MITSUBISHI ECLIPSE 1990 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 1 of 391

Page 2 of 391

SAFETY NOTICE

CAUTIONALL SERVICE AND REBUILDING INSTRUCTIONS CONTAINED HEREIN ARE

APPLICABLE TO, AND FOR THE CONVENIENCE OF, THE AUTOMOTIVE

TRADE ONLY. All test and repair procedures on components or assemblies in

non-automotive applications should be repaired in accordance with instructions

supplied by the manufacturer of the total product.

Proper service and repair is important to the safe, reliable, operation of all motor vehicles.

The service procedures recommended and described in this publication were developedfor professional

servlTe personnel and are effective methods for performing vehicle

repair.Following these procedures will help assure efficient economical vehicleperformance

and service reliability. Some of these service procedures require the use of

special tools designed for specific procedures. These special tools should be used when

recommended throughout this publication.

Special attention should be exercised when working with spring or tension loaded

fasteners and devices such as E-Clips, Circlips, Snap rings, etc., as careless removal

may cause personal injury. Always wear safety goggles whenever working on

vehicles or vehicle components.

7

It is important to note that this publication contains various Cautions and Warnings.These

should be carefully read in order to minimize the risk of personal injury, or thepossibility

that, improper service methods may damage the vehicle or render it unsafe.It

is important to note that these Cautions and Warnings cover only the situations and

procedures Chrysler Motors has encountered and recommended. Chrysler Motors couldnot possibly know,

evaluate, and advise the service trade of all conceivable ways thatservice

may *be performed, or of the possible hazards of each. Consequently, ChryslerMotors

has not undertaken any such broad service review. Accordingly, anyone who

uses a service procedure, or tool, that is not recommended in this publication, must assure

oneself thoroughly that neither personal safety, nor vehicle safety, be jeopardized bythe service

methods they select.

WE SrjPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION

THROUGH

Page 3 of 391

TALON

BACKUP

README.N or for additional information

PreViOUSlVmanufactured.a *-a- .I._..-1-L,.* _____ #Q ^_^__ l L.-Orintul in U.S.A.

GROUP INDEXROSA. - -

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . .

Front Suspensio n................................

.

Brakes - Eir$rii. . . . . . . . . . . . . . . . . . . . . . . . . . ..s...

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling. . . . . . :. . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . ..-..................

Engine....................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Shaft and Universal. . . . . . . .

ml

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power steeringCD

ManualTransaxl e - Automatic....................

m

Bodym

Heaters and Air ConditioningRI

A

Emission Control Systems

Page 4 of 391

._._ -_- 1 -.

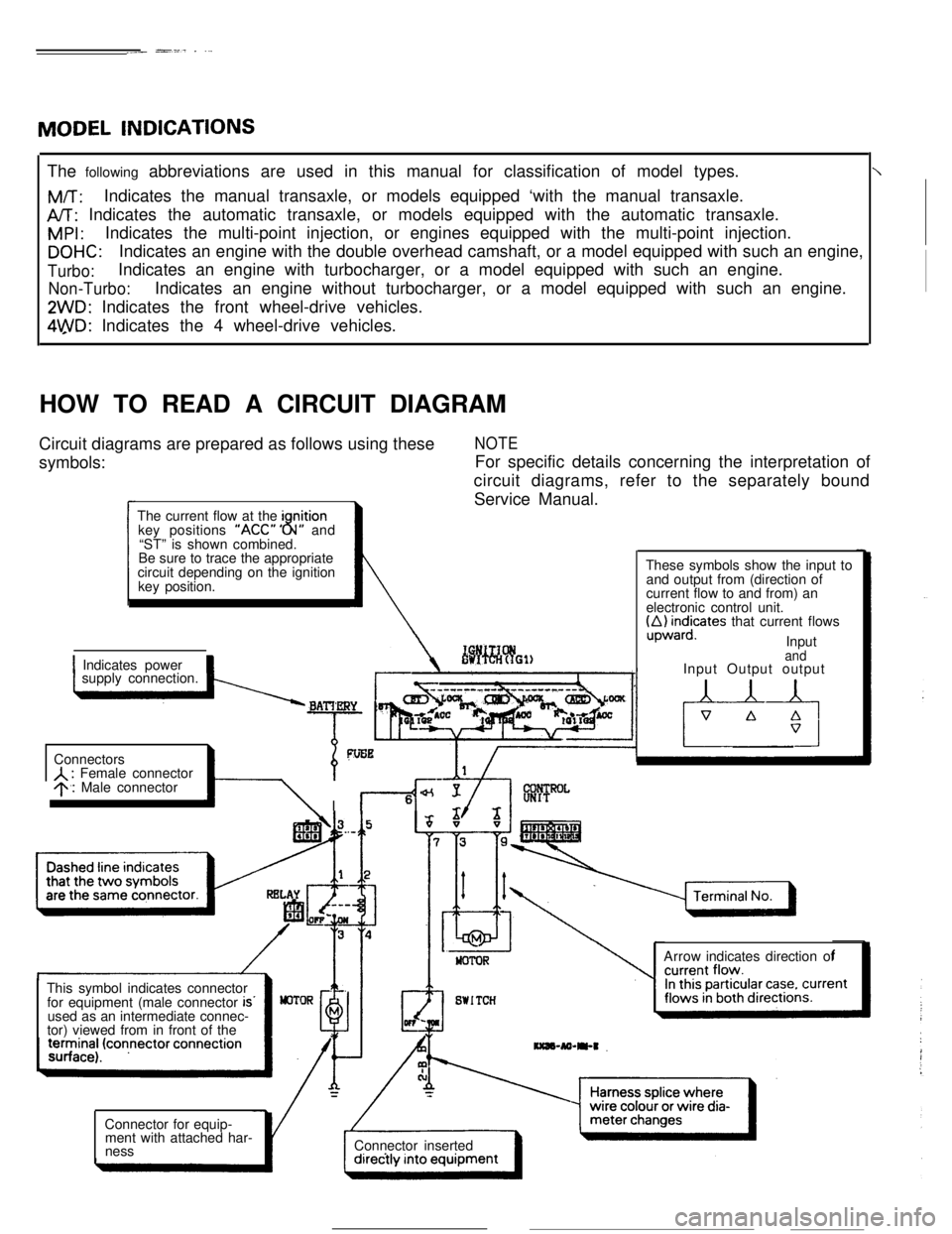

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.\

M/T: Indicates the manual transaxle, or models equipped ‘with the manual t\

ransaxle.

A/T: Indicates the automatic transaxle, or models equipped with the automatic\

transaxle.

MPI: Indicates the multi-point injection, or engines equipped with the multi-\

point injection.

DOHC: Indicates an engine with the double overhead camshaft, or a model equipp\

ed with such an engine,

Turbo: Indicates an engine with turbocharger, or a model equipped with such an \

engine.

2WD: Indicates the front wheel-drive vehicles.

4WD: Indicates the 4 wheel-drive vehicles.

HOW TO READ A CIRCUIT DIAGRAM

initionkey positions “ACC” ” N” and8“ST” is shown combined.

~

Service Manual.

o&ficates that current flows

Input

1 Indicates power1supply connection.

A : Female connector9.1 Male connector

\ Il-4’

Input Output output

is..used as an intermediate connec-

Page 5 of 391

GENERAL

---- -~- -------l

O-l

CONTENTS

GENERAL DATA AND SPECIFICATIONS . . . . . . . ..._..................._........_ 9

TECHNICAL FEATURES

4WD (Four-wheel Drive)........................................710

PJT Safety-lock Syste m........................................7

..__............................... 3

Theft-alarm System (Option for 4WD

Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . .._._........_..................... 8

Page 6 of 391

o-2GENERAL - Technical Features

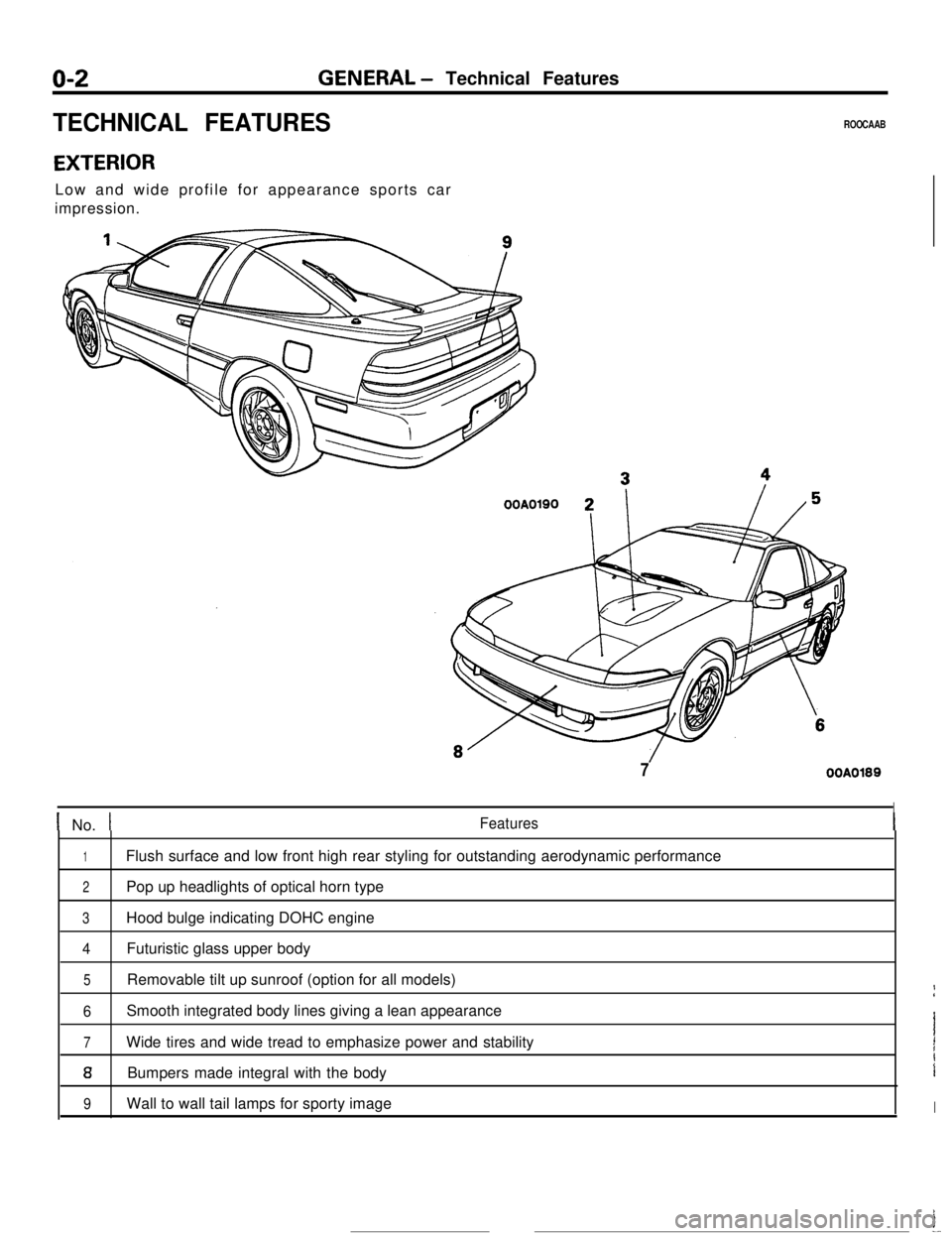

TECHNICAL FEATURESROOCAAB

EXTERIORLow and wide profile for appearance sports car

impression.

OOA0190 2

7OOA0189

I

1 No. tFeatures

1Flush surface and low front high rear styling for outstanding aerodynamic performance

2Pop up headlights of optical horn type

3Hood bulge indicating DOHC engine

4Futuristic glass upper body

5Removable tilt up sunroof (option for all models)If

6Smooth integrated body lines giving a lean appearance

7Wide tires and wide tread to emphasize power and stabilityI1

aBumpers made integral with the bodyi

9Wall to wall tail lamps for sporty imageIi

--

Page 7 of 391

YGENERAL

- Technical Featureso-3

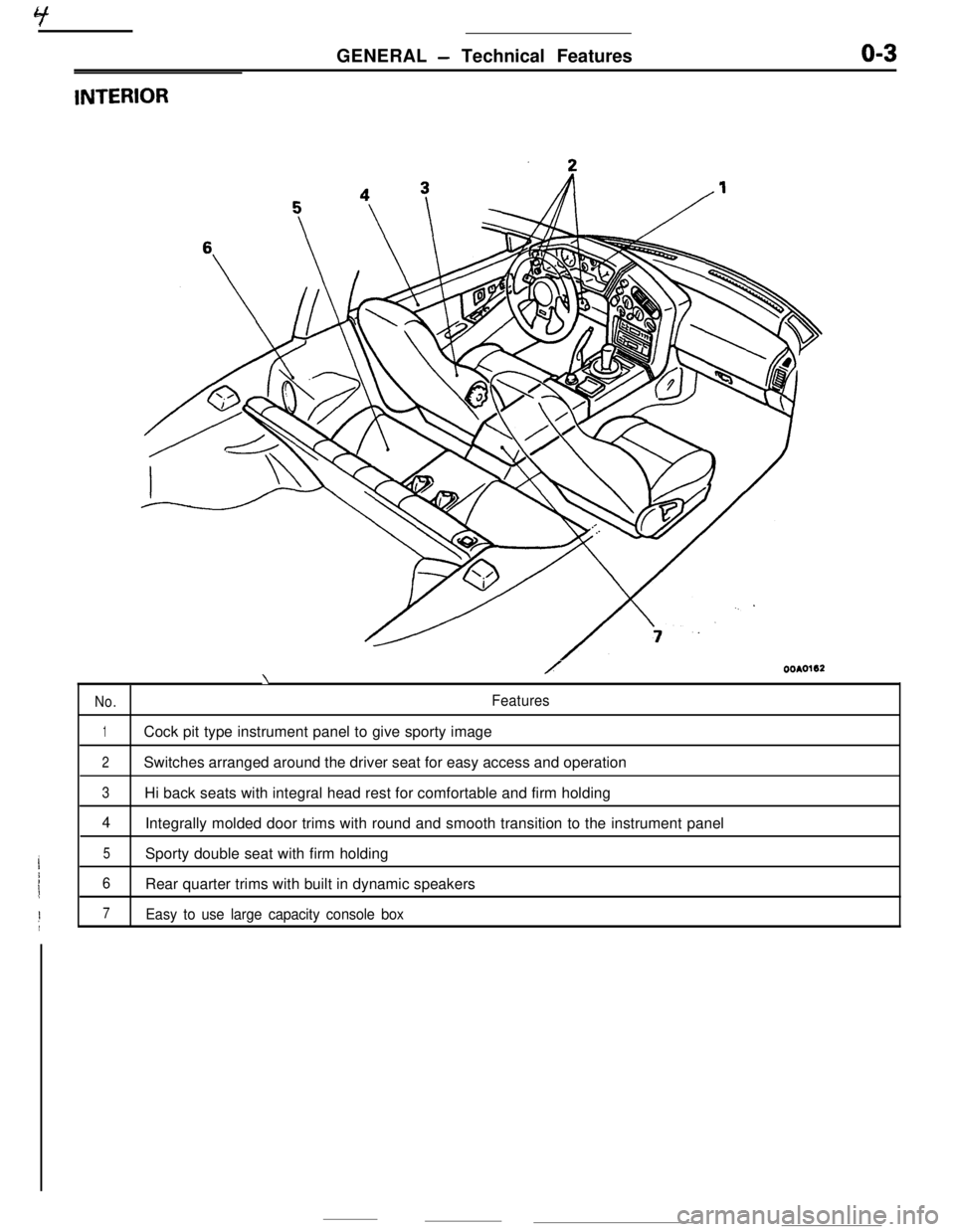

INTERIOR

/OOAO162\

No.Features

1Cock pit type instrument panel to give sporty image

2Switches arranged around the driver seat for easy access and operation

3Hi back seats with integral head rest for comfortable and firm holding

4

Integrally molded door trims with round and smooth transition to the instrument panel

,I5Sporty double seat with firm holding

i!6Rear quarter trims with built in dynamic speakers

!7Easy to use large capacity console boxI

Page 8 of 391

o-4GENERAL - Technical Features

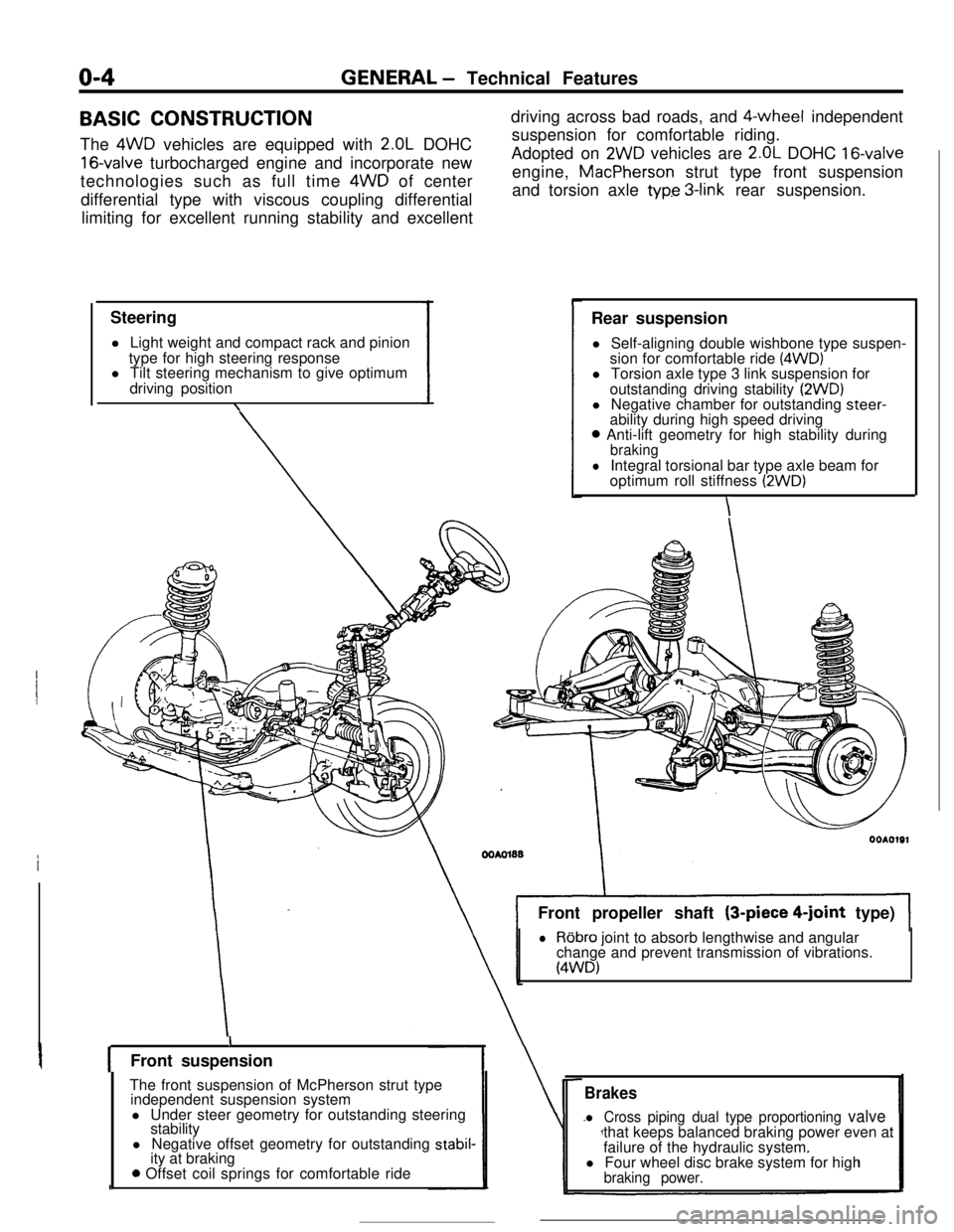

BASIC CONSTRUCTION

The 4WD vehicles are equipped with

2.OL DOHC

16-valve turbocharged engine and incorporate new

technologies such as full time 4WD of center

differential type with viscous coupling differential

limiting for excellent running stability and excellent

Steering

l Light weight and compact rack and pinion

type for high steering response

l Tilt steering mechanism to give optimum

driving position

\driving across bad roads, and $-wheel independent

suspension for comfortable riding.

Adopted on

2WD vehicles are 2.OL DOHC 16-valveengine, MacPherson strut type front suspension

and torsion axle

typ.e 3-link rear suspension.

Rear suspension

l Self-aligning double wishbone type suspen-

sion for comfortable ride

(4WD)l Torsion axle type 3 link suspension for

outstanding driving stability

(2WD)l Negative chamber for outstanding steer-

ability during high speed driving

0 Anti-lift geometry for high stability duringbraking

lIntegral torsional bar type axle beam for

optimum roll stiffness (2WD)

\Front propeller shaft (3-piece

4-joint type)

lRobro joint to absorb lengthwise and angular

change and prevent transmission of vibrations.

(4WD)

IFront suspension

The front suspension of McPherson strut type

independent suspension system

l Under steer geometry for outstanding steering

stability

l Negative offset geometry for outstanding

stabil-ity at braking

0 Offset coil springs for comfortable ride

Brakes

l Cross piping dual type proportioning valvethat keeps balanced braking power even at

failure of the hydraulic system.

l Four wheel disc brake system for high

braking power.

Page 9 of 391

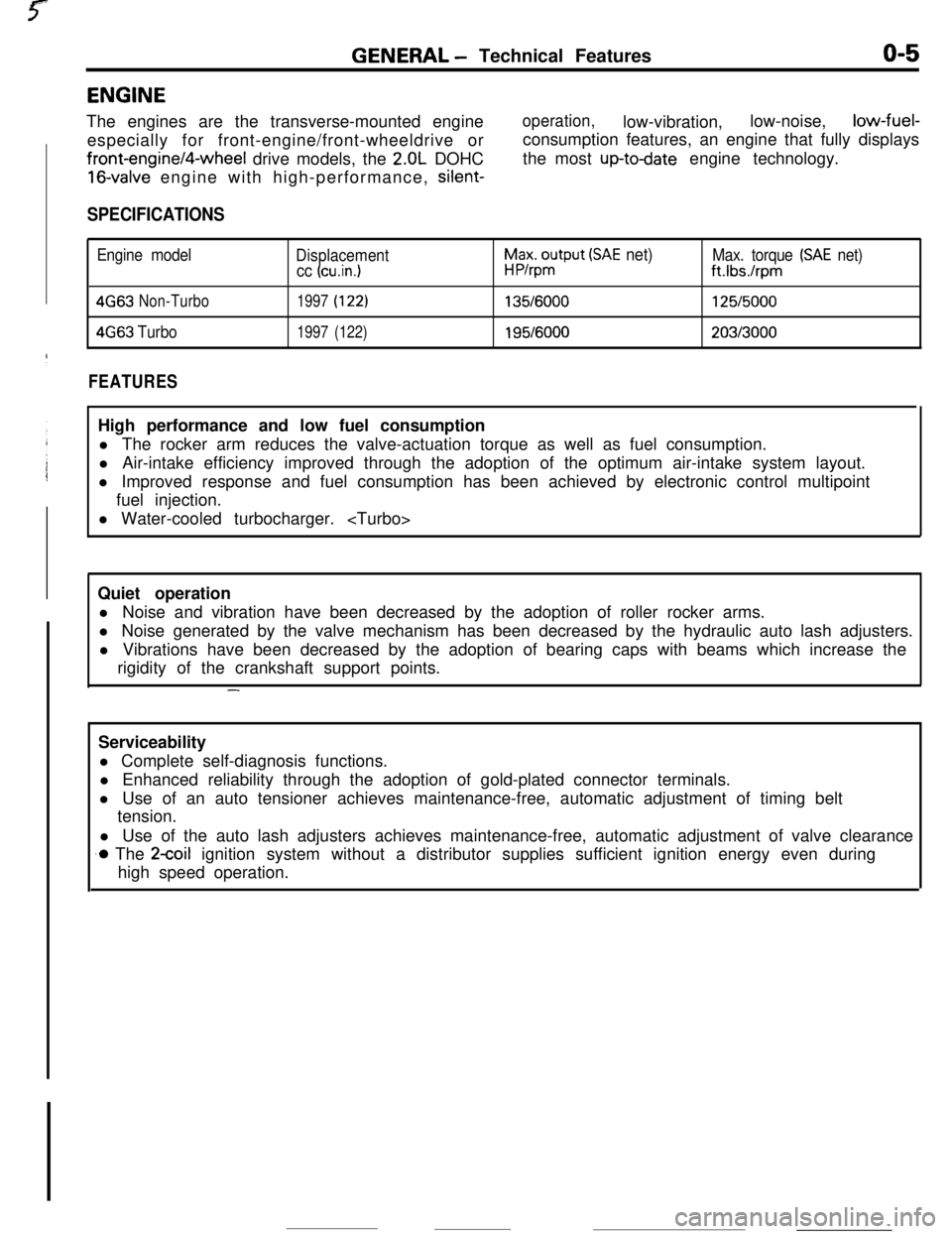

GENERAL - Technical Featureso-5ENGINE

The engines are the transverse-mounted engine

especially for front-engine/front-wheeldrive orfront-engine/4-wheel drive models, the

2.OL DOHC

16-valve engine with high-performance, silent-

operation,low-vibration,low-noise,low-fuel-

consumption features, an engine that fully displays

the most

up-todate engine technology.

SPECIFICATIONS

Engine model

Displacement

cc (cu.in.1

h$xo$put (SAE net)Max. torque (SAE net)

ft.Ibs./rpm

4G63Non-Turbo1997(122)135/6000125/5000

4663Turbo1997(122)195/6000203/3000

FEATURESHigh performance and low fuel consumption

l The rocker arm reduces the valve-actuation torque as well as fuel consumption.

l Air-intake efficiency improved through the adoption of the optimum air-intake system layout.

l Improved response and fuel consumption has been achieved by electronic control multipoint

fuel injection.

l Water-cooled turbocharger.

Quiet operation

l Noise and vibration have been decreased by the adoption of roller rocker arms.

l Noise generated by the valve mechanism has been decreased by the hydraulic auto lash adjusters.

l Vibrations have been decreased by the adoption of bearing caps with beams which increase the

rigidity of the crankshaft support points.

-Serviceability

l Complete self-diagnosis functions.

l Enhanced reliability through the adoption of gold-plated connector terminals.

l Use of an auto tensioner achieves maintenance-free, automatic adjustment of timing belt

tension.

l Use of the auto lash adjusters achieves maintenance-free, automatic adjustment of valve clearance

.o The 2coil ignition system without a distributor supplies sufficient ignition energy even during

high speed operation.

Page 10 of 391

O-6GENERAL - Technical Features

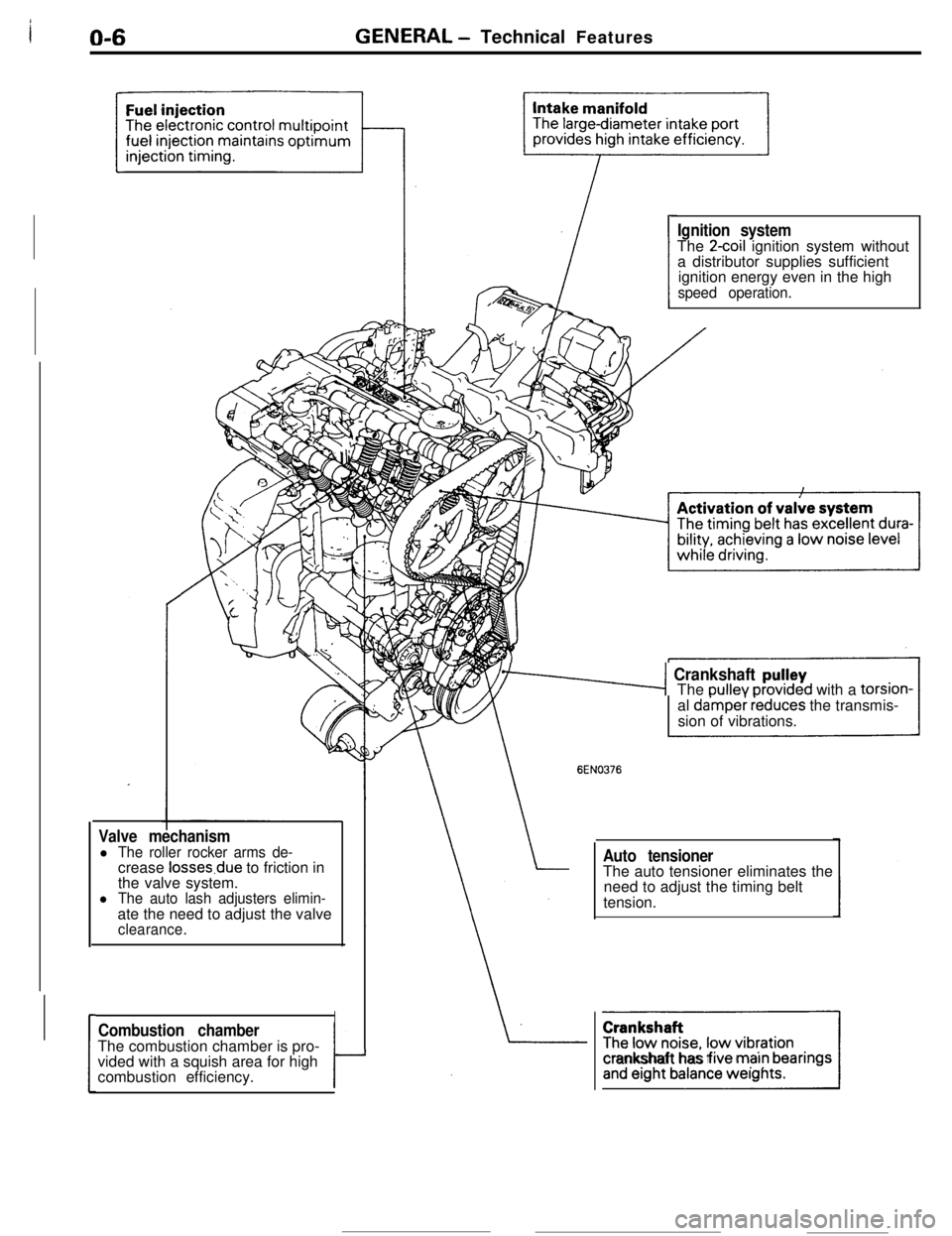

Valve mechanisml The roller rocker arms de-crease losses.due to friction in

the valve system.

l The auto lash adjusters elimin-ate the need to adjust the valve

clearance.

ICombustion chamberThe combustion chamber is pro-

vided with a squish area for high

combustion efficiency.

tJ

Ignition systemThe 2coil ignition system without

a distributor supplies sufficient

ignition energy even in the high

speed operation.

76-4 Crankshaft pu!leyThe oullev orovrded with a torsion-

al

da’mper ieduces the transmis-

sion of vibrations.

EN0376

Auto tensionerThe auto tensioner eliminates the

need to adjust the timing belt

tension.

]Icrankshaft has five marn bearings