catalytic converter MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 93 of 408

.

3-32 ENGINEANDENGINEOVERHAUL

9. Inspect the oil pan for damage and cracks.

Replace if faulty, While the pan is removed, inspect

the oil screen for clogging, damage and cracks, Re-

place if faulty.

To install: 10. Using a wire brush or other tool, scrape clean

all gasket surfaces of the cylinder block and the oil

pan so that all loose material is removed. Clean seal-

ing surfaces of all dirt and oil.

11, Apply sealant around the gasket surfaces of

the oil pan in such a manner that all bolt holes are

circled and there is a continuous bead of sealer

around the entire perimeter of the oil pan.

*The continuous bead of sealer should be

applied in a bead approximately 0.16 in.

(4mm) in diameter.

12. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 4-6 ft. Ibs. (68 Nm).

13. Install the oil return pipe using a new gasket,

if removed. Tighten retainers to 5-7 ft. Ibs. (7-10

Nm).

14. Install the left member and tighten the forward

retainer bolts to 72 ft. Ibs. (100 Nm). Tighten the

rearward left member bolts to 58 ft. Ibs. (80 Nm).

15. Install the transfer assembly and right drive-

shaft.

16. Connect the exhaust pipe from the engine

manifold with new gasket in place. Tighten the ex-

haust pipe to manifold flange nuts to 29 ft. Ibs. (40

Nm).

17. Install the oil drain plug and tighten to 33 ft.

Ibs.

18. Lower the vehicle and fill the crankcase to the

proper level with clean engine oil.

Operating the engine without the proper

amount and type of engine oil will result in

severe enaine damage.

19. Connect the negative battery cable. Start the

engine and check for leaks.

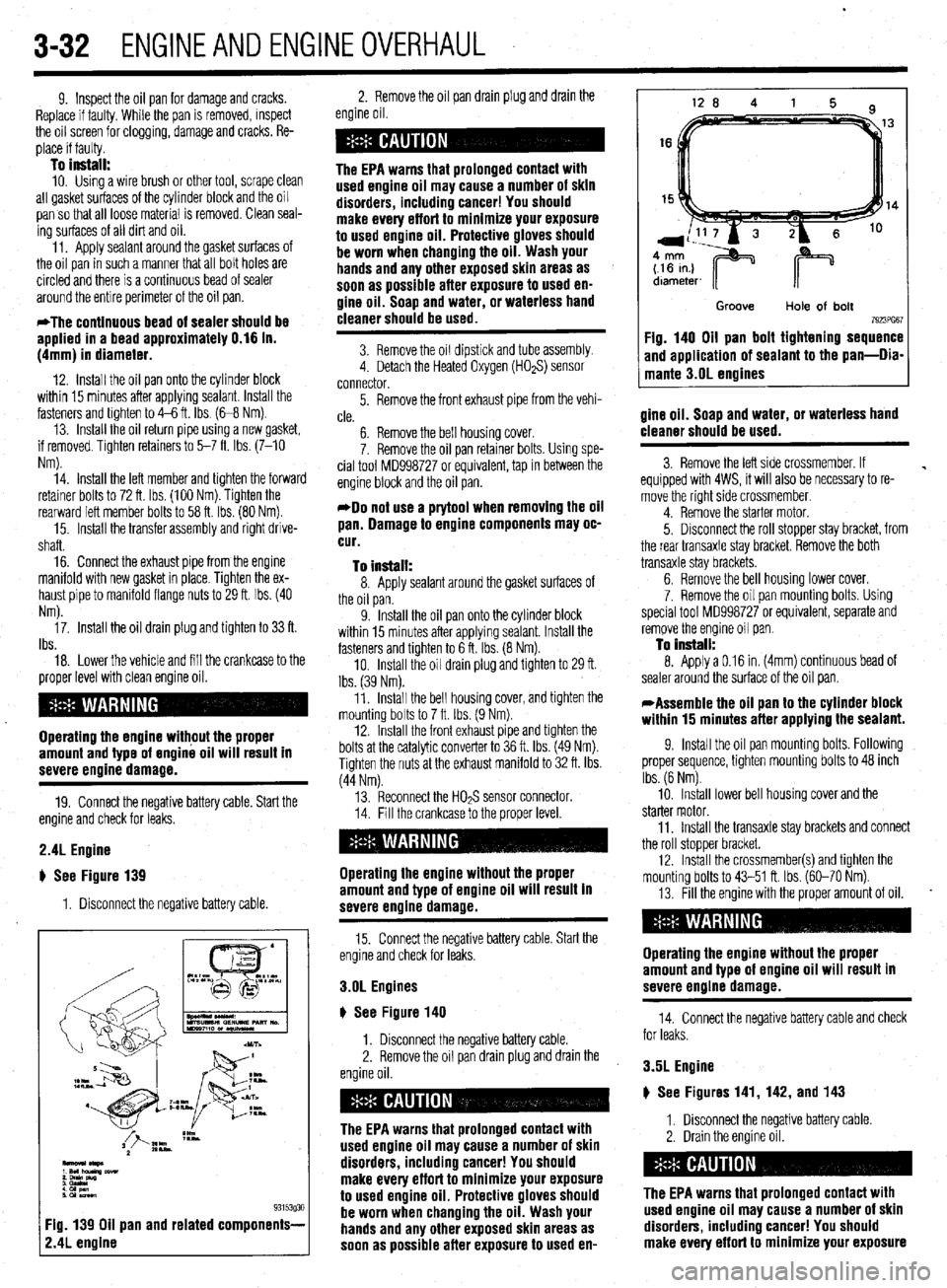

2.4L Engine

) See Figure 139

1, Disconnect the negative battery cable. -

,(L.. K%

2 mM_

-Ip

t 8*t.almcwr

:y&pn

::Elm

93153g30 Fig. 139 Oil pan and related components-

2.4L engine

2. Remove the oil pan drain plug and drain the

engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the oil dipstick and tube assembly.

4. Detach the Heated Oxygen (HOaS) sensor

connector.

5. Remove the front exhaust pipe from the vehi-

cle.

6. Remove the bell housing cover.

7. Remove the oil pan retainer bolts. Using spe-

cial tool MD998727 or equivalent, tap in between the

engine block and the oil pan.

*Do not use a prytool when removing the oil

pan. Damage to engine components may oc-

cur.

To install:

8. Apply sealant around the gasket surfaces of

the oil pan.

9. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 6 ft. Ibs. (8 Nm).

10. Install the oil drain plug and tighten to 29 ft.

Ibs. (39 Nm).

11. Install the bell housing cover, and tighten the

mounting bolts to 7 ft. Ibs. (9 Nm).

12. Install the front exhaust pipe and tighten the

bolts at the catalytic converter to 36 ft. Ibs. (49 Nm).

Tighten the nuts at the exhaust manifold to 32 ft. Ibs.

(44 Nm).

13. Reconnect the HOPS sensor connector.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

15. Connect the negative battery cable. Start the

engine and check for leaks.

3.OL Engines

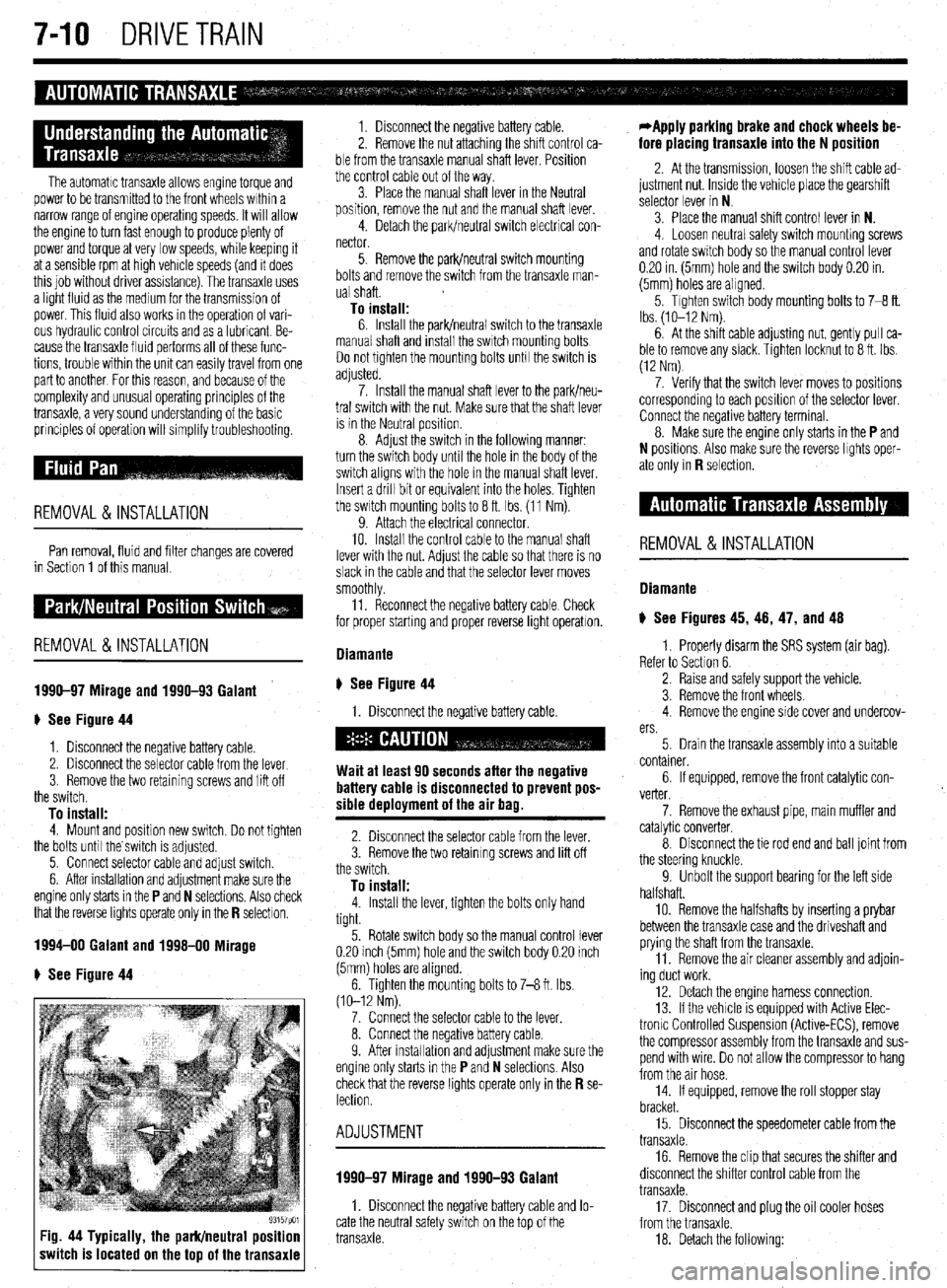

u See Figure 140

1. Disconnect the negative battery cable.

2. Remove the oil pan drain plug and drain the

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

Groove

Hole of bolt 7923PG67 Fig. 140 Oil pan bolt tightening sequence

and application of sealant to the pan-Dia-

mante 3.OL engines

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the left side crossmember. If

equipped with 4WS, it will also be necessary to re-

move the right side crossmember.

4. Remove the starter motor.

5. Disconnect the roll stopper stay bracket, from

the rear transaxle stay bracket. Remove the both

transaxle stay brackets.

6. Remove the bell housing lower cover.

7. Remove the oil pan mounting bolts. Using

special tool MD998727 or equivalent, separate and

remove the engine oil pan.

To install: 8. Apply a 0.16 in. (4mm) continuous bead of

sealer around the surface of the oil pan.

*Assemble the oil pan to the cylinder block

within 15 minutes after applying the sealant.

9. Install the oil pan mounting bolts. Following

proper sequence, tighten mounting bolts to 48 inch

Ibs. (6 Nm).

10. Install lower bell housing cover and the

starter motor.

11, Install the transaxle stay brackets and connect

the roll stopper bracket.

12. Install the crossmember and tighten the

mounting bolts to 43-51 ft. Ibs. (60-70 Nm).

13. Fill the engine with the proper amount of oil.

.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

14. Connect the negative battery cable and check

for leaks.

3.5L Engine

p See Figures 141, 142, and 143

1, Disconnect the negative battery cable.

2. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, includina cancer! You should

make eve’ry effort to minimize your exposure

Page 289 of 408

7-10 DRIVETRAIN

The automatic transaxle allows engine torque and

power to be transmitted to the front wheels within a

narrow range of engine operating speeds. It will allow

the engine to turn fast enough to produce plenty of

power and torque at very low speeds, while keeping it

at a sensible rpm at high vehicle speeds (and it does

this job without driver assistance). The transaxle uses

a light fluid as the medium for the transmission of

power. This fluid also works in ths operation of vari-

ous hydraulic control circuits and as a lubricant. Be-

cause the transaxle fluid performs all of these func-

tions, trouble within the unit can easily travel from one

part to another For this reason, and because of the

complexity and unusual operating principles of the

transaxle, a very sound understanding of the basic

principles of operation will simplify troubleshooting

REMOVAL &INSTALLATION

Pan removal, fluid and filter

in Section 1 of this manual changes are covered

REMOVAL &INSTALLATION

1990-97 Mirage and 1990-93 Galant

# See Figure 44

1. Disconnect the negative battery cable.

2. Disconnect the selector cable from the lever

3. Remove the two retaining screws and lift off

the switch.

To install: 4. Mount and position new switch. Do not tighten

the bolts until the switch is adjusted.

5. Connect selector cable and adjust switch.

6. After installation and adjustment make sure the

engine only starts in the

P and N selections. Also check

that the reverse lights operate only in the R selectlon.

1994-00 Galant and 1998-00 Mirage

e See Figure 44

93157pm Fig. 44 Typically, the park/neutral position

switch is located on the top of the transaxle

1. Disconnect the negative battery cable.

2. Remove the nut attaching the shift control ca-

ble from the transaxle manual shaft lever. Position

the control cable out of the way.

3. Place the manual shaft lever in the Neutral

position, remove the nut and the manual shaft lever.

4. Detach the park/neutral switch electrical con-

nector.

5. Remove the park/neutral switch mounting

bolts and remove the switch from the transaxle man-

ual shaft.

To install: 6. Install the park/neutral switch to the transaxle

manual shaft and install the switch mounting bolts

Do not tighten the mounting bolts unh the switch is

adjusted.

7. Install the manual shaft lever to the park/neu-

tral switch with the nut. Make sure that the shaft lever

is in the Neutral position.

8. Adjust the switch in the following manner:

turn the switch body until the hole in the body of the

switch aligns with the hole in the manual shaft lever.

Insert a drill bit or equivalent into the holes. Tighten

the switch mounting bolts to 8 ft. Ibs. (11 Nm).

9. Attach the electrical connector.

10. Install the control cable to the manual shaft

lever with the nut. Adjust the cable so that there is no

slack in the cable and that the selector lever moves

smoothly

11. Reconnect the negative battery cable Check

for proper starting and proper reverse light operatron.

Diamante

ti See Figure 44

1. Disconnect the negative battery cable.

Wait at least 90 seconds after the negative

battery cable is disconnected to prevent pos-

sible deployment of the air bag.

2. Disconnect the selector cable from the lever.

3. Remove the two retaining screws and lift off

the switch.

To install: 4. Install the lever, tighten the bolts only hand

tight.

5. Rotate switch body so the manual control lever

0.20 inch (5mm) hole and the switch body 0.20 inch

(5mm) holes are aligned.

6. Tighten the mounting bolts to 7-8 ft. Ibs.

(10-12 Nm).

7. Connect the selector cable to the lever.

8. Connect the negative battery cable.

9. After installahon and adjustment make sure the

engine only starts in the

P and N selections. Also

check that the reverse lights operate only in the R se- lection.

ADJUSTMENT

1990-97 Mirage and 1990-93 Galant

1. Disconnect the negative battery cable and lo-

cate the neutral safety switch on the top of the

transaxle.

*Apply parking brake and chock wheels be-

fore placing transaxle into the N position

2. At the transmission, loosen the shift cable ad-

justment nut. Inside the vehicle place the gearshift

selector lever in N

3. Place the manual shift control lever in N.

4. Loosen neutral safety switch mounhng screws

and rotate switch body so the manual control lever

0.20 in. (5mm) hole and the switch body 0.20 in.

(5mm) holes are aligned.

5. Tighten switch body mounting bolts to 7-8 ft.

Ibs. (lo-12 Nm).

6. At the shift cable adjusting nut, gently pull ca-

ble to remove any slack. Tighten locknut to 8 ft. Ibs.

(12 Nm)

7. Verify that the switch lever moves to positions

corresponding to each position of the selector lever.

Connect the negative battery terminal.

8. Make sure the engine only starts in the

P and

N positions. Also make sure the reverse lights oper-

ate only in

R selection.

REMOVAL&INSTALLATION

Diamante

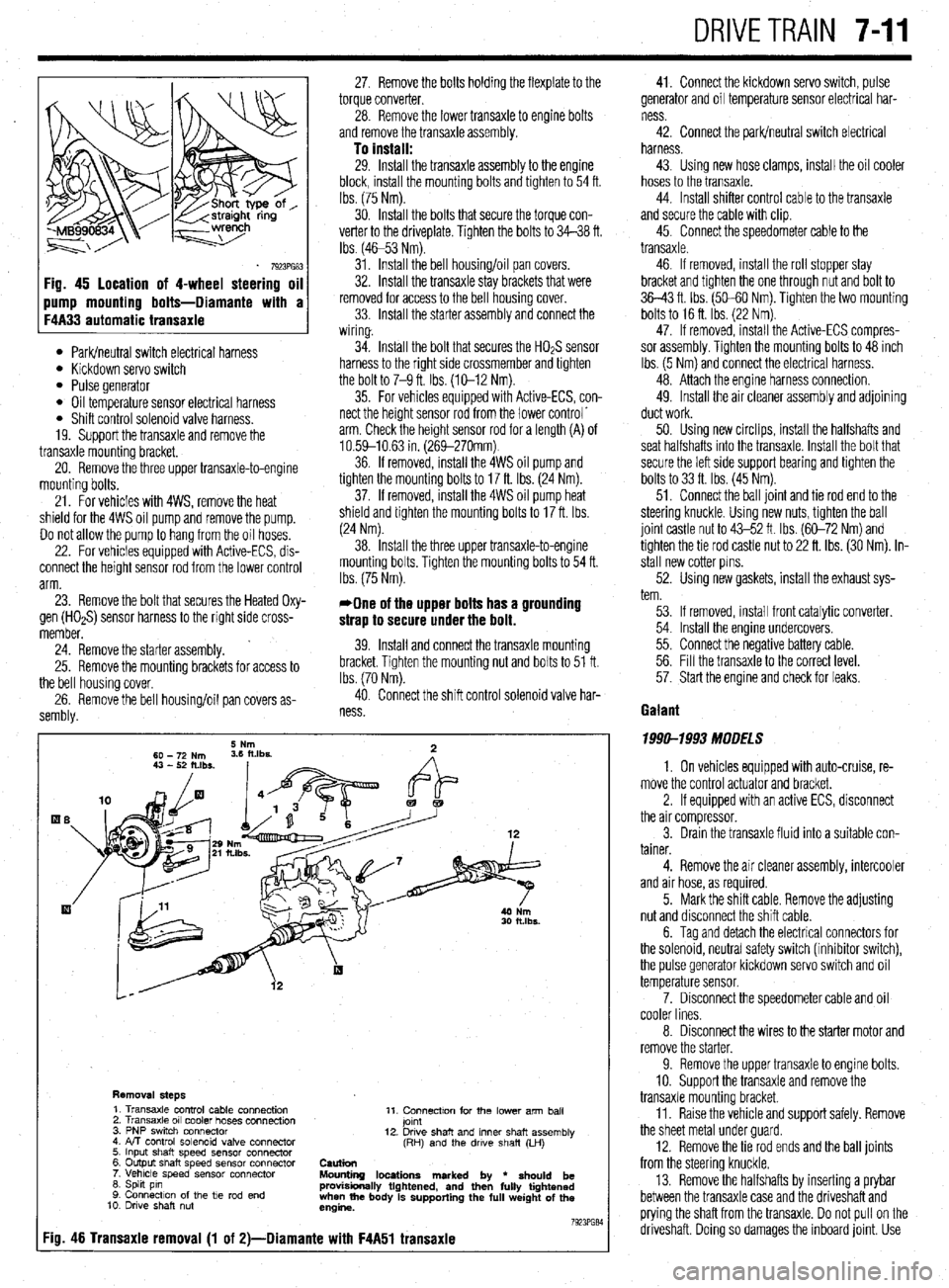

) See Figures 45, 46, 47, and 48

1. Properly disarm the SRS system (air bag).

Refer to Section 6.

2. Raise and safely support the vehicle.

3. Remove the front wheels.

4. Remove the engine side cover and undercov-

ers.

5. Drain the transaxle assembly into a suitable

container.

6. If equipped, remove the front catalytic con-

verter.

7. Remove the exhaust pipe, main muffler and

catalytic converter.

8. Disconnect the tie rod end and ball joint from

the steering knuckle.

9. Unbolt the support bearing for the left side

halfshaft.

10. Remove the halfshafts by inserting a prybar

between the transaxle case and the driveshaft and

prying the shaft from the transaxle.

11. Remove the air cleaner assembly and adjoin-

ing duct work.

12. Detach the engine harness connection.

13. If the vehicle is equipped with Active Elec-

tronlc Controlled Suspension (Active-ECS), remove

the compressor assembly from the transaxle and sus-

pend with wire. Do not allow the compressor to hang

from the air hose.

14. If equipped, remove the roll stopper stay

bracket.

15. Disconnect the speedometer cable from the

transaxle.

16. Remove the clip that secures the shifter and

disconnect the shifter control cable from the

transaxle.

17. Disconnect and plug the oil cooler hoses

from the transaxle.

18. Detach the following:

Page 290 of 408

DRIVETRAIN 7-11

Fig. 45 location of 4-wheel steering oil

l Park/neutral switch electrical harness l Kickdown servo switch l Pulse generator l Oil temperature sensor electrical harness l Shift control solenoid valve harness.

19. Support the transaxle and remove the

transaxle mounting bracket.

20. Remove the three upper transaxle-to-engine

mounting bolts.

21. For vehicles with 4WS, remove the heat

shield for the 4WS oil pump and remove the pump.

Do not allow the pump to hang from the oil hoses.

22. For vehicles equipped with Active-ECS, dis-

connect the height sensor rod from the lower control

arm.

23. Remove the bolt that secures the Heated Oxy-

gen (HOaS) sensor harness to the right side cross-

member.

’ 24. Remove the starter assembly.

25. Remove the mounting brackets for access to

the bell housing cover,

26. Remove the bell housing/oil pan covers as-

sembly. 27. Remove the bolts holding the flexplate to the

torque converter.

28. Remove the lower transaxle to engine bolts

and remove the transaxle assembly.

To install: 29. Install the transaxle assembly to the engine

block, install the mounting bolts and tighten to 54 ft.

tbs. (75 Nm).

30. Install the bolts that secure the torque con-

verter to the driveplate. Tighten the bolts to 34-38 ft.

Ibs (4653 Nm).

31. Install the bell housing/oil pan covers.

32. Install the transaxle stay brackets that were

removed for access to the bell housing cover.

33. Install the starter assembly and connect the

wiring.

34. Install the bolt that secures the HO& sensor

harness to the right side crossmember and tighten

the bolt to 7-9 ft. Ibs. (X-12 Nm).

35. For vehicles equipped with Active-ECS, con-

nect the height sensor rod from the lower control’

arm. Check the height sensor rod for a length (A) of

10.59-10.63 in. (269-270mm)

36. If removed, install the 4WS oil pump and

tighten the mounting bolts to 17 ft. Ibs. (24 Nm).

37. If removed, install the 4WS oil pump heat

shield and tighten the mounting bolts to 17 ft. Ibs.

(24 Nm).

38. Install the three upper transaxle-to-engine

mounting bolts. Tighten the mounting bolts to 54 ft.

Ibs. (75 Nm).

*One of the upper bolts has a grounding

strap to secure under the bolt.

39. Install and connect the transaxle mounting

bracket. Tighten the mounting nut and bolts to 51 ft.

Ibs. (70 Nm).

40. Connect the shift control solenoid valve har-

ness

Removal steps 1. Transaxle control cable connection

2. Transaxle 011 cooler hoses connection

3. PNP swrtch connector

4. FvT control solenoid valve connector

5. Input shaft speed sensor connector

6. Output shaft speed sensor connector

7. Vehicle speed sensor connector

6. Spht pin

9. Connection of the tie rod end

10. Drwe shaft nut 11. Connectton for the lower arm ball

jomt

12. Drwe shaft and inner shaft assembly

(RH) and the drwe shaft (LH)

Caution

Mounting locations marked by

l should be

provisionally tightened, and then fully tightened

when the body is supporting the full weight of the

engine.

7923PG84

:io. 46 Transaxie removal (1 of 2)-Diamante with F4A51 transaxie

41. Connect the kickdown servo switch, pulse

generator and oil temperature sensor electrical har-

ness

42. Connect the park/neutral switch electrical

harness.

43. Using new hose clamps, install the oil cooler

hoses to the transaxle.

44. Install shifter control cable to the transaxle

and secure the cable with clip.

45. Connect the speedometer cable to the

transaxle.

46. If removed, install the roll stopper stay

bracket and tighten the one through nut and bolt to

36-43 ft. Ibs. (50-60 Nm). Tighten the two mounting

bolts to 16 ft. Ibs. (22 Nm).

47. If removed, install the Active-ECS compres-

sor assembly. Tighten the mounting bolts to 48 inch

Ibs. (5 Nm) and connect the electrical harness.

48. Attach the engine harness connection.

49. Install the air cleaner assembly and adjoining

duct work.

50. Using new circlips, install the halfshafts and

seat halfshafts into the transaxle. Install the bolt that

secure the left side support bearing and tighten the

bolts to 33 ft. Ibs. (45 Nm).

51. Connect the ball joint and tie rod end to the

steering knuckle. Using new nuts, tighten the ball

joint castle nut to 43-52 ft. Ibs. (60-72 Nm) and

tighten the tie rod castle nut to 22 ft. ibs. (30 Nm). in-

stall new cotter pins.

52. Using new gaskets, install the exhaust sys-

tem.

53. If removed, install front catalytic converter.

54. Install the engine undercovers.

55. Connect the negative battery cable.

56. Fill the transaxle to the correct level.

57. Start the engine and check for leaks.

Gaiant

1999-1993 MODELS

1. On vehicles equipped with auto-cruise, re-

move the control actuator and bracket.

2. If equipped with an active ECS, disconnect

the air compressor.

3. Drain the transaxle fluid into a suitable con-

tainer.

4. Remove the air cleaner assembly, intercooler

and air hose, as required.

5. Mark the shift cable. Remove the adjusting

nut and disconnect the shift cable.

6. Tag and detach the electrical connectors for

the solenoid, neutral safety switch (inhibitor switch),

the pulse generator kickdown servo switch and oil

temperature sensor.

7. Disconnect the speedometer cable and oil

cooler lines.

8. Disconnect the wires to the starter motor and

remove the starter.

9. Remove the upper transaxle to engine bolts.

10. Support the transaxle and remove the

transaxle mounting bracket.

11. Raise the vehicle and support safely. Remove

the sheet metal under guard

12. Remove the tie rod ends and the bail joints

from the steering knuckle.

13. Remove the halfshafts by inserting a prybar

between the transaxle case and the driveshaft and

prying the shaft from the transaxle. Do not pull on the

driveshaft. Doing so damages the inboard joint. Use

Page 389 of 408

TROUBLESHOOiNG 11-7

4. Starter motor spins, but does not engage

a. Check the starter motor for a seized or binding pinion gear.

b. Remove the flywheel inspection plate and check for a damaged ring gear.

Gasoline Engines

1. Engine runs poor/y, hesiiates

a. Check the engine ignition system operation and adjust if possible, or replace defective

parts.

b. Check for restricted fuel injectors and replace as necessary.

c. Check the fuel pump output and delivery. Inspect fuel lines for restrictions. If the fuel

pump pressure is below specification, replace the fuel pump.

d. Check the operation of the engine management system and repair as necessary.

2. Enfline lacks power

a. Check the engine’s tune-up status. Note the tune-up specifications and check for items

such as severely worn spark plugs; adjust or replace as needed. On vehicles with

manually adjusted valve clearances, check for tight valves and adjust to specification.

b. Check the air filter and air intake system. Replace the air filter if it is dirty or contami-

nated. Check the fresh air intake system for restrictions or blockage.

c. Check the operation of the engine fuel and ignition management systems. Check the

sensor operation and wiring. Check for low fuel pump pressure and repair or replace

components as necessary.

d. Check the throttle linkage adjustments. Check to make sure the linkage is fully open-

ing the throttle. Replace any worn or defective bushings or linkages.

e. Check for a restricted exhaust system. Check for bent or crimped exhaust pipes, or in-

ternally restricted mufflers or catalytic converters. Compare inlet and outlet tempera-

tures for the converter or muffler. If the inlet is hot, but outlet cold, the component is

restricted.

f. Check for a loose or defective knock sensor. A loose, improperly torqued or defective

knock sensor will decrease spark advance and reduce power. Replace defective knock

sensors and install using the recommended torque specification.

g. Check for engine mechanical conditions such as low compression, worn piston rings,

worn valves, worn camshafts and related parts. An engine which has severe mechani-

cal wear, or has suffered internal mechanical damage must be rebuilt or replaced to re-

store lost power.

h. Check the engine oil level for being overfilled. Adjust the engine’s oil level, or change

the engine oil and filter, and top off to the correct level.

i. Check for an intake manifold or vacuum hose leak. Replace leaking gaskets or worn

vacuum hoses.

j. Check for dragging brakes and replace or repair as necessary.

k. Check tire air pressure and tire wear. Adjust the pressure to the recommended set-

tings. Check the tire wear for possible alignment problems causing increased rolling

resistance, decreased acceleration and increased fuel usage.

I. Check the octane rating of the fuel used during refilling, and use a higher octane rated

fuel.

3. Poor fuel economy

a. Inspect the air filter and check for any air restrictions going into the air filter housing.

Replace the air filter if it is dirty or contaminated.

b. Check the engine for tune-up and related adjustments. Replace worn ignition parts,

check the engine ignition timing and fuel mixture, and set to specifications if possible.

c. Check the tire size, tire wear, alignment and tire pressure. Large tires create more

rolling resistance, smaller tires require more engine speed to maintain a vehicle’s road

speed. Excessive tire wear can be caused by incorrect tire pressure, incorrect wheel

alignment or a suspension problem. All of these conditions create increased rolling

resistance, causing the engine to work harder to accelerate and maintain a vehicle’s

speed.

d. Inspect the brakes for binding or excessive drag. A sticking brake caliper, overly ad-

justed brake shoe, broken brake shoe return spring, or binding parking brake cable or

linkage can create a significant drag, brake wear and loss of fuel economy. Check the

brake system operation and repair as necessary.

4. Engine runs on (diesels) when turned off

a. Check for idle speed set too high and readjust to specification.

b. Check the operation of the idle control valve, and replace if defective.

c. Check the ignition timing and adjust to recommended settings.

Check for defective

sensors or related components and replace if defective.

d. Check for a vacuum leak at the intake manifold or vacuum hose

and replace defective

gaskets or hoses.

e. Check the engine for excessive carbon build-up in the combustion chamber. Use a

recommended decarbonizing fuel additive or disassemble the cylinder head to remove

the carbon.

f. Check the operation of the engine fuel management system and replace defective sen-

sors or control units.

g. Check the engine operating temperature for overheating and repair as necessary. 5. Engine knocks and pinfls during heavy accele/ation, and on steep hills

a. Check the octane rating of the fuel used during refilling, and use a higher octane rated

fuel.

b. Check the ignition timing and adjust to recommended settings. Check for defective

sensors or related components and replace if defective.

c. Check the engine for excessive carbon build-up in the combustion chamber. Use a

recommended decarbonizing fuel additive or disassemble the cylinder head to remove

the carbon.

d. Check the spark plugs for the correct type, electrode gap and heat range. Replace worn

or damaged spark plugs. For severe or continuous high speed use, install a spark plug

that is one heat range colder.

e. Check the operation of the engine fuel management system and replace defective sen-

sors or control units.

f. Check for a restricted exhaust system. Check for bent or crimped exhaust pipes, or in-

ternally restricted mufflers or catalytic converters. Compare inlet and outlet tempera-

tures for the converter or muffler. If the inlet is hot, but outlet cold, the component is

restricted.

6. Engine atxelerates, but vehicle does not gain speed

a. On manual transmission vehicles, check for causes of a slipping clutch. Refer to the

clutch troubleshooting section for additional information.

b. On automatic transmission vehicles, check for a slipping transmission” Check the

transmission fluid level and condition. If the fluid level is too high, adjust to the cor-

rect level. If the fluid level is low, top off using the recommended fluid type. If the fluid

exhibits a burning odor, the transmission has been slipping internally. Changing the

fluid and filter may help temporarily, however in this situation a transmission may re-

quire overhauling to ensure long-term reliability.

Diesel Engines

1. Engine runs pOOr!y a. Check the injection pump timing and adjust to specification.

b. Check for air in the fuel lines or leaks, and bleed the air from the fuel system.

c. Check the fuel filter, fuel feed and return lines for a restriction and repair as necessary.

d. Check the fuel for contamination, drain and flush the fuel tank and replenish with fresh

fuel.

2. Enfline lacks power

a. Inspect the air intake system and air filter for restrictions and, if necessary, replace the

air filter.

b. Verify the injection pump timing and reset if out of specification.

c. Check the exhaust for an internal restriction and replace failed parts.

d. Check for a restricted fuel filter and, if restricted, replace the filter.

e. Inspect the fuel filler cap vent. When removing the filler cap, listen for excessive hiss-

ing noises indicating a blockage in the fuel filler cap vents, If the filler cap vents are

blocked, replace the cap.

f. Check the fuel system for restrictions and repair as necessary.

g. Check for low engine compression and inspect for external leakage at the glow plugs

or nozzles. If no external leakage is noted, repair or replace the engine.

ENGINE PERFORMANCE TROUBLESHOOTING HINTS When troubleshooting an engine running or performance condition, the mechanical

condition of the engine should be determined before lengthy troubleshooting procedures

are performed.

The engine fuel management systems in fuel injected vehicles rely on electronic sen-

sors to provide information to the engine control unit for precise fuel metering. Unlike

carburetors, which use the incoming air speed to draw fuel through the fuel metering jets

in order to provide a proper fuel-to-air ratio, a fuel injection system provides a specific

amount of fuel which is introduced by the fuel injectors into the intake manifold or intake

port, based on the information provided by electronic sensors.

The sensors monitor the engine’s operating temperature, ambient temperature and the

amount of air entering the engine, engine speed and throttle position to provide informa-

tion to the engine control unit, which, in turn, operates the fuel injectors by electrical

pulses. The sensors provide information to the engine control unit using low voltage

electrical signals. As a result, an unplugged sensor or a poor electrical contact could

cause a poor running condition similar to a failed sensor.

When troubleshooting a fuel related engine condition on fuel injected vehicles, care-

fully inspect the wiring and electrical connectors to the related components. Make sure

the electrical connectors are fully connected, clean and not physically damaged. If neces-

sary, clean the electrical contacts using electrical contact cleaner. The use of cleaning

agents not specifically designed for electrical contacts should not be used, as they could

leave a surface film or damage the insulation of the wiring.

The engine electrical system provides the necessary electrical power to operate the ve-

hicle’s electrical accessories, electronic control units and sensors. Because engine man-

agement systems are sensitive to voltage changes, an alternator which over or under-

charges could cause engine running problems or component failure. Most alternators

utilize internal voltage regulators which cannot be adjusted and must be replaced indi-

vidually or as a unit with the alternator.

Page 390 of 408

11-8 TROUBLESHOOTING

Ignition systems may be controlled by, or linked to, the engine fuel management sys-

tem. Similar to the fuel injection system, these ignition systems rely on electronic sen-

sors for information to determine the optimum ignition timing for a given engine speed

and load. Some ignition systems no longer allow the ignition timing to be adjusted.

Feedback from low voltage electrical sensors provide information to the control unit to

determine the amount of ignition advance. On these systems, if a failure occurs the failed

component must be replaced. Before replacing suspected failed electrical components,

carefully inspect the wiring and electrical connectors to the related components. Make

sure the electrical connectors are fully connected, clean and not physically damaged. If

necessary, clean the electrical contacts using electrical contact cleaner. The use of clean-

ing agents not specifically designed for electrical contacts should be avoided, as they

could leave a surface film or damage the insulation of the wiring.

1. Engine makes a knocking or pinging noise when accelerating

a. Check the octane rating of the fuel being used. Depending on the type of driving or

driving conditions, it may be necessary to use a higher octane fuel.

b. Verify the ignition system settings and operation. Improperly adjusted ignition timing

or a failed component, such as a knock sensor, may cause the ignition timing to ad-

vance excessively or prematurely. Check the ignition system operation and adjust, or

replace components as needed.

c. Check the spark plug gap, heat range and condition. If the vehicle is operated in se-

vere operating conditions or at continuous high speeds, use a colder heat range spark

plug. Adjust the spark plug gap to the manufacturer’s recommended specification and

replace worn or damaged spark plugs.

2. Sfarter motor grinds when used

a. Examine the starter pinion gear and the engine ring gear for damage, and replace dam-

aged parts.

b. Check the starter mounting bolts and housing. If the housing is cracked or damaged

replace the starter motor and check the mounting bolts for tightness.

3. Engine makes a screeching noise

a. Check the accessory drive belts for looseness and adjust as necessary.

b. Check the accessory drive belt tensioners for seizing or excessive bearing noises and

replace if loose, binding, or excessively noisy.

c. Check for a seizing water pump. The pump may not be leaking; however, the bearing

may be faulty or the impeller loose and jammed. Replace the water pump.

4. Engine makes a growling noise

a. Check for a loose or failing water pump. Replace the pump and engine coolant.

b. Check the accessory drive belt tensioners for excessive bearing noises and replace if

loose or excessively noisy.

5. Engine makes a ticking or tapping noise

a. On vehicles with hydraulic lash adjusters, check for low or dirty engine oil and top off

or replace the engine oil and filter.

b. On vehicles with hydraulic lash adjusters, check for collapsed lifters and replace failed

components.

c. On vehicles with hydraulic lash adjusters, check for low oil pressure caused by a re-

stricted oil filter, worn engine oil pump, or oil pressure relief valve.

d. On vehicles with manually adjusted valves, check for excessive valve clearance or

worn valve train parts. Adjust the valves to specification or replace worn and defective

parts.

e. Check for a loose or improperly tensioned timing belt or timing chain and adjust or re-

place parts as necessary.

f. Check for a bent or sticking exhaust or intake valve. Remove the engine cylinder head

to access and replace.

6. Engine makes a heavy knocking noise

a. Check for a loose crankshaft pulley or flywheel; replace and torque the mounting

bolt(s) to specification.

b. Check for a bent connecting rod caused by a hydro-lock condition. Engine disassem-

bly is necessary to inspect for damaged and needed replacement parts.

c. Check for excessive engine rod bearing wear or damage. This condition is also asso-

ciated with low engine oil pressure and will require engine disassembly to inspect for

damaged and needed replacement parts,

7. Vehicle has a fuel odor when driven ’ a. Check the fuel gauge level. If the fuel gauge registers full, it is possible that the odor is

caused by being filled beyond capacity, or some spillage occurred during refueling.

The odor should clear after driving an hour, or twenty miles, allowing the vapor canis-

ter to purge.

b. Check the fuel filler cap for looseness or seepage. Check the cap tightness and, if

loose, properly secure. If seepage is noted, replace the filler cap.

c. Check for loose hose clamps, cracked or damaged fuel delivery and return lines, or

leaking components or seals, and replace or repair as necessary. d. Check the vehicle’s fuel economy. If fuel consumption has increased due to a failed

component, or if the fuel is not properly ignited due to an ignition related failure, the

catalytic converter may become contaminated. This condition may also trigger the

check engine warning light. Check the spark plugs for a dark, rich condition or verify

the condition by testing the vehicle’s emissions. Replace fuel fouled spark plugs, and

test and replace failed components as necessary.

5. Vehicle has a rotten egg odor when driven

a. Check for a leaking intake gasket or vacuum leak causing a lean running condition. A

lean mixture may result in increased exhaust temperatures, causing the catalytic con-

verter to run hotter than normal. This condition may also trigger the check engine

warning light. Check and repair the vacuum leaks as necessary.

b. Check the vehicle’s alternator and battery condition. If the alternator is overcharging,

the battery electrolyte can be boiled from the battery, and the battery casing may begin

to crack, swell or bulge, damaging or shorting the battery internally. If this has oc-

curred, neutralize the battery mounting area with a suitable baking soda and water

mixture or equivalent, and replace the alternator or voltage regulator. Inspect, service,

and load test the battery, and replace if necessary.

9. Vehicle has a sweet odor when driven

a. Check for an engine coolant leak caused by a seeping radiator cap, loose hose clamp,

weeping cooling system seal, gasket or cooling system hose and replace or repair as

needed.

b. Check for a coolant leak from the radiator, coolant reservoir, heater control valve or

under the dashboard from the heater core, and replace the failed part as necessary.

c. Check the engine’s exhaust for white smoke in addition to a sweet odor. The presence

of white, steamy smoke with a sweet odor indicates coolant leaking into the combus-

tion chamber. Possible causes include a failed head gasket, cracked engine block or

cylinder head. Other symptoms of this condition include a white paste build-up on the

inside of the oil filler cap, and softened, deformed or bulging radiator hoses.

19. Engine vibraies when idling

a. Check for loose, collapsed, or damaged engine or transmission mounts and repair or

replace as necessary.

b. Check for loose or damaged engine covers or shields and secure or replace as neces-

sary.

11. Engine vibrates during acceleration

a. Check for missing, loose or damaged exhaust system hangers and mounts; replace or

repair as necessary.

b. Check the exhaust system routing and fit for adequate clearance or potential rubbing;

repair or adjust as necessary.

7. Battery goes dead while driving

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test. If the battery loses fluid while driving, check for an overcharg-

ing condition. If the alternator is overcharging, replace the alternator or voltage regula-

tor. (A voltage regulator is typically built into the alternator, necessitating alternator re-

placement or overhaul.)

b. Check the battery cable condition. Clean or replace corroded cables and clean the bat-

tery terminals.

c. Check the alternator and voltage regulator operation. If the charging system is over or

undercharging, replace the alternator or voltage regulator, or both.

d. Inspect the wiring and wire connectors at the alternator for looseness, a missing .

ground or defective terminal, and repair as necessary.

e. Inspect the alternator drive belt tension, tensioners and condition. Properly tension the

drive belt, replace weak or broken tensioners, and replace the drive belt if worn or

cracked.

2. Battery goes dead overnight

a. Check the battery condition. Replace the battery if the battery will not hold a charge or

fails a battery load test.

b. Check for a voltage draw, such as a trunk light, interior light or glove box light staying

on. Check light switch position and operation, and replace if defective.

c. Check the alternator for an internally failed diode, and replace the alternator if defec-

tive.

1. Engine overheats

a. Check the coolant level. Set the heater temperature to full hot and check for internal air

pockets, bleed the cooling system and inspect for leakage. Top off the cooling system

with the correct coolant mixture.

b. Pressure test the cooling system and radiator cap for leaks. Check for seepage caused

by loose hose clamps, failed coolant hoses, and cooling system components such as

the heater control valve, heater core, radiator, radiator cap, and water pump. Replace

defective parts and fill the cooling system with the recommended coolant mixture.

Page 391 of 408

TROUBLESHOOTING 11-9

c. On vehicles with electrically controlled cooling fans, check the cooling fan operation.

Check for blown fuses or defective fan motors, temperature sensors and relays, and

replace failed components.

d. Check for a coolant leak caused by a failed head gasket, or a porous water jacket cast-

ing in the cylinder head or engine block. Replace defective parts as necessary.

e. Check for an internally restricted radiator. Flush the radiator or replace if the blockage

is too severe for flushing.

f. Check for a damaged water pump. If coolant circulation is poor, check for a loose wa-

ter pump impeller. If the impeller is loose, replace the water pump.

2. Engine loses coolant

a. Pressure test the cooling system and radiator cap for leaks. Check for seepage caused

by loose hose clamps, failed coolant hoses, and cooling system components such as

the heater control valve, heater core, radiator, radiator cap, and water pump. Replace

defective parts and fill the cooling system with the recommended coolant mixture.

b. Check for a coolant leak caused by a failed head gasket, or a porous water jacket cast-

ing in the cylinder head or engine block. Replace defective parts as necessary.

3. Engine temperature remains co/d when driving

a. Check the thermostat operation. Replace the thermostat if it sticks in the open posi-

tion.

b. On vehicles with electrically controlled cooling fans, check the cooling fan operation.

Check for defective temperature sensors and stuck relays, and replace failed compo-

nents.

c. Check temperature gauge operation if equipped to verify proper operation of the

gauge. Check the sensors and wiring for defects, and repair or replace defective com-

ponents.

4. Engine runs hot

a. Check for an internally restricted radiator. Flush the radiator or replace if the blockage

is too severe for flushing.

b. Check for a loose or slipping water pump drive belt. Inspect the drive belt condition.

Replace the belt if brittle, cracked or damaged. Check the pulley condition and prop-

erly tension the belt.

c. Check the cooling fan operation. Replace defective fan motors, sensors or relays as

necessary.

d. Check temperature gauge operation if equipped to verify proper operation of the

gauge. Check the sensors and wiring for defects, and repair or replace defective com-

ponents.

e. Check the coolant level. Set the heater temperature to full hot, check for internal air

pockets, bleed the cooling system and inspect for leakage. Top off the cooling system

with the correct coolant mixture. Once the engine is cool, recheck the fluid level and

top off as needed.

NOTE: The engine cooling system can also be affected by an engine’s me-

chanical condition. A failed head gasket or a porous casting in the engine

block or cylinder head could cause a loss of coolant and result in engine

overheating.

Some cooling systems rely on electrically driven cooling fans to cool the radiator and

use electrical temperature sensors and relays to operate the cooling fan. When diagnos-

ing these systems, check for blown fuses, damaged wires and verify that the electrical

connections are fully connected, clean and not physically damaged. If necessary, clean

the electrical contacts using electrical contact cleaner. The use of cleaning igents not specifically designed for electrical contacts could leave a film or damage the insulation of

the wiring.

1. Exhaust rattles at idle speed

a. Check the engine and transmission mounts and replace mounts showing signs of

damage or wear.

b. Check the exhaust hangers, brackets and mounts. Replace broken, missing or dam-

aged mounts.

c. Check for internal damage to mufflers and catalytic converters. The broken pieces from

the defective component may travel in the direction of the exhaust flow and collect

and/or create a blockage in a component other than the one which failed, causing en-

gine running and stalling problems. Another symptom of a restricted exhaust is low

engine manifold vacuum. Remove the exhaust system and carefully remove any loose

or broken pieces, then replace any failed or damaged parts as necessary.

d. Check the exhaust system clearance, routing and alignment. If the exhaust is making

contact with the vehicle in any manner, loosen and reposition the exhaust system.

2. Exhaust system vibrates when driving

a. Check the exhaust hangers, brackets and mounts. Replace broken, missing or dam-

aged mounts.

b. Check the exhaust system clearance, routing and alignment. If the exhaust is making

contact with the vehicle in any manner, check for bent or damaged components and

replace, then loosen and reposition the exhaust system.

c. Check for internal damage to mufflers and catalytic converters. The broken pieces from

the defective component may travel in the direction of the exhaust flow and collect

and/or create a blockage in a component other than the one which failed, causing en-

gine running and stalling problems. Another symptom of a restricted exhaust is low

engine manifold vacuum. Remove the exhaust system and carefully remove any loose

or broken pieces, then replace any failed or damaged parts as necessary.

3. Exhaust system hangs too low

a. Check the exhaust hangers, brackets and mounts. Replace broken, missing or dam-

aged mounts.

b. Check the exhaust routing and alignment. Check and replace bent or damaged com-

ponents. If the exhaust is not routed properly, loosen and reposition the exhaust sys-

tern.

4. Exhaust sounds loud

a. Check the system for looseness and leaks. Check the exhaust pipes, clamps, flange

bolts and manifold fasteners for tightness. Check and replace any failed gaskets.

b. Check and replace exhaust silencers that have a loss of efficiency due to internally

broken baffles or worn packing material.

c. Check for missing mufflers and silencers that have been replaced with straight pipes

or with non-original equipment silencers.

NOTE: Exhaust system rattles, vibration and proper alignment should not

be overlooked. Excessive vibration caused by collapsed engine mounts,

damaged or missing exhaust hangers and misalignment may cause surface

cracks and broken welds, creating exhaust leaks or internal damage to ex-

haust components such as the catalytic converter, creating a restriction to

exhaust flow and loss of power.

1. Transmission shit& erratically

a. Check and if not within the recommended range, add or remove transmission fluid to

obtain the correct fluid level. Always use the recommended fluid type when adding

transmission fluid.

b. Check the fluid level condition. If the fluid has become contaminated, fatigued from

excessive heat or exhibits a burning odor, change the transmission fluid and filter us-

ing the recommended type and amount of fluid. A fluid which exhibits a burning odor

indicates that the transmission has been slipping internally and may require future re-

pairs.

c. Check for an improperly installed transmission filter, or missing filter gasket, and re-

pair as necessary.

d. Check for loose or leaking gaskets, pressure lines and fittings, and repair or replace as

necessary.

e. Check for loose or disconnected shift and throttle linkages or vacuum hoses, and re-

pair as necessary. ,

2. Transmission will not engage

a. Check the shift linkage for looseness, wear and proper adjustment, and repair as nec-

essary. b. Check for a loss of transmission fluid and top off as needed with the recommended

fluid.

c. If the transmission does not engage with the shift linkage correctly installed and the

proper fluid level, internal damage has likely occurred, requiring transmission removal

and disassembly.

3. Transmission will not downshift during heavy acceleration

a. On computer controlled transmissions, check for failed sensors or control units and

repair or replace defective components.

b. On vehicles with kickdown linkages or vacuum servos, check for proper linkage ad-

justment or leaking vacuum hoses or servo units.

NOTE: Mlany automatic transmissions use an electronic control module,

electrical sensors and solenoids to control transmission shifting. When

troubleshooting a vehicle with this type of system, be sure the electrical

connectors are fully connected, clean and not physically damaged. If nec-

essary, clean the electrical contacts using electrical contact cleaner. The

use of cleaning agents not specifically designed for electrical contacts

could leave a film or damage the insulation of the wiring.

Page 399 of 408

GLOSSARY 11-17

AIR/FUEL RATIO: The ratio of air-to-gasoline by weight in the fuel mixture

drawn into the engine.

AIR INJECTION: One method of reducing harmful exhaust emissions by in-

jecting air into each of the exhaust ports of an engine. The fresh air entering

the hot exhaust manifold causes any remaining fuel to be burned before it can

exit the tailpipe.

ALTERNATOR: A device which produces AC (alternating current) which is

converted to DC (direct current) to charge the car battery.

AMMETER: An instrument, calibrated in amperes, used to measure the flow

of an electrical current in a circuit. Ammeters are always connected in series

with the circuit being tested.

AMPERE: The rate of flow of electrical current present when one volt of elec-

trical pressure is applied against one ohm of electrical resistance.

ANALOG COMPUTER: Any microprocessor that uses similar (analogous)

electrical signals to make its calculations.

ARMATURE: A laminated, soft iron core wrapped by a wire that converts elec-

trical energy to mechanical energy as in a motor or relay. When rotated in

a magnetic field, it changes mechanical energy into electrical energy as in a

generator.

ATMOSPHERIC PRESSURE: The pressure on the Earth’s surface caused

by the weight of the air in the atmosphere. At sea level, this pressure is 14.7

psi at 32°F (101 kPa at OOC).

ATOMIZATION: The breaking down of a liquid into a fine mist that can be

suspended in air.

AXIAL PLAY: Movement parallel to a shaft or bearing bore.

BACKFIRE: The sudden combustion of gases in the intake or exhaust sys-

tem that results in a loud explosion.

BACKLASH: The clearance or play between two parts, such as meshed gears.

BACKPRESSURE: Restrictions in the exhaust system that slow the exit of

exhaust gases from the combustion chamber.

BAKELITE[reg]: A heat resistant, plastic insulator material commonly used

in printed circuit boards and transistorized components.

BALL BEARING: A bearingmade up of hardened inner and outer races be-

tween which hardened steel’balls roll.

BALLAST RESISTOR: A resistor in the primary ignition circuit that lowers

voltage after the engine is started to reduce wear on ignition components.

BEARING: A friction reducing, supportive device usually located between a

stationary part and a moving part.

BI-METAL TEMPERATURE SENSOR: Anv sensor or switch made of two

dissimilar types of metal that bend when heated or cooled due to the different

expansion rates of the alloys. These types of sensors usually function as an

on/off switch. BLOW-BY: Combustion gases, composed of water vapor and unburned fuel,

that leak past the piston rings into the crankcase during normal engine oper-

ation. These gases are removed by the PCV system to prevent the buildup of

harmful acids in the crankcase.

BRAKE PAD: A brake shoe and lining assembly used with disc brakes.

BRAKE SHOE: The backing for the brake lining. The term is, however, usu-

ally applied to the assembly of the brake backing and lining.

BUSHING: A liner, usually removable, for a bearing; an anti-friction liner used

in place of a bearing.

CALIPER: A hydraulically activated device in a disc brake system, which is

mounted straddling the brake rotor (disc). The caliper contains at least one

piston and two brake pads. Hydraulic pressure on the piston(s) forces the pads

against the rotor.

CAMSHAFT: A shaft in the engine on which are the lobes (cams) which op-

erate the valves. The camshaft is driven by the crankshaft, via a belt, chain or

gears, at one half the crankshaft speed.

CAPACITOR: A device which stores an electrical charge.

CARBON MONOXIDE (CO): A colorless, odorless gas given off as a nor-

mal byproduct of combustion. It is poisonous and extremely dangerous in con-

fined areas, building up slowly to toxic levels without warning if adequate ven-

tilation is not available.

CARBURETOR: A device, usually mounted on the intake manifold of an en-

gine, which mixes the air and fuel in the proper proportion to allow even com-

bustion

CATALYTIC CONVERTER: A device installed in the exhaust system, like a

muffler, that converts harmful byproducts of combustion into carbon dioxide

and water vapor by means of a heat-producing chemical reaction.

CENTRIFUGAL ADVANCE: A mechanical method of advancing the spark

timing by using flyweights in the distributor that react to centrifugal force gen-

erated by the distributor shaft rotation.

CHECK VALVE: Any one-way valve installed to permit the flow of air, fuel or

vacuum in one direction only.

CHOKE: The valve/plate that restricts the amount of air entering an engine on

the induction stroke, thereby enriching the air:fuel ratio.

CIRCUIT: Any unbroken path through which an electrical current can flow.

Also used to describe fuel flow in some instances.

CIRCUIT BREAKER: A switch which protects an electrical circuit from

overload by opening the circuit when the current flow exceeds a pre-

determined level. Some circuit breakers must be reset manually, while most

reset automatically.

COIL (IGNITION): Part of the ignition system that boosts the relatively low

voltage supplied by the car’s electrical system to the high voltage required to

fire the spark plugs.