light MITSUBISHI ECLIPSE 1990 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 85 of 391

ELECTRICAL - Theft-alarm System8-33ARMING THE SYSTEM

After the following procedures have been completed, the SECURITY light illuminates for about 20 seconds,

and when illumination stops, the system is armed.

(1) Pull out the ignition key from the key cylinder.

(2) Open a door. (The other door is closed.)

(3) Lock the door with the key or the

keyless-locking method.

(The central door locking system will then function to lock all doors.)

NOTE(1) The system is set regardless of whether the hood and liftgate are open or

closed, and is armed as

soon as the light goes out.

(2) Even after the system has been armed, if the key is used to open the liftgate, the system will not be

activated; when the liftgate is then

closed, moreover, the system will be armed.

DISARMING THE SYSTEM

(1) The system will be disarmed if the key is used to unlock a door.

(2) If the system is armed while the driver is still in the vehicle, the system can be disarmed by inserting the

ignition key and turning it to the ACC or ON position.

(3) If the door lock is unlocked while closing the door or the door is ajar.

(4) If the door is unfastened while the SECURITY light illuminates.

ACTIVATING THE ALARM

(1) if an attempt is made to open a door, the liftgate or the hood, without using the key, while the system is

armed, the horn will sound intermittently and the headlights will flash on and off for approximately

three,

minutes.Furthermore, the starter circuit is interrupted at this time also, making starting of the engine impossible.

(2) if a further attempt at *forcible entry is made after the first three-minute alarm has finished, the

three-minute alarm will be activated again.

DEACTIVATING THE ALARM

(1) To deactivate the alarm, insert the key into the door’s key cylinder and turn the key.

(2) The alarm is deactivated and the system is disarmed when the iiftgate is unlocked with the key.

CHECKING THE SYSTEM OPERATION

The activation/operation of the system can be checked by following the steps below.

(1) Turn the ignition key to the ON position and then use the power-window switch to fully open the window

at the driver’s seat side.

(2) Turn the ignition key to the LOCK position and then remove the key from the ignition.

(3) Open only the driver’s door, and close all the other doors, as well as the hood and the rear hatch.

(4) Lock the driver’s door by the key or the

keyless-locking method.

(5) All doors will then be

locked, and the SECURITY light (within the combination meter) will illuminate; check

to be sure that illumination stops in about 20 seconds.

(6) After about two seconds have passed after the SECURITY light illumination stopped, reach through the

window of the driver’s door, pull up the lock lever to unlock the door, and then open the door.

(7) Check to be sure that, when the door is opened, the horn starts sounding and the headlights flash on and

Off.

(8) To stop the alarm, insert the key into the door’s key cylinder and turn the key.

!?iEeck the alarm for the opening of the liftgate or hood open the liftgate (or the hood) by using the

remote liftgate release lever (or the hood release lever),

located at the driver’s seat side either before the

alarm is activated by the opening of a door, or after the finish of the first three-minute alarm.

Page 119 of 391

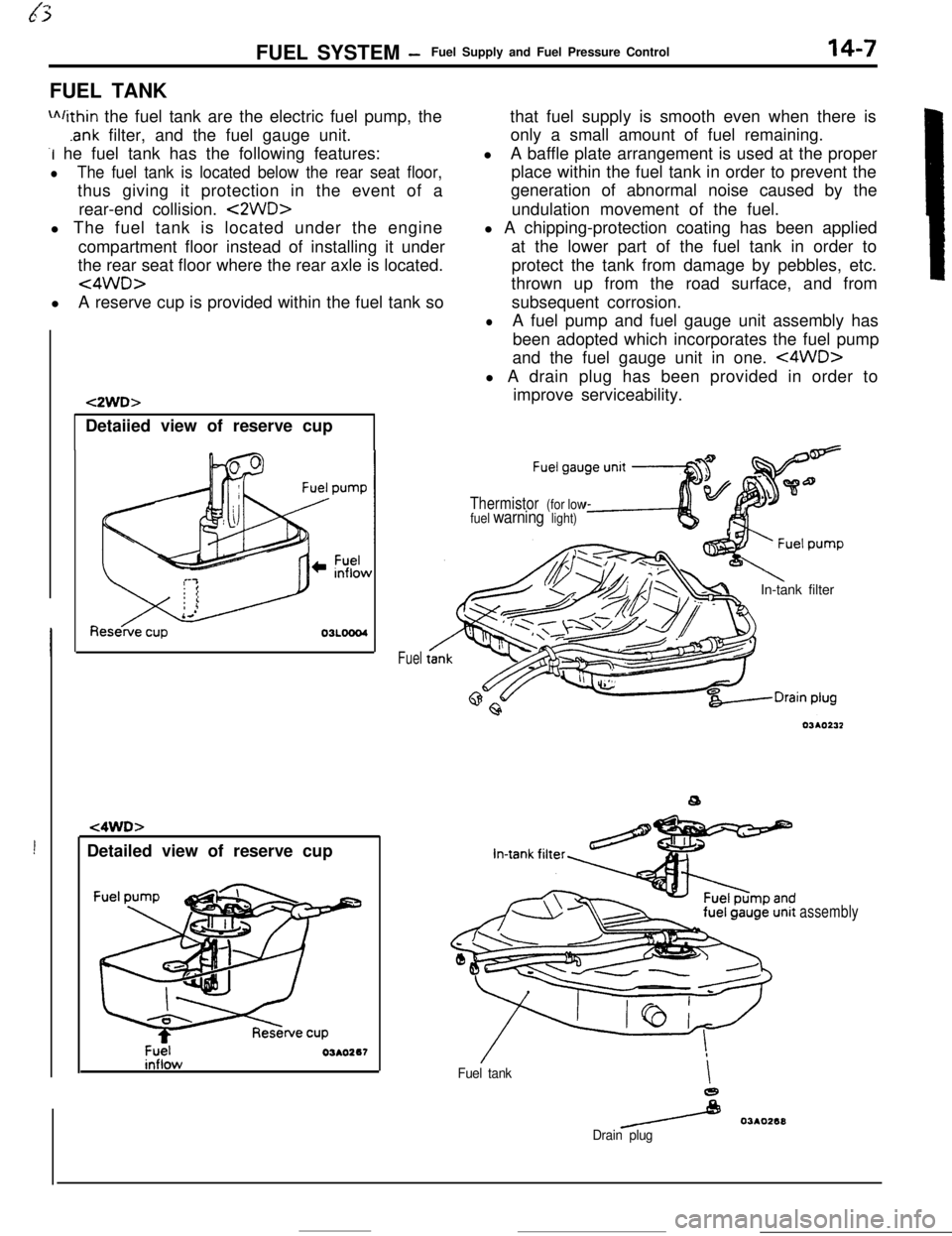

FUEL SYSTEM -Fuel Supply and Fuel Pressure Control14-7FUEL TANK

m/ithin the fuel tank are the electric fuel pump, the

.ank filter, and the fuel gauge unit.

-I he fuel tank has the following features:

lThe fuel tank is located below the rear seat floor,thus giving it protection in the event of a

rear-end collision.

<2WD>l The fuel tank is located under the engine

compartment floor instead of installing it under

the rear seat floor where the rear axle is located.

<4WD>lA reserve cup is provided within the fuel tank so

!Detailed view of reserve cup

t2WD>Detaiied view of reserve cup

t4WD>

Fuel03AO267

Fuelthat fuel supply is smooth even when there is

only a small amount of fuel remaining.

lA baffle plate arrangement is used at the proper

place within the fuel tank in order to prevent the

generation of abnormal noise caused by the

undulation movement of the fuel.

l A chipping-protection coating has been applied

at the lower part of the fuel tank in order to

protect the tank from damage by pebbles, etc.

thrown up from the road surface, and from

subsequent corrosion.

lA fuel pump and fuel gauge unit assembly has

been adopted which incorporates the fuel pump

and the fuel gauge unit in one.

<4WD>l A drain plug has been provided in order to

improve serviceability.

Thermistor (for low

fuel warning light)In-tank filter

Fuel tankI

e

/ 03AO268

Drain plug

assembly

Page 132 of 391

FUEL SYSTEM - Sensors

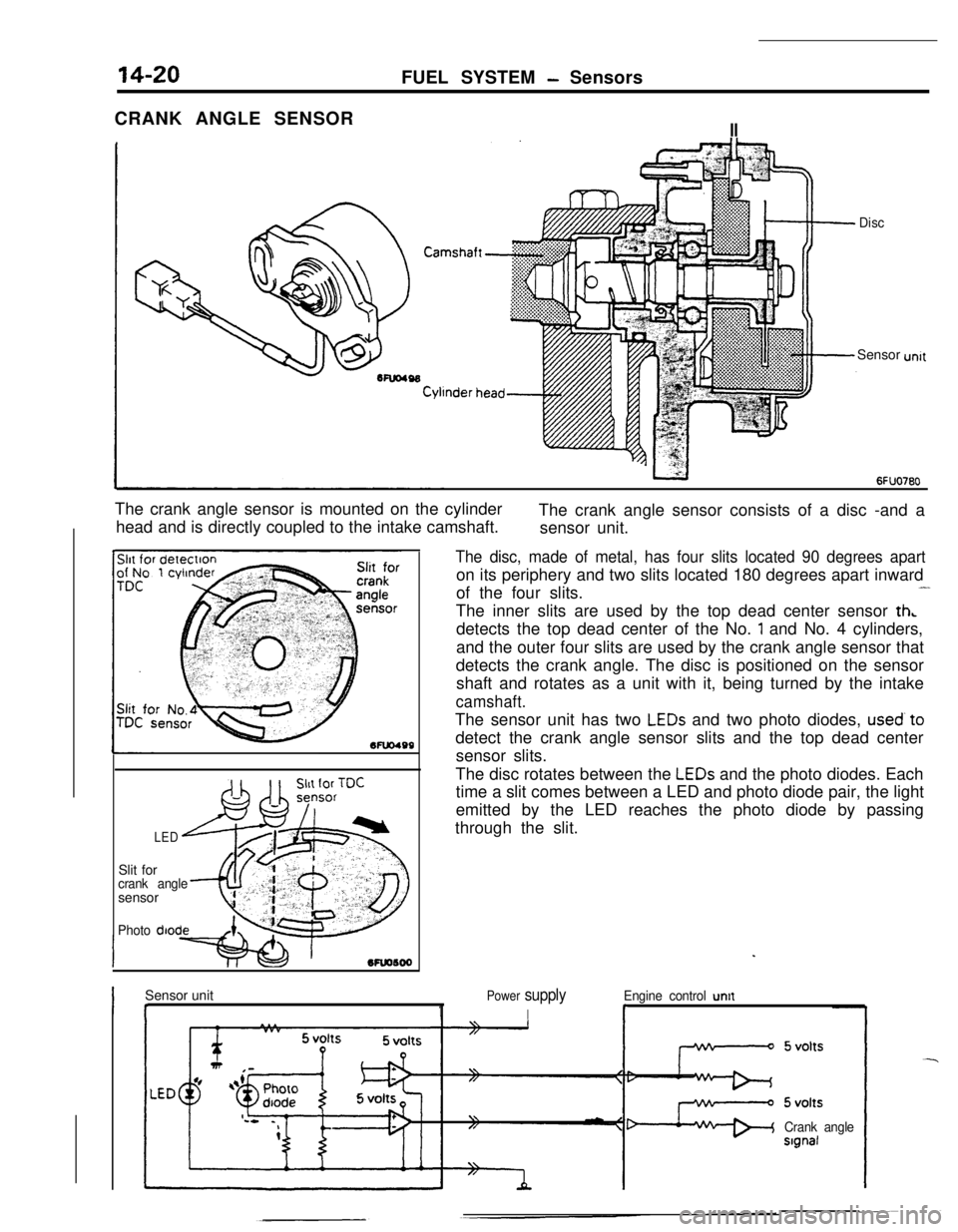

CRANK ANGLE SENSOR

II

DiscSensor

The crank angle sensor is mounted on the cylinder

head and is directly coupled to the intake camshaft.The crank angle sensor consists of a disc -and a

sensor unit.

Mu0499Slit for

crank anglesensor

Photo diode

LED

The disc, made of metal, has four slits located 90 degrees aparton its periphery and two slits located 180 degrees apart inward

of the four slits.

-The inner slits are used by the top dead center sensor

th,detects the top dead center of the No.

1 and No. 4 cylinders,

and the outer four slits are used by the crank angle sensor that

detects the crank angle. The disc is positioned on the sensor

shaft and rotates as a unit with it, being turned by the intake

camshaft.The sensor unit has two

LEDs and two photo diodes, used’to

detect the crank angle sensor slits and the top dead center

sensor slits.

The disc rotates between the

LEDs and the photo diodes. Each

time a slit comes between a LED and photo diode pair, the light

emitted by the LED reaches the photo diode by passing

through the slit.

Sensor unit

I I1

Power supply

I

Engine control untt

r

Crank angleslgnal

Page 133 of 391

FUEL SYSTEM - Sensors14-21When exposed to light, the photo diode conducts

urrent in a direction opposite to an ordinary diode.

.s a result, current flows in the direction indicated

by the arrow and dotted line and a voltage (5 volts) isapplied to the comparator of the sensor unit so that

the terminal voltage of the engine control unit

becomes 5 volts. When the disc rotates further andthe slit moves beyond the space between the

LED/photo diode pair, the light can no longer reach

the photo diode, thus the current indicated by the

dotted line ceases to flow and the terminal voltage

of the engine control unit becomes 0 volt.

tn this

way, pulse signals are sent to the engine control

unit from the sensor unit.

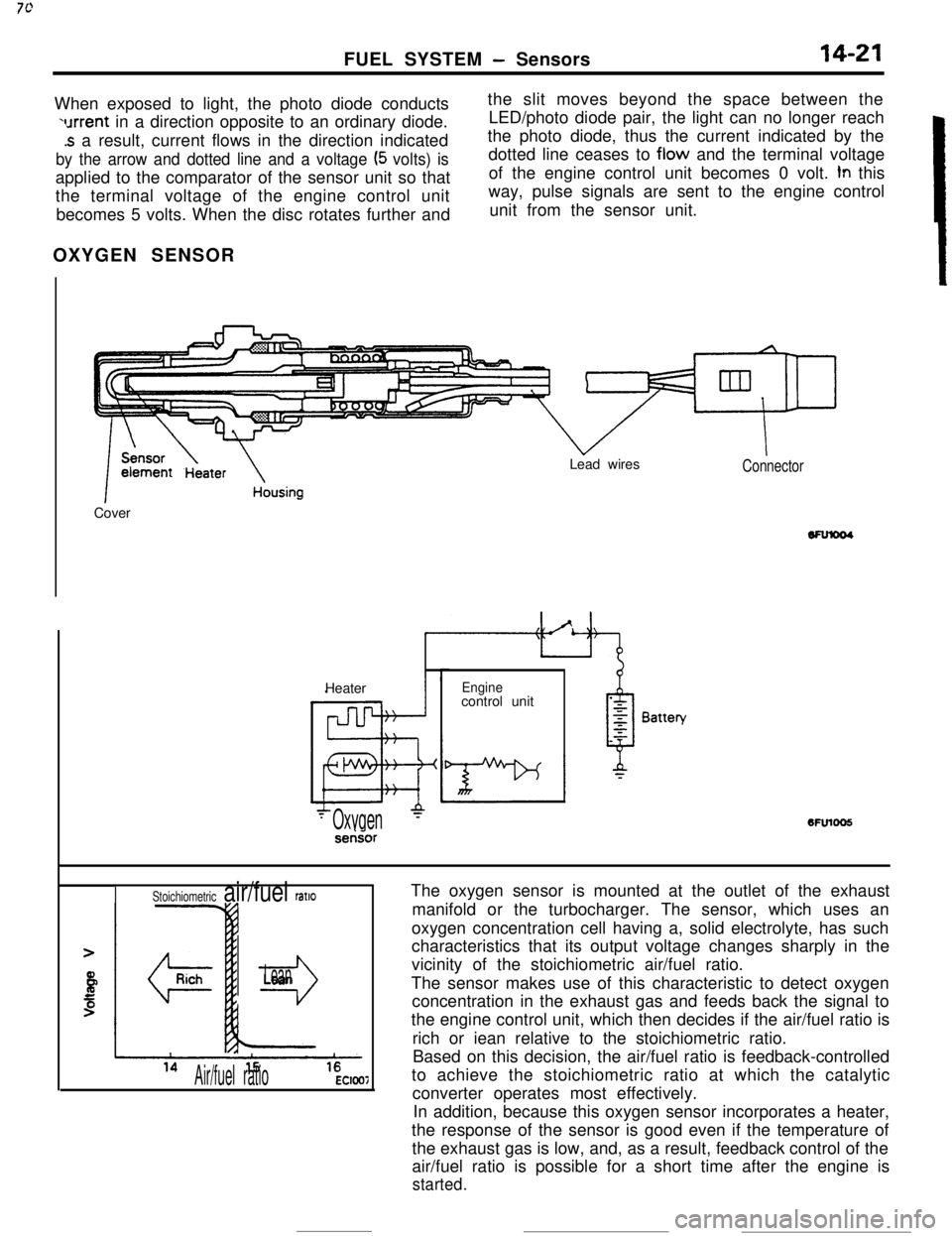

OXYGEN SENSOR

k

1 ~~~~t13ate~ousingCoverLead wiresConnectorHeater

Enginecontrol unit6FUlOO5

- Oxygen‘-serisor

The oxygen sensor is mounted at the outlet of the exhaust

manifold or the turbocharger. The sensor, which uses an

oxygen concentration cell having a, solid electrolyte, has such

characteristics that its output voltage changes sharply in the

vicinity of the stoichiometric air/fuel ratio.

The sensor makes use of this characteristic to detect oxygen

concentration in the exhaust gas and feeds back the signal to

the engine control unit, which then decides if the air/fuel ratio is

rich or iean relative to the stoichiometric ratio.

Based on this decision, the air/fuel ratio is feedback-controlled

to achieve the stoichiometric ratio at which the catalytic

converter operates most effectively.

In addition, because this oxygen sensor incorporates a heater,

the response of the sensor is good even if the temperature of

the exhaust gas is low, and, as a result, feedback control of the

air/fuel ratio is possible for a short time after the engine is

started.

Stoichiometric air/fuel ratlo

r3

Lean

Air/fuel ratioEC1007

Page 140 of 391

---_-

14-28FUEL SYSTEM- Ennine Control Unit

The engine control unit has an

onboard diagnosis

function, which is used mainly to diagnose the

sensors, thus facilitating system checks and troub-leshooting. It also has a fail-safe/backup function tc

ensure passenger and vehicle safety.

Onboard self-

diagnosisMainly for detecting failure of sensors

and foroutputting diagnosis code.

for detecting failure of sensors, etc. related

toemission control and to turn ON warning light

(Malfunction indicator light).

> Codes can be read by voltmeter.

ENGINE CHECK light is turned

2 ON.

The engine control unit is mounted in the passenger compart-

ment, at the location indicated in the illustration.,

Page 141 of 391

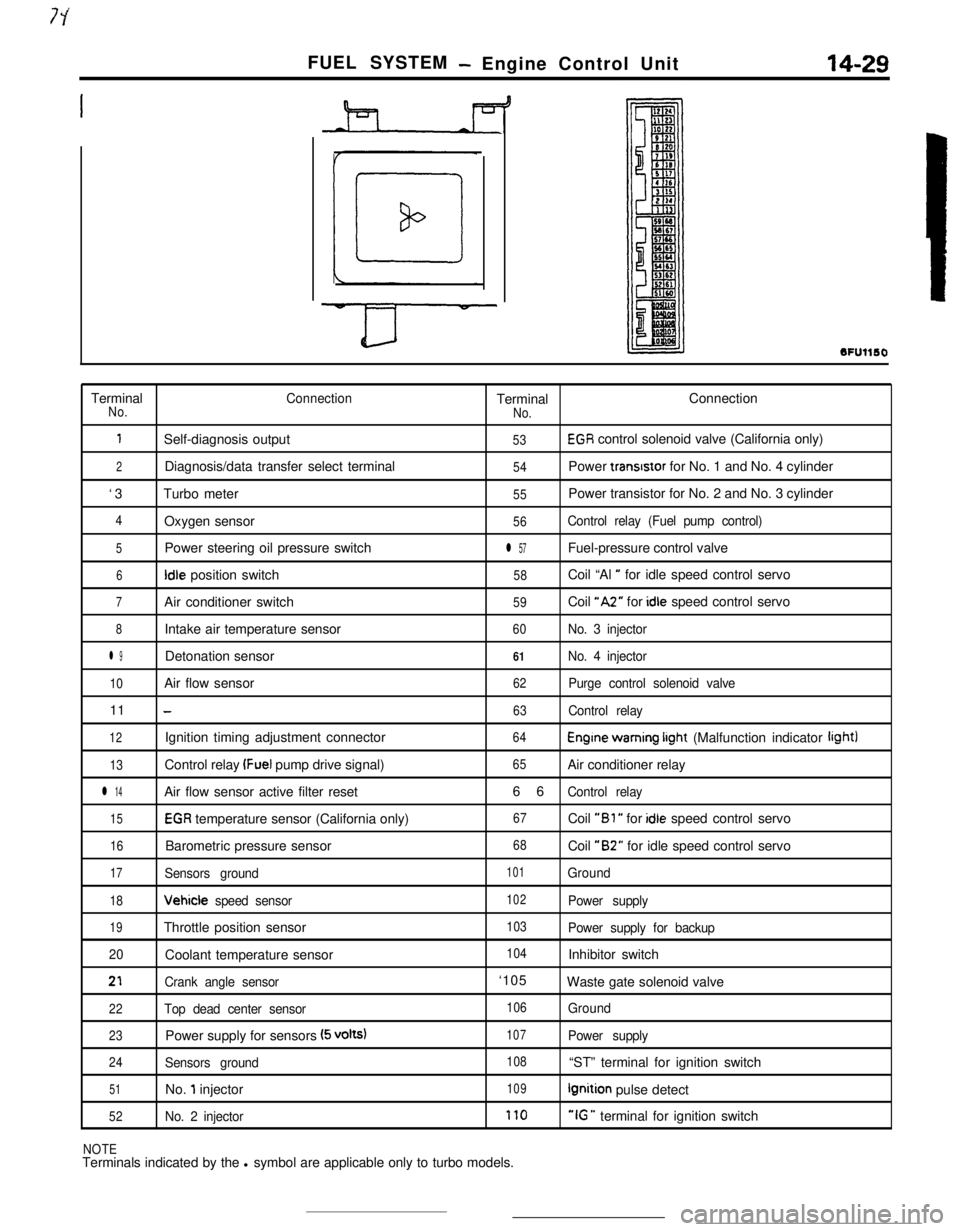

FUEL SYSTEM- Engine Control Unit14-29

SFUllSOTerminal

ConnectionTerminalConnectionNo.

No.

1Self-diagnosis output53EGR control solenoid valve (California only)

2Diagnosis/data transfer select terminal54Power transrstor for No. 1 and No. 4 cylinder

‘3Turbo meter

55Power transistor for No. 2 and No. 3 cylinder

4Oxygen sensor56Control relay (Fuel pump control)

5Power steering oil pressure switchl 57Fuel-pressure control valve

6Idle position switch58Coil “Al ” for idle speed control servo

7Air conditioner switch59Coil “A2” for idle speed control servo

8Intake air temperature sensor60No. 3 injector

l 9Detonation sensor61No. 4 injector

10Air flow sensor62Purge control solenoid valve11

-63Control relay

12Ignition timing adjustment connector64Engine warning irght (Malfunction indicator light)

13Control relay (Fuel pump drive signal)65Air conditioner relay

l 14Air flow sensor active filter reset66Control relay

15EGR temperature sensor (California only)67Coil “Bl ” for idle speed control servo

16Barometric pressure sensor68Coil “B2” for idle speed control servo

17Sensors ground101Ground

18Vehicle speed sensor102Power supply

19Throttle position sensor103Power supply for backup

20Coolant temperature sensor

104Inhibitor switch

21Crank angle sensor‘105

Waste gate solenoid valve

22Top dead center sensor106Ground

23Power supply for sensors (5 volts)107Power supply

24Sensors ground108“ST” terminal for ignition switch

51No. 1 injector109Ignition pulse detect

52No. 2 injector170“IG ” terminal for ignition switch

NOTETerminals indicated by the l symbol are applicable only to turbo models.

Page 142 of 391

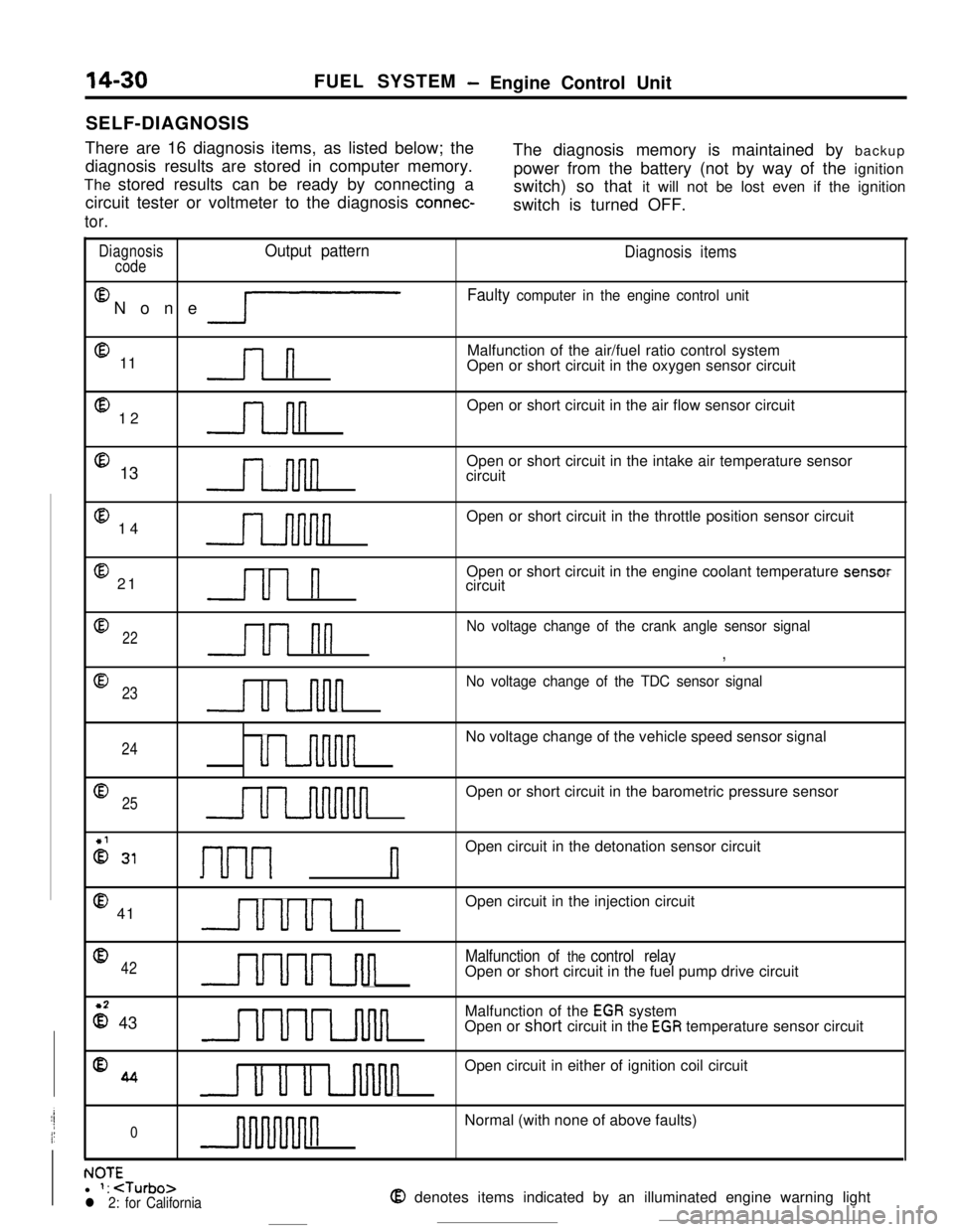

14-30SELF-DIAGNOSISFUEL SYSTEM- Engine Control Unit

There are 16 diagnosis items, as listed below; the

diagnosis results are stored in computer memory.The diagnosis memory is maintained by backup

The stored results can be ready by connecting apower from the battery (not by way of the ignition

circuit tester or voltmeter to the diagnosis

connec-switch) so that it will not be lost even if the ignition

switch is turned OFF.

tor.

DiagnosisOutput pattern

codeEl

None

lP

@ 11l-l

@ 12n@ 13

@ 14

@ 21Ul n

Diagnosis items

Faulty computer in the engine control unitMalfunction of the air/fuel ratio control system

Open or short circuit in the oxygen sensor circuit

Open or short circuit in the air flow sensor circuit

Open or short circuit in the intake air temperature sensor

circuit

Open or short circuit in the throttle position sensor circuit

Open or short circuit in the engine coolant temperature sensor

circuit

022u1 nn

No voltage change of the crank angle sensor signal

,

@

23

u u-inn

No voltage change of the TDC sensor signal

24uu-uvinnnnNo voltage change of the vehicle speed sensor signal

Q25uuuuuunnnnnOpen or short circuit in the barometric pressure sensor

2 31I-~-~---~ nOpen circuit in the detonation sensor circuit

@ 41uuul nOpen circuit in the injection circuit

042UUuLJul

Malfunction of the control relayOpen or short circuit in the fuel pump drive circuit

z 43UUULnlulMalfunction of the

EGR system

Open or short circuit in the EGR temperature sensor circuit

%4u u u uvinnOpen circuit in either of ignition coil circuit

0nNormal (with none of above faults)

. IA-r-NUltl 1:

Page 143 of 391

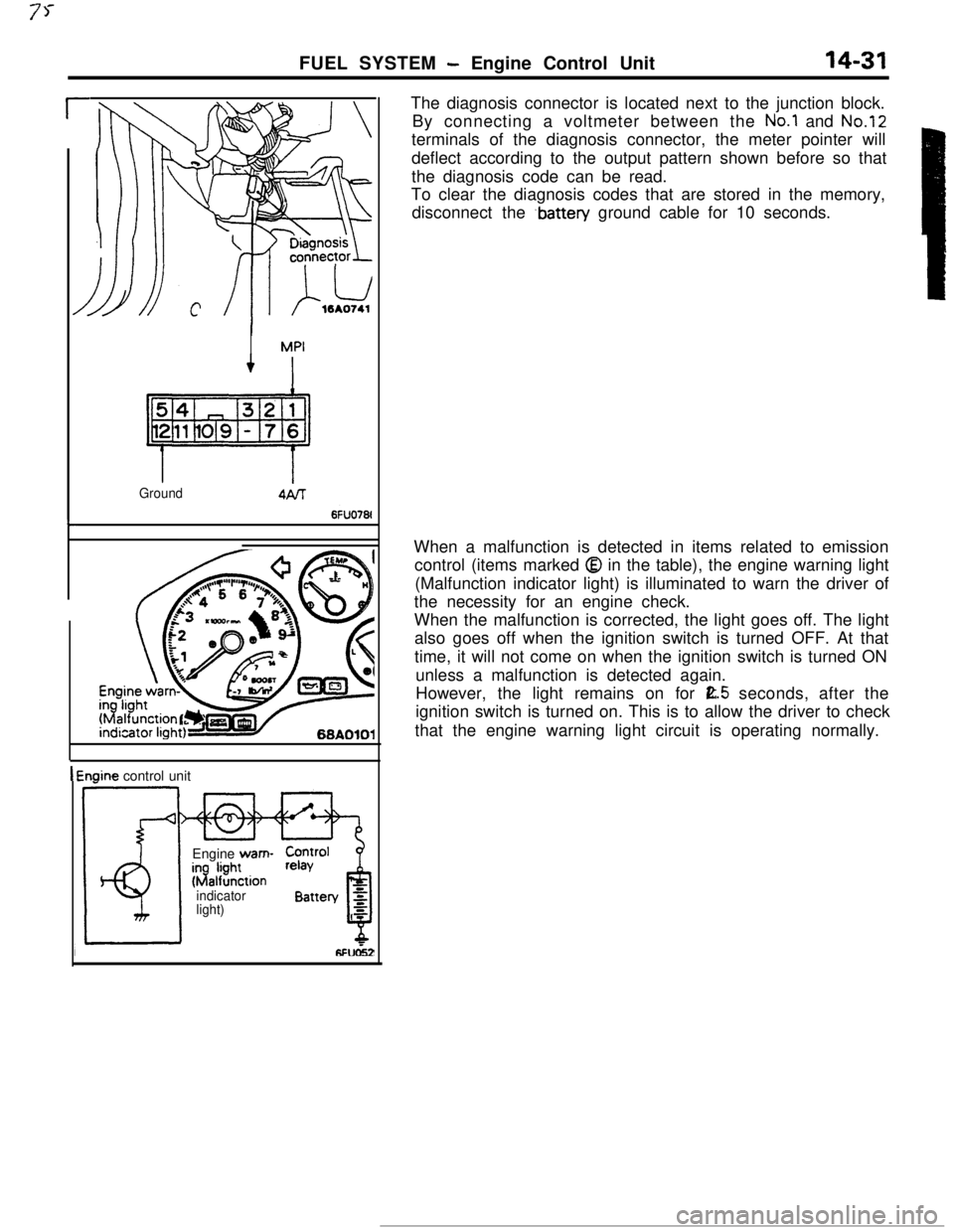

FUEL SYSTEM - Engine Control Unit14-31

r

L

IMPI

Ground

1 Engine control unit

Engine wam-

$b?Stionindicator

light)The diagnosis connector is located next to the junction block.

By connecting a voltmeter between the

No.1 and No.12terminals of the diagnosis connector, the meter pointer will

deflect according to the output pattern shown before so that

the diagnosis code can be read.

To clear the diagnosis codes that are stored in the memory,

disconnect the

.battery ground cable for 10 seconds.

When a malfunction is detected in items related to emission

control (items marked

Q in the table), the engine warning light

(Malfunction indicator light) is illuminated to warn the driver of

the necessity for an engine check.

When the malfunction is corrected, the light goes off. The light

also goes off when the ignition switch is turned OFF. At that

time, it will not come on when the ignition switch is turned ON

unless a malfunction is detected again.

However, the light remains on for

E.5 seconds, after the

ignition switch is turned on. This is to allow the driver to check

that the engine warning light circuit is operating normally.

Page 144 of 391

__.-~-..- -

FUEL SYSTEM- Ermine Control Unit

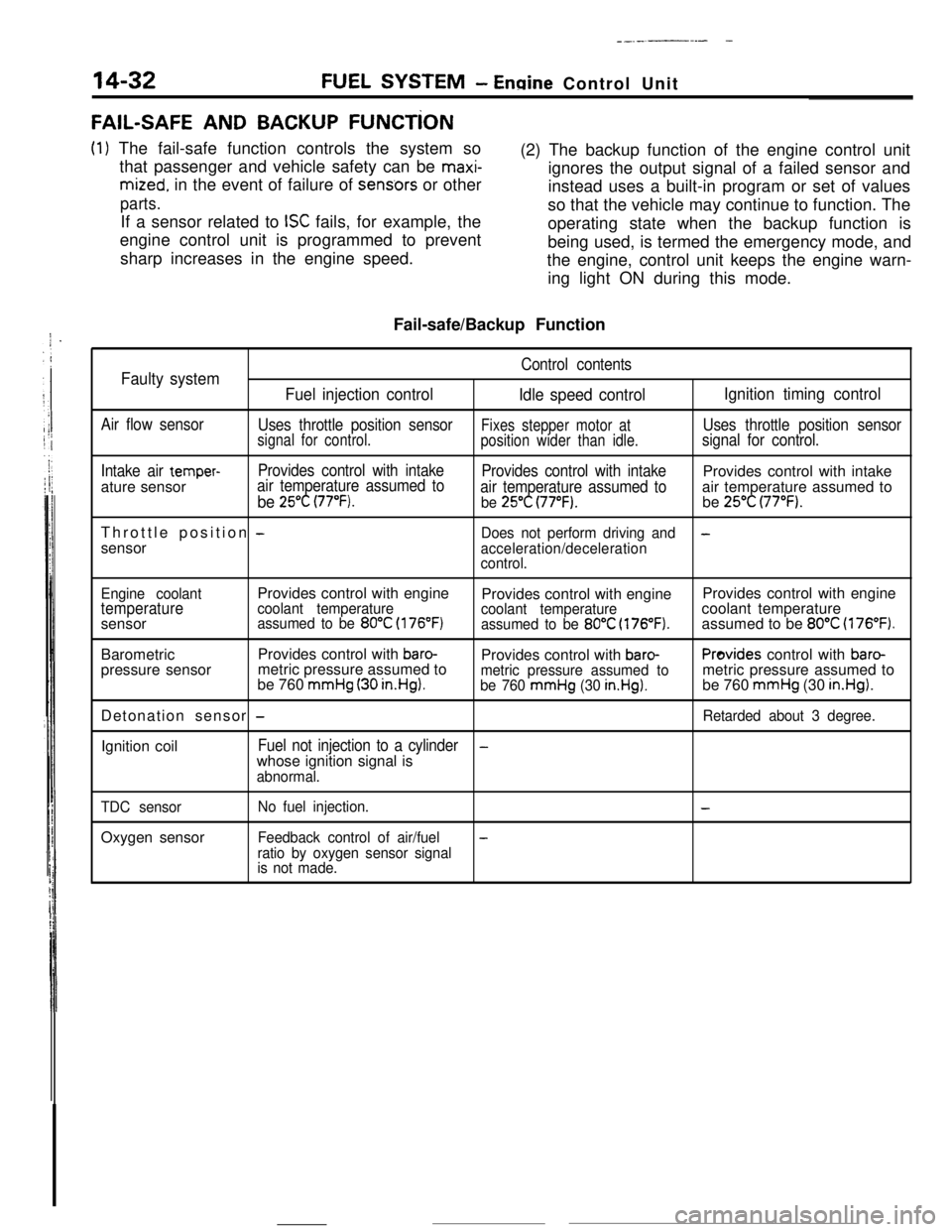

FAIL-SAFE AND BACKUP FUNCTiON

(1) The fail-safe function controls the system so

that passenger and vehicle safety can be

maxi-

mized. in the event of failure of sens.ors or other

parts.If a sensor related to

ISC fails, for example, the

engine control unit is programmed to prevent

sharp increases in the engine speed.(2) The backup function of the engine control unit

ignores the output signal of a failed sensor and

instead uses a built-in program or set of values

so that the vehicle may continue to function. The

operating state when the backup function is

being used, is termed the emergency mode, and

the engine, control unit keeps the engine warn-

ing light ON during this mode.

Fail-safe/Backup Function

Control contentsFaulty system

Fuel injection control

Idle speed controlIgnition timing control

Air flow sensor

Uses throttle position sensorFixes stepper motor atUses throttle position sensorsignal for control.

position wider than idle.signal for control.

Intake air

temper-Provides control with intake

Provides control with intakeProvides control with intake

ature sensorair temperature assumed to

be 25°C (77°F).air temperature assumed toair temperature assumed tobe 25°C (77°F).be 25°C (77°F).Throttle position

-Does not perform driving and-sensor

acceleration/deceleration

control.

Engine coolantProvides control with engine

Provides control with engineProvides control with engine

temperaturecoolant temperature

coolant temperaturecoolant temperature

sensorassumed to be 80°C (176°F)assumed to be 80°C (176°F).assumed to be 80°C (176°F).BarometricProvides control with

baro-Provides control with baro-Provides control with baro-pressure sensormetric pressure assumed to

be 760

mmHg (30 in.HgI.metric pressure assumed tometric pressure assumed tobe 760 mmHg (30 in.Hg).be 760 mmHg (30 in.Hg).Detonation sensor

-Retarded about 3 degree.Ignition coil

Fuel not injection to a cylinder-whose ignition signal is

abnormal.

TDC sensorOxygen sensor

No fuel injection.-

Feedback control of air/fuel-

ratio by oxygen sensor signal

is not made.

Page 171 of 391

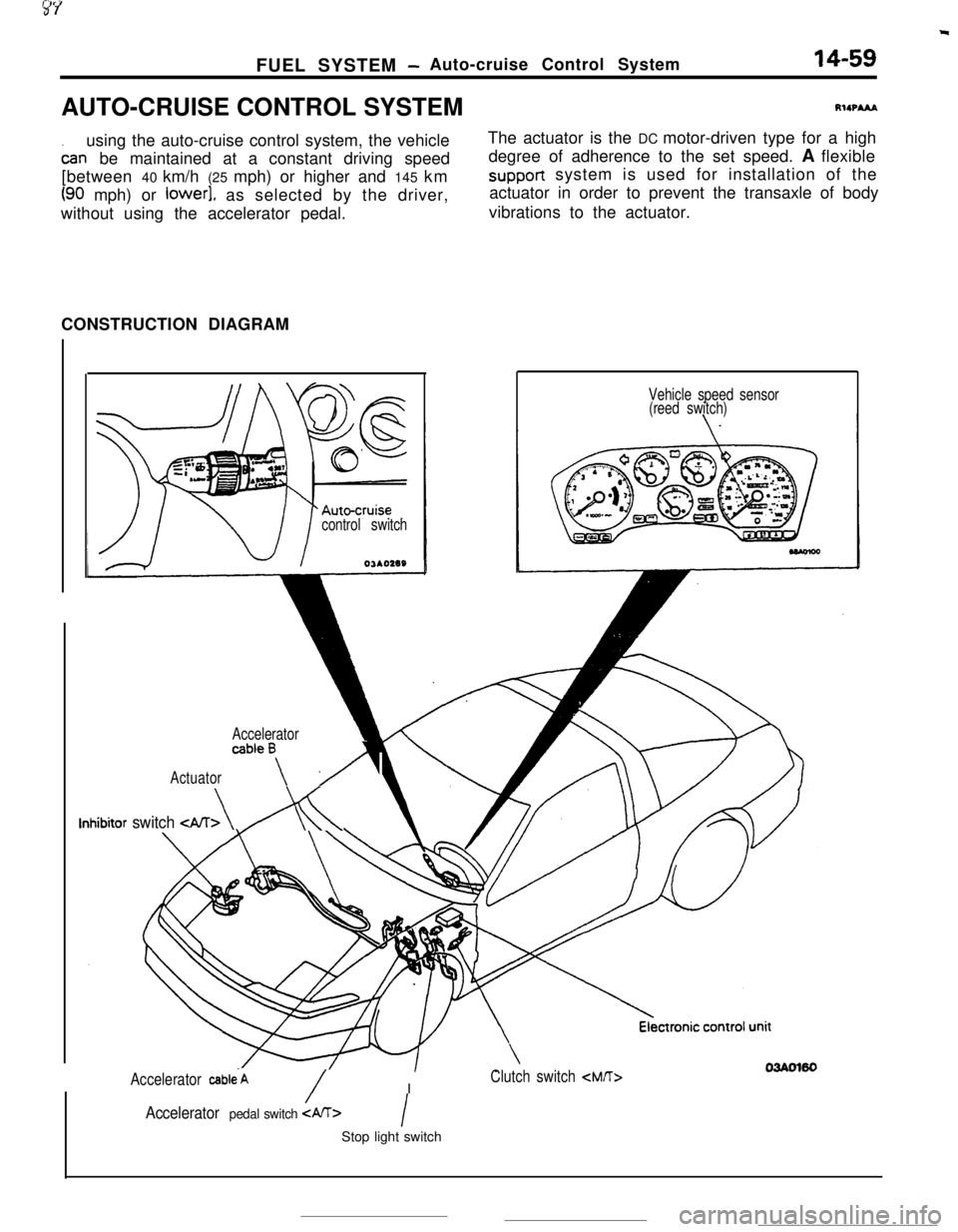

FUEL SYSTEM -Auto-cruise Control System14-59AUTO-CRUISE CONTROL SYSTEMRIIPA&A

using the auto-cruise control system, the vehicle

oar-rbe maintained at a constant driving speed

[between 40 km/h (25 mph) or higher and 145 km

(90 mph) or lower], as selected by the driver,

without using the accelerator pedal.The actuator is the DC motor-driven type for a high

degree of adherence to the set speed. A flexiblesupport system is used for installation of the

actuator in order to prevent the transaxle of body

vibrations to the actuator.

CONSTRUCTION DIAGRAM

control switchOJAO2SS

Accelerator

Actuator

ab’ea\ A

Inhibitor switch

(reed switch)

Accelerator cab1e.A/IClutch switch

/Accelerator pedal switch IStop light switch