diagram MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 4 of 391

._._ -_- 1 -.

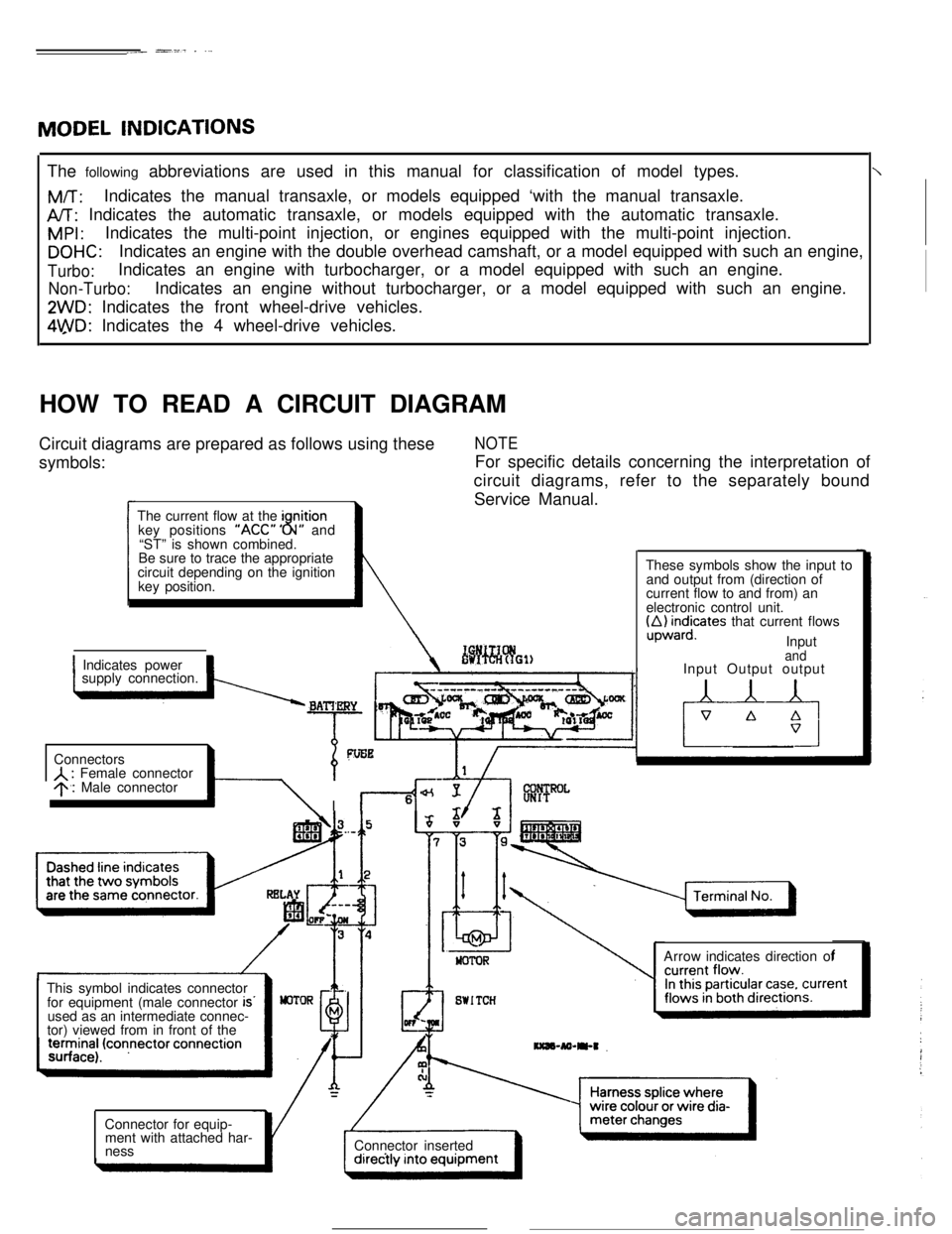

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.\

M/T: Indicates the manual transaxle, or models equipped ‘with the manual t\

ransaxle.

A/T: Indicates the automatic transaxle, or models equipped with the automatic\

transaxle.

MPI: Indicates the multi-point injection, or engines equipped with the multi-\

point injection.

DOHC: Indicates an engine with the double overhead camshaft, or a model equipp\

ed with such an engine,

Turbo: Indicates an engine with turbocharger, or a model equipped with such an \

engine.

2WD: Indicates the front wheel-drive vehicles.

4WD: Indicates the 4 wheel-drive vehicles.

HOW TO READ A CIRCUIT DIAGRAM

initionkey positions “ACC” ” N” and8“ST” is shown combined.

~

Service Manual.

o&ficates that current flows

Input

1 Indicates power1supply connection.

A : Female connector9.1 Male connector

\ Il-4’

Input Output output

is..used as an intermediate connec-

Page 20 of 391

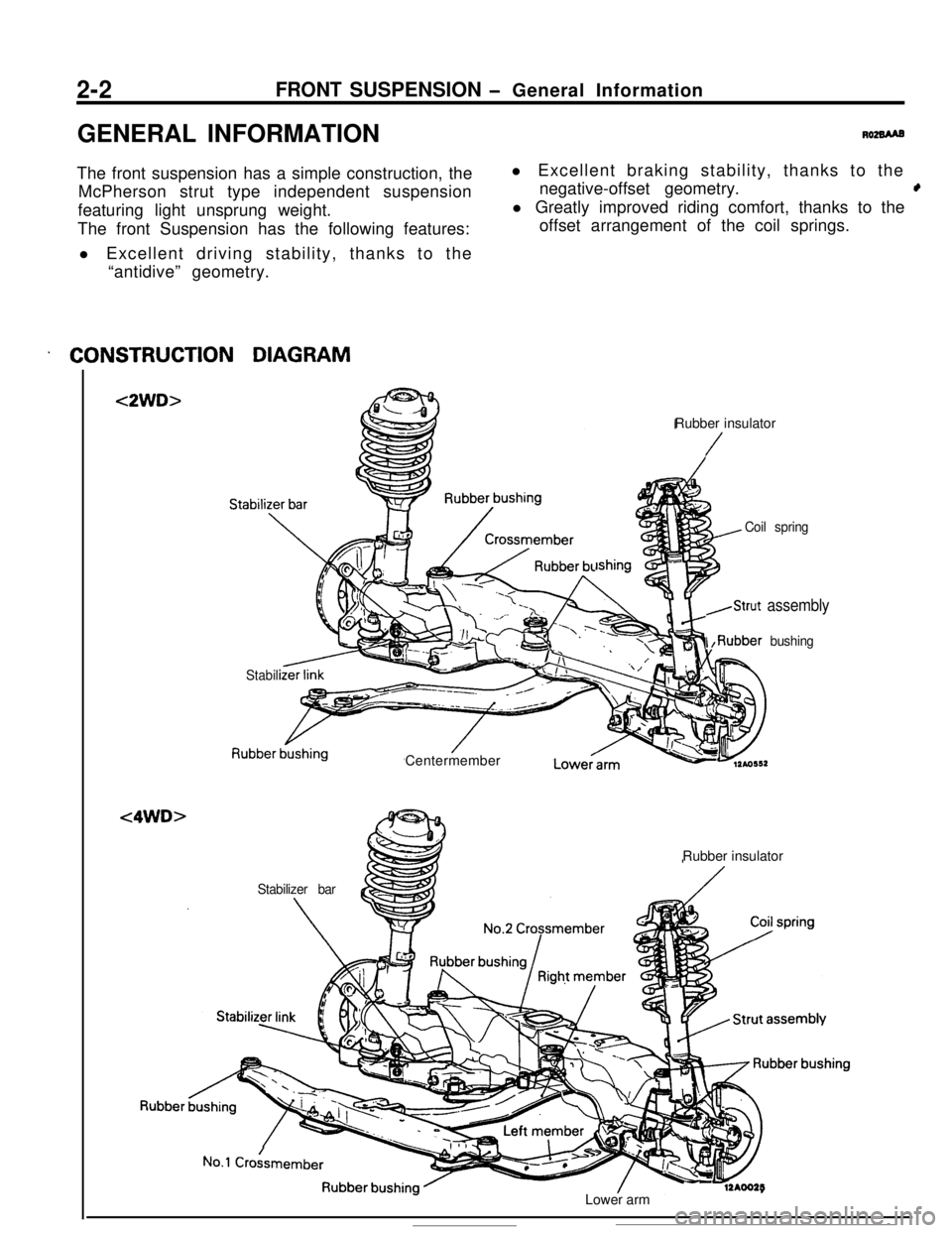

2-2

t

featuring light unsprung weight.

. CONSTRUCTION DIAGRAM

<2WD>

<4WD>

Rubber insulator

/

lshing

Coil spring

,Strut assembly

I ,Rubber bushing

Stabili

Lowecarm

Rubber insulator

No.1 Crokmember

- -12AOO25Lower arm

Page 29 of 391

-.-...- ..v:T

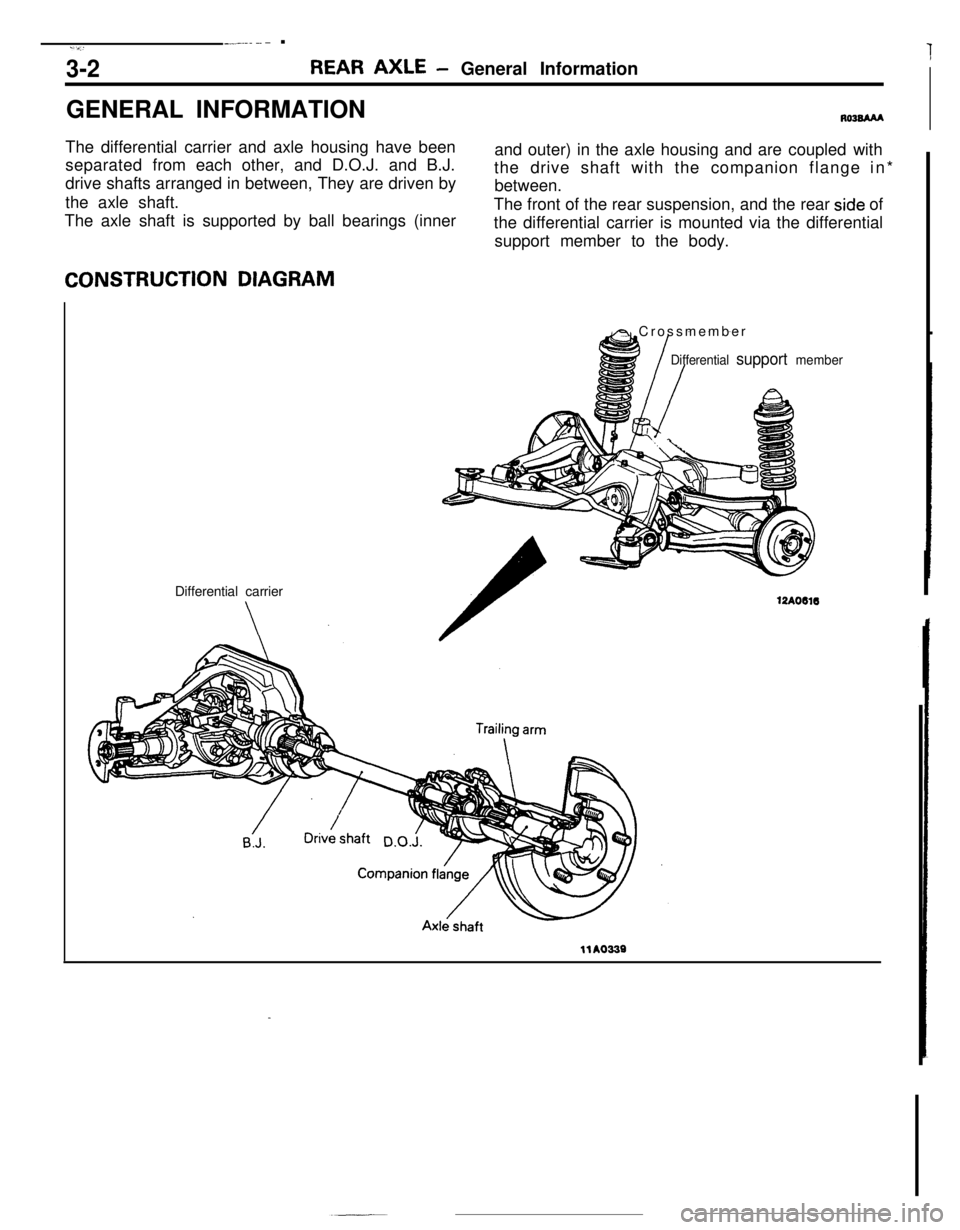

3-2REAR AXLE- General Information

GENERAL INFORMATION

RO3BAAAThe differential carrier and axle housing have been

separated from each other, and D.O.J. and B.J.

drive shafts arranged in between, They are driven by

the axle shaft.

The axle shaft is supported by ball bearings (innerand outer) in the axle housing and are coupled with

the drive shaft with the companion flange in*

between.

The front of the rear suspension, and the rear

side of

the differential carrier is mounted via the differential

support member to the body.CONSTRUCTION DIAGRAM

Differential carrier

A Crossmember

Differential support member

12AO616

llA0339

Page 43 of 391

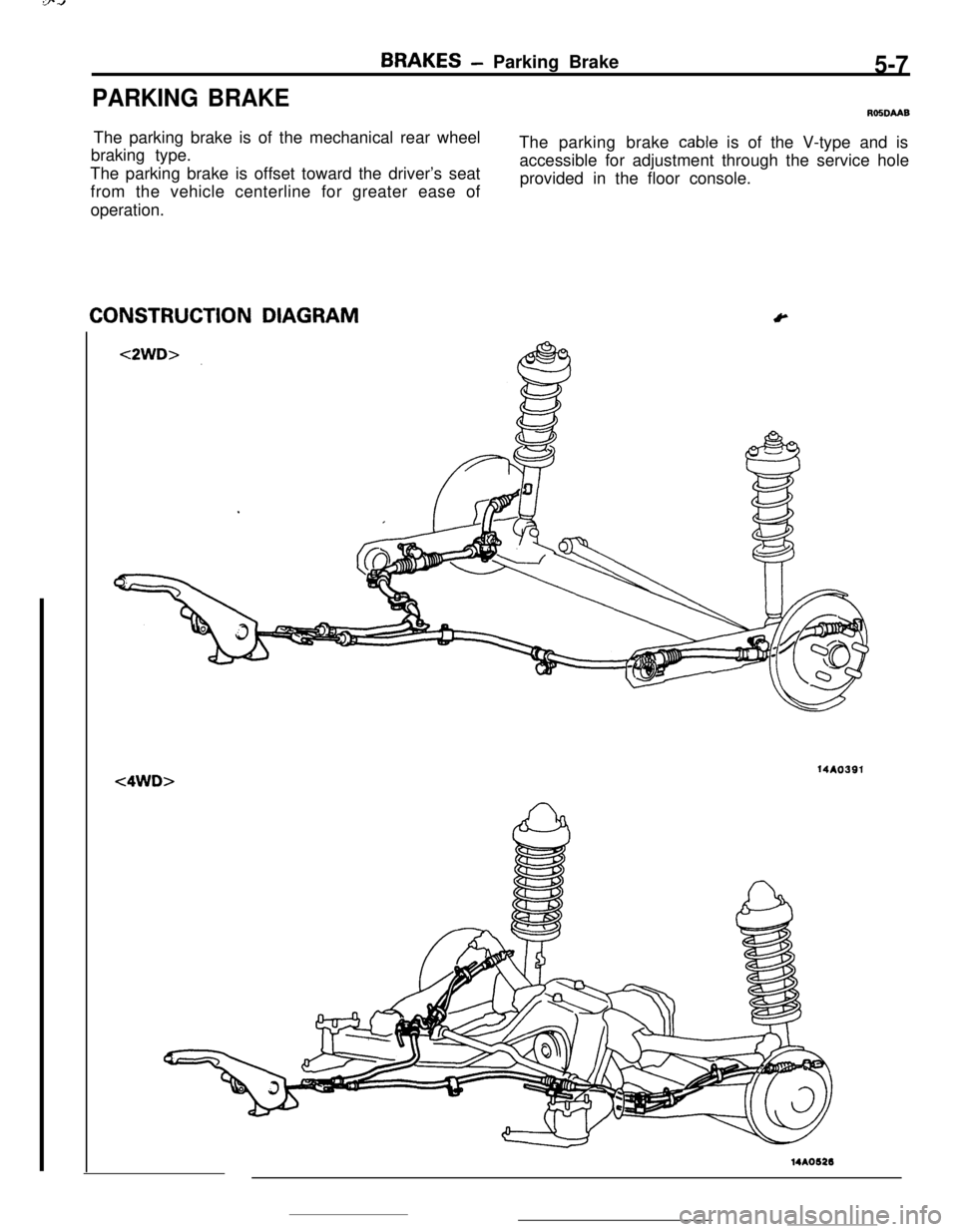

PARKING BRAKE

BRAKES- Parking Brake5-7

ROSDMBThe parking brake is of the mechanical rear wheel

braking type.The parking brake

cable is of the V-type and is

The parking brake is offset toward the driver’s seataccessible for adjustment through the service hole

provided in the floor console.

from the vehicle centerline for greater ease of

operation.CONSTRUCTION DIAGRAM

Y14AO391

<4WD>14A0626

Page 57 of 391

3i

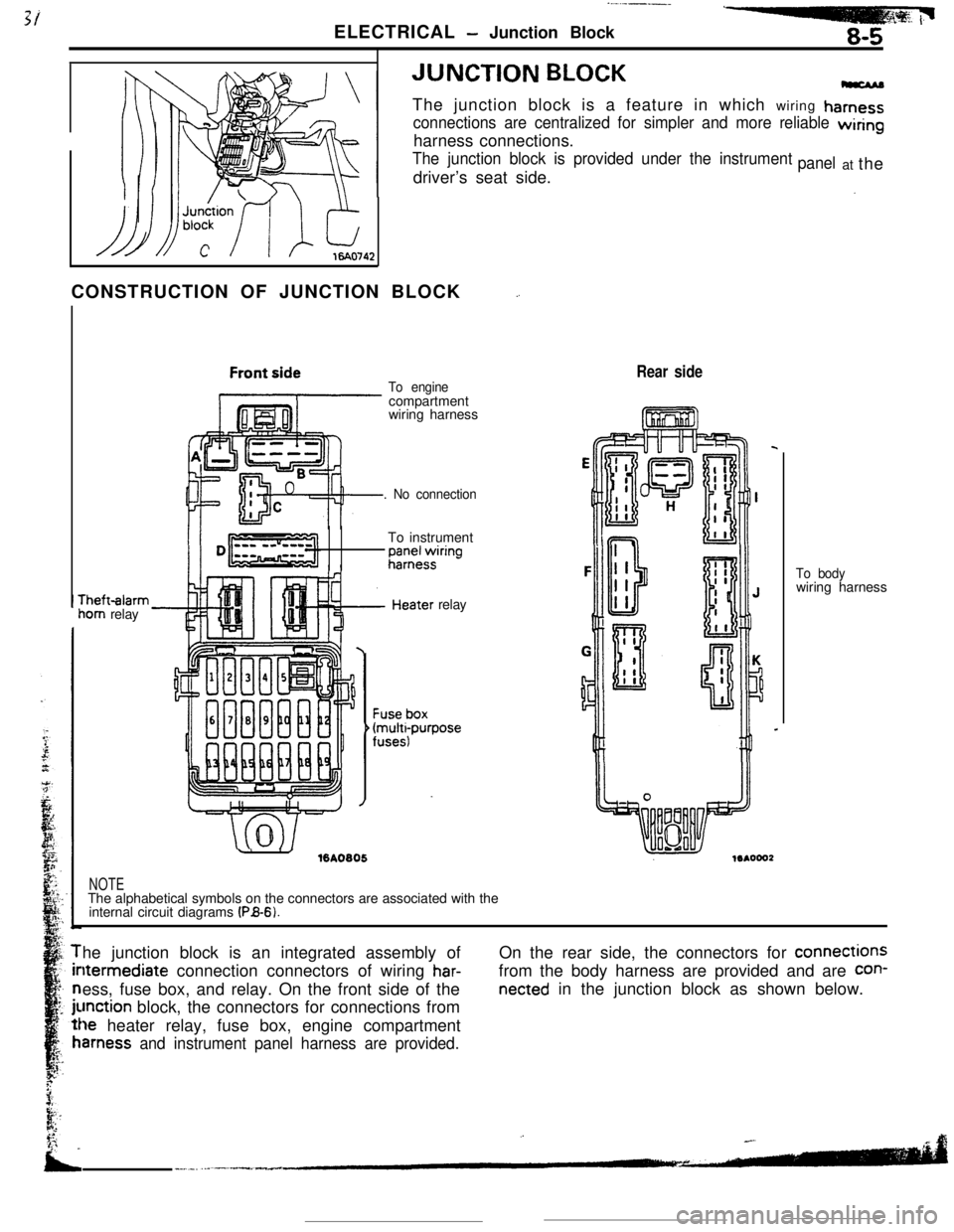

ELECTRICAL - Junction Block8-5JUNCTION

BLOCKThe junction block is a feature in which wiring

hamess

connections are centralized for simpler and more reliable wiringharness connections.

The junction block is provided under the instrumentdriver’s seat side.panelat the

CONSTRUCTION OF JUNCTION BLOCK

_.rheft-alarm

iom relay

To enginecompartment

wiring harness

. No connectionTo instrument

;;;+$ring

.’ ./%A0805relay

Rear side

NOTEThe alphabetical symbols on the connectors are associated with the

internal circuit diagrams

(PB-6).To bodywiring harness

he junction block is an integrated assembly ofltermediate connection connectors of wiring

har-ess, fuse box, and relay. On the front side of the

unction block, the connectors for connections from

le heater relay, fuse box, engine compartment

amess and instrument panel harness are provided.On the rear side, the connectors for connections

from the body harness are provided and are

con-

netted in the junction block as shown below.

Page 58 of 391

__._._ -.. .-

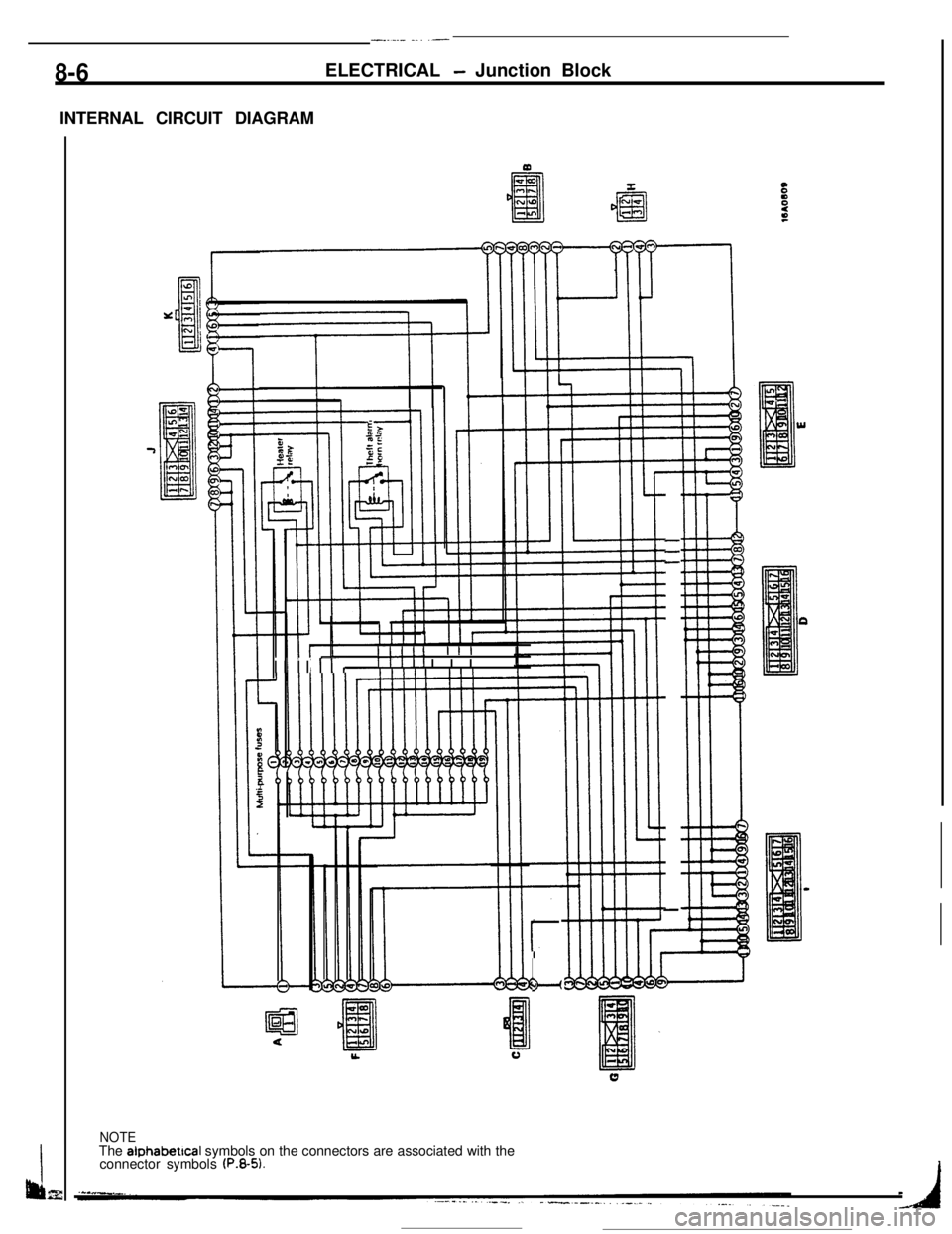

8-6ELECTRICAL - Junction Block

INTERNAL CIRCUIT DIAGRAM

---

-

Illll IIII

I II Irr,Illll IIII

r

L”

NOTEThe alphabetical symbols on the connectors are associated with the

connector symbols

(P.8-5).

Page 80 of 391

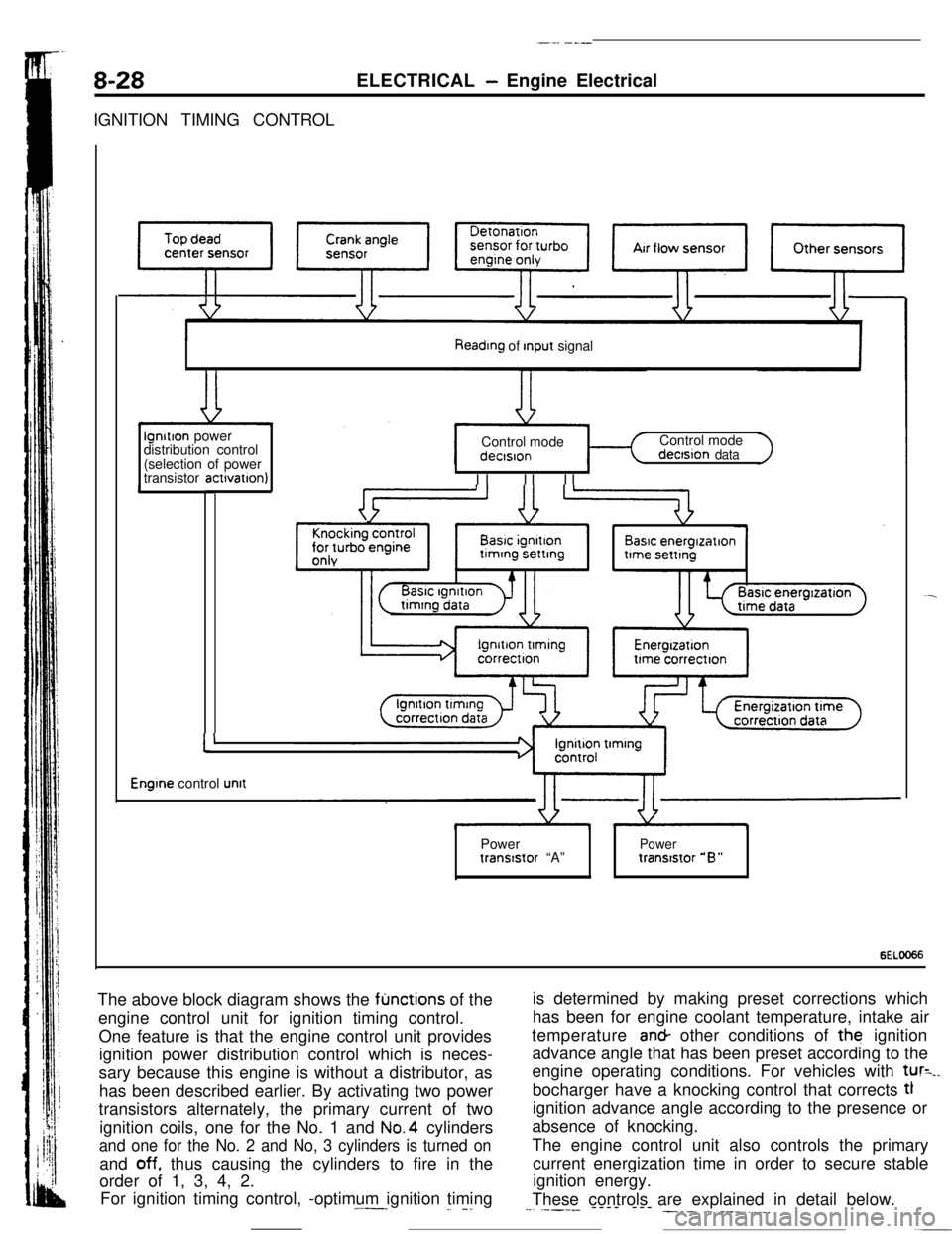

8-28ELECTRICAL- Engine Electrical

IGNITION TIMING CONTROL

Reading of Input signallgnitlon power

distribution control

(selection of power

transistor actlvatlon)Control mode

I II II IControl mode

dectsion data

Basic energlzatlon

I’

Engine control unitPower

Powertranststor “A”tranststor “B”

6ELOO66The above block diagram shows the

fljnctions of the

engine control unit for ignition timing control.

One feature is that the engine control unit provides

ignition power distribution control which is neces-

sary because this engine is without a distributor, as

has been described earlier. By activating two power

transistors alternately, the primary current of two

ignition coils, one for the No. 1 and No.4 cylinders

and one for the No. 2 and No, 3 cylinders is turned onand

off. thus causing the cylinders to fire in the

order of 1, 3, 4, 2.

For ignition timing control, -optimum ignition timing.^--_

_. -.is determined by making preset corrections which

has been for engine coolant temperature, intake air

temperature an& other conditions of the ignition

advance angle that has been preset according to the

engine operating conditions. For vehicles with

tur=_.bocharger have a knocking control that corrects tl

ignition advance angle according to the presence or

absence of knocking.

The engine control unit also controls the primary

current energization time in order to secure stable

ignition energy.

These controls are explained in detail below.

--. .----- ---- --- ___. .-. ___.,.__

Page 106 of 391

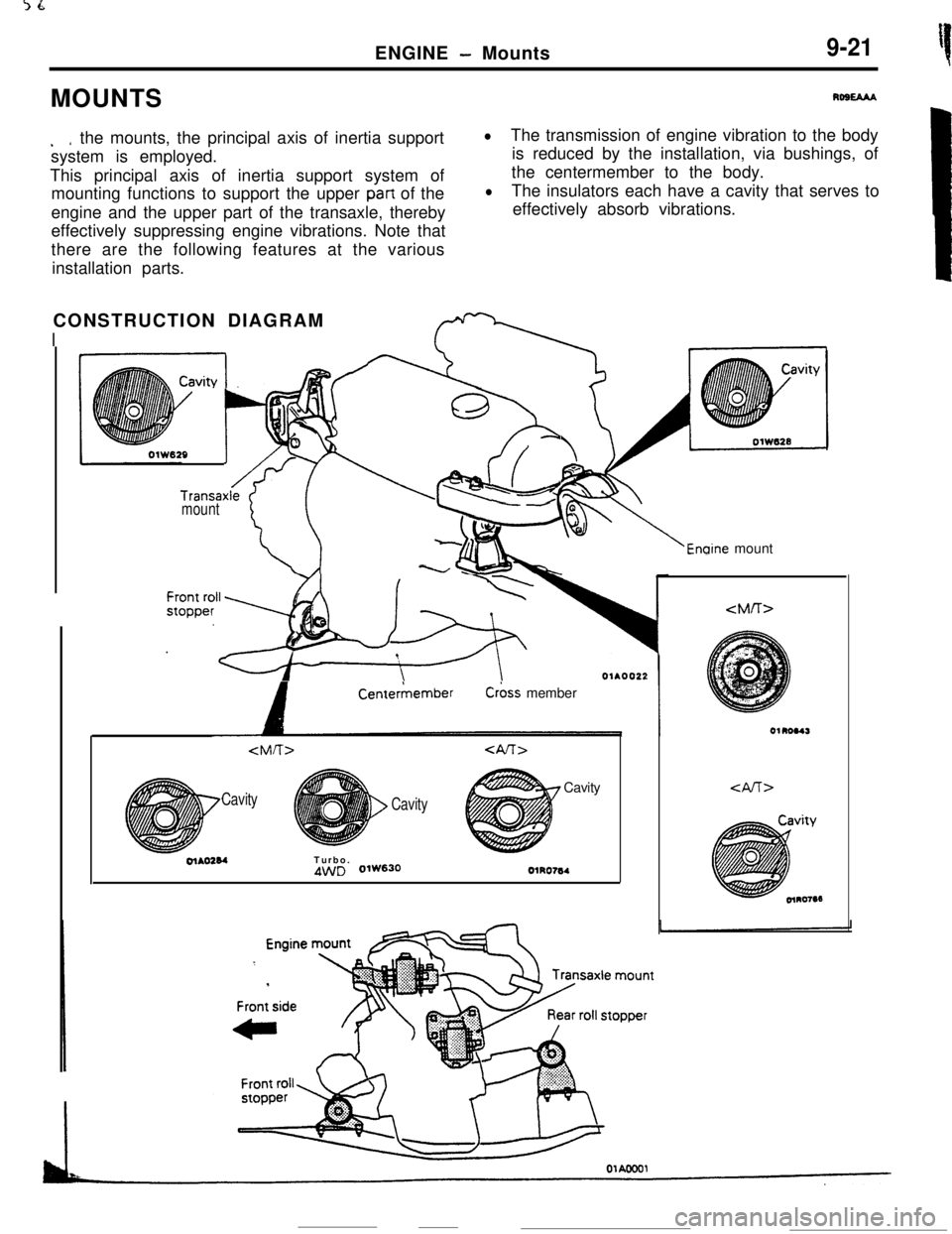

L1ENGINE

- Mounts9-21MOUNTS

Rost3u

. *the mounts, the principal axis of inertia support

system is employed.

This principal axis of inertia support system of

mounting functions to support the upper

part of the

engine and the upper part of the transaxle, thereby

effectively suppressing engine vibrations. Note that

there are the following features at the various

installation parts.

lThe transmission of engine vibration to the body

is reduced by the installation, via bushings, of

the centermember to the body.

lThe insulators each have a cavity that serves to

effectively absorb vibrations.

CONSTRUCTION DIAGRAM

I

Transaxlemount

‘i::

+g

/v 1b-8

8-,

Enaine mount

A

CenterkemberC&s member

Cavity

CavityCavityolAO284Turbo.

4WD 0lW630OlRO764

Page 112 of 391

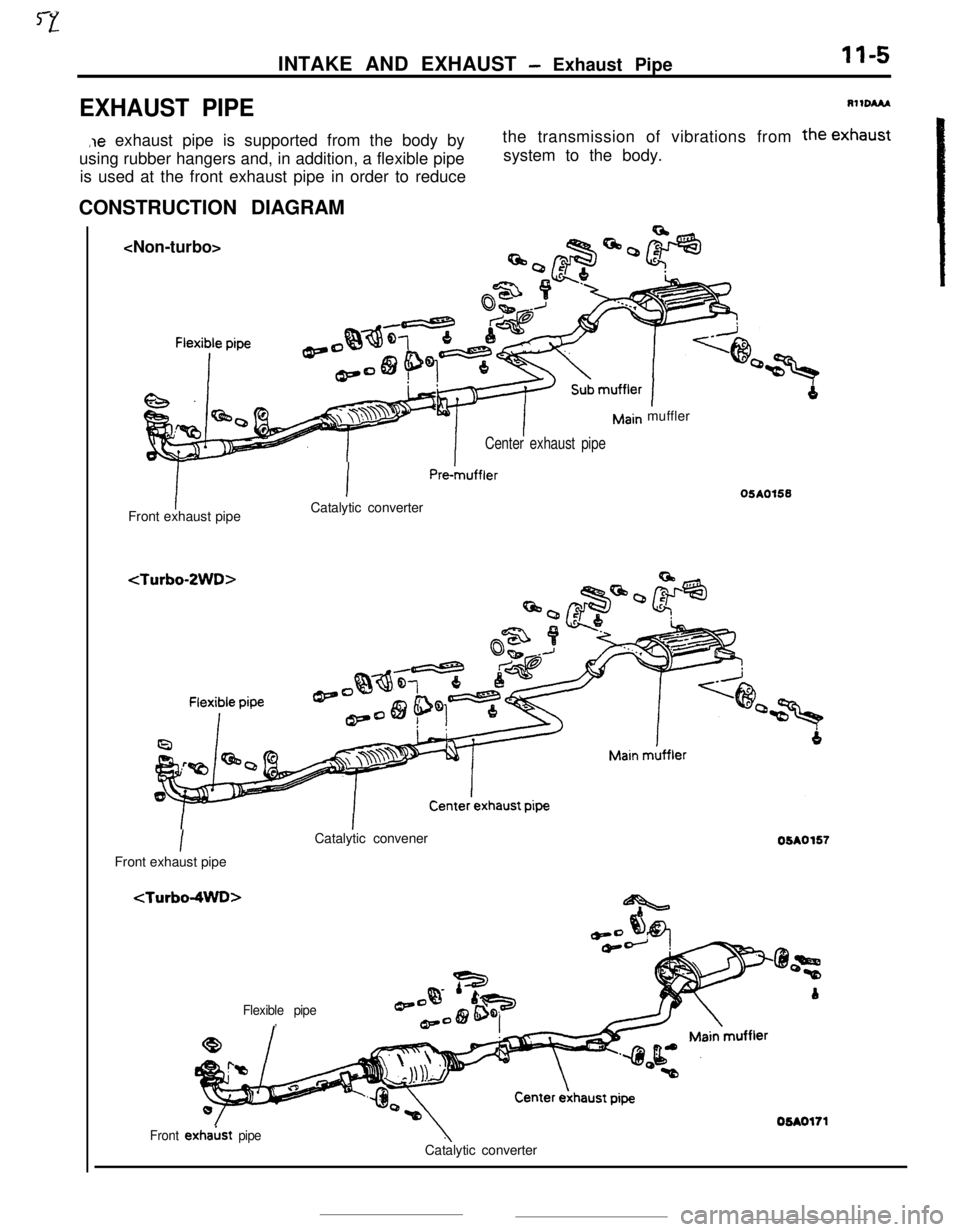

INTAKE AND EXHAUST - Exhaust PipeII-5

EXHAUST PIPERllDAM

,le exhaust pipe is supported from the body by

using rubber hangers and, in addition, a flexible pipe

is used at the front exhaust pipe in order to reducethe transmission of vibrations from the exhaust

system to the body.

CONSTRUCTION DIAGRAM

Center exhaust pipeFront exhaust pipe

IPm-muffler

Catalytic converter

Imuffler

IFront exhaust pipeCatalytic convener

Flexible pipe,05AO155

05A0157

Front exhakt pipeCatalytic converter

Page 121 of 391

FUEL SYSTEM -Fuel Supply and Fuel Pressure Control14-9

03Poo4:Diaphragm

from intake

4Fuel from delivery pipe

4m

B(42.7)QQ

2

sl -196 2

(26.4) g

t

$!a d

9

0)Positive5 z‘. pressure

(E.2)

w

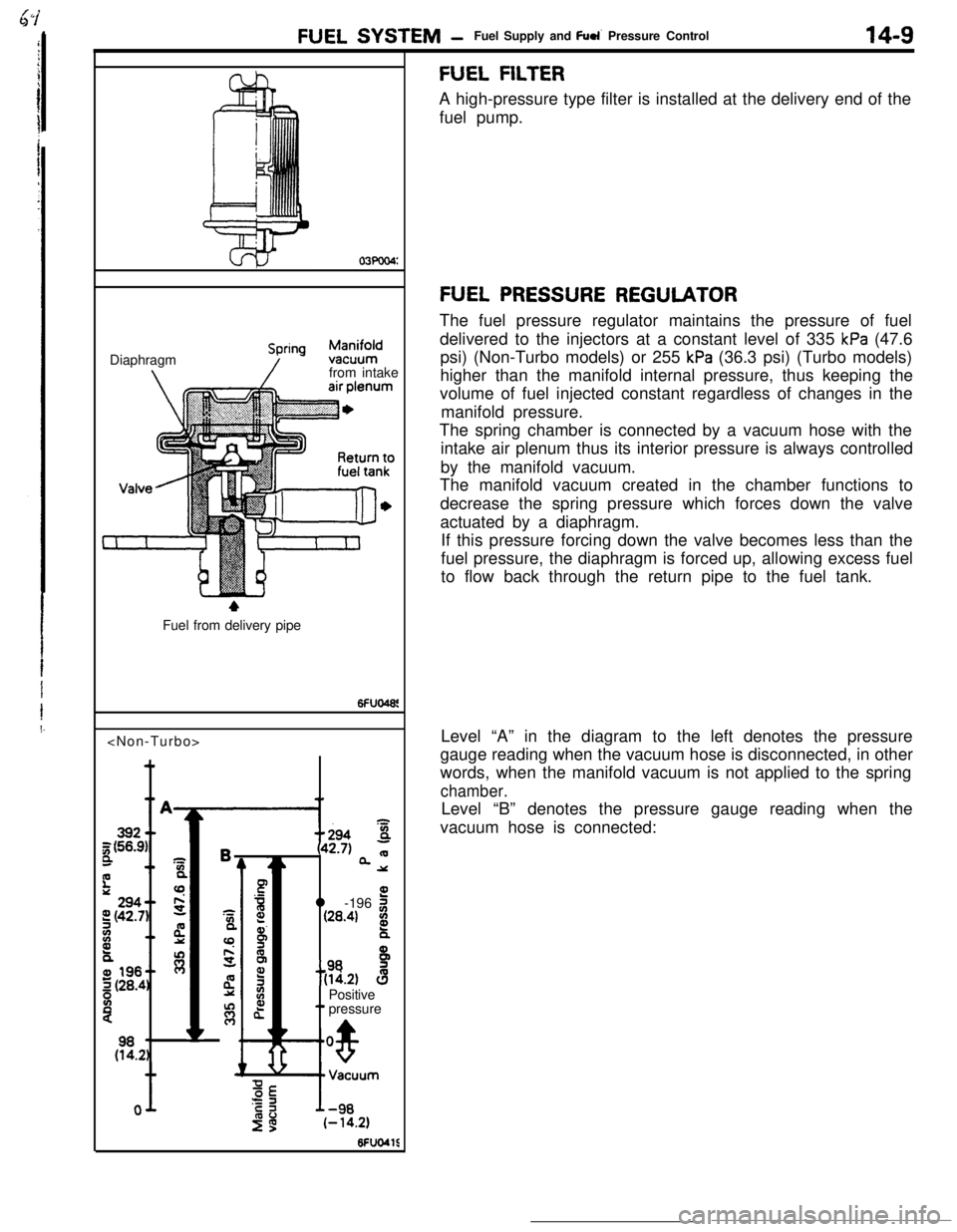

FUEL FILTERA high-pressure type filter is installed at the delivery end of the

fuel pump.

FUEL PRESSURE REGULATORThe fuel pressure regulator maintains the pressure of fuel

delivered to the injectors at a constant level of 335

kPa (47.6

psi) (Non-Turbo models) or 255

kPa (36.3 psi) (Turbo models)

higher than the manifold internal pressure, thus keeping the

volume of fuel injected constant regardless of changes in the

manifold pressure.

The spring chamber is connected by a vacuum hose with the

intake air plenum thus its interior pressure is always controlled

by the manifold vacuum.

The manifold vacuum created in the chamber functions to

decrease the spring pressure which forces down the valve

actuated by a diaphragm.

If this pressure forcing down the valve becomes less than the

fuel pressure, the diaphragm is forced up, allowing excess fuel

to flow back through the return pipe to the fuel tank.

Level “A” in the diagram to the left denotes the pressure

gauge reading when the vacuum hose is disconnected, in other

words, when the manifold vacuum is not applied to the spring

chamber.Level “B” denotes the pressure gauge reading when the

vacuum hose is connected: