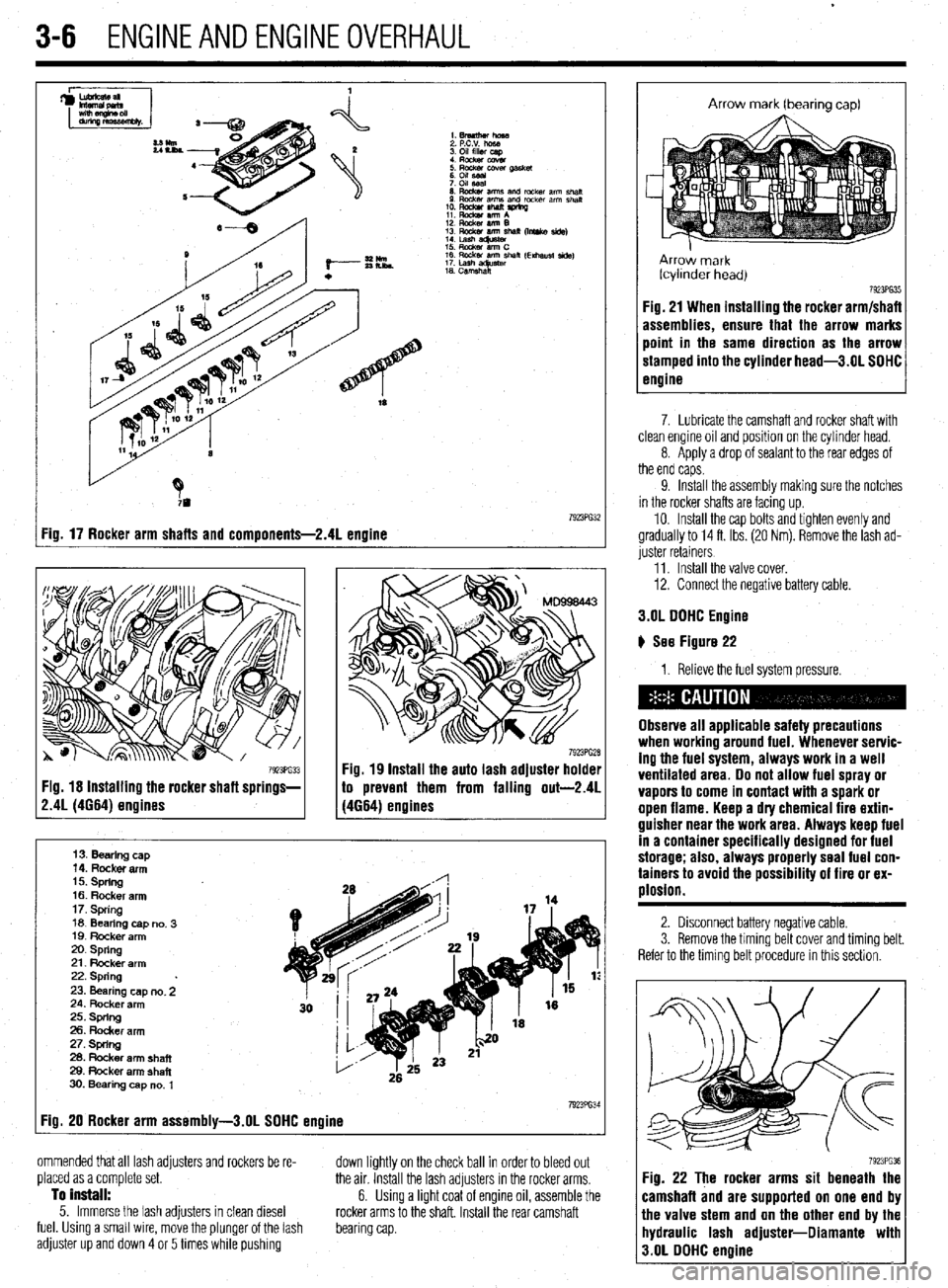

# See Figures 17, 16, and 19

1. Disconnect the negative battery cable.

2. Remove the accelerator cable from the retain-

ing clamps and position the accelerator cable out of

the way.

3. Remove the air intake hose.

4. Disconnect the breather hose and the PCV

hose.

5. Disconnect the spark plug cables from the

spark plugs.

6. Remove the rocker cover and gasket.

7. Install lash adjuster retainer tools MD998443

or equivalent, to the rocker arm.

8. Remove the rocker shaft hold-down bolts

gradually and evenly and remove the rocker shaft/arm

assemblies.

9. Disassemble the rockers and the rocker shaft

springs from the rocker shafts. If they are to be

reused, note the location and positionrng of all rocker

shaft components. It is recommended that all lash

adjusters and rockers be replaced as a complete set.

To install: 10. Immerse the lash adjusters in clean diesel

fuel, and using a small wire, move the plunger up

and down four or five times. while pushing down

lightly on the check ball in order to bleed the air from

the adjuster.

11. Install the lash adjusters to the rocker arms

and attach the special holding tool.

12. Lubricate the rocker shaft with clean engine

oil and install the rocker arms.

13. Temporarily tighten the rocker shaft assembly

with the mounting bolts so that all rocker arms on the

inlet valve side do not push on the valves,

14. Fit the rocker shaft springs from above and

position them so that they are at right angles to the

plug side. Install the rocker springs before installing

the exhaust side rocker shaft and rocker arm assem-

bly.

15. Install the exhaust side rocker shaft assembly

in the engine. Tighten the rocker shaft mounting bolts

gradually and evenly to 23 ft. Ibs. (32 Nm).

16. Remove the lash adjuster retaining tools.

17. Install the rocker cover and tighten the

mounting bolts to 30 inch Ibs. (3 Nm).

18. Reinstall the spark plug wires to the spark

plugs.

19. Reconnect the PCV and breather hoses.

20. Install the air intake hose.

21. Reattach the accelerator cable brackets and

reconnect the accelerator cable.

22. Connect the negative battery cable.

3.OL SOHC Engine

6 See Figures 20 and 21

On this engine, the hydraulic lash adjusters are

built into the rocker arms,

1. Disconnect the negative battery cable.

2. Remove the valve cover. Install lash adjuster

retainer tools MD998443 or equivalent, to prevent the

auto-lash adjuster from falling out of the rocker arm.

3. Loosen rocker arm and shaft assembly evenly

in several steps. Remove the rocker arm and shaft as-

sembly as a complete unit.

4. Remove the rear camshaft bearing cap and

slide the rocker arms, springs and washers from the

shaft. If they are to be reused, note the location and

positioning of all rocker shaft components. It is rec-

Page 67 of 408

.

3-6 ENGINEANDENGINEOVERHAUL

I Fig. 17 Rocker arm shafts and components-2.41 engine

Fig. 18 Installing the rocker shaft springs- 79231632

13. Bearing cap

14. Rocker arm

15. spring

16. Rocker arm

17. Spring

16 Bearing no. cap 3

IQ. Rocker arm

20. spring

21. Rocker arm

22. Spring

23. Bearing no. cap 2

24. Rocker arm

25. spring

26. Rocker arm

27. Spring

28. Rocker arm shaft

29. Rocker arm shaft

30. Bearing no. cap 1

Fig. 20 Rocker arm assembly-3.01 SOHC engine 7923PG3

ommended that all lash adjusters and rockers be re-

placed as a complete set.

To install:

5. Immerse the lash adjusters in clean diesel

fuel. Using a small wire, move the plunger of the lash

adjuster up and down 4 or 5 times while pushing down lightly on the check ball in order to bleed out

the air. Install the lash adjusters in the rocker arms.

6. Using a light coat of engine oil, assemble the

rocker arms to the shaft. Install the rear camshaft

bearing cap.

Arrow mark (bearing cap)

Arrow mark

fcyllnder head)

7923PG35 Fig. 21 When installing the rocker arm/shafi

assemblies, ensure that the arrow marks

point in the same direction as the arrow

stamped into the cylinder head-3.01 SOHC

engine

7. Lubricate the camshaft and rocker shaft with

clean engine oil and position on the cylinder head.

8. Apply a drop of sealant to the rear edges of

the end caps.

9. Install the assembly making sure the notches

in the rocker shafts are facing up.

10. Install the cap bolts and tighten evenly and

gradually to 14 ft. Ibs. (20 Nm). Remove the lash ad-

juster retainers

11. Install the valve cover.

12. Connect the negative battery cable.

3.OL OOHC Engine

) See Figure 22

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. 00 not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dty chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect battery negative cable.

3. Remove the timino belt cover and timina belt.

Refer to the timing belt procedure in this section.

7923PG3 Fig. 22 The rocker arms sit beneath the

camshaft and are supported on one end bl

the valve stem and on the other end by the

hydraulic lash adjuster-Oiamante wit1

3.OL OOHC engine

Page 68 of 408

ENGINEANDENGINEOVERHAUL 3-7

4. Remove the center cover, breather and PCV

hoses, and spark plug cables.

5. Remove the rocker cover.

6. Remove the throttle body stay, both camshaft

sprockets, and oil seals.

7. Remove the Camshaft Position fCMP) sensor 3. install the lash adjuster clips on the rocker

arms, then loosen the bearing cap bolts. Do not re-

move the bolts from the bearing caps.

4. Remove the rocker arms, shafts and bearing

caps as an assembly.

lo hlstall: unless it is contaminated or is several years old.

3. Remove any necessary components to access

the thermostat.

4. Remove the thermostat housinq retaininq

nd adapter from the rear of the camshah. ’

8. Remove the intake and exhaust camshafts.

9. Remove rocker arms and lash adjusters from

he head. It is recommended that all lash adjusters

md rockers be replaced as a complete set.

To Install:

10. Immerse the lash adjusters in clean diesel

uel. Using a small wire, move the plunger of the lash

tdjuster up and down four or five times while push-

ng down lightly on the check ball in order to bleed

jut the air. Lubricate and install the lash adjusters in

he cylinder head.

11. Lubricate the camshafts with clean enqine oil

nd position the camshafts on the cylinder head.

12. Install the bearing caps. Tighten the caps in

sequence, in 2 or 3 steps. Caps 2,3 and 4 have a

ront mark. Install with the mark aligned with the front

nark on the cylinder head. Intake caps have I

stamped on the cap and exhaust caps have E. Also,

)e sure the rocker arm is correctly mounted on the

ash adjuster and the valve stem end. Torque the front

md rear retaining cap bolts to 14 ft. Ibs. (20 Nm) and

ighten the center 3 retaining cap bolts to 8 ft. Ibs.

11 Nm).

13. Apply a coating of engine oil to the oil seals

md install.

14. Install the timing belt, valve cover and all re-

ated parts. Refer to the timing belt procedure in this

;ection. 5. Install the bearing caps/rocker arm assem-

blies. Tighten the bolts to 23 ft. Ibs. (31 Nm).

6. Remove the lash adjuster clips.

7. Install the rocker arm cover using a new gas-

ket.

8. Connect the negative battery cable.

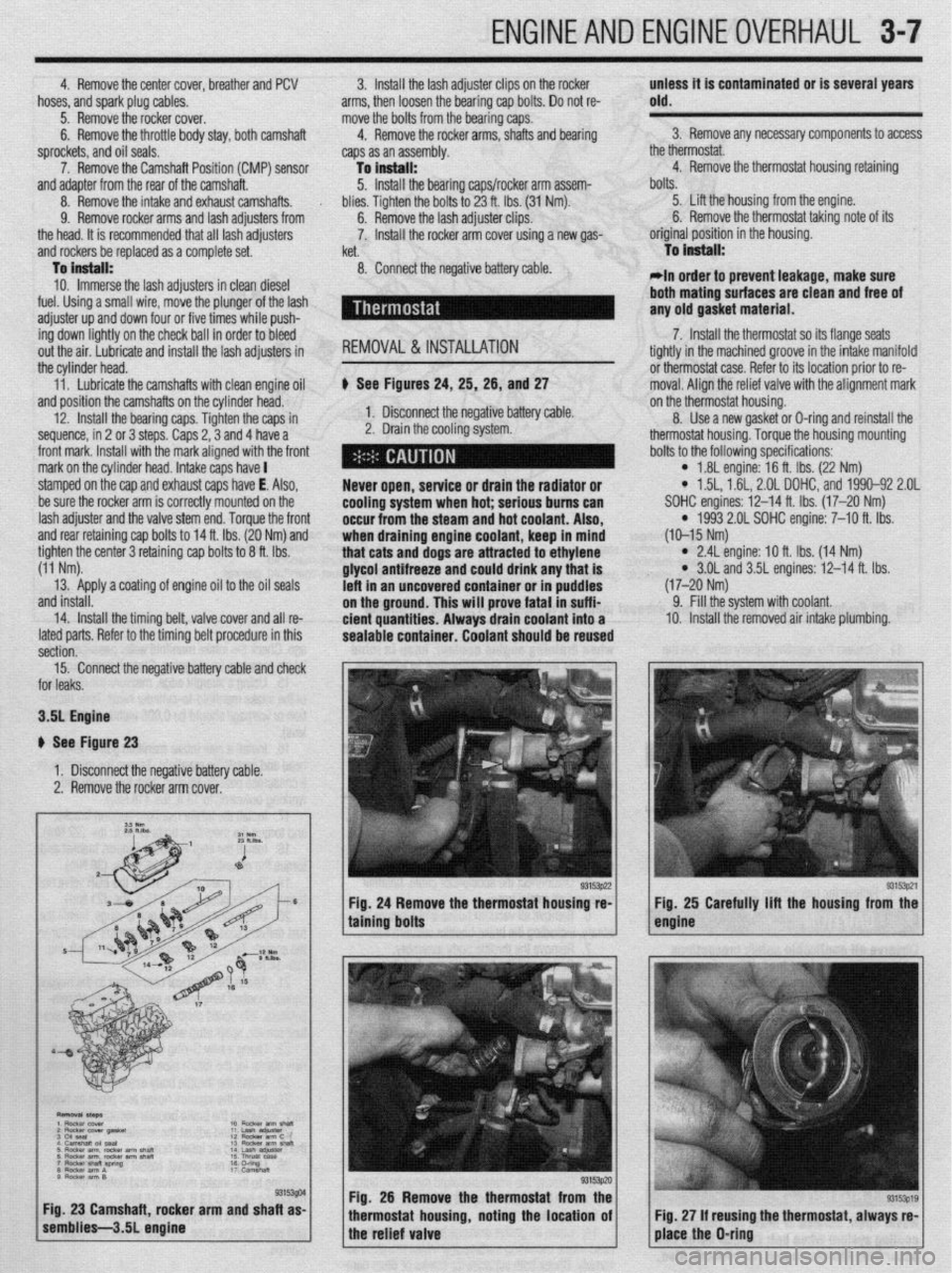

REMOVAL &INSTALLATION

b See Figures 24, 25, 26, and 27

1. Disconnect the negative battery cable.

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious bums can

occur from the

steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused bolts.

5. Lift the housing from the engine.

6. Remove the thermostat taking note of its

original position in the housing.

To Install:

*In order to prevent leakage, make sure

both mating

surfaces are clean and free of

any old gasket material.

7. Install the thermostat so its flange seats

tightly in the machined groove in the intake manifold

or thermostat case. Refer to its location prior to re-

moval. Aliqn the relief valve with the alignment mark

on the thermostat housing.

8. Use a new gasket or D-ring and reinstall the

thermostat housing. Torque the housing mounting

bolts to the following specifications:

l 1.8L engine: 16 ft. Ibs. (22 Nm) l 1.5L, 1.61, 2.OL DOHC, and 1990-92 2.OL

SOHC engines: 12-14 ft. Ibs. (17-20 Nm)

l 1993 2.01 SOHC engine: 7-10 ft. Ibs.

(10-15 Nm)

l 2.4L engine: IO ft. Ibs. (14 Nm) l 3.OL and 3.5L engines: 12-14 ft. Ibs.

(17-20 Nm)

9. Fill the system with coolant.

10. Install the removed air intake plumbing.

15. Connect the negative battery cable and check

or leaks.

3.51 Engine

I See Figure 23

1. Disconnect the negative battery cable.

2. Remove the rocker arm cover.

g. 26 Remove the thermostat from the

ousing, noting the location of using the thermostat, always re-