fuel type MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 8 of 408

GENERALINFORMATIONAND MAINTENANCE l-9

Fig. 27 A click type or breakaway torque

wrench-note that this one has a pivoting

head

v

WRONG WRONG

PIVOTED HANDLE TOR(IUE WRENCH tccS1041 Fig. 28 Torque wrenches with pivoting

heads must be grasped and used properly

to prevent an incorrect reading

Rigid Case (Direct Reading)

# See Figure 29

A rigid case or direct reading torque wrench is

equipped with a dial indicator to show torque values.

One advantage of these wrenches is that they can be

held at any position on the wrench without affecting

accuracy. These wrenches are often preferred be-

cause they tend to be compact, easy to read and have

a great degree of accuracy.

lccs1042 Fig. 29 The rigid case (direct reading)

torque wrench uses a dial indicator to show

torque

TORQUEANGLEMETERS

# See Figure 30

Because the frictional characteristics of each fas-

tener or threaded hole will vary, clamp loads which

are based strictly on torque will vary as well. In most

applications, this variance IS not significant enough

to cause worry. But, in certain applications, a manu-

facturers engineers may determine that more precise

clamp loads are necessary (such is the case with :ig. 30 Some specifications require the use

rf a torque angle meter (mechanical pro.

ractor)

many aluminum cylinder heads). In these cases, a

torque angle method of installation would be speci-

fied. When installing fasteners which are torque angle

tightened, a predetermined seating torque and stan- dard torque wrench are usually used first to remove

any compliance from the joint. The fastener is then

tightened the specified additional portion of a turn

measured in degrees. A torque angle gauge (mechan-

ical protractor) is used for these applications.

) See Figure 31

Throughout this manual, specifications are given to

help you determine the condition of various compo-

nents on your vehicle, or to assist you in their installa-

tion. Some of the most common measurements in-

clude length (in. or cm/mm), torque (ft. Ibs., inch Ibs.

or Nm) and pressure (psi, in. Hg, kPa or mm Hg). In

most cases, we strive to provide the proper measure-

ment as determined by the manufacturers engineers.

Though, in some cases, that value may not be con-

veniently measured with what is available in your

toolbox. Luckily, many of the measuring devices

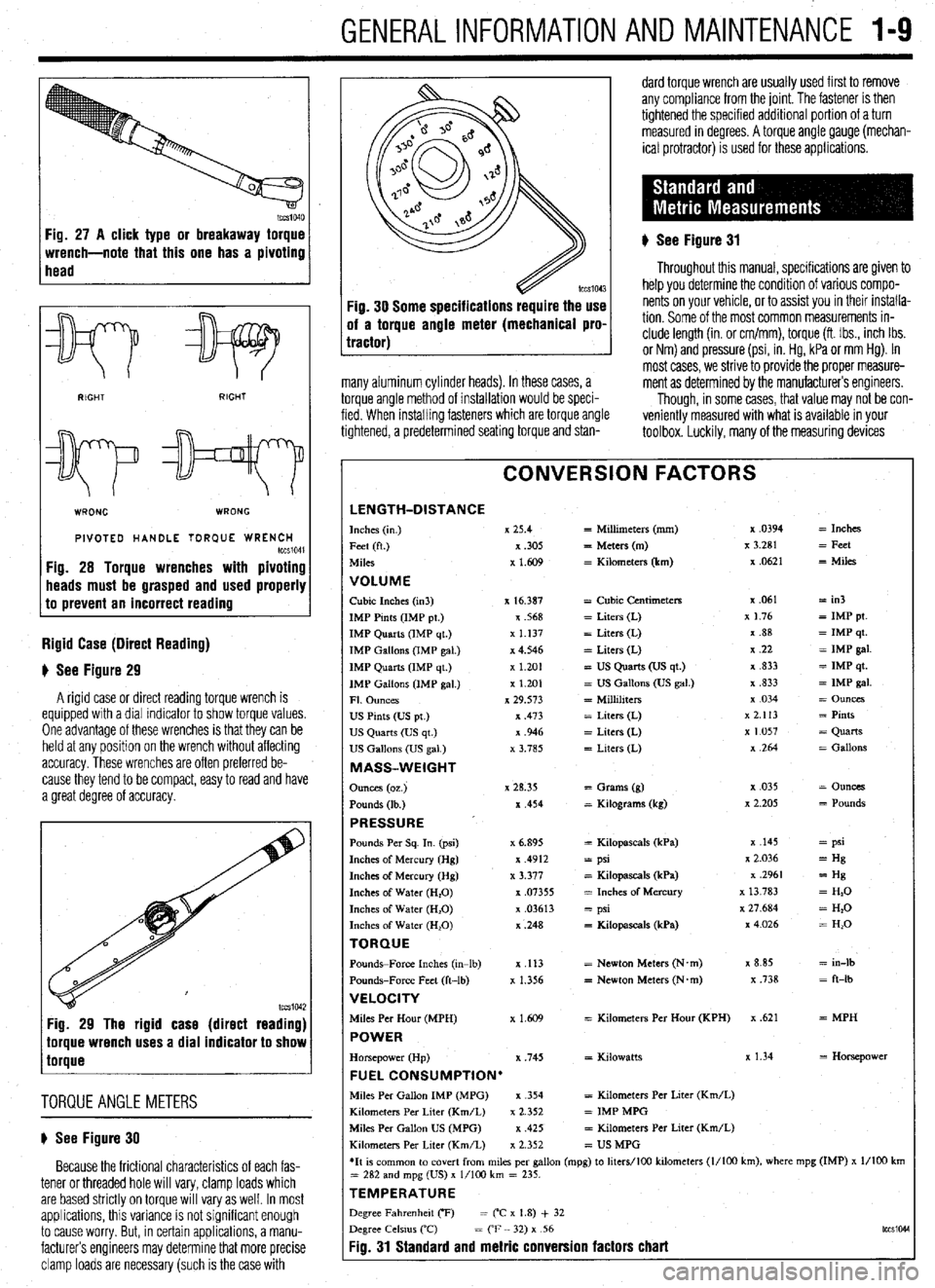

CONVERSION FACTORS

LENGTH-DISTANCE Inches (I”.) x 25.4 = Millimeters (mm) x .0394 = Inches

Feet (ft.) x ,305

= Meters (m) x 3.281 = Feet

Miles x 1.609 = Kilometers (km) x .0621

= Miles

VOLUME Cubic Inches (in3) x 16.387 = Cubic Centimeters x .061 = in3

IMP Pints (IMP pt.) x .568 = Liters (L) x 1.76

= IMP pt.

IMP Quarts (IMP qt.) x 1.137 = Liters (L) x .88 = IMP qt.

IMP Gallons (IMP gal.) x 4.546 = Liters (L) 7, .22

= IMP gal.

IMP Quarts (IMP qt ) x 1.201 = US Quarts (US qt.) x ,833 = IMP qt.

IMP Gallons (IMP gal.) x 1.201

= US Gallons (US gal.) x ,833

= IMP gal.

Fl. Ounces x 29.573 = Millihters x 034

= Ounces

us Pints (Us pt.) x ,473 = Liters (L) x 2.113 = Pints

US Quarts (US qt.) x .946 = Liters (L) x 1.057

= Quarts

US Gallons (US gal.) x 3.785 = Liters (L) x ,264 = Gallons

MASS-WEIGHT

Ounces (oz.) x 28.35

= Grams (g) x ,035

= Ounces

Pounds (lb ) x ,454 = Kdograms (kg) x 2.205

= Pounds

PRESSURE ’ Pounds Per Sq. In. (psi) x 6.895 = Kilopascals (kPa) x ,145 = psi

Inches of Mercury (Hg) x .4912

= psi x 2.036 = Hg

Inches of Mercury (Hg) x 3.377 = Kilopascals (kPa) x .2961

= Hg

Inches of Water (H,O)

x .07355 = Inches of Mercury x 13 783 = H,O

Inches of Water (H,O) x .03613 = psi x 27.684

= Hz0

Inches of Water (H,O) x ,248

= Kilopascals (kPa) x4026

= H,O

TORQUE Pounds-Force Inches (in-lb)

x ,113 = Newton Meters (N.m) x 8.85 = in-lb

Pounds-Force Feet (ft-lb)

x 1.356 = Newton Meters (N*m) x ,738 = ft-lb

VELOCITY Miles Per Hour (MPH)

x 1.609 = Kilometers Per Hour (KPH) x .621 = MPH POWER Horsepower (Hp) x ,745 = Kdowatts x 1.34

= Horsepower FUEL CONSUMPTION’ Mdes Per Gallon IMP (MPG) x .354

= Kilometers Per Liter (Km/L)

Kilometers Per Liter (Km/L)

x 2.352 = IMP MPG

Miles Per Gallon US (MPG) x ,425

= Kilometers Per Liter (Km/L)

Kdometers Per Liter (Km/L) x 2.352

= US MPG

*It 1s common to covert from miles per gallon (mpg) to hters/lOO kilometers (l/100 km), where mpg (IMP) x l/ID0 km

= 282 and mpg (US) x l/lo0 km = 235.

TEMPERATURE Degree Fahrenheit CF) = (“C x 1.8) + 32

Degree Celsms (‘C)

= CF - 32) x 56

tccsio4d

Fig. 31 Standard and metric conversion factors chart

Page 9 of 408

.

l-10 GENERALINFORMATIONAND MAINTENANCE

which are available today will have two scales so the

The conversion factor chart is used by taking the

Standard or Metric measurements may easily be given specification and multiplying it by the neces-

taken. If any of the various measuring tools which are sary conversion factor. For instance, looking at the

available to you do not contain the same scale as first line, if you have a measurement in inches such

listed in the specifications, use the accompanying

as “free-play should be 2 in.” but your ruler reads

conversion factors to determine the proper value. only in millimeters, multiply 2 in. by the conversion factor of 25.4 to get the metric equivalent of 50.8mm.

Likewise, if the specification was given only in a Met-

ric measurement, for example in Newton Meters

(Nm), then look at the center column first. If the mea-

surement is 100 Nm, multiply it by the conversion

factor of 0.738 to get 73.8 ft. Ibs.

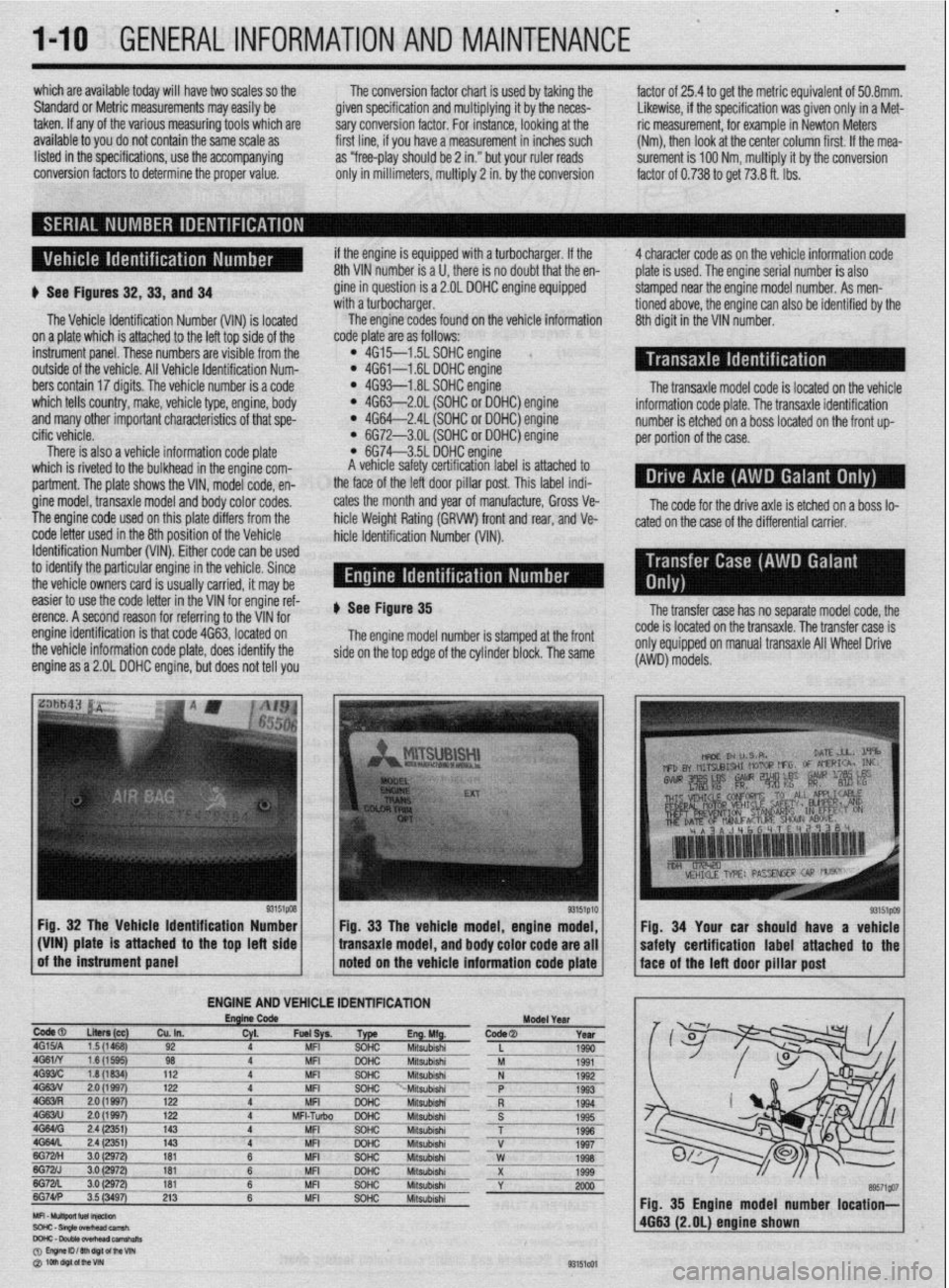

b See Figures 32,33, and 34

The Vehicle Identification Number (VIN) is located

on a plate which is attached to the left top side of the

instrument panel. These numbers are visible from the

outside of the vehicle. All Vehicle Identification Num-

bers contain 17 digits. The vehicle number is a code

which tells country, make, vehicle type, engine, body

and many other important characteristics of that spe-

cific vehicle.

There is also a vehicle information code plate

which is riveted to the bulkhead in the engine com-

partment. The plate shows the VIN, model code, en-

gine model, transaxle model and body color codes.

The engine code used on this plate differs from the

code letter used in the 8th position of the Vehicle

Identification Number (VIN). Either code can be used

to identify the particular engine in the vehicle. Since

the vehicle owners card is usually carried, it may be if the engine is equipped with a turbocharger. If the

8th VIN number is a U, there is no doubt that the en-

gine in question is a 2.OL DOHC engine equipped

with a turbocharger.

The engine codes found on the vehicle information

code plate are as follows:

l 4G15--1.5L SOHC engine l 4G61-1.6L DOHC engine l 4G93-1.8L SOHC engine l 4G63-2.OL (SOHC or DOHC) engine l 4G64-2.4L (SOHC or DOHC) engine l 6G72-3.OL (SOHC or DOHC) engine l 6G74-3.5L DOHC engine

A vehicle safety certification label is attached to

the face of the left door pillar post. This label indi-

cates the month and year of manufacture, Gross Ve-

hicle Weight Rating (GRVW) front and rear, and Ve-

hicle Identification Number (VIM). 4 character code as on the vehicle information code

plate is used. The engine serial number is also

stamped near the engine model number. As men-

tioned above, the engine can also be identified by the

8th digit in the VIN number.

The transaxle model code is located on the vehicle

information code plate. The transaxle identification

number is etched on a boss located on the front up-

per portion of the case.

The code for the drive axle is etched on a boss lo-

cated on the case of the differential carrier.

easier to use the code letter in the VIN for engine ref-

erence. A second reason for referring to the VIN for

engine identification is that code 4663, located on

the vehicle information code plate, does identify the

engine as a 2.OL DOHC engine, but does not tell you ) See Figure 35

The engine model number is stamped at the front

side on the top edge of the cylinder block. The same

Fig. 32 The Vehicle Identification Number

g3’51p’o of the instrument panel _I:^1 / Fig. 33 The vehicle model, engine model,

(VIN) plate is attached to the top left side

bansaxle model, and body color code are all

noted on the vehicle information code plate

ENGINE AND VEHiCLE IDENTlFlCATlON

EnglnCode

ModelYerr

todeal

LIten (cc)

Cu. In. W. Fuel+ Type m.hWg. Code@ Year ,G15JA 1.5 (1468) 92 4 MFI SOHC Mitsubishi

L 1990

IG61N 1.6(15QQ) 98 4 MFI DOHC

Mitsubishi M 1991

1G93lC 1.8 (1834) 112 4 MFI SOHC Mitsubishi N 1992

IG63N 2.0 (1997) 122 4 MFI SOHC “-Mitsubishi P

1993

!G63Fi 2.0 (1997) 122 4 MFI DOHC Mitsubishi

R 1994

,G63iU 2.0 (1997) 122 4 MFI-Tuibo DOHC Mitsubishi

S 1995

.GMffi 2.4 (2351) 143 4 MFI SOHC

Mitsubishi T 1996

iG64L 2.4 (2351) 143 4 MFI DOHC Mitsubishi V

lEzH 3.0 1997

(2972) 161 6 MFI SOHC Mitsubishi W 1998

;G7ZJ 3.0 (2Q72) 161 6 MFI GQHC Mitsubishi

~.. X 1999

iG7zL 3.0 (2972) 181

~ 6 MFI SOHC ___-___ Miisubishi

Y 2000

iG74lP 3.5 (3497) 213 6 MFI SOHC Miisubishi

The transfer case has no separate model code, the

code is located on the transaxle. The transfer case is

onlv eoUiODed on manual transaxle All Wheel Drive

(AWD)‘mbdels.

Fig. 34 Your car should have a vehicle

Fig. 35 Engine model number location-

4663 (2.OL) engine shown

Page 21 of 408

l-22 GENERALINFORMATIONAND MAINTENANCE

tears. If the boot is damaged, it should be replaced

trode is to the block’s cooling passages) the cooler it

your driving is long distance, high speed travel, use a

immediately. Please refer to Section 7 for procedures.

will operate. A plug that absorbs little heat and re-

colder plug; if most of your driving is stop and go,

mains too cool will quickly accumulate deposits of

use a hotter plug. Original equipment plugs are gen-

oil and carbon since it is not hot enough to burn

erally a good compromise between the 2 styles and

them off. This leads to plug fouling and consequently

most people never have the need to change their

to misfiring. A plug that absorbs too much heat will

plugs from the factory-recommended heat range.

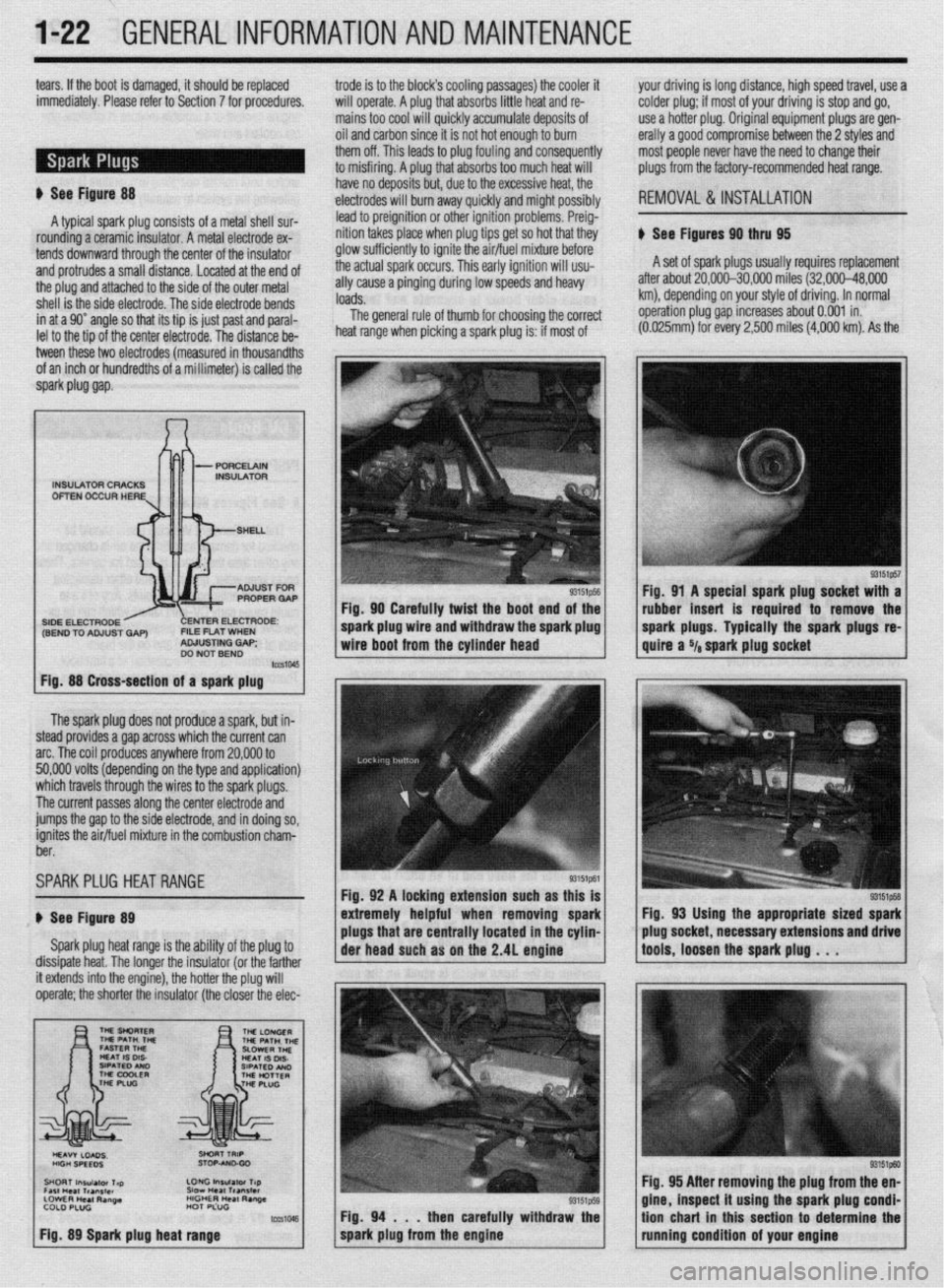

ti See Figure 88 have no deposits but, due to the excessive heat, the

,electrodes will burn away quickly and might possibly

REMOVAL &INSTALLATION

A typical spark plug consists of a metal shell sur- lead to preignition or other ignition problems. Preig-

rounding a ceramic insulator. A metal electrode ex- nition takes place when plug tips get so hot that they

ti See Figures 90 thru 95

tends downward through the center of the insulator glow sufficiently to ignite the air/fuel mixture before

and protrudes a small distance. Located at the end of the actual spark occurs. This early ignition will usu- A set of spark plugs usually requires replacement

the plug and attached to the side of the outer metal ally cause a pinging during low speeds and heavy after about 20,000-30,000 miles (32,000-48,000

shell is the side electrode. The side electrode bends loads. km), depending on your style of driving. In normal

in at a 90” angle so that its tip is just past and paral- The general rule of thumb for choosing the correct operation plug gap increases about 0.001 in.

lel to the tio of the center electrode. The distance be- heat range when picking a spark plug is: if most of (0.025mrn) for every 2,500 miles

(4,000 km). As the

tween these two electrodes (measured in thousandths

of an inch or hundredths of a millimeter) is called the

spark piug gap.

The spark plug does not produce a spark, but in-

steed provides a gap across which the current can

arc. The coil produces anywhere from 20,000 to

50,000 volts (depending on the type and application)

which travels through the wires to the spark plugs.

The current passes along the center electrode and

jumps the gap to the side electrode, and in doing so,

ignites the air/fuel mixture in the combustion charn-

ber.

SPARKPLUG HEATRANGE

ti See Figure 89

Spark plug heat range is the ability of the plug to

dissipate heat. The longer the insulator (or the farther

INSULATOR CRACKS

OFTEN OCCUR HERE

SIDE ELECTRODE ENTER ELECTRODE:

(SEND TO ADJUST GAP) FILE FLAT WHEN

ADJUSTING GAP;

DO NOT BEND

Fig. 88 Cross-section of a spark plug

it extends into the engine), the hotter the plug will

operate; the shorter the insulator (the closer the elec- Fig. 90 Carefully twist the boot end of the

I

spark plug wire and withdraw the spark plug

wire boot from the cylinder head

Fig. 92 A locking extension such as this is

extremely helpful when removing spark

plugs that are centrally located in the cyhn-

Fig. 94 . . .

then carefully withdraw the

spark plug from the engine Fig. 91 A special spark plug socket with a

rubber insert is required to remove the

spark plugs. Typically the spark plugs

re-

quire a Ya spark plug socket

Fig, 93 Using the appropriate sized spark

plug socket, necessary extensions and drive

tools, loosen the spark plug . . .

93151ptxl Fig. 95 After removing the plug from the en-

gine, inspect it using the spark plug condi-

tion chart in this section to determine the

running condition of your engine

Page 22 of 408

t

GENERALINFORMATIONAND MAINTENANCE l-23

gap increases, the plug’s voltage requirement also in-

creases. It requires a greater voltage to jump the the spark plug counterclockwise to loosen and re-

move the spark plug from the bore.

wider gap and about &o to three times as much volt-

age to fire the plug at high speeds than at idle. The

improved air/fuel ratio control of modern fuel injec-

tion combined with the higher voltage output of mod- Be sure not to use a flexible extension on the place. The click may be felt or heard, then gently pull

ern ignition systems will often allow an engine to run socket. Use of a flexible extension may allow back on the boot to assure proper contact.

.___. . _

significantly longer on a set of standard spark plugs, a shear force to be agptf’ ea to me plug.

A 12. On the 3.OL fSOHC and DOHC) and 3.5L en-

LL_ _I___ -u I_ IL-

but keep in mind that efficiency will drop as the gap shear force could break tne pug on III me

tion 3 for the installation procedure.

widens (along with fuel economy and power). cylinder head, leading to costly and frustrat-

13. If equipped, install the center cover.

When you’re removing spark plugs, work on one ing repairs.

at a time. Don’t start by removing the plug wires all at

once, because, unless you number them, they may To install:

INSPECTION & GAPPING

11. Apply a small amount of silicone dielectric

compound to the end of the spark plug lead or inside

the spark plug boot to prevent sticking, then install

the boot to the spark plug and push until it clicks into

gines, install the upper intake manifold. Refer to Sec-

,,Y” ..1111 uy”’ 1 the neaative bat&v cable and if become mixed up. Take a minute before you begin

and number the wrrpc with +sne

1. Disconnect. ~~.~

--..-., -..-.-, -..-

thevehicle has been run recently, allow the engine to

thoroughly cool.

2. If equipped, remove the center cover.

3. On the 3.OL (SOHC and DOHC) and 3.5L en-

gines, the upper intake manifold must be removed to

access the rear spark plugs. Refer to Section 3 for the

removal procedure.

4. Carefully twist the spark plug wire boot to

loosen it, then pull upward and remove the boot from

the plug. Be sure to pull on the boot and not on the

wire, otherwise the connector located inside the boot

may become separated.

5. Using compressed air, blow any water or de-

bris from the spark plug well to assure that no harm-

ful contaminants are allowed to enter the combustion

chamber when the spark plug is removed. If com-

pressed air is not available, use a raa or a brush to must be replaced.

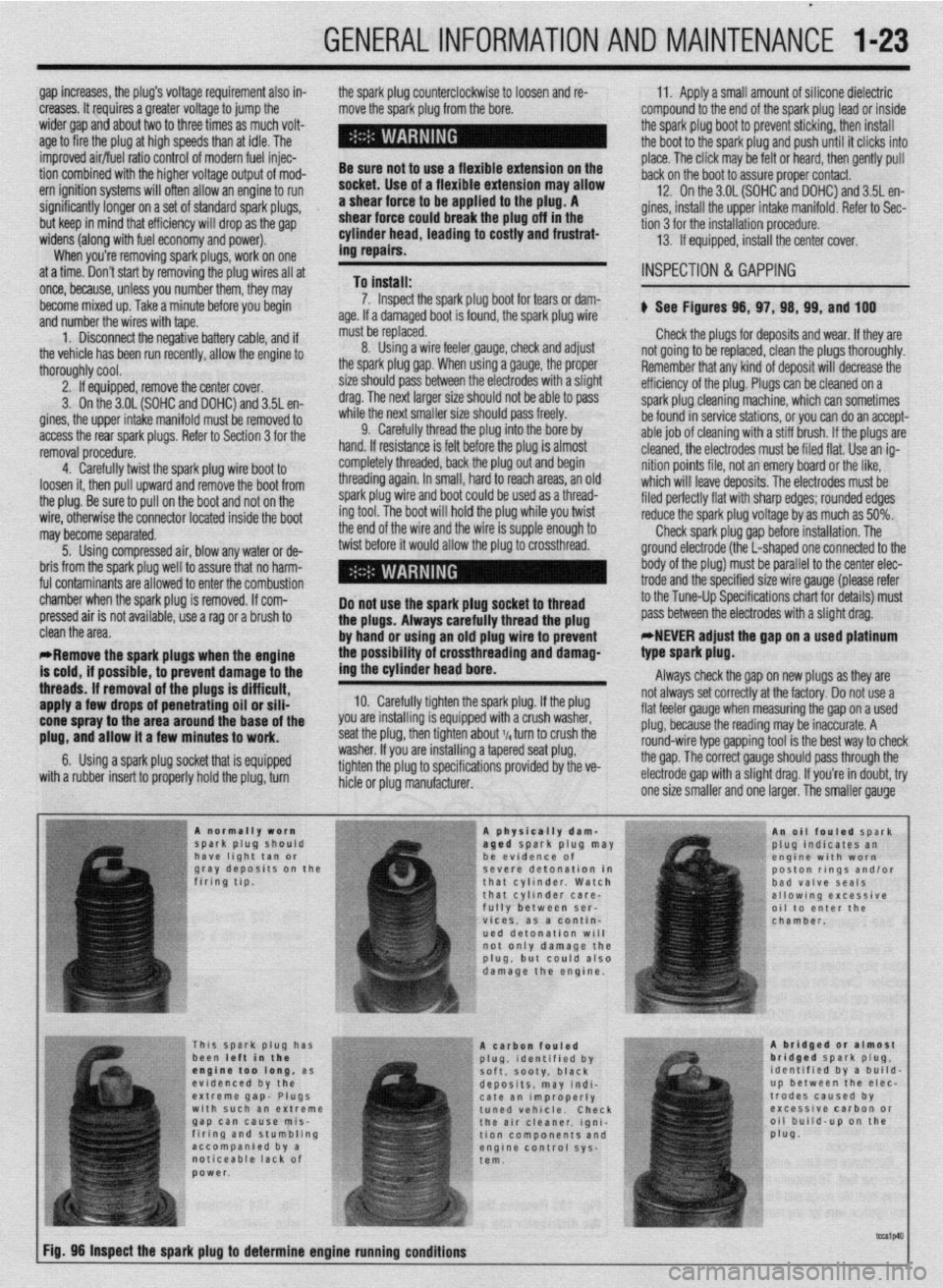

Check the plugs for deposits and wear, If they are 7. Inspect the spark plug boot for tears or dam-

age. If.a damaged boot is found, the spark plug wire

8. Using a wire feelergauge, check and adjust

the spark plug gap. When using a gauge, the proper

size should pass between the electrodes with a slight

drag. The next larger size should not be able to pass

while the next smaller size should pass freely.

9. Carefully thread the plug into the bore by

hand. If resistance is felt before the plug is almost

completely threaded, back the plug out and begin

threading again. In small, hard to reach areas, an old

spark plug wire and boot could be used as a thread-

ing tool. The boot will hold the plug while you twist

the end of the wire and the wire is supple enough to

twist before it would allow the plug to crossthread.

Do not use the spark plug sock?

l -- K-rrA tha nhme Alwmm rarntdlv thw GL I” IlllGa”

the possibility of crossthreading and damag- lad the plug

. ..Y f..“YY. rn”Y,‘““mY*“.‘, .I**” by hand or using an old plug wire to prevent

ing the cylinder head bore.

10. Carefully tighten the spark plug. If the plug

you are installing is equipped with a crush washer,

seat the plug, then tighten about I/, turn to crush the

washer. If you are installing a tapered seat plug,

tighten the plug to specifications provided by the ve-

hicle or plug manufacturer. b See Figures 98, 97, 98, 99, and 100

not going to be replaced, clean the plugs thoroughly.

Remember that any kind of deposit will decrease the

efficiency of the plug. Plugs can be cleaned on a

spark plug cleaning machine, which can sometimes

be found in service stations, or you can do an accept-

able job of cleaning with a stiff brush. If the plugs are’

cleaned, the electrodes must be filed flat. Use an ig-

nition points file, not an emery board or the like,

which will leave deposits. The electrodes must be

filed perfectly flat with sharp edges; rounded edges

reduce the spark plug voltage by as much as 50%.

Check spark plug gap before installation. The

ground electrode (the L-shaped one connected to the

body of the plug) must be parallel to the center elec-

trode and the specified size wire gauge (please refer

to the Tune-Up Specifications chart for details) must

pass between the electrodes with a slight drag:

*,NEVER adjust the gap on a used platinum

. clean the area.

*Remove the spark plugs when the engine

is cold, if possible, to prevent damage to the

threads. If removal of the plugs is difficult,

apply a few drops of penetrating oil or sili-

cone spray to the area around the base of the

plug, and allow it a few minutes to work.

6. Using a spark plug socket that is equipped

with a rubber insert to properly hold the plug, turn type spark plug.

Always check the gap on new plugs as they are

not always set correctly at the factory. Do not use a

flat feeler gauge when measuring the gap on a used

plug, because the reading may be inaccurate. A

round-wire type gapping tool is the best way to check

the gap. The correct gauge should pass through the

electrode gap with a slight drag. If you’re in doubt, try

one size smaller and one laraer. The smaller aauqe

Page 31 of 408

.

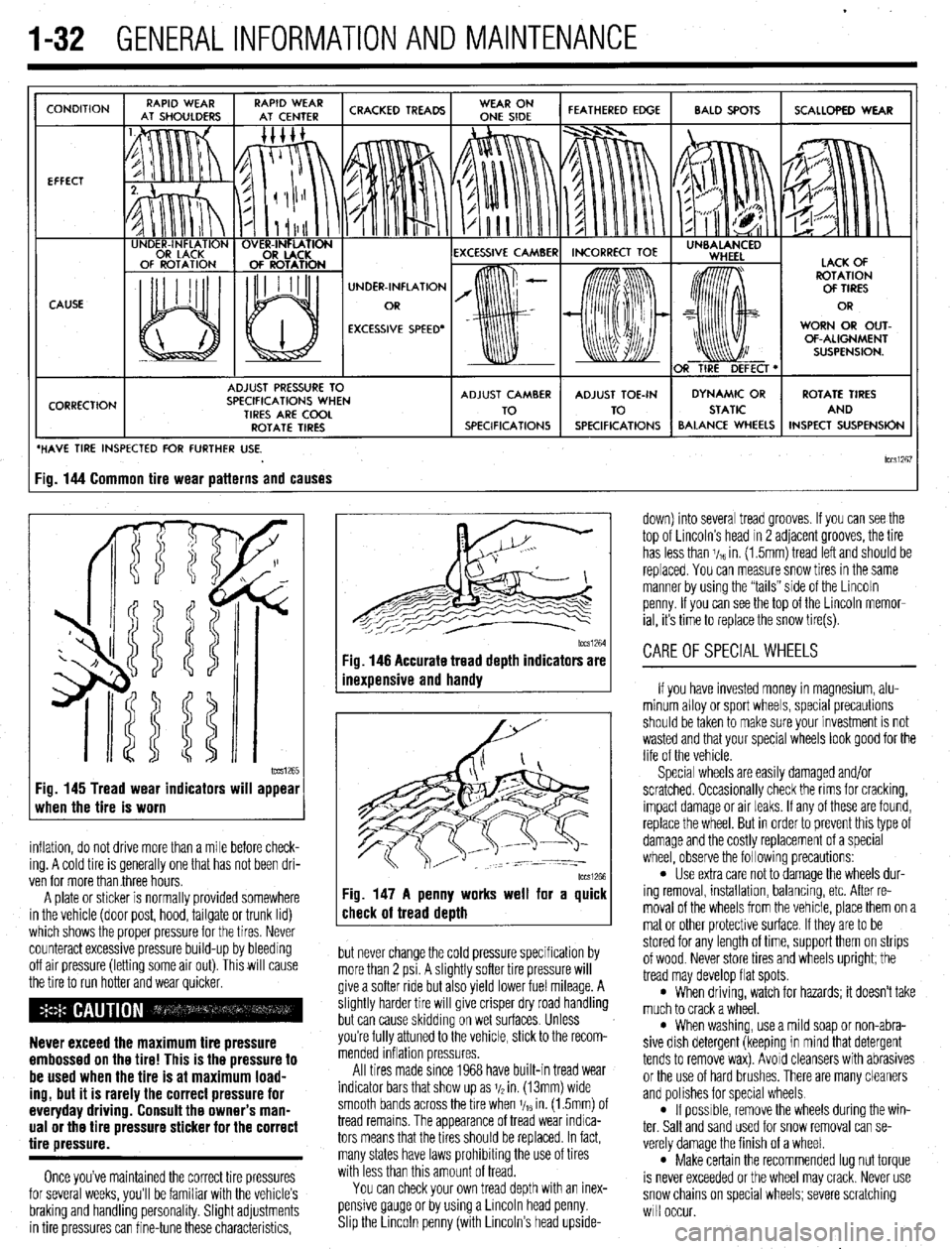

1-32 GENERALINFORMATIONAND MAINTENANCE

CONDITION

EFFECT

CAUSE

CORRECTION UNDER-INFLATION

EXCESSIVE SPEED’ WORN OR OUT-

OF-ALIGNMENT

ADJUST PRESSURE TO

SPECIFICATIONS WHEN

TIRES ARE COOL

ROTATE TIRES

/ BALANCE WHEELS INSPECT SUSPENSION

HAVE TIRE INSPECTED FOR FURTHER USE.

lCCSi267 ig. 144 Common tire wear patterns and causes

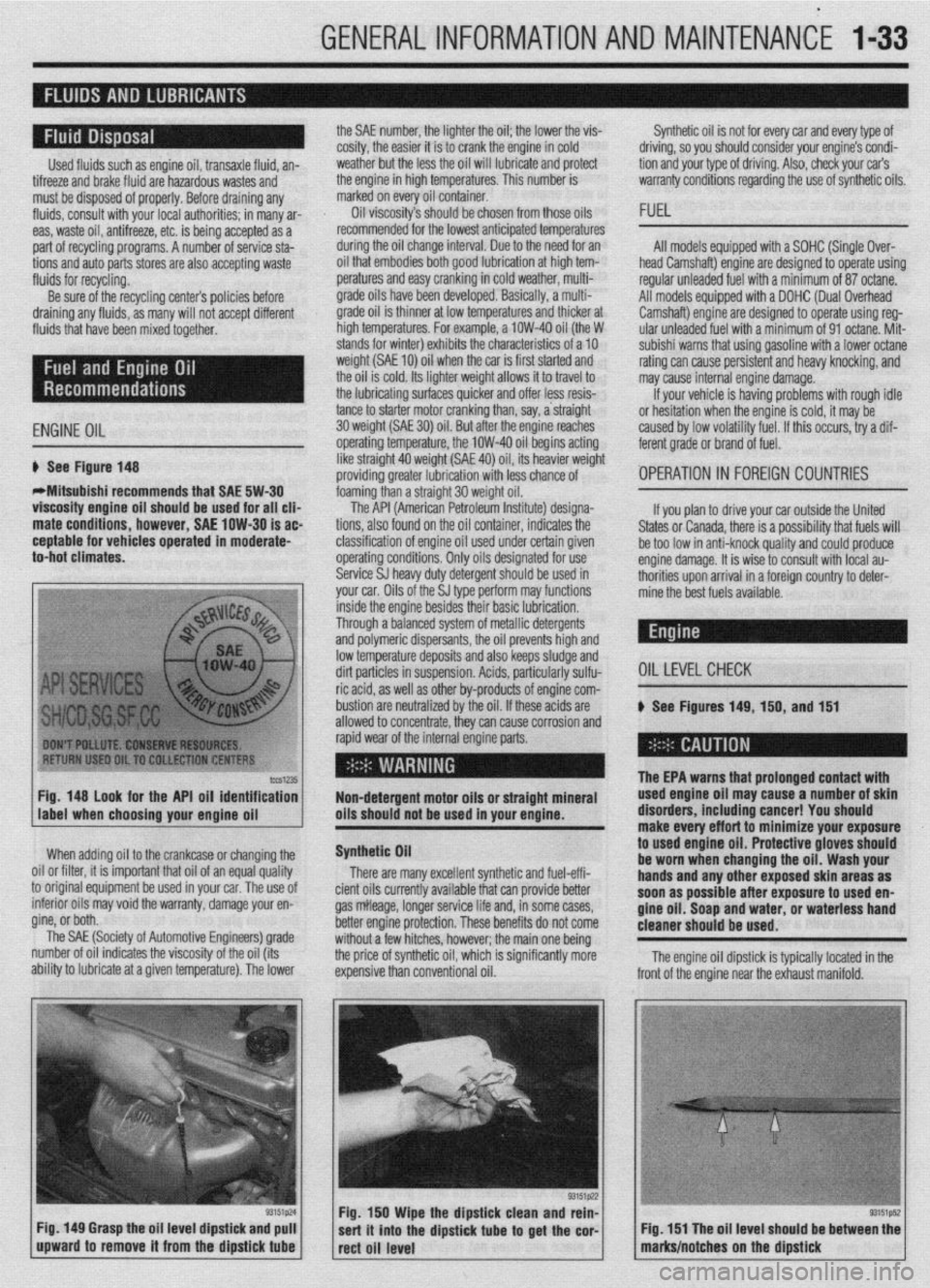

1~~~1265 Fig. 145 Tread wear indicators will appear

when the tire is worn

inflation, do not drive more than a mile before check-

ing. A cold tire is generally one that has not been dri-

ven for more than three hours.

A plate or sticker is normally provided somewhere

in the vehicle (door post, hood, tailgate or trunk lid)

which shows the proper pressure for the tires. Never

counteract excessive pressure build-up by bleeding

off air pressure (letting some air out). This will cause

the tire to run hotter and wear quicker.

Never exceed the maximum tire pressure

embossed on the tire! This is the pressure to

be used when the tire is at maximum load-

ing, but it is rarely the correct pressure for

everyday driving. Consult the owner’s man-

ual or the tire pressure sticker for the correct

tire pressure.

Once you’ve maintained the correct tire pressures

for several weeks, you’ll be familiar with the vehicle’s

braking and handling personality. Slight adjustments

in tire pressures can fine-tune these characteristics,

1~~~1264 Fig. 146 Accurate tread depth indicators are

inexuensive and handv

Fig. 147 A penny works well for a quick

check of tread death

but never change the cold pressure specification by

more than 2 psi. A slightly softer tire pressure will

give a softer ride but also yield lower fuel mileage. A

slightly harder tire will give crisper dry road handling

but can cause skidding on wet surfaces. Unless

you’re fully attuned to the vehicle, stick to the recom-

mended inflation pressures.

All tires made since 1968 have built-in tread wear

indicator bars that show up as j/2 in. (13mm) wide

smooth bands across the bre when V,~ in. (1.5mm) of

tread remains. The appearance of tread wear indica-

tors means that the tires should be replaced. In fact,

many states have laws prohibiting the use of tires

with less than this amount of tread.

You can check your own tread depth with an inex-

pensive gauge or by using a Lincoln head penny.

Shp the Lrncoln penny (with Lincoln’s head upside- down) into several tread grooves. If you can see the

top of Lincoln’s head in 2 adjacent grooves, the tire

has less than V,~ in. (1.5mm) tread left and should be

replaced. You can measure snow tires in the same

manner by using the “tails” side of the Lincoln

penny. If you can see the top of the Lincoln memor-

ial, its time to replace the snow tire(s).

CAREOFSPECIALWHEELS

If you have invested money in magnesium, alu-

minum alloy or sport wheels, special precautions

should be taken to make sure your investment is not

wasted and that your special wheels look good for the

life of the vehicle.

Special wheels are easily damaged and/or

scratched. Occasionally check the rims for cracking,

impact damage or air leaks. If any of these are found,

replace the wheel. But in order to prevent this type of

damage and the costly replacement of a special

wheel, observe the following precautions:

l Use extra care not to damage the wheels dur-

ing removal, installation, balancing, etc. After re-

moval of the wheels from the vehicle, place them on a

mat or other protective surface. If they are to be

stored for any length of time, support them on strips

of wood. Never store tires and wheels upright; the

tread may develop flat spots.

l When driving, watch for hazards; it doesn’t take

much to crack a wheel.

l When washing, use a mild soap or non-abra-

sive dish detergent (keeping in mind that detergent

tends to remove wax). Avoid cleansers with abrasives

or the use of hard brushes. There are many cleaners

and polishes for special wheels.

l If possrble, remove the wheels during the win-

ter. Salt and sand used for snow removal can se-

verely damage the finish of a wheel.

l Make certain the recommended lug nut torque

is never exceeded or the wheel may crack. Never use

snow chains on special wheels; severe scratching

will occur.

Page 32 of 408

GENERALINFORMATIONAND MAINTENANC-E 1133

Used fluids such as engine oil, transaxle fluid, an-

tifreeze and brake fluid are hazardous wastes and

must be disposed of properly. Before draining any

fluids, consult with your local authorities; in many ar-

eas, waste oil, antifreeze, etc. is being accepted as a

part of recycling programs. A number of service sta-

tions and auto parts stores are also accepting waste

fluids for recycling.

Be sure of the recycling center’s policies before

draining any fluids, as many will not accept different

fluids that have been mixed together.

ENGINE OIL

6 See Figure 148

WMitsubishi recommends that SAE 5W-30

viscosity engine oil should be used for all clia

mate conditions, however, SAE low-30 is ac

ceptable for vehicles operated in moderate-

to-hot climates. the SAE number, the lighter the oil; the lower the vis-

cosity, the easier it is to crank the engine in cold

weather but the less the oil will lubricate and protect

the engine in high temperatures. This number is

marked on every oil container.

Oil viscosity’s should be chosen from those oils

recommended for the lowest anticipated temperatures

during the oil change interval. Due to the need for an

oil that embodies both good lubrication at high tem-

peratures and easy cranking in cold weather, multi-

grade oils have been developed. Basically, a multi-

grade oil is thinner at low temperatures and thicker at

high temperatures. For example, a low-40 oil (the W

stands for winter) exhibits the characteristics of a 10

weight (SAE 10) oil when the car is first started and

the oil is cold. Its lighter weight allows it to travel to

the lubricating surfaces quicker and offer less resis-

tance to starter motor cranking than, say, a straight

30 weight (SAE 30) oil. But atier the ensine reaches

operating temperature, the low-40 oil begins acting

like straight 40 weight (SAE 40) oil, its heavier weight

providing greater lubrication with less chance of

foaming than a straight 30 weight oil. Synthetic oil is not for every car and every type of

driving, so you should consider your engine’s condi-

tion and your type of driving. Also, check your car’s

warranty conditions regarding the use of synthetic oils.

FUEL

All models equipped with a SOHC (Single Over-

head Camshaft) engine are designed to operate using

regular unleaded fuel with a minimum of 87 octane.

All models equipped with a DOHC (Dual Overhead

Camshaft) engine are designed to operate using reg-

ular unleaded fuel with a minimum of 91 octane. Mit-

subishi warns that using gasoline with a lower octane

rating can cause persistent and heavy knocking, and

may cause internal engine damage.

If your vehicle is having problems with rough idle

or hesitation when the enoine is cold, it mav be

caused by low volatility fuel. If this occurs, iry a dif-

ferent grade or brand of fuel.

'OPERATION 1~ FOREIGN COUNTRIES

lccS1235 Fig. 148 look for the API oil identification

Non-detergent motor oils or straight mineral

label when choosing your enaine oil oils should not be used in your engine.

When adding oil to the crankcase or changing the

0 Nil or filter, it is important that oil of an equal quality

I original equipment be used in your car. The use of

. tc mtenor 011s may void the warranty, damage your en-

gine, or both. __

The SAE (Society of Automotive Engineers) grade

number of oil indicates the viscosity of the oil (its

ability to lubricate at a given temperature). The lower

Fig. 149 Grasp the oil level dipstick and pull

upward to remove it from the dipstick

tube

The API (American Petroleum Institute) designa-

tions, also found on the oil container, indicates the

classification of engine oil used under certain given

operating conditions. Only oils designated for use

Service SJ heavy duty detergent should be used in

your car. Oils of the SJ type perform may functions If you plan to drive your car outside the United

States or Canada, there is a possibility that fuels will

be too low in anti-knock quality and could produce

engine damage. It is wise to consult with local au-

thorities upon arrival in a foreign country to deter-

mine the best fuels available.

inside the engine besides their basic lubrication.

Through a balanced system of metallic detergents

and polymeric dispersants, the oil prevents high and

low temperature deposits and also keeps sludge and

dirt particles in suspension. Acids, particularly sulfu-

OILLEVELCHECK ric acid, as well as other by-products of engine com-

bustion are neutralized by the oil. If these acids are

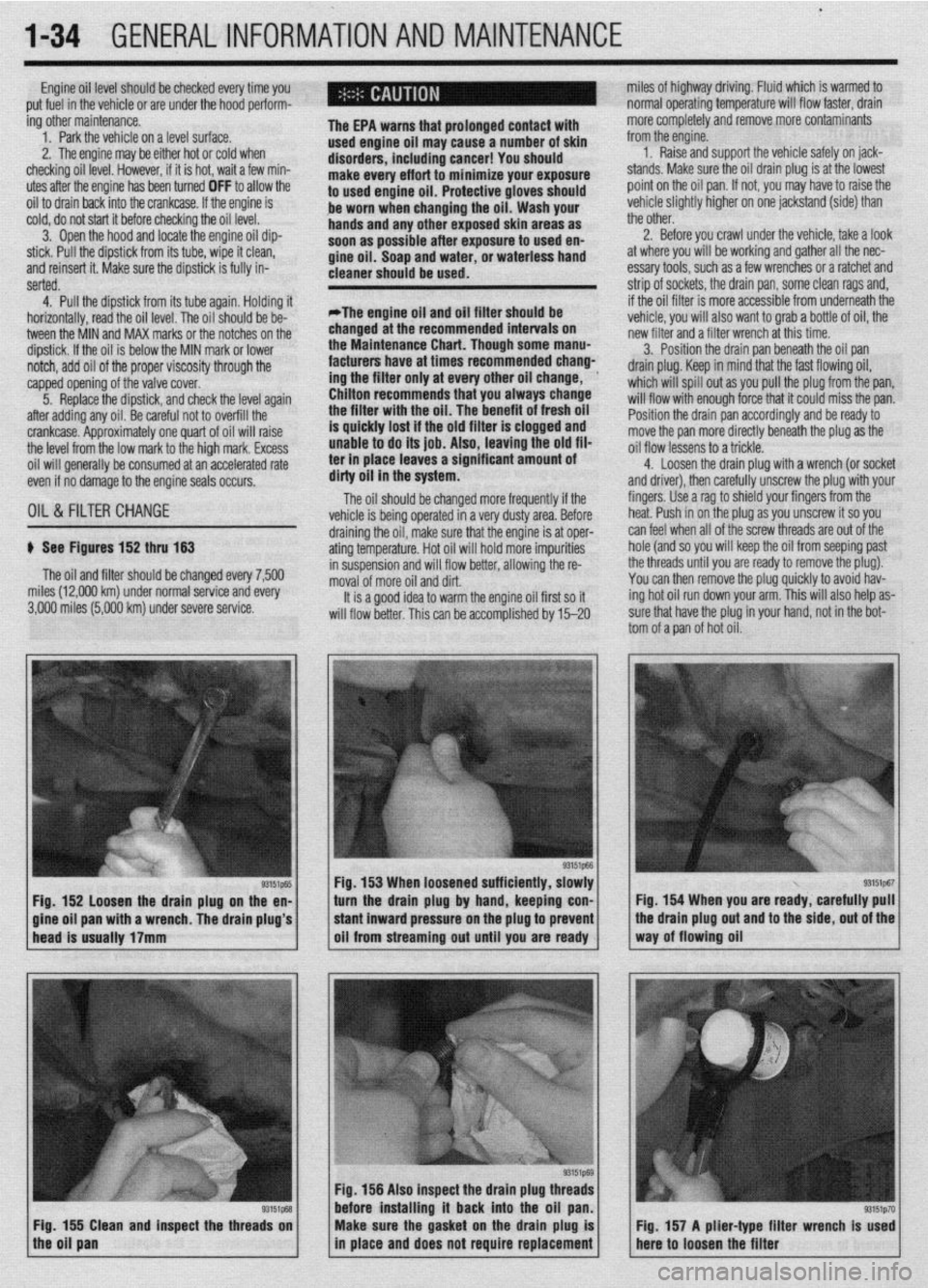

# See Figures 149, 150, and 151

allowed to concentrate, thev can cause corrosion and

rapid wear of the internal engine parts.

Synthetic Oil

There are many excellent synthetic and fuel-effi-

cient oils currently available that can provide better

gas mileage, longer service life and, in some cases,

better engine protection. These benefits do not come

without a few hitches, however; the main one being

the price of synthetic oil, which is significantly more

expensive than conventional oil.

.

The EPA warns that urolonoed contact with used engine oil ma; cause-a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to

used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

Fig. 150 Wipe the dipstick clean and rein-

sert it into the dipstick

tube to get the cor-

rect oil level The engine oil dipstick is typically located in the

Fig. 151 The oil level should be between the

marks/notches on the dipstick

Page 33 of 408

.

l-34 GENERALINFORMATIONAND MAINTENANCE

Engine oil level should be checked every time you

put fuel in the vehicle or are under the hood perform- miles of highway driving. Fluid which is warmed to

normal operating temperature will flow faster, drain

ing other maintenance.

1. Park the vehicle on a level surface.

2. The enaine mav be either hot or cold when

, if it is hot, wait a few min- checking oil level. The EPA warns that prolonged contact with

used engine oil may cause a num’ * * *

dianrAnrr inrldinn ranrnrl V#lll more completely and remove more contaminants

frnm tho clnnine

utes after the engine has been turned OFF to allow the

oil to drain back into the crankcase. If the engine is

cold, do not start it before checking the oil level. point on the oil pan. If not, you may have to raise the

vehicle slightly higher on one jackstand (side) than

3. Open the hood and locate the engine oil dip-

stick. Pull the dipstick from its tube, wipe it clean,

and reinsert it. Make sure the diDstick is fullv in-

serted.

4. Pull the dipstick from its tube again. Holding it to used engin

be worn whet

handsandan

so*m ..#a . . . . .

IDer 01 SKlll u,yu,u=,+, ,,,u,uu,,,u uu,,u=, i , vu should

uff art to minimize your exposure

le oil. Protective gloves should

1 changing the oil. Wash your

y other exposed skin areas as

111 aJ vv4ble after exposure to used en-

m nil St-mn mwl w&or nr umtarlncr hand gin Y “II. ““up “ll” .,U.“I, “rn W.Y.“. .““I .I....” cleaner should be used.

horizontally, read the oil level. The oilshould be be-

tween the MIN and MAX marks or the notches on the

dipstick. If the oil is below the MIN mark or lower

notch, add oil of the proper viscosity through the

capped opening of the valve cover. *The engine oil and oil filter should be

changed at the recommended intervals on

the Maintenance Chart. Though some manu-

facturers have at times recommended chang-

ing the filter only at every other oil change, ’

Chilton recommends that you always change

ll”,,, Cl>” ““y”‘“. 1. Raise and support the vehicle safely on jack-

stands. Make sure the oil drain olua is at the lowest

the other.

2. Before you crawl under the vehicle, take a look

at where you will be working and gather all the nec-

essary tools, such as a few wrenches or a ratchet and

strip of sockets, the drain pan, some clean rags and,

if the oil filter is more accessible from underneath the

vehicle, you will also want to grab a bottle of oil, the

new filter and a filter wrench at this time.

5. Reolace the diostick. and check the level aaain

. The benefit of fresh oil

p See Figures 152 thru 153

The oil and filter should be changed every 7,500

miles (12,000 km) under normal service and every

3,000 miles (5,000 km) under severe service.

93151p-55 Fig. 152 loosen the drain plug on the en-

a wrench. The drain plug’s 3. Position the drain pan beneath the oil pan

drain plug. Keep in mind that the fast flowing oil,

which will spill out as you pull the plug from the pan,

will flow with enough force that it could miss the pan.

Position the drain pan accordingly and be ready to

move the pan more directly beneath the plug as the

oil flow lessens to a trickle.

4. Loosen the drain ~lua with a wrench (or socket

and driver), then carefuliy unscrew the plug with your

fingers. Use a rag to shield your fingers from the

heat. Push in on the plug as you unscrew it so you

draining the oil, make sure that the engine is at oper- can feel when all of the screw threads are out of the

ating temperature. Hot oil will hold more impurities hole (and so you will keep the oil from seeping past

in suspension and will flow better, allowing the re- the threads until you are ready to remove the plug).

moval of more oil and dirt. You can then remove the plug quickly to avoid hav-

It is a good idea to warm the engine oil first so it ing hot oil run down your arm. This will also help as-

will flow better. This can be accomolished bv 15-20 sure that have the plug in your hand, not in the bot-

tom of a pan of hot oil.

Fig. 153 When loosened sufficiently, slowly

turn the drain plug by hand, keeping con- Fig. 154 When you are ready, carefully pull

Fig. 156 Also inspect the drain plug th

before installing it back into the oil

Fig. 155 Clean and inspect the threads on

the oil pan Make sure the gasket on the drain plug is

in place and does not require replacement Fig. 157 A plier-type filter wrench Is used

here to loosen the filter

Page 52 of 408

ENGlNEELECTRliAL 2-5

Fig. 19 Adjusting the distributor-1.5L en-

gine shown, others similar

4. Install the hold-down nut.

5. Attach the distributor harness connectors.

6. Install the distributor cap.

7. Connect the negative battery cable.

8. Adjust the ignition timing and tighten the hold-

down nut to 8 ft. Ibs. (11 Nm).

For procedures on the position sensors, please re-

fer to Section 4 in this manual.

The ignition system found on the 1.6L, 1997-60

1.8L, 2.OL DOHC, 1999-00 2.4L SOHC, 2.4L DOHC,

and 3.OL DOHC engines is a distributorless type.

The advance of this system, like the distributor type

ignition, is controlled by the Engine Control Unit

(ECU) or Powertrain Control Module (PCM). The

distributorless ignition system contains a crank an-

gle/position sensor which detects the crank angle or

position to each cylinder and converts this data into

pulse signals. These signals are sent to the

ECLVPCM, which calculates the engine rpm and

regulates the fuel injection and ignition timing ac-

cordingly. The system also contains a top dead cen-

ter sensor which detects the top dead center position

of each cylinder and converts this data into pulse

signals. These signals are then sent to the

ECU/PCM, which calculates the sequence of fuel in-

jection and engine rpm.

When the ignition switch is turned ON, battery

voltage is applied to the ignition coil primary wind-

ing. As the crank angle sensor shaft rotates, ignition

signals are transmitted from the multi port injection

control unit to the power transistor. These signals

activate the power transistor to cause ignition coil

primary winding current to flow from the ignition

coil negative terminal through the power transistor

to ground or be interrupted, repeatedly. This action

induces high voltage in the secondary winding of

the ignition coil. From the ignitron coil, the sec-

ondary winding current produced flows through the

spark plug to ground, thus causing ignition in each

cylinder.

Refer to Diagnosis and Testing under Distributor

Ignition in this section,

There are no adjustments to the distributorless ig-

nition system other than the ignition timing adjust-

ment. Refer to section 1 for ignition timing adjust-

ment.

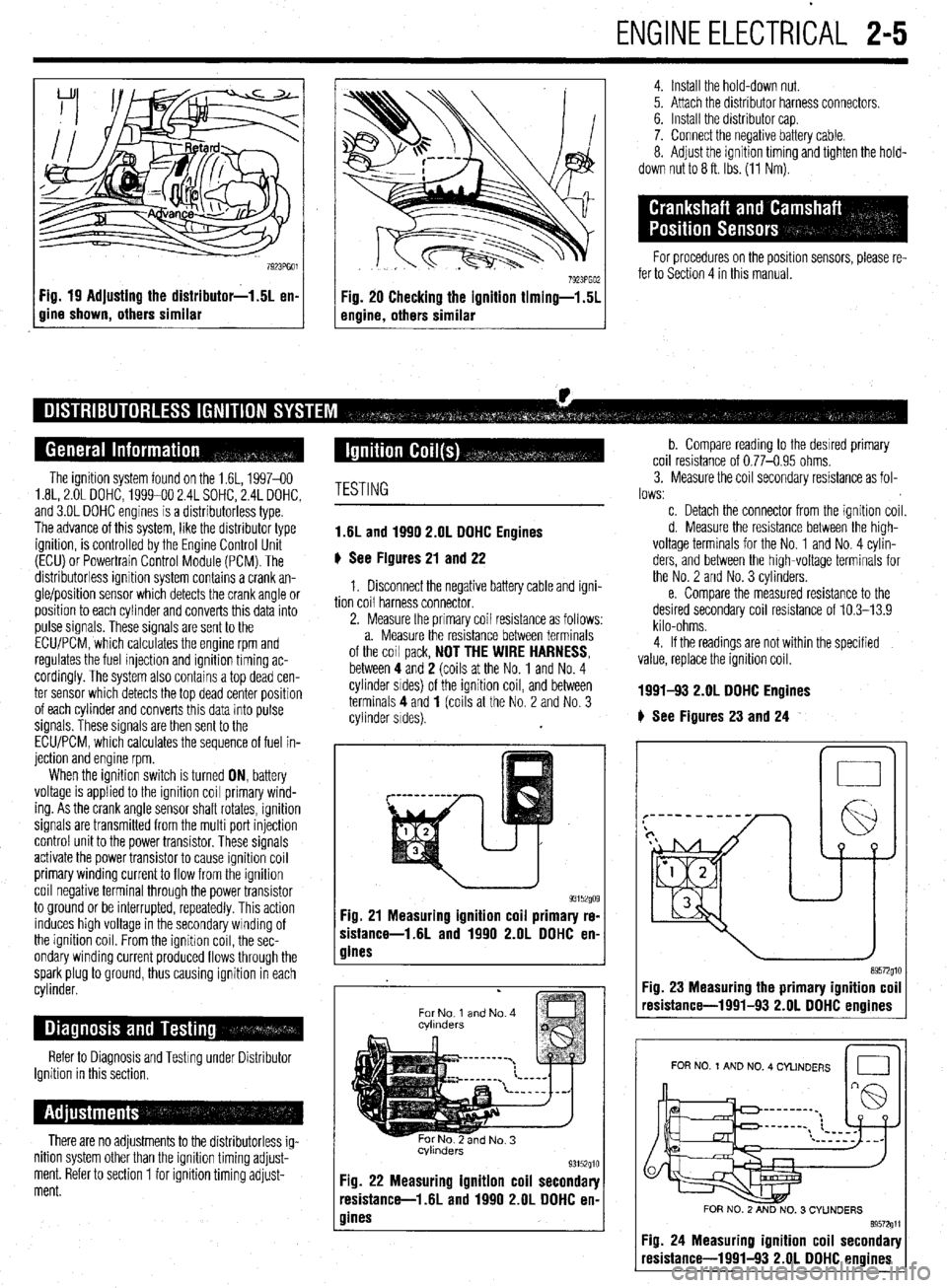

TESTING

1.6L and 1990 2.OL DOHC Engines

6 See Figures 21 and 22

1. Disconnect the negative battery cable and igni-

tion coil harness connector.

2. Measure the primary coil resistance as follows:

a. Measure the resistance between terminals

of the coil pack,

NOT THE WIRE HARNESS, between 4 and 2 (coils at the No. 1 and No. 4

cylinder srdes) of the ignition coil, and between

terminals 4 and

1 (coils at the No. 2 and No. 3

cylinder sides).

93152go9 Fig. 21 Measuring ignition coil primary re-

sistance-1.6L and 1990 2.OL DDHC en-

gines

.

For No 1 and No. 4

cvlmders

Fig. 22 Measuring ignition coil secondary

resistance-l .6L and 1990 2.OL DOHC en-

gines

b. Compare reading to the desrred primary

coil resistance of 0.77-0.95 ohms.

3. Measure the coil secondary resistance as fol-

lows:

c. Detach the connector from the ignition coil.

d. Measure the resistance between the high-

voltage terminals for the No. 1 and No. 4 cylin-

ders, and between the high-voltage terminals for

the No. 2 and No. 3 cylinders.

e. Compare the measured resistance to the

desired secondary coil resistance of 10.3-13.9

kilo-ohms.

4. If the readings are not within the specified

value, replace the ignition coil.

1991-!I3 2.OL DDHC Engines

# See Figures 23 and 24

n 0

Fig. 23 Measuring the primary ignition coil

resistance-1991-93 2.OL DOHC enoines

I I

FOR NO 1 AND NO. 4 CYLINDERS

Id

FOR NO. 2 AND NO. 3 CYUNDERS

89572611

Fig. 24 Measuring ignition coil secondary

resistance-1991-93 2.OL DOHC engines

Page 87 of 408

3-26 ENGINEANDENGINEOVERHAUL

18. Remove the self-locking nuts and the small

retaining bolt holding the exhaust pipe to the bottom

of the exhaust manifold. Separate the pipe from the

manifold and remove the gasket.

19. Remove the bolts holding the support brace

to the bottom of the intake manifold.

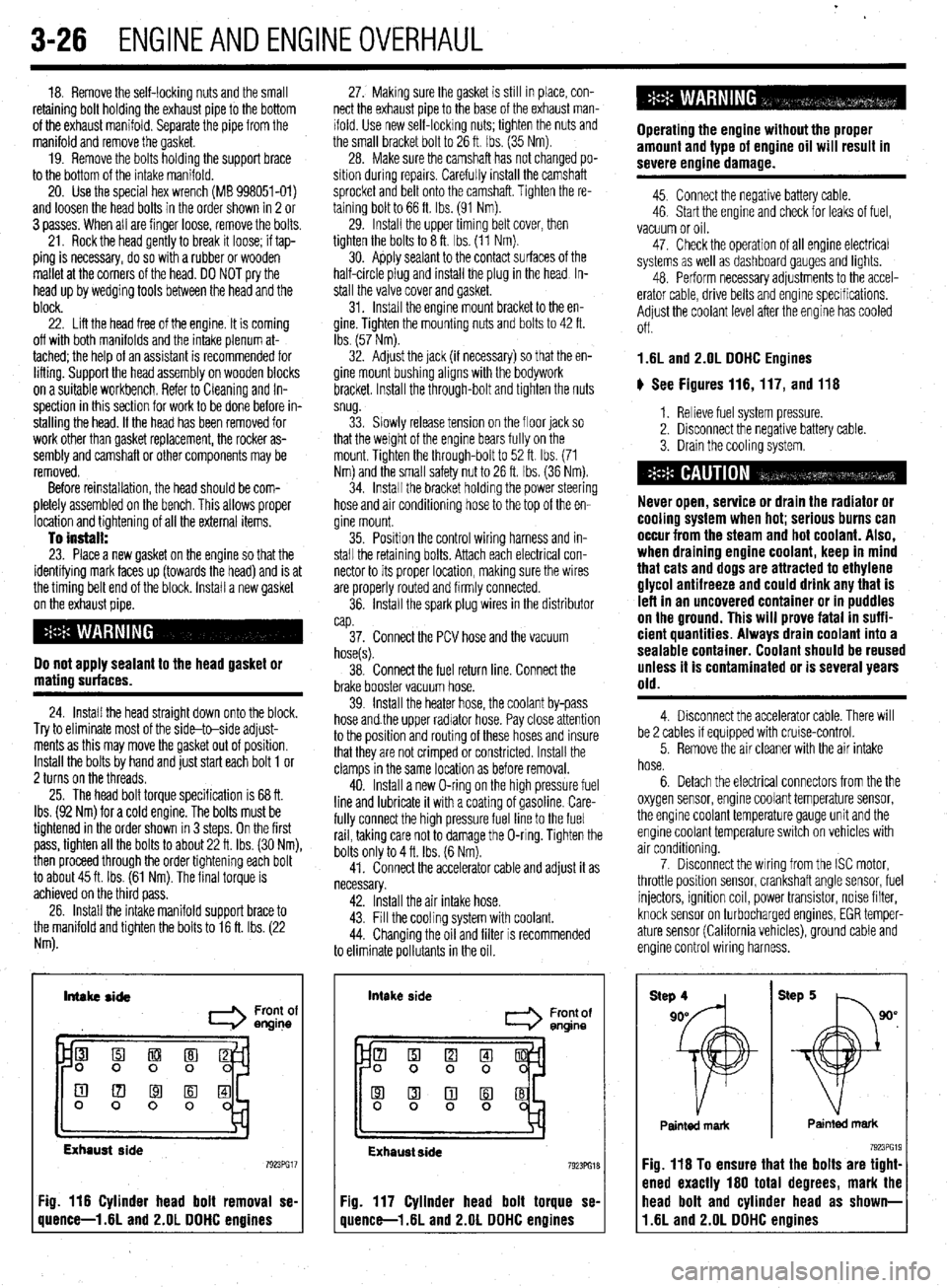

20. Use the special hex wrench (MB 998051-01)

and loosen the head bolts in the order shown in 2 or

3 passes. When all are finger loose, remove the bolts.

21. Rock the head gently to break it loose; if tap-

ping is necessary, do so with a rubber or wooden

mallet at the corners of the head. DO NOT pry the

head up by wedging tools between the head and the

block.

22. Lift the head free of the engine. It is coming

off with both manifolds and the intake plenum at-

tached; the help of an assistant is recommended for

lifting. Support the head assembly on wooden blocks

on a suitable workbench. Refer to Cleaning and In-

spection in this section for work to be done before in-

stalling the head. If the head has been removed for

work other than gasket replacement, the rocker as-

sembly and camshaft or other components may be

removed.

Before reinstallation, the head should be com-

pletely assembled on the bench. This allows proper

location and tightening of all the external items.

To install: 23. Place a new gasket on the engine so that the

identifying mark faces up (towards the head) and is at

the timing belt end of the block. Install a new gasket

on the exhaust pipe.

Do not apply sealant to the head gasket or

mating surfaces.

24. Install the head straight down onto the block.

Try to eliminate most of the side-to-side adjust-

ments as this may move the gasket out of position.

Install the bolts by hand and just start each bolt 1 or

2 turns on the threads.

25. The head bolt torque specification is 68 ft.

Ibs. (92 Nm) for a cold engine. The bolts must be

tightened in the order shown in 3 steps. On the first

pass, tighten all the bolts to about 22 ft. Ibs. (30 Nm),

then proceed through the order tightening each bolt

to about 45 ft. Ibs. (61 Nm). The final torque is

achieved on the third pass.

26. Install the intake manifold support brace to

the manifold and tighten the bolts to 16 ft. Ibs. (22

Nm). 27. Making sure the gasket is still in place, con-

nect the exhaust pipe to the base of the exhaust man-

ifold. Use new self-locking nuts; tighten the nuts and

the small bracket bolt to 26 ft. Ibs. (35 Nm).

28. Make sure the camshaft has not changed po-

sition during repalrs. Carefully install the camshaft

sprocket and belt onto the camshaft. Tighten the re-

taining bolt to 66 ft. Ibs. (91 Nm).

29. Install the upper timing belt cover, then

tighten the bolts to 8 ft. Ibs. (11 Nm).

30. Apply sealant to the contact surfaces of the

half-circle plug and install the plug in the head In-

stall the valve cover and gasket.

31. Install the engine mount bracket to the en-

gine. Tighten the mounting nuts and bolts to 42 ft.

Ibs. (57 Nm).

32. Adjust the jack (if necessary) so that the en-

gine mount bushing aligns with the bodywork

bracket. Install the through-bolt and tighten the nuts

snug.

33. Slowly release tension on the floor jack so

that the weight of the engine bears fully on the

mount. Tighten the through-bolt to 52 ft. Ibs. (71

Nm) and the small safety nut to 26 ft. tbs. (36 Nm).

34. Install the bracket holding the power steering

hose and air conditioning hose to the top of the en-

gine mount.

35. Position the control wiring harness and in-

stall the retaining bolts. Attach each electrical con-

nector to its proper location, making sure the wires

are properly routed and firmly connected.

36. Install the spark plug wires in the distributor

cap.

37. Connect the PCV hose and the vacuum

hose(s).

38. Connect the fuel return line. Connect the

brake booster vacuum hose.

39. Install the heater hose, the coolant by-pass

hose and.the upper radiator hose. Pay close attention

to the position and routing of these hoses and insure

that they are not crimped or constricted. Install the

clamps in the same location as before removal.

40. Install a new O-ring on the high pressure fuel

line and lubricate it with a coating of gasoline. Care-

fully connect the high pressure fuel line to the fuel

rail, taking care not to damage the O-ring. Tighten the

bolts only to 4 ft. Ibs. (6 Nm).

41. Connect the accelerator cable and adjust it as

necessary.

42. Install the air intake hose.

43. Fill the cooling system with coolant.

44. Changing the oil and filter is recommended

to eliminate pollutants in the oil.

Intake side

I Front of

engine

Exhaust side

Fig. 116 Cylinder head bolt removal se-

quence-l .6L and 2.OL DDHC engines intake

side

Front of

entine

Exhaust side 7923PG18

Fig. 117 Cylinder head bolt torque se-

quence-l .6L and 2.OL DDHC engines Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

45. Connect the negative battery cable.

46. Start the engine and check for leaks of fuel,

vacuum or oil.

47. Check the operation of all engine electrical

systems as well as dashboard gauges and lights.

48. Perform necessary adjustments to the accel-

erator cable, drive belts and engine specifications.

Adjust the coolant level after the engine has cooled

Off.

1.6L and 2.OL DDHC Engines

ti See Figures 116,117, and 116

1. Relieve fuel system pressure.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Disconnect the accelerator cable. There will

be 2 cables if equipped with cruise-control.

5. Remove the air cleaner with the air intake

hose.

6. Detach the electrical connectors from the the

oxygen sensor, engine coolant temperature sensor,

the engine coolant temperature gauge unit and the

engine coolant temperature switch on vehicles with

air conditioning.

7. Disconnect the wiring from the ISC motor,

throttle position sensor, crankshaft angle sensor, fuel

injectors, ignition coil, power transistor, noise filter,

knock sensor on turbocharged engines, EGR temper-

ature sensor (California vehicles), ground cable and

engine control wiring harness.

Painted mark Painted mark

Fig. 116 To ensure that the bolts are tight-

ened exactly 160 total degrees, mark the

11.6L and 2.OL DDHC engines head bolt and cylinder head as shown-

Page 117 of 408

3-56 ENGINEANDENGINEOVERHAUL

,

F C

F

t

. Fig.

220 Example of a badly deteriorated ex- 1 Fig. 221 inspect flanges for gaskets that

haust pipe have deteriorated and need replacement Fig. 222 Some systems, like this one, use

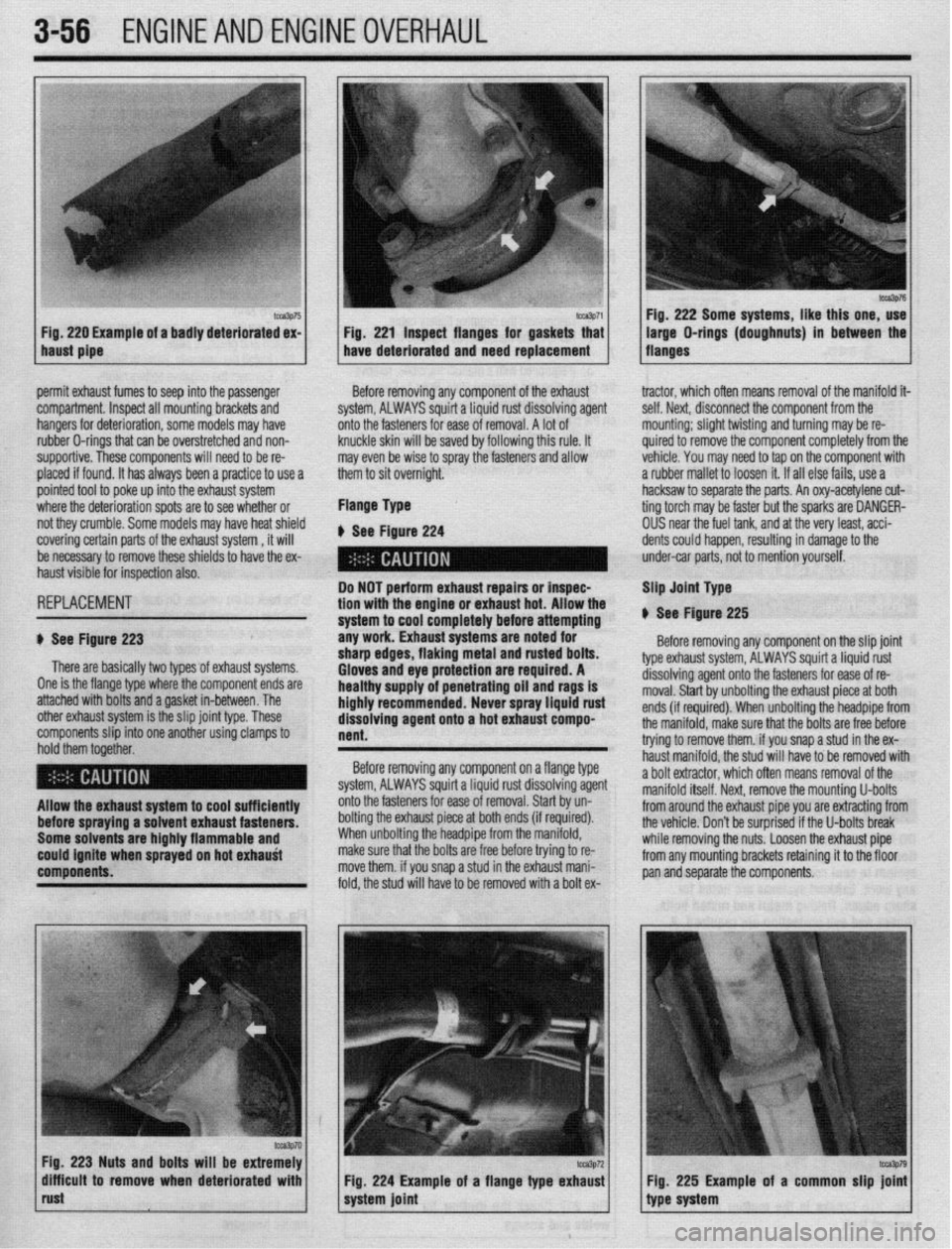

)ermit exhaust fumes to seep into the passenger

:ompartment. Inspect all mounting brackets and

bangers for deterioration, some models may have

ubber O-rings that can be overstretched and non-

supportive. These components will need to be re-

Ilaced if found. It has always been a practice to use a

)ointed tool to poke up into the exhaist system

vhere the deterioration spots are to see whether or

d they crumble. Some models may have heat shield

:overing certain parts of the exhaust system , it will

te necessary to remove these shields to have the ex-

laust visible for inspection also. Before removing any component of the exhaust

system, ALWAYS squirt a Liquid rust dissolving agent

onto the fasteners for ease of removal. A lot of

knuckle skin will be saved by following this rule. It

may even be wise to spray the fasteners and allow

them to sit overniqht.

Flange Type

b See Figure 224 tractor, which oflen means removal of the manifold it

self. Next, disconnect the component from the

mounting; slight twisting and turning may be re-

quired to remove the component completely from thr

vehicle. You may need to tap on the component with

a rubber mallet to loosen it. If all else fails, use a

hacksaw to sep; arate the parts. An oxy-acetylene cut-

ting torch may I 3e faster but the sparks are OANGER-

OUS near the fuel tank, ant 1 at the very least, acci-

dents could happen, result ing in damage to the

under-car parts, not to mei ition yourself.

3EPLACEMEMT

1 See Figure 223

There are basically two types of exhaust systems.

)ne is the flange type where the component ends are

attached with bolts and a gasket in-between. The

)ther exhaust system is the slip joint type. These

:omponents slip into one another using clamps to

iold them together. Do NOT perform exhaust repairs or inspec-

tion with the engine or exhaust hot. Allow the

system to cool completely before attempting

any work. Exhaust systems are noted for

sharp edges, flaking metal and rusted bolts.

Gloves and eye protection are required. A

healthy supply of penetrating oil and

rags is

highly recommended. Never spray liquid rust

dissolving agent onto a hot exhaust compo-

nent. Slip Joint Type

V See Figure 225

Before removing any component on the slip joint

type exhaust system, ALWAYS squirt a liquid rust

dissolving agent onto the fasteners for ease of re-

moval. Start by unbolting the exhaust piece at both

ends (if required). When unbolting the headpipe fron

the manifold, make sure that the bolts are free before

trying to remove them. if you snap a stud in the ex-

haust manifold. the stud will have to be removed wit1

Before removing any component on a flange type

system, ALWAYS squirt a liquid rust dissolving agent a bolt extractor, which often means removal of the

._ manifold itself. Next. remove the mountina U-bolts

liiow the exhaust system to cool sufficiently

Iefore spraying a solvent exhaust fasteners.

Some solvents are highly flammable and

:ould ignite when sprayed on hot exhauti

:omponents. onto the fasteners for ease of removal. Start by un-

bolting the exhaust piece at both ends (if required).

When unbolting the headpipe from the manifold,

make sure that the bolts are free before trying to re-

move them. if you snap a stud in the exhaust mani-

fold, the stud will have to be removed with a bolt ex-

ka3p70 Fig. 223 Nuts and bolts will be extremely

difflcuit to remove when deteriorated with

rust Fig. 224 Example of a flange type exhaust

system joint from around the exhaust pipe you are ext&ting from

the vehicle. Don’t be surprised if the U-bolts break

while removing the nuts. Loosen the exhaust pipe

from any mounting brackets retaining it to the floor

pan and separate the components.

Fig. 225 Example of a common slip joini

type system