reset MITSUBISHI ECLIPSE 1990 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 165 of 391

FUEL SYSTEM -Idle Speed Control I Power Supply Control14-53

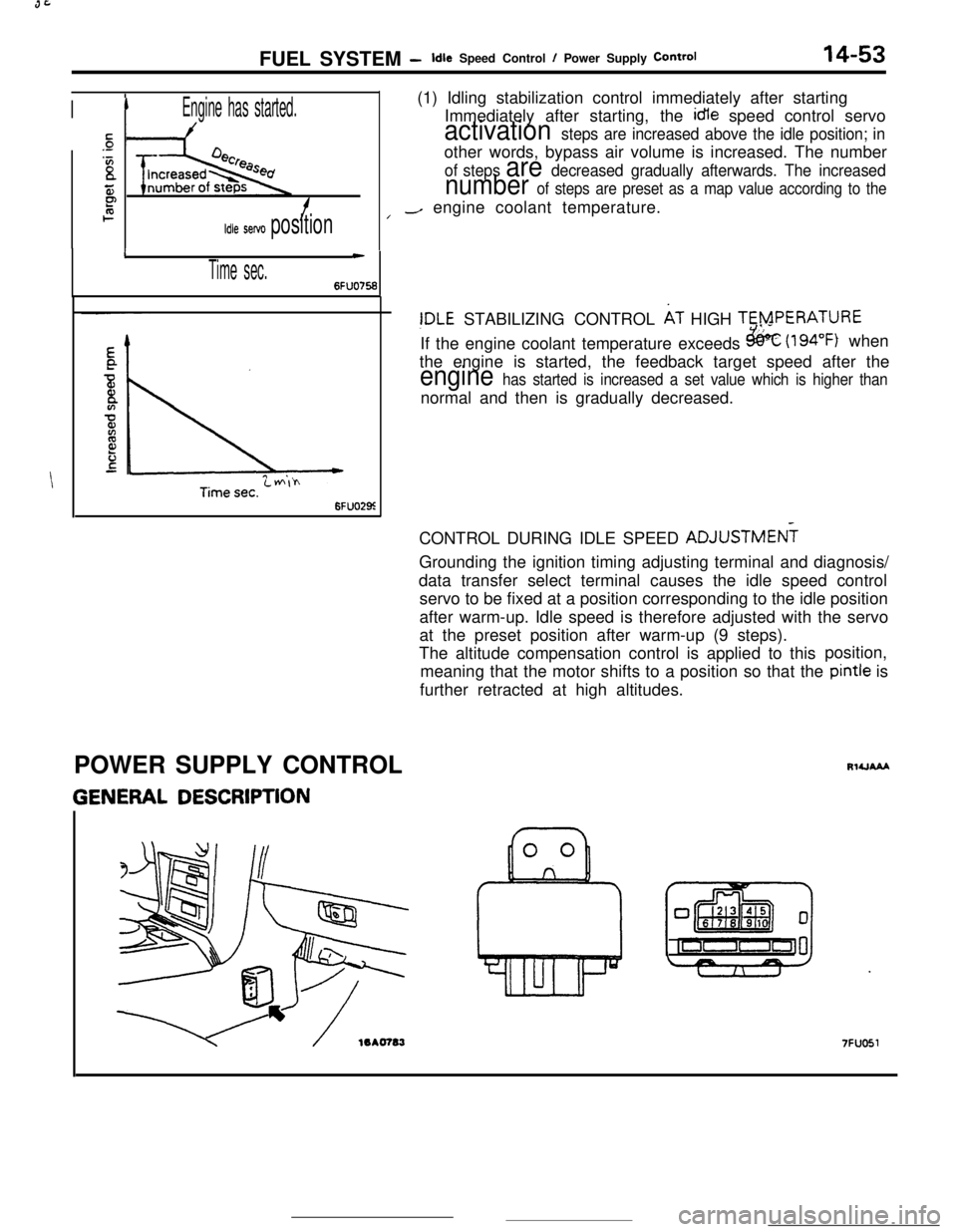

IIEngine has started.(1) Idling stabilization control immediately after starting

Immediately after starting, the idle speed control servo

sactivation steps are increased above the idle position; in.-

‘Bother words, bypass air volume is increased. The numberof steps are decreased gradually afterwards. The increased

55number of steps are preset as a map value according to theP2f/-/ engine coolant temperature.

Idle servo position

I

Time sec.

c

6FUO756

6FUO29z

!DLE STABILIZING CONTROL AT HIGH TERPERATURE

If the engine coolant temperature exceeds

&k (194°F) when

the engine is started, the feedback target speed after the

engine has started is increased a set value which is higher thannormal and then is gradually decreased.

CONTROL DURING IDLE SPEED ADJUSTMEN?

Grounding the ignition timing adjusting terminal and diagnosis/

data transfer select terminal causes the idle speed control

servo to be fixed at a position corresponding to the idle position

after warm-up. Idle speed is therefore adjusted with the servo

at the preset position after warm-up (9 steps).

The altitude compensation control is applied to thisposition,

meaning that the motor shifts to a position so that the pintle is

further retracted at high altitudes.

POWER SUPPLY CONTROL

GENERAL DESCRIPTION

RlUAAA

7FUO51

Page 169 of 391

FUEL SYSTEMAir Flow Sensor (AFSI Filter Reset Control

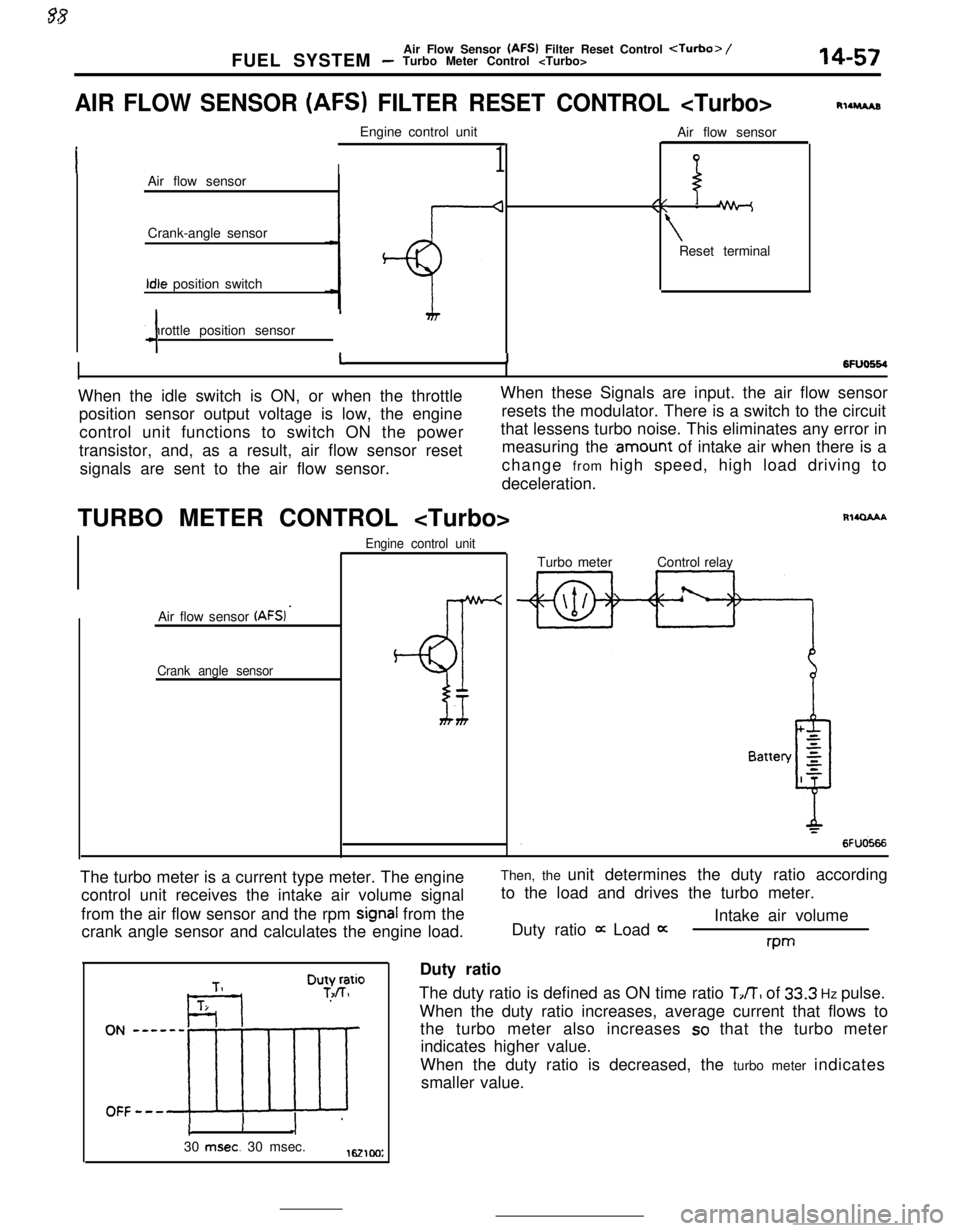

AIR FLOW SENSOR (AFS) FILTER RESET CONTROL

I1Air flow sensor

Crank-angle sensorIdle position switch

Throttle position sensor

4Air flow sensor

//\\ -

\Reset terminal

RllruAs

6FlJo664I11When the idle switch is ON, or when the throttleWhen these Signals are input. the air flow sensor

position sensor output voltage is low, the engineresets the modulator. There is a switch to the circuit

control unit functions to switch ON the powerthat lessens turbo noise. This eliminates any error in

transistor, and, as a result, air flow sensor resetmeasuring the

.amount of intake air when there is a

signals are sent to the air flow sensor.change from high speed, high load driving to

deceleration.

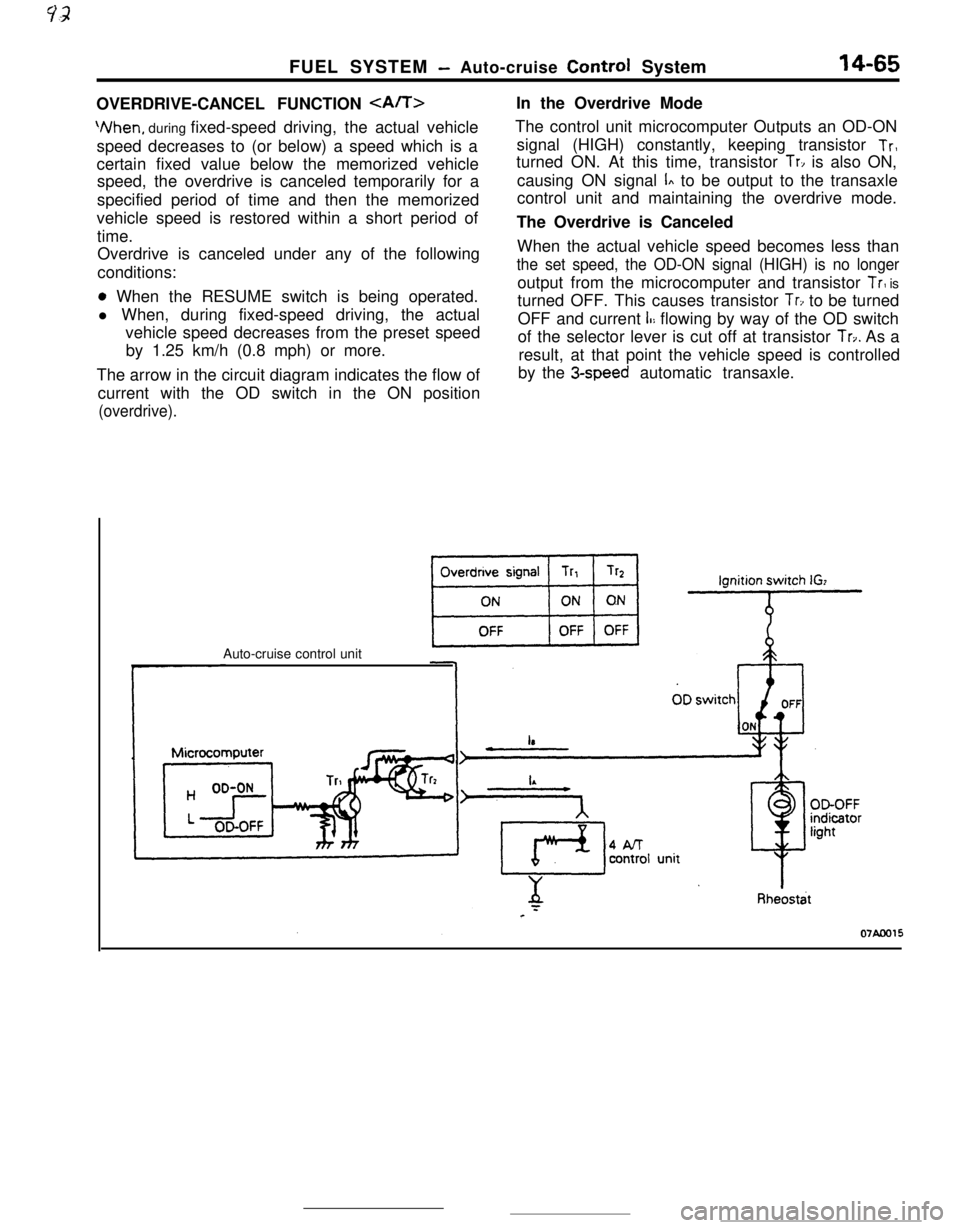

TURBO METER CONTROL

Air flow sensor

(AFSI ’

Crank angle sensorEngine control unit

BT

Rl4QAAATurbo meterControl relay

The turbo meter is a current type meter. The engine

control unit receives the intake air volume signal

from the air flow sensor and the rpm

signal from the

crank angle sensor and calculates the engine load.Then, the unit determines the duty ratio according

to the load and drives the turbo meter.

Intake air volume

Duty ratio

it Load 0:rwDuty ratio

The duty ratio is defined as ON time ratio

TJT, of 33.3 Hz pulse.

When the duty ratio increases, average current that flows to

the turbo meter also increases

so that the turbo meter

indicates higher value.

When the duty ratio is decreased, the turbo meter indicates

smaller value.

cI30

msec. 30 msec.1621cm:

Page 175 of 391

FUEL SYSTEM - Auto-cruise Control System14-63

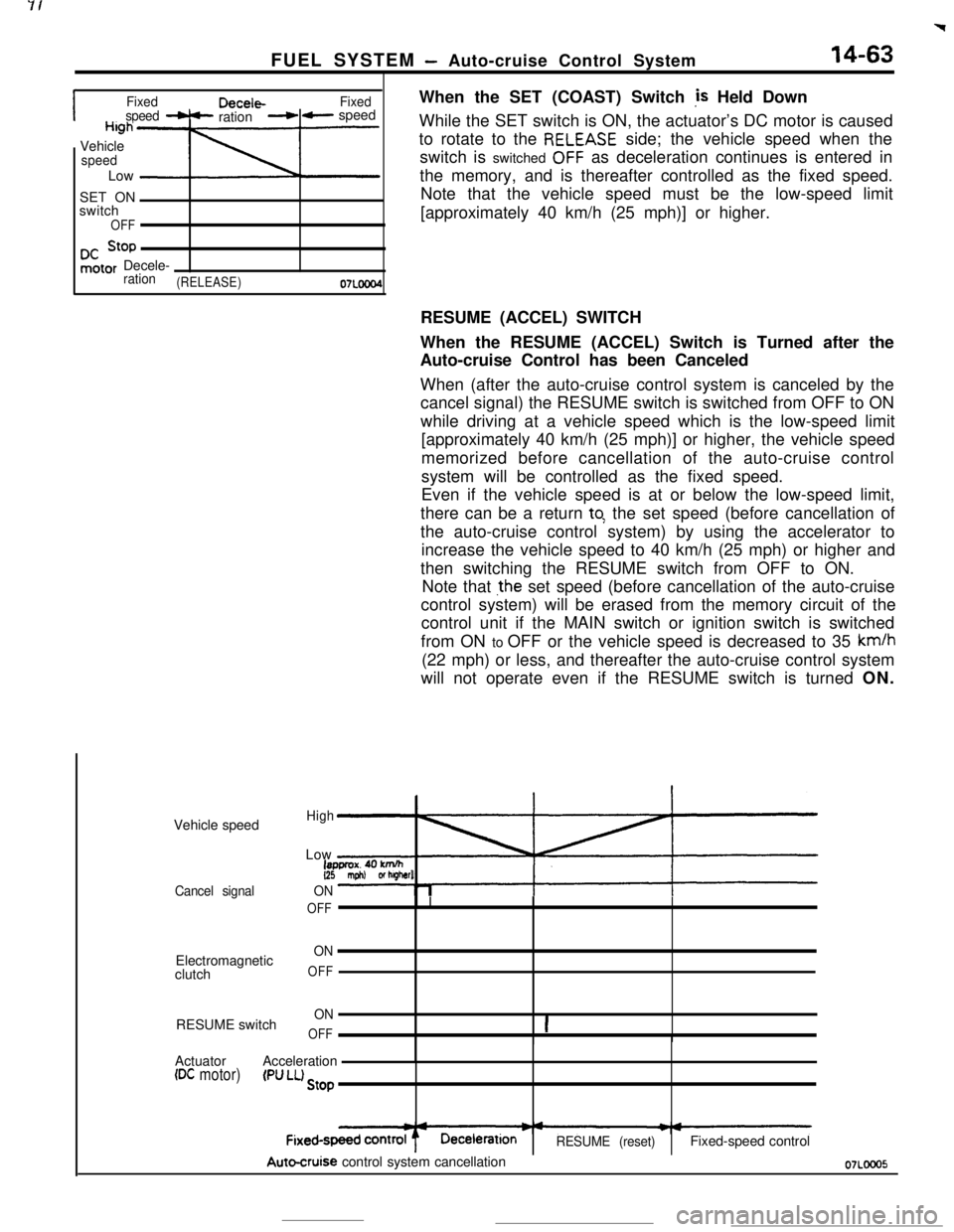

FixedDecebFixed

speed -bb-Highration+ c- speed

Vehicle

speedLow

SET ON

switch

OFF

DC StoPmotor Decele-

ration(RELEASE)07LOcaWhen the SET (COAST) Switch

,is Held Down

While the SET switch is ON, the actuator’s DC motor is caused

to rotate to the

RELEASE side; the vehicle speed when the

switch is switched

OFF as deceleration continues is entered in

the memory, and is thereafter controlled as the fixed speed.

Note that the vehicle speed must be the low-speed limit

[approximately 40 km/h (25 mph)] or higher.

Vehicle speed

Cancel signalElectromagnetic

clutch

RESUME switchRESUME (ACCEL) SWITCH

When the RESUME (ACCEL) Switch is Turned after the

Auto-cruise Control has been Canceled

When (after the auto-cruise control system is canceled by the

cancel signal) the RESUME switch is switched from OFF to ON

while driving at a vehicle speed which is the low-speed limit

[approximately 40 km/h (25 mph)] or higher, the vehicle speed

memorized before cancellation of the auto-cruise control

system will be controlled as the fixed speed.

Even if the vehicle speed is at or below the low-speed limit,

there can be a return

to: the set speed (before cancellation of

the auto-cruise control system) by using the accelerator to

increase the vehicle speed to 40 km/h (25 mph) or higher and

then switching the RESUME switch from OFF to ON.

Note that

jhe set speed (before cancellation of the auto-cruise

control system) will be erased from the memory circuit of the

control unit if the MAIN switch or ignition switch is switched

from ON to OFF or the vehicle speed is decreased to 35 km/h

(22 mph) or less, and thereafter the auto-cruise control system

will not operate even if the RESUME switch is turned ON.

HighLow

18pprOX.40 knVh(25 mph) or lugharl

ON

OFFI

ON

OFF

ON

OFF1IActuatorAcceleration

(DC motor)(Pff LL) Stop

RESUME (reset)Fixed-speed control

Autocruise control system cancellation07LOOO5

Page 177 of 391

Page 181 of 391

FUEL SYSTEM- Auto-cruise Control System14-69

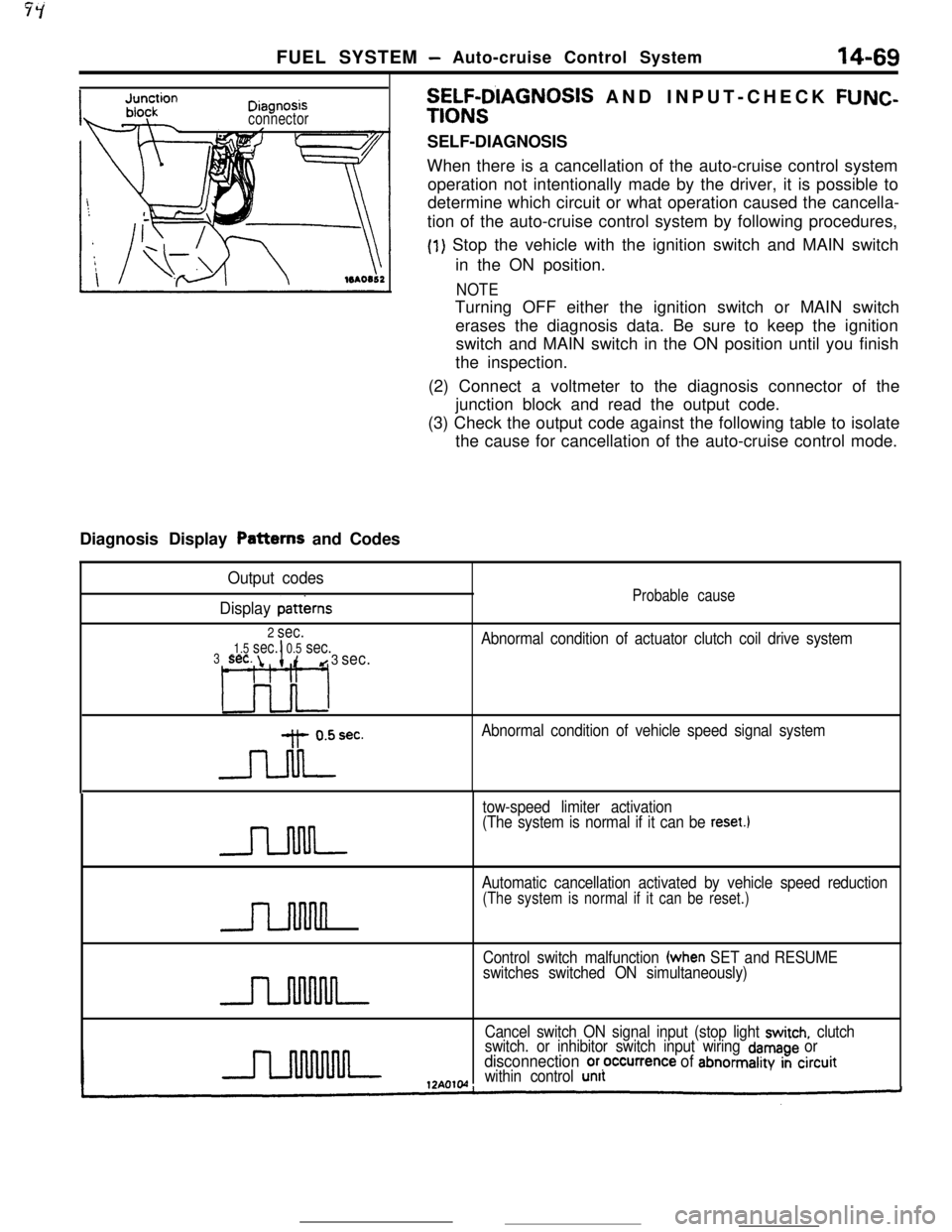

ni2nnncisv,“y’I”“.-

connectorDiagnosis Display Patterns and Codes

SELF-D’IAGNOSIS AND INPUT-CHECK FUNC-

TIONSSELF-DIAGNOSIS

When there is a cancellation of the auto-cruise control system

operation not intentionally made by the driver, it is possible to

determine which circuit or what operation caused the cancella-

tion of the auto-cruise control system by following procedures,

(1) Stop the vehicle with the ignition switch and MAIN switch

in the ON position.

NOTETurning OFF either the ignition switch or MAIN switch

erases the diagnosis data. Be sure to keep the ignition

switch and MAIN switch in the ON position until you finish

the inspection.

(2) Connect a voltmeter to the diagnosis connector of the

junction block and read the output code.

(3) Check the output code against the following table to isolate

the cause for cancellation of the auto-cruise control mode.

Output codes

Display

patterns

2 sec.

1.5 sec.I0.5 sec.3sec. id 3 sec.

L3o-l

-Jdrec.

Probable cause

Abnormal condition of actuator clutch coil drive system

Abnormal condition of vehicle speed signal system

tow-speed limiter activation

(The system is normal if it can be

reset.1

n

Automatic cancellation activated by vehicle speed reduction

(The system is normal if it can be reset.)

Control switch malfunction (when SET and RESUME

switches switched ON simultaneously)

Cancel switch ON signal input (stop light

switch, clutch

switch. or inhibitor switch input wiring damage ordisconnection or,occurrence of abnormality in circuitwithin control unit

Page 182 of 391

14-70

-_FUEL SYSTEM

- Auto-cruise Control System

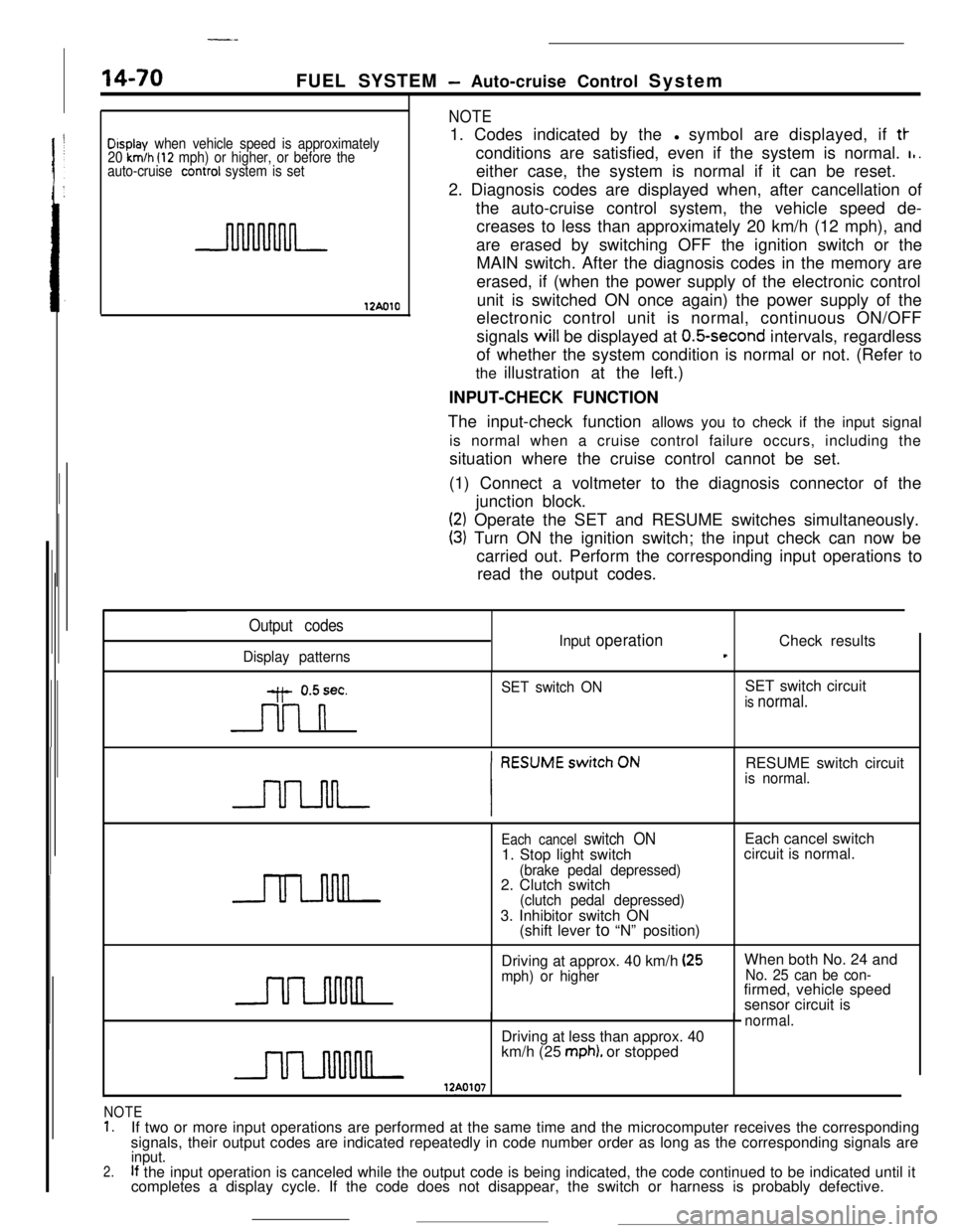

Display when vehicle speed is approximately

20 km/h (12 mph) or higher, or before the

auto-cruise conrrol system is set

12AolO

NOTE1. Codes indicated by thel symbol are displayed, if

tt-conditions are satisfied, even if the system is normal.

I,.either case, the system is normal if it can be reset.

2. Diagnosis codes are displayed when, after cancellation of

the auto-cruise control system, the vehicle speed de-

creases to less than approximately 20 km/h (12 mph), and

are erased by switching OFF the ignition switch or the

MAIN switch. After the diagnosis codes in the memory are

erased, if (when the power supply of the electronic control

unit is switched ON once again) the power supply of the

electronic control unit is normal, continuous ON/OFF

signals will be displayed at

O.&second intervals, regardless

of whether the system condition is normal or not. (Refer to

the illustration at the left.)

INPUT-CHECK FUNCTION

The input-check function allows you to check if the input signal

is normal when a cruise control failure occurs, including the

situation where the cruise control cannot be set.

(1) Connect a voltmeter to the diagnosis connector of the

junction block.

(2) Operate the SET and RESUME switches simultaneously.

(3) Turn ON the ignition switch; the input check can now be

carried out. Perform the corresponding input operations to

read the output codes.

Output codes

Display patternsInput

operationCheck resultst

y- 0.5sec.

n

SET switch ONSET switch circuitis normal.RESUME switch circuit

is normal.

Each cancel switch ON1. Stop light switch

(brake pedal depressed)2. Clutch switch

(clutch pedal depressed)3. Inhibitor switch ON

(shift lever to “N” position)Each cancel switch

circuit is normal.

Driving at approx. 40 km/h

(25mph) or higherWhen both No. 24 andNo. 25 can be con-firmed, vehicle speed

sensor circuit is

normal.Driving at less than approx. 40

km/h (25

mph). or stopped

NOTE1.If two or more input operations are performed at the same time and the microcomputer receives the corresponding

signals, their output codes are indicated repeatedly in code number order as long as the corresponding signals are

2.input.If the input operation is canceled while the output code is being indicated, the code continued to be indicated until it

completes a display cycle. If the code does not disappear, the switch or harness is probably defective.

Page 188 of 391

- -----.--..

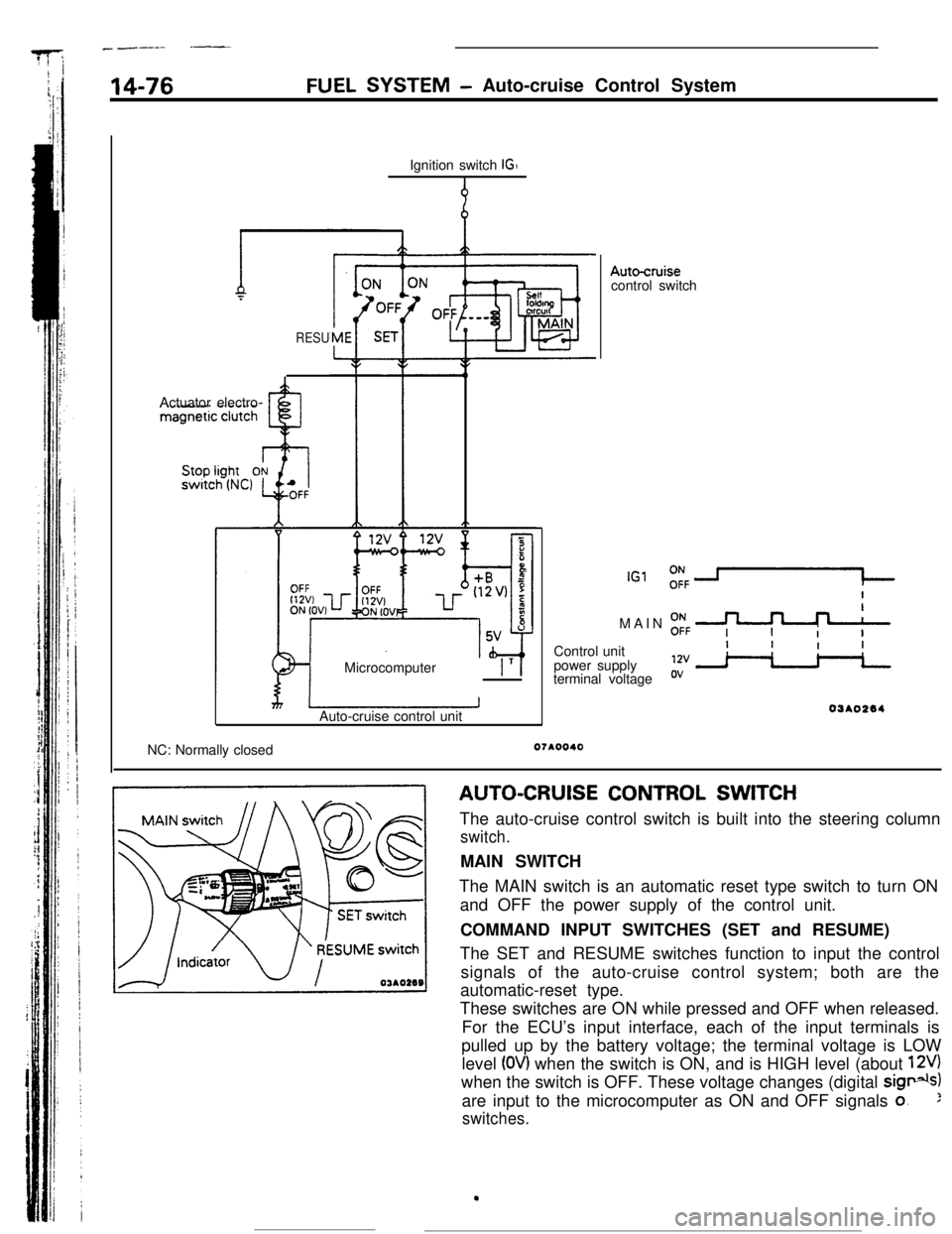

14-76FUEL SYSTEM -Auto-cruise Control System

Ignition switch

IGI

9

RESUActuator electro-

Microcomputer

1 T 1

rn’Auto-cruise control unit

Autocruisecontrol switch

IGlMAIN

;FF -+++&Control unit

power supply

terminal voltage

03AO264NC: Normally closed

07*0040

AUTO-CRUISE CONTROL SWITCH

The auto-cruise control switch is built into the steering column

switch.MAIN SWITCH

The MAIN switch is an automatic reset type switch to turn ON

and OFF the power supply of the control unit.

COMMAND INPUT SWITCHES (SET and RESUME)

The SET and RESUME switches function to input the control

signals of the auto-cruise control system; both are the

automatic-reset type.

These switches are ON while pressed and OFF when released.

For the ECU’s input interface, each of the input terminals is

pulled up by the battery voltage; the terminal voltage is LOW

level

(OV) when the switch is ON, and is HIGH level (about 12V)when the switch is OFF. These voltage changes (digital

sig*)are input to the microcomputer as ON and OFF signals

o.:

switches.

.

Page 265 of 391

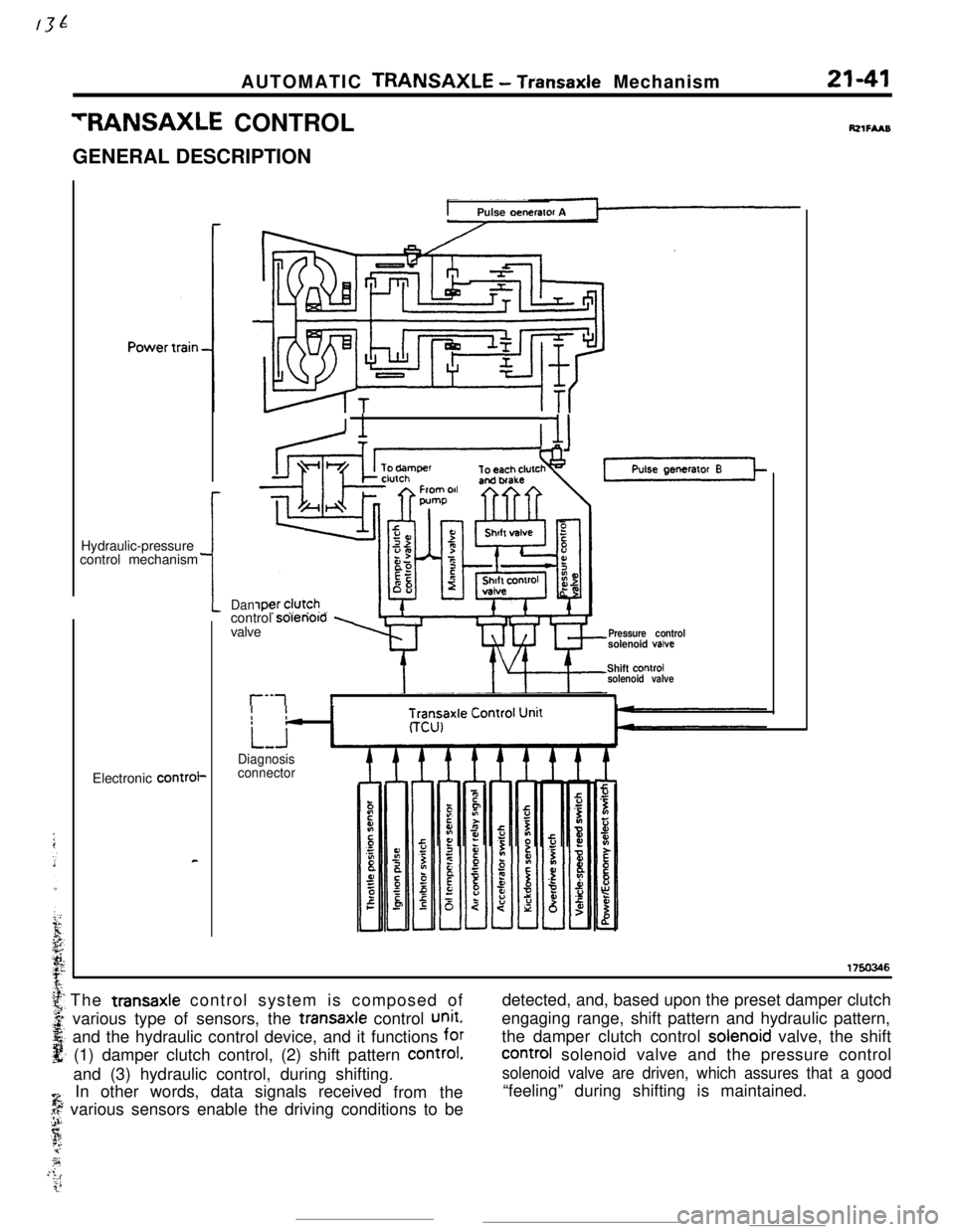

AUTOMATIC TRANSAXLE - Transaxle Mechanism21-41

YWNSAXLE CONTROL

GENERAL DESCRIPTION

Hydraulic-pressure

control mechanism

Electronic

control-

r

1Pulse oenerator A

DanI

iI11. . . .

control solenola

valve

Pressure controlsolenoid valve

Shift cOntrOisolenoid valve

r-7i1

Diagnosis

connector

Ft2iFu~The transaxle control system is composed of

various type of sensors, the transaxle control

unit.and the hydraulic control device, and it functions for

(1) damper clutch control, (2) shift pattern

Control.and (3) hydraulic control, during shifting.

%, In other words, data signals received

fromthe

.$ various sensors enable the driving conditions to beJ-

sj.q’74:i.&f’detected, and, based upon the preset damper clutch

engaging range, shift pattern and hydraulic pattern,

the damper clutch control solenoid valve, the shift

Control solenoid valve and the pressure control

solenoid valve are driven, which assures that a good“feeling” during shifting is maintained.