windshield wipers MITSUBISHI DIAMANTE 1900 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 1 of 408

HOW TO USE THIS BOOK 1-2

WHERE TOBEGIN l-2

AVOIDINGTROUBLE 1-2

MAINTENANCEORREPAIR? 1-2

AVOIDINGTHEMOSTCOMMONMISTAKES l-2

TOOLS AND EQUIPMENT 1-2

SPECIALTOOLS l-4

YOUR VEHICLE SAFELY 1-4

DON'TS l-6

FASTENERS, MEASUREMENTS AND

CONVERSIONS l-6

BOLTS,NUTSANDOTHERTHREADED

RETAINERS 1-6

TORQUE l-7

TORQUEWRENCHES l-7

TORQUEANGLEMETERS 1-9

STANDARDANDMETRIC MEASUREMENTS l-9

SERIAL NUMBER IDENTIFICATION l-10

VEHICLE IDENTIFICATION NUMBER l-10

ENGINE IDENTIFICATION NUMBER I-10

TRANSAXLEIDENTIFICATION I-10

DRlVEAXLE(AWDGALANTONLY) l-10

TRANSFERCASE(AWDGALANTONLY) l-10

ROUTINE MAINTENANCE AND TUNE-UP l-14

AIRCLEANER(ELEMENT) 1-14

REMOVAL&INSTALLATION 1-14

FUELFILTER 1-15

REMOVAL &INSTALLATION l-15

PCVVALVE l-15

REMOVAL&INSTALLATION l-15

EVAPORATIVECANISTER l-16

SERVICING 1-16

BATTERY 1-16

PRECAUTIONS I-16

GENERALMAINTENANCE 1-16

BEL BATTERYFLUID 1-16

CABLES I-17

CHARGING I-18

REPLACEMENT 1-18

TS 1-18

INSPECTiON l-18

ADJUSTMENT 1-18

REMOVAL&INSTALLATION 1-18

TIMINGBELTS l-20

INSPECTION l-20

HOSES I-20

INSPECTION l-20

REMOVAL&INSTALLATION

CV-BOOTS 1-21

INSPECTION l-21

SPARKPLUGS l-22

SPARKPLUGHEATRANGE

REMOVAL&INSTALLATION

INSPECTION &GAPPING 1.

SPARKPLUG WIRES 1-24

TESTING 1-24

REMOVAL&INSTALLATION

DISTRIBUTORCAPANDROTOR

REMOVAL&INSTALLATION

INSPECTION 1-25

IGNITIONTIMING 1-25

. GENERALINFORAMTION l-

lNSPECTlON&ADJUSTMENl

VALVE LASH l-27

ADJUSTMENT l-27

IDLESPEED 1-28 1-21

l-22

l-22

-23

1-24

l-25

l-25

.25

1-26

AIR CONDITIONING SYSTEM 1-28

SYSTEMSERVlCEiiREPAlR l-28

PREVENTIVEMAINTENANCE 1-28

SYSTEM INSPECTION l-29

WINDSHIELD WIPERS l-29

ELEMENT(REFILL)CARE&

REPLACEMENT l-29

TIRESANDWHEELS l-30

TIRE ROTATION I-30

TIRE DESIGN 1-31

TIRESTORAGE l-31

INFLATION &INSPECTION l-31

CARE OFSPECIALWHEELS l-32 OPERATION INFOREIGNCOUNTRIES l-33

ENGINE l-33

OILLEVELCHECK 1-33

OIL& FILTER CHANGE l-34

MANUALTRANSAXLE l-35

FLUIDRECOMMENDATIONS l-35

LEVELCHECK l-35

DRAIN&REFILL l-36

AUTOMATICTRANSAXLE l-36

FLUIDRECOMMENDATIONS l-36

LEVELCHECK 1-36

DRAIN&REFILL l-36

PAN & FILTERSERVICE 1-36

TRANSFERCASE(AWDGAlANT ONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

REARDRlVEAXLE(AWDGALANTONLY) l-38

FLUIDRECOMMENDATIONS l-38

LEVELCHECK l-38

DRAIN&REFILL l-38

COOLINGSYSTEM l-39

FLUIDRECOMMENDATIONS l-39

iM-41

FLUIDS AND LUBRICANTS 1-33

FLUID DISPOSAL 1-33

FlJELANDENGlNEOILRECOMMENDATlONS

ENGINE OIL l-33

FUEL l-33

Page 28 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-29

i

*Bug screens which are mounted in front of

the condenser (unless they are original

equipment) are regarded as obstructtons.

l The condensation drain tube expels any water

which accumulates on the bottom of the evaporator

housing into the engine compartment. If this tube is

obstructed, the air conditioning performance can be

restricted and condensation buildup can spill over

onto the vehicle’s floor.

l Make sure the air passage selection lever is

operating correctly. Start the engine and warm it to

normal operating temperature, then make sure the

temperature selection lever is operating correctly.

-w

~1 ELEMENT(REFILL)CARE& REPLACEMENT

SYSTEM INSPECTION

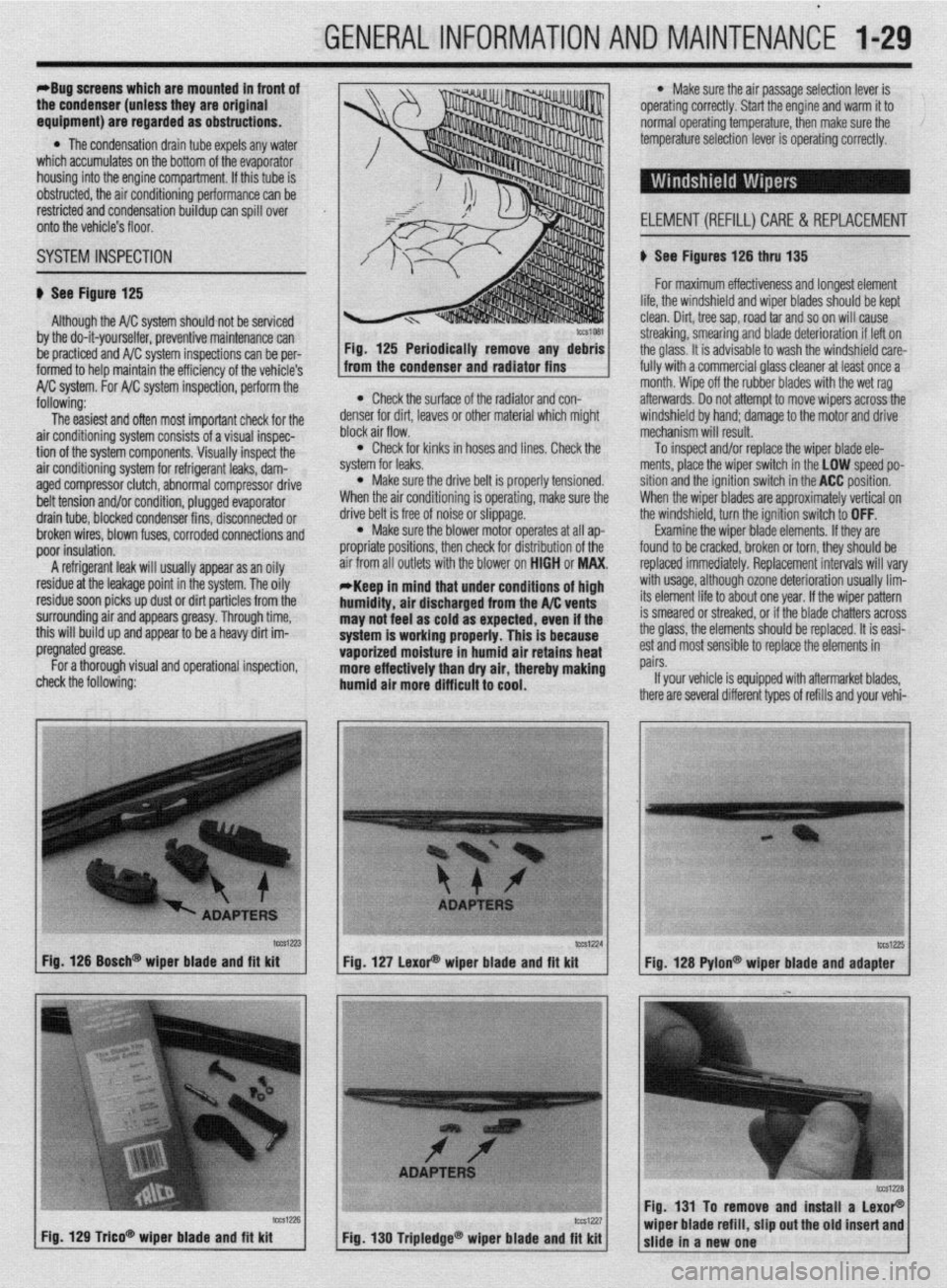

b See Figure 125 b See Figures 126 thru 135

For maximum effectiveness and longest element

Although the A/C system should not be serviced

by the do-it-yourselfer, preventive maintenance can

be practiced and A/C system inspections can be per-

formed to help maintain the efficiency of the vehicle’s

A/C system. For A/C system inspection, perform the

following:

The easiest and often most important check for the

air conditioning system consists of a visual inspec-

tion of the system components. Visually inspect the

air conditioning system for refrigerant leaks, dam-

aged compressor clutch, abnormal compressor drive

belt tension and/or condition, plugged evaporator

drain tube, blocked condenser fins, disconnected or

broken wires, blown fuses, corroded connections and

poor insulation.

A refrigerant leak will usually appear as an oily

residue at the leakage point in the system. The oily

residue soon picks up dust or dirt particles from the

surrounding air and appears greasy. Through time,

this will build up and appear to be a heavy dirt im-

pregnated grease.

For a thorough visual and operational inspection,

check the following: * Check the surface of the radiator and con-

denser for dirt, leaves or other material which might

block air flow.

l Check for kinks in hoses and lines. Check the

system for leaks.

l Make sure the drive belt is properly tensioned.

When the air conditioning is operating, make sure the

drive belt is free of noise or slippage.

l Make sure the blower motor operates at all ap-

propriate positions, then check for distribution of the

air from all outlets with the blower on HIGH or MAX.

*Keep in mind that under conditions of high

humidity, air discharged from the A/C vents

may not feel as cold as expected, even if the

system is working properly. This is because

vaporized moisture in humid air retains heat

more effectively than dry air, thereby making

humid air more difficult to cool.

lifp thp winrkhi&i nnri winor hlarlP~ shmM hP kmt . ..“. .I.” . . * ““I.. “.” I..” ...r”* “.“““” “, ,““,” “” ,~“r~ clean. Dirt, tree sap, road tar and so on will cause

streaking, smearing and blade deterioration if left on

the glass. It is advisable to wash the windshield care-

fully with a commercial glass cleaner at least once a

month. Wipe off the rubber blades with the wet rag

afterwards. Do not attempt to move wipers across the

windshield by hand; damage to the motor and drive

mechanism will result.

To inspect and/or replace the wiper blade ele-

ments, place the wiper switch in the LOW speed po-

sition and the ignition switch in the ACC position.

When the wiper blades are approximately vertical on

the windshield, turn the ignition switch to OFF.

Examine the wiper blade elements. If they are

found to be cracked, broken or torn, they should be

replaced immediately. Replacement intervals will vary

with usage, although ozone deterioration usually lim-

its element life to about one year. If the wiper pattern

is smeared or streaked, or if the blade chatters across

the glass, the elements should be replaced. It is easi-

est and most sensible to replace the elements in

pairs.

If your vehicle is equipped with aftermarket blades,

there are several different types of refills and your vehi-

tcca-23 Fig. 126 Bosch@ wiper blade and fft kit

Fig. 129 T&o* wioer blade and fit kit tCS1224

lW1Z?5 Fig. 127 LexoP wiper blade and fit kit

Fig. 128 Pylon@ wiper blade and adapter

Fig. 131 To remove and install a LexoP

Fig, 130 Tripledge@ wiper blade and fit kit wiper blade refill, slip out the old insert and

slide in a new one

Page 204 of 408

UNDERSTANDING AND

TROUBLESHOOTING

ELECTRICAL SYSTEMS 6-2

BASIC ELECTRICALTHEORY 6-2

HOW DOES ELECTRICITY WORK:

THEWATERANALOGY 6-2

OHM'S LAW 6-2

ELECTRICALCOMPONENTS 6-2

POWERSOURCE 6-2

GROUND 6-3

PROTECTIVE DEVICES 6-3

SWITCHES&RELAYS 6-3

LOAD 6-3

WIRING & HARNESSES 6-3

CONNECTORS 6-4

TEST EQUIPMENT 6-4

JUMPER WIRES 6-4

TEST LIGHTS 6-4

MULTIMETERS 6-5

TROUBLESHOOTING ELECTRICAL

SYSTEMS 6-5

TESTING 6-5

OPEN CIRCUITS 6-5

SHORT CIRCUITS 6-6

VOLTAGE 6-6

VOLTAGE DROP 6-6

RESISTANCE 6-8

WIRE AND CONNECTORREPAIR 6-6

BATTERY CABLES 6-7

DISCONNECTING THE CABLES 6-7

AIR BAG (SUPPLEMENTAL

RESTRAINT SYSTEM) 6-7

GENERALINFORMATION 6-7

SERVICE PRECAUTIONS 6-7

DISARMING 6-7

REARMING 6-7

HEATING AND AIR

CONDITIONING 6-7

BLOWER MOTOR 6-7

REMOVAL &INSTALLATION 6-7

HEATER CORE 6-9 INSTRUMENTS AND SWITCHES 6-17

INSTRUMENTCLUSTER 6-17

REMOVAL &INSTALLATION 6-17

GAUGES 6-18

REMOVAL&INSTALLATION 6-18

WINDSHIELD WIPER SWITCH 6-19

REMOVAL&INSTALLATION 6-19

REARWINDOWWIPERSWITCH 6-19

REMOVAL &INSTALLATION 6-19

DIMMER SWITCH 6-19

REMOVAL & INSTALLATION 6-19 .

HEADLIGHT SWITCH 6-19

REMOVAL & INSTALLATION 6-19

LIGHTING 6-19

HEADLIGHTS 6-19

REMOVAL &INSTALLATION 6-19

AIMINGTHEHEADLIGHTS 6-20

SIGNAL AND MARKER LIGHTS 6-21

REMOVAL &INSTALLATION 6-21

CIRCUIT PROTECTION 6-27

FUSES 6-27

REPLACEMENT 6-27

FUSIBLE LINKS 6-27

CIRCUIT BREAKERS 6-28

RESETTING AND/OR

REPLACEMENT 6-28

FLASHERS 6-28

REPLACEMENT 6-28

WIRING DIAGRAMS 6-31

REMOVAL & INSTALLATION 6-9

AIR CONDITIONING COMPONENTS 6-11

REMOVAL & INSTALLATION 6-11

CONTROLCABLES 6-12

ADJUSTMENT 6-12

CONTROL PANEL 6-12

REMOVAL & INSTALLATION 6-12

CRUISE CONTROL 6-13

ENTERTAINMENT SYSTEMS 6-14

RADIO RECEIVER/AMPLIFIER/TAPE

PLAYER/CD PLAYER 6-14

SPEAKERS 6-14

REMOVAL & INSTALLATION 6-14

WINDSHIELD WIPERS AND

WASHERS 6-15

WINDSHIELD WIPER BLADE AND

ARM 6-15

REMOVAL & INSTALLATION 6-15

WINDSHIELD WIPER MOTOR 6-16 _

REMOVAL &INSTALLATION 6-16

WINDSHIELD WASHER PUMP 6-17

REMOVAL &INSTALLATION 6-17

Page 210 of 408

I I

CHASSIS ELECTRICAL 6-7

When working on any electrical component on the

vehicle, it is always a good idea to disconnect the

negative (-) battery cable. This will prevent potential

damage to many sensitive electrical components

such as the Powertrain Control Module (PCM), radio,

alternator, etc.

*Any time you disengage the battery cables,

it is recommended that you disconnect the negative (-) battery cable first. This will pre-

vent your accidentally grounding the positive

(+) terminal to the body of the vehicle when

disconnecting it, thereby preventing damage

to the above mentioned components.

Before you disconnect the cable(s), first turn the

ignition to the OFF position. This will prevent a draw

on the battery which could cause arcing (electricity

trying to ground itself to the body of a vehicle, just

like a spark plug jumping the gap) and, of course, damaging some components such as the alternator

diodes.

When the battery cable(s) are reconnected (nega-

tive cable last), be sure to check that your lights,

windshield wipers and other electrically operated

safety components are all working correctly. If your

vehicle contains an Electronically Tuned Radio (ETR),

don’t forget to also reset your radio stations. Ditto for

the clock.

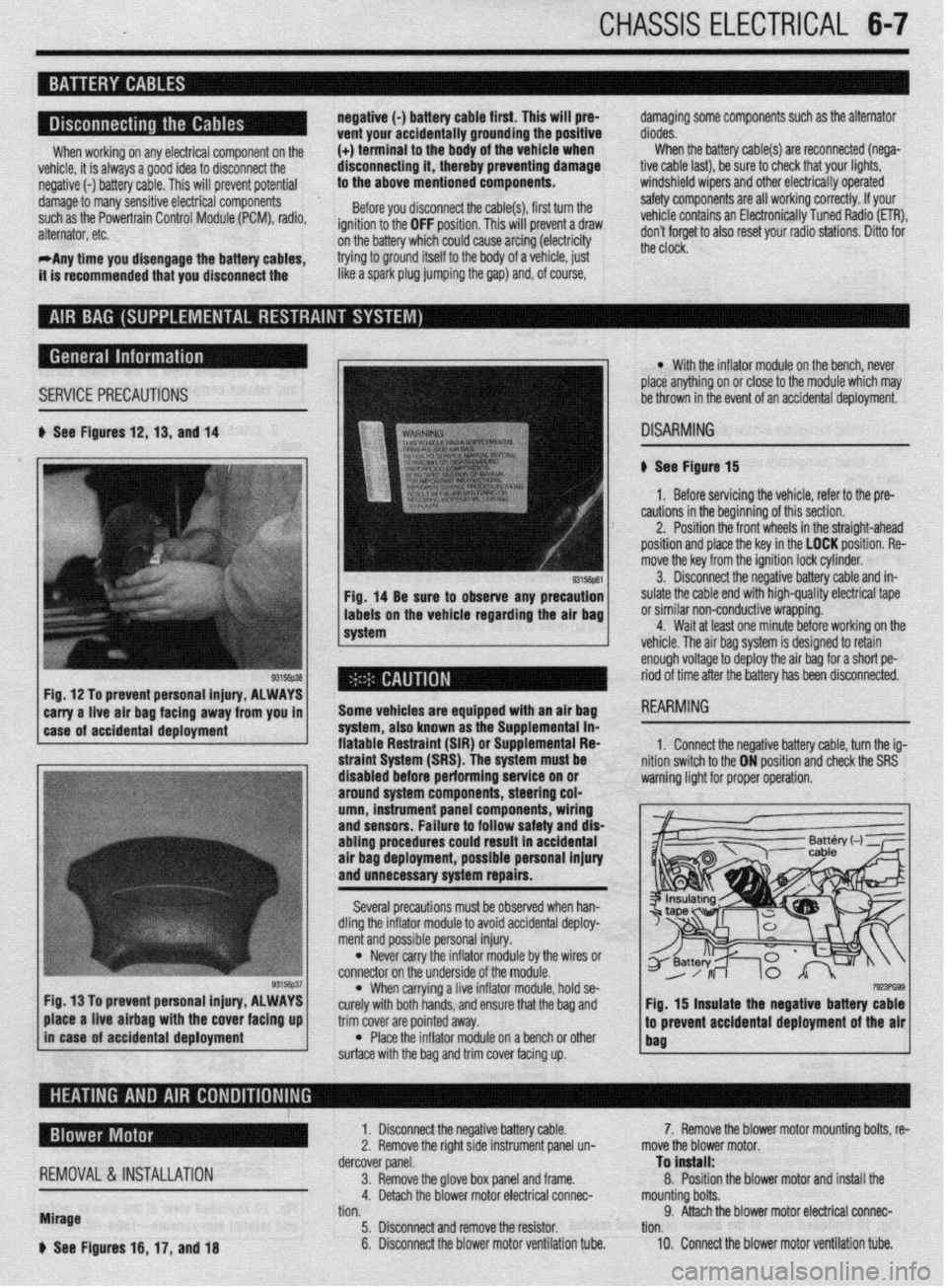

SERVICE PRECAUTIONS

b See Figures 12,13, and 14

Fig, 14 Be sure to observe any precaution

labels on the vehicle regarding the air bag

system

Fig. 12 To prevent personal injury, ALWAYS

*

carry a-live -ah bag fac!ng away from you in 1

1 case of accidental deployment Some vehicles are equipped wtth an air bag

-.-‘--

syr1em, aiscl Known as I11 -I-- ‘------- -- sLe Supplemental in- fiatable Restraint (SIR) o r Suouiementai Fiea

l With the inflator module on the bench, never

place anything on or close to the module which may

be thrown in the event of an accidental deployment.

DISARMING

# See Figure 15

1. Before servicing the vehicle, refer to the pre-

cautions in the beginning of this section.

2. Position the front wheels in the straight-ahead

position and place the key in the LOCK position. Re-

move the key from the ignition lock cylinder.

3. Disconnect the negative battery cable and in-

sulate the cable end with high-quality electrical tape

or similar non-conductive wrapping.

4. Wait at least one minute before working on the

vehicle. The air baa svstem is desianed to retain

enough voltage to deploy the air bag for a short pe-

riod of time after the battery has been disconnected.

1. Connect the neoative batters cable. turn the ia-

3, hold se-

e bag and

trim cover are pointed away.

l Place the inflator module on a bench or other

surface with the bag and trim cover facing up.

7!r!3PG93 Fig. 15 insulate the negative battery cable

.I

to prevent accidental deployment of the air

bag place a live airbag with the cover facing up

in case of accidental deployment

REMOVAL &INSTALLATION

Mirage

b See Figures 16, 17, and 18 1. Disconnect the negative battery cable.

2. Remove the right side instrument panel un-

dercover panel.

3. Remove the glove box panel and frame.

4. Detach the blower motor electrical connec-

tion.

5. Disconnect and remove the resistor.

6. Disconnect the blower motor ventilation tube. 7. Remove the blower motor mounting bolts, re-

move the blower motor.

To install:

8. Position the blower motor and install the

mounting bolts.

9. Attach the blower motor electrical connec-

tion.

10. Connect the blower motor ventilation tube.

Page 383 of 408

TROUBLESHOOTING INDEX 11-2

SECTION 1: ENGINE 11-2

SECTION 2: DRIVE TRAIN

11-3

SECTION 3:BRAKESYSTEM 11-3

SECTION 4:WHEELS,TIRES, STEERING,

AND SUSPENSION II-4

SECTION 5: ELECTRICAL

ACCESSORIES II-4

SECTION 6:lNSTRUMENTSAND

GAUGES II-5

SECTION 7:CLlMATE CONTROL II-5

DIAGNOSTIC PROCEDURES II-6

SECTION 1: ENGINE II-6

ENGINE STARTING PROBLEMS II-6

ENGINE RUNNING CONDITIONS II-7

ENGINE NOISES,ODORSAND

VIBRATIONS II-8

ENGINE ELECTRICALSYSTEM 11-8

ENGINE COOLING SYSTEM II-8

ENGINE EXHAUSTSYSTEM II-9

SECTION 2: DRIVE TRAIN

II-9

AUTOMATIC TRANSMISSION II-9

MANUALTRANSMISSION II-10

CLUTCH II-10

DIFFERENTIAL AND FINAL

DRIVE II-10

TRANSFER ASSEMBLY II-10

DRIVESHAFT II-10

AXLES II-II

OTHER DRIVE TRAIN

CONDITIONS II-II

SECTION 3:BRAKE SYSTEM II-II

BRAKESYSTEM

TROUBLESHOOTING II-II

SECTION 4:WHEELS, TIRES, STEERING

AND SUSPENSION II-12

WHEELSAND WHEEL

BEARINGS II-12

TIRES II-12

STEERING II-12

SUSPENSION II-12

DRIVING NOISES AND

VIBRATIONS II-13

SECTION 5:ELECTRlCAL

ACCESSORIES II-13 -

HEADLIGHTS II-13

TAIL, RUNNING AND SIDE MARKER

LIGHTS II-13

INTERIOR LIGHTS II-14

BRAKE LIGHTS II-14

WARNING LIGHTS II-14

TURN SlGNALAND4-WAYHAZARD

LIGHTS II-15

WINDSHIELD WIPERS II-15

SECTION 6:lNSTRUMENTSAND

GAUGUES II-15

I

SPEEDOMETER(CABLE

OPERATED) II-15

SPEEDOMETER(ELECTRONICALLY

OPERATED) II-16

FUEL,TEMPERATUREAkJD OIL

PRESSURE GAUGES II-16 SECTION 7:CLlMATECON

AIR CONDITIONER ll-

HEATER II-16 TR(

-16 IL II-16

Page 387 of 408

.

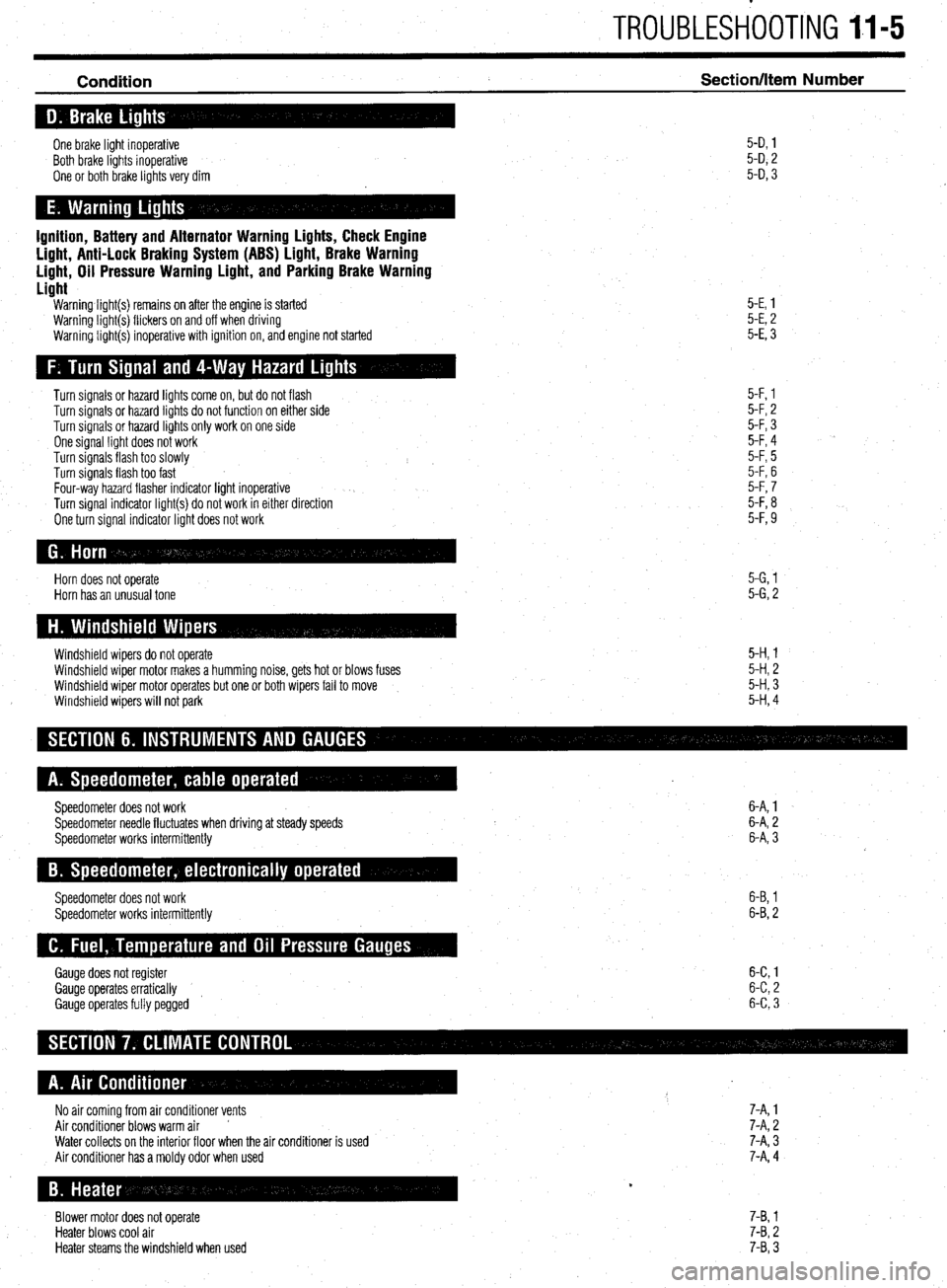

TROUBLESHOOTING II-5

Condition Section/Item Number

One brake light inoperative

Both brake lights inoperative

One or both brake lights very dim 5-D, 1

5-D, 2

5-D, 3

Ignition, Battery and Alternator Warning Lights, Check Engine

Light, Anti-Lock Braking System (ABS) Light, Brake Warning

Light, Oil Pressure Warning Light, and Parking Brake Warning

Light

Warning light(s) remains on after the engine is started

Warning light(s) flickers on and off when driving

Warning light(s) inoperative with ignition on, and engine not started 5-E, 1

5-E, 2

5-E, 3

Turn signals or hazard lights come on, but do not flash

Turn signals or hazard lights do not function on either side

Turn signals or hazard lights only work on one side

One signal light does not work

Turn signals flash too slowly

Turn signals flash too fast

Four-way hazard flasher indicator light inoperative

Turn signal indicator light(s) do not work in either direction

One turn signal indicator light does not work 5-F, 1

5-F, 2

5-F, 3

5-F, 4

5-F, 5

5-F, 6

5-F, 7

5-F, 8

5-F, 9

Horn does not operate

Horn has an unusual tone 5-G, 1

5-G, 2

Windshield wipers do not operate

Windshield wiper motor makes a humming noise, gets hot or blows fuses

Windshield wiper motor operates but one or both wipers fail to move

Windshield wipers will not park 5-H, 1

5-H, 2

5-H, 3

5-H, 4

Speedometer does not work

Speedometer needle fluctuates when driving at steady speeds

Speedometer works intermittently 6-A, 1

6-A, 2

6-A, 3

Speedometer does not work

Speedometer works intermittently 6-B, 1

6-B, 2

Gauge does not register 6-C 1

Gauge operates erratically 6-C 2

’

Gauge operates fully pegged 6-C 3

No air coming from air conditioner vents 7-A, 1

Air conditioner blows warm air ’ 7-A, 2

Water collects on the interior floor when the air conditioner is used

Air conditioner has a moldy odor when used 7-A, 3

7-A, 4

Blower motor does not operate

Heater blows cool air

Heater steams the windshield when used 7-B, 1

7-B, 2

7-B, 3

Page 397 of 408

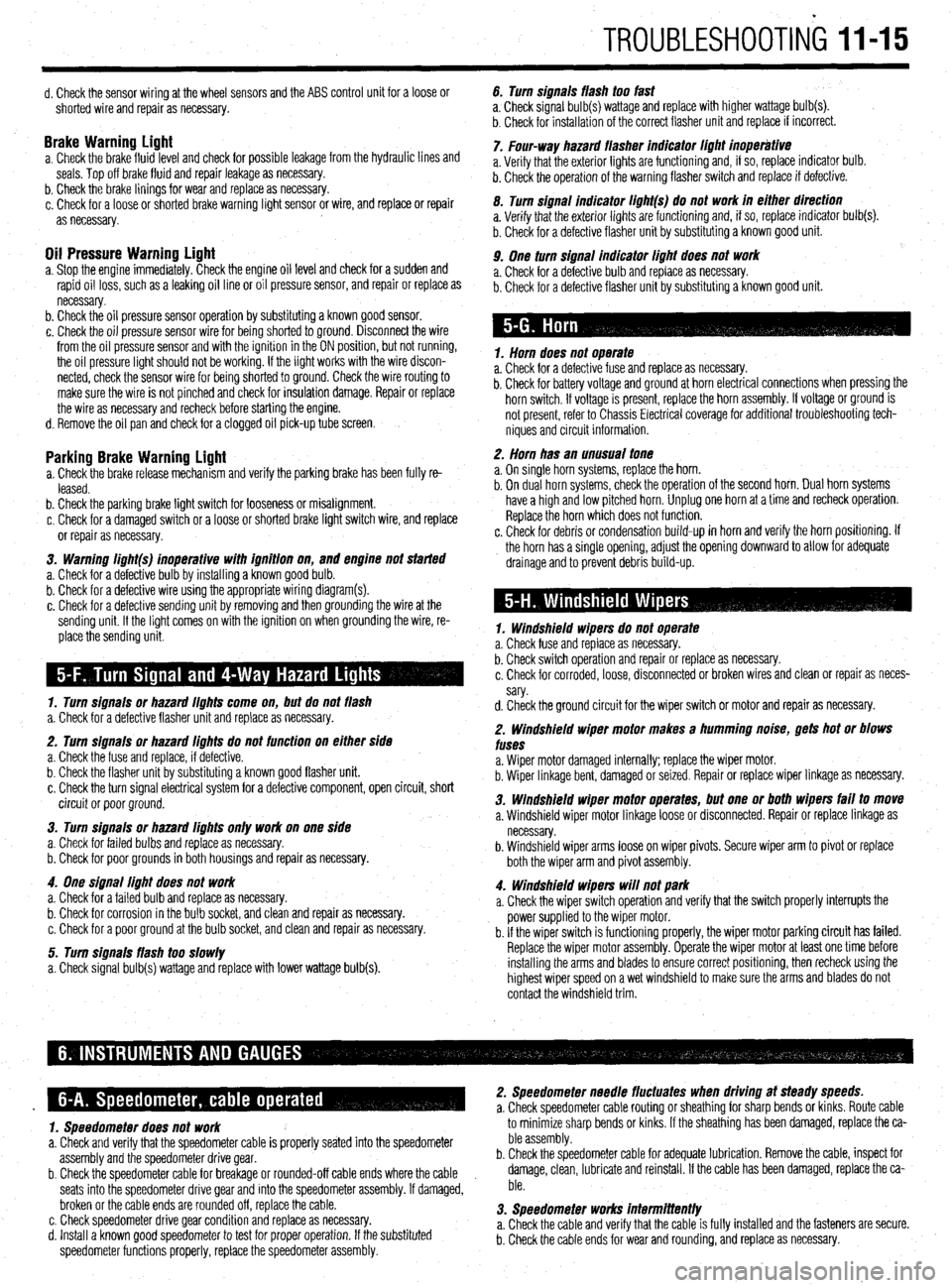

TROUBLESHOOTING 1145

d. Check the sensor wiring at the wheel sensors and the ABS control unit for a loose or

shorted wire and repair as necessary.

Brake Warninu Liaht a. Check the brakefluid~evel and check for possible leakage from the hydraulic lines and

seals. Top off brake fluid and repair leakage as necessary.

b. Check the brake linings for wear and replace as necessary.

c. Check for a loose or shorted brake warning light sensor or wire, and replace or repair

as necessary.

Oil Pressure Warning Light a. Stop the engine immediately. Check the engine oil level and check for a sudden and

rapid oil loss, such as a leaking oil line or oil pressure sensor, and repair or replace as

necessary.

b. Check the oil pressure sensor operation by substituting a known good sensor.

c. Check the oil pressure sensor wire for being shorted to ground. Disconnect the wire

from the oil pressure sensor and with the ignition in the ON position, but not running,

the oil pressure light should not be working. If the light works with the wire discon-

nected, check the sensor wire for being shorted to ground. Check the wire routing to

make sure the wire is not pinched and check for insulation damage. Repair or replace

the wire as necessary and recheck before starting the engine.

d. Remove the oil pan and check for a clogged oil pick-up tube screen.

Parking Brake Warning Light a. Check the brake release mechanism and verify the parking brake has been fully re-

leased.

b. Check the parking brake light switch for looseness or misalignment.

c. Check for a damaged switch or a loose or shorted brake light switch wire, and replace

or repair as necessary.

3. Warning li#ht(s) inoperative with iflnition on,

and engine not started

a. Check for a defective bulb by installing a known good bulb.

b. Check for a defective wire using the appropriate wiring diagram(s).

c. Check for a defective sending unit by removing and then grounding the wire at the

sending unit. If the light comes on with the ignition on when grounding the wire, re-

place the sending unit.

1. Turn siflnais or hazard iiflhts come on, but do not flash

a. Check for a defective flasher unit and replace as necessary.

2. Turn signals or hazard iiflhts do not function on either side

a. Check the fuse and replace, if defective.

b. Check the flasher unit by substituting a known good flasher unit.

c. Check the turn signal electrical system for a defective component, open circuit, short

circuit or poor ground.

3. Turn siflnais or hazard lights only work on one side

a. Check for failed bulbs and replace as necessary.

b. Check for poor grounds in both housings and repair as necessary.

4. One siflnai light does not work

a. Check for a failed bulb and replace as necessary.

b. Check for corrosion in the bulb socket, and clean and repair as necessary.

c. Check for a poor ground at the bulb socket, and clean and repair as necessary.

5. Turn signals flash too slowly

a. Check signal bulb(s) wattage and replace with lower wattage bulb(s). 6. Turn signals flash too fast

a, Check signal bulb(s) wattage and replace with higher wattage bulb(s).

b. Check for installation of the correct flasher unit and replace if incorrect.

7. Four-way hazard flasher indicator iiflhi inoperative

a. Verify that the exterior lights are functioning and, if so, replace indicator bulb.

b. Check the operation of the warning flasher switch and replace if defective.

0. Turn signal indicator ii#ht(s) do not work in either direction

a. Verify that the exterior lights are functioning and, if so, replace indicator bulb(s).

b. Check for a defective flasher unit by substituting a known good unit.

9. One turn signal indicator liflht does not work

a. Check for a defective bulb and replace as necessary.

b. Check for a defective flasher unit by substituting a known good unit.

1. Horn does not operate

a. Check for a defective fuse and replace as necessary.

b. Check for battery voltage and ground at horn electrical connections when pressing the

horn switch. If voltage is present, replace the horn assembly. If voltage or ground is

not present, refer to Chassis Electrical coverage for additional troubleshooting tech-

niques and circuit information.

2. Horn has an unusual tone

a. On single horn systems, replace the horn.

b. On dual horn systems, check the operation of the second horn. Dual horn systems

have a high and low pitched horn. Unplug one horn at a time and recheck operation.

Replace the horn which does not function.

c. Check for debris or condensation build-up in horn and verify the horn positioning. If

the horn has a single opening, adjust the opening downward to allow for adequate

drainage and to prevent debris build-up.

1. Windshield wipers do not operate

a. Check fuse and replace as necessary.

b. Check switch operation and repair or replace as necessary.

c. Check for corroded, loose, disconnected or broken wires and clean or repair as neces-

sary.

d. Check the ground circuit for the wiper switch or motor and repair as necessary.

2. Windshield wiper motor makes a humming noise, gets hot or blows

fuses

a. Wiper motor damaged internally; replace the wiper motor.

b. Wiper linkage bent, damaged or seized. Repair or replace wiper linkage as necessary.

3. Windshield wiper motor operates, but one or both wipers fail to move

a. Windshield wiper motor linkage loose or disconnected. Repair or replace linkage as

necessary.

b. Windshield wiper arms loose on wiper pivots. Secure wiper arm to pivot or replace

both the wiper arm and pivot assembly.

4. Windshield wipers will not park

a. Check the wiper switch operation and verify that the switch properly interrupts the

power supplied to the wiper motor.

b. If the wiper switch is functioning properly, the wiper motor parking circuit has failed.

Replace the wiper motor assembly. Operate the wiper motor at least one time before

installing the arms and blades to ensure correct positioning, then recheck using the

highest wiper speed on a wet windshield to make sure the arms and blades do not

contact the windshield trim.

1. Speedometer does not work to minimize sharp bends or kinks.

If the sheathing has been

damaged, replace the ca-

a. Check and verify that the speedometer cable is properly seated into the speedometer ble assembly.

assembly and the speedometer drive gear. b. Check the speedometer cable for adequate lubrication. Remove the cable, inspect for

b. Check the speedometer cable for breakage or rounded-off cable ends where the cable damage, clean, lubricate and reinstall. If the cable has been damaged, replace the ca-

seats into the speedometer drive gear and into the speedometer assembly. If damaged, ble.

broken or the cable ends are rounded off, replace the cable.

c. Check speedometer drive gear condition and replace as necessary. 3. Speedometer works intermittently

d. Install a known good speedometer to test for proper operation. If the substituted a. Check the cable and verify that the cable is fully installed and the fasteners are secure.

speedometer functions properly, replace the speedometer assembly. b. Check the cable ends for wear and rounding, and replace as necessary.

Page 408 of 408

11-26 MASTER INDEX

WATER PUMP 3-20

REMOVAL&INSTALLATION

WHEEL ALIGNMENT 8-16

CAMBER 8-17

CASTER 8-16

TOE 8-17 .

WHEEL ASSEMBLY 8-2 '

INSPECTION 8-2

REMOVAL&INSTALLATION

WHEEL BEARINGS 1-44

REPACKING l-44

WHEELCYLINDERS 9-19

OVERHAUL 9-19

REMOVAL&INSTALLATION

WHEEL LUG STUDS 8-2

REMOVAL&INSTALLATION

WHEELS 8-2 3-20 WHERETO BEGIN 1-2

WINDSHIELD WASHER PUMP 6-17

REMOVAL & INSTALLATION 6-17

WINDSHIELD WIPER BLADE AND ARM 6-15

REMOVAL & INSTALLATION 6-15

WINDSHIELD WIPER MOTOR 6-16

REMOVAL &INSTALLATION 6-16

8-2

9-19

8-2 WINDSHIELD WIPER SWITCH 6-19

REMOVAL & INSTALLATION 6-19

WINDSHIELD WIPER SWITCH 8-29

REMOVAL & INSTALLATION 8-29

WINDSHIELD WIPERS AND WASHERS 6-15

WINDSHIELD WIPERS l-29

ELEMENT(REFILL)CARE&REPLACEMENT 1-29

WIRE AND CONNECTOR REPAIR 6-6

WIRING DIAGRAMS 6-31