towing MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 35 of 408

.

l-36 GENERALINFORMATIONAND MAINTENANCE

Install the drain plug and tighten to 22 ft. Ibs.

(304Nm)

5. Refill the transaxle to the proper level, as

shown in the Capacities chart, with the appropriate

fluid. The oil level should be at the bottom of the oil

filler hole. I

6. When the oil reaches the orooer level, install

the filler plug and tighten to 22 ft. Ibs. (30 Nm).

FLUID RECOMMENDATIONS

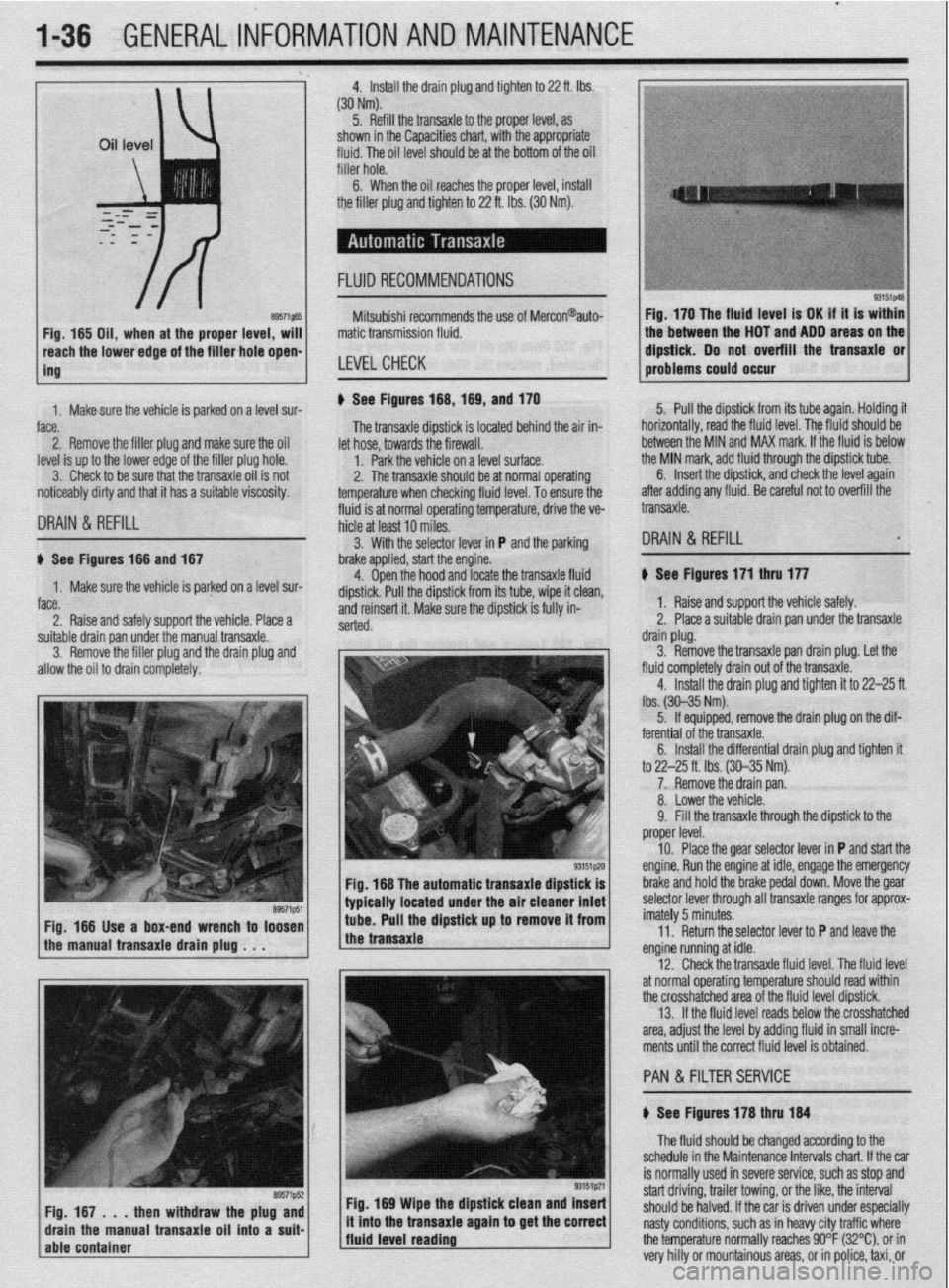

8957i565 Fig, 165 Oil, when at the proper level, will

reach the lower edge of tC=+ frfr*r u*rn -non-

ing Mitsubishi recommends the use of Mercon@auto-

matic transmission fluid.

LEVELCHECK

Fig. 170 The fluid level is OK if it is within

the between the HOT and ADD areas on the

&&i& Do not overfill the transaxle or

-.*".."... -- .*"- problems could o ccur

1. Makesure the vehicle is oarked on a level sur-

face.

2. Remove the filler plug and make sure the oil

level is up to the lower edge of the filler plug hole.

3. Check to be sure that the transaxle oil is not

noticeably dirty and that it has a suitable viscosity. u See Figures 168,169, and 170

fluid is at normal operating temperature, drive the ve- The transaxle dipstick is located behind the air in-

hicle at least 10 miles. let hose, towards the firewall.

1. Park the vehicle on a level surface.

2. The transaxle should be at normal operating

temperature when checking fluid level. To ensure the 5. Pull the dipstick from its tube again. Holding it

horizontally, road the fluid level. The fkrid should be

between the MIN and MAX mark. If the fluid is below

the MIN mark, add fluid through the dipstick tube.

DRAIN & REFILL

6. Insert the dipstick, and check the level again

after adding any fluid. Be careful not to overfill the

transaxle.

3. With the selector lever in P and the parking

DRAIN & REFILL u See Figures 166 and 167

1. Make sure the vehicle is parked on a level sur-

face.

2. Raise and safely support the vehicle. Place a brake applied, start the engine.

4. Open the hood and locate the transaxle fluid

dipstick. Pull the dipstick from its tube, wipe it clean,

and reinsert it. Make sure the dipstick is fully in-

serted.

suitable drain pan under the manual transaxle.

3. Remove the filler plug and the drain plug and

allow the oil to drain completely.

Fig. 166 The automatic transaxle dipstick is

typically located under the air cleaner inlet

Fig. 166 Use a box-end wrench to loosen

the manual transaxle drain plug . . . tube. Pull the dipstick up to remove it from

the transaxle

Fig. 169 Wipe the dipstick clean and Insert

/fluid level reading ., it mto the transaxle agam to get the correct

j The fluid should be changed according to the

schedule in the Maintenance Intervals chart. If the car

is normally used in severe service, such as stop and

start driving, trailer towing, or the like, the interval

should be halved. If the car is driven under especially

nasty conditions, such as in heavy city traffic where

the temperature normally reaches 90°F (32%), or in

very hilly or mountainous areas, or in police, taxi, or b See Figures 171 thru 177

1. Raise and support the vehicle safely.

2. Place a suitable drain pan under the transaxle

drain plug.

3. Remove the transaxle pan drain plug. Let the

fluid completely drain out of the transaxle.

4. Install the drain plug and tighten it to 22-25 ft.

lbs. (30-35 Nm).

5. If equipped, remove the drain plug on the dif-

ferential of the transaxle.

6. Install the differential drain plug and tighten ft

to 22-25 ft. Ibs. (30-35 Nm).

7. Remove the drain pan.

8. Lower the vehicle.

9. Fill the transaxle through the dipstick to the

proper level.

10. Place the gear selector lever in P and start the

engine. Run the engine at idle, engage the emergency

brake and hold the brake pedal down. Move the gear

selector lever through all transaxle ranges for approx-

imately 5 minutes.

11. Return the selector lever to P and leave the

engine running at idle.

12. Check the transaxle fluid level. The fluid level

at normal operating temperature should read within

the crosshatched area of the fluid level dipstick.

13. If the fluid level reads below the crosshatched

area, adjust the level by adding fluid in small incre-

ments until the correct fluid level is obtained.

PAN &FILTER SERVICE

b See Figures 178 thru 184

Page 43 of 408

1-44 GENERALINFORMATIONAND MAINTENANCE

INTERIOR CLEANING

Upholstery

Fabric can usually be cleaned with soapy water or

a proper detergent. For more difficult spots caused by

oil, ice cream, soda, etc., use a fabric cleaner avail-

able at most parts stores. Be sure when purchasing

the cleaner to read the label to ensure it is safe to use

on your type of fabric. A safe method of testing the

cleaner is to apply a small amount to an area usually

unseen, such as under a seat, or other areas. Wart a

while, perhaps even a day to check the spot for fad-

ing, discoloring, etc., as some cleaners will only

cause these problems after they have dried

Leather upholstery requrres special care, it can be

cleaned with a mild soap and a soft cloth. It is recom-

mended that a special leather cleaner be used to

clean but also treat the leather surfaces in your vehi-

cle. Leather surfaces can age quickly and can crack if

not properly taken care of, so it is vital that the leather

surfaces be maintained.

Floor Mats and Carpet

The floor mats and carpet should be vacuumed or

brushed regularly. They can be cleaned with a mild

soap and water. Special cleaners are available to

clean the carpeted surfaces of your vehicle, but take

care in choosing them, and again it is best to test

them in a usually unseen spot.

Dashboard, Console, Door Panels, Etc.

The dashboard, console, door panels, and other

plastic, vinyl, or wood surfaces can be cleaned using

a mild soap and water. Caution must be taken to keep

water out of electronic accessories and controls to

avoid shorts or ruining the components Again spe-

cial cleaners are available to clean these surfaces, as

with other cleaners care must taken in purchasmg

and using such cleaners.

There are protectants available which can treat the

various surfaces in your car giving them a “shiny new

look”, however some of these protectants can cause

more harm than good in the long run. The shine that

is placed on your dashboard attracts sunlight accel-

erating the aging, fading and possibly even cracking

the surfaces. These protectants also attract more dust

to stick to the surfaces they treat, Increasing the cleaning you must do to maintain the appearance of

your vehicle. Personal discretion is advised here.

On most models covered by this manual, the

wheel bearmgs used are sealed units and do not re-

quire routine maintenance. However on some Galant

and Mirage models, the rear wheel bearing do require

periodic repacking. For removal and installation in-

structions, please refer to Section 7 (for rear bear-

ings) or Section 8 (for front bearings).

REPACKING

*Sodium based grease is not compatible

with lithium based grease. Read the package

labels and be careful not to mix the two

types. If there is any doubt as to the type of

grease used, completely clean the old

grease from the bearing and hub before re-

placing.

Before handling the bearings, there are a few

things that you should remember to do and not to do.

DO the following: l Remove all outside dirt from the housing be-

fore exposing the bearing.

l Treat a used bearing as gently as you would a

new one.

l Work with clean tools in clean surroundings. l Use clean, dry gloves, or at least clean, dry

hands.

l Clean solvents and flushing fluids are a must. l Use clean paper when laying out the bearings

to dry.

l Protect drsassembled bearings from rust and

dirt. Cover them up.

l Use clean, lint-free rags to wipe the bearings. l Keep the bearings in oil-proof paper when they

are to be stored or are not in use.

l Clean the inside of the housing before replac-

ing the bearin

Do NOT do he followino: El, l Do not work in dirty sirroundings. l Do not use dirty, chipped or damaged tools. l Do not work on wooden work benches or use

wooden mallets.

l Do not handle bearings with dirty or moist

hands.

l Do not use gasoline for cleaning. Use a safe

solvent.

l Do not spin dry bearings with compressed air.

They will be damaged.

l Do not use cotton waste or dirty cloths to wipe

bearings.

l Do not scratch or nick bearing surfaces. l Do not allow the bearina to come in contact

” with dirt or rust at any time.

The rear wheel bearinas on some Galant and Mi-

rage models require periodic maintenance. A pre-

mium high melting point grease meeting Grade

Multipurpose Grease NLGI Grade #2 or equivalent

must be used. Long fiber type greases must not be

used. This service is recommended every 30,000

miles (48,000 km).

*For information on Wheel Bearing removal

and installation, refer to Section 7 of this

manual.

1. Remove the wheel bearing.

2. Clean all parts in a non-flammable solvent and

let them air dry.

*Only use lint-free rags to dry the bearings.

Never spin-dry a bearing with compressed

air, as this will damage the rollers.

3. Check for excessive wear and damage. Replace

the bearing as necessary.

*Packina wheel bearinos with arease is

best accomplished by u&g a wheel bearing

packer (available at most automotive parts

stores).

4. If a wheel bearing packer is not available, the

bearings may be packed by hand.

a. Place a “healthy’ glob of grease in the

palm of one hand.

b. Force the edge of the bearing into the

grease so that the grease fills the space between

the rollers and the bearing cage.

c. Keep rotating the bearing while continuing

to push the grease through.

d. Continue until the grease is forced out the

other side of the bearing.

5. Place the packed bearing on a clean surface

and cover it until it is time for installation.

6. Install the wheel bearing.

# See Figures 219 and 220

To prevent the bumper from deforming, these vehi-

cles cannot be towed by a wrecker using sling-type

equipment. If these vehicles require towing, use a

wheel lift or flat bed equipment. It is recommended

that the vehicle be towed from the front If a flat bed is

not available.

Manual transaxle vehicles may be towed from the

rear provided that the transaxle is in Neutral and the

driveline has not been damaged. The steering wheel

must be clamped in the straight-ahead positron with a

steering wheel clamping device designed for towing

service use.

Do not use the steering column lock to secure

the front wheel uosition for towina.

Automatic transaxle vehicles may be towed on the

front wheels at speeds not to exceed 30 mph (50

km/h) for a distance not to exceed 18 miles (30 km).

If these limits can not be met, then the front wheels

must be placed on a tow dolly.

# See Figure 221

All Wheel Drive (AWD) vehicles should only be

towed with all 4 wheels on the ground or lifted from

the road surface. This means that the vehicle is to be

towed either with flatbed equipment, with all wheels

on dollies or flat towed. Damage to the viscous cou-

pling may result if the vehicle is towed with only 2

wheels on the ground.

p See Figure 222

Whenever a vehicle is jump started, precautions

must be followed In order to prevent the possibility of

Page 44 of 408

GENERALINFORMATIONAND MAINTENANCE 1-45

SLING TYPE

WHEEL LIFT TYPE

cles

SUNG TYPE

WHEEL LIFT TYPE

FLAT BED TYPE

Fig. 220 Rear towing position-FWD vehi

cles

personal injury. Remember that batteries contain a

small amount of explosive hydrogen gas which is a

by-product of battery charging. Sparks should always

be avoided when working around batteries, especially

when attaching jumper cables. To minimize the pos-

sibility of accidental sparks, follow the procedure

carefully.

NEVER hook the batteries up in a series cir-

cuit or the entire electrical system will go up

in smoke. includino the starter!

Vehicles equipped with a diesel engine may utilize

two 12 volt batteries. If so, the batteries are con-

nected in a parallel circuit (positive terminal to posi-

tive terminal, negative terminal to negative terminal).

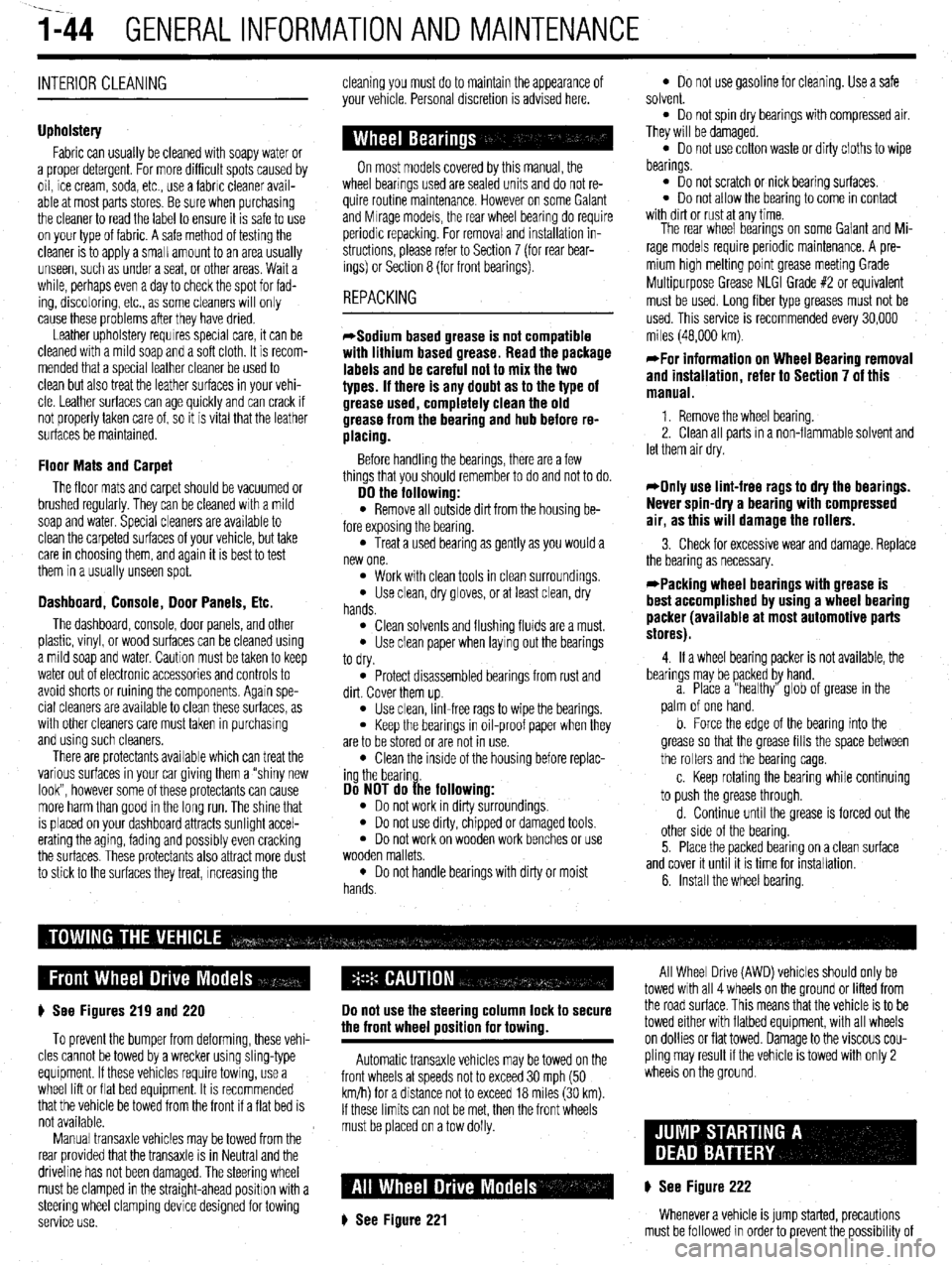

owrng methods

a tow truck IS used

Lrftrng method for 4 wheels-Good

Front wheels lifted-No good

Front wheels lifted-No good

Rear wheels lifted-No good

Towing by rope or cable-Good

e9571g92 qemarks

. For4WD models, the basic principle is that

all four wheels are to be rarsed before

towing.

. The shift lever should be set to 1 st gear and

the parking brake should be applied.

l The vehicle must not be towed by tofacing

only its front wheels or only the rear wheels

on a rollino dollv, because to do so will

result in d&e&ration of the visfx~s

coupling and result in the viscous coupling

causing the vehicle to jump forward

suddenly.

l If only the front wheels or only the rear

wheels are lifted for towing, the bumper

wrll bedamyd.

In addrtron. II trng of the rear wheels causes

the or1 to flow forward. and may result in

heat damage to the rear bushing of the

transfer, and so should never be done.

l The front and rear wheels must rotate

normally.

l The various mechanisms must function

normally.

l The shift lever must be set to the neutral

~Asi&n and the ignition key must be set to

Fig. 221 Towing instructions-AWD models

Hooking the batteries up in parallel circuit increases

battery cranking power without increasing total bat-

tery voltage output. Output remains at 12 volts. On

the other hand, hooking two 12 volt batteries up in a

series circuit (positive terminal to negative terminal,

positive terminal to negative terminal) increases total

battery output to 24 volts (12 volts plus 12 volts).

l Be sure that both batteries are of the same volt-

age. Vehicles covered by this manual and most vehi-

cles on the road today utilize a 12 volt charging sys-

tem.

l Be sure that both batteries are of the same po-

larity (have the same terminal, in most cases NEGA-

TIVE grounded).

l Be sure that the vehicles are not touching or a

short could occur.

l On serviceable batteries, be sure the vent cap

holes are not obstructed.

l Do not smoke or allow sparks anywhere near

the batteries.

l In cold weather, make sure the battery elec-

trolyte is not frozen, This can occur more readily in a

battery that has been in a state of discharge.

l Do not allow electrolyte to contact your skin or

clothing.

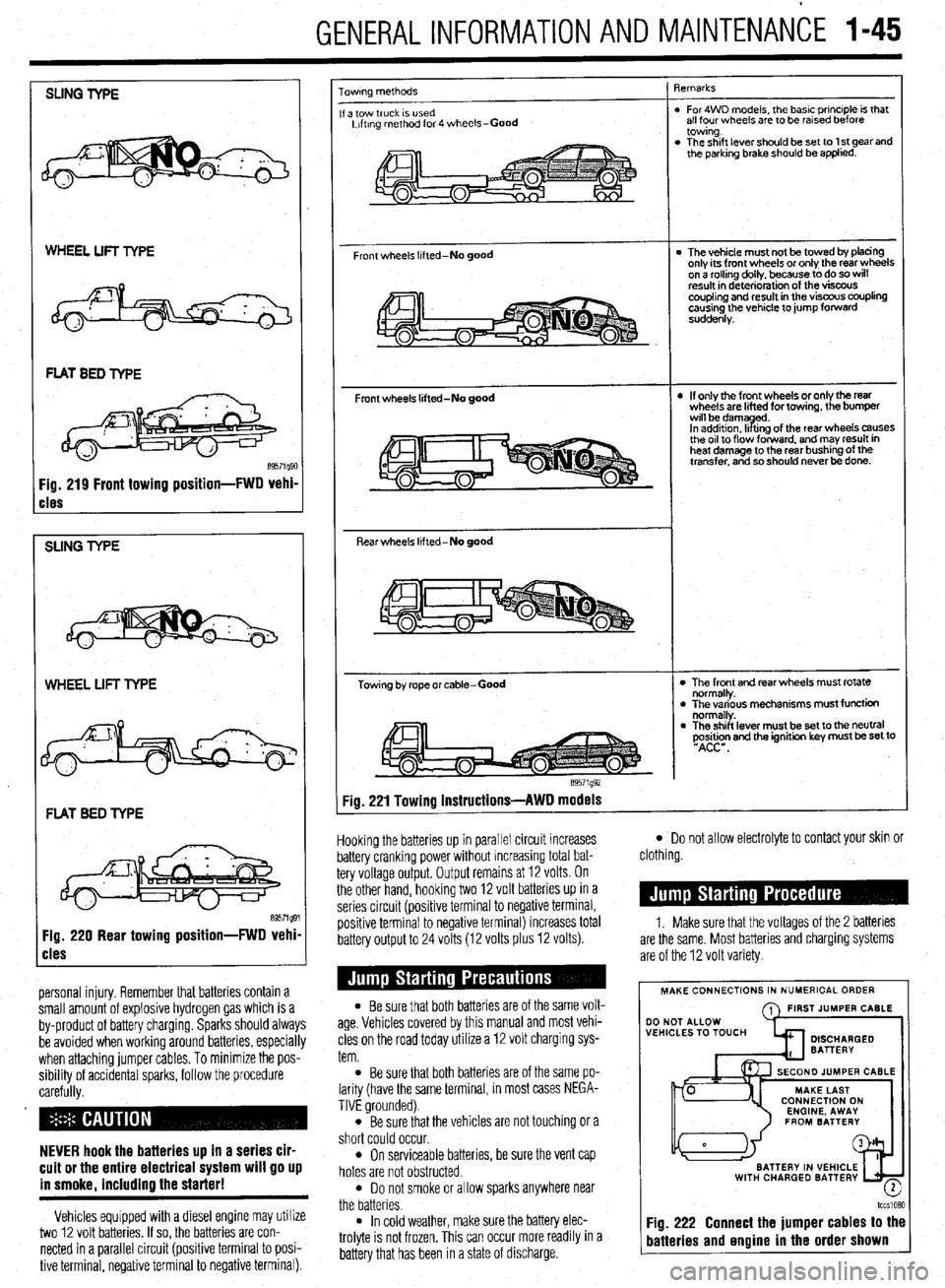

1. Make sure that the voltages of the 2 batteries

are the same. Most batteries and charging systems

are of the 12 volt variety.

MAKE CONNECTIONS IN NUMERICAL ORDER

A FIRST JUMPER CABLE

WITH CHARGED BATTERY

-

lccslQ?,Q

Fig. 222 Connect the jumper cables to the

batteries and engine in the order shown

Page 46 of 408

GENERAL INFORMATION AND MAINTENANCE 1-47

ramps are also a handy and safe way to both raise l When the drive wheels are to remain on the

and support the vehicle. Be careful though, some ground, leave the vehicle in gear to help prevent it

ramps may be too steep to drive your vehicle onto

The following safety points cannot be overempha- from rolling.

without scraping the front bottom panels. Never sup-

sized:

l Always use jackstands to support the vehicle

port the vehicle on any suspension member (unless l Always block the opposite wheel or wheels to when you are working underneath. Place the stands

specifically instructed to do so by a repair manual) or

keep the vehicle from rolling off the jack. beneath the vehrcle’s jacking brackets Before climb-

by an underbody panel.

l When raising the front of the vehicle, firmly ap- ing underneath, rock the vehicle a bit to make sure it

ply the parking brake. is firmly supported.

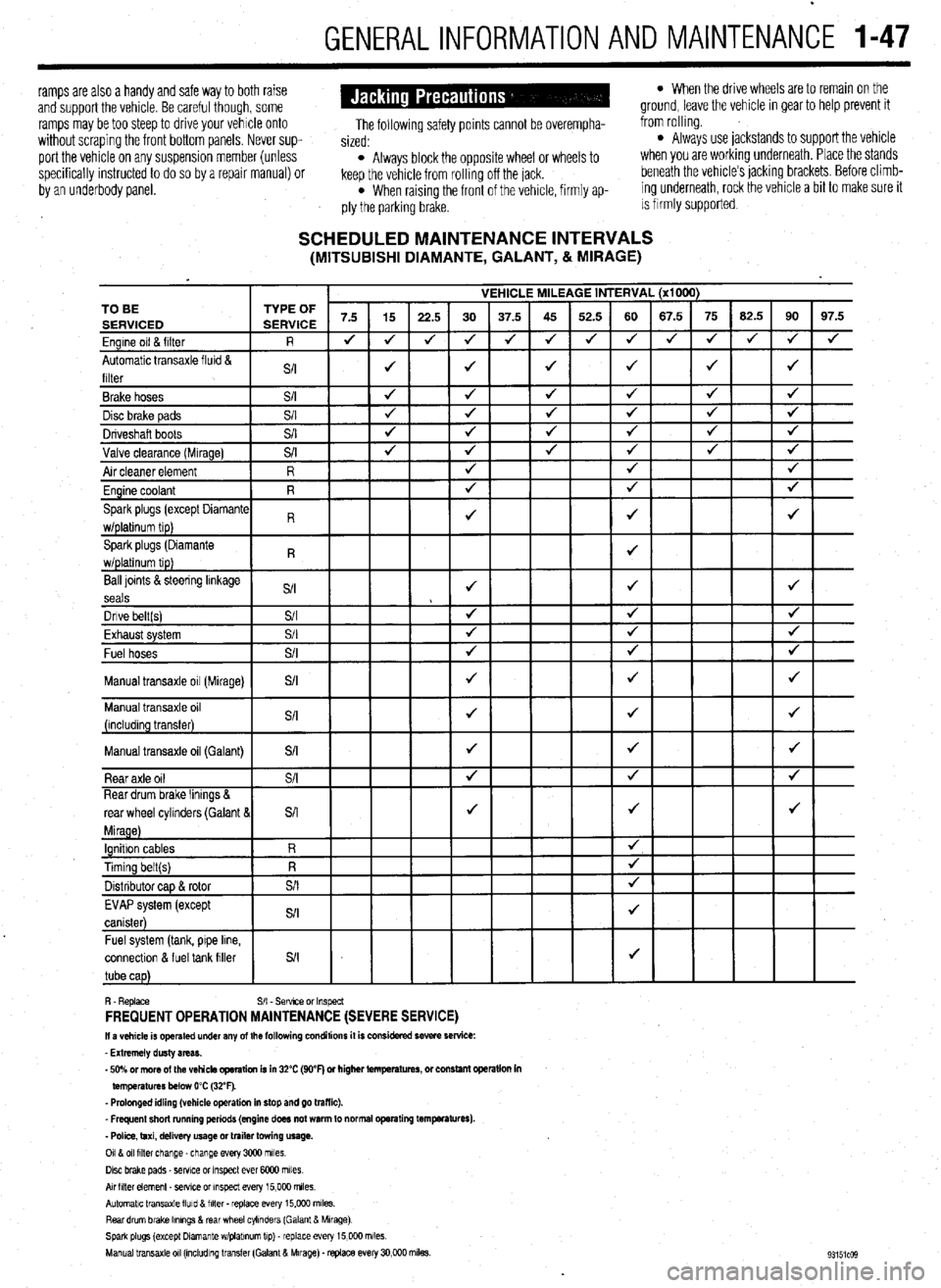

SCHEDULED MAINTENANCE INTERVALS (MITSUBISHI DIAMANTE, GALANT, & MIRAGE)

VEHICLE MILEAGE INTERVAL (x1000)

7.5 15

22.5 30 37.5 45 52.5 60 67.5 75 62.5 90 97.5

J J

J 4 J J 4 4 4 J J

J 4

4

J J J J 4 TO BE

Ball loints &steering linkage

S/I J J J

seals

Dnve belt(s) S/I 4 4 J

Fvha,,rt cvctom $/I

J J J LmI,..“w. “,YL”,‘. Fuel hoses

+

Manual transaxle oil (Galant)

connectlon & fuel tank filler

R. Replace S/I - Sefwce or Inspect FREQUENT OPERATION MAINTENANCE (SEVERE SERVICE) II a vehicle is operated under any of the following conditions it is considered severe service:

- Extremely dusty areas.

- 50% or more of the vehicle operation is in 32% (WF) or higher temperatures, or constant opsralion in

temperatures below 0% (32°F).

- Prolonged idling (vehicle operation in stop and go traffic).

_ Frequent short running periods (engine does not warm to normal operating temfwatures).

- Police, taxi, delivery usage or trailer towing usage.

0118 011 filter change-change every 3CQO miles.

Disc brake pads - sewce or Inspect ever 6COO miles

AN hlter element _ setwe or inspect every 15,000 miles.

Automatic transaxle lluld 8 filter . replace every 15,COO m&s.

Rear drum brake Ikmngs & rear wheel cylinders (Galant & Mirage)

Spark plugs (except Dlamante wlplabnum tip) - replace every 15,COO miles.

Manual transaxle 011 (mcludlng transfer (Galant & Mirage). replace every 30,000 miles.

Page 407 of 408

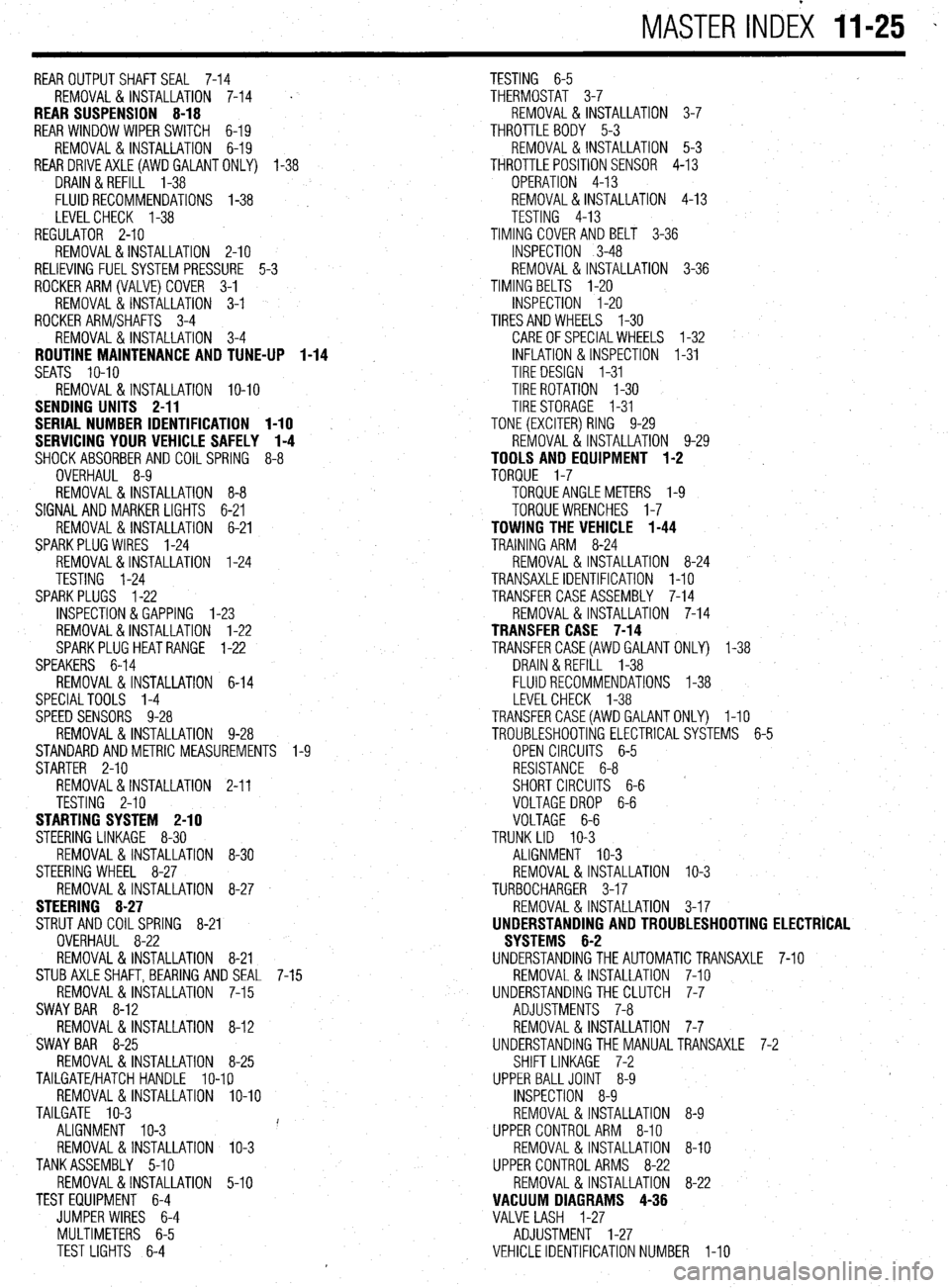

MASTER INDEX 11-25 -

REAROUTPUTSHAFTSEAL 7-14

TESTING 6-5

REMOVAL & INSTALLATION 7-14

' THERMOSTAT 3-7

REAR SUSPENSION 8-18 REMOVAL & INSTALLATION 3-7

REAR WINDOW WIPER SWITCH 6-19 THROTTLE BODY 5-3

REMOVAL&INSTALLATION 6-19 REMOVAL & INSTALLATION 5-3

REARDRlVEAXLE(AWDGALANTONLY) l-38

THROTTLEPOSITIONSENSOR 4-13

DRAIN &REFILL 1-38

OPERATION 4-13

FLUIDRECOMMENDATIONS 1-38 , REMOVAL&INSTALLATION 4-13

LEVELCHECK l-38

TESTING 4-13

REGULATOR 2-10 TIMING COVERAND BELT 3-36

REMOVAL&INSTALLATION 2-10

INSPECTION 3-48

RELIEVING FUELSYSTEM PRESSURE 5-3 REMOVAL & INSTALLATION 3-36

ROCKERARM(VALVE)COVER 3-1

TIMING BELTS l-20

REMOVAL & INSTALLATION 3-1

INSPECTION I-20

ROCKER ARM/SHAFTS 3-4

TIRESANDWHEELS I-30

REMOVAL & INSTALLATION 3-4

CAREOFSPECIALWHEELS l-32

ROUTINE MAINTENANCE AND TUNE-UP 1-14 INFLATION & INSPECTION I-31

SEATS IO-IO

TIRE DESIGN I-31

REMOVAL&INSTALLATION IO-IO TIRE ROTATION I-30

SENDING UNITS 2-11

TIRESTORAGE I-31

SERIAL NUMBER IDENTIFICATION l-10

TONE (EXCITER) RING 9-29

SERVICING YOUR VEHICLE SAFELY I-4

REMOVAL & INSTALLATION 9-29

SHOCKABSORBERAND COILSPRING 8-8

TOOLS AND EQUIPMENT 1-2

OVERHAUL 8-9

TORQUE 1-7

REMOVAL&INSTALLATION 8-8 TORQUEANGLEMETERS l-9

SIGNAL AND MARKER LIGHTS 6-21

TORQUEWRENCHES l-7

REMOVAL & INSTALLATION 6-21

TOWING THE VEHICLE 1-44

SPARKPLUG WIRES 1-24

TRAINING ARM 8-24

REMOVAL&INSTALLATION 1-24

REMOVAL & INSTALLATION 8-24

TESTING 1-24

TRANSAXLEIDENTIFICATION I-10

SPARKPLUGS l-22

TRANSFER CASE ASSEMBLY 7-14

INSPECTION &GAPPING l-23

REMOVAL & INSTALLATION 7-14

REMOVAL&INSTALLATION 1-22

TRANSFER CASE 7-14

SPARKPLUGHEATRANGE 1-22

TRANSFERCASE(AWD GALANT ONLY) 1-38

SPEAKERS 6-14

DRAIN &REFILL 1-38

REMOVAL & INSTALLATION 6-14

FLUIDRECOMMENDATIONS 1-38

SPECIALTOOLS 1-4

LEVELCHECK 1-38

SPEED SENSORS 9-28

TRANSFERCASE(AWDGALANTONLY) I-10

REMOVAL & INSTALLATION 9-28

TROUBLESHOOTING ELECTRICALSYSTEMS 6-5

STANDARDANDMETRIC MEASUREMENTS l-9

OPEN CIRCUITS 6-5

STARTER 2-10

RESISTANCE 6-8

REMOVAL&INSTALLATION 2-11

SHORT CIRCUITS 6-6

TESTING 2-10

VOLTAGEDROP 6-6

STARTING SYSTEM 2-10

VOLTAGE 6-6

STEERING LINKAGE 8-30

TRUNK LID IO-3

REMOVAL &INSTALLATION 8-30

ALIGNMENT IO-3

STEERING WHEEL 8-27

REMOVAL & INSTALLATION IO-3

REMOVAL &INSTALLATION 8-27

TURBOCHARGER 3-17

STEERING 8-27

REMOVAL & INSTALLATION 3-17

STRUT AND COIL SPRING

8-21

UNDERSTANDING AND TROUBLESHOOTING ELECTRICAL

OVERHAUL 8-22

SYSTEMS 6-2

REMOVAL & INSTALLATION 8-21

UNDERSTANDINGTHEAUTOMATICTRANSAXLE 7-10

STUBAXLESHAFT,BEARlNG AND SEAL 7-15

REMOVAL & INSTALLATION 7-10

REMOVAL&INSTALLATION 7-15

UNDERSTANDINGTHECLUTCH 7-7

SWAY BAR 8-12

ADJUSTMENTS 7-8

REMOVAL 8, INSTALLATION 8-12

REMOVAL&INSTALLATION 7-7

SWAY BAR 8-25

UNDERSTANDINGTHE MANUALTRANSAXLE 7-2

REMOVAL&INSTALLATION 8-25

SHIFT LINKAGE 7-2

TAILGATE/HATCH HANDLE lo-19

UPPER BALLJOINT 8-9

REMOVAL &INSTALLATION lo-10

INSPECTION 8-9

TAILGATE IO-3

REMOVAL &INSTALLATION 8-9

ALIGNMENT IO-3 i'

UPPER CONTROLARM 8-10

REMOVAL & INSTALLATION IO-3

REMOVAL & INSTALLATION 8-10

TANKASSEMBLY 5-10

UPPER CONTROL ARMS 8-22

REMOVAL&INSTALLATION 5-10

REMOVAL & INSTALLATION 8-22

TEST EQUIPMENT 6-4

VACUUM DIAGRAMS 4-36

JUMPER WIRES 6-4

VALVE LASH 1-27

MULTIMETERS 6-5

ADJUSTMENT 1-27

TEST LIGHTS 6-4

VEHICLE IDENTIFICATION NUMBER I-10