tire size MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 2 of 408

.

1-2 GENERALINFORMATIONAND MAINTENANCE

Chitton’s Total Car Care manual for the 199M10

Mitsubishi Mirage, Galant and Diamante is intended

to help you learn more about the inner workings of

your vehicle while saving you money on its upkeep

and operation.

The beginning of the book will likely be referred to

the most, since that is where you will find information

for maintenance and tune-up. The other sections deal

with the more complex systems of your vehicle. Oper-

ating systems from engine through brakes are cov-

ered to the extent that the average do-it-yourselfer be-

comes mechanically involved. This book will not

explain such things as rebuilding a differential for the

simple reason that the expertise required and the in-

vestment in special tools make this task uneconomi-

cal. It will, however, give you detailed instructions to

help you change your own brake pads and shoes, re-

place spark plugs, and perform many more jobs that

can save you money, give you personal satisfaction

and help you avoid expensive problems.

A secondary purpose of this book is a reference for

owners who want to understand their vehicle and/or

their mechanics better. In this case, no tools at all are

required.

Before removing any bolts, read through the entire

procedure. This will give you the overall view of what

tools and supplies will be required. There is nothing

more frustrating than having to walk to the bus stop

on Monday morning because you were short one bolt

on Sunday afternoon. So read ahead and plan ahead.

Each operation should be approached logically and

all procedures thoroughly understood before attempt-

ing any work.

All sections contain adjustments, maintenance, re-

moval and installation procedures, and in some cases,

repair or overhaul procedures. When repair is not con-

sidered practical, we tell you how to remove the part

and then how to install the new or rebuilt replacement.

In this way, you at least save labor costs. “Backyard”

repair of some components is just not practical.

Many procedures in this book require you to “label

and disconnect. . ” a group of lines, hoses or wires.

Don’t be lulled into thinking you can remember where

everything goes-you won’t. If you hook up vacuum

or fuel lines incorrectly, the vehicle may run poorly, if

at all. If you hook up electrical wiring incorrectly, you

may instantly learn a very expensive lesson.

You don’t need to know the official or engineering

name for each hose or line. A piece of masking tape

on the hose and a piece on its fitting will allow you to

assign your own label such as the letter A or a short name. As long as you remember your own code, the

lines can be reconnected by matching similar letters

or names. Do remember that tape will dissolve in

gasolrne or other fluids; if a component is to be

washed or cleaned, use another method of identifica-

tion. A permanent felt-tipped marker or a metal scribe

can be very handy for marking metal parts. Remove

any tape or paper labels after assembly.

It’s necessary to mention the difference between

maintenance and repair Maintenance includes rou-

tine inspections, adjustments, and replacement of

parts which show signs of normal wear Maintenance

compensates for wear or deterioration. Repair implies

that something has broken or is not working. A need

for repair is often caused by lack of maintenance. Ex-

ample, draining and refilling the automatic transaxle

fluid is maintenance recommended by the manufac-

turer at specific mileage intervals. Failure to do this

can shorten the life of the transmission/transaxle, re-

quiring very expensive repairs. While no maintenance

program can prevent items from breaking or wearing

out, a general rule can be stated: MAINTENANCE IS

CHEAPER THAN REPAIR.

Two basic mechanrc’s rules should be mentioned

here. First, whenever the left side of the vehicle or en-

gine is referred to, it is meant to specify the drivers

side. Conversely, the right side of the vehicle means

the passengers side. Second, screws and bolts are

removed by turning counterclockwise, and tightened

by turning clockwrse unless specifically noted.

Safety is always the most important rule. Con-

stantly be aware of the dangers involved in working

on an automobile and take the proper precautions.

See the informatron in this section regarding SER-

VICING YOUR VEHICLE SAFELY and the SAFETY

NOTICE on the acknowledgment page.

Pay attention to the instructions provided. There

are 3 common mistakes in mechanical work:

1. Incorrect order of assembly, disassembly or

adjustment. When taking something apart or putting

it together, performing steps in the wrong order usu-

ally just costs you extra time; however, it CAN break

something. Read the entire procedure before begin-

ning disassembly. Perform everything in the order in

which the instructions say you should, even if you

can’t immedrately see a reason for it. When you’re

taking apart something that is very intricate, you

might want to draw a picture of how it looks when as-

sembled at one point in order to make sure you get everything back in its proper position. We will supply

exploded views whenever possible. When making

adjustments, perform them in the proper order. One

adjustment possibly will affect another.

2. Overtorquing (or undertorquing). While it is

more common for overtorquing to cause damage,

undertorquing may allow a fastener to vibrate loose

causing serious damage. Especially when dealing

with aluminum parts, pay attention to torque specifi-

cations and utilize a torque wrench in assembly. If a

torque figure is not available, remember that if you

are using the right tool to perform the job, you will

probably not have to strain yourself to get a fastener

tight enough. The pitch of most threads is so slight

that the tension you put on the wrench will be multi-

plied many times in actual force on what you are

tightening. A good example of how critical torque is

can be seen in the case of spark plug installation, es-

pecially where you are putting the plug into an alu-

minum cylinder head. Too little torque can fail to

crush the gasket, causing leakage of combustion

gases and consequent overheating of the plug and

engine parts. Too much torque can damage the

threads or distort the plug, changing the spark gap.

There are many commercial products available for

ensuring that fasteners won’t come loose, even if they

are not torqued just right (a very common brand is

Loctite? If you’re worried

about getting something

together tight enough to hold, but loose enough to

avoid mechanical damage during assembly, one of

these products might offer substantial insurance. Be-

fore choosing a threadlocking compound, read the

label on the package and make sure the product is

compatible with the materials, fluids, etc. involved.

3. Crossthreading. This occurs when a part such

as a bolt is screwed into a nut or casting at the wrong

angle and forced. Crossthreading is more likely to

occur if access is difficult. It helps to clean and lubri-

cate fasteners, then to start threading the bolt, spark

plug, etc. with your fingers If you encounter resis-

tance, unscrew the part and start over again at a dif-

ferent angle until it can be inserted and turned several

times without much effort. Keep in mind that many

parts, especially spark plugs, have tapered threads,

so that gentle turning will automatically bring the part

you’re threading to the proper angle. Don’t put a

wrench on the part until its been tightened a couple

of turns by hand. If you suddenly encounter resis-

tance, and the part has not seated fully, don’t force it.

Pull it back out to make sure it’s clean and threading

properly.

Be sure to take your time and be patient, and al-

ways plan ahead. Allow yourself ample time to per-

form repairs and maintenance You may find main-

taining your car a satisfying and enjoyable

experience.

b See Figures 1 thru 15

Naturally, without the proper tools and equipment

it is impossible to properly service your vehicle. It

would also be virtually impossible

to catalog every

tool that you would need to perform all of the opera-

tions in this book. Of course, It would be unwise for

the amateur to rush out and buy an expensive set of

tools on the theory that he/she may need one or more

of them at some time, The best approach is to proceed slowly, gathering savings will

be far outweighed by frustration and

a good quality set of those tools that are used most mangled knuckles.

frequently Don’t be misled by the low cost of bargain Begin accumulating those tools that are used most

tools. It is far better to spend a little more for better frequently: those associated with routine maintenance

quality. Forged wrenches, 6 or 12-point sockets and and tune-up. In addition to the normal assortment of

fine tooth ratchets are by far preferable to their less screwdrivers and pliers, you should have the follow-

expensive counterparts. As any good mechanic can ing tools:

tell you, there are few worse experiences than trying

l Wrenches/sockets and combination open

to work on a vehicle with bad tools. Your monetary end/box end wrenches in sizes from %-% in. or

Page 23 of 408

l-24 GENERALINFORMATIONAND MAINTENANCE

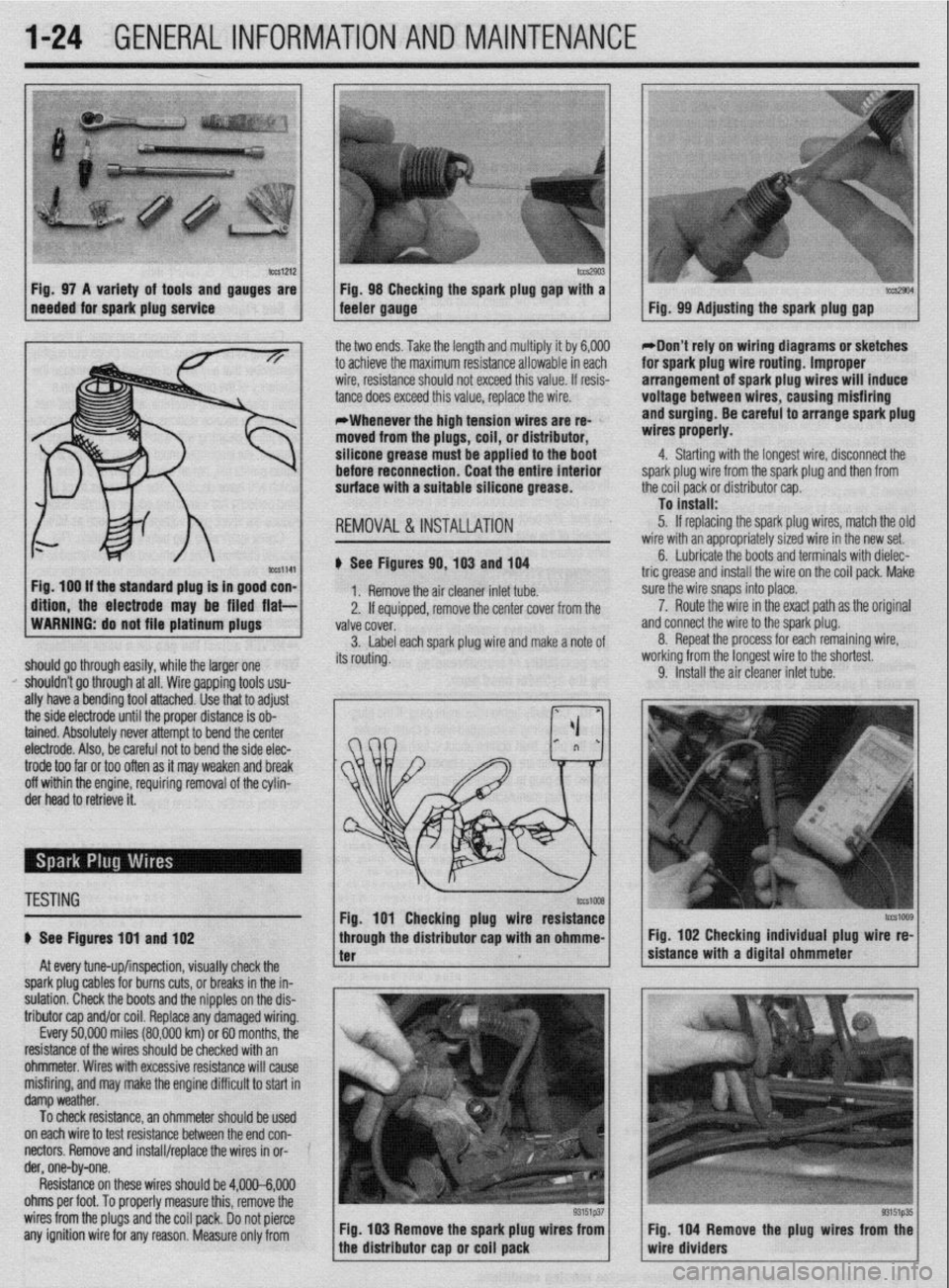

b%slZl2 Fig. 97 A variety of tools and gauges are

needed for spark plug service tm2903 Fig. 98 Checking the spark plug @au with a tccs2904 feeler gauge. - Fig. 99 Adjusting the spark plug gap

ig. 100 If the standard plug Is in good con-

ftlon, the electrode may be filed flat- the two ends. Take the length and multiply it by 6,000

to achieve the maximum resistance allowable in each

wire, resistance should not exceed this value. If resis-

tance does exceed this value, replace the wire.

*Whenever the high tension wires are re- ’

moved from the plugs, coil, or distributor,

silicone grease must be applied to the boot

before reconnection. Coat the entire Interior

surface with a suitable silicone grease.

REMOVAL &INSTALLATION

# See Figures 90,103 and 104

1. Remove the air cleaner inlet tube.

2. If eouiooed, remove the center cover from the

WARNING: do not file platinum plugs

valve covei.

3. Label each spark plug wire and make a note of

should go through easily, while the larger one its routing.

I’ shouldn’t go through at all. Wire gapping tools usu-

ally have a bending tool attached. Use that to adjust

the side electrode until the proper distance is ob-

tained. Absolutely never attempt to bend the center

electrode. Also, be careful not to bend the side elec- *Don’t rely on wiring diagrams or sketches

for spark plug wire routing. Improper

arrangement of spark plug wires will induce

voltage between wires, causing misfiring

and surging. Be careful to arrange spark plug

wires properly.

4. Starting with the longest wire, disconnect the

spark plug wire from the spark plug and then from

the coil pack or distributor cap.

To install:

5. If replacing the spark plug wires, match the olc

wire with an appropriately sized wire in the new set.

6. Lubricate the boots and terminals with dielec-

tric grease and install the wire on the coil pack. Make

sure the wire snaps into place.

a 7. Route the wire in the exact path as the original

nd connect the wire to the spark plug.

8. Repeat the process for each remaining wire,

iorking from the longest wire to the shortest.

9. Install the air cleaner inlet tube.

trode too far or too often as it may weaken and break

off within the engine, requiring removal of the cylin-

der head to retrieve it.

TESTING

# See Figures 191 and 102

At every tune-up/inspection, visually check the

spark plug cables for burns cuts, or breaks in the in-

sulation. Check the boots and the nipples on the dis-

tributor cap and/or coil. Replace any damaged wiring.

Every 50,000 miles (80,000 km) or 60 months, the

resistance of the wires should be checked with an

ohmmeter. Wires with excessive resistance will cause

misfiring, and may make the engine difficult to start in

damp weather.

To check resistance, an ohmmeter should be used ’

on each wire to test resistance between the end con-

nectors. Remove and install/replace the wires in or- ’

der, one-by-one.

Resistance on these wires should be 4,000-6,000

ohms per foot. To properly measure this, remove the

wires from the plugs and the coil pack. Do not pierce

any ignition wire for any reason. Measure only from Fig. 103 Remove the spark plug wires from

tcG1009 Fig. 102 Checking individual plug wire re-

sistance with a digital ohmmeter

Fig. 104 Remove the plug wires from the

wire dividers

Page 30 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-31

When rotating “unidirectional tires,” make sure

that they always roll in the same direction. This

means that a tire used on the left side of the vehicle

must not be switched to the right side and vice-versa.

Such tires should only be rotated front-to-rear or

rear-to-front, while always remaining on the same

side of the vehicle. These tires are marked on the

sidewall as to the direction of rotation; observe the

marks when reinstalling the tire(s).

Some styled or “mag” wheels may have different

offsets front to rear. In these cases, the rear wheels

must not be used up front and vice-versa. Further-

more, if these wheels are equipped with unidirectional

tires, they cannot be rotated unless the tire is re-

mounted for the proper direction of rotation.

*The compact or space-saver spare is

strictly for emergency use. it must never be

included in the tire rotation or placed on the

vehicle for everyday use. check the installed tire for any sign of interference

with the body or suspension while the vehicle is stop-

ping, turning sharply or heavily loaded.

Snow Tires

Good radial tires can produce a big advantage in

slippery weather, but in snow, a street radial tire does

not have sufficient tread to provide traction and con-

trol. The small grooves of a street tire quickly pack

with snow and the tire behaves like a billiard ball on a

marble floor, The more open, chunky tread of a snow

tire will self-clean as the tire turns, providing much

better grip on snowy surfaces.

To satisfy municipalities requiring snow tires dur-

ing weather emergencies, most snow tires carry either

an M + S designation after the tire size stamped on

the sidewall, or the designation “all-season.” In gen-

eral, no change in tire size is necessary when buying

snow tires.

Most manufacturers stronqlv recommend the use styled wheels, see if inexpensive steel

wheels are available, Although the look of

the vehicle will change, the expensive

wheels will be protected from salt, curb hits

and pothole damage.

TIRESTORAGE

If they are mounted on wheels, store the tires at

proper inflation pressure. All tires should be kept in a

cool, dry place. If they are stored in the garage or

basement, do not let them stand on a concrete floor;

set them on strips of wood, a mat or a large stack of

newspaper. Keeping them away from direct moisture

is of paramount importance. Tires should not be

stored upright, but in a flat position.

INFLATION & INSPECTION

b See Figures 140 thru 147

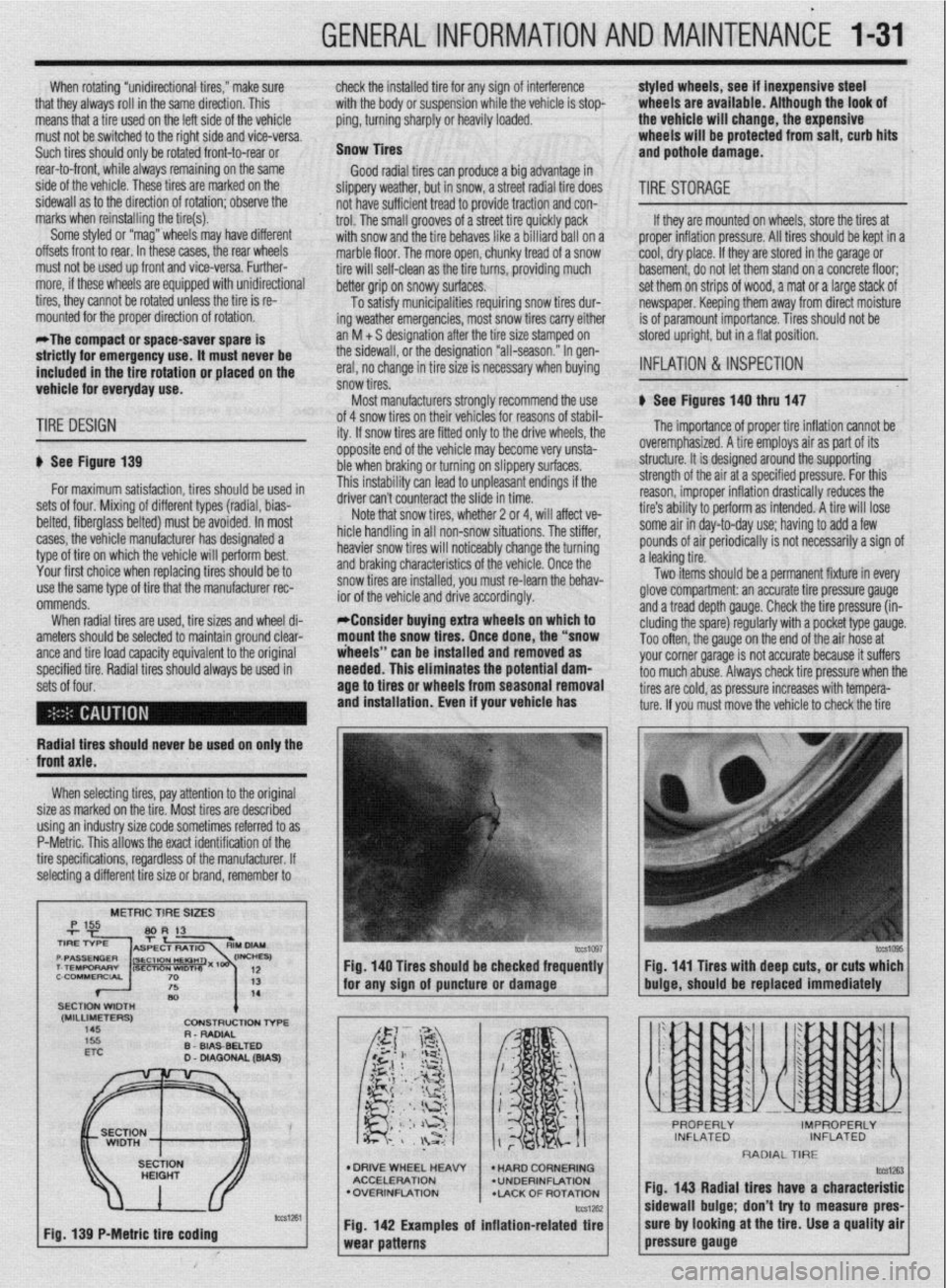

TIRE DESIGN

p See Figure 139

for maximum satisfaction, tires should be used in

sets of four. Mixing of different types (radial, bias-

belted, fiberglass belted) must be avoided. In most

cases, the vehicle manufacturer has designated a

type of tire on which the vehicle will perform best.

Your first choice when replacing tires should be to

use the same type of tire that the manufacturer rec-

ommends.

When radial tires are used, tire sizes and wheel di-

ameters should be selected to maintain ground clear-

ante and tire load caoacitv eauivalent to the oriainal

specified tire. Radial tiresshould always be used in

sets of four. of 4 snow tires on their

lehicies for reasons of stabil-

ity. If snow tires are fitter

1 only to the drive wheels, the

opposite end of the vehil cle may become very unsta-

ble when braking or turn

ring on slippery surfaces.

This instability can lead to unpleasant endings if the

A*:,,“- r-..l, ^_.. ..& ^_^^, &I.

UIIVU MII I LUUII~~MLL iue slide in time.

Note that snow tires, whether 2 or 4, will affect ve-

hicle handling in all non-snow situations. The stiffer,

heavier snow tires will noticeably change the turning

and braking characteristics of the vehicle. Once the

snow tires are installed, you must re-learn the behav-

ior of the vehicle and drive accordingly.

*Consider buying extra wheels on which to

mount the snow tires. Once done, the “snow

iheeis” can be installed and removed as

needed. This eliminates the potential

dam- age to tires or wheels from seasonal removal

and installation. Even if your vehicle has

lb The importance of proper tire inflation cannot be

overemphasized. A tire employs air as part of its

structure. It is designed around the supporting

strength of the air at a specified pressure. For this

reason, improper inflation drastically reduces the

tire’s ability to perform as intended. A tire will lose

some air in day-to-day use; having to add a few

pounds of air periodically is not necessarily a sign of

a leaking tire.

Two items should be a permanent fixture in every

glove compartment: an accurate tire pressure gauge

and a tread depth gauge. Check the tire pressure (in-

eluding the spare) regularly with a pocket type gauge.

Too often, the gauge on the end of the air hose at

vnr rr corner narane is not accurate because it suffers

~rs check tire oressure when the

Radial tires should never be used on only the

XI I._.

‘-’ --“‘“’ J s too much abuse. Alwa!

tires are cold, as pressure increases with tempera-

ture. If you must move the vehicle to check the tire

front axle.

When selecting tires, pay attention to the original

size as marked on the tire. Most tires are described

using an industry size code sometimes referred to as

P-Metric. This allows the exact identification of the

tire specifications, regardless of the manufacturer. If

selecting a different tire size or brand, remember to

METRIC TIRE SIZES

(MILLIMETERS)

145 CDNStRUCtlDN l-6-E

R - RADIAL

D

WA9

Fig. 139 P-Metric tire coding Fig. 140 Tires should be checked frequently

I I Fig. 141 Tires with deep cuts, or cuts which

for any sion of auncture or damaoe

buioe, should be replaced immediately

l DRIVE WHEEL HEAW

ACCELERATION

l OVERINFLATION

*LACK OF ROTATION

Fig. 142 Examples of inflation-related tire

RADIAL TIRE

fig. 143 Radial tires have a characteristic

sidewall bulge; don’t try to measure pres-

sure by looking at the tire. Use a quality air

pressure gauge

Page 127 of 408

3-66 ENGINEANDENGINEOVERHAUL

should be performed on all of the components, but

just because you don’t see a crack does not mean it

is not there. Some more reliable methods for inspect-

ing for cracks include Magnaflux? a magnetic

process or Zyglo@‘, a dye penetrant. Magnaflux@ is

used only on ferrous metal (cast iron). Zyglo@ uses a

spray on fluorescent mixture along with a black light

to reveal the cracks. It is strongly recommended to

have your engine block checked professionally for

cracks, especially if the engine was known to have

overheated and/or leaked or consumed coolant. Con-

tact a local shop for availability and pricing of these

services.

Engine Block

ENGINE BLOCK BEARING ALIGNMENT

Remove the main bearing caps and, if still in:

stalled, the main bearing inserts. Inspect all of the

main bearing saddles and caps for damage, burrs or

high spots. If damage is found, and it is caused from

a spun main bearing, the block will need to be align-

bored or, if severe enough, replacement. Any burrs or

high spots should be carefully removed with a metal

file.

Place a straightedge on the bearing saddles, in the

engine block, along the centerline of the crankshaft. If

any clearance exists between the straightedge and the

saddles, the block must be align-bored.

Align-boring consists of machining the main

bearing saddles and caps by means of a flycutter that

runs through the bearing saddles.

DECK FLATNESS

The top of the engine block where the cylinder

head mounts is called the deck. Insure that the deck

surface is clean of dirt, carbon deposits and old gas-

ket material. Place a straightedge across the surface

of the deck along its centerline and, using feeler

gauges, check the clearance along several points. Re-

peat the checking procedure with the straightedge

placed along both diagonals of the deck surface. If

the reading exceeds 0.003 in. (0.076mm) within a 6.0

in. (152cm) span, or 0.006 in. (0.152mm) over the

total length of the deck, it must be machined.

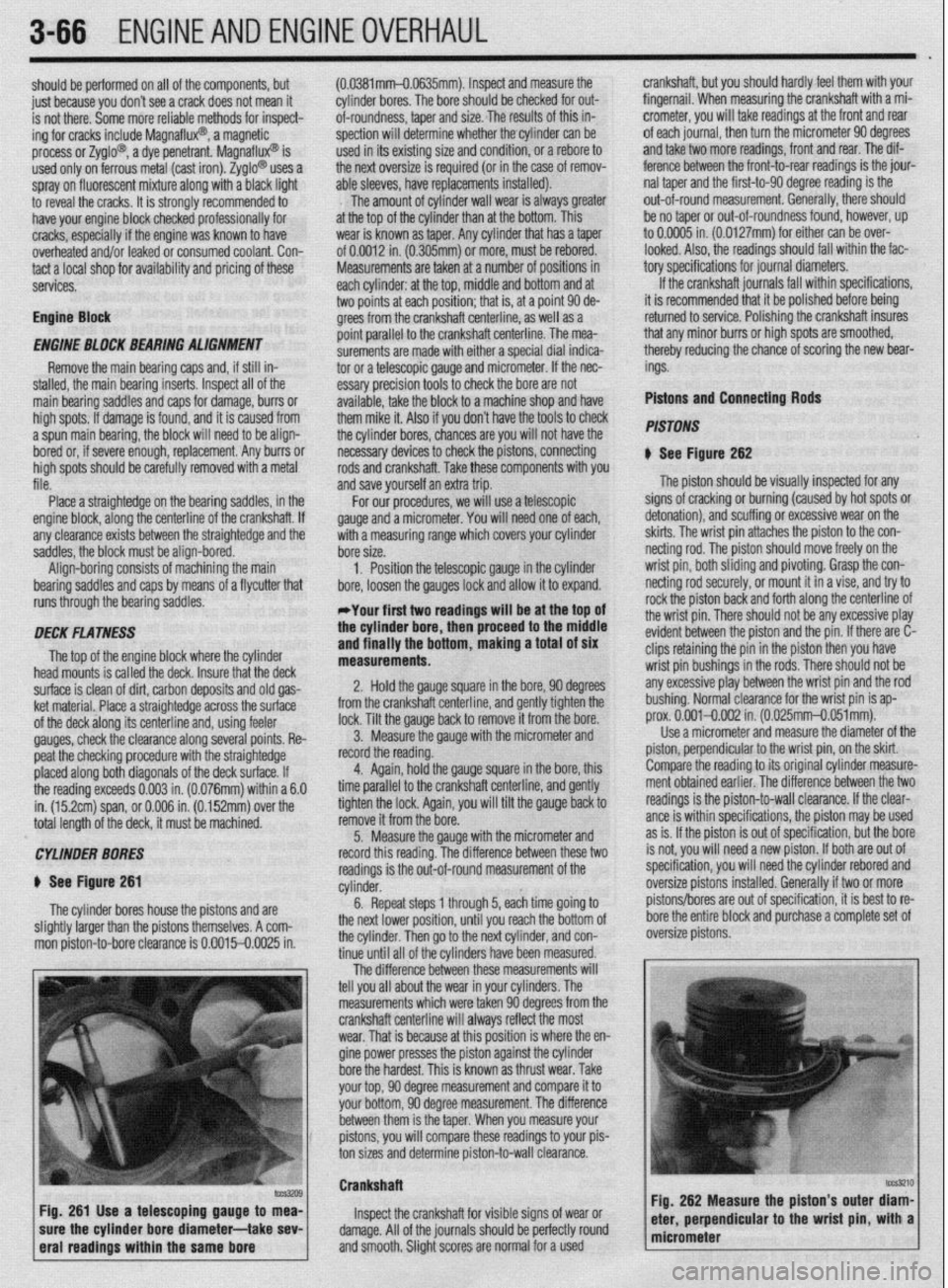

CYLINDER BORES

$ See Figure 261

The cylinder bores house the pistons and are

slightly larger than the pistons themselves. A com-

mon piston-to-bore clearance is 0.0015-0.0025 in. (0.0381mm-O.0635mm). Inspect and measure the

cylinder bores. The bore should be checked for out-

of-roundness, taper and size. The results of this in-

spection will determine whether thecylinder can be

used in its existing size and condition, or a rebore to

the next oversize is required (or in the case of remov-

able sleeves, have replacements installed).

The amount of cylinder wall wear is always greater

at the top of the cylinder than at the bottom. This

wear is known as taper. Any cylinder that has a taper

of 0.0012 in. (0.305mm) or more, must be rebored.

Measurements are taken at a number of positions in

each cylinder: at the top, middle and bottom and at

two points at each position; that is, at a point 90 de-

grees from the crankshaft centerline, as well as a

point parallel to the crankshaft centerline. The mea-

surements are made with either a special dial indica-

tor or a telescopic gauge and micrometer. If the nec-

essary precision tools to check the bore are not

available, take the block to a machine shop and have

them mike it. Also if you don’t have the tools to check

the cylinder bores, chances are you will not have the

necessary devices to check the pistons, connecting

rods and crankshaft. Take these components with you

and save yourself an extra trip.

For our procedures, we will use a telescopic

gauge and a micrometer. You will need one of each,’

with a measuring range which covers your cylinder

bore size.

1, Position the telescopic gauge in the cylinder

bore, loosen the gauges lock and allow it to expand.

*Your first two readings will be at the top of

the cylinder bore, then proceed to the middle

and finally the bottom, making a total of six

measurements.

2. Hold the gauge square in the bore, 90 degrees

from the crankshaft centerline, and gently tighten the

lock. Tilt the gauge back to remove it from the bore.

3. Measure the gauge with the micrometer and

record the reading.

4. Again, hold the gauge square in the bore, this

time parallel to the crankshaft centerline, and gently

tighten the lock. Again, you will tilt the gauge back to

remove it from the bore.

5. Measure the gauge with the micrometer and

record this reading. The difference between these two

readings is the out-of-round measurement of the

cylinder.

6. Repeat steps 1 through 5, each time going to

the next lower position, until you reach the bottom of

the cylinder. Then go to the next cylinder, and con-

tinue until all of the cylinders have been measured.

The difference between these measurements will

tell you all about the wear in your cylinders. The

measurements which were taken 90 degrees from the

crankshaft centerline will always reflect the most

wear.,That is because at this position is where the en-

gine power presses the piston against the cylinder

bore the hardest. This is known as thrust wear. Take

your top, 90 degree measurement and compare it to

your bottom, 90 degree measurement. The difference

between them is the taper. When you measure your

pistons, you will compare these readings to your pis-

ton sizes and determine piston-to-wall clearance. crankshaft, but you should hardly feel them with your

fingernail. When measuring the crankshaft with a mi-

crometer, you will take readings at the front and rear

of each journal, then turn the micrometer 90 degrees

and take two more readings, front and rear. The dif-

ference between the front-to-rear readings is the jour-

nal taper and the first-to-90 degree reading is the

out-of-round measurement. Generally, there should

be no taper or out-of-roundness found, however, up

to 0.0005 in. (0.0127mm) for either can be over-

looked. Also, the readings should fall within the fac-

tory specifications for journal diameters.

If the crankshaft journals fall within specifications,

it is recommended that it be polished before being

returned to service. Polishing the crankshaft insures

that any minor burrs or high spots are smoothed,

thereby reducing the chance of scoring the new bear-

ings.

Pistons and Connecting Rods

PISTONS

N See Figure 262

The piston should be visually inspected for any

signs of cracking or burning (caused by hot spots or

detonation), and scuffing or excessive wear on the

skirts. The wrist pin attaches the piston to the con-

netting rod. The piston should move freely on the

wrist pin, both sliding and pivoting. Grasp the con-

netting rod securely, or mount it in a vise, and try to

rock the piston back and forth along the centerline of

the wrist pin. There should not be any excessive play

evident between the piston and the pin. If there are C-

clips retaining the pin in the piston then you have

wrist pin bushings in the rods. There should not be

any excessive play between the wrist pin and the rod

bushing. Normal clearance for the wrist pin is ap-

prox. 0.001-0.002 in. (0.025mm-0.051mm).

Use a micrometer and measure the diameter of the

piston, perpendicular to the wrist pin, on the skirt.

Compare the reading to its original cylinder measure-

ment obtained earlier. The difference between the two

readings is the piston-to-wall clearance. If the clear-

ante is within specifications, the piston may be used

as is. If the piston is out of specification, but the bore

is not, you will need a new piston. If both are out of

specification, you will need the cylinder rebored and

oversize pistons installed. Generally if two or more

pistons/bores are out of specification, it is best to re-

bore the entire block and purchase a complete set of

oversize pistons.

Crankshaft

Inspect the crankshaft for visible signs of wear or

damage. All of the journals should be perfectly round

and smooth. Slight scores are normal for a used

Page 128 of 408

ENGINEANDENGINEOVERHAUL 3-67

CONNECTING ROD

You should have the connecting rod checked for

StraiQhtness at a machine shop. If the connecting rod

is bent, it will unevenly wear the bearing and piston,

as well as place greater stress on these components.

Any bent or twisted connecting rods must be re-

placed. If the rods are straight and the wrist pin clear-

ance is within specifications, then only the bearing

end of the rod need be checked. Place the connecting

rod into a vice, with the bearing inserts in place, in-

stall the cap to the rod and torque the fasteners to

specifications. Use a telescoping gauge and carefully

measure the inside diameter of the bearings. Com-

pare this reading to the rods original crankshaft jour-

nal diameter measurement. The difference is the oil

clearance. If the oil clearance is not within specifica-

tions, install new bearings in the rod and take another

.

specifica- L

need to

shop as the pistons must be installed in the con measurement. it the Clearance is still out of :

tions, and the crankshaft is not, the rod will

be reconditioned by a machine shop.

*You can also use Plastigage’

@to check the

bearing clearances. The assen- . ...= - _______

Mm sectinn has complete instructions on its use.

Camshaft

Inspect the camshaft and lifters/followers as de

scribed earlier in this section.

Bearings

All of the enaine bearinos should be visuallv in-

~~~ I~ .- - -- ..-_-..,

spected for we; and/or damage. The bearing should

look evenly worn all around with no deep scores or

pits. If the bearing is severely worn, scored, pitted or

heat blued, then the bearing, and the components

that use it, should be brought to a machine shop for

block. ,ect

relationshipto the rod or engine damage can occur,

Pistons and Connecting Rods

I

b See Fiaute 264 --- --*------

Only pistons with the wrist pin retained by C-clips

are serviceable by the home-mechanic. Press fit pis-

tons require special presses and/or heaters to re- I”

rr

rove/install the connecting rod and should only be

PC srformed by a machine shop.

All pistons will have a mark indicating the direc-

tir 9n to the front of the engine and the must be in-

stalled into the engine in that manner. Usually it is a

notch or arrow on the top of the piston, or it may be

the letter F cast or stamped into the piston.

ASEtiBlY

1

crankshaft. Replace any freeze or oil galley plugs

which were removed during disassembly.

Crankshaft

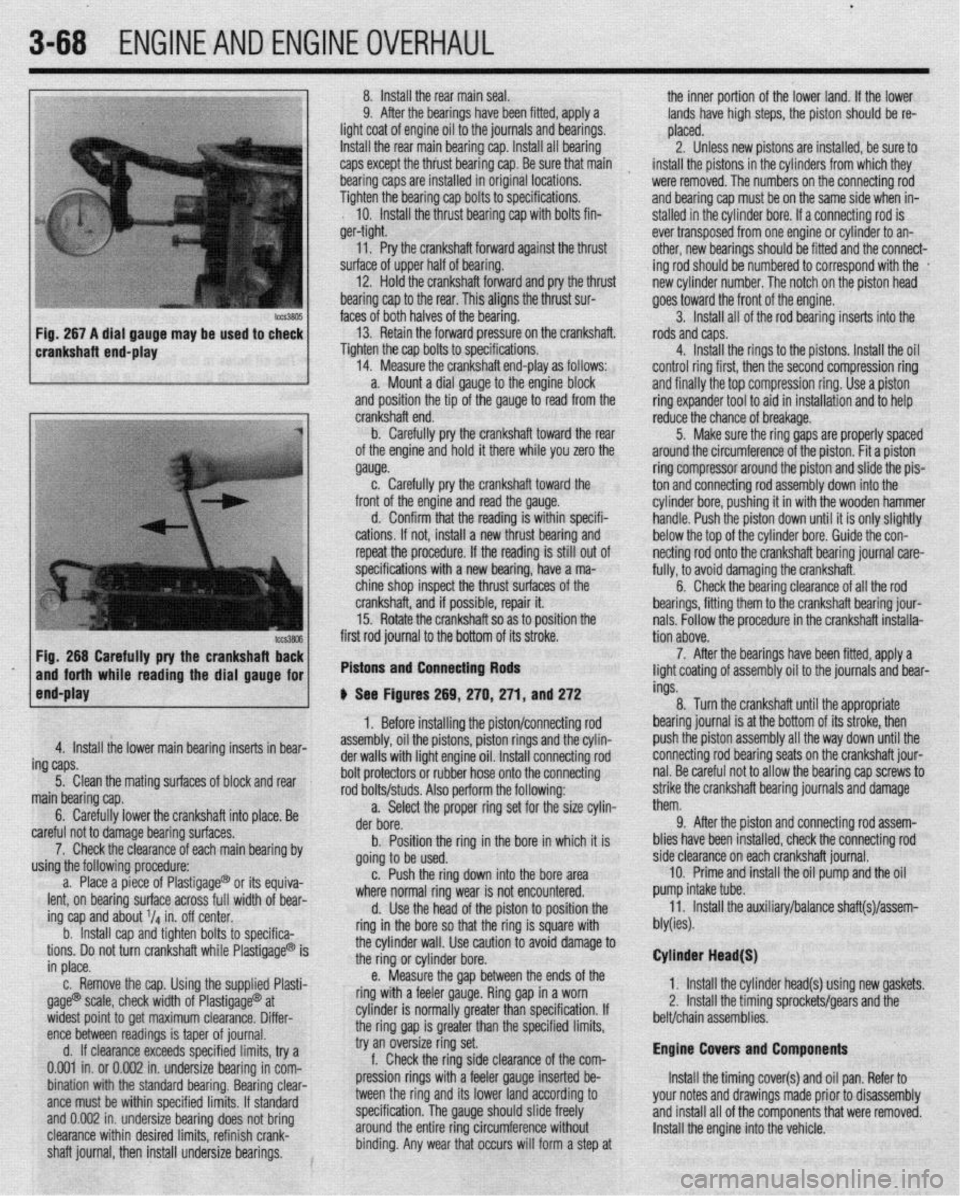

u See Figures 265, 266, 267, and 266

1. Remove the main bearing inserts from the

block and bearing caps.

2. If the crankshaft main bearing journals have

been refinished to a definite undersize, install the

correct undersize bearina. Be sure that the bearina

inserts and bearing bores are clean. Foreign mateiial

under inserts will distort bearinq and cause failure.

3. Place the upper main bearing inserts in bores

*The oil holes in the bearing inserts must

be aligned with the oil holes in the cylinder

. . .

inspection. Full-circle bearings (used on most

camshafts, auxiliary shafts, balance shafts, etc.) re-

quire specialized tools for removal and installation, ’

and should be brought to a machine shop for service.

Oil Pump Before you begin assembling the engine, first give

yourself a clean, dirt free work area. Next, clean every

engine component again. The key to a QOOd assem-

hhr io da~nlinmw “‘I Ia ~rGiOllll,lc7.Ja. Mount the engine block into the engine stand and

II

*The oil pump is responsible fo

r providing wasn It one last time usmg water and detergent (dish-

unrhinn rldarnant ~nrirc well), While washing it, with a soft bristle brush and

: oil oassaoes. Comoletelv constant lubrication to the whole engine and 1ILl.M 0, ,y “GSGl ycx II ““1 n

so it is recommended that a new oil pump be scrub the cylinder bore:

installed when rebuilding the engine. thoroughly clean all oft

dry the engine and spra

Completely disassemble the oil pump and thor- with an anti-rust solutio

oughly clean all of the components. Inspect the oil

pro

pump Qears and housing for wear and/or damage. In- exe

sure that the pressure relief valve operates properly sac

and there is no binding or sticking due to varnish or

debris. If all of the parts are in proper working condi-

tion, lubricate the gears and relief valve, and assem-

r

j ht

y the entire assembly down’

in such as WD-4Q@ or similar Fig. 265 Apply a strip of gauging material

Iduct. Take a clean lint-free rag and wipe up any

less anti-rust solution from the bores, bearing

Idles, etc. Repeat the final cleaning process on the !torguethe~~p * ,’ / to the bearmg lournal, then mstall and

ble the pump.

REFINISHING

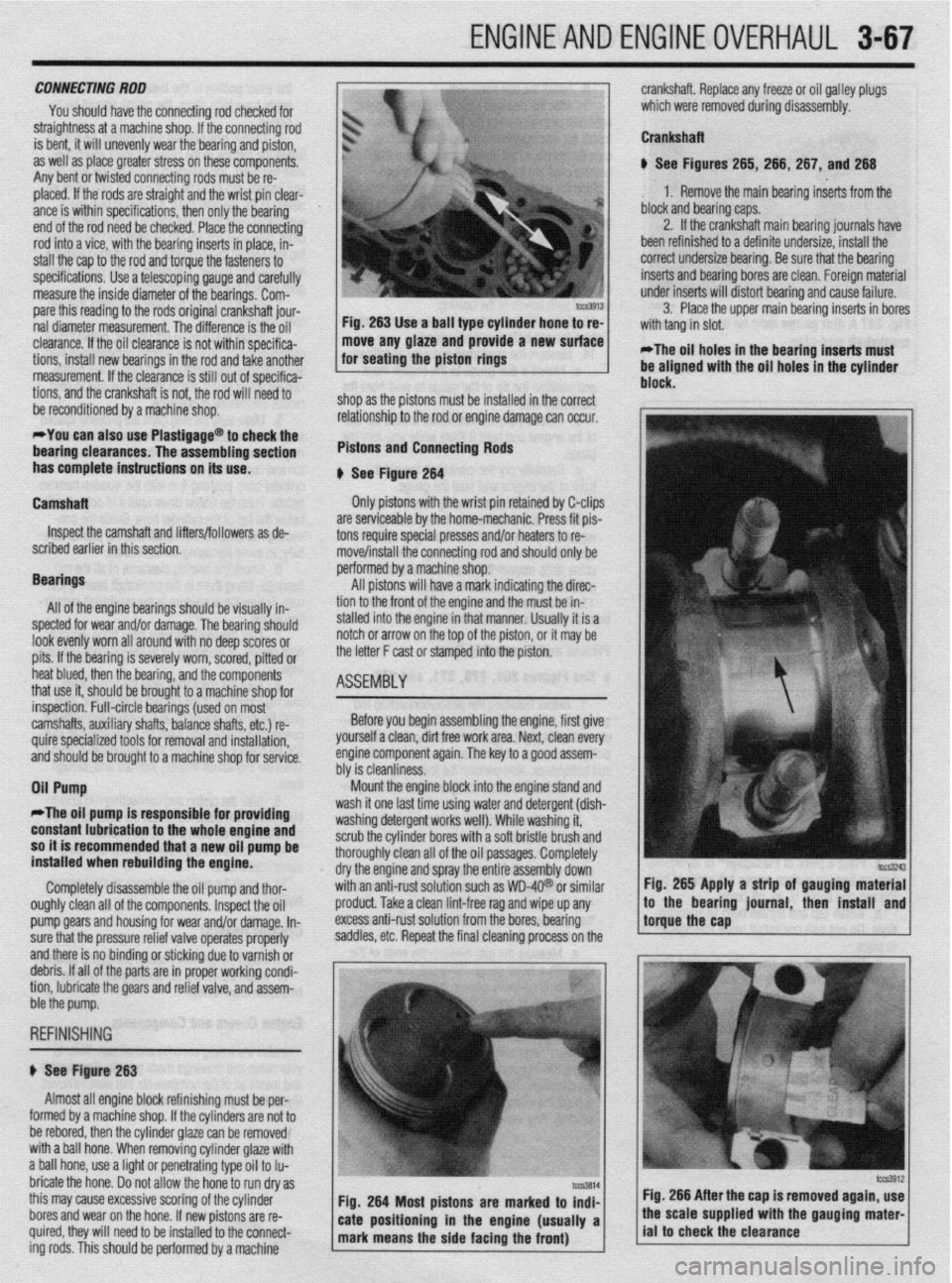

# See Figure 263

Almost all engine block refinishing must be per-

I

IUIIII~U uy a macnme snap. ir me cynnoers are nor ro

be rebored, then the cylinder glaze can be removed

with a ball hone. When removing cylinder glaze with

a ball hone, use a light or penetrating type oil to Iu-

bricate the hone. Do not allow the hone to run dry as

this may cause excessive scoring of the cylinder

bores and wear on the hone. If new pistons are re-

quired, they will need to be installed to the connect-

ing rods. This should be oerformed bv a machine Fig. 266 After the cap is removed again, use

Page 129 of 408

.

3-68 ENGINEANDENGINEOVERHAUL

crankshaft end-play 8. Install the rear main seal.

the inner portion of the lower land. If the lower

9. After the bearings have been fitted, apply a

lands have high steps, the piston should be re-

light coat of engine oil to the journals and bearings.

placed.

Install the rear main bearing cap. Install all bearing

2. Unless new pistons are installed, be sure to

caps except the thiust bearing cap. Be sure that main

I

install the pistons in the cylinders from which they

bearing caps are installed in original locations.

were removed. The numbers on the connecting rod

Tighten the bearing cap bolts to specifications.

and bearing cap must be on the same side when in-

10. Install the thrust bearing cap with bolts fin-

stalled in the cylinder bore. If a connecting rod is

ger-tight.

ever transposed from one engine or cylinder to an-

11. Pry the crankshaft forward against the thrust

other, new bearings should be fitted and the connect-

surface of upper half of bearing.

ing rod should be numbered to correspond with the *

12. Hold the crankshaft forward and pry the thrust

new cylinder number. The notch on the piston head

bearing cap to the rear. This aligns the thrust sur-

goes toward the front of the engine.

faces of both halves of the bearing.

3. Install all of the rod bearing inserts into the

13. Retain the forward pressure on the crankshaft.

rods and caps.

Tighten the cap bolts to specifications.

4. Install the rings to the pistons. Install the oil

14. Measure the crankshaft end-play as follows:

control ring first, then the second compression ring

a. Mount a dial gauge to the engine block

and finally the top compression ring. Use a piston

and position the tip of the gauge to read from the

ring expander tool to aid in installation and to help

Fig. 266 Carefully pry the crankshafl Ez

and forth while reading the dial gauge for

end-play first rod journal to the bottom of its stroke.

Pistons and Connecting Rods

4. Install the lower main bearing inserts in bear-

ing caps.

5. Clean the mating surfaces of block and rear

main bearing cap.

6. Carefully lower the crankshaft into place. Be

careful not to damage bearing surfaces.

7. Check the clearance of each main bearing by

using the following procedure:

a. Place a piece of Plastigage@ or its equiva-

lent, on bearing surface across full width of bear-

ing cap and about V4 in. off center.

b. Install cap and tighten bolts to specifica-

tions. Do not turn crankshaft while Plastigage@ is

in place.

c. Remove the cap. Using the supplied Plasti-

gage@ scale, check width of Plastigage@ at

widest point to get maximum clearance. Differ-

ence between readings is taper of journal.

d. If clearance exceeds specified limits, try a

0.001 in. or 0.002 in. undersize bearing in com-

bination with the standard bearing. Bearing clear-

ante must be within specified limits. If standard

and 0.002 in. undersize bearing does not bring

clearance within desired limits, refinish crank-

shaft journal, then install undersize bearings. crankshaft end.

b. Carefully pry the crankshaft toward the rear

of the engine and hold it there while you zero the

gauge.

c. Carefully pry the crankshaft toward the

front of the engine and read the gauge.

d. Confirm that the reading is within specifi-

cations. If not, install a new thrust bearing and

repeat the procedure. If the reading is still out of

specifications with a new bearing, have a ma-

chine shop inspect the thrust surfaces of the

crankshaft, and if possible, repair it.

15. Rotate the crankshaft so as to position the

# See Figures 269, 270,271, and 272

1. Before installing the piston/connecting rod

assembly, oil the pistons, piston rings and the cylin-

der walls with light engine oil. Install connecting rod

bolt protectors or rubber hose onto the connecting

rod bolts/studs. Also perform the following:

a. Select the proper ring set for the size cylin-

der bore.

b. Position the ring in the bore in which it is

going to be used.

c. Push the ring down into the bore area

where normal ring wear is not encountered.

d. Use the head of the piston to position the

ring in the bore so that the ring is square with

the cylinder wall. Use caution to avoid damage to

the ring or cylinder bore.

e. Measure the gap between the ends of the

ring with a feeler gauge. Ring gap in a worn

cylinder is normally greater than specification. If

the ring gap is greater than the specified limits,

try an oversize ring set.

f. Check the ring side clearance of the com-

pression rings with a feeler gauge inserted be-

tween the ring and its lower land according to

specification. The gauge should slide freely

around the entire ring circumference without

binding. Any wear that occurs will form a step at reduce the chance of breakage.

5. Make sure the ring gaps are properly spaced

around the circumference of the piston. Fit a piston

ring compressor around the piston and slide the pis-

ton and connecting rod assembly down into the

cylinder bore, pushing it in with the wooden hammer

handle. Push the piston down until it is only slightly

below the top of the cylinder bore. Guide the con-

netting rod onto the crankshaft bearing journal care-

fully, to avoid damaging the crankshaft.

6. Check the bearing clearance of all the rod

bearings, fitting them to the crankshaft bearing jour-

nals. Follow the procedure in the crankshaft installa-

tion above.

7. After the bearings have been fitted, apply a

light coating of assembly oil to the journals and bear-

ings.

8. Turn the crankshaft until the appropriate

bearing journal is at the bottom of its stroke, then

push the piston assembly all the way down until the

connecting rod bearing seats on the crankshaft jour-

nal. Be careful not to allow the bearing cap screws to

strike the crankshaft bearing journals and damage

them.

9. After the piston and connecting rod assem-

blies have been installed, check the connecting rod

side clearance on each crankshaft journal.

10. Prime and install the oil pump and the oil

pump intake tube.

11. Install the auxiliary/balance shaft(s)/assem-

bly(ies).

Cylinder Head(S)

1. Install the cylinder head(s) using new gaskets.

2, Install the timing sprockets/gears and the

belt/chain assemblies.

Engine Covers and Components

Install the timing cover(s) and oil pan. Refer to

your notes and drawings made prior to disassembly

and install all of the components that were removed.

Install the engine into the vehicle.

Page 207 of 408

I

6-4 CHASSIS ELECTRICAL

I

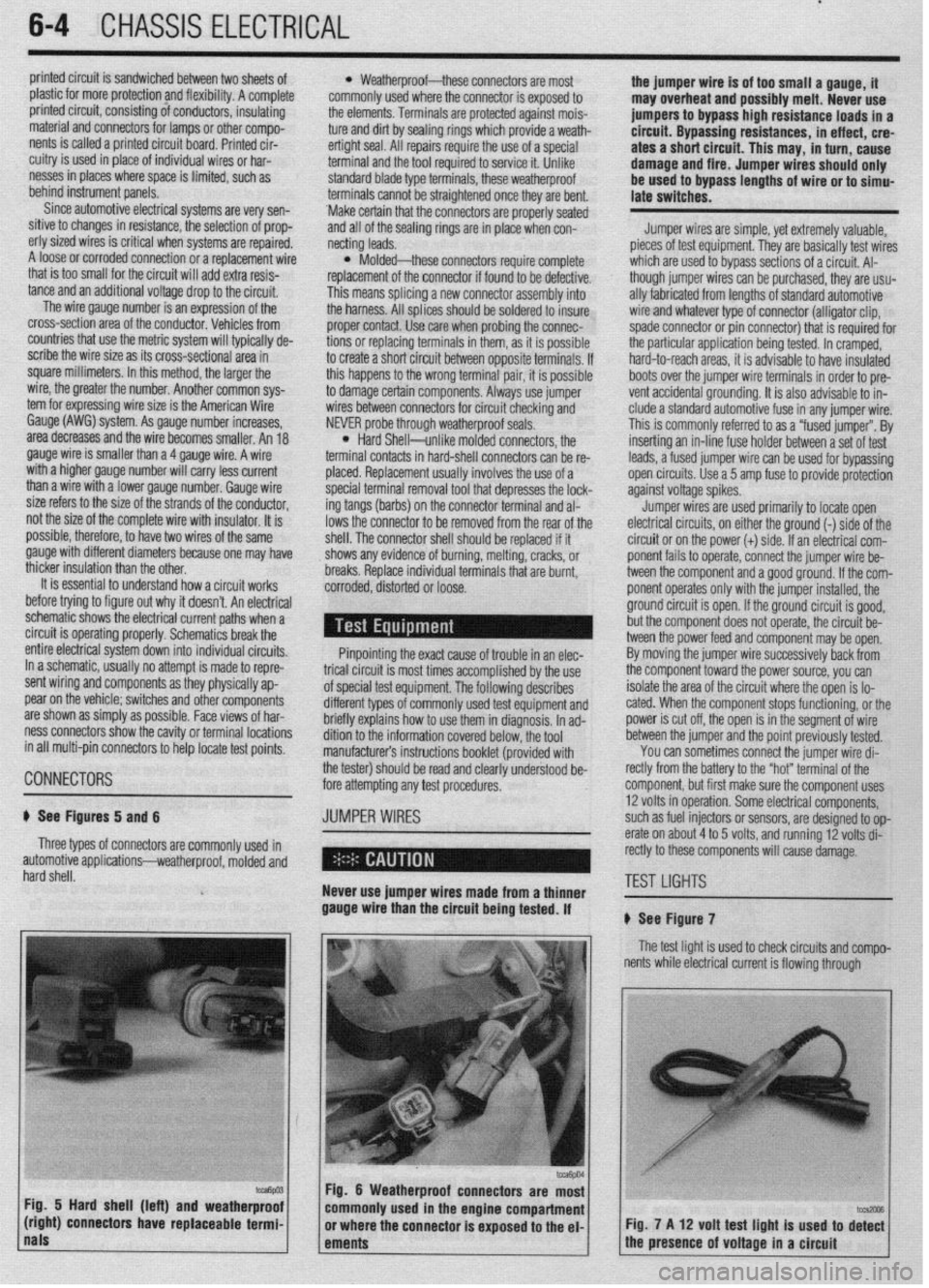

printed circuit is sandwiched between two sheets of

plastic for more protection and flexibility. A complete l Weatherproof-these connectors are most the jumper wire is of too small a gauge, it

printed circuit, consisting of conductors, insulating commonly used where the connector is exposed to

may overheat and possibly melt. Never use

material and connectors for lamps or other compo- the elements. Terminals are protected against mois-

nents is called a printed circuit board. Printed cir- ture and dirt by sealing rings which provide a weath- jumpers to bypass high resistance loads in a

et-tight seal. All repairs require the use of a special circuit. Bypassing resistances, in effect, cre-

cuitry is used in place of individual wires or har- ates a short circuit. This may, in turn, cause

nesses in places where space is limited, such as terminal and the tool required to service it. Unlike

behind instrument panels. standard blade type terminals, these weatherproof damage and fire. Jumper wires should only

be used to bypass lengths of wire or to simu-

Since automotive electrical systems are very sen- terminals cannot be straightened once they are bent. late switches.

sitive to changes in resistance, the selection of prop- ‘Make certain that the connectors are properly seated

erly sized wires is critical when systems are repaired, and all of the sealing rings are in place when con-

netting leads. Jumper wires are simple, yet extremely valuable,

A loose or corroded connection or a replacement wire pieces of test equipment. They are basically test wires

that is too small for the circuit will add extra resis-

l Molded-these connectors require complete which are used to bypass sections of a circuit. Al-

replacement of the connector if found to be defective.

tance and an additional voltage drop to the circuit. though jumper wires can be purchased, they are usu-

The wire gauge number is an expression of the This means splicing a new connector assembly into ally fabricated from lengths of standard automotive

cross-section area of the conductor. Vehicles from the harness. All splices should be soldered to insure

proper contact. Use care when probing the connec- wire and whatever type of connector (alligator clip,

countries that use the metric system will typically de- spade connector or pin connector) that is required for

scribe the wire size as its cross-sectional area in tions or replacing terminals in them, as it is possible

square millimeters. In this method, the larger the to create a short circuit between opposite terminals. If the particular application being tested. In cramped,

hard-to-reach areas, it is advisable to have insulated

wire, the greater the number. Another common sys- this happens to the wrong terminal pair, it is possible

to damage certain components. Always use jumper boots over the jumper wire terminals in order to pre-

tern for expressing wire size is the American Wire vent accidental grounding. It is also advisable to in-

Gauge (AWG) system. As gauge number increases, wires between connectors for circuit checking and

NEVER probe through weatherproof seals. elude a standard automotive fuse in any jumper wire.

area decreases and the wire becomes smaller. An 18

gauge wire is smaller than a 4 gauge wire. A wire

l Hard Shell-unlike molded connectors, the This is commonly referred to as a “fused jumper”. By

inserting an in-line fuse holder between a set of test

terminal contacts in hard-shell connectors can be re-

with a higher gauge number will carry less current

placed. Replacement usually involves the use of a leads, a fused jumper wire can be used for bypassing :

than a wire with a lower gauge number. Gauge wire open circuits. Use a 5 amp fuse to provide protection

size refers to the size of the strands of the conductor, special terminal removal tool that depresses the lock- against voltage spikes.

not the size of the complete wire with insulator. It is ing tangs (barbs) on the connector terminal and al-

lows the connector to be removed from the rear of the Jumper wires are used primarily to locate open

possible, therefore, to have two wires of the same

shell. The connector shell should be replaced if it electrical circuits, on either the ground (-) side of the

gauge with different diameters because one may have

thicker insulation than the other. shows any evidence of burning, melting, cracks, or circuit or on the power (+) side. If an electrical corn-

breaks. Replace individual terminals that are burnt, ponent fails to operate, connect the jumper wire be-

It is essential to understand how a circuit works

corroded, distorted or loose. tween the component and a good ground. If the corn-

before trying to figure out why it doesn’t. An electrical ponent operates only with the jumper installed, the

schematic shows the electrical current paths when a ground circuit is open. If the ground circuit is good,

circuit is operating properly. Schematics break the but the component does not operate, the circuit be-

entire electrical system down into individual circuits. tween the power feed and component may be open. ’

In a schematic, usually no attempt is made to repre- Pinpointing the exact cause of trouble in an elec- By moving the jumper wire successively back from

trical circuit is most times accomplished by the use the component toward the power source, you can

; : sent wiring and components as they physically ap-

pear on the vehicle; switches and other components of special test equipment. The following describes isolate the area of the circuit where the open is lo-

are shown as simply as possible. Face views of har- different types of commonly used test equipment and cated. When the component stops functioning, or the f

j

ness connectors show the cavity or terminal locations briefly explains how to use them in diagnosis. In ad- power is cut off, the open is in the segment of wire j

in all multi-pin connectors to help locate test points. dition to the information covered below, the tool between the jumper and the point previously tested.

! manufacturer’s instructions booklet (provided with You can sometimes connect the jumper wire di-

the tester) should be read and clearly under.$ood be- rectly from the battery to the “hot” terminal of the I

CONNECTORS 1 fore attempting any test procedures. component, but first make sure the component uses 1

# See Figures 5 and 6 JUMPER WIRES 12 volts in operation. Some electrical components, i

such as fuel injectors or sensors, are designed to op-

Three types of connectors are commonly used in erate on about 4 to 5 volts, and running 12 volts di- j

)

automotive applications-weatherproof, molded and rectly to these components will cause damage.

hard shell.

Never use jumper wires made from a thinner TEST LIGHTS I

gauge wire than the circuit being tested. If

# See Figure 7

The test light is used to check circuits and compo-

I nents while electrical current is flowing through

Fig. 5 Hard shell (left) and weatherproof

(right) connectors have replaceable termi- Fig. 7 A 12 volt test light is used to di%

nals

ements 1 the presence of voltage in a circuit

Page 294 of 408

DRIVETRAiN 7-15

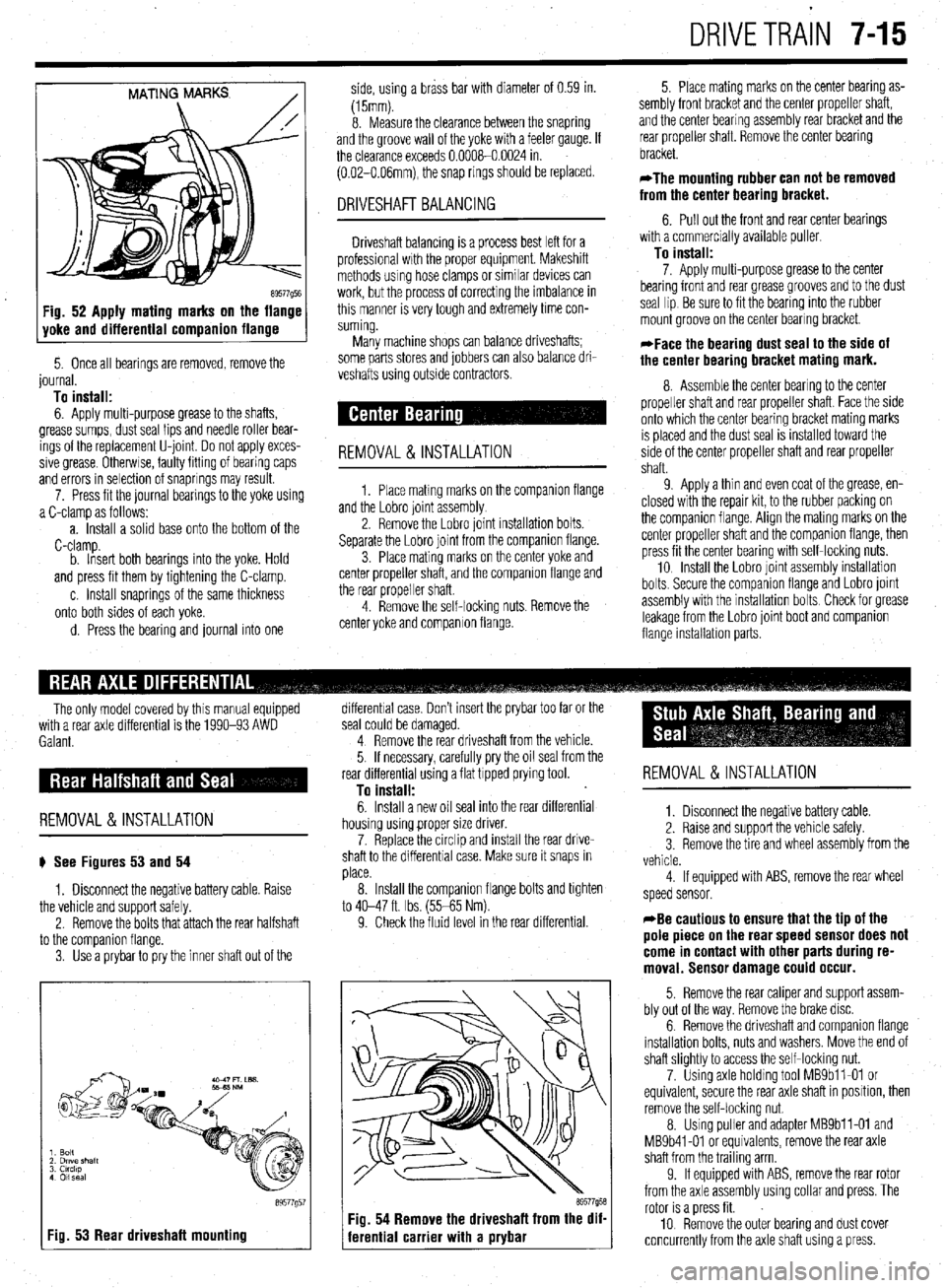

MATING MARKS

/

89577Q5E Fig. 52 Apply mating marks on the flange

yoke and differential companion flange

5. Once all bearings are removed, remove the

journal.

To install:

6. Apply multi-purpose grease to the shafts,

grease sumps, dust seal lips and needle roller bear-

ings of the replacement U-joint Do not apply exces-

sive grease Otherwse, faulty fitting of bearing caps

and errors in selection of snaprings may result.

7. Press fit the journal bearings to the yoke using

a C-clamp as follows:

a. Install a solid base onto the bottom of the

C-clamp.

b. Insert both bearings into the yoke. Hold

and press fit them by tightening the C-clamp.

c. Install snaprings of the same thickness

onto both sides of each yoke.

d. Press the bearing and journal into one side, using a brass bar with diameter of 0.59 in.

(15mm).

8. Measure the clearance between the snapring

and the groove wall of the yoke with a feeler gauge. If

the clearance exceeds 0.0008-0.0024 in.

(0.02-O.O6mm), the snap rings should be replaced.

DRIVESHAFT BALANCING

Driveshaft balancing is a process best left for a

professional wrth the proper equipment. Makeshift

methods using hose clamps or similar devices can

work, but the process of correcting the imbalance in

this manner is very tough and extremely time con-

suming.

Many machine shops can balance driveshafts;

some parts stores and jobbers can also balance dri-

veshafts using outside contractors.

REMOVAL&INSTALLATION

1. Place matmg marks on the companron flange

and the Lobro joint assembly

2. Remove the Lobro joint installation bolts.

Separate the Lobro joint from the companion flange.

3. Place mating marks on the center yoke and

center propeller shaft, and the companion flange and

the rear propeller shaft.

4. Remove the self-locking nuts. Remove the

center yoke and companion flange. 5. Place mating marks on the center bearing as-

sembly front bracket and the center propeller shaft,

and the center bearing assembly rear bracket and the

rear propeller shaft. Remove the center bearing

bracket.

*The mounting rubber can not be removed

from the center bearing bracket.

6. Pull out the front and rear center bearings

with a commercially available puller

To install:

7. Apply multi-purpose grease to the center

bearing front and rear grease grooves and to the dust

seal lip Be sure to fit the bearing into the rubber

mount groove on the center bearing bracket.

*Face the bearing dust seal to the side of

the center bearing bracket mating mark.

8. Assemble the center bearing to the center

propeller shaft and rear propeller shaft. Face the side

onto which the center bearing bracket mating marks

IS placed and the dust seal is installed toward the

side of the center propeller shaft and rear propeller

shaft.

9 Apply a thin and even coat of the grease, en-

closed with the repair kit, to the rubber packing on

the companion flange. Align the mating marks on the

center propeller shaft and the companion flange, then

press fit the center bearing with self-locking nuts.

10 Install the Lobro joint assembly installation

bolts. Secure the companron flange and Lobro joint

assembly with the installation bolts Check for grease

leakage from the Lobro joint boot and companion

flange installabon parts.

The only model covered by this manual equipped

with a rear axle differential is the 1990-93 AWD

Galant.

REMOVAL &INSTALLATION

# See Figures 53 and 54

1. Disconnect the negative battery cable. Raise

the vehicle and support safely.

2. Remove the bolts that attach the rear halfshaft

to the comoanion flanae.

3. Use’a prybar topry the inner shaft out of the

I Fig. 53 Rear driveshaft mounting

89577g5

differential case. Don’t insert the prybar too far or the

seal could be damaged.

4 Remove the rear driveshaft from the vehicle.

5. If necessary, carefully pry the oil seal from the

rear differential using a flat tipped prying tool.

To install:

6. Install a new oil seal into the rear differential

housing using proper size driver.

7. Replace the circlip and install the rear drive-

shaft to the differential case. Make sure it snaps in

place.

8. Install the companion flange bolts and tighten

to 40-47 ft. Ibs. (55-65 Nm).

9. Check the fluid level in the rear differential.

69577958 Fig. 54 Remove the driveshaft from the dif-

ferential carrier with a prybar

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable.

2. Raise and support the vehicle safely.

3 Remove the tire and wheel assembly from the

vehicle.

4 If equipped with ABS, remove the rear wheel

speed sensor.

*Be cautious to ensure that the tip of the

pole piece on the rear speed sensor does not

come in contact with other parts during re-

moval. Sensor damage could occur.

5. Remove the rear caliper and support assem-

bly out of the way. Remove the brake disc.

6. Remove the driveshaft and companion flange

installation bolts, nuts and washers. Move the end of

shaft slightly to access the self-locking nut.

7. Using axle holding tool MBSbll-01 or

equivalent, secure the rear axle shaft in position, then

remove the self-locking nut.

8. Using puller and adapter MBSbll-01 and

MB9b41-01 or equivalents, remove the rear axle

shaft from the trailing arm

9. If equipped with ABS, remove the rear rotor

from the axle assembly using collar and press. The

rotor is a press fit.

10 Remove the outer bearing and dust cover

concurrently from the axle shaft using a press.

Page 322 of 408

8-26 SUSPENSION AND STEERING

torqued to specifications. The wheel bearings are

sealed units and are not adjustable. If defective, re-

placement is the only option.

REMOVAL &INSTALLATION

Mirage

7996-92 MODELS

1. Raise the vehicle and support safely.

2. Remove the tire and wheel assembly.

3. If equipped with rear disc brakes, remove the

caliper from the disc and remove the brake disc.

4. Remove the dust cap and bearing nut. Do not

use an air gun to remove the nut.

5. Remove the outer wheel bearing.

6. Remove the drum and/or axle hub with the

inner wheel bearing and the grease seal.

7. Remove the grease seal and remove the inner

bearing.

To install: 8. Lubricate the inner bearing and install to the

drum or hub.

9. Install a new grease seal.

10. To determine if the self-locking nut is

reusable:

a. Screw in the self-locking nut until about

0.07-0.11 in. (2-3mm) of thread is visible under

the nut.

b. Measure the torque required to turn the

self-locking nut counterclockwise.

c. The lowest allowable torque is 48 inch Ibs.

(6 Nm). If the measured torque is less than the

specification, replace the nut.

11. Install the drum and/or hub to the vehicle.

12. Lubricate and install the outer wheel bearing

to the spindle.

13. Tighten the self-locking nut to 108-145 ft.

Ibs. (150-200 Nm).

14. Set up a dial indicator and measure the end-

play while moving the hub or drum in and out. If the

endplay exceeds 0.008 in. (0.002mm) retorque the

nut. If still beyond the limit, replace the bearings.

15. Install the grease cap and wheel assembly.

7993-60 MODELS

*Never disassemble the rear hub bearing.

The wheel bearing is serviced by replace-

ment of the hub.

1. If equipped with ABS, remove the wheel

speed sensor.

2. Raise and safely support the vehicle.

3. Remove the rear wheel.

4. Remove the caliper and brake disc or brake

drum.

5. Remove the dust cap and flange nut.

6. Remove the rear hub assembly.

To install: 7. Install the rear hub assembly using a new

flange nut. Tighten the flange nut to 130 ft. Ibs. (180

Nm).

8. install the dust cap.

9. Install the wheel speed sensor if removed.

The air gap should be 0.012-0.035 in. (0.3-0.9mm).

10. Install the brake disc and caliper, or brake

drum.

11. Install the rear wheel assembly and lower the

vehicle to the floor.

1990-93 Galant

DRUM BRAKE VEHICLES

1. Raise the vehicle and support it safely.

2. Remove the wheel and tire assemblies.

3. Remove the grease cap and the hub nut.

4. Remove the brake drum. The outer bearing

will fall out while the drum is coming off. Do not drop

it. Remove the hub and rotor assembly.

5. Pry out and discard the oil seal.

6. Remove the inner bearing.

*Check the bearing races. If any scoring,

heat checking or damage is noted, they

should be replaced. When bearing or races

need replacement, replace them as a set.

7. If the bearings and races are to be replaced,

drive out the race with a brass drift.

To install: 8. Before installing new races, coat them with

wheel bearing grease. Drive into place with proper

size driver. Make sure they are fully seated.

9. Thoroughly pack the bearings and lubricate

the hubs with wheel bearing grease. Install the inner

bearing and coat the lip and rim of the grease seal

with grease. Drive the seal into place with a seal dri-

ver.

10. Install the drum assembly on the axle.

11, Lubricate and install the outer wheel bearing,

washer and nut. To properly adjust the wheel bearing

preload:

a. Tighten the wheel bearing nut to 20 ft. Ibs.

(27 Nm) while rotating the drum.

b. Back off the adjusting nut to remove the

preload, then tighten it to 7 ft. Ibs. (10 Nm).

c. Install the nut lock and a new cotter pin.

12. Install the wheel and lower the vehicle.

O/SC BRAKE VEHICLES

1. Raise the vehicle and support safely.

2. Remove the tire and wheel assembly.

3. Remove the bolt(s) holding the speed sensor

bracket to the knuckle and remove the assembly from

the vehicle.

The speed sensor has a pole piece projecting

from it. This exposed tip must be protected

from impact or scratches. Do not allow the

oole oiece to contact the toothed wheel dur-

in0 removal or installation.

4. Remove the caliper from the brake disc and

suspend with a wire.

5. Remove the brake rotor.

6. Remove the grease cap, locking nut and

tongued washer.

7. Remove the rear hub and bearing assembly.

*The rear hub assembly can not be disas-

sembled. If bearing replacement is required,

replace the assembly as a unit.

8. If replacing the hub assembly, remove the

two bolts securing the speed sensor ring to the hub.

To install: 9. Install the speed sensor to the hub and bear-

ing assembly. Tighten the mounting bolts to 8 ft. Ibs.

(11 Nm). 10. Install the hub and bearing assembly to the

axle shaft.

11, Install the tongued washer and a new locking

nut. Tighten the locknut to 144-188 ft. Ibs. (200-260

Nm). Once the locknut has been properly torqued,

crimp the nut flange over the slot in the spindle, and

install the grease cap.

12. Install the brake caliper and rotor.

13. Install the speed sensor and tighten the

mounting bolt to 8 ft. Ibs. (11 Nm).

14. Install the tire and wheel assembly.

Be sure to pump the brake pedal until it’s

firm, before moving vehicle.

1994-00 Galant

DRUM BRAKE VEHICLES

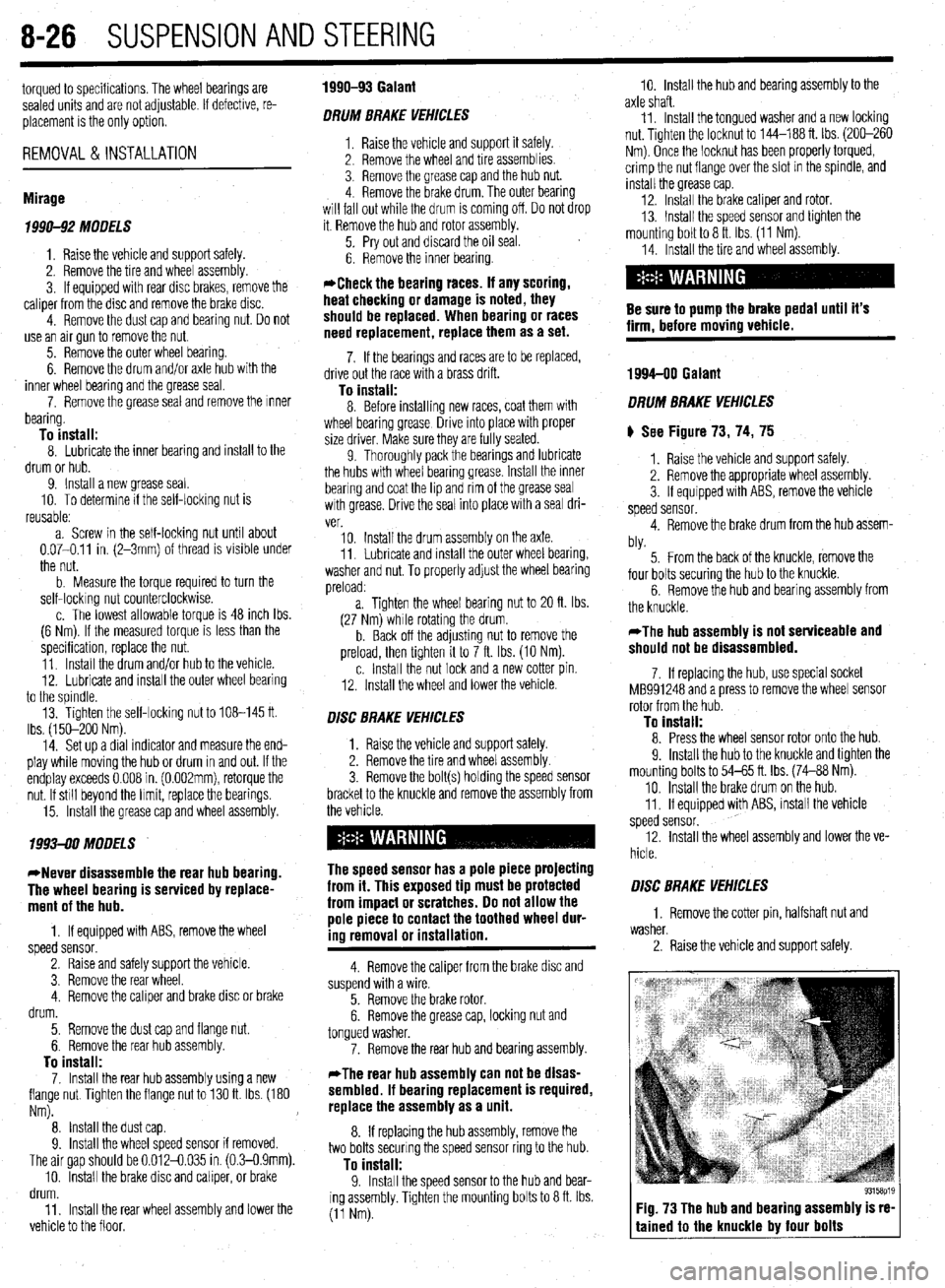

) See Figure 73, 74, 75

1. Raise the vehicle and support safely.

2. Remove the appropriate wheel assembly.

3. If equipped with ABS, remove the vehicle

speed sensor.

4. Remove the brake drum from the hub assem-

bly.

5. From the back of the knuckle, remove the

four bolts securing the hub to the knuckle.

6. Remove the hub and bearing assembly from

the knuckle.

*The hub assembly is not serviceable and

should not be disassembled.

7. If replacing the hub, use special socket

MB991248 and a press to remove the wheel sensor

rotor from the hub.

To install: 8. Press the wheel sensor rotor onto the hub.

9. Install the hub to the knuckle and tighten the

mounting bolts to 54-65 ft. Ibs. (74-88 Nm).

10. Install the brake drum on the hub.

11. If equipped with ABS, install the vehicle

speed sensor.

12. Install the wheel assembly and lower the ve-

hicle.

O/SC BRAKE VEHICLES

1. Remove the cotter pin, halfshaft nut and

washer.

2. Raise the vehicle and support safely.

Fig. 73 The hub and bearing assembly is re-

tained to the knuckle by four bolts

Page 349 of 408

BRAKiS 9-13

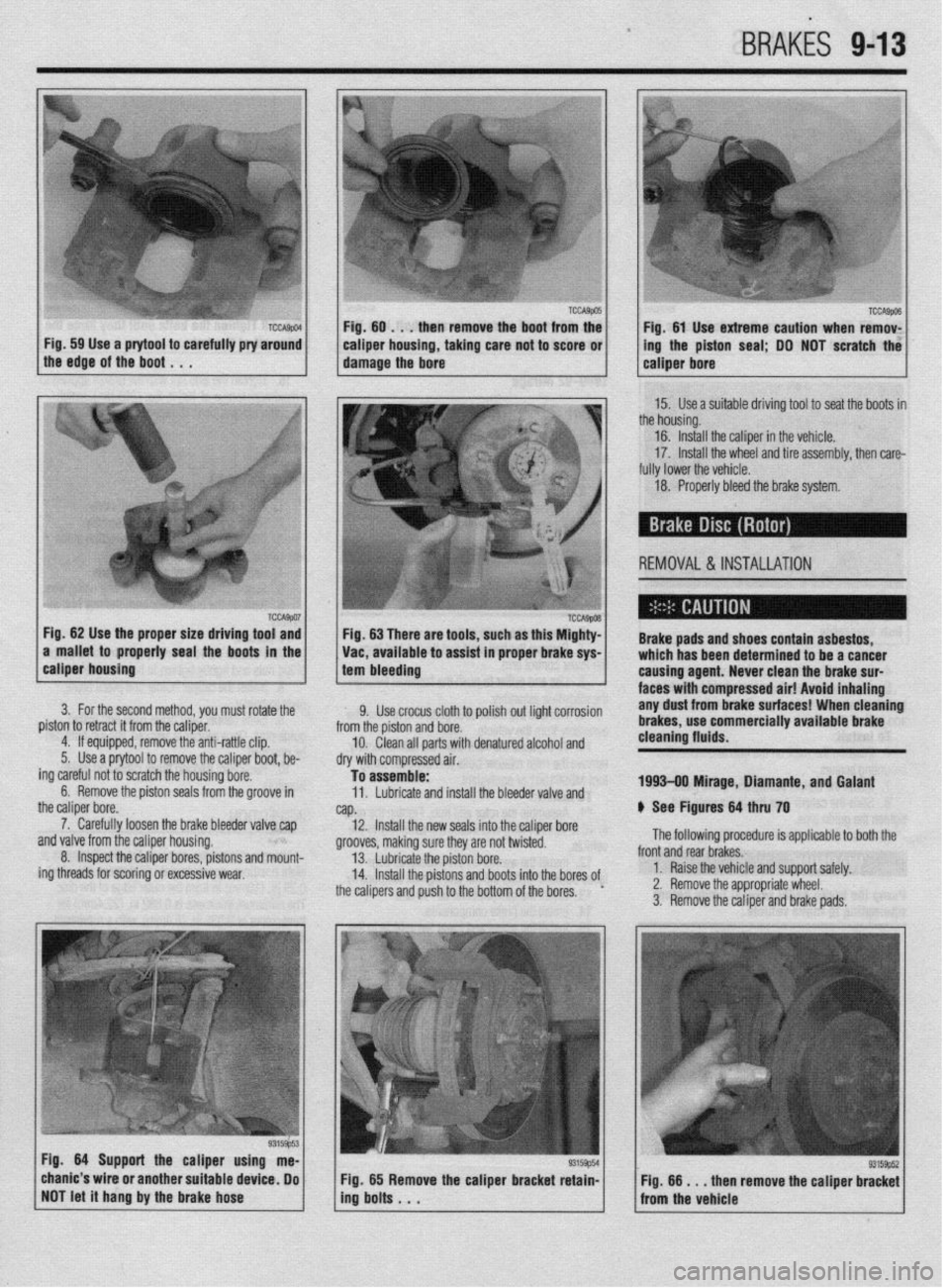

Fig. 59 Use a prytool to carefully pry around 1

the edge of the boot , , . caiper housing, taking care not to score or 1

damage the bore ing the piston seal; DO NOT scratch the

15. Use a suitable driving tool to seat the boots in

the housing.

16. Install the caliper in the vehicle.

17. Install the wheel and tire assembly, then care-

fully lower the vehicle.

18. Properly bleed the brake system.

REMOVAL &INSTALLATION

Fig. 62 Use the proper size driving tool and

a mallet to properly seal the boots in the Fig. 63 There are tools, such as this Mighty-

Vat, available to assist in proper brake sys- Brake pads and shoes contain asbestos,

which has been determined to be a cancer

calmer housino

1 tam hlasrlinn . --~-~~~v

3. For the second method, you must rotate the

piston to retract it from the caliper.

4. If equipped, remove the anti-rattle clip.

5. Use a prytool to remove the caliper boot, be-

ing careful not to scratch the housing bore.

6. Remove the piston seals from the groove in

the caliper bore.

7. Carefully loosen the brake bleeder valve cap

~nrl \I~IWJ frnm the r~linor hnlwinn

I causina aaent. LL.....” rlrr.. .I.,. l.uLr I..”

Yll” .UI”Y ll”lll LIIb rro,spl tI”“Jlly. 8. Inspect the caliper bores, pistons and mount-

ing threads for scoring or excessive wear,

--... -.---...= ’ I.twla lilci(lll Lllli uranl$ au,- faces with-compressed air! Avoid Inhaling

9. Use crocus cloth to polish out light corrosion any dust from brake surfaces! When cleaning

from the piston and bore. brakes, use commercially available brake

10. Clean all parts with denatured alcohol and cleaning fluids.

dry with compressed air.

To assemble:

11. Lubricate and install the bleeder valve and 1993-09 Mirage, Diamante, and Galant

NP. 6 See Figures 64 thru 70

12. Install the new seals into the caliper bore

nrnnlrhr m”lr;nn Clln-. M..-.., nrn n.4 h..‘“‘“~ The following procedure is applicable to both the ytvvvca, lllanllly 3”IC o,ey ale II”, IWI~LCL. 13. Lubricate the piston bore.

14. Install the pistons and boots into the bores of

the calipers and push to the bottom of the bores. ’ front and rear brakes.

1. Raise the vehicle and support safely.

2. Remove the appropriate wheel.

3. Remove the caliper and brake pads.

Fia. 64 Suoaarl the calmer usina me-

., -----= -..- chanic’s wire or another suitable device, Do

NOT let it hang by the brake hose Fig. 65 Remove the caliper bracket retain-

ing bolts . . . Fig. 66 m . . then remove the caliper bracket

from the vehicle