differential MITSUBISHI ECLIPSE 1990 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 120 of 391

14-8

rFUEL SYSTEM

-Fuel Supply and Fuel Pressure Control

FUEL PUMP

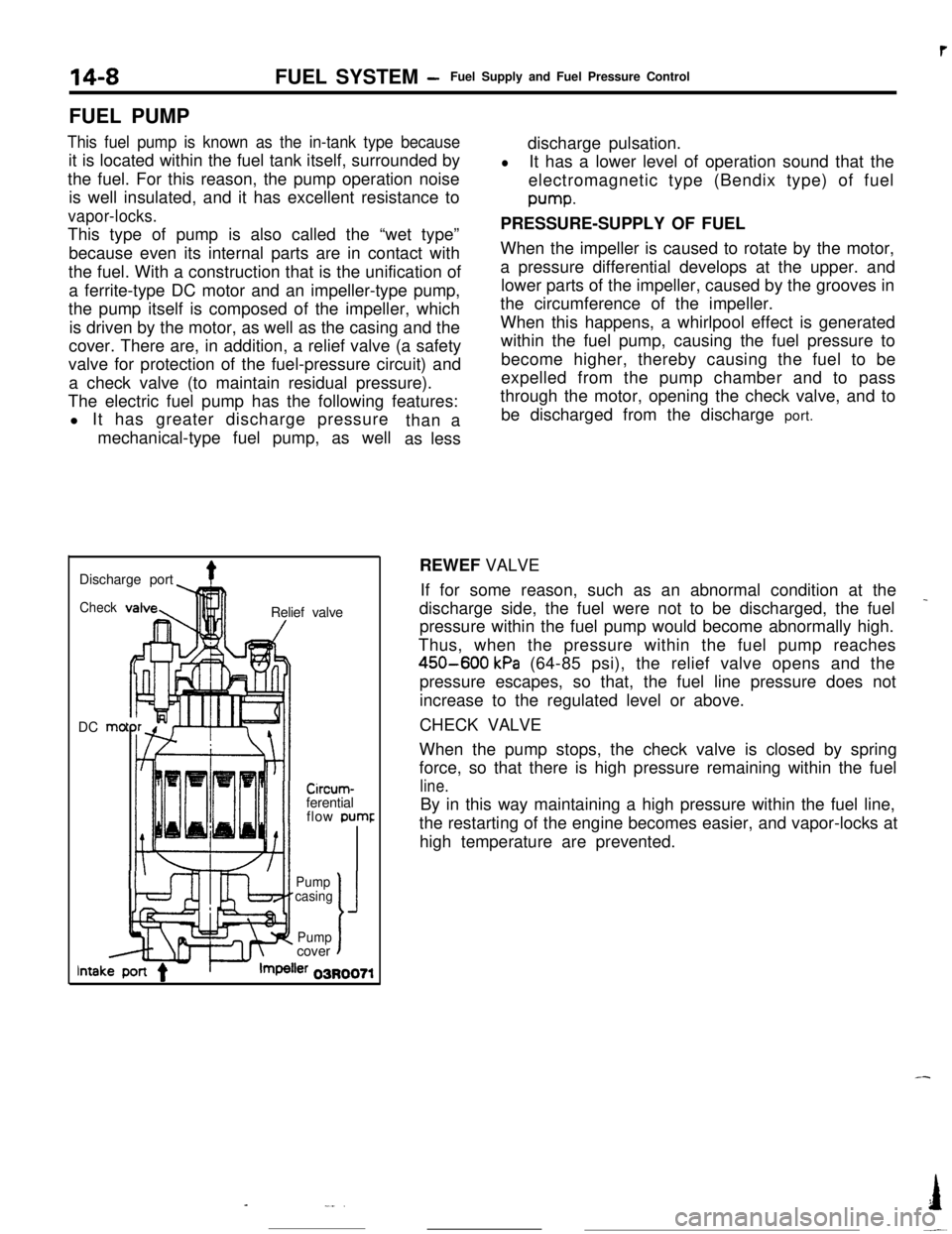

This fuel pump is known as the in-tank type becauseit is located within the fuel tank itself, surrounded by

the fuel. For this reason, the pump operation noise

is well insulated, and it has excellent resistance to

vapor-locks.This type of pump is also called the “wet type”

because even its internal parts are in contact with

the fuel. With a construction that is the unification of

a ferrite-type DC motor and an impeller-type pump,

the pump itself is composed of the impeller, which

is driven by the motor, as well as the casing and the

cover. There are, in addition, a relief valve (a safety

valve for protection of the fuel-pressure circuit) and

a check valve (to maintain residual pressure).

The electric fuel pump has the following features:

l It has greater discharge pressure

mechanical-type fuel pump, as wellthan a

as lessdischarge pulsation.

lIt has a lower level of operation sound that the

electromagnetic type (Bendix type) of fuelpump.

PRESSURE-SUPPLY OF FUEL

When the impeller is caused to rotate by the motor,

a pressure differential develops at the upper. and

lower parts of the impeller, caused by the grooves in

the circumference of the impeller.

When this happens, a whirlpool effect is generated

within the fuel pump, causing the fuel pressure to

become higher, thereby causing the fuel to be

expelled from the pump chamber and to pass

through the motor, opening the check valve, and to

be discharged from the discharge port.

Discharge port

4Check!nRelief valve

DC mo

-lllll1 I/

Circum-ferential

flow pumr

II’ f-Pump

casing

J

Pumpcovert

lntakler 03R0071REWEF VALVE

If for some reason, such as an abnormal condition at the

_discharge side, the fuel were not to be discharged, the fuel

pressure within the fuel pump would become abnormally high.

Thus, when the pressure within the fuel pump reaches

450-600 kPa (64-85 psi), the relief valve opens and the

pressure escapes, so that, the fuel line pressure does not

increase to the regulated level or above.

CHECK VALVE

When the pump stops, the check valve is closed by spring

force, so that there is high pressure remaining within the fuel

line.By in this way maintaining a high pressure within the fuel line,

the restarting of the engine becomes easier, and vapor-locks at

high temperature are prevented.

-

-_..I

-~

Page 206 of 391

-

REAR SUSPENSION -Double Wishbone Suspension17-13

Member supponbushingI

12AOO5

Upper arm

Link diagram of ordinarydouble wishbone suspension system

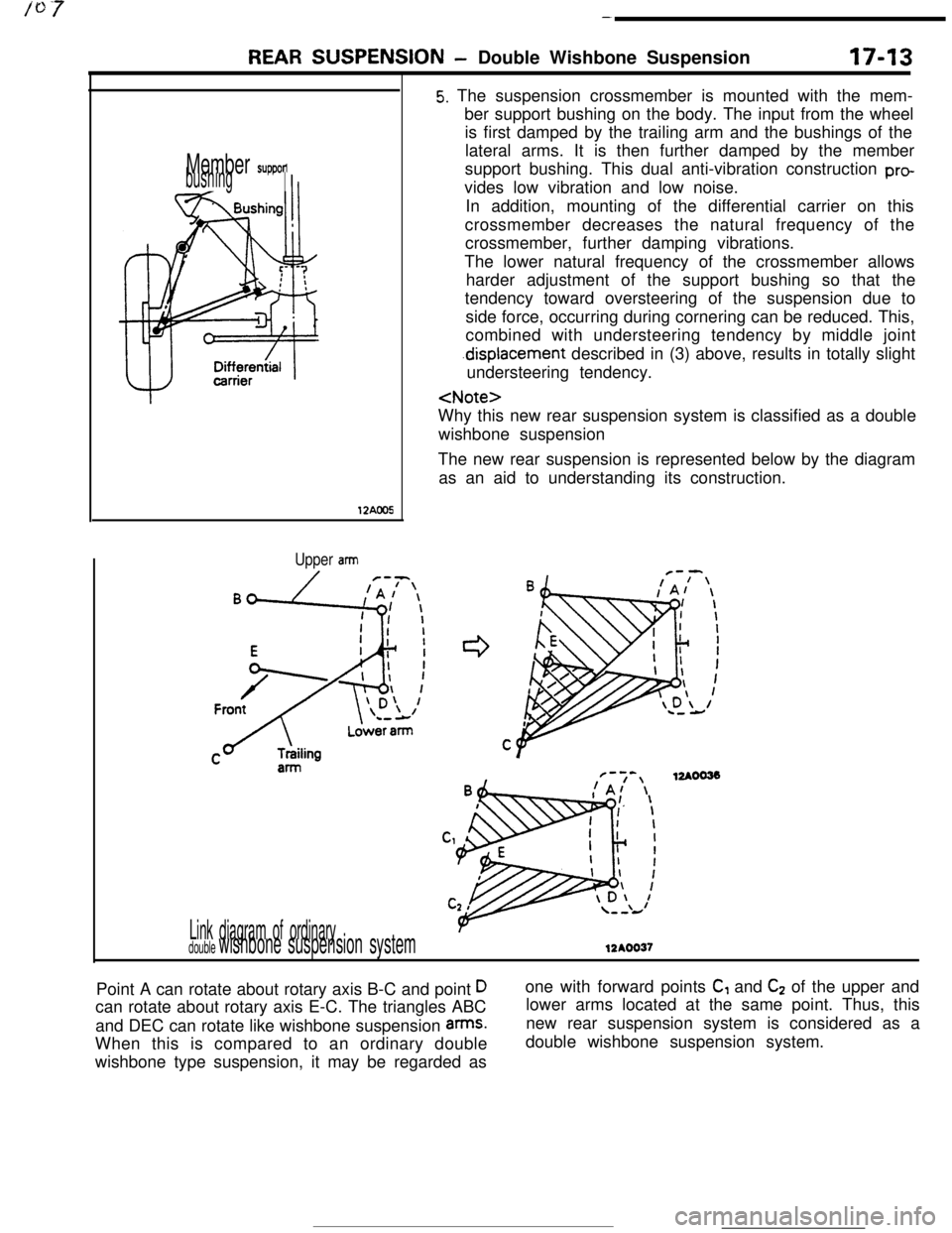

5. The suspension crossmember is mounted with the mem-

ber support bushing on the body. The input from the wheel

is first damped by the trailing arm and the bushings of the

lateral arms. It is then further damped by the member

support bushing. This dual anti-vibration construction

provides low vibration and low noise.

In addition, mounting of the differential carrier on this

crossmember decreases the natural frequency of the

crossmember, further damping vibrations.

The lower natural frequency of the crossmember allows

harder adjustment of the support bushing so that the

tendency toward oversteering of the suspension due to

side force, occurring during cornering can be reduced. This,

combined with understeering tendency by middle joint

.displacement described in (3) above, results in totally slight

understeering tendency.

wishbone suspension

The new rear suspension is represented below by the diagram

as an aid to understanding its construction.

F-7-,12AOO33!A/ \

12AOO37Point A can rotate about rotary axis B-C and point

Dcan rotate about rotary axis E-C. The triangles ABC

and DEC can rotate like wishbone suspension

arms.When this is compared to an ordinary double

wishbone type suspension, it may be regarded asone with forward points

C, and C2 of the upper and

lower arms located at the same point. Thus, this

new rear suspension system is considered as a

double wishbone suspension system.

Page 228 of 391

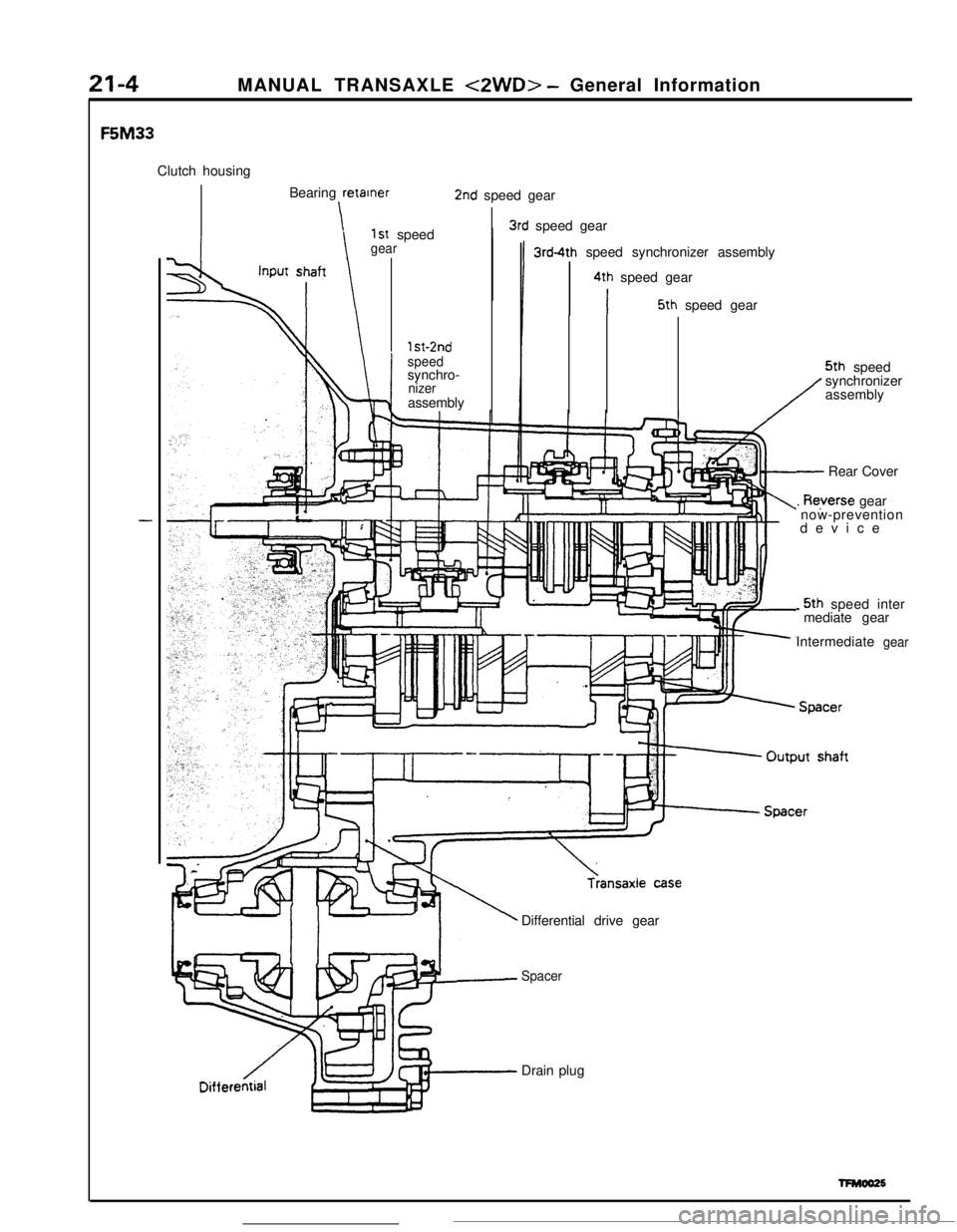

MANUAL TRANSAXLE <2WD> - General InformationF5M33

Clutch housing

Bearing retainer

\1st speedgear

2nd speed gear

I3rd speed gear

3rd-4th speed synchronizer assembly

4th speed gear

I5th speed gear

1 st-2nd

speedsynchro-

nizerassembly5th speed

synchronizer

assembly

- Rear Cover

. Reyerse gear

now-prevention

device

-5th speed inter

mediate gear

Intermediate

Differential drive gear

SpacerDrain plug

gear

Page 230 of 391

MANUAL TRANSAXLE <4WD> - General Information

MANUAL TRANSAXLE <4WD>

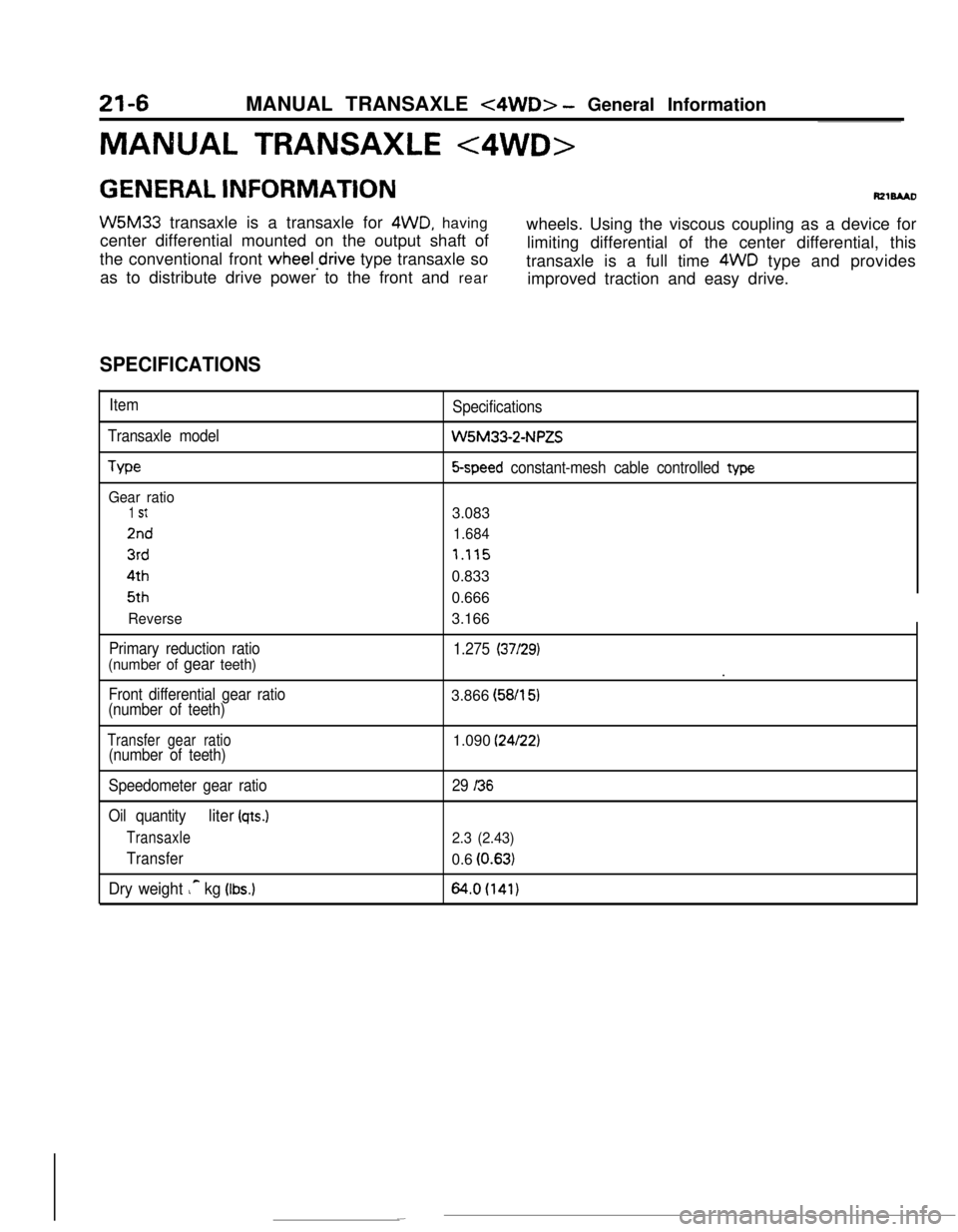

GENERAL INFORMATION

W5M33 transaxle is a transaxle for 4WD, having

center differential mounted on the output shaft ofwheels. Using the viscous coupling as a device for

the conventional front

wheeledrive type transaxle solimiting differential of the center differential, this

as to distribute drive power to the front and reartransaxle is a full time 4WD type and provides

improved traction and easy drive.

SPECIFICATIONS

Item

Transaxle model

We

Gear ratio

1 St

2nd

3rd4th5th

Reverse

Primary reduction ratio

(number of gear teeth)

Front differential gear ratio

(number of teeth)Specifications

W5M33-2-NPZS

5-speed constant-mesh cable controlled type3.083

1.684

7.1150.833

0.666

3.166

1.275 (37/29).

3.866 (58/l

51

Transfer gear ratio(number of teeth)1.090 (24/22)

Speedometer gear ratio

Oil quantity

liter (qts.)

Transaxle

Transfer

Dry weight ic kg (Ibs.)

29 I36

2.3 (2.43)0.6

(0.63)

64.0(141)

Page 231 of 391

--.-.--_ _ _-MANUAL TRANSAXLE

<4WD> - General Information

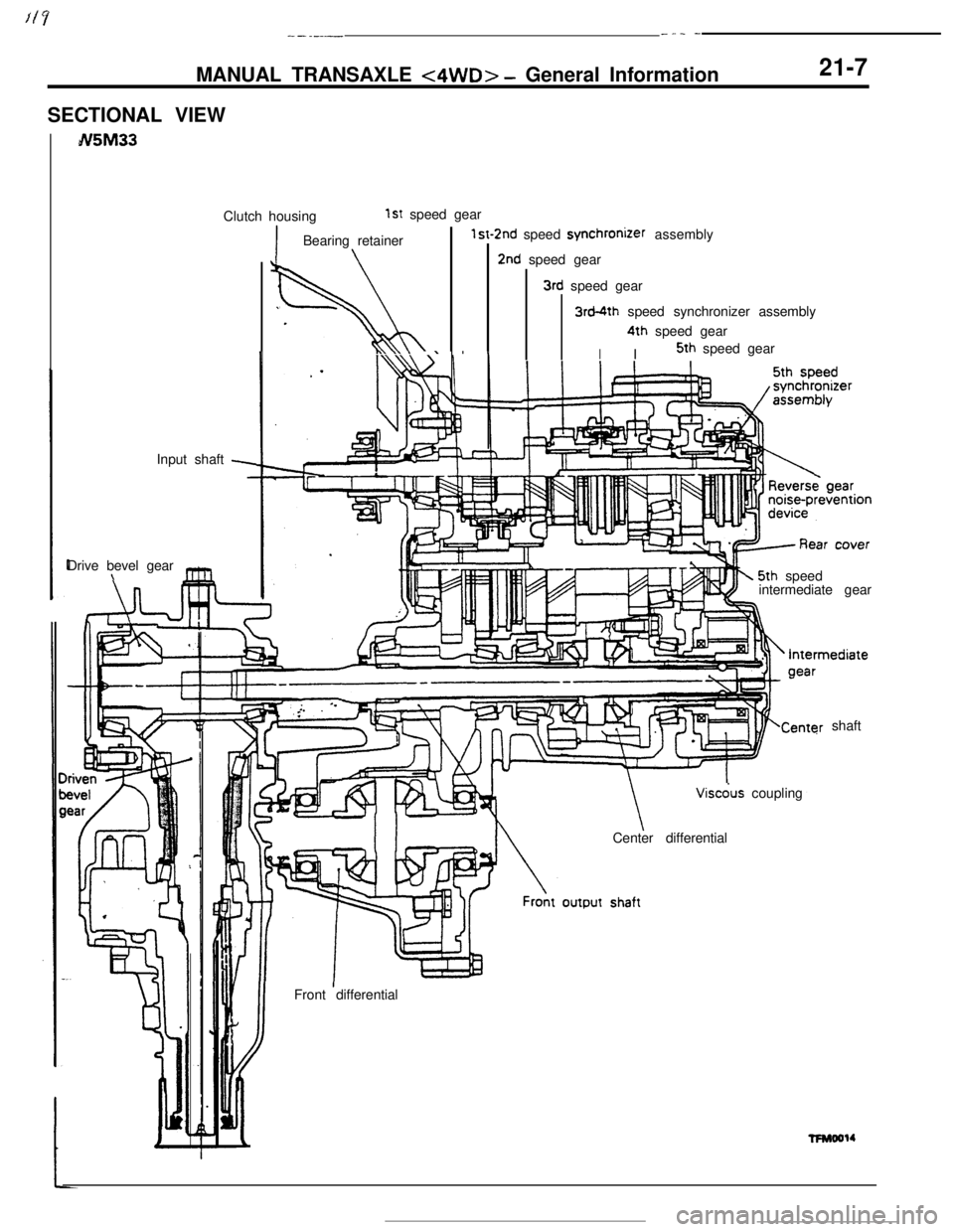

SECTIONAL VIEWN5M3321-7Clutch housing

1st speed gear

Input shaft

-Drive bevel gear

\r

l!

.IBearing retainer\

St-1

w

.

I,..\\I \ I I

2nd speed synchronizer assembly

2nd speed gear

3rd speed gear

3rd-4th speed synchronizer assembly

I4th speed gear

I5th speed gear

5th speed

intermediate gear

shaft

Center differential

Front differentialViscdus coupling

wMool4

Page 232 of 391

_.c.

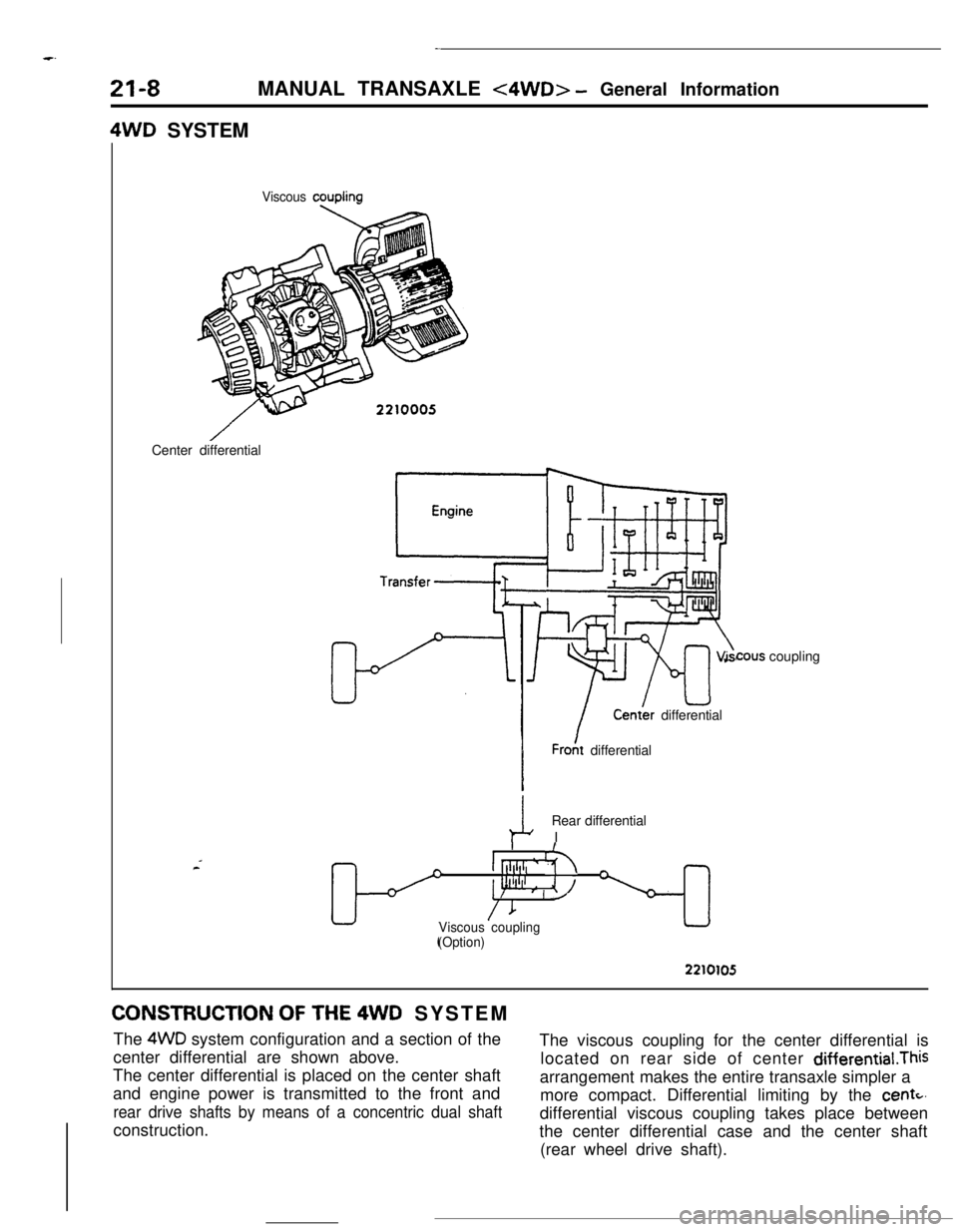

21-8MANUAL TRANSAXLE <4WD> - General Information4WD SYSTEM

Viscous couplingCenter differential

cous coupling

kCenth differential

I

IFro& differential

Rear differential

I

I

I [[lll,i, ‘- h-

1 p’f’ ,* , l/i\

/IViscous couplingL

(Option)

3

2210105CONSTRUCTION

OF THE 4WD SYSTEM

The 4WD system configuration and a section of the

center differential are shown above.The viscous coupling for the center differential is

The center differential is placed on the center shaftlocated on rear side of center differential.This

and engine power is transmitted to the front andarrangement makes the entire transaxle simpler a

rear drive shafts by means of a concentric dual shaftmore compact. Differential limiting by the

centc,construction.differential viscous coupling takes place between

the center differential case and the center shaft

(rear wheel drive shaft).

Page 233 of 391

-MANUAL TRANSAXLE

<4WD> - General information

21-9

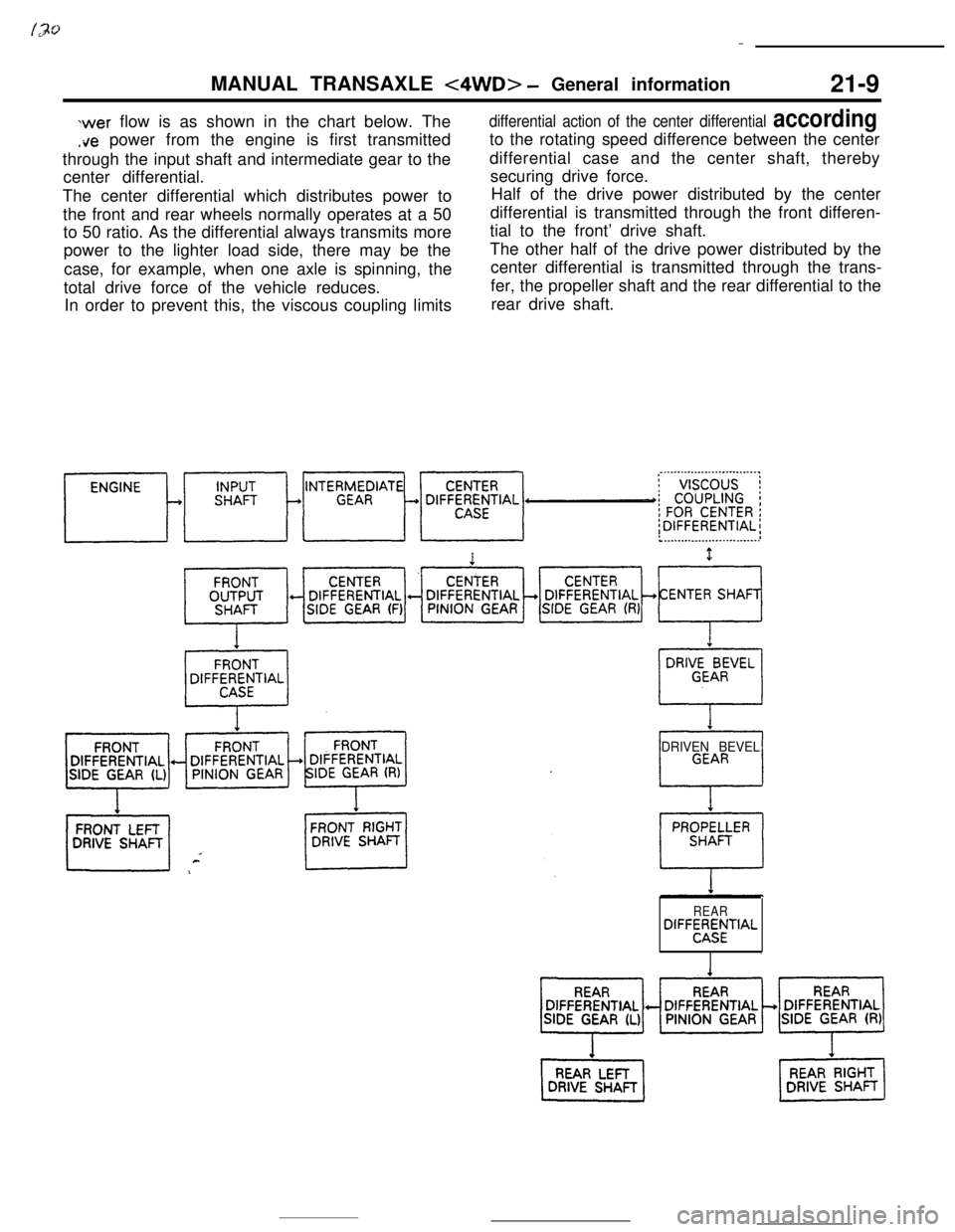

wer flow is as shown in the chart below. The

.ire power from the engine is first transmitted

through the input shaft and intermediate gear to the

center differential.

The center differential which distributes power to

the front and rear wheels normally operates at a 50

to 50 ratio. As the differential always transmits more

power to the lighter load side, there may be the

case, for example, when one axle is spinning, the

total drive force of the vehicle reduces.

In order to prevent this, the viscous coupling limits

differential action of the center differential accordingto the rotating speed difference between the center

differential case and the center shaft, thereby

securing drive force.

Half of the drive power distributed by the center

differential is transmitted through the front differen-

tial to the front’ drive shaft.

The other half of the drive power distributed by the

center differential is transmitted through the trans-

fer, the propeller shaft and the rear differential to the

rear drive shaft.

DRIVEN BEVEL

REARDIFF~;MfTIAL

,

Page 234 of 391

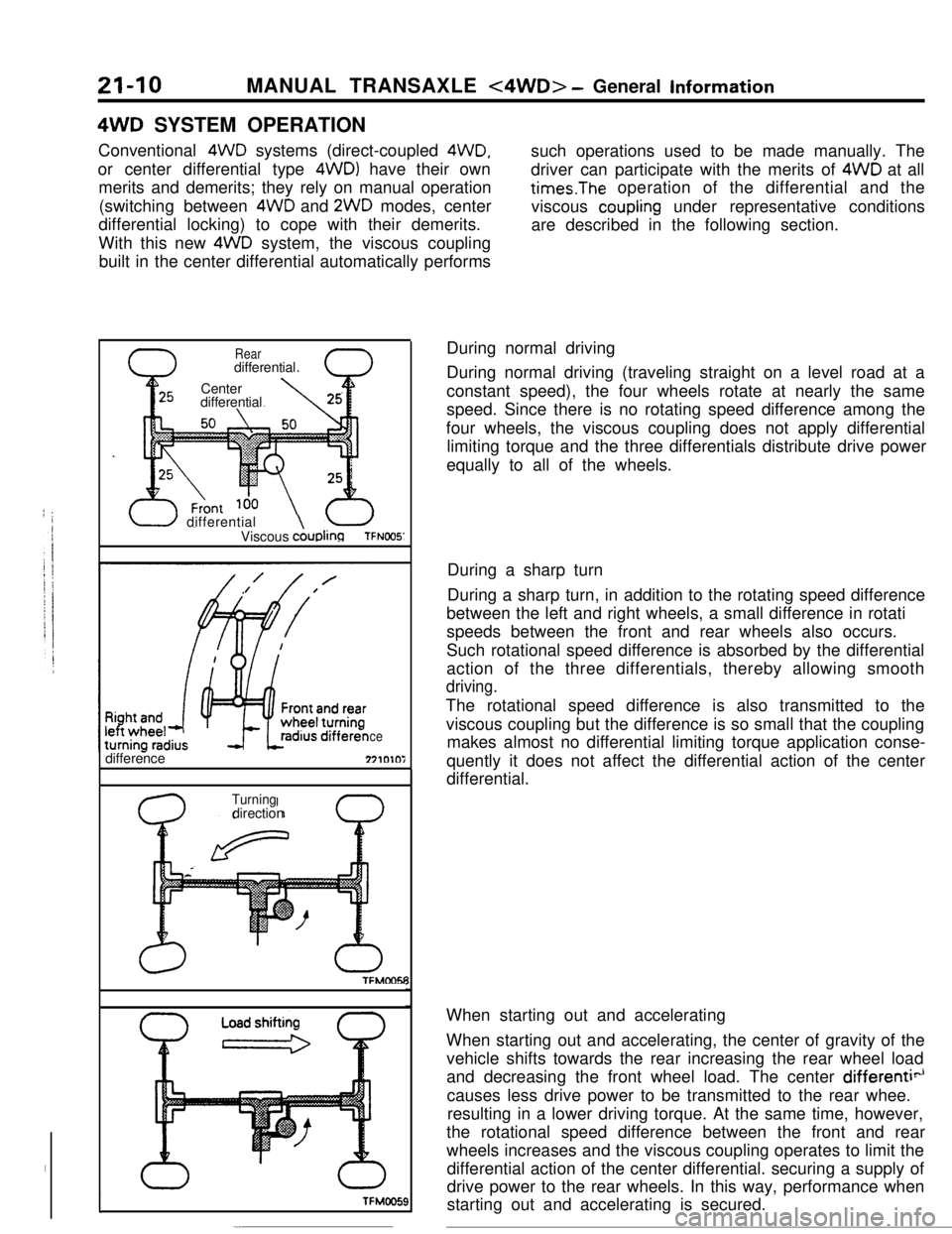

21-10MANUAL TRANSAXLE <4WD> - General Information4WD SYSTEM OPERATION

Conventional 4WD systems (direct-coupled

4WD,or center differential type 4WDl have their own

merits and demerits; they rely on manual operation

(switching between 4WD and 2WD modes, center

differential locking) to cope with their demerits.

With this new 4WD system, the viscous coupling

built in the center differential automatically performssuch operations used to be made manually. The

driver can participate with the merits of 4WD at alltimes.The operation of the differential and the

viscous

coupling under representative conditions

are described in the following section.

I

Reardifferential

Center

differential

U differential

Viscous AuDk?TFNOO5’difference

ce271010i

TFMMYTFMMY

0

Turningdirection

ITFMOO!X

-.During normal driving

During normal driving (traveling straight on a level road at a

constant speed), the four wheels rotate at nearly the same

speed. Since there is no rotating speed difference among the

four wheels, the viscous coupling does not apply differential

limiting torque and the three differentials distribute drive power

equally to all of the wheels.

During a sharp turn

During a sharp turn, in addition to the rotating speed difference

between the left and right wheels, a small difference in rotati

speeds between the front and rear wheels also occurs.

Such rotational speed difference is absorbed by the differential

action of the three differentials, thereby allowing smooth

driving.The rotational speed difference is also transmitted to the

viscous coupling but the difference is so small that the coupling

makes almost no differential limiting torque application conse-

quently it does not affect the differential action of the center

differential.

When starting out and accelerating

When starting out and accelerating, the center of gravity of the

vehicle shifts towards the rear increasing the rear wheel load

and decreasing the front wheel load. The center

differenti”causes less drive power to be transmitted to the rear whee.

resulting in a lower driving torque. At the same time, however,

the rotational speed difference between the front and rear

wheels increases and the viscous coupling operates to limit the

differential action of the center differential. securing a supply of

drive power to the rear wheels. In this way, performance when

starting out and accelerating is secured.

Page 235 of 391

MANUAL TRANSAXLE <4WD> - General Information21-I 1When driving on rough roads. . .In case either a front or rear wheel starts spinning on a slippery

or muddy road or when the vehicle is stuck in mud and one tire

spins, the drive power will be decreased by differential action.

However, as this also causes a sharp increase of speed

difference of the viscous coupling, a large differential limiting

torque is now applied, with more power transmitted to the tires

that are not spinning so that the vehicle can drive through or

getout of mud.A

Page 236 of 391

21-12MANUAL TRANSAXLE <4WD> - Viscous Coupling (VCU)

VISCOUS COUPLING (VCU)

RZlL

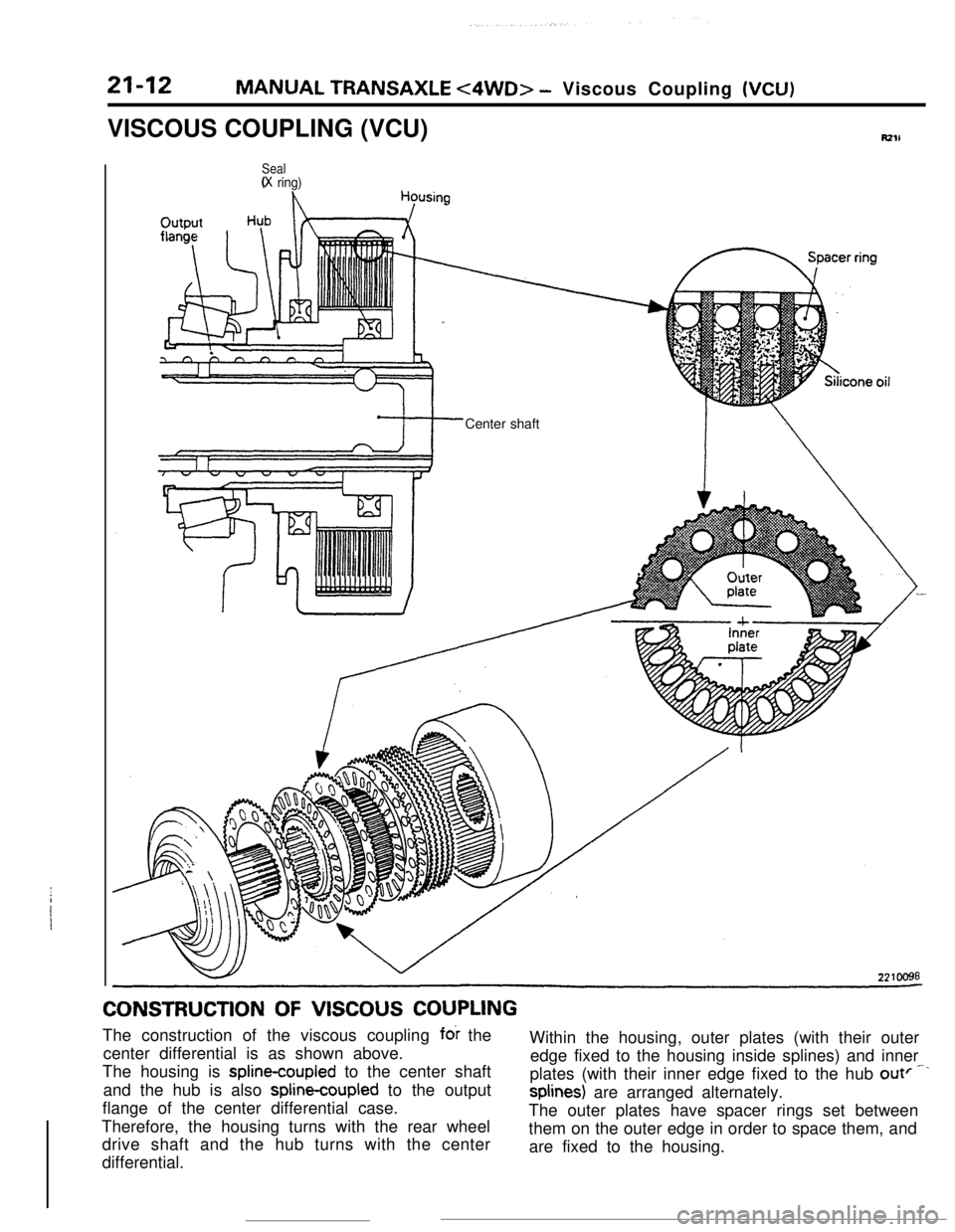

Seal(X ring)Center shaftCONSTRUCTION

OF VISCOUS COUPLINGThe construction of the viscous coupling

fck the

Within the housing, outer plates (with their outer

center differential is as shown above.

edge fixed to the housing inside splines) and inner

The housing is splinecoupled to the center shaft

plates (with their inner edge fixed to the hub

outF--and the hub is also

spline-coupled to the outputsplines) are arranged alternately.

flange of the center differential case.

The outer plates have spacer rings set between

Therefore, the housing turns with the rear wheel

them on the outer edge in order to space them, and

drive shaft and the hub turns with the center

are fixed to the housing.

differential.