4WD MITSUBISHI ECLIPSE 1990 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 39 of 391

BRAKES - Service Brakes 5-3

$eTandem (with level sensor)

(718)

Brake boosterTYpeEffective dia. of

y3tt$;ivacuum-boost type

powmermc&;der

Proportioning valve Type Dual type

(597)

kPa (psi)

Decompression 0. 3

(15/l 6)

Multiple-vacuum-boost type

c

4,200 (597)

TypeM-R44VM-R44V

cyhnxLy.53.9 (2’/8) 53.9 (2%)

Clearance Automatic Automati

c

I

TypeAD30PAD30P

Cyl~itl;.~. 30.1 (13/16) 30.1 (13/16)

Clearance Automatic Automatic

*:4WD

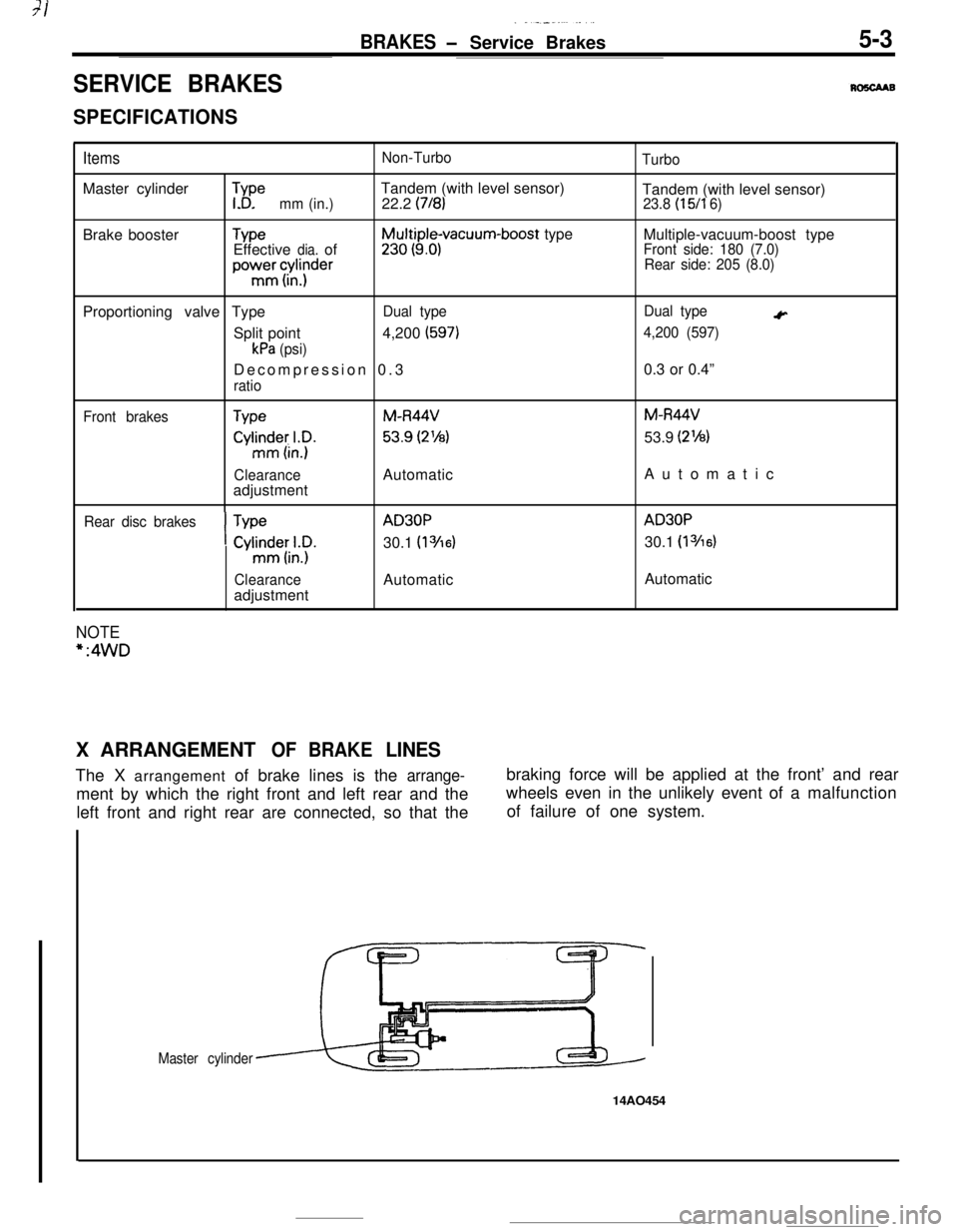

X

ARRANGEMENT OF BRAKE LINES

Page 41 of 391

7-.

BRAKES - Service Brakes5-5

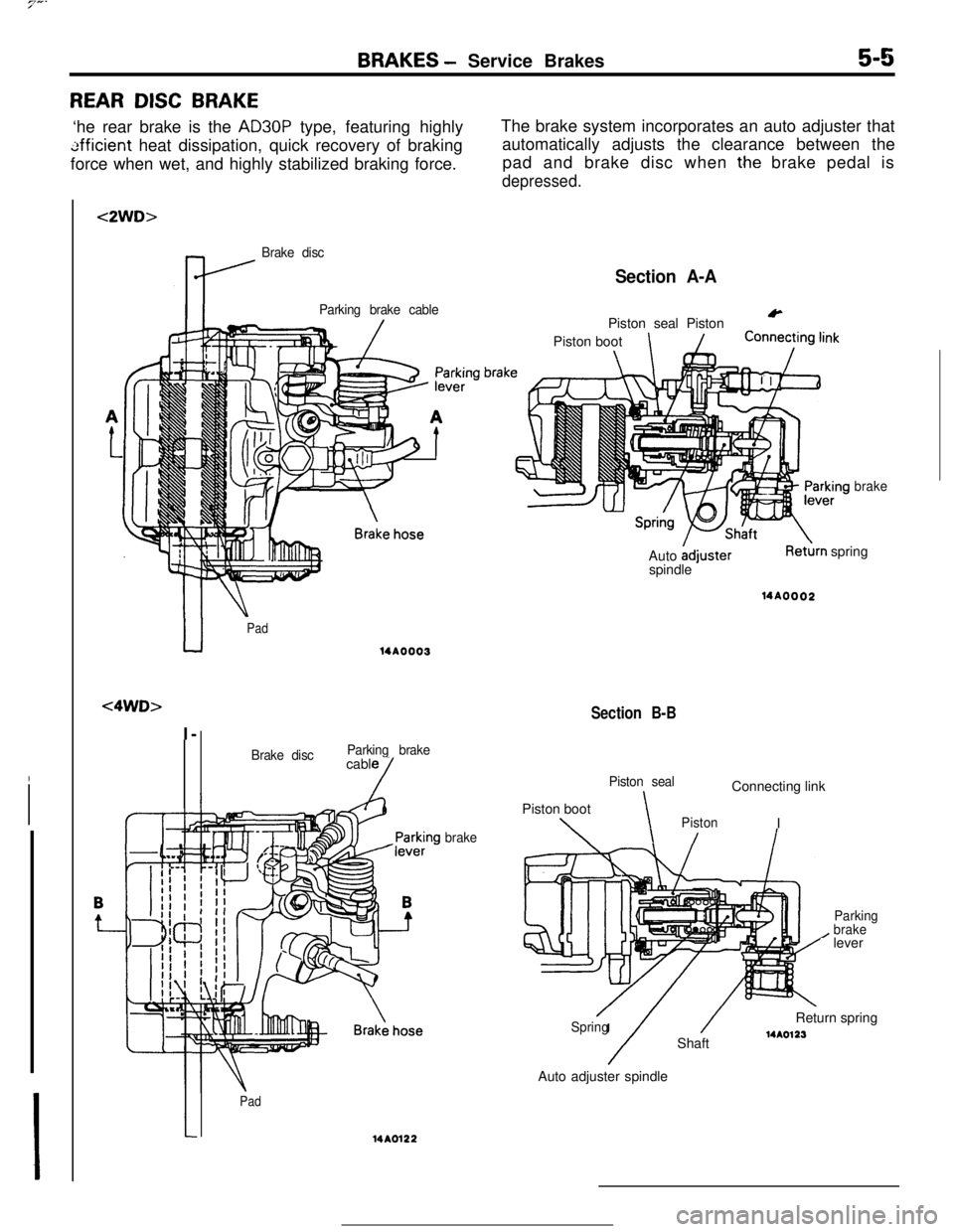

REAR DISC BRAKE‘he rear brake is the

AD30P type, featuring highly

tifficient heat dissipation, quick recovery of braking

force when wet, and highly stabilized braking force.The brake system incorporates an auto adjuster that

automatically adjusts the clearance between the

pad and brake disc when

t.he brake pedal is

depressed.

<2WD>

Brake disc

Parking brake cable

Section A-A

&

u

Pad

<4WD>I-

14A0003

Brake discParking brakecable

/

Pad14A0122

brake

brakPiston seal Piston

Piston boot

\

brakeAuto

AdjusterspindleRet&n spring14AOOO2

Section B-B

Piston sealConnecting link

Piston boot

\\PistonI

/

Parking

brakelever

/Spring

/

/Return spring

Shaft14A0123Auto adjuster spindle

Page 42 of 391

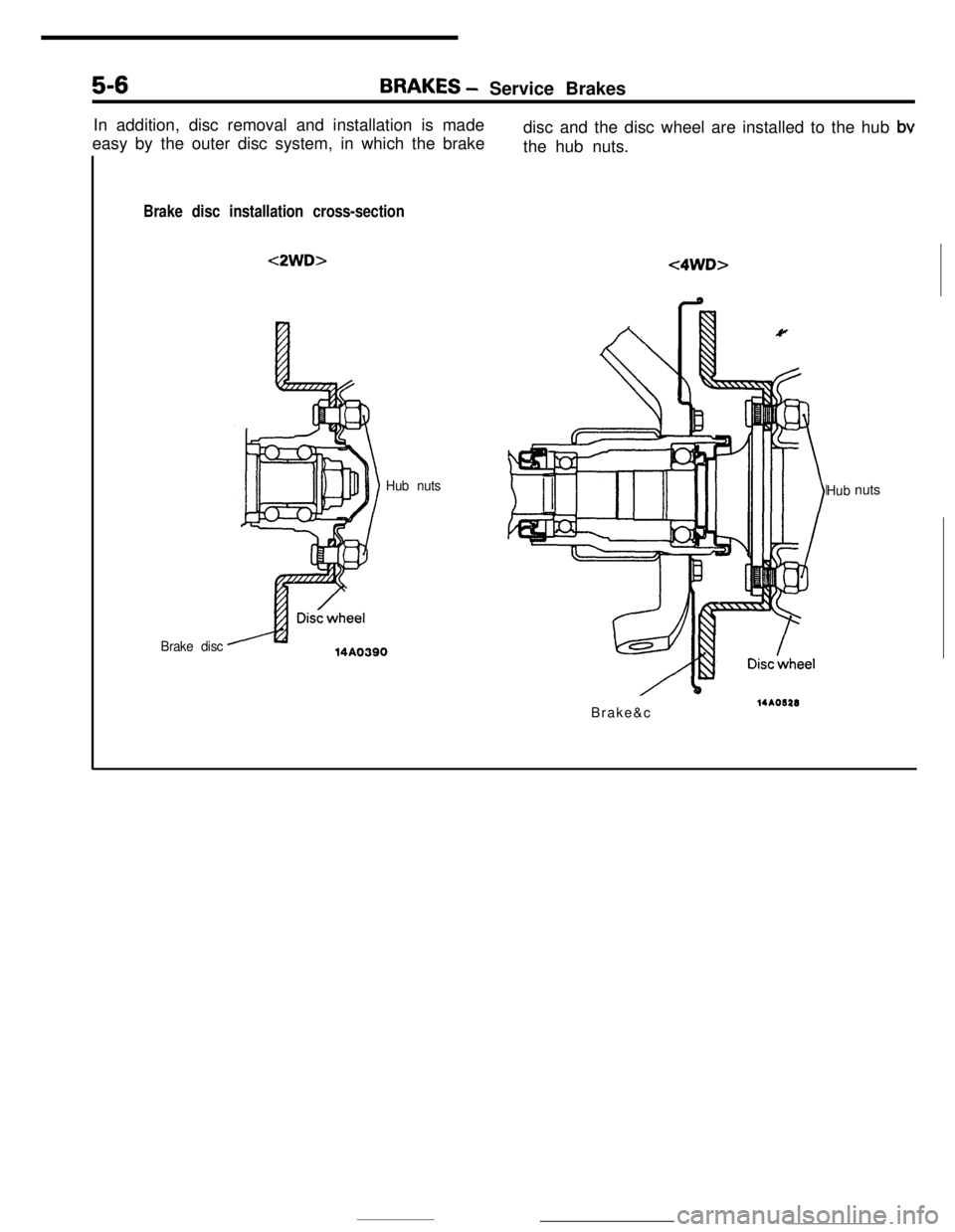

5-6BRAKES - Service Brakes

In addition, disc removal and installation is made

easy by the outer disc system, in which the brakedisc and the disc wheel are installed to the hub

bvthe hub nuts.

Brake disc installation cross-section<2WD>

<4WD>

Hub nuts

Brake disc14AO390Hubnuts

Brake&c

14AO622

Page 43 of 391

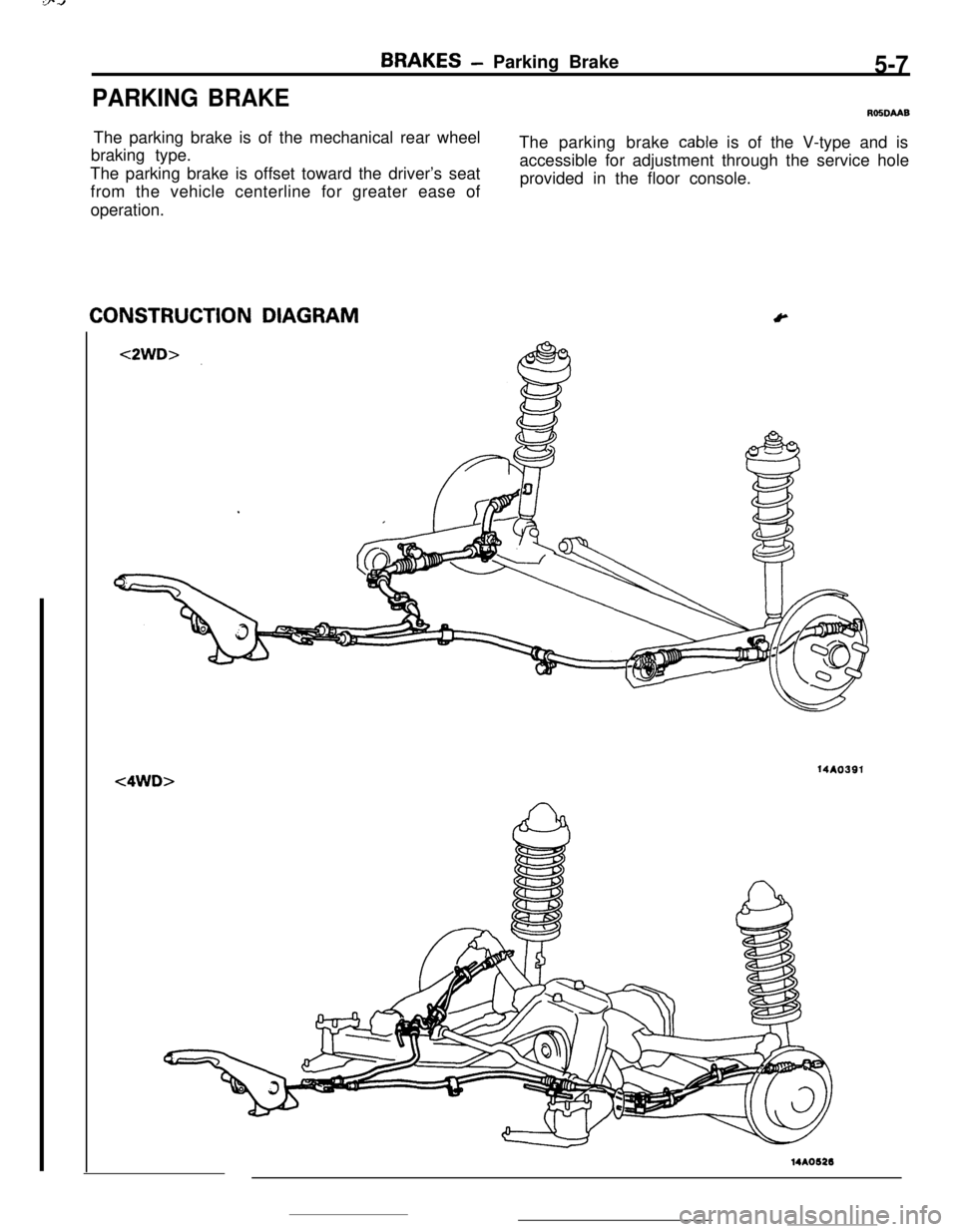

PARKING BRAKE

BRAKES- Parking Brake5-7

ROSDMBThe parking brake is of the mechanical rear wheel

braking type.The parking brake

cable is of the V-type and is

The parking brake is offset toward the driver’s seataccessible for adjustment through the service hole

provided in the floor console.

from the vehicle centerline for greater ease of

operation.CONSTRUCTION DIAGRAM

Y14AO391

<4WD>14A0626

Page 106 of 391

L1ENGINE

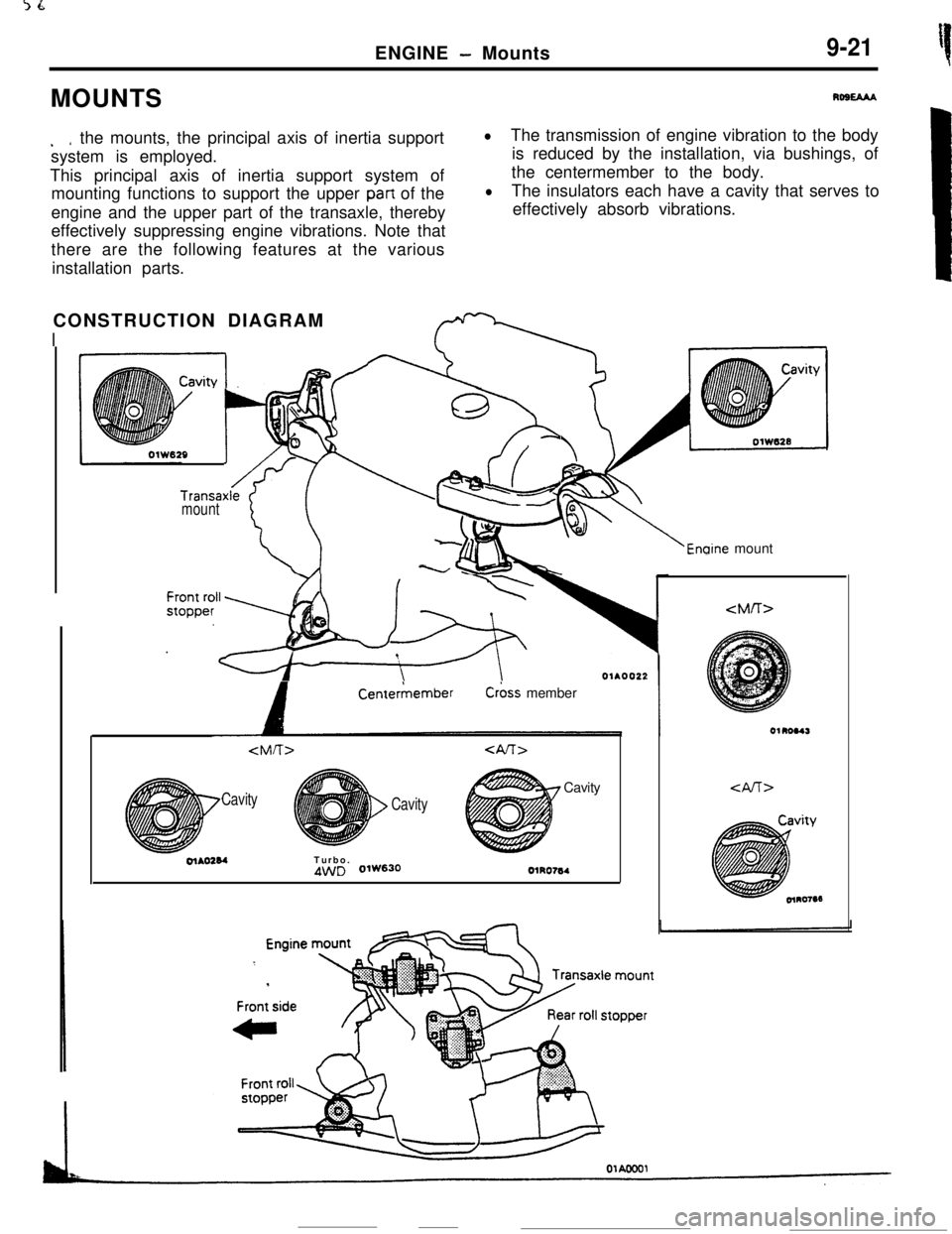

- Mounts9-21MOUNTS

Rost3u

. *the mounts, the principal axis of inertia support

system is employed.

This principal axis of inertia support system of

mounting functions to support the upper

part of the

engine and the upper part of the transaxle, thereby

effectively suppressing engine vibrations. Note that

there are the following features at the various

installation parts.

lThe transmission of engine vibration to the body

is reduced by the installation, via bushings, of

the centermember to the body.

lThe insulators each have a cavity that serves to

effectively absorb vibrations.

CONSTRUCTION DIAGRAM

I

Transaxlemount

‘i::

+g

/v 1b-8

8-,

Enaine mount

A

CenterkemberC&s member

Cavity

CavityCavityolAO284Turbo.

4WD 0lW630OlRO764

Page 117 of 391

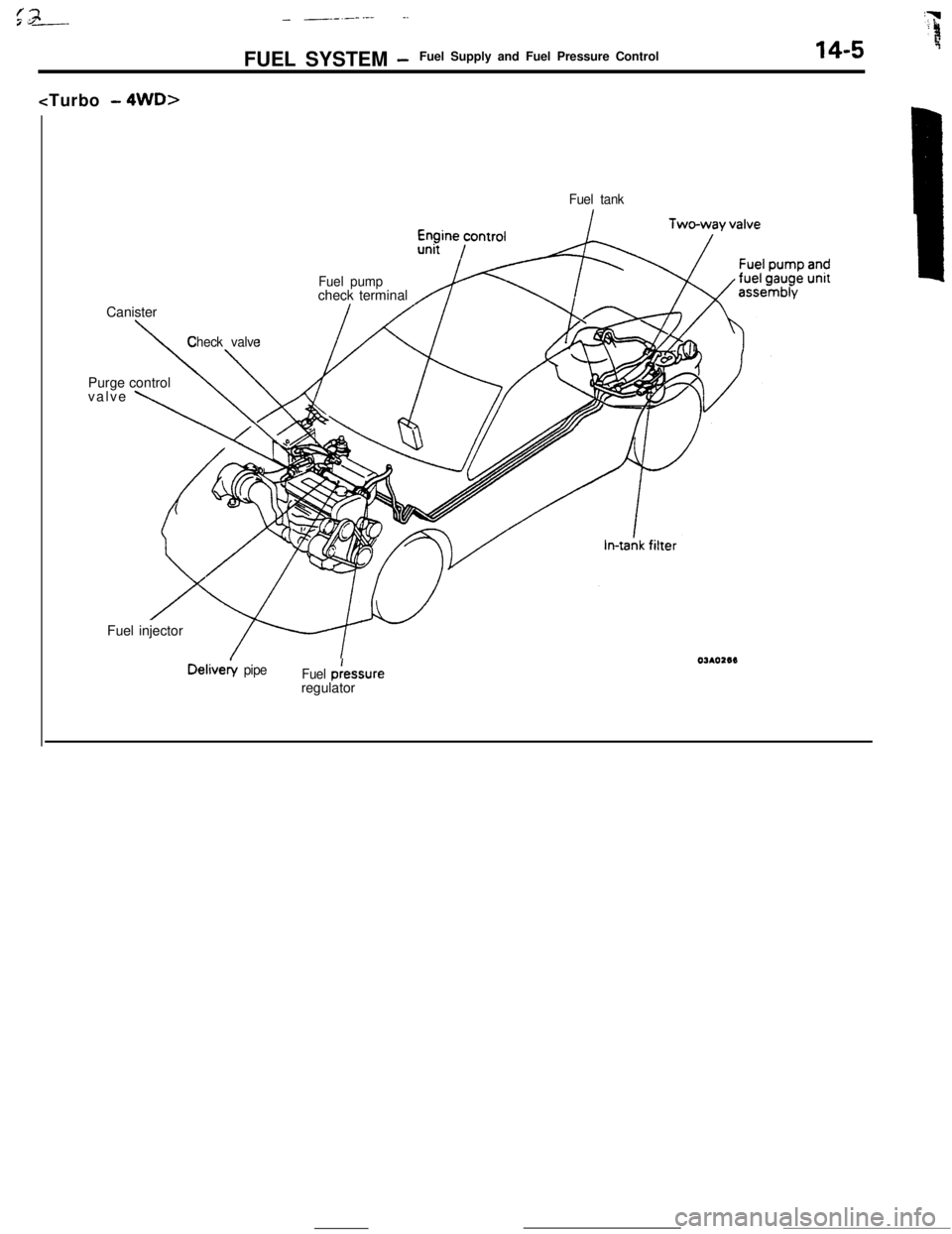

_ --_-_ .-..__FUEL SYSTEM

-Fuel Supply and Fuel Pressure Control14-5Canister

Fuel tank

Fuel pumpcheck terminal

\

Check valvePurge control

valve

\Fuel injectorDelivery

pipe

Fuel p:essure

regulator

Page 119 of 391

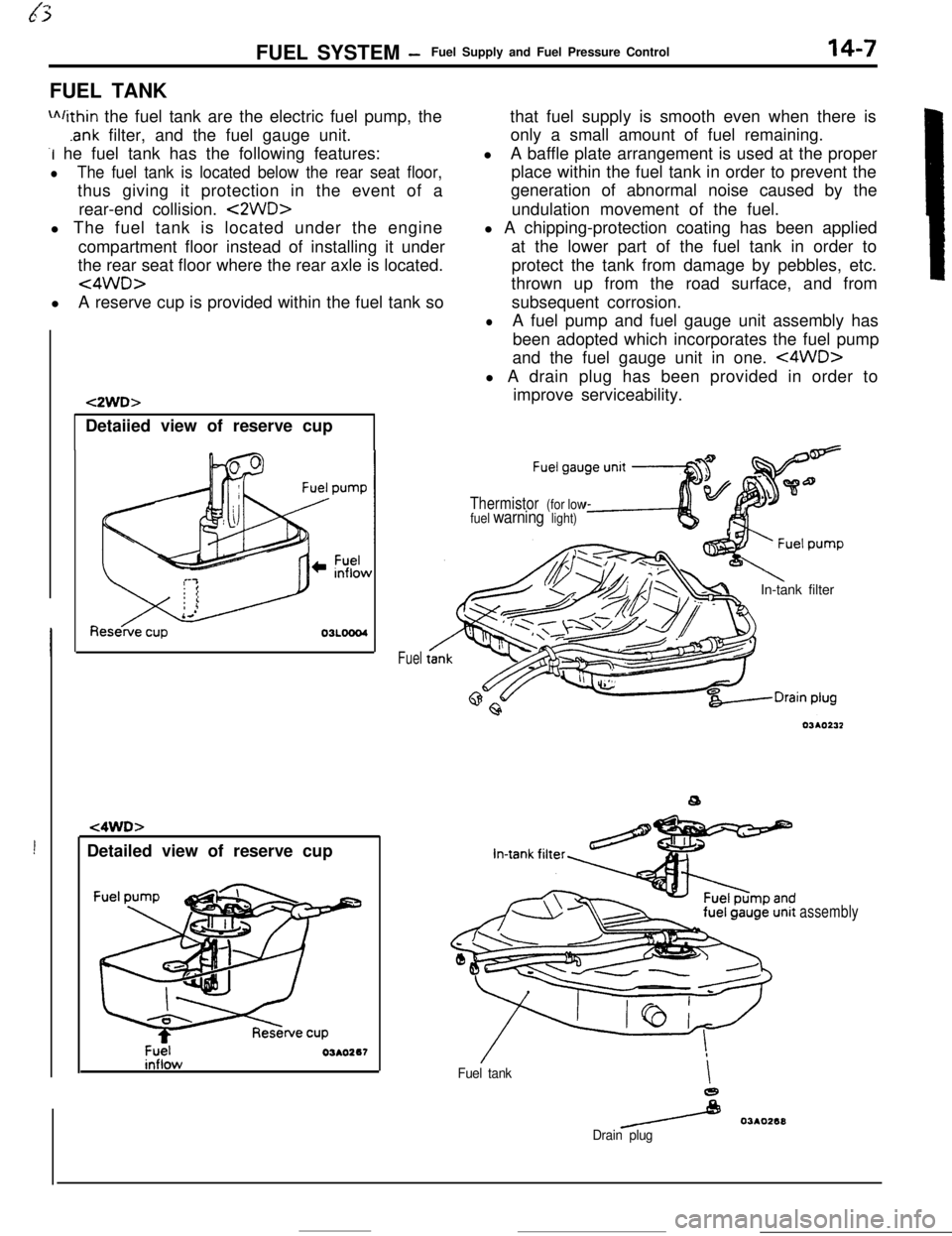

FUEL SYSTEM -Fuel Supply and Fuel Pressure Control14-7FUEL TANK

m/ithin the fuel tank are the electric fuel pump, the

.ank filter, and the fuel gauge unit.

-I he fuel tank has the following features:

lThe fuel tank is located below the rear seat floor,thus giving it protection in the event of a

rear-end collision.

<2WD>l The fuel tank is located under the engine

compartment floor instead of installing it under

the rear seat floor where the rear axle is located.

<4WD>lA reserve cup is provided within the fuel tank so

!Detailed view of reserve cup

t2WD>Detaiied view of reserve cup

t4WD>

Fuel03AO267

Fuelthat fuel supply is smooth even when there is

only a small amount of fuel remaining.

lA baffle plate arrangement is used at the proper

place within the fuel tank in order to prevent the

generation of abnormal noise caused by the

undulation movement of the fuel.

l A chipping-protection coating has been applied

at the lower part of the fuel tank in order to

protect the tank from damage by pebbles, etc.

thrown up from the road surface, and from

subsequent corrosion.

lA fuel pump and fuel gauge unit assembly has

been adopted which incorporates the fuel pump

and the fuel gauge unit in one.

<4WD>l A drain plug has been provided in order to

improve serviceability.

Thermistor (for low

fuel warning light)In-tank filter

Fuel tankI

e

/ 03AO268

Drain plug

assembly

Page 201 of 391

.-_. -

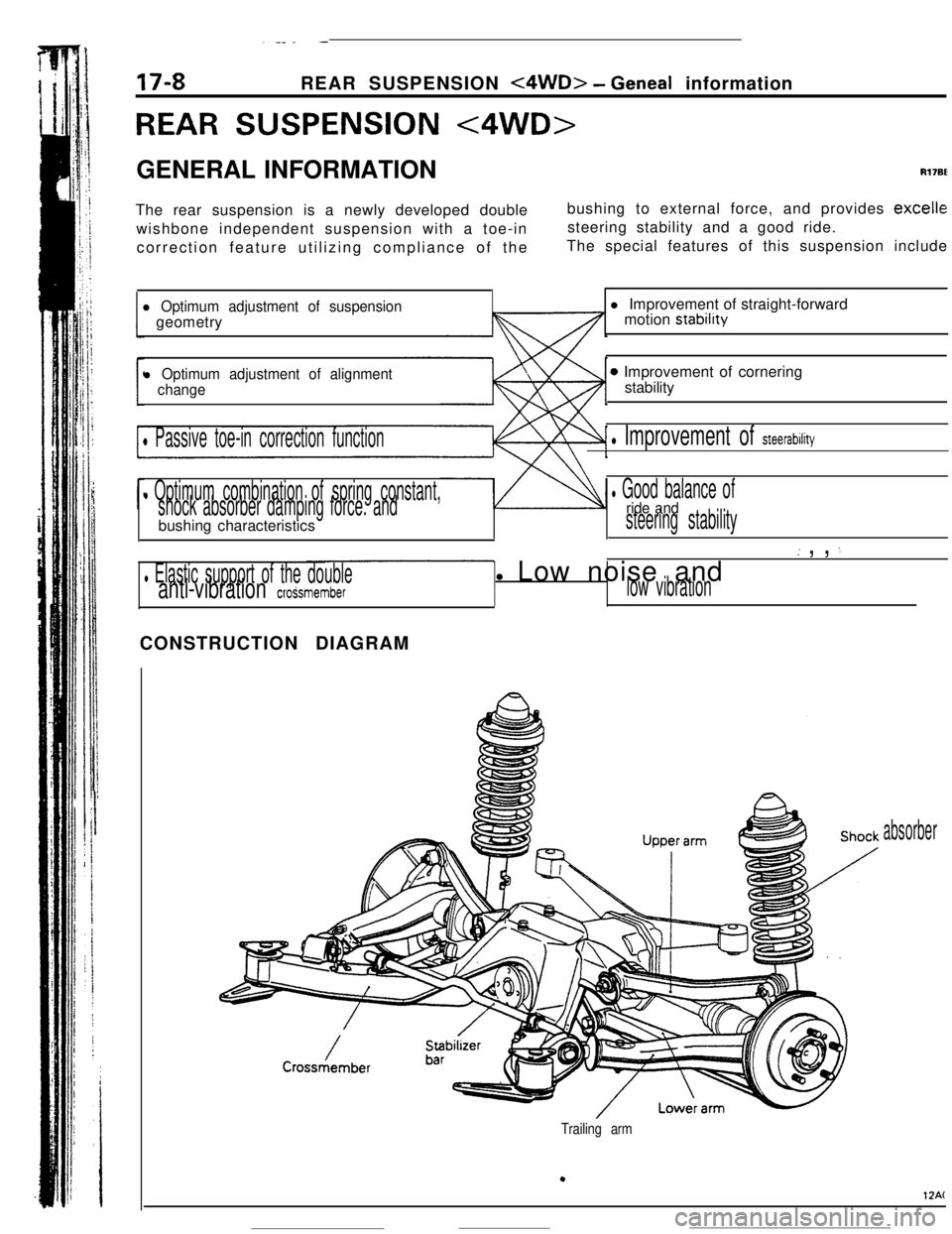

17-8REAR SUSPENSION <4WD> - Geneal information

REAR SUSPENSION <4WD>GENERAL INFORMATION

Rl7BEThe rear suspension is a newly developed double

wishbone independent suspension with a toe-in

correction feature utilizing compliance of thebushing to external force, and provides

excellesteering stability and a good ride.

The special features of this suspension include

l Optimum adjustment of suspensiongeometry

l Optimum adjustment of alignment

change

0 Passive toe-in correction function

l Optimum combination of spring constant,

shock absorber damping force. andbushing characteristics

l Elastic support of the doubleanti-vibration croSsmemberl Improvement of straight-forward

motion stability

0 Improvement of cornering

stability

l Improvement of steerability

l Good balance ofride andsteering stability

( , , :l Low noise and

low vibrationCONSTRUCTION DIAGRAM

absorber

Trailing arm

.

12AC

Page 202 of 391

_ -. ..__ .-

REAR SUSPENSION

<4WD> - Geneal (nformation

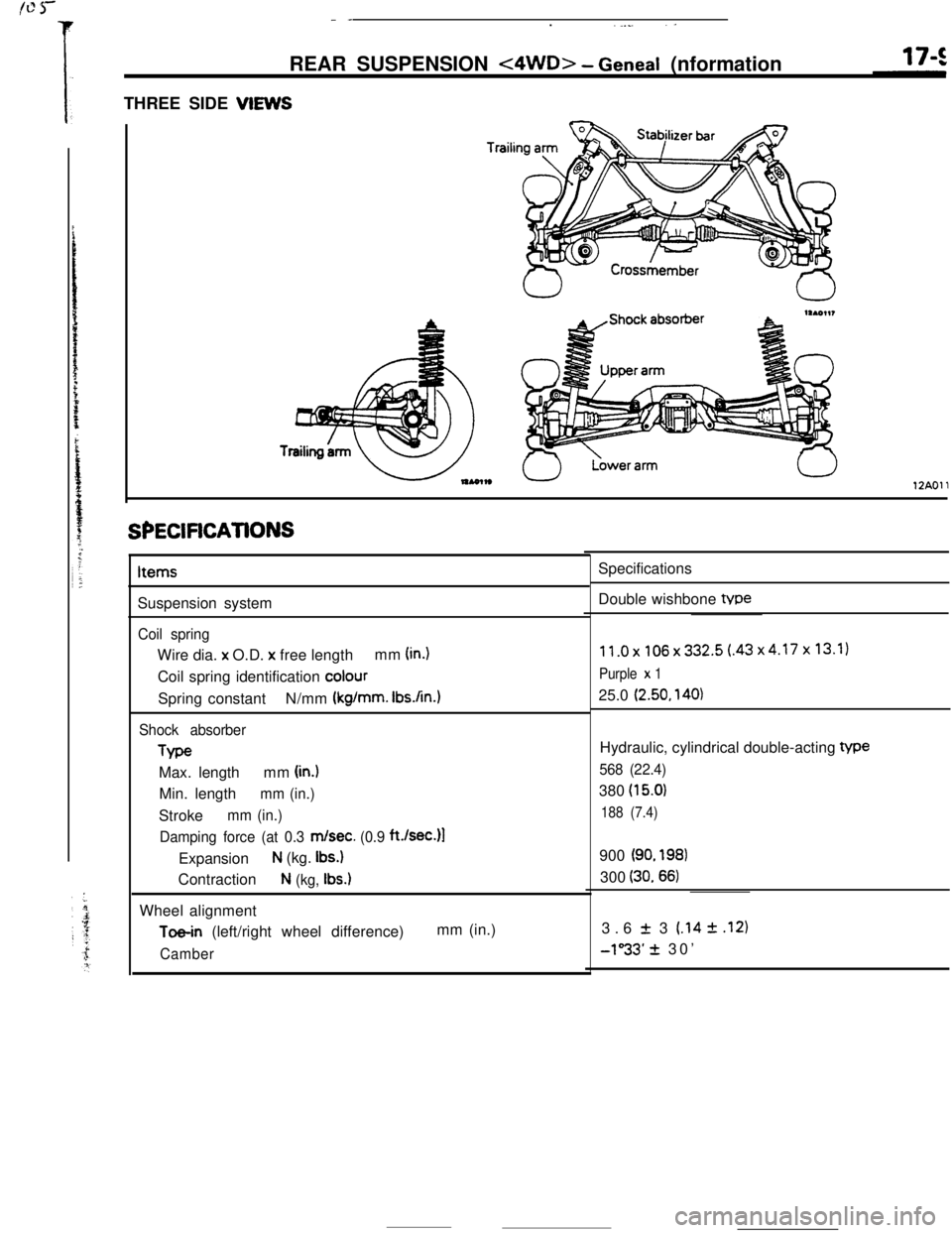

THREE SIDE VIEWS

Trailil

12AOll

SPECiFiCATiONSItems

Suspension system

Coil springWire dia. x O.D.

x free lengthmm (in.)Coil spring identification

colourSpring constantN/mm

(kg/mm. Ibs.An.1

Shock absorberType

Max. lengthmm

(in.)Min. length

mm (in.)Stroke

mm (in.)

Damping force (at 0.3

m/set. (0.9 ft./sec.)l

Expansion

N (kg. Ibs.)Contraction

N (kg, Ibs.)Wheel alignment

Toe-in (left/right wheel difference)mm (in.)

CamberSpecifications

Double wishbone tvpe

11.0x106x332.5(.43x4.17x13.1)

Purple x 125.0

(2.50, 140)Hydraulic, cylindrical double-acting

We

568 (22.4)380

(15.0)

188 (7.4)900

(90. 198)300

(30.66)3.6

f 3 (.14 2 .I21

-1”33’ + 30’

Page 203 of 391

REAR SUSPENSION <4WD> - Wheel Alignment

WHEEL ALIGNMENT

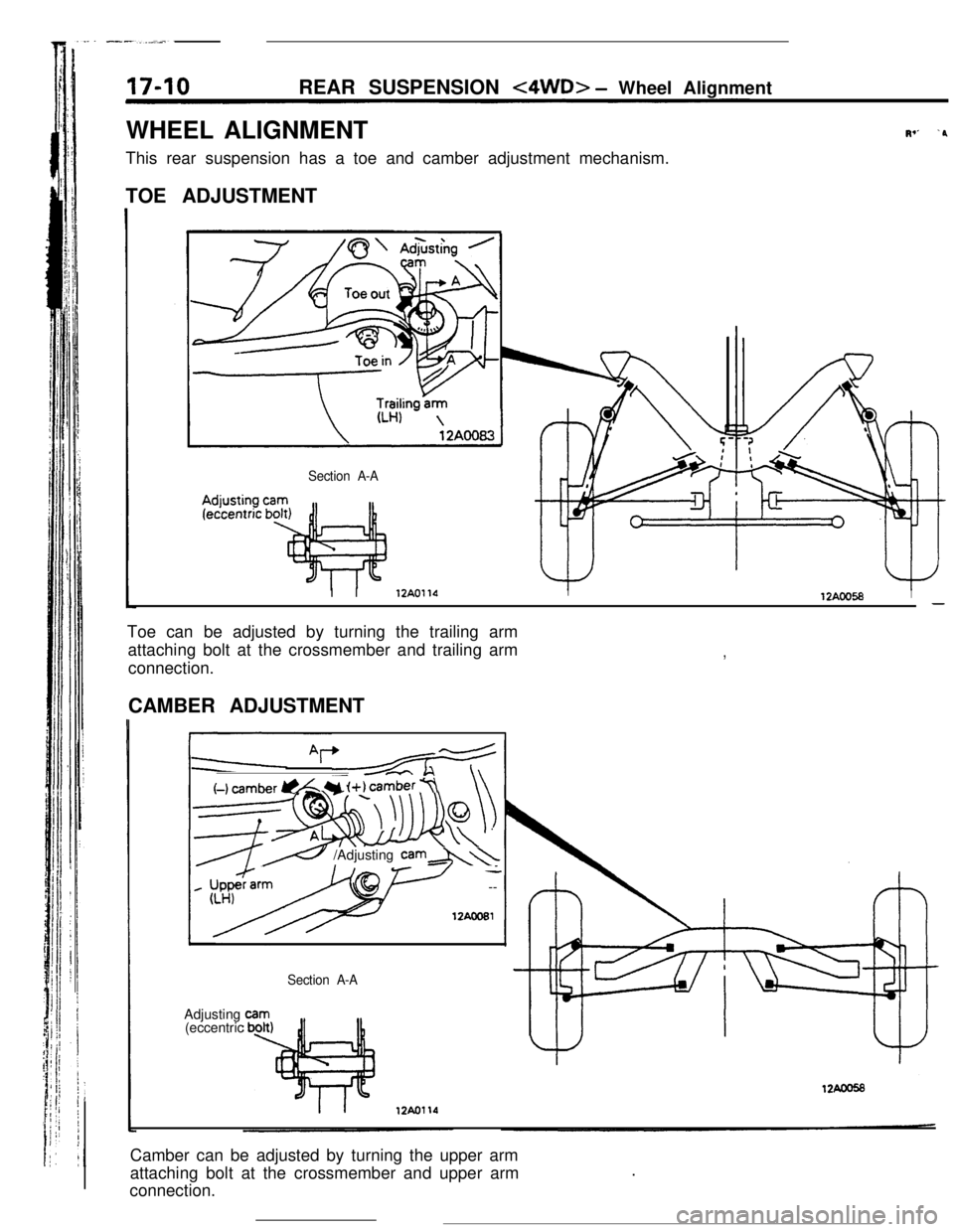

This rear suspension has a toe and camber adjustment mechanism.

TOE ADJUSTMENT

Section A-A

Iv’ ‘PI I

12AOllOI12AOO58I-Toe can be adjusted by turning the trailing arm

attaching bolt at the crossmember and trailing arm

connection.

,CAMBER ADJUSTMENT

I

(-1 cam&r @L Y i+) camber 7\\

__cc \

----7--w

’ --

12AcoEl

e /Adjusting cam&\\Adjusting

(eccentric

Section A-ACamber can be adjusted by turning the upper arm

attaching bolt at the crossmember and upper arm

connection..