differential MITSUBISHI ECLIPSE 1990 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 237 of 391

MANUAL TRANSAXLE <4WD> - Viscous Coupling .(VClJ)21-13In contrast, the inner plates have no such spacer rings, and

each can slide to some extent over the hub spline shaft

between the outer plates.

The space between the housing and outer and inner plates is

filled with mixture of silicone oil and air.

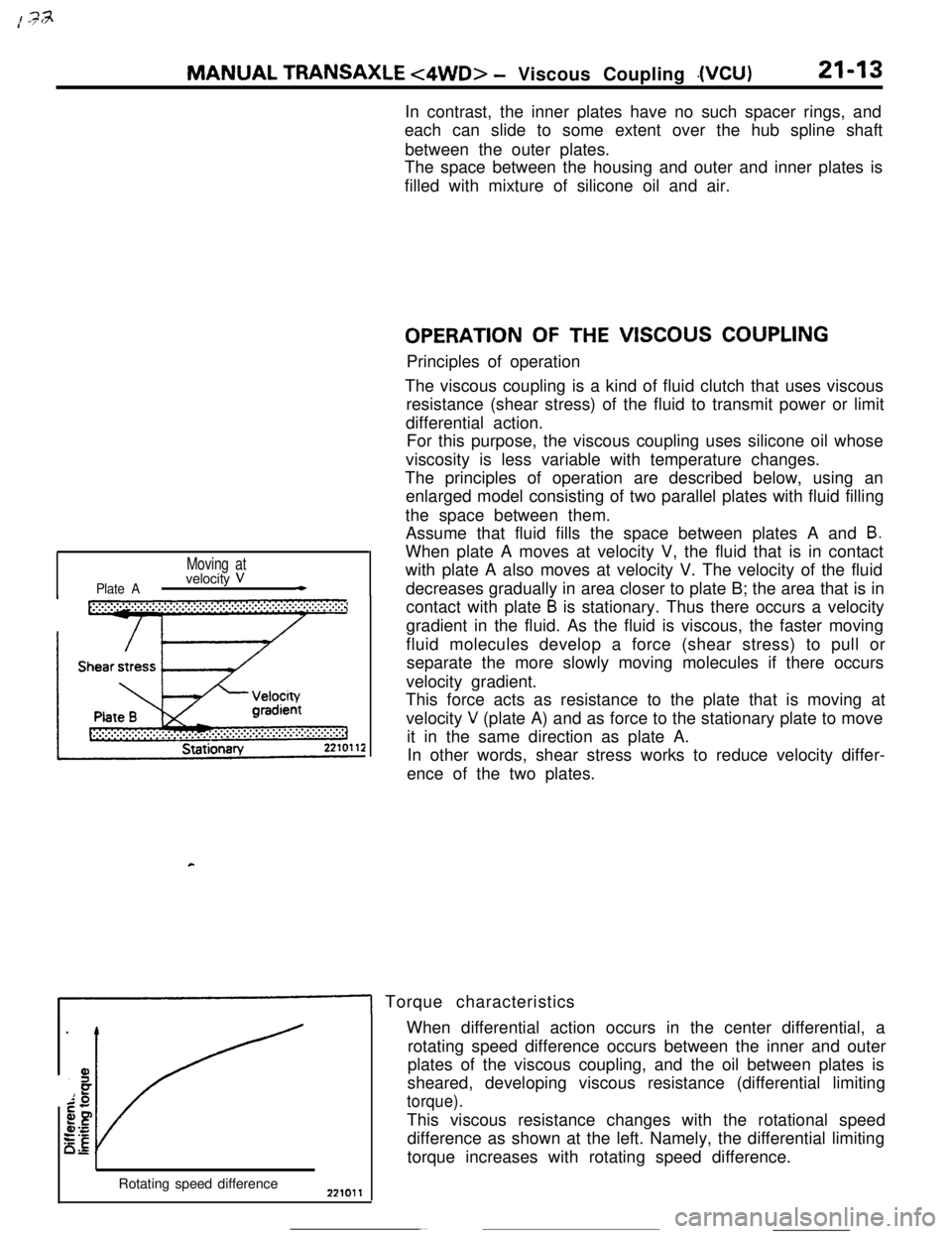

Plate A

Moving atvelocity V*

OPERATION OF THE VISCOUS COUPLINGPrinciples of operation

The viscous coupling is a kind of fluid clutch that uses viscous

resistance (shear stress) of the fluid to transmit power or limit

differential action.

For this purpose, the viscous coupling uses silicone oil whose

viscosity is less variable with temperature changes.

The principles of operation are described below, using an

enlarged model consisting of two parallel plates with fluid filling

the space between them.

Assume that fluid fills the space between plates A and

B.When plate A moves at velocity V, the fluid that is in contact

with plate A also moves at velocity V. The velocity of the fluid

decreases gradually in area closer to plate B; the area that is in

contact with plate

B is stationary. Thus there occurs a velocity

gradient in the fluid. As the fluid is viscous, the faster moving

fluid molecules develop a force (shear stress) to pull or

separate the more slowly moving molecules if there occurs

velocity gradient.

This force acts as resistance to the plate that is moving at

velocity

V (plate A) and as force to the stationary plate to move

it in the same direction as plate A.

In other words, shear stress works to reduce velocity differ-

ence of the two plates.

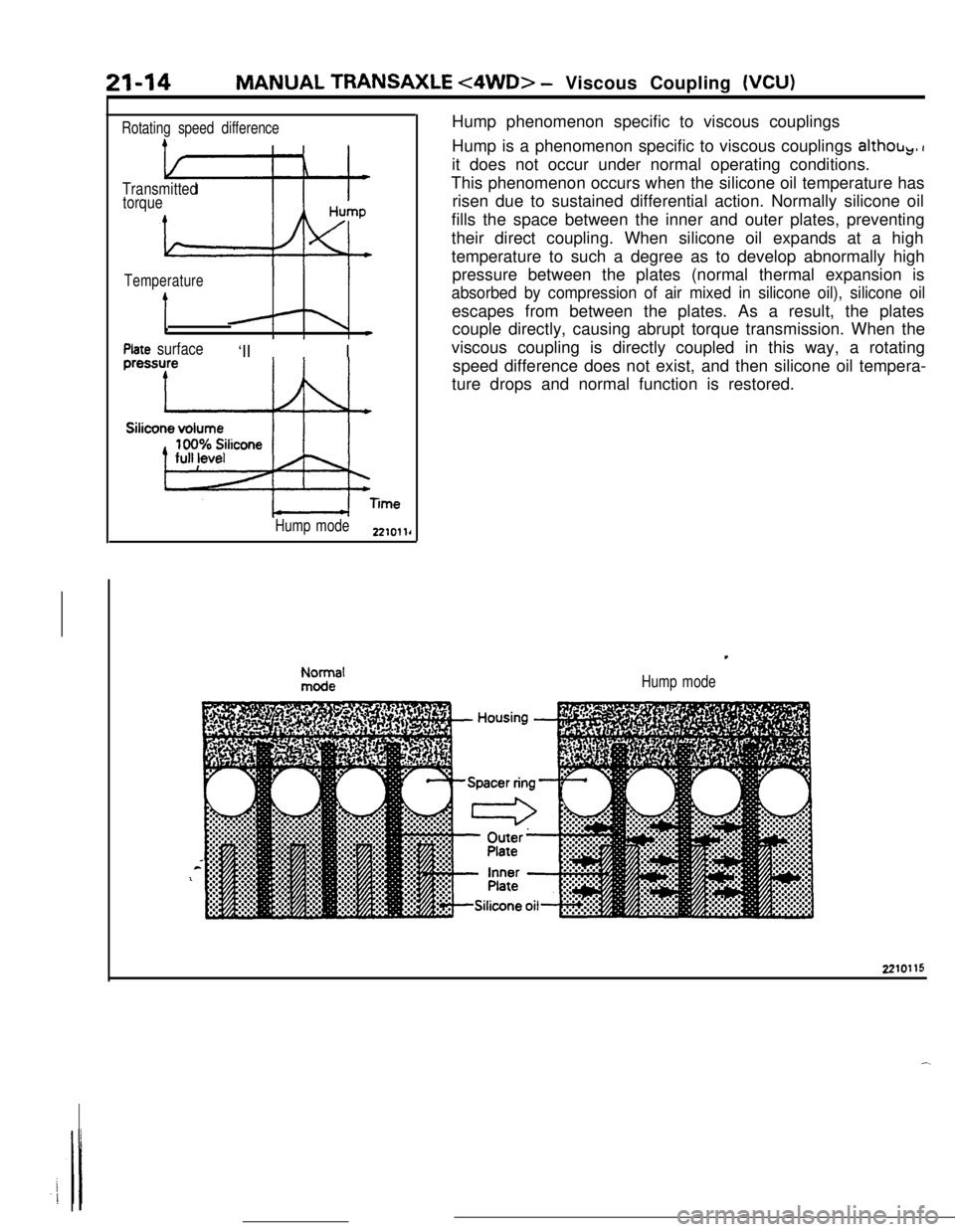

1 Torque characteristics

Rotating speed differenceWhen differential action occurs in the center differential, a

rotating speed difference occurs between the inner and outer

plates of the viscous coupling, and the oil between plates is

sheared, developing viscous resistance (differential limiting

torque).This viscous resistance changes with the rotational speed

difference as shown at the left. Namely, the differential limiting

torque increases with rotating speed difference.

Page 238 of 391

21-14MANUAL TRANSAXLE t4WD> - Viscous Coupling (VCU)

Rotating speed difference

Transmitted

torque

TemperatureII I

t

/

IIc

P&e surface‘II I

preTYl-LLL

Hump mode2210llrHump phenomenon specific to viscous couplings

Hump is a phenomenon specific to viscous couplings

althob,, Iit does not occur under normal operating conditions.

This phenomenon occurs when the silicone oil temperature has

risen due to sustained differential action. Normally silicone oil

fills the space between the inner and outer plates, preventing

their direct coupling. When silicone oil expands at a high

temperature to such a degree as to develop abnormally high

pressure between the plates (normal thermal expansion is

absorbed by compression of air mixed in silicone oil), silicone oilescapes from between the plates. As a result, the plates

couple directly, causing abrupt torque transmission. When the

viscous coupling is directly coupled in this way, a rotating

speed difference does not exist, and then silicone oil tempera-

ture drops and normal function is restored.

Hump mode2210115

Page 240 of 391

_-

21-16AUTOMATIC TRANSAXLE - General InformationAUTOMATIC

TRANSAXLE

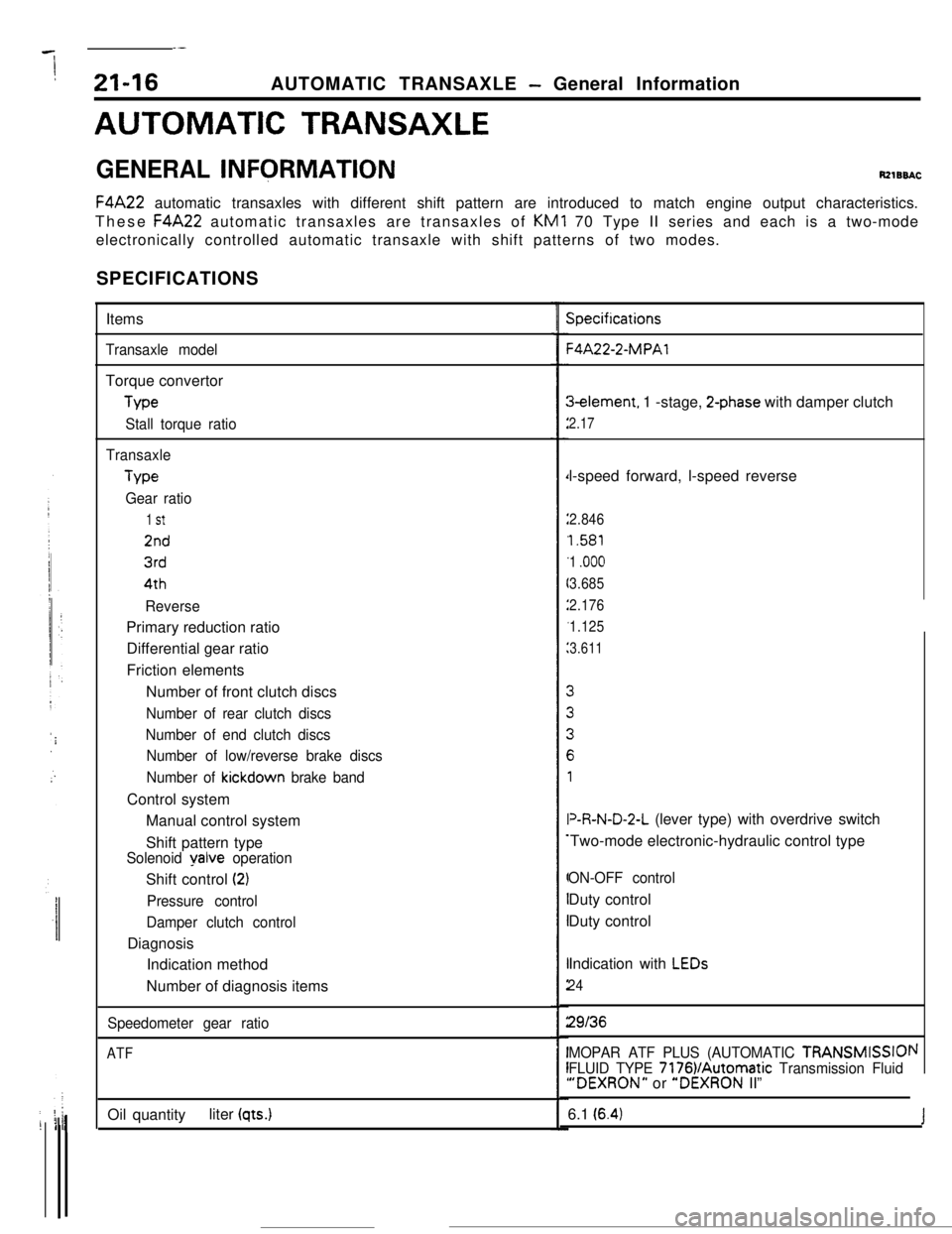

GENERAL INFQRMATIONRzlBBACF4A22 automatic transaxles with different shift pattern are introduced to match engine output characteristics.

These F4A22 automatic transaxles are transaxles of KM1 70 Type II series and each is a two-mode

electronically controlled automatic transaxle with shift patterns of two modes.

SPECIFICATIONS

Items

Transaxle modelTorque convertor

Me

Stall torque ratio

TransaxleType

Gear ratio

1 St

2nd

3rd4th

ReversePrimary reduction ratio

Differential gear ratio

Friction elements

Number of front clutch discs

Number of rear clutch discs

Number of end clutch discs

Number of low/reverse brake discs

Number of

kickdown brake bandControl system

Manual control system

Shift pattern type

Solenoid yalve operationShift control

(2)

Pressure control

Damper clutch controlDiagnosis

Indication method

Number of diagnosis items

Speedometer gear ratio

ATFOil quantityliter

(qts.)

Specifications-4A22-2-MPAl3element, 1 -stage,

2-phase with damper clutch

2.17l-speed forward, l-speed reverse

2.846

1.581

1

.ooo

3.685

2.176

1.125

3.611V&N-D-2-L (lever type) with overdrive switch

Two-mode electronic-hydraulic control type

ON-OFF controlDuty control

Duty control

Indication with

LEDs

24

29136

MOPAR ATF PLUS (AUTOMATIC TRANSMISSIOI

FLUID TYPE 7176VAutomatic Transmission Fluid“DEXRON” or “DEXRON II”

\I6.1

(6.4)J

Page 327 of 391

BODY - Main Bodv23-9

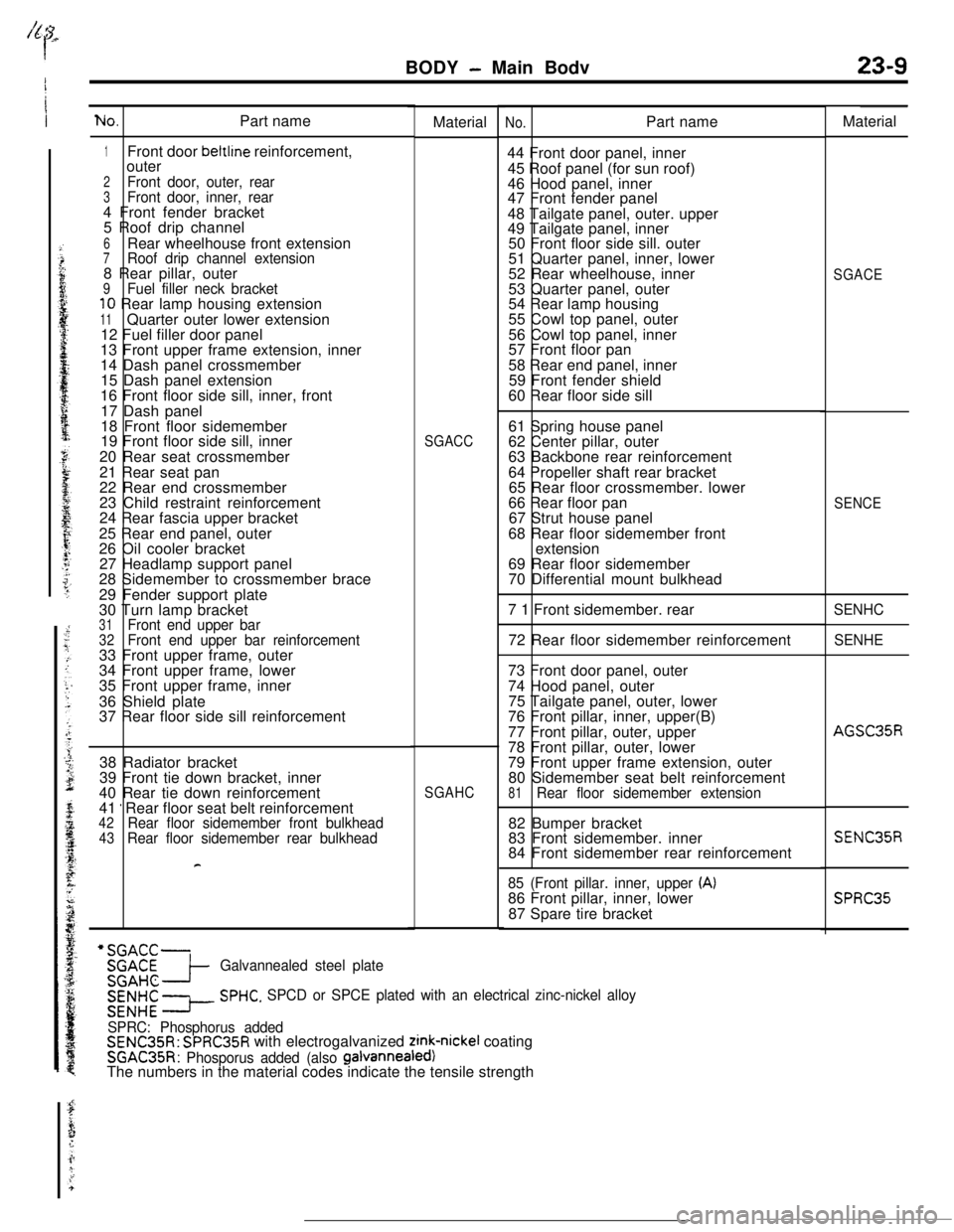

No.Part name

1Front door beltline reinforcement,

outer

2Front door, outer, rear3Front door, inner, rear4 Front fender bracket

5 Roof drip channel

6Rear wheelhouse front extension7Roof drip channel extension8 Rear pillar, outer

9Fuel filler neck bracket10 Rear lamp housing extension

11Quarter outer lower extension

12 Fuel filler door panel

13 Front upper frame extension, inner

14 Dash panel crossmember

15 Dash panel extension

16 Front floor side sill, inner, front

17 Dash panel

18 Front floor sidemember

19 Front floor side sill, inner

20 Rear seat crossmember

21 Rear seat pan

22 Rear end crossmember

23 Child restraint reinforcement

24 Rear fascia upper bracket

25 Rear end panel, outer

26 Oil cooler bracket

27 Headlamp support panel

28 Sidemember to crossmember brace

29 Fender support plate

30 Turn lamp bracket

31Front end upper bar32Front end upper bar reinforcement33 Front upper frame, outer

34 Front upper frame, lower

35 Front upper frame, inner

36 Shield plate

37 Rear floor side sill reinforcementMaterial

No.Part name

44 Front door panel, inner

45 Roof panel (for sun roof)

46 Hood panel, inner

47 Front fender panel

48 Tailgate panel, outer. upper

49 Tailgate panel, inner

50 Front floor side sill. outer

51 Quarter panel, inner, lower

52 Rear wheelhouse, inner

53 Quarter panel, outer

54 Rear lamp housing

55 Cowl top panel, outer

56 Cowl top panel, inner

57 Front floor pan

58 Rear end panel, inner

59 Front fender shield

60 Rear floor side sill

SGACC61 Spring house panel

62 Center pillar, outer

63 Backbone rear reinforcement

64 Propeller shaft rear bracket

65 Rear floor crossmember. lower

66 Rear floor pan

67 Strut house panel

68 Rear floor sidemember front

extension

69 Rear floor sidemember

70 Differential mount bulkhead

7 1 Front sidemember. rear

72 Rear floor sidemember reinforcement

38 Radiator bracket

39 Front tie down bracket, inner

40 Rear tie down reinforcement

41

’ Rear floor seat belt reinforcement42Rear floor sidemember front bulkhead43Rear floor sidemember rear bulkhead

F

SGAHC73 Front door panel, outer

74 Hood panel, outer

75 Tailgate panel, outer, lower

76 Front pillar, inner, upper(B)

77 Front pillar, outer, upper

78 Front pillar, outer, lower

79 Front upper frame extension, outer

80 Sidemember seat belt reinforcement81Rear floor sidemember extension82 Bumper bracket

83 Front sidemember. inner

84 Front sidemember rear reinforcement

85 (Front pillar. inner, upper (A)86 Front pillar, inner, lower

87 Spare tire bracket

x::-SGAHC-I-Galvannealed steel plate

E% x--

SPHC. SPCD or SPCE plated with an electrical zinc-nickel alloy

SPRC: Phosphorus added

SENC35R: SPRC35R with electrogalvanized zink-nickel coating

SGAC35R: Phosporus added (also galvanneafed)The numbers in the material codes indicate the tensile strengthMaterial

SGACE

SENCE

SENHC

SENHE

AGSC35R

SENC35R

SPRC35