tires MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 1 of 408

HOW TO USE THIS BOOK 1-2

WHERE TOBEGIN l-2

AVOIDINGTROUBLE 1-2

MAINTENANCEORREPAIR? 1-2

AVOIDINGTHEMOSTCOMMONMISTAKES l-2

TOOLS AND EQUIPMENT 1-2

SPECIALTOOLS l-4

YOUR VEHICLE SAFELY 1-4

DON'TS l-6

FASTENERS, MEASUREMENTS AND

CONVERSIONS l-6

BOLTS,NUTSANDOTHERTHREADED

RETAINERS 1-6

TORQUE l-7

TORQUEWRENCHES l-7

TORQUEANGLEMETERS 1-9

STANDARDANDMETRIC MEASUREMENTS l-9

SERIAL NUMBER IDENTIFICATION l-10

VEHICLE IDENTIFICATION NUMBER l-10

ENGINE IDENTIFICATION NUMBER I-10

TRANSAXLEIDENTIFICATION I-10

DRlVEAXLE(AWDGALANTONLY) l-10

TRANSFERCASE(AWDGALANTONLY) l-10

ROUTINE MAINTENANCE AND TUNE-UP l-14

AIRCLEANER(ELEMENT) 1-14

REMOVAL&INSTALLATION 1-14

FUELFILTER 1-15

REMOVAL &INSTALLATION l-15

PCVVALVE l-15

REMOVAL&INSTALLATION l-15

EVAPORATIVECANISTER l-16

SERVICING 1-16

BATTERY 1-16

PRECAUTIONS I-16

GENERALMAINTENANCE 1-16

BEL BATTERYFLUID 1-16

CABLES I-17

CHARGING I-18

REPLACEMENT 1-18

TS 1-18

INSPECTiON l-18

ADJUSTMENT 1-18

REMOVAL&INSTALLATION 1-18

TIMINGBELTS l-20

INSPECTION l-20

HOSES I-20

INSPECTION l-20

REMOVAL&INSTALLATION

CV-BOOTS 1-21

INSPECTION l-21

SPARKPLUGS l-22

SPARKPLUGHEATRANGE

REMOVAL&INSTALLATION

INSPECTION &GAPPING 1.

SPARKPLUG WIRES 1-24

TESTING 1-24

REMOVAL&INSTALLATION

DISTRIBUTORCAPANDROTOR

REMOVAL&INSTALLATION

INSPECTION 1-25

IGNITIONTIMING 1-25

. GENERALINFORAMTION l-

lNSPECTlON&ADJUSTMENl

VALVE LASH l-27

ADJUSTMENT l-27

IDLESPEED 1-28 1-21

l-22

l-22

-23

1-24

l-25

l-25

.25

1-26

AIR CONDITIONING SYSTEM 1-28

SYSTEMSERVlCEiiREPAlR l-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION l-29

WINDSHIELD WIPERS l-29

ELEMENT(REFILL)CARE&

REPLACEMENT l-29

TIRESANDWHEELS l-30

TIRE ROTATION I-30

TIRE DESIGN 1-31

TIRESTORAGE l-31

INFLATION &INSPECTION l-31

CARE OFSPECIALWHEELS l-32 OPERATION INFOREIGNCOUNTRIES l-33

ENGINE l-33

OILLEVELCHECK 1-33

OIL& FILTER CHANGE l-34

MANUALTRANSAXLE l-35

FLUIDRECOMMENDATIONS l-35

LEVELCHECK l-35

DRAIN&REFILL l-36

AUTOMATICTRANSAXLE l-36

FLUIDRECOMMENDATIONS l-36

LEVELCHECK 1-36

DRAIN&REFILL l-36

PAN & FILTERSERVICE 1-36

TRANSFERCASE(AWDGAlANT ONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

REARDRlVEAXLE(AWDGALANTONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

COOLINGSYSTEM l-39

FLUIDRECOMMENDATIONS l-39

iM-41

FLUIDS AND LUBRICANTS 1-33

FLUID DISPOSAL 1-33

FlJELANDENGlNEOILRECOMMENDATlONS

ENGINE OIL l-33

FUEL l-33

Page 29 of 408

.

l-30 GENERAL'INFORMATIONAND MAINTENANCE

n Pylon@ inserts, the clip

be removed prior to siidi then the insert can be re

After installing the replacement

strip and pull up while twisting counterclockwise.

The backing strip will snap out of the retaining tab.

Do this for the remaining tabs until the refill is free of

the blade. The length of these refills is molded into

the end and they should be replaced with identical

types. cate the front end is out of alignment or that the tires

are out of balance.

TIRE ROTATION

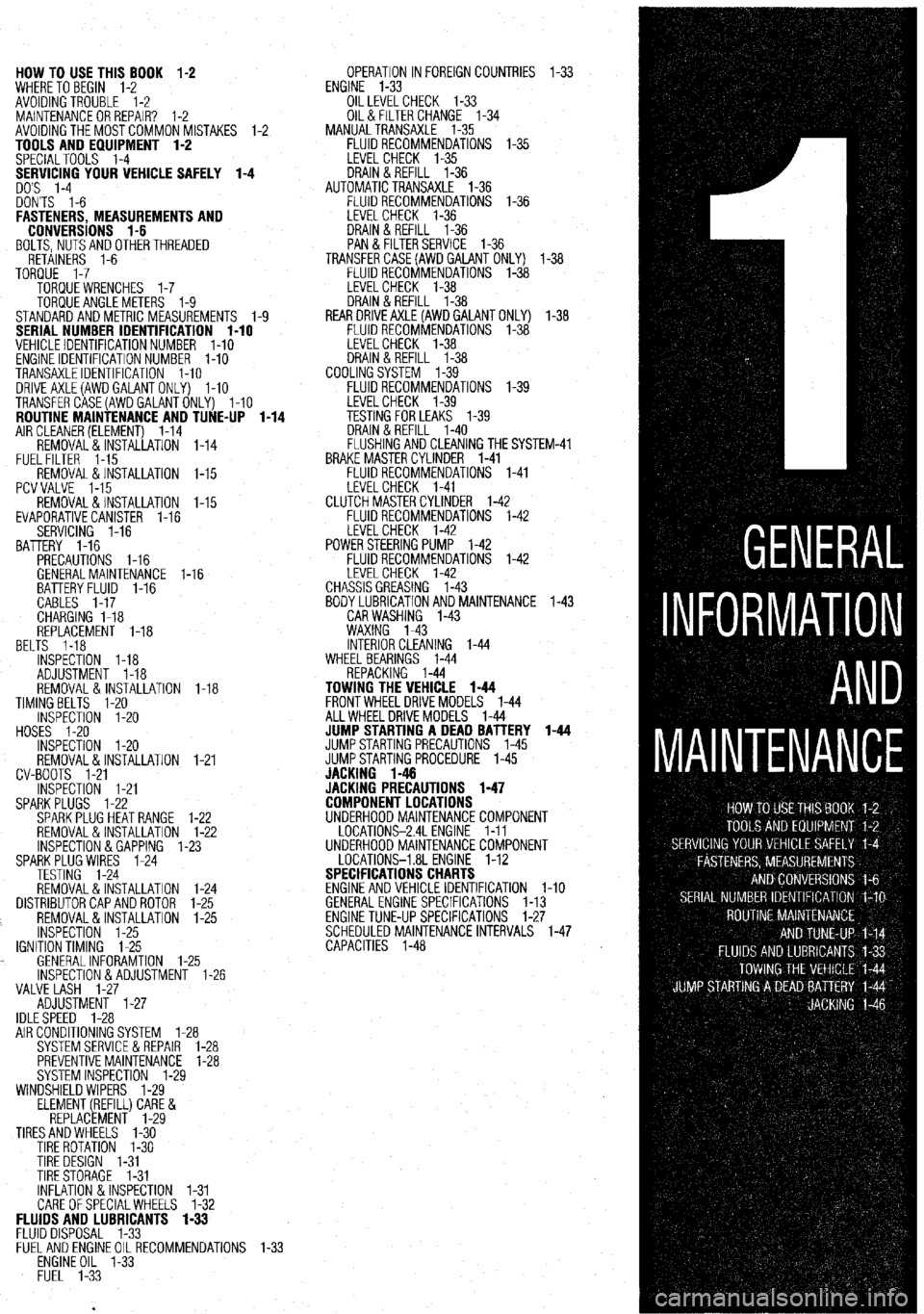

# See Figures 137 and 138

Tires must be rotated periodically to equalize wear

patterns that vary with a tire’s position on the vehicle.

Tires will also wear in an uneven way as the front

1 Fin 1% Tha Trinlarlna@

cle might have any kind. Aftermarket blades and arms

rarely use the exact same type blade or refill as the

original equipment. Here are some typiel aftermarket

blades; not all may be available for your vehicle:

The Anco@ type uses a release button that is

pushed down to allow the refill to slide out of the

yoke jaws. The new refill slides back into the frame

,

and locks in place.

Some Trico@ refills are removed by locating where

the metal backing strip or the refill is wider. Insert a

small screwdriver blade between the frame and metal

backing strip. Press down to release the refill from

the retaining tab.

Other types of Trico@’ refills have two metal tabs

which are unlocked by squeezing them together. The

rubber filler can then be withdrawn from the frame

iaws. A new refill is installed bv insertina the refill lowed to touch the olass steering/suspension system wears to the point where

the alianment should be reset.

# See Figure 138

Common sense and good driving habits will af-

ford maximum tire life. Fast starts, sudden stops

and hard cornering are hard on tires and will

shorten their useful life span. Make sure that you

don’t overload the vehicle or run with incorrect

pressure in the tires. Both of these practices will in-

crease tread wear.

*For optimum tire life, keep the fires prop

eriy inflated, rotate them often and have the

wheel alignment checked periodically.

Inspect your tires frequently. Be especially care-

ful to watch for bubbles in the tread or sidewall,

deep cuts or underinflation. Replace any tires with

bubbles in the sidewall. If cuts are so deep that they

penetrate to the cords, discard the tire. Any cut in

the sidewall of a radial tire renders it unsafe. Also

look for uneven tread wear patterns that may indi- Rotating the tires will ensure maximum life for the

tires as a set, so you will not have to discard a tire

early due to wear on only part of the tread. Regular

DIRECTIONAL TIRES DIRECTIONAL TIRES

jnto the front frame jaws and &ding it rearward to

engage the remaining frame jaws. There are usually

four jaws; be certain when installing that the refill is

engaged in all of them. At the end of its travel, the

tabs will lock into place on the front jaws of the wiper

blade frame.

Another type of refill is made from polycarbonate.

The refill has a simple locking device at one end

which flexes downward out of the groove into which

the jaws of the holder fit, allowing easy release. By

sliding the new refill through all the jaws and push-

ing through the slight resistance when it reaches the

end of its travel, the refill will lock into position.

To replace the Tridon@ refill, it is necessary to re-

move the wiper blade. This refill has a plastic backing

strip with a notch about 1 in. (25mm) from the end.

Hold the blade (frame) on a hard surface so that the

frame is tightly bowed. Grip the tip of the backing Fig. 138 A label with information concern-

ing the tires is typically located on one of

the door pillars

tion”

Page 30 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-31

When rotating “unidirectional tires,” make sure

that they always roll in the same direction. This

means that a tire used on the left side of the vehicle

must not be switched to the right side and vice-versa.

Such tires should only be rotated front-to-rear or

rear-to-front, while always remaining on the same

side of the vehicle. These tires are marked on the

sidewall as to the direction of rotation; observe the

marks when reinstalling the tire(s).

Some styled or “mag” wheels may have different

offsets front to rear. In these cases, the rear wheels

must not be used up front and vice-versa. Further-

more, if these wheels are equipped with unidirectional

tires, they cannot be rotated unless the tire is re-

mounted for the proper direction of rotation.

*The compact or space-saver spare is

strictly for emergency use. it must never be

included in the tire rotation or placed on the

vehicle for everyday use. check the installed tire for any sign of interference

with the body or suspension while the vehicle is stop-

ping, turning sharply or heavily loaded.

Snow Tires

Good radial tires can produce a big advantage in

slippery weather, but in snow, a street radial tire does

not have sufficient tread to provide traction and con-

trol. The small grooves of a street tire quickly pack

with snow and the tire behaves like a billiard ball on a

marble floor, The more open, chunky tread of a snow

tire will self-clean as the tire turns, providing much

better grip on snowy surfaces.

To satisfy municipalities requiring snow tires dur-

ing weather emergencies, most snow tires carry either

an M + S designation after the tire size stamped on

the sidewall, or the designation “all-season.” In gen-

eral, no change in tire size is necessary when buying

snow tires.

Most manufacturers stronqlv recommend the use styled wheels, see if inexpensive steel

wheels are available, Although the look of

the vehicle will change, the expensive

wheels will be protected from salt, curb hits

and pothole damage.

TIRESTORAGE

If they are mounted on wheels, store the tires at

proper inflation pressure. All tires should be kept in a

cool, dry place. If they are stored in the garage or

basement, do not let them stand on a concrete floor;

set them on strips of wood, a mat or a large stack of

newspaper. Keeping them away from direct moisture

is of paramount importance. Tires should not be

stored upright, but in a flat position.

INFLATION & INSPECTION

b See Figures 140 thru 147

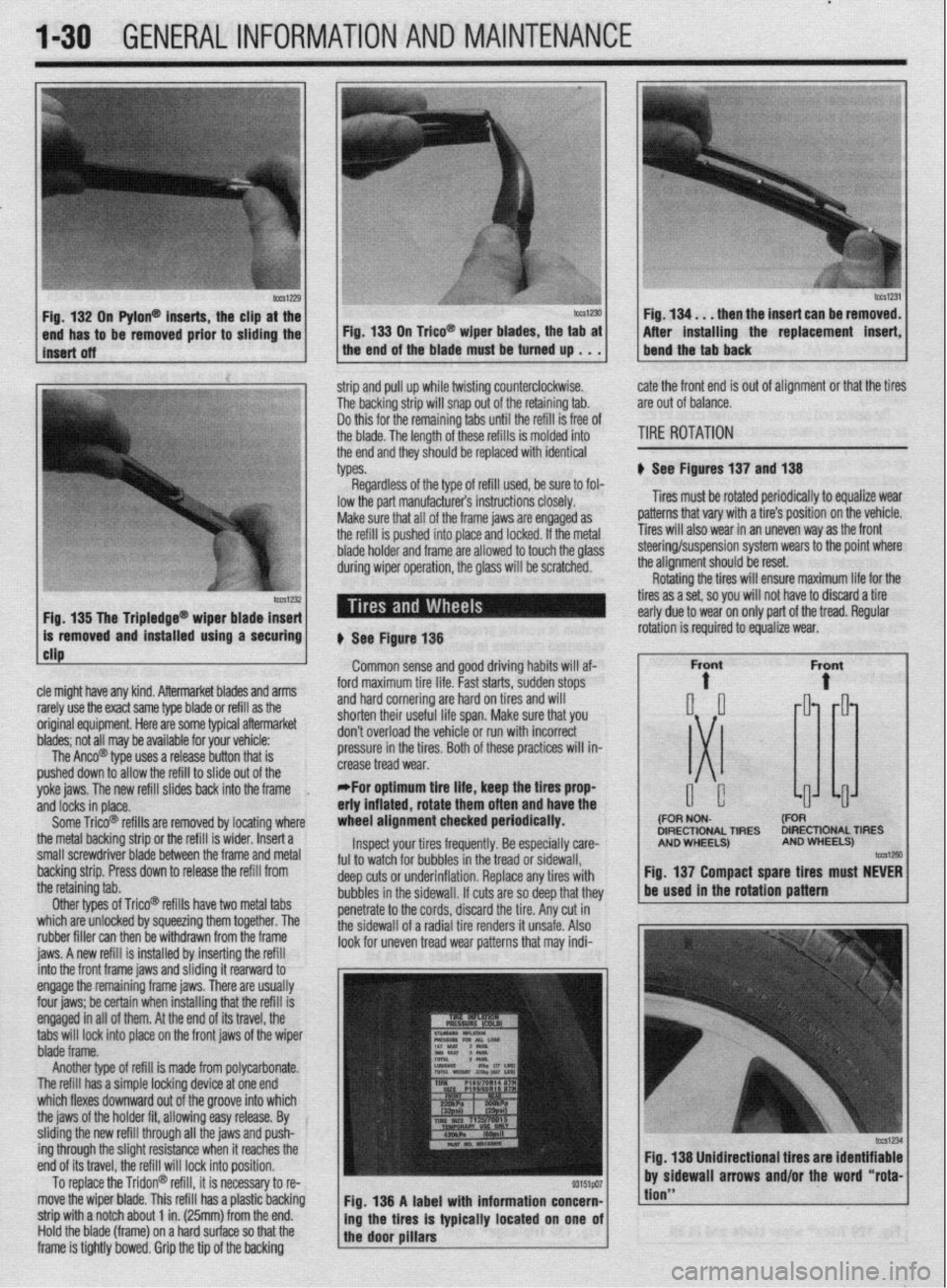

TIRE DESIGN

p See Figure 139

for maximum satisfaction, tires should be used in

sets of four. Mixing of different types (radial, bias-

belted, fiberglass belted) must be avoided. In most

cases, the vehicle manufacturer has designated a

type of tire on which the vehicle will perform best.

Your first choice when replacing tires should be to

use the same type of tire that the manufacturer rec-

ommends.

When radial tires are used, tire sizes and wheel di-

ameters should be selected to maintain ground clear-

ante and tire load caoacitv eauivalent to the oriainal

specified tire. Radial tiresshould always be used in

sets of four. of 4 snow tires on their

lehicies for reasons of stabil-

ity. If snow tires are fitter

1 only to the drive wheels, the

opposite end of the vehil cle may become very unsta-

ble when braking or turn

ring on slippery surfaces.

This instability can lead to unpleasant endings if the

A*:,,“- r-..l, ^_.. ..& ^_^^, &I.

UIIVU MII I LUUII~~MLL iue slide in time.

Note that snow tires, whether 2 or 4, will affect ve-

hicle handling in all non-snow situations. The stiffer,

heavier snow tires will noticeably change the turning

and braking characteristics of the vehicle. Once the

snow tires are installed, you must re-learn the behav-

ior of the vehicle and drive accordingly.

*Consider buying extra wheels on which to

mount the snow tires. Once done, the “snow

iheeis” can be installed and removed as

needed. This eliminates the potential

dam- age to tires or wheels from seasonal removal

and installation. Even if your vehicle has

lb The importance of proper tire inflation cannot be

overemphasized. A tire employs air as part of its

structure. It is designed around the supporting

strength of the air at a specified pressure. For this

reason, improper inflation drastically reduces the

tire’s ability to perform as intended. A tire will lose

some air in day-to-day use; having to add a few

pounds of air periodically is not necessarily a sign of

a leaking tire.

Two items should be a permanent fixture in every

glove compartment: an accurate tire pressure gauge

and a tread depth gauge. Check the tire pressure (in-

eluding the spare) regularly with a pocket type gauge.

Too often, the gauge on the end of the air hose at

vnr rr corner narane is not accurate because it suffers

~rs check tire oressure when the

Radial tires should never be used on only the

XI I._.

‘-’ --“‘“’ J s too much abuse. Alwa!

tires are cold, as pressure increases with tempera-

ture. If you must move the vehicle to check the tire

front axle.

When selecting tires, pay attention to the original

size as marked on the tire. Most tires are described

using an industry size code sometimes referred to as

P-Metric. This allows the exact identification of the

tire specifications, regardless of the manufacturer. If

selecting a different tire size or brand, remember to

METRIC TIRE SIZES

(MILLIMETERS)

145 CDNStRUCtlDN l-6-E

R - RADIAL

D

WA9

Fig. 139 P-Metric tire coding Fig. 140 Tires should be checked frequently

I I Fig. 141 Tires with deep cuts, or cuts which

for any sion of auncture or damaoe

buioe, should be replaced immediately

l DRIVE WHEEL HEAW

ACCELERATION

l OVERINFLATION

*LACK OF ROTATION

Fig. 142 Examples of inflation-related tire

RADIAL TIRE

fig. 143 Radial tires have a characteristic

sidewall bulge; don’t try to measure pres-

sure by looking at the tire. Use a quality air

pressure gauge

Page 31 of 408

.

1-32 GENERALINFORMATIONAND MAINTENANCE

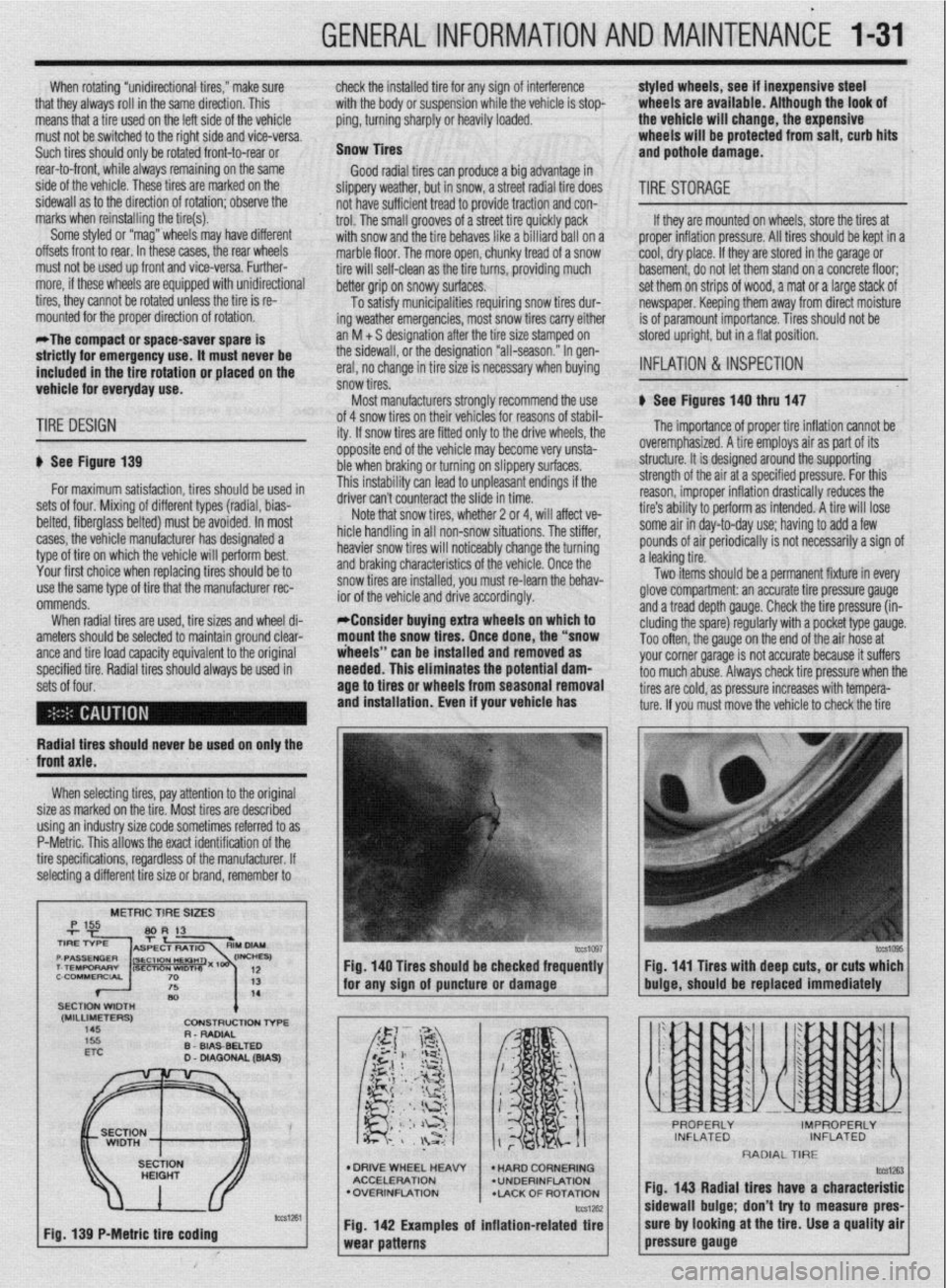

CONDITION

EFFECT

CAUSE

CORRECTION UNDER-INFLATION

EXCESSIVE SPEED’ WORN OR OUT-

OF-ALIGNMENT

ADJUST PRESSURE TO

SPECIFICATIONS WHEN

TIRES ARE COOL

ROTATE TIRES

/ BALANCE WHEELS INSPECT SUSPENSION

HAVE TIRE INSPECTED FOR FURTHER USE.

lCCSi267 ig. 144 Common tire wear patterns and causes

1~~~1265 Fig. 145 Tread wear indicators will appear

when the tire is worn

inflation, do not drive more than a mile before check-

ing. A cold tire is generally one that has not been dri-

ven for more than three hours.

A plate or sticker is normally provided somewhere

in the vehicle (door post, hood, tailgate or trunk lid)

which shows the proper pressure for the tires. Never

counteract excessive pressure build-up by bleeding

off air pressure (letting some air out). This will cause

the tire to run hotter and wear quicker.

Never exceed the maximum tire pressure

embossed on the tire! This is the pressure to

be used when the tire is at maximum load-

ing, but it is rarely the correct pressure for

everyday driving. Consult the owner’s man-

ual or the tire pressure sticker for the correct

tire pressure.

Once you’ve maintained the correct tire pressures

for several weeks, you’ll be familiar with the vehicle’s

braking and handling personality. Slight adjustments

in tire pressures can fine-tune these characteristics,

1~~~1264 Fig. 146 Accurate tread depth indicators are

inexuensive and handv

Fig. 147 A penny works well for a quick

check of tread death

but never change the cold pressure specification by

more than 2 psi. A slightly softer tire pressure will

give a softer ride but also yield lower fuel mileage. A

slightly harder tire will give crisper dry road handling

but can cause skidding on wet surfaces. Unless

you’re fully attuned to the vehicle, stick to the recom-

mended inflation pressures.

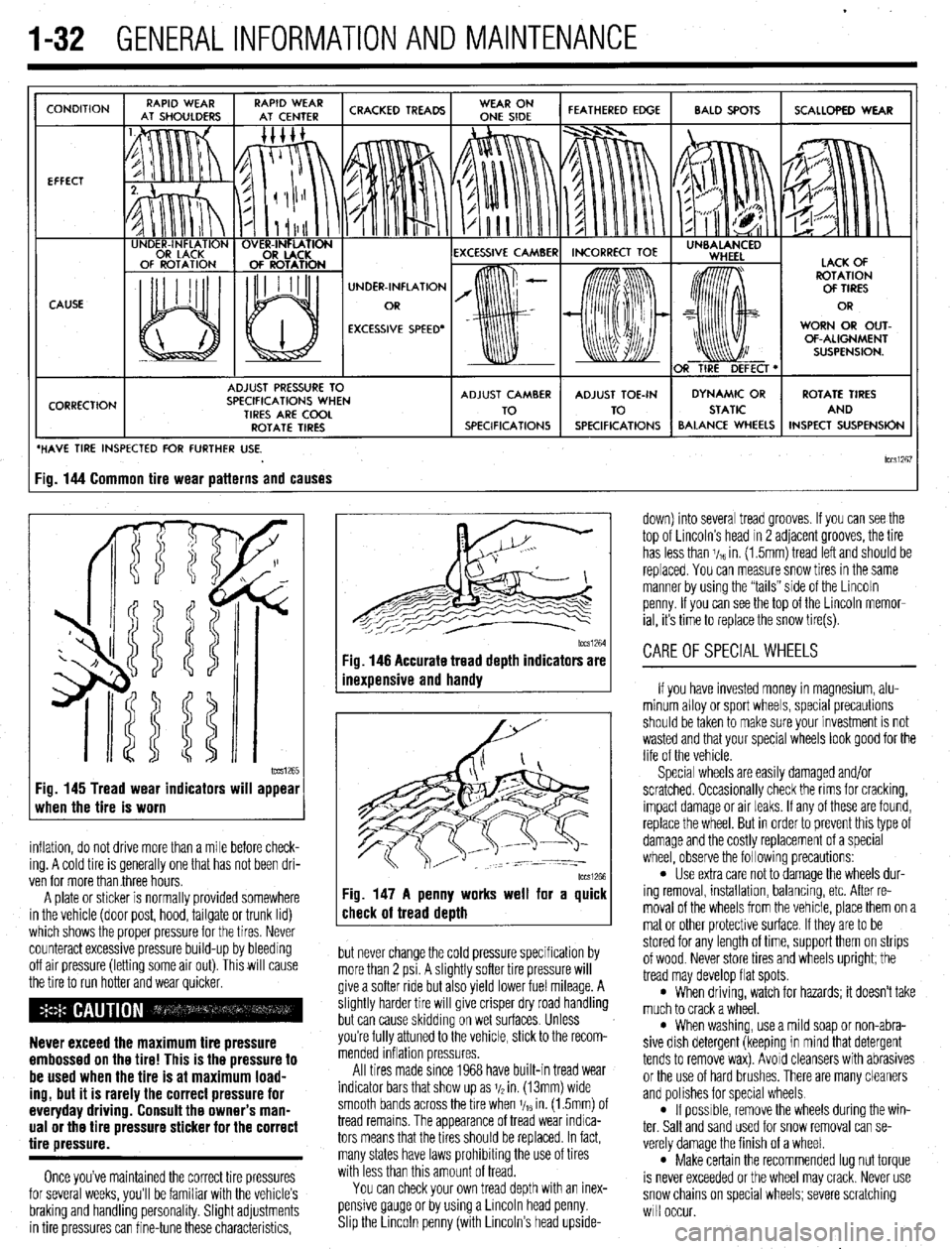

All tires made since 1968 have built-in tread wear

indicator bars that show up as j/2 in. (13mm) wide

smooth bands across the bre when V,~ in. (1.5mm) of

tread remains. The appearance of tread wear indica-

tors means that the tires should be replaced. In fact,

many states have laws prohibiting the use of tires

with less than this amount of tread.

You can check your own tread depth with an inex-

pensive gauge or by using a Lincoln head penny.

Shp the Lrncoln penny (with Lincoln’s head upside- down) into several tread grooves. If you can see the

top of Lincoln’s head in 2 adjacent grooves, the tire

has less than V,~ in. (1.5mm) tread left and should be

replaced. You can measure snow tires in the same

manner by using the “tails” side of the Lincoln

penny. If you can see the top of the Lincoln memor-

ial, its time to replace the snow tire(s).

CAREOFSPECIALWHEELS

If you have invested money in magnesium, alu-

minum alloy or sport wheels, special precautions

should be taken to make sure your investment is not

wasted and that your special wheels look good for the

life of the vehicle.

Special wheels are easily damaged and/or

scratched. Occasionally check the rims for cracking,

impact damage or air leaks. If any of these are found,

replace the wheel. But in order to prevent this type of

damage and the costly replacement of a special

wheel, observe the following precautions:

l Use extra care not to damage the wheels dur-

ing removal, installation, balancing, etc. After re-

moval of the wheels from the vehicle, place them on a

mat or other protective surface. If they are to be

stored for any length of time, support them on strips

of wood. Never store tires and wheels upright; the

tread may develop flat spots.

l When driving, watch for hazards; it doesn’t take

much to crack a wheel.

l When washing, use a mild soap or non-abra-

sive dish detergent (keeping in mind that detergent

tends to remove wax). Avoid cleansers with abrasives

or the use of hard brushes. There are many cleaners

and polishes for special wheels.

l If possrble, remove the wheels during the win-

ter. Salt and sand used for snow removal can se-

verely damage the finish of a wheel.

l Make certain the recommended lug nut torque

is never exceeded or the wheel may crack. Never use

snow chains on special wheels; severe scratching

will occur.

Page 250 of 408

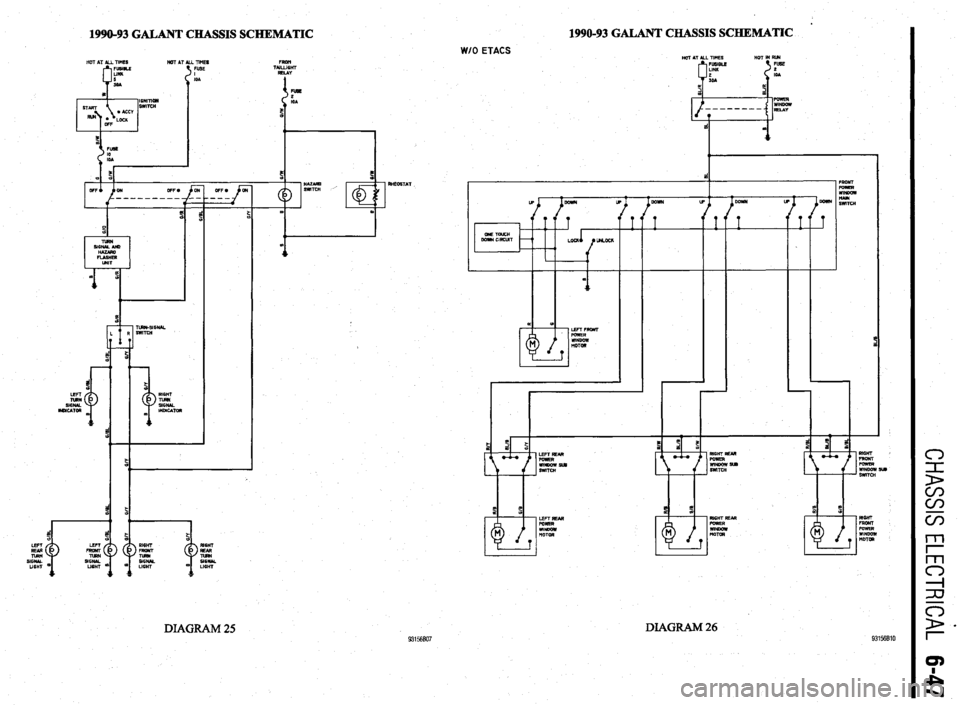

1990-93 GALANT CHASSIS SCHEMATIC

HOT AT ALL TINGG

HOT AT

IGNITION

SWITCN L TIMEG

FUSE

2 6

z

%

SlGtEL

HAzmo

FLAGHER

lmll

c

is

TLWN-SIGNAL

L ” R GWWW

. 4 . y

2

e TA!!HT

ELAY

DIAGRAM 25 93156607

1990-93 GALANT CHASSIS SCHEMATIC

W/O ETACS HOT AT ALL TIRES HOT IN RW

DJAGRAM 26 93156610

Page 297 of 408

.

8-2 SUSPENSION AND STEERING

b

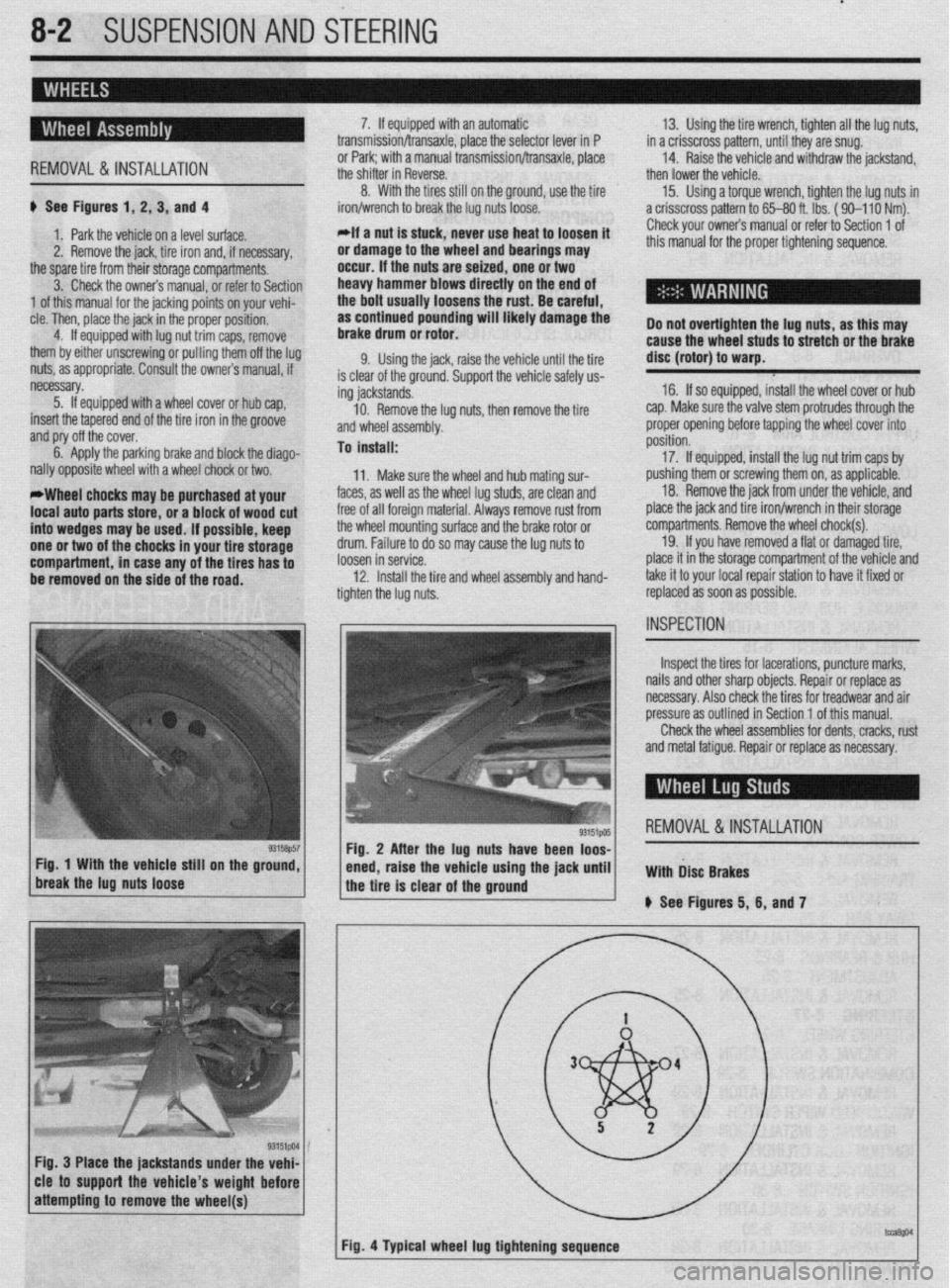

REMOVAL &INSTALLATION

# See Figures 1, 2, 3, and 4

1. Park the vehicle on a level surface.

2. Remove the jack, tire iron and, if necessary,

the spare tire from their storage compartments.

3. Check the owners manual, or refer to Section

1 of this manual for the jacking points on your vehi-

cle. Then, place the jack in the proper position,

4. If equipped with lug nut trim caps, remove

them by either unscrewing or pulling them off the lug

nuts, as appropriate. Consult the owners manual, if

necessary.

5. If equipped with a wheel cover or hub cap,

insert the tapered end of the tire iron in the groove

and pry off the cover.

6. Apply the parking brake and block the diago-

nally opposite wheel with a wheel chock or two.

*Wheel chocks may be purchased at your

local auto parts store, or a block of wood cut

into wedges may be used. If possible, keep

one or two of the chocks in your tire storage

compartment, in case any of the tires has to

be removed on the side of the road. 7. If equipped with an automatic

transmission/transaxle, place the selector lever in P

or Park; with a manual transmission/transaxle, place

the shifter in Reverse.

8. With the tires still on the ground, use the tire

iron/wrench to break the lug nuts loose.

*If a nut is stuck, never use heat to loosen it

or damage to the wheel and bearings may

occur. If the nuts are seized, one or two

heavy hammer blows directly on the end of

the bolt usually loosens the rust. Be careful,

as continued pounding will likely damage the

brake drum or rotor.

9. Using the jack, raise the vehicle until the tire

is clear of the ground. Support the vehicle safely us-

ing jackstands.

10. Remove the lug nuts, then remove the tire

and wheel assembly.

To install:

11. Make sure the wheel and hub mating sur-

faces, as well as the wheel lug studs, are clean and

free of all foreign material. Always remove rust from

the wheel mounting surface and the brake rotor or

drum. Failure to do so may cause the lug nuts to

loosen in service.

12. Install the tire and wheel assembly and hand-

tighten the lug nuts. 13. Using the tire wrench, tighten all the lug nuts,

in a crisscross pattern, until they are snug.

14. Raise the vehicle and withdraw the jackstand,

then lower the vehicle.

15. Using a torque wrench, tighten the lug nuts in

a crisscross pattern to 65-80 ft. lbs. ( 90-l 10 Nm).

Check your owners manual or refer to Section 1 of

this manual for the proper tightening sequence.

Do not overtighten the lug nuts, as this may

cause the wheel studs to stretch or the brake

disc (rotor) to warp.

16. If so equipped, install the wheel cover or hub

cap. Make sure the valve stem protrudes through the

proper opening before tapping the wheel cover into

position.

17. If equipped, install the lug nut trim caps by

pushing them or screwing them on, as applicable.

18. Remove the jack from under the vehicle, and

place the jack and tire iron/wrench in their storage

compartments. Remove the wheel chock(s).

19. If you have removed a flat or damaged tire,

place it in the storage compartment of the vehicle and

take it to your local repair station to have it fixed or

replaced as soon as possible.

Inspect the tires for lacerations, puncture marks,

nails and other sharp objects. Repair or replace as

necessary. Also check the tires for treadwear and air

pressure as outlined in Section 1 of this manual.

Check the wheel assemblies for dents, cracks, rust

and metal fatigue. Repair or replace as necessary.

REMOVAL&INSTALLATION

Fig. 3 Place the jackstands under the vehi-

cle to support the vehicle’s weight before

Page 311 of 408

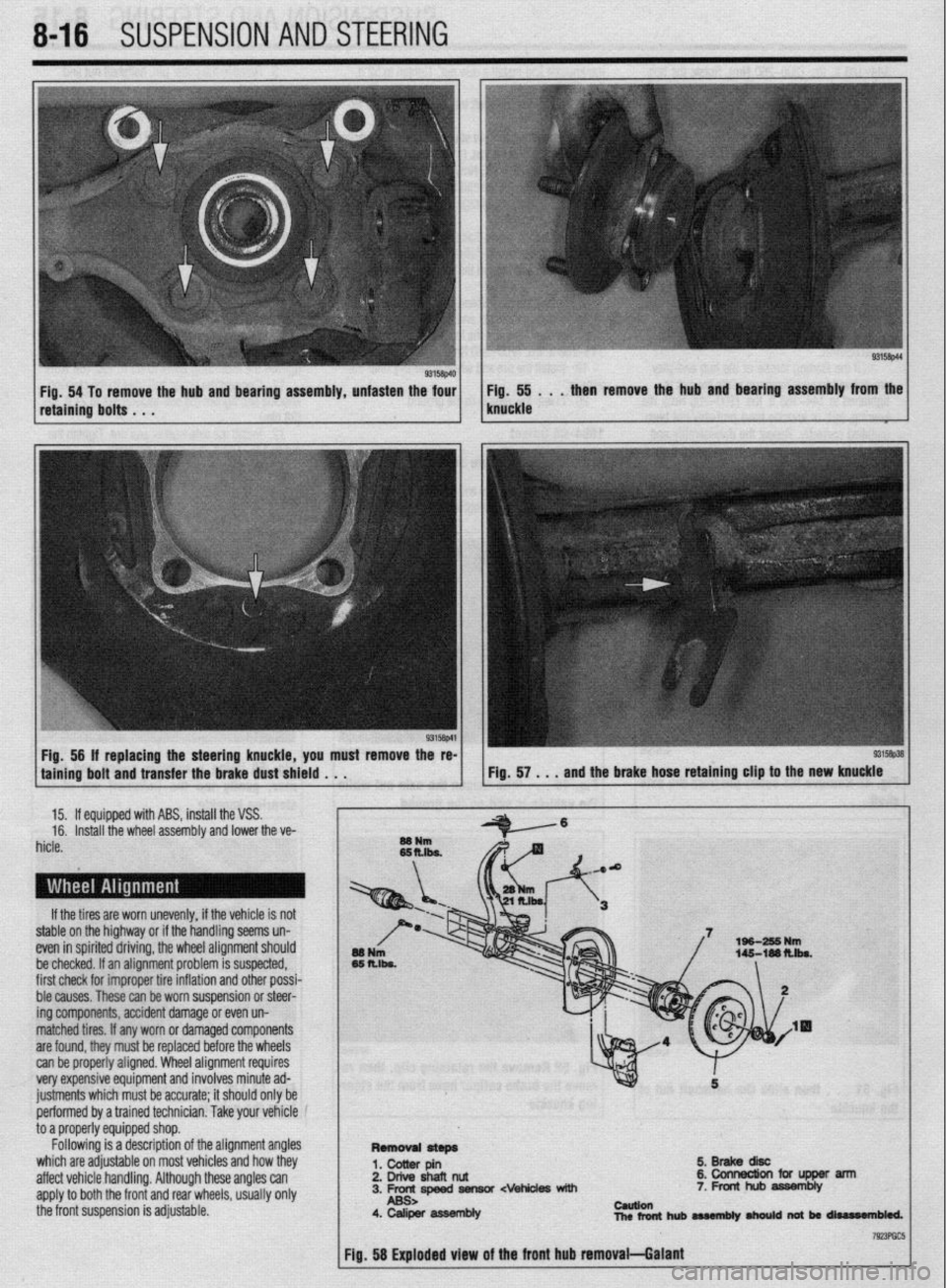

8116 SUSPENSION AND STEERING

Fig. 54 To remove the hub and bearing assembly, unfasten the four Fig. 55 . . . then remove the hub and bearing assembly from the

retaining bolts . . . knuckle

Fig, 56 If replacing the steering knuckle, you must remove the re-

taining bolt and transfer the brake dust shield . . .

15. If equipped with ABS, install the VSS.

16. Install the wheel assembly and lower the ve-

hicle.

If the tires are worn unevenly, if the vehicle is not

stable on the highway or if the handling seems un-

even in spirited driving, the wheel alignment should

be checked. If an alignment problem is suspected,

first check for improper tire inflation and other possi-

ble causes. These can be worn suspension or steer-

ing components, accident damage or even un-

matched tires. If any worn or damaged components

are found, they must be replaced before the wheels

can be properly aligned. Wheel alignment requires

very expensive equipment and involves minute ad-

justments which must be accurate; it should only be

performed by a trained technician. Take your vehicle

to a properly equipped shop.

Following is a description of the alignment angles

which are adjustable on most vehicles and how they

affect vehicle handling. Although these angles can

apply to both the front and rear wheels, usually only

the front suspension is adjustable.

5.BrakediW

2. Drive shafl nut &collnectionfciflJpperarm

3. Frc-rc,speed fiensor cvehides with 7. Front hub assembly

4. Caliper asWmbly cauuen

nlcrfonthubaMmbly~natbrrliurr#n61ed.

Page 383 of 408

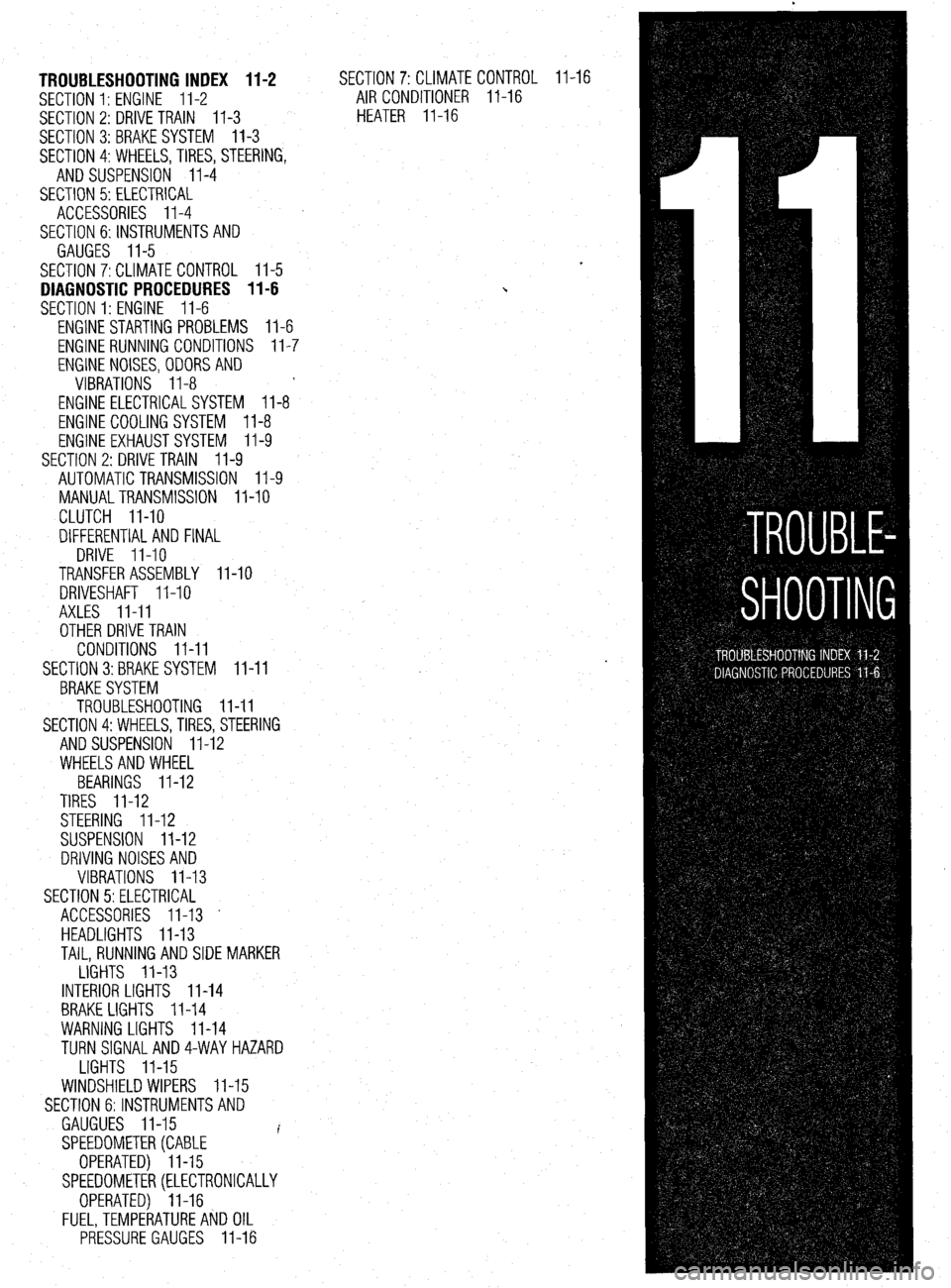

TROUBLESHOOTING INDEX 11-2

SECTION 1: ENGINE 11-2

SECTION 2: DRIVE TRAIN

11-3

SECTION 3:BRAKESYSTEM 11-3

SECTION 4:WHEELS,TIRES, STEERING,

AND SUSPENSION II-4

SECTION 5: ELECTRICAL

ACCESSORIES II-4

SECTION 6:lNSTRUMENTSAND

GAUGES II-5

SECTION 7:CLlMATE CONTROL II-5

DIAGNOSTIC PROCEDURES II-6

SECTION 1: ENGINE II-6

ENGINE STARTING PROBLEMS II-6

ENGINE RUNNING CONDITIONS II-7

ENGINE NOISES,ODORSAND

VIBRATIONS II-8

ENGINE ELECTRICALSYSTEM 11-8

ENGINE COOLING SYSTEM II-8

ENGINE EXHAUSTSYSTEM II-9

SECTION 2: DRIVE TRAIN

II-9

AUTOMATIC TRANSMISSION II-9

MANUALTRANSMISSION II-10

CLUTCH II-10

DIFFERENTIAL AND FINAL

DRIVE II-10

TRANSFER ASSEMBLY II-10

DRIVESHAFT II-10

AXLES II-II

OTHER DRIVE TRAIN

CONDITIONS II-II

SECTION 3:BRAKE SYSTEM II-II

BRAKESYSTEM

TROUBLESHOOTING II-II

SECTION 4:WHEELS, TIRES, STEERING

AND SUSPENSION II-12

WHEELSAND WHEEL

BEARINGS II-12

TIRES II-12

STEERING II-12

SUSPENSION II-12

DRIVING NOISES AND

VIBRATIONS II-13

SECTION 5:ELECTRlCAL

ACCESSORIES II-13 -

HEADLIGHTS II-13

TAIL, RUNNING AND SIDE MARKER

LIGHTS II-13

INTERIOR LIGHTS II-14

BRAKE LIGHTS II-14

WARNING LIGHTS II-14

TURN SlGNALAND4-WAYHAZARD

LIGHTS II-15

WINDSHIELD WIPERS II-15

SECTION 6:lNSTRUMENTSAND

GAUGUES II-15

I

SPEEDOMETER(CABLE

OPERATED) II-15

SPEEDOMETER(ELECTRONICALLY

OPERATED) II-16

FUEL,TEMPERATUREAkJD OIL

PRESSURE GAUGES II-16 SECTION 7:CLlMATECON

AIR CONDITIONER ll-

HEATER II-16 TR(

-16 IL II-16

Page 384 of 408

11-2 TROUBLESHOOTING

Condition

Section/Item Number

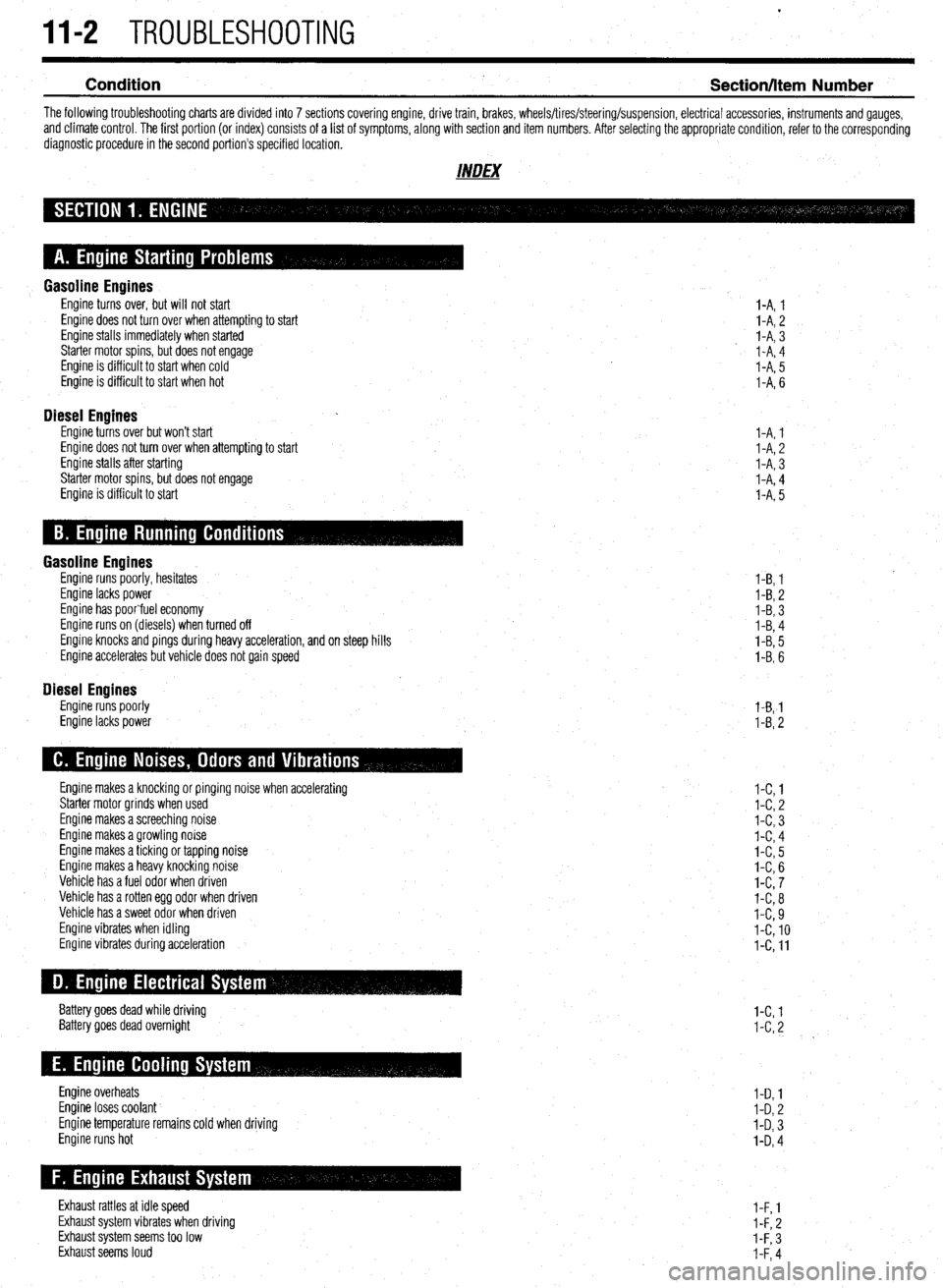

The following troubleshooting charts are divided into 7 sections covering engine, drive train, brakes, wheels/tires/steering/suspension, electrical accessories, instruments and gauges,

and climate control. The first portion (or index) consists of a list of symptoms, along with section and item numbers. After selecting the appropriate condition, refer to the corresponding

diagnostic procedure in the second portion’s specified location.

INDEX

Gasoline Engines Engine turns over, but will not start

Engine does not turn over when attempting to start

Engine stalls immediately when started

Starter motor spins, but does not engage

Engine is difficult to start when cold

Engine is difficult to start when hot

Diesel Engines Engine turns over but won’t start

Engine does not turn over when attempting to start

Engine stalls after starting

Starter motor spins, but does not engage

Engine is difficult to start I-A, 1

l-A, 2

I-A, 3

I-A, 4

I-A, 5

I-A, 6

I-A, 1

l-A, 2

I-A, 3

I-A, 4

l-A, 5

Gasoline Engines Engine runs poorly, hesitates

Engine lacks power

Engine has poorfuel economy

Engine runs on (diesels) when turned off

Engine knocks and pings during heavy acceleration, and on steep hills

Engine accelerates but vehicle does not gain speed

Diesel Engines Engine runs poorly

Engine lacks power l-B, 1

I-B, 2

l-B, 3

I-B, 4

l-B, 5

I-B, 6

l-B,-1

l-B, 2

Engine makes a knocking or pinging noise when accelerating

Starter motor grinds when used

Engine makes a screeching noise

Engine makes a growling noise

Engine makes a ticking or tapping noise

Engine makes a heavy knocking noise

Vehicle has a fuel odor when driven

Vehicle has a rotten egg odor when driven

Vehicle has a sweet odor when driven

Engine vibrates when idling

Engine vibrates during acceleration

Battery goes dead while driving

Battery goes dead overnight

Engine overheats

Engine loses coolant

Engine temperature remains cold when driving

Engine runs hot

Exhaust rattles at idle speed

Exhaust system vibrates when driving

Exhaust system seems too low

Exhaust seems loud l-C, 1

l-C, 2

l-C, 3

I-C, 4

l-C, 5

I-C, 6

l-C, 7

l-C, 8

I-C, 9

I-C, 10

l-C, 11

l-C, 1

I-C, 2

I-D, 1

I-D, 2

I-D, 3

I-D, 4

l-F, 1

l-F, 2

I-F, 3

I-F, 4

Page 386 of 408

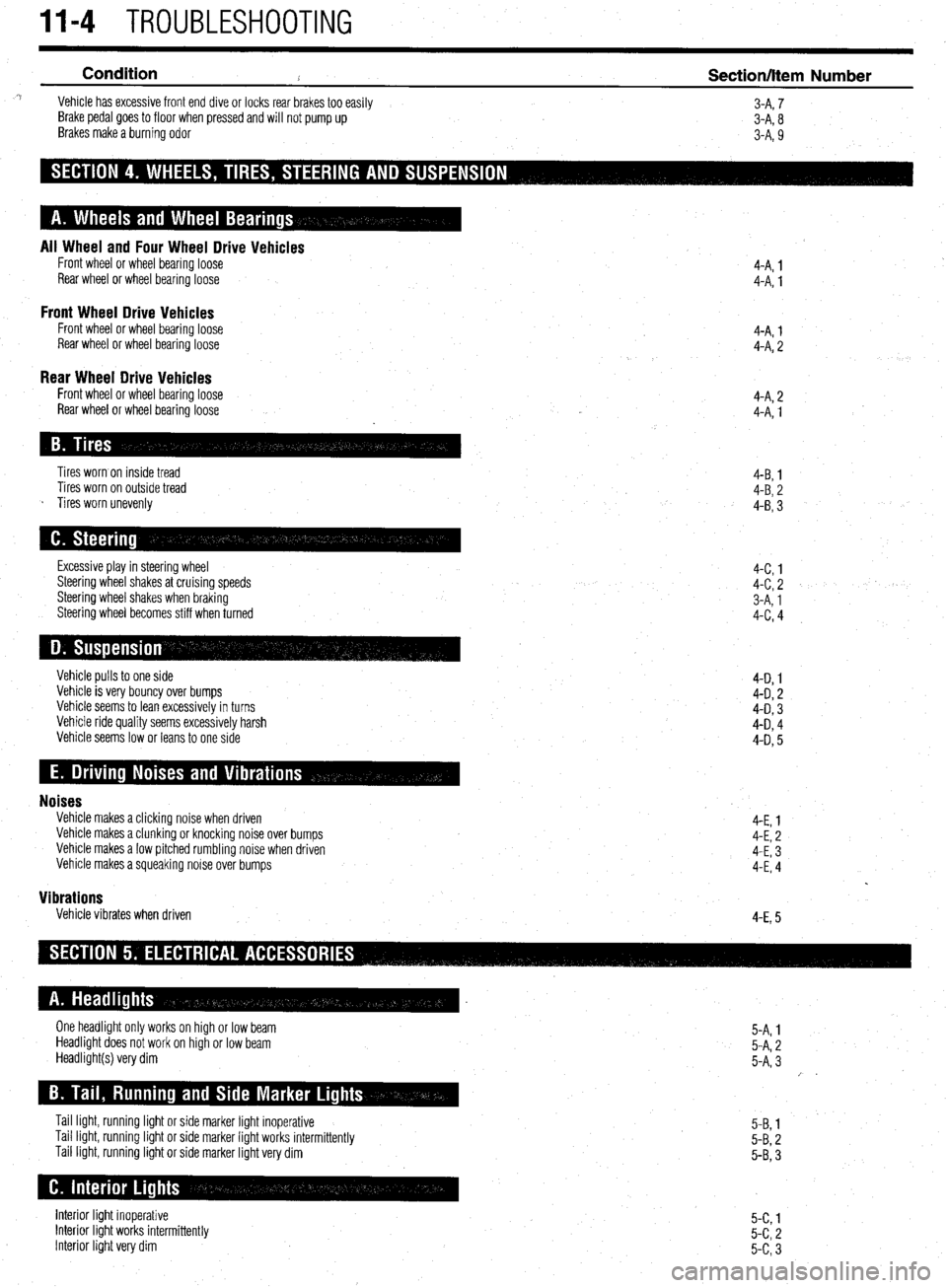

11-4 TROUBLESHOOTING

Condition

2 Section/Item Number ^i Vehicle has excessive front end dive or locks rear brakes too easily

3-A, 7

Brake pedal goes to floor when pressed and will not pump up

3-A, 8

Brakes make a burning odor

3-A, 9

All Wheel and Four Wheel Drive Vehicles Front wheel or wheel bearing loose

Rear wheel or wheel bearingloose

Front Wheel Drive Vehicles Front wheel or wheel bearing loose

Rear wheel or wheel bearing loose 4-A. 1

4-A: 1

4-A, 1

4-A, 2

Rear Wheel Drive Vehicles Front wheel or wheel bearing loose

Rear wheel or wheel bearing loose 4-A, 2

4-A, 1

Tires worn on inside tread

Tires worn on outside tread

s Tires worn unevenly 4-B, 1

4-B, 2

4-B, 3

Excessive play in steering wheel

Steering wheel shakes at cruising speeds

Steering wheel shakes when braking

Steering wheel becomes stiff when turned 4-c, 1

4-c, 2

3-A, 1

4-c, 4

Vehicle pulls to one side

Vehicle is very bouncy over bumps

Vehicle seems to lean excessively in turns

Vehicle ride quality seems excessively harsh

Vehicle seems low or leans to one side 4-D 1

4-D, 2

4-D, 3

4-D, 4

4-D, 5

Noises Vehicle makes a clicking noise when driven

Vehicle makes a clunking or knocking noise over bumps

Vehicle makes a low pitched rumbling noise when driven

Vehicle makes a squeaking noise over bumps

Vibrations Vehicle vibrates when driven 4-E, 1

4-E, 2

4-E, 3

4-E, 4

4-E, 5

One headlight only works on high or low beam

Headlight does not work on high or low beam

Headlight(s) very dim

Tail light, running light or side marker light inoperative

Tail light, running light or side marker light works intermittently

Tail light, running light or side marker light very dim 5-A, 1

5-A, 2

5-A, 3

/ .

5-B, 1

5-B, 2

5-B, 3

Interior light inoperative

Interior light works intermittently

Interior light very dim 5-c, 1

5-c, 2

5-c, 3