fuel MITSUBISHI ECLIPSE 1990 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 132 of 391

FUEL SYSTEM - Sensors

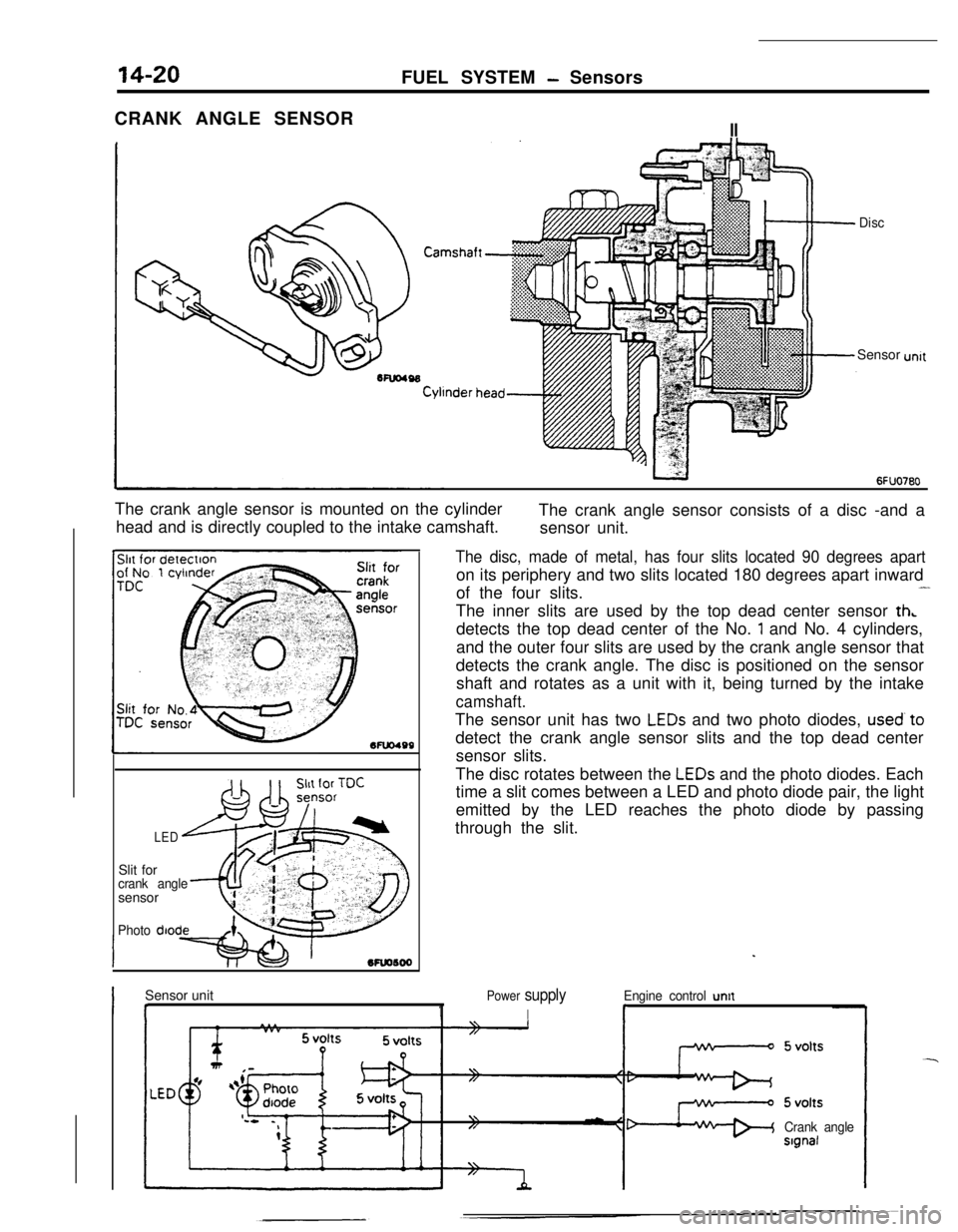

CRANK ANGLE SENSOR

II

DiscSensor

The crank angle sensor is mounted on the cylinder

head and is directly coupled to the intake camshaft.The crank angle sensor consists of a disc -and a

sensor unit.

Mu0499Slit for

crank anglesensor

Photo diode

LED

The disc, made of metal, has four slits located 90 degrees aparton its periphery and two slits located 180 degrees apart inward

of the four slits.

-The inner slits are used by the top dead center sensor

th,detects the top dead center of the No.

1 and No. 4 cylinders,

and the outer four slits are used by the crank angle sensor that

detects the crank angle. The disc is positioned on the sensor

shaft and rotates as a unit with it, being turned by the intake

camshaft.The sensor unit has two

LEDs and two photo diodes, used’to

detect the crank angle sensor slits and the top dead center

sensor slits.

The disc rotates between the

LEDs and the photo diodes. Each

time a slit comes between a LED and photo diode pair, the light

emitted by the LED reaches the photo diode by passing

through the slit.

Sensor unit

I I1

Power supply

I

Engine control untt

r

Crank angleslgnal

Page 133 of 391

FUEL SYSTEM - Sensors14-21When exposed to light, the photo diode conducts

urrent in a direction opposite to an ordinary diode.

.s a result, current flows in the direction indicated

by the arrow and dotted line and a voltage (5 volts) isapplied to the comparator of the sensor unit so that

the terminal voltage of the engine control unit

becomes 5 volts. When the disc rotates further andthe slit moves beyond the space between the

LED/photo diode pair, the light can no longer reach

the photo diode, thus the current indicated by the

dotted line ceases to flow and the terminal voltage

of the engine control unit becomes 0 volt.

tn this

way, pulse signals are sent to the engine control

unit from the sensor unit.

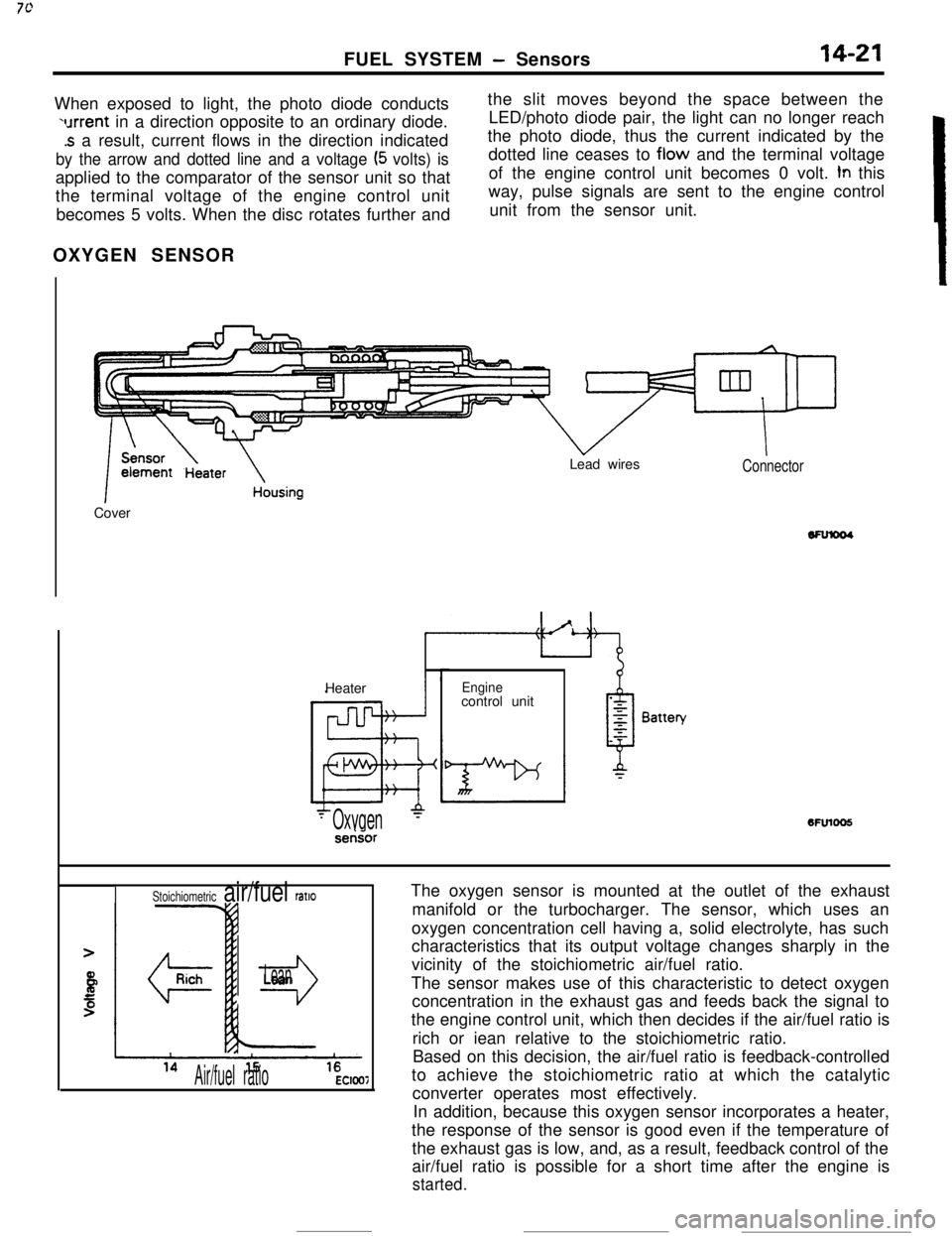

OXYGEN SENSOR

k

1 ~~~~t13ate~ousingCoverLead wiresConnectorHeater

Enginecontrol unit6FUlOO5

- Oxygen‘-serisor

The oxygen sensor is mounted at the outlet of the exhaust

manifold or the turbocharger. The sensor, which uses an

oxygen concentration cell having a, solid electrolyte, has such

characteristics that its output voltage changes sharply in the

vicinity of the stoichiometric air/fuel ratio.

The sensor makes use of this characteristic to detect oxygen

concentration in the exhaust gas and feeds back the signal to

the engine control unit, which then decides if the air/fuel ratio is

rich or iean relative to the stoichiometric ratio.

Based on this decision, the air/fuel ratio is feedback-controlled

to achieve the stoichiometric ratio at which the catalytic

converter operates most effectively.

In addition, because this oxygen sensor incorporates a heater,

the response of the sensor is good even if the temperature of

the exhaust gas is low, and, as a result, feedback control of the

air/fuel ratio is possible for a short time after the engine is

started.

Stoichiometric air/fuel ratlo

r3

Lean

Air/fuel ratioEC1007

Page 134 of 391

14-22FUEL SYSTEM - Sensors

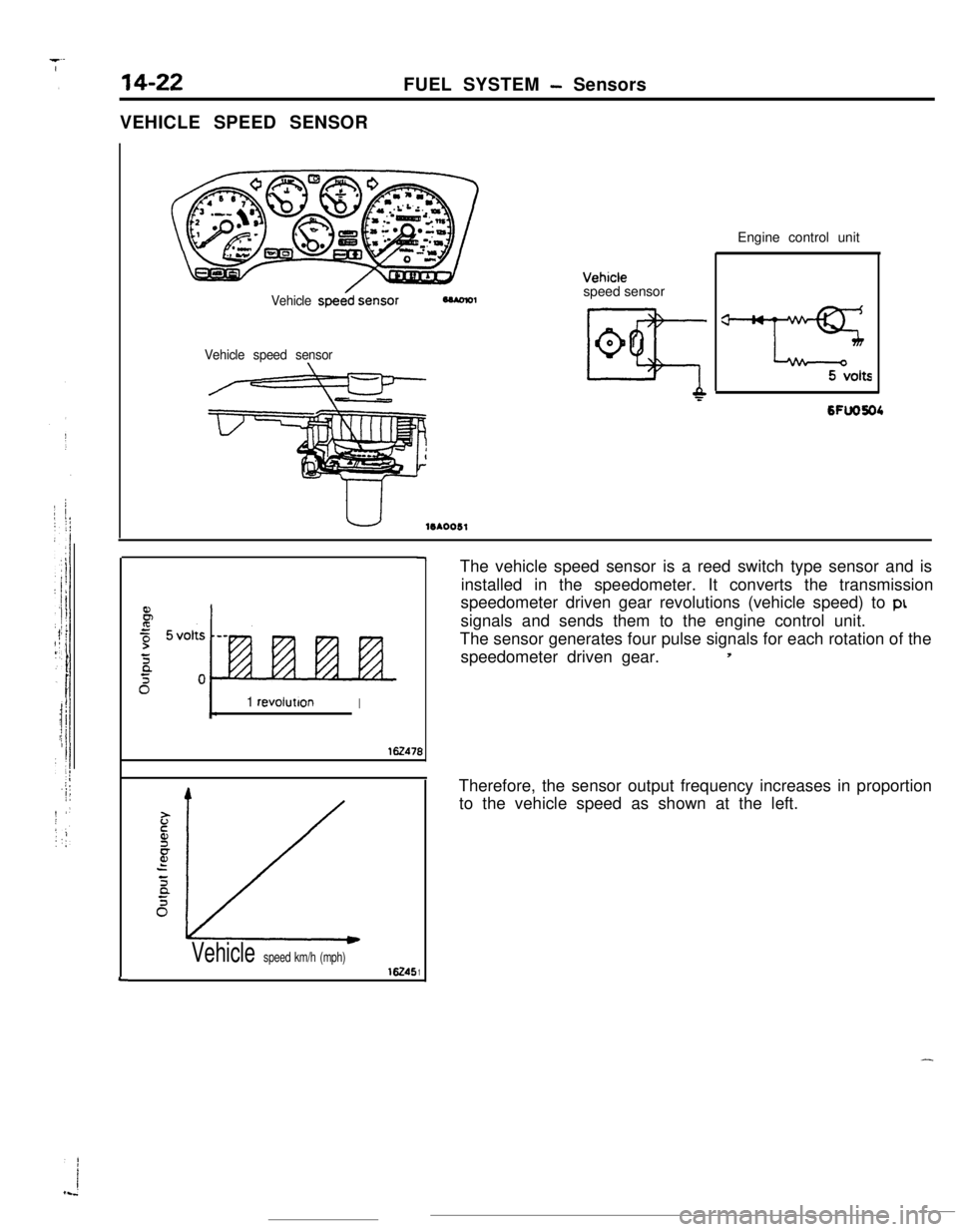

VEHICLE SPEED SENSOR

L

Vehicle speessensor

Vehicle speed sensor

10*0051speed sensorEngine control unit

6FlJO604

1 revoluttonI

‘r’471

16245

7

B

1Vehicle speed km/h (mph)The vehicle speed sensor is a reed switch type sensor and is

installed in the speedometer. It converts the transmission

speedometer driven gear revolutions (vehicle speed) to

ptsignals and sends them to the engine control unit.

The sensor generates four pulse signals for each rotation of the

speedometer driven gear.

5Therefore, the sensor output frequency increases in proportion

to the vehicle speed as shown at the left.

-

Page 135 of 391

‘7JFUEL SYSTEM

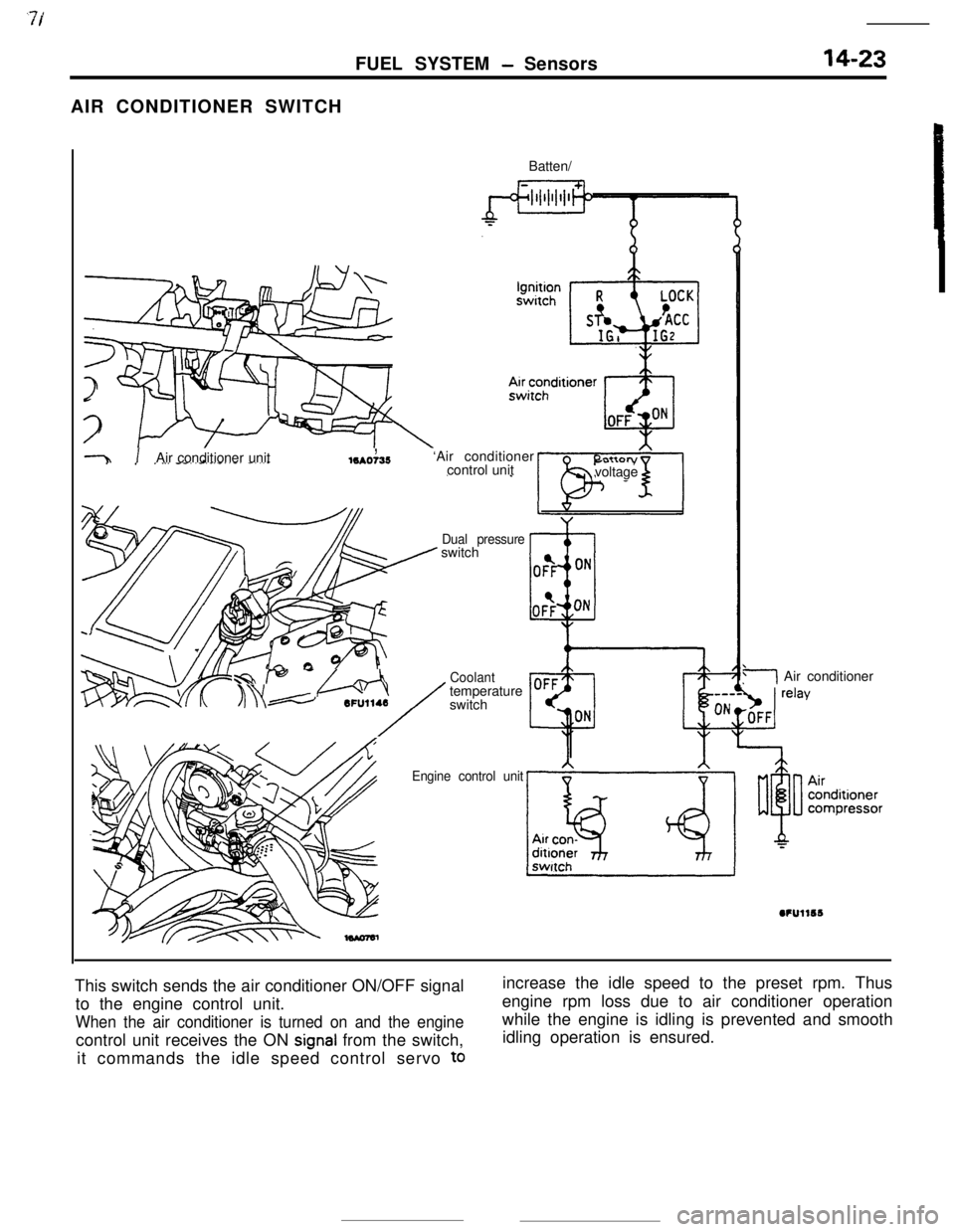

- Sensors14-23AIR CONDITIONER SWITCH

Batten/

-31 .,Air conditioner unitlSAO735‘Air conditioner

control unitI”.._. ,voltage

Dual pressureswitch

-f@ -//Q.j

/

Coolanttemperature6FU1148

switch

Engine control unit

3Air conditioner

This switch sends the air conditioner ON/OFF signal

to the engine control unit.

When the air conditioner is turned on and the enginecontrol unit receives the ON

signal from the switch,

it commands the idle speed control servo

toincrease the idle speed to the preset rpm. Thus

engine rpm loss due to air conditioner operation

while the engine is idling is prevented and smooth

idling operation is ensured.

Page 136 of 391

--

,

14-24FUEL SYSTEM - Sensors

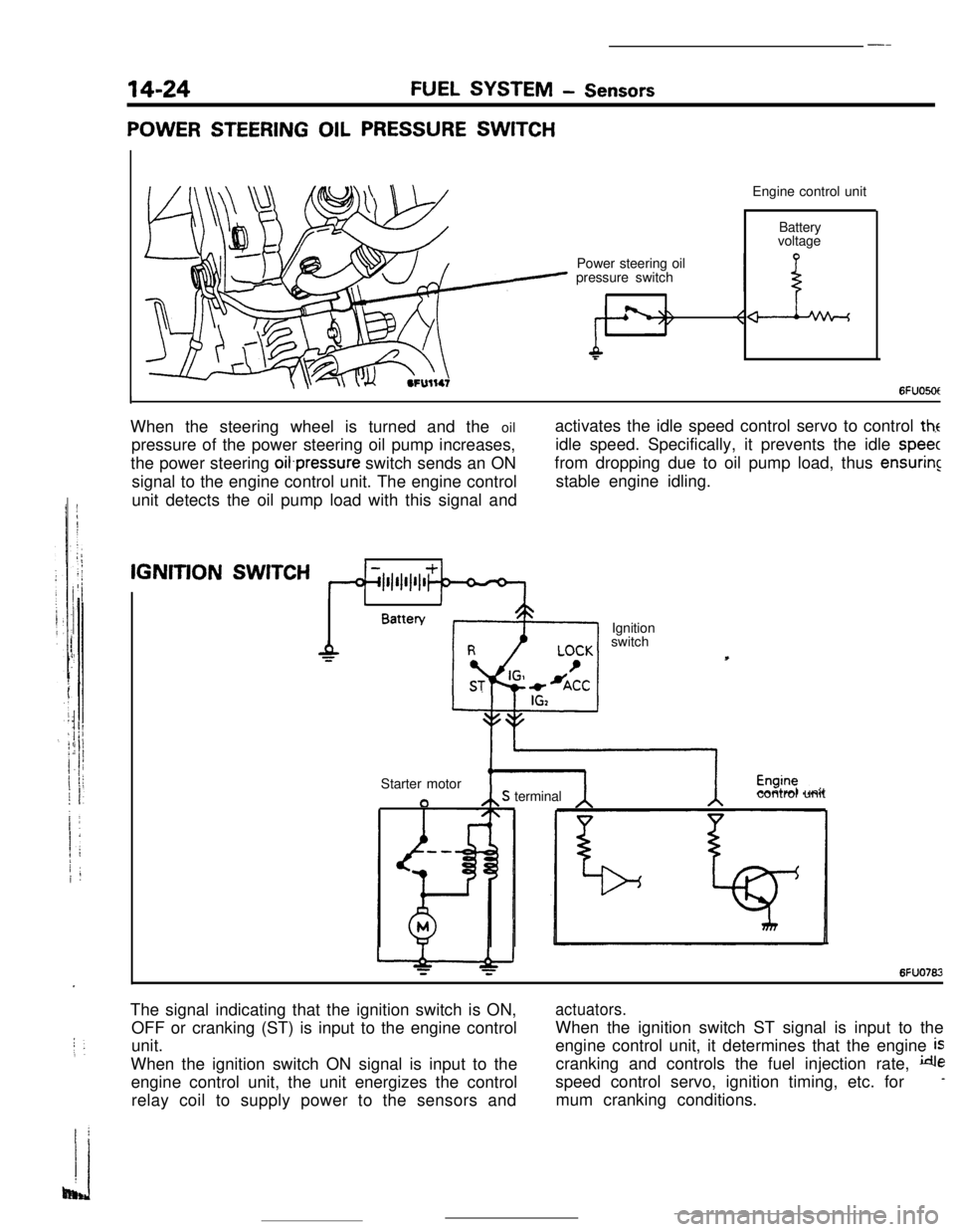

POWER STEERING OIL PRESSURE SWITCHEngine control unit

Power steering oil

pressure switchBattery

voltage

6FUO5OtIWhen the steering wheel is turned and the oil

pressure of the power steering oil pump increases,

the power steering oifpressure switch sends an ON

signal to the engine control unit. The engine control

unit detects the oil pump load with this signal andactivates the idle speed control servo to control

theidle speed. Specifically, it prevents the idle

speecfrom dropping due to oil pump load, thus

ensuringstable engine idling.IGNITION

SWITCH

1IBattery

Ignition

switch

Starter motor

aS terminalcontrol unit

6FUO762The signal indicating that the ignition switch is ON,

OFF or cranking (ST) is input to the engine control

unit.

When the ignition switch ON signal is input to the

engine control unit, the unit energizes the control

relay coil to supply power to the sensors and

actuators.When the ignition switch ST signal is input to the

engine control unit, it determines that the engine

iscranking and controls the fuel injection rate,

despeed control servo, ignition timing, etc. for

-mum cranking conditions.

Page 137 of 391

FUEL SYSTEM - Sensors14-25Terminal for

ignition timing

adjustment

l-l6FUO51:7

W$ht(/.

Piezo-electncelements

I6FUOSlO

DetonationEngine control

unit

sensor

I-

I t i A-- >--t.--‘-3 -

wt4rlIGNITION TlMlNG ADJUSTMENT TERMINAL

This terminal

is used when adjusting the basic ignition timing or

basic idle speed.

When this terminal is shorted to ground, the engine control unit

cancels the

ignition timing control and idle speed control, and

sets the ignition

timing and idle speed control servos in their

adjusting mode.

For the basic idle speed adjustment, the diagnosis terminal is

also shorted to ground.

DETONATION SENSOR

The detonation sensor is installed at a position where it can

detect, with a high degree of precision, knocking generated at

each cylinder; it detects cylinder block vibrations caused by

knocking, and outputs voltage proportional to the magnitude of

those vibrations.

Because cylinder block vibrations caused by knocking vary

from engine to engine, the engine control unit passes this

through a frequncy filter, detecting only the knocking, thus

resulting in a spark retardation of the ignition timing that

corresponds to the strength of the knocking.

Page 138 of 391

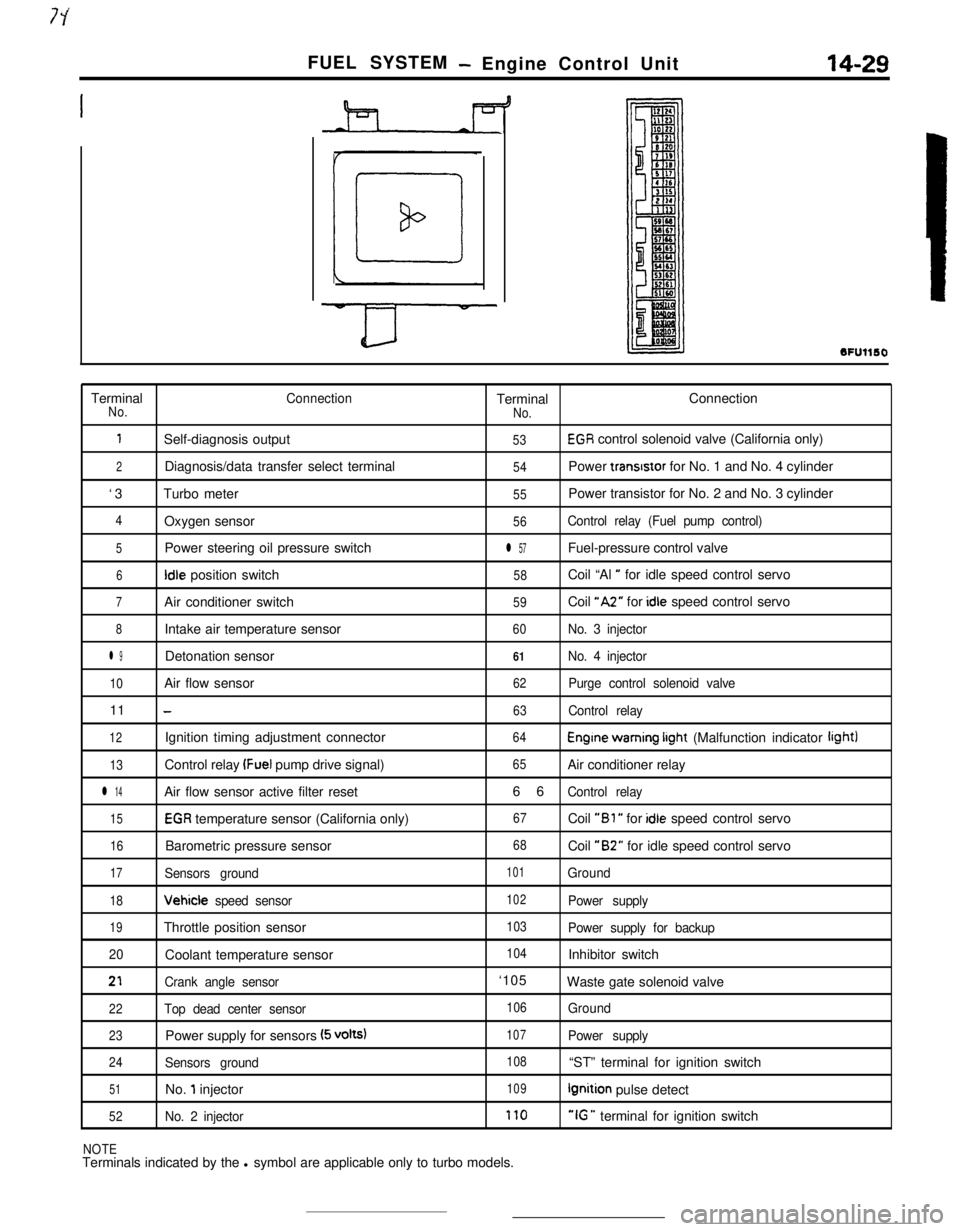

Page 139 of 391

‘73.- .-_ _ .-__ .- -..- - .-----___. _____^. -._ __--.

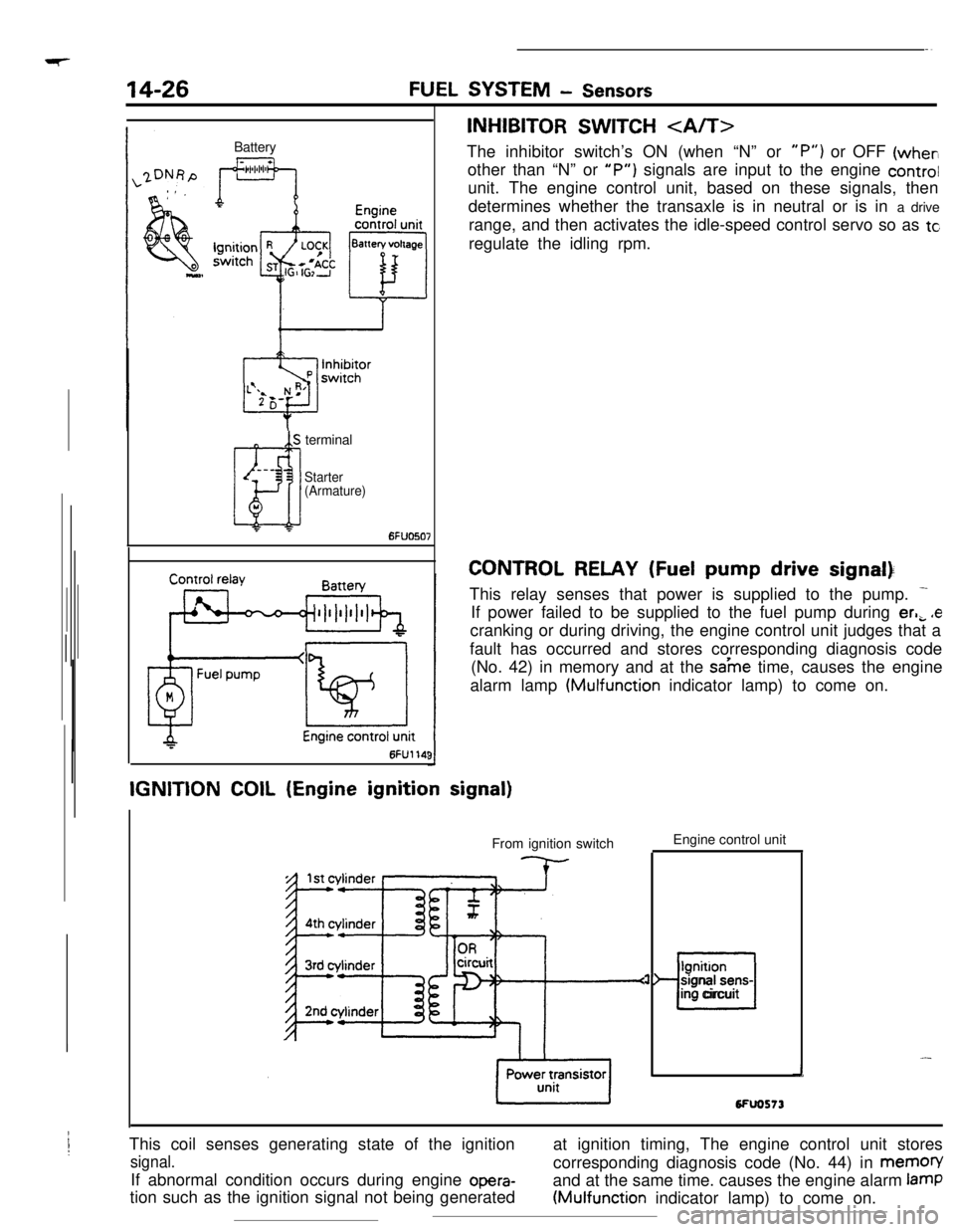

FUEL SYSTEM- Enaine Control Unit14-27

ENGINE CONTROL UNITRI4FhAA

GENERAL DESCRIPTIONEngine control unit

~

~~:~~~~~~~~~:~~

~. . . . .. .. . . . ... . . . . ... .. :+:.:.:.:.:.:.:.~.:.~+~.

6FUO76The engine control unit consists of an

8-bit micro

computer, a random access memory, a read only

memory and an input/output interface.

It determines the engine operating state based on

various information (input

signals) it receives fromthe sensors described earlier, and then controls and

activates the necessary actuators as shown in the

table below to achieve optimum engine operating

conditions.

Engine control unit

Control items

Fuel injection control

Idle speed control

Power supply control

A&;;;ditioner relay

Ignition timing control

SuTpuegohzrging control

$r;ir;;ter control

Fuel pressure control

For controlling injector driving timing

and duration based on multipoint’sequential injection.

For controlling bypass air quantity foridle speed control by activating the

idle speed control servo.

I3 Idle speed control

servo

For controlling power supply to the

sensors and actuators by controlling

the control relay.For controlling the

ON/OFF position of

the air conditioner relay.For controlling the ignition timing.

For controlling the supercharging pres-sure by regulating of the waste gate

actuator activation pressure.

For controlling the turbo meter and

displaying the supercharge pressure.

3 Ai;acenditioner

Power transistor

1

Page 140 of 391

---_-

14-28FUEL SYSTEM- Ennine Control Unit

The engine control unit has an

onboard diagnosis

function, which is used mainly to diagnose the

sensors, thus facilitating system checks and troub-leshooting. It also has a fail-safe/backup function tc

ensure passenger and vehicle safety.

Onboard self-

diagnosisMainly for detecting failure of sensors

and foroutputting diagnosis code.

for detecting failure of sensors, etc. related

toemission control and to turn ON warning light

(Malfunction indicator light).

> Codes can be read by voltmeter.

ENGINE CHECK light is turned

2 ON.

The engine control unit is mounted in the passenger compart-

ment, at the location indicated in the illustration.,

Page 141 of 391

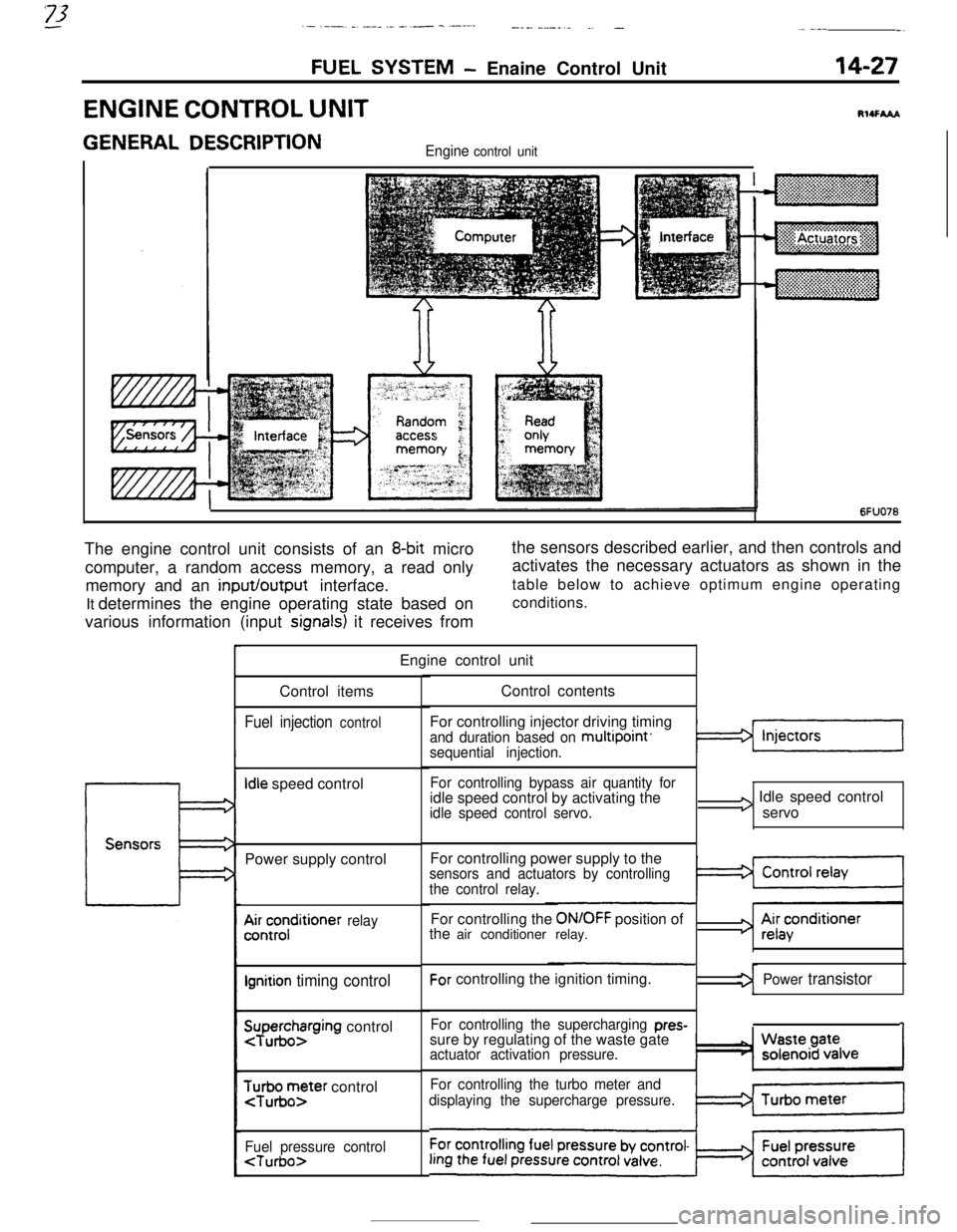

FUEL SYSTEM- Engine Control Unit14-29

SFUllSOTerminal

ConnectionTerminalConnectionNo.

No.

1Self-diagnosis output53EGR control solenoid valve (California only)

2Diagnosis/data transfer select terminal54Power transrstor for No. 1 and No. 4 cylinder

‘3Turbo meter

55Power transistor for No. 2 and No. 3 cylinder

4Oxygen sensor56Control relay (Fuel pump control)

5Power steering oil pressure switchl 57Fuel-pressure control valve

6Idle position switch58Coil “Al ” for idle speed control servo

7Air conditioner switch59Coil “A2” for idle speed control servo

8Intake air temperature sensor60No. 3 injector

l 9Detonation sensor61No. 4 injector

10Air flow sensor62Purge control solenoid valve11

-63Control relay

12Ignition timing adjustment connector64Engine warning irght (Malfunction indicator light)

13Control relay (Fuel pump drive signal)65Air conditioner relay

l 14Air flow sensor active filter reset66Control relay

15EGR temperature sensor (California only)67Coil “Bl ” for idle speed control servo

16Barometric pressure sensor68Coil “B2” for idle speed control servo

17Sensors ground101Ground

18Vehicle speed sensor102Power supply

19Throttle position sensor103Power supply for backup

20Coolant temperature sensor

104Inhibitor switch

21Crank angle sensor‘105

Waste gate solenoid valve

22Top dead center sensor106Ground

23Power supply for sensors (5 volts)107Power supply

24Sensors ground108“ST” terminal for ignition switch

51No. 1 injector109Ignition pulse detect

52No. 2 injector170“IG ” terminal for ignition switch

NOTETerminals indicated by the l symbol are applicable only to turbo models.