air filter MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 121 of 391

FUEL SYSTEM -Fuel Supply and Fuel Pressure Control14-9

03Poo4:Diaphragm

from intake

4Fuel from delivery pipe

4m

B(42.7)QQ

2

sl -196 2

(26.4) g

t

$!a d

9

0)Positive5 z‘. pressure

(E.2)

w

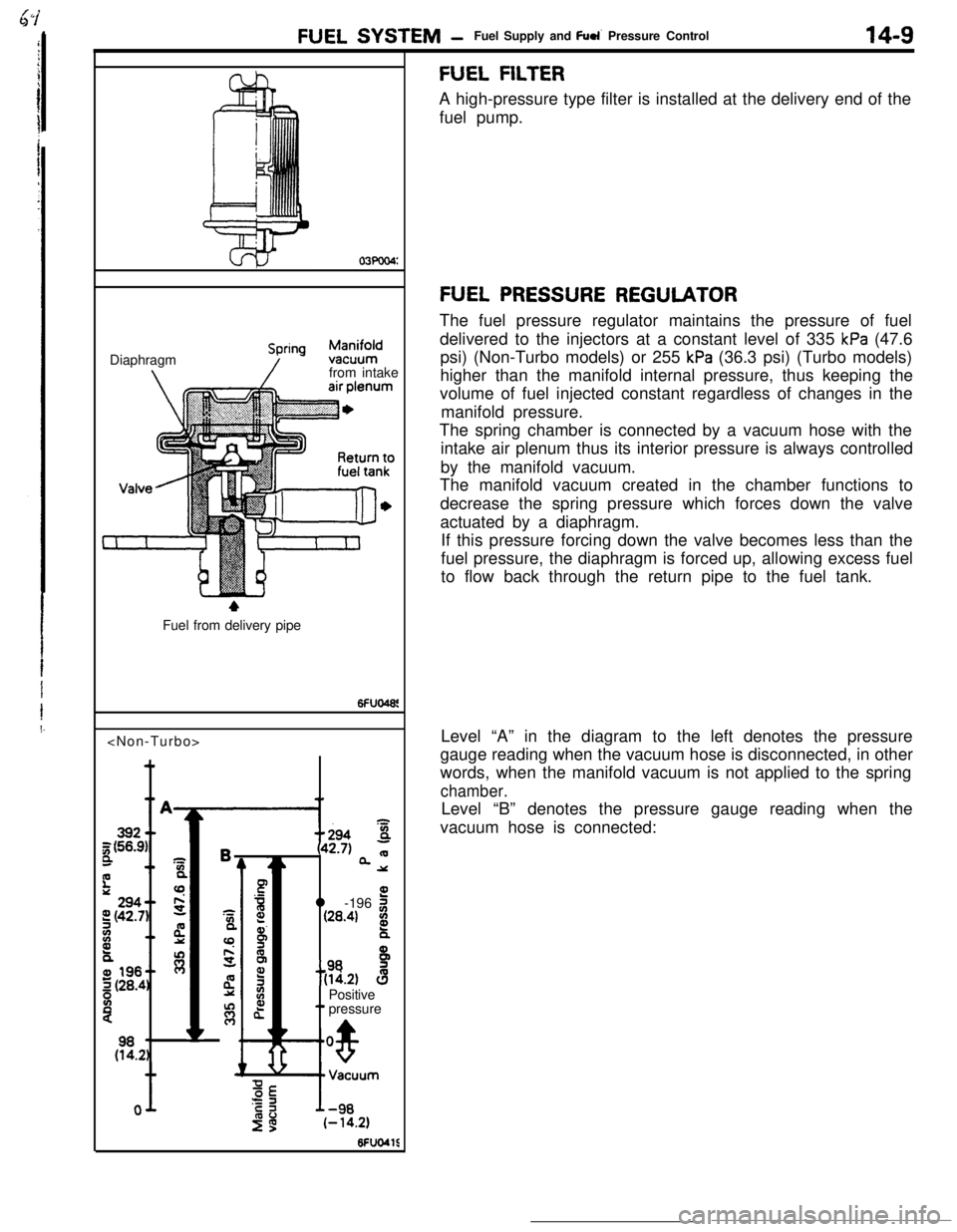

FUEL FILTERA high-pressure type filter is installed at the delivery end of the

fuel pump.

FUEL PRESSURE REGULATORThe fuel pressure regulator maintains the pressure of fuel

delivered to the injectors at a constant level of 335

kPa (47.6

psi) (Non-Turbo models) or 255

kPa (36.3 psi) (Turbo models)

higher than the manifold internal pressure, thus keeping the

volume of fuel injected constant regardless of changes in the

manifold pressure.

The spring chamber is connected by a vacuum hose with the

intake air plenum thus its interior pressure is always controlled

by the manifold vacuum.

The manifold vacuum created in the chamber functions to

decrease the spring pressure which forces down the valve

actuated by a diaphragm.

If this pressure forcing down the valve becomes less than the

fuel pressure, the diaphragm is forced up, allowing excess fuel

to flow back through the return pipe to the fuel tank.

Level “A” in the diagram to the left denotes the pressure

gauge reading when the vacuum hose is disconnected, in other

words, when the manifold vacuum is not applied to the spring

chamber.Level “B” denotes the pressure gauge reading when the

vacuum hose is connected:

Page 141 of 391

FUEL SYSTEM- Engine Control Unit14-29

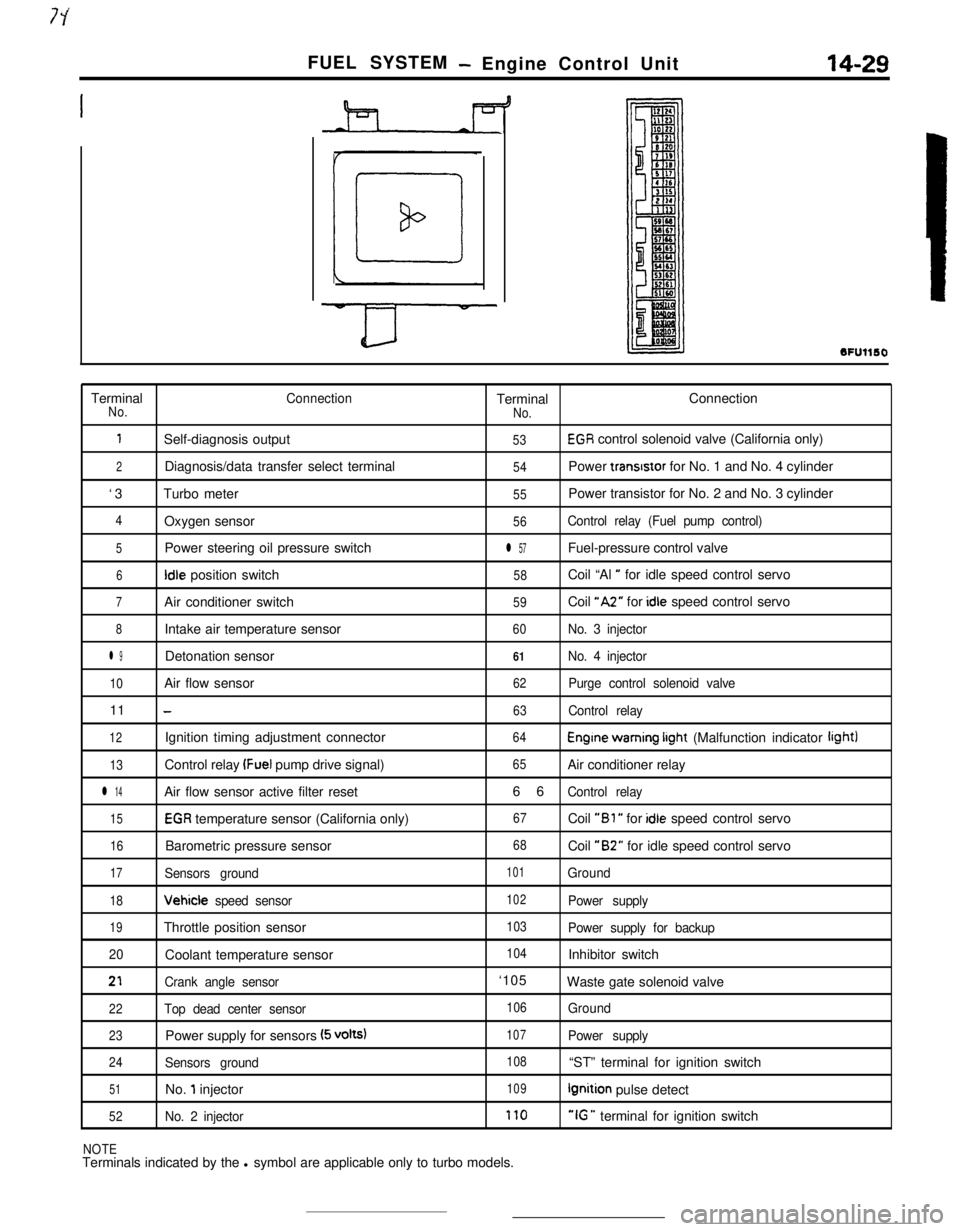

SFUllSOTerminal

ConnectionTerminalConnectionNo.

No.

1Self-diagnosis output53EGR control solenoid valve (California only)

2Diagnosis/data transfer select terminal54Power transrstor for No. 1 and No. 4 cylinder

‘3Turbo meter

55Power transistor for No. 2 and No. 3 cylinder

4Oxygen sensor56Control relay (Fuel pump control)

5Power steering oil pressure switchl 57Fuel-pressure control valve

6Idle position switch58Coil “Al ” for idle speed control servo

7Air conditioner switch59Coil “A2” for idle speed control servo

8Intake air temperature sensor60No. 3 injector

l 9Detonation sensor61No. 4 injector

10Air flow sensor62Purge control solenoid valve11

-63Control relay

12Ignition timing adjustment connector64Engine warning irght (Malfunction indicator light)

13Control relay (Fuel pump drive signal)65Air conditioner relay

l 14Air flow sensor active filter reset66Control relay

15EGR temperature sensor (California only)67Coil “Bl ” for idle speed control servo

16Barometric pressure sensor68Coil “B2” for idle speed control servo

17Sensors ground101Ground

18Vehicle speed sensor102Power supply

19Throttle position sensor103Power supply for backup

20Coolant temperature sensor

104Inhibitor switch

21Crank angle sensor‘105

Waste gate solenoid valve

22Top dead center sensor106Ground

23Power supply for sensors (5 volts)107Power supply

24Sensors ground108“ST” terminal for ignition switch

51No. 1 injector109Ignition pulse detect

52No. 2 injector170“IG ” terminal for ignition switch

NOTETerminals indicated by the l symbol are applicable only to turbo models.

Page 146 of 391

-

14-34FUEL SYSTEM - Fuel Injection Control

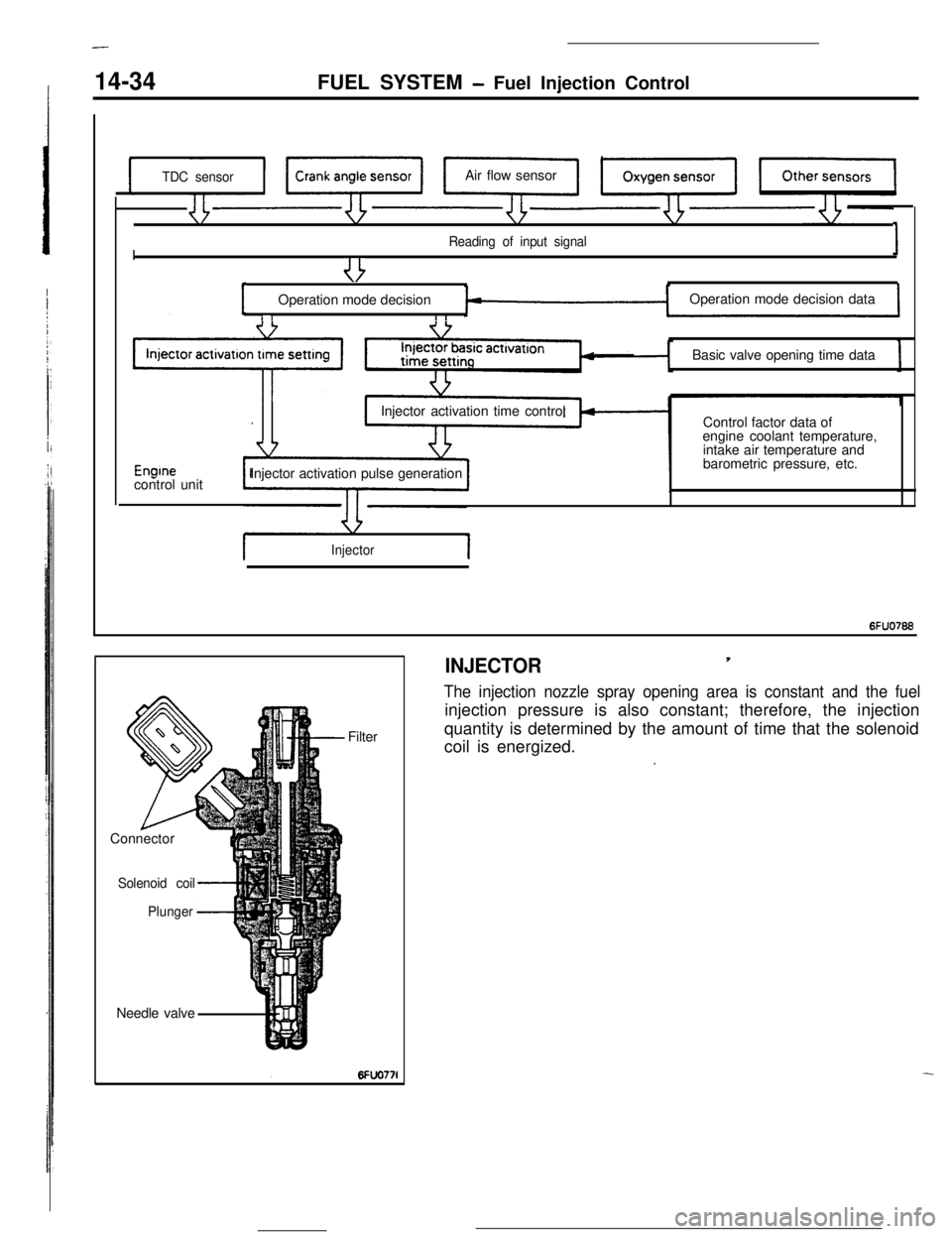

TDC sensorAir flow sensor

I

Reading of input signal1

I ,,

uOperation mode decisionOperation mode decision data

I rBasic valve opening time data

Enginecontrol unitInjector activation time control

Injector activation pulse generationControl factor data of

engine coolant temperature,

intake air temperature and

barometric pressure, etc.

Injector1

6FUO766Needle valveFilter

Connector

Solenoid coil

Plunger

-4

INJECTOR,

The injection nozzle spray opening area is constant and the fuelinjection pressure is also constant; therefore, the injection

quantity is determined by the amount of time that the solenoid

coil is energized.

.

Page 169 of 391

FUEL SYSTEMAir Flow Sensor (AFSI Filter Reset Control

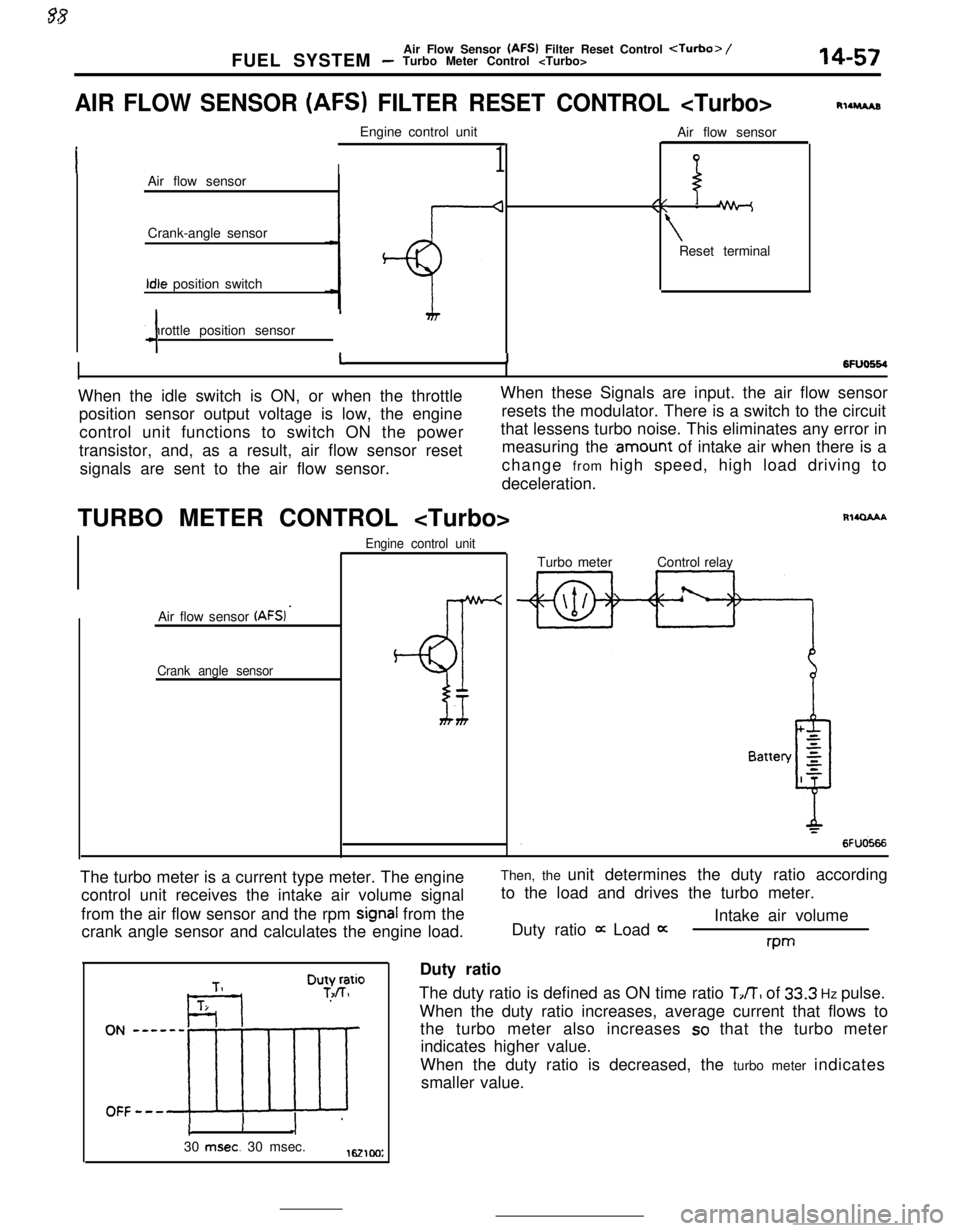

AIR FLOW SENSOR (AFS) FILTER RESET CONTROL

I1Air flow sensor

Crank-angle sensorIdle position switch

Throttle position sensor

4Air flow sensor

//\\ -

\Reset terminal

RllruAs

6FlJo664I11When the idle switch is ON, or when the throttleWhen these Signals are input. the air flow sensor

position sensor output voltage is low, the engineresets the modulator. There is a switch to the circuit

control unit functions to switch ON the powerthat lessens turbo noise. This eliminates any error in

transistor, and, as a result, air flow sensor resetmeasuring the

.amount of intake air when there is a

signals are sent to the air flow sensor.change from high speed, high load driving to

deceleration.

TURBO METER CONTROL

Air flow sensor

(AFSI ’

Crank angle sensorEngine control unit

BT

Rl4QAAATurbo meterControl relay

The turbo meter is a current type meter. The engine

control unit receives the intake air volume signal

from the air flow sensor and the rpm

signal from the

crank angle sensor and calculates the engine load.Then, the unit determines the duty ratio according

to the load and drives the turbo meter.

Intake air volume

Duty ratio

it Load 0:rwDuty ratio

The duty ratio is defined as ON time ratio

TJT, of 33.3 Hz pulse.

When the duty ratio increases, average current that flows to

the turbo meter also increases

so that the turbo meter

indicates higher value.

When the duty ratio is decreased, the turbo meter indicates

smaller value.

cI30

msec. 30 msec.1621cm:

Page 385 of 391

__..--. -._ _^__. __--- -._ _..EMISSION CONTROL SYSTEMS

- Evaporative Emission Control Svsvem25-l 1

,VAPORATlVE EMISSION CON-

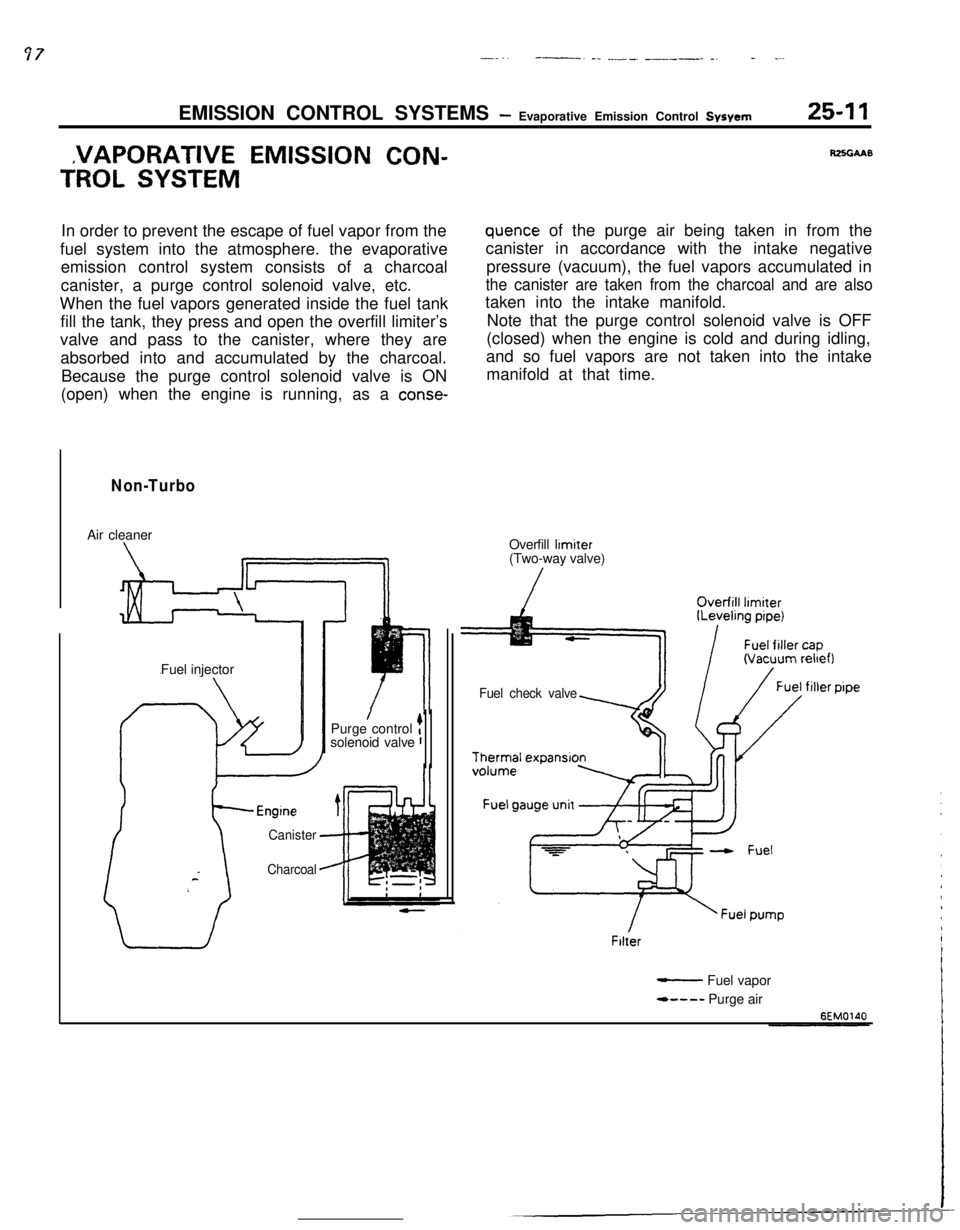

TROL SYSTEMIn order to prevent the escape of fuel vapor from the

fuel system into the atmosphere. the evaporative

emission control system consists of a charcoal

canister, a purge control solenoid valve, etc.

When the fuel vapors generated inside the fuel tank

fill the tank, they press and open the overfill limiter’s

valve and pass to the canister, where they are

absorbed into and accumulated by the charcoal.

Because the purge control solenoid valve is ON

(open) when the engine is running, as a

conse-

Non-TurboAir cleaner

Fuel injector

Canister

Charcoal

/Purge control tsolenoid valve r

RZSGAAB

quence of the purge air being taken in from the

canister in accordance with the intake negative

pressure (vacuum), the fuel vapors accumulated in

the canister are taken from the charcoal and are alsotaken into the intake manifold.

Note that the purge control solenoid valve is OFF

(closed) when the engine is cold and during idling,

and so fuel vapors are not taken into the intake

manifold at that time.

Overfill

limiter(Two-way valve)

Fuel check valveFilter

- Fuel vapor

*---- Purge air

Page 386 of 391

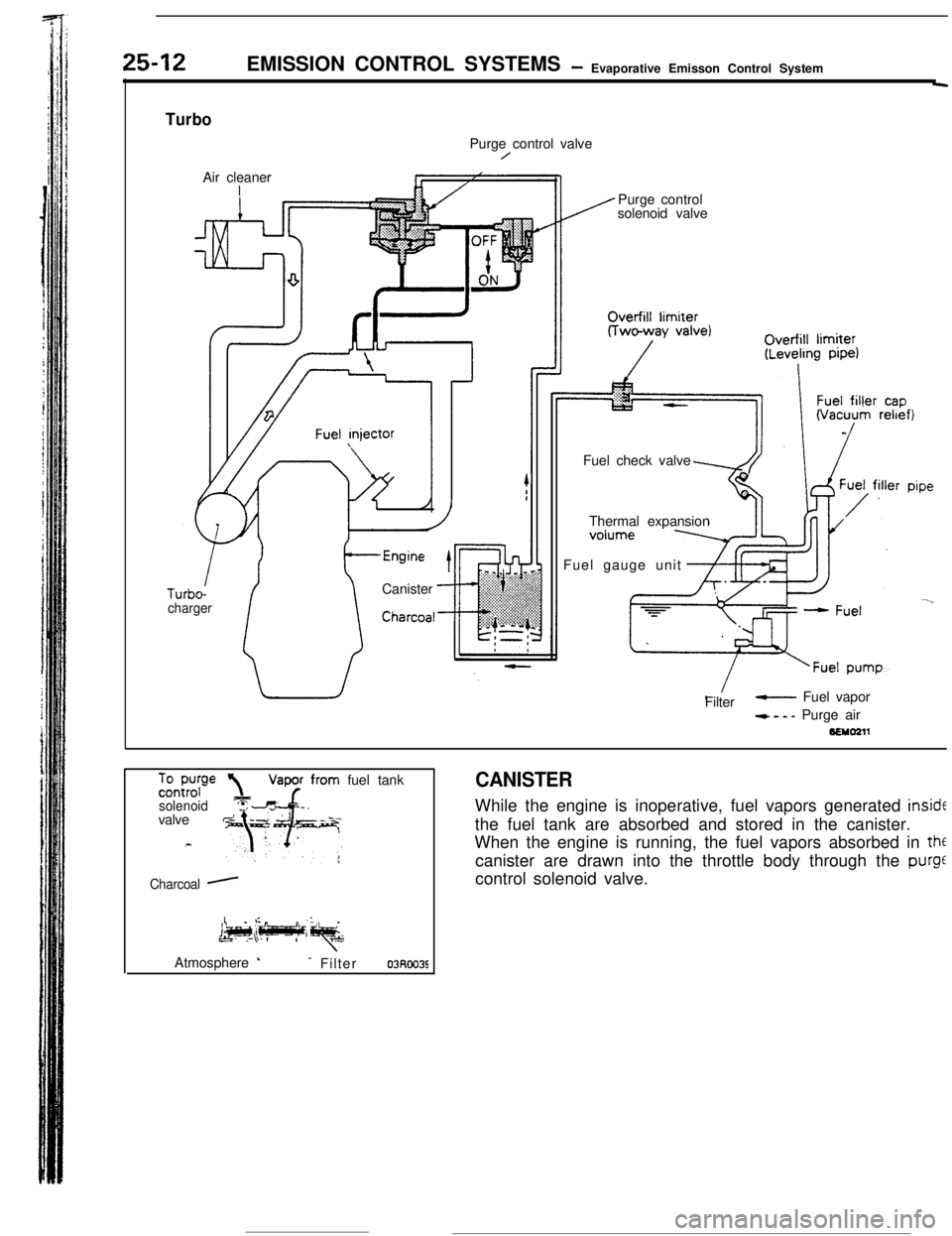

25-12EMISSION CONTROL SYSTEMS- Evaporative Emisson Control System-

TurboPurge control valve

/Air cleaner

Canister

-Charcoal-ITurbo-

chargerPurge control

solenoid valve

Fuel check valve

Thermal expansion

Fuel gauge unit

Filter

- Fuel vapor

- - - - Purge air

BEMO211

%-E?”solenoidvalve

Charcoal -fuel tank

CANISTERWhile the engine is inoperative, fuel vapors generated

insidEthe fuel tank are absorbed and stored in the canister.

When the engine is running, the fuel vapors absorbed in

thfcanister are drawn into the throttle body through the

purgecontrol solenoid valve.

Atmosphere

L- Filter03Roo3E