display MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 9 of 391

GENERAL - Technical Featureso-5ENGINE

The engines are the transverse-mounted engine

especially for front-engine/front-wheeldrive orfront-engine/4-wheel drive models, the

2.OL DOHC

16-valve engine with high-performance, silent-

operation,low-vibration,low-noise,low-fuel-

consumption features, an engine that fully displays

the most

up-todate engine technology.

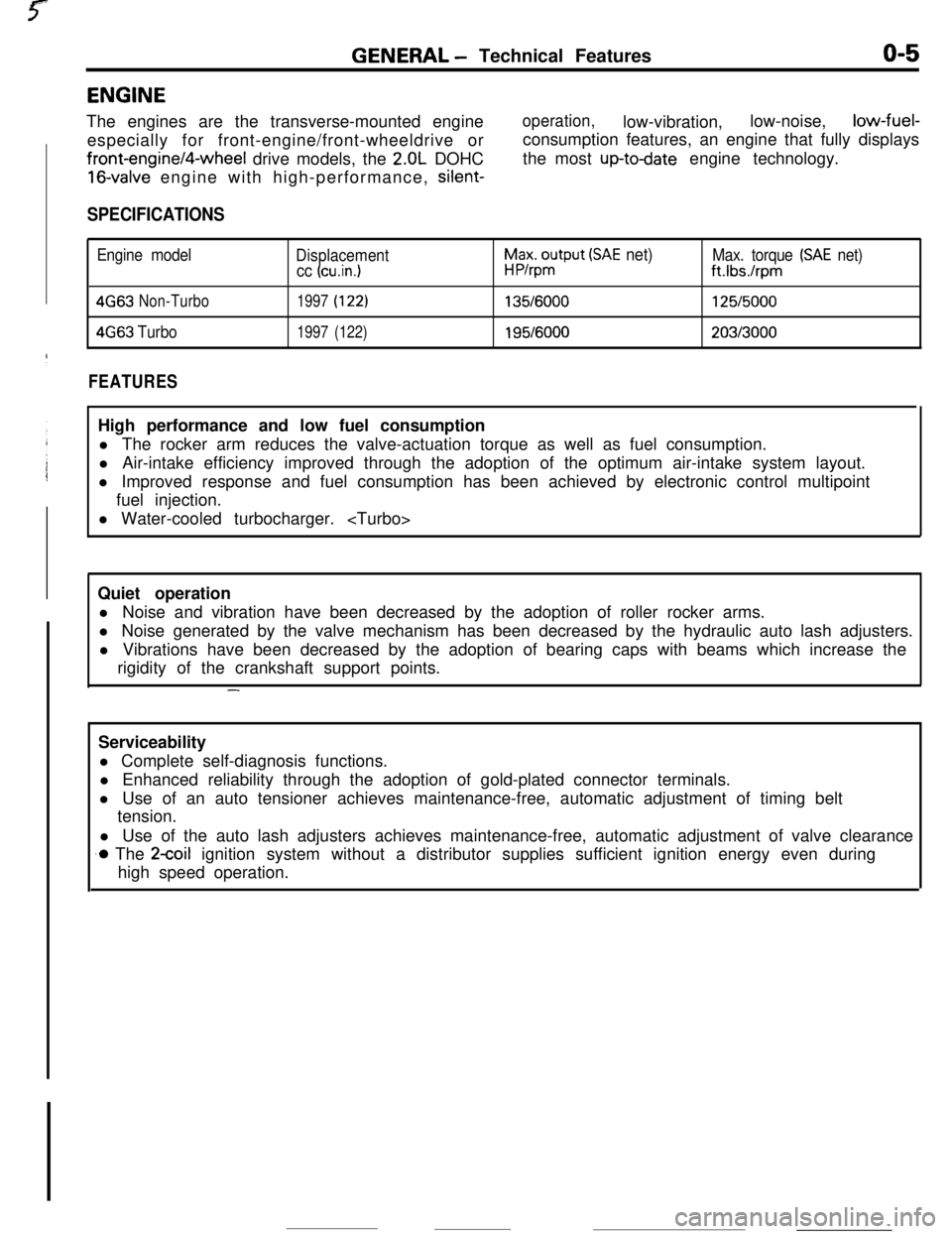

SPECIFICATIONS

Engine model

Displacement

cc (cu.in.1

h$xo$put (SAE net)Max. torque (SAE net)

ft.Ibs./rpm

4G63Non-Turbo1997(122)135/6000125/5000

4663Turbo1997(122)195/6000203/3000

FEATURESHigh performance and low fuel consumption

l The rocker arm reduces the valve-actuation torque as well as fuel consumption.

l Air-intake efficiency improved through the adoption of the optimum air-intake system layout.

l Improved response and fuel consumption has been achieved by electronic control multipoint

fuel injection.

l Water-cooled turbocharger.

Quiet operation

l Noise and vibration have been decreased by the adoption of roller rocker arms.

l Noise generated by the valve mechanism has been decreased by the hydraulic auto lash adjusters.

l Vibrations have been decreased by the adoption of bearing caps with beams which increase the

rigidity of the crankshaft support points.

-Serviceability

l Complete self-diagnosis functions.

l Enhanced reliability through the adoption of gold-plated connector terminals.

l Use of an auto tensioner achieves maintenance-free, automatic adjustment of timing belt

tension.

l Use of the auto lash adjusters achieves maintenance-free, automatic adjustment of valve clearance

.o The 2coil ignition system without a distributor supplies sufficient ignition energy even during

high speed operation.

Page 139 of 391

‘73.- .-_ _ .-__ .- -..- - .-----___. _____^. -._ __--.

FUEL SYSTEM- Enaine Control Unit14-27

ENGINE CONTROL UNITRI4FhAA

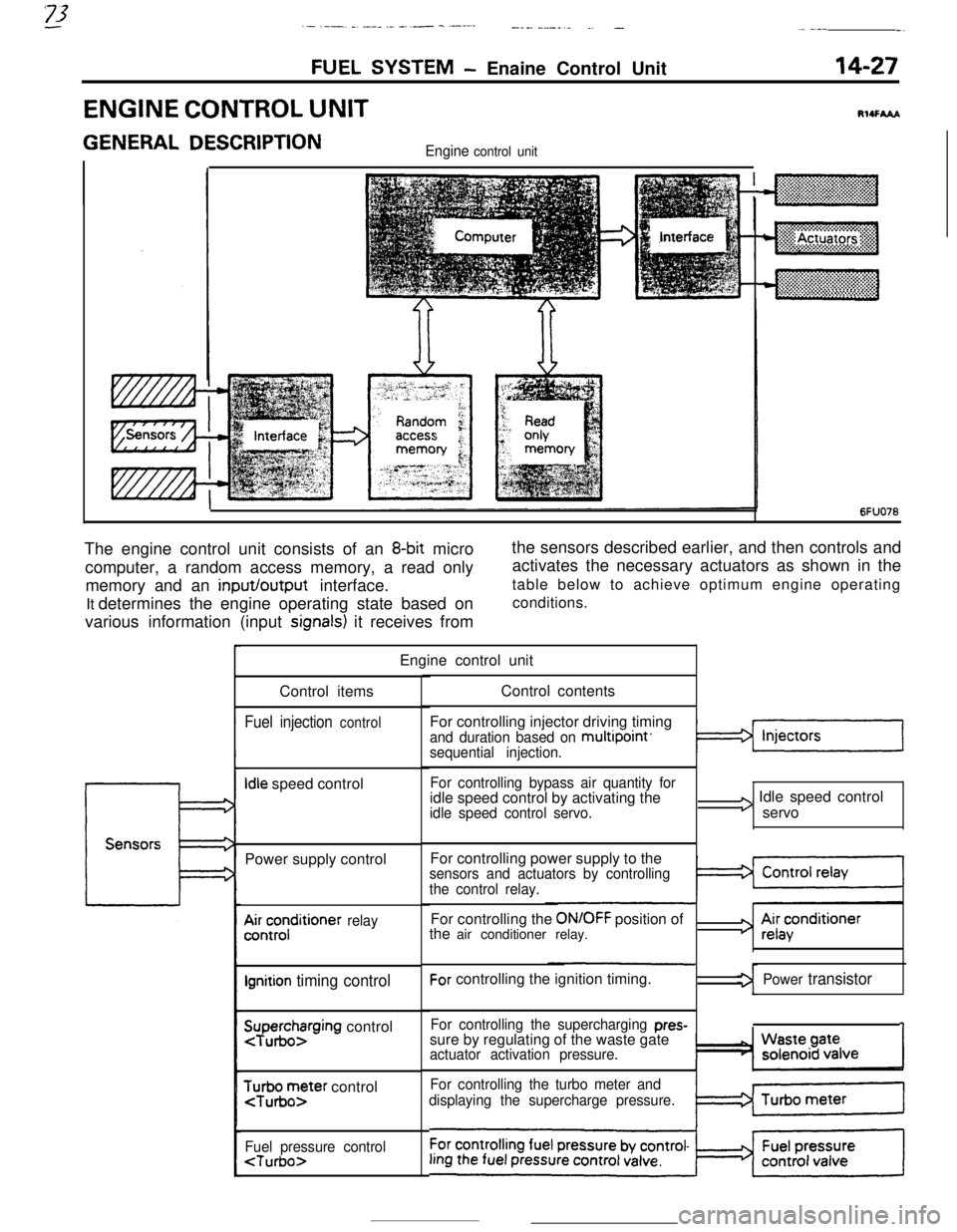

GENERAL DESCRIPTIONEngine control unit

~

~~:~~~~~~~~~:~~

~. . . . .. .. . . . ... . . . . ... .. :+:.:.:.:.:.:.:.~.:.~+~.

6FUO76The engine control unit consists of an

8-bit micro

computer, a random access memory, a read only

memory and an input/output interface.

It determines the engine operating state based on

various information (input

signals) it receives fromthe sensors described earlier, and then controls and

activates the necessary actuators as shown in the

table below to achieve optimum engine operating

conditions.

Engine control unit

Control items

Fuel injection control

Idle speed control

Power supply control

A&;;;ditioner relay

Ignition timing control

SuTpuegohzrging control

$r;ir;;ter control

Fuel pressure control

For controlling injector driving timing

and duration based on multipoint’sequential injection.

For controlling bypass air quantity foridle speed control by activating the

idle speed control servo.

I3 Idle speed control

servo

For controlling power supply to the

sensors and actuators by controlling

the control relay.For controlling the

ON/OFF position of

the air conditioner relay.For controlling the ignition timing.

For controlling the supercharging pres-sure by regulating of the waste gate

actuator activation pressure.

For controlling the turbo meter and

displaying the supercharge pressure.

3 Ai;acenditioner

Power transistor

1

Page 181 of 391

FUEL SYSTEM- Auto-cruise Control System14-69

ni2nnncisv,“y’I”“.-

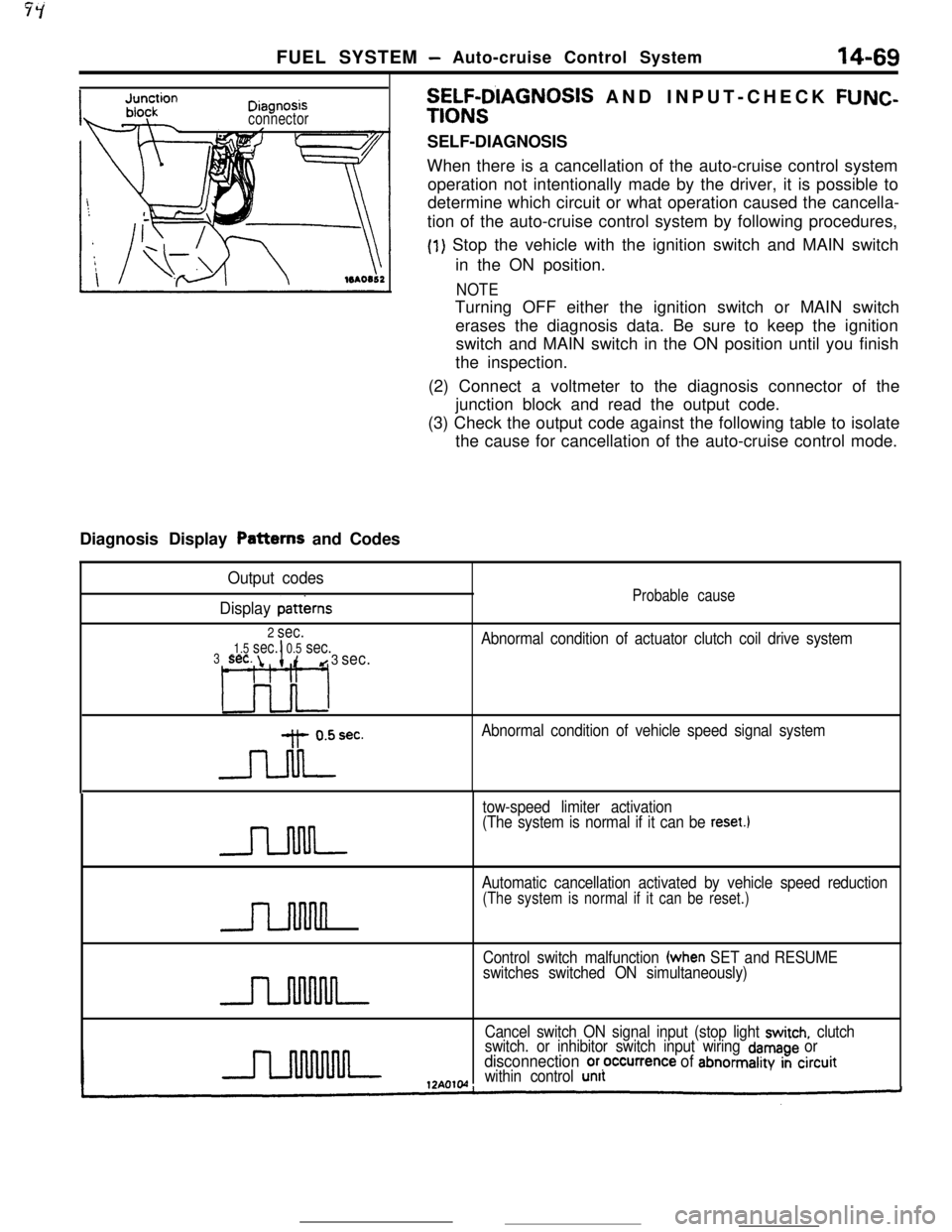

connectorDiagnosis Display Patterns and Codes

SELF-D’IAGNOSIS AND INPUT-CHECK FUNC-

TIONSSELF-DIAGNOSIS

When there is a cancellation of the auto-cruise control system

operation not intentionally made by the driver, it is possible to

determine which circuit or what operation caused the cancella-

tion of the auto-cruise control system by following procedures,

(1) Stop the vehicle with the ignition switch and MAIN switch

in the ON position.

NOTETurning OFF either the ignition switch or MAIN switch

erases the diagnosis data. Be sure to keep the ignition

switch and MAIN switch in the ON position until you finish

the inspection.

(2) Connect a voltmeter to the diagnosis connector of the

junction block and read the output code.

(3) Check the output code against the following table to isolate

the cause for cancellation of the auto-cruise control mode.

Output codes

Display

patterns

2 sec.

1.5 sec.I0.5 sec.3sec. id 3 sec.

L3o-l

-Jdrec.

Probable cause

Abnormal condition of actuator clutch coil drive system

Abnormal condition of vehicle speed signal system

tow-speed limiter activation

(The system is normal if it can be

reset.1

n

Automatic cancellation activated by vehicle speed reduction

(The system is normal if it can be reset.)

Control switch malfunction (when SET and RESUME

switches switched ON simultaneously)

Cancel switch ON signal input (stop light

switch, clutch

switch. or inhibitor switch input wiring damage ordisconnection or,occurrence of abnormality in circuitwithin control unit

Page 182 of 391

14-70

-_FUEL SYSTEM

- Auto-cruise Control System

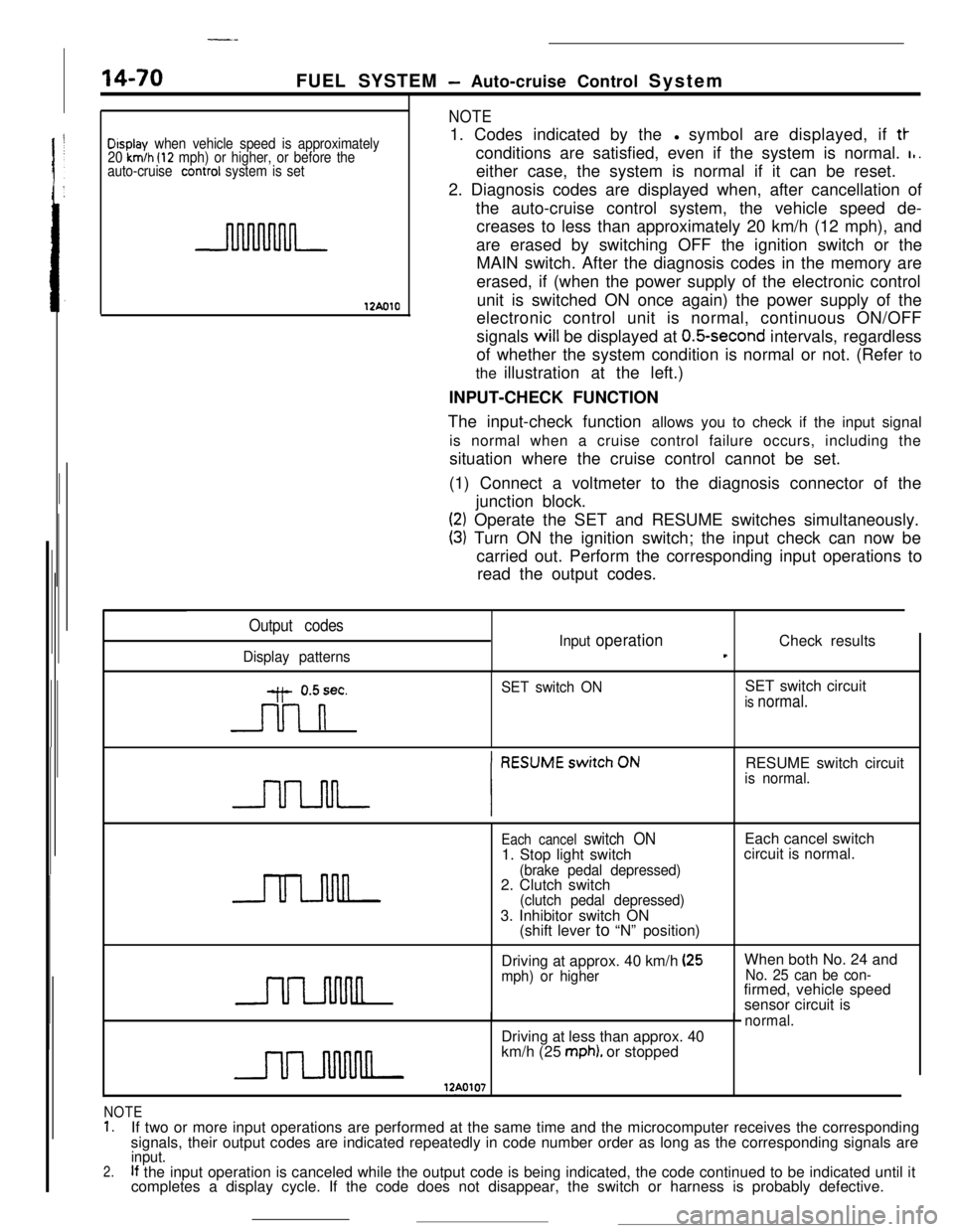

Display when vehicle speed is approximately

20 km/h (12 mph) or higher, or before the

auto-cruise conrrol system is set

12AolO

NOTE1. Codes indicated by thel symbol are displayed, if

tt-conditions are satisfied, even if the system is normal.

I,.either case, the system is normal if it can be reset.

2. Diagnosis codes are displayed when, after cancellation of

the auto-cruise control system, the vehicle speed de-

creases to less than approximately 20 km/h (12 mph), and

are erased by switching OFF the ignition switch or the

MAIN switch. After the diagnosis codes in the memory are

erased, if (when the power supply of the electronic control

unit is switched ON once again) the power supply of the

electronic control unit is normal, continuous ON/OFF

signals will be displayed at

O.&second intervals, regardless

of whether the system condition is normal or not. (Refer to

the illustration at the left.)

INPUT-CHECK FUNCTION

The input-check function allows you to check if the input signal

is normal when a cruise control failure occurs, including the

situation where the cruise control cannot be set.

(1) Connect a voltmeter to the diagnosis connector of the

junction block.

(2) Operate the SET and RESUME switches simultaneously.

(3) Turn ON the ignition switch; the input check can now be

carried out. Perform the corresponding input operations to

read the output codes.

Output codes

Display patternsInput

operationCheck resultst

y- 0.5sec.

n

SET switch ONSET switch circuitis normal.RESUME switch circuit

is normal.

Each cancel switch ON1. Stop light switch

(brake pedal depressed)2. Clutch switch

(clutch pedal depressed)3. Inhibitor switch ON

(shift lever to “N” position)Each cancel switch

circuit is normal.

Driving at approx. 40 km/h

(25mph) or higherWhen both No. 24 andNo. 25 can be con-firmed, vehicle speed

sensor circuit is

normal.Driving at less than approx. 40

km/h (25

mph). or stopped

NOTE1.If two or more input operations are performed at the same time and the microcomputer receives the corresponding

signals, their output codes are indicated repeatedly in code number order as long as the corresponding signals are

2.input.If the input operation is canceled while the output code is being indicated, the code continued to be indicated until it

completes a display cycle. If the code does not disappear, the switch or harness is probably defective.

Page 275 of 391

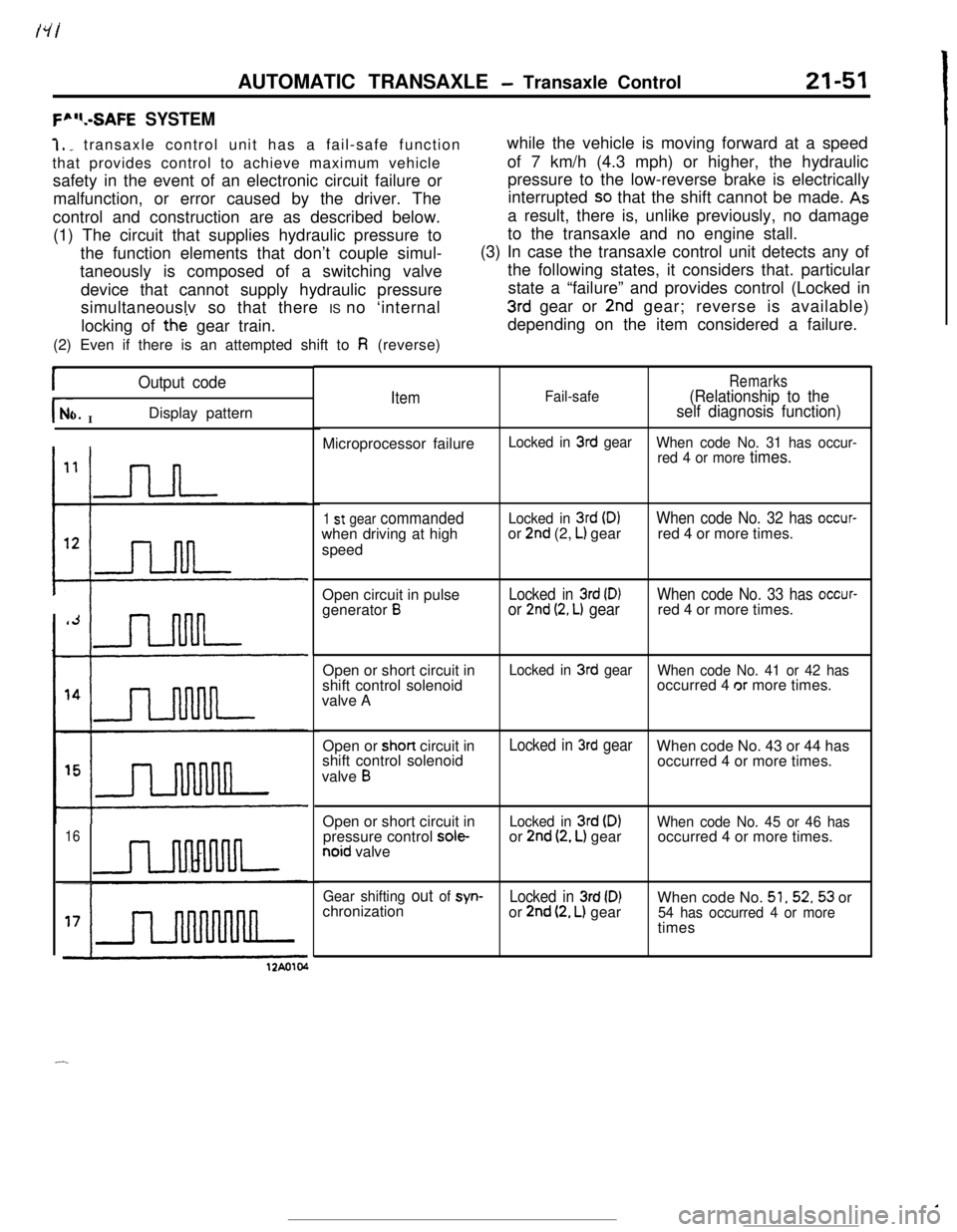

AUTOMATIC TRANSAXLE - Transaxle Control21-51

F”“.-SAFE SYSTEM7,

_ transaxle control unit has a fail-safe function

that provides control to achieve maximum vehicle

safety in the event of an electronic circuit failure or

malfunction, or error caused by the driver. The

control and construction are as described below.

(1) The circuit that supplies hydraulic pressure to

the function elements that don’t couple simul-

taneously is composed of a switching valve

device that cannot supply hydraulic pressure

simultaneouslv so that there IS no ‘internal

locking of the gear train.

(2) Even if there is an attempted shift to

Fi (reverse)while the vehicle is moving forward at a speed

of 7 km/h (4.3 mph) or higher, the hydraulic

pressure to the low-reverse brake is electrically

interrupted

SO that the shift cannot be made. Asa result, there is, unlike previously, no damage

to the transaxle and no engine stall.

(3) In case the transaxle control unit detects any of

the following states, it considers that. particular

state a “failure” and provides control (Locked in

3rd gear or 2nd gear; reverse is available)

depending on the item considered a failure.

IOutput code

r- INo.Display pattern

16

ItemFail-safeRemarks(Relationship to the

self diagnosis function)Microprocessor failure

Locked in 3rd gear

When code No. 31 has occur-

red 4 or more

times.

1 st gear commandedwhen driving at high

speedLocked in 3rd (D)or 2nd (2, L) gearWhen code No. 32 has occur-red 4 or more times.

Open circuit in pulse

generator

BLocked in 3rd (D)or 2nd (2, L) gearWhen code No. 33 has occur-red 4 or more times.

Open or short circuit in

shift control solenoid

valve A

Locked in 3rd gear

When code No. 41 or 42 hasoccurred 4 or more times.

Open or short circuit in

shift control solenoid

valve

B

Locked in 3rd gearWhen code No. 43 or 44 has

occurred 4 or more times.

Open or short circuit in

pressure control

sole-noid valve

Locked in 3rd (DIor 2nd (2, L) gearWhen code No. 45 or 46 hasoccurred 4 or more times.

Gear shifting out of syn-Locked in 3rd (D)When code No. 51,52,53 or

chronization

or 2nd (2, L) gear54 has occurred 4 or moretimes

12Ao104

-

Page 276 of 391

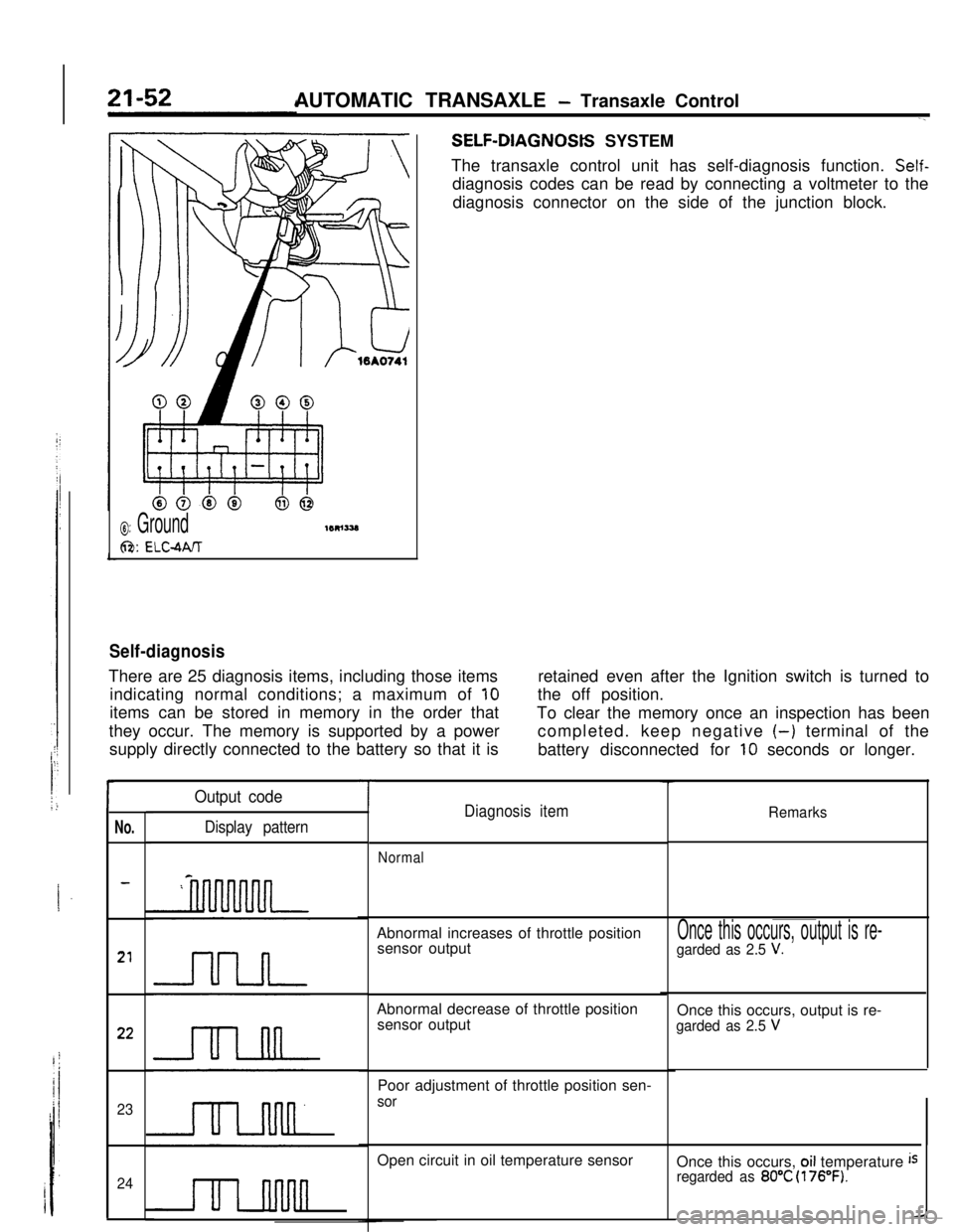

AUTOMATIC TRANSAXLE - Transaxle ControlSELF-DIAGNOStS SYSTEM

The transaxle control unit has self-diagnosis function.

Self-diagnosis codes can be read by connecting a voltmeter to the

diagnosis connector on the side of the junction block.

0: Ground

6%: ELC-MIT

Self-diagnosisThere are 25 diagnosis items, including those items

indicating normal conditions; a maximum of

10items can be stored in memory in the order that

they occur. The memory is supported by a power

supply directly connected to the battery so that it isretained even after the Ignition switch is turned to

the off position.

To clear the memory once an inspection has been

completed. keep negative

(-) terminal of the

battery disconnected for

10 seconds or longer.

r

No.

23

24

Output code

Display pattern

TDiagnosis itemRemarks

NormalAbnormal increases of throttle position

sensor output

Abnormal decrease of throttle position

sensor output

Poor adjustment of throttle position sen-

sorOpen circuit in oil temperature sensor

Once this occurs, output is re-

garded as 2.5 V.Once this occurs, output is re-

garded as 2.5 VOnce this occurs,

oil temperature isregarded as 80°C (176°F).

Page 277 of 391

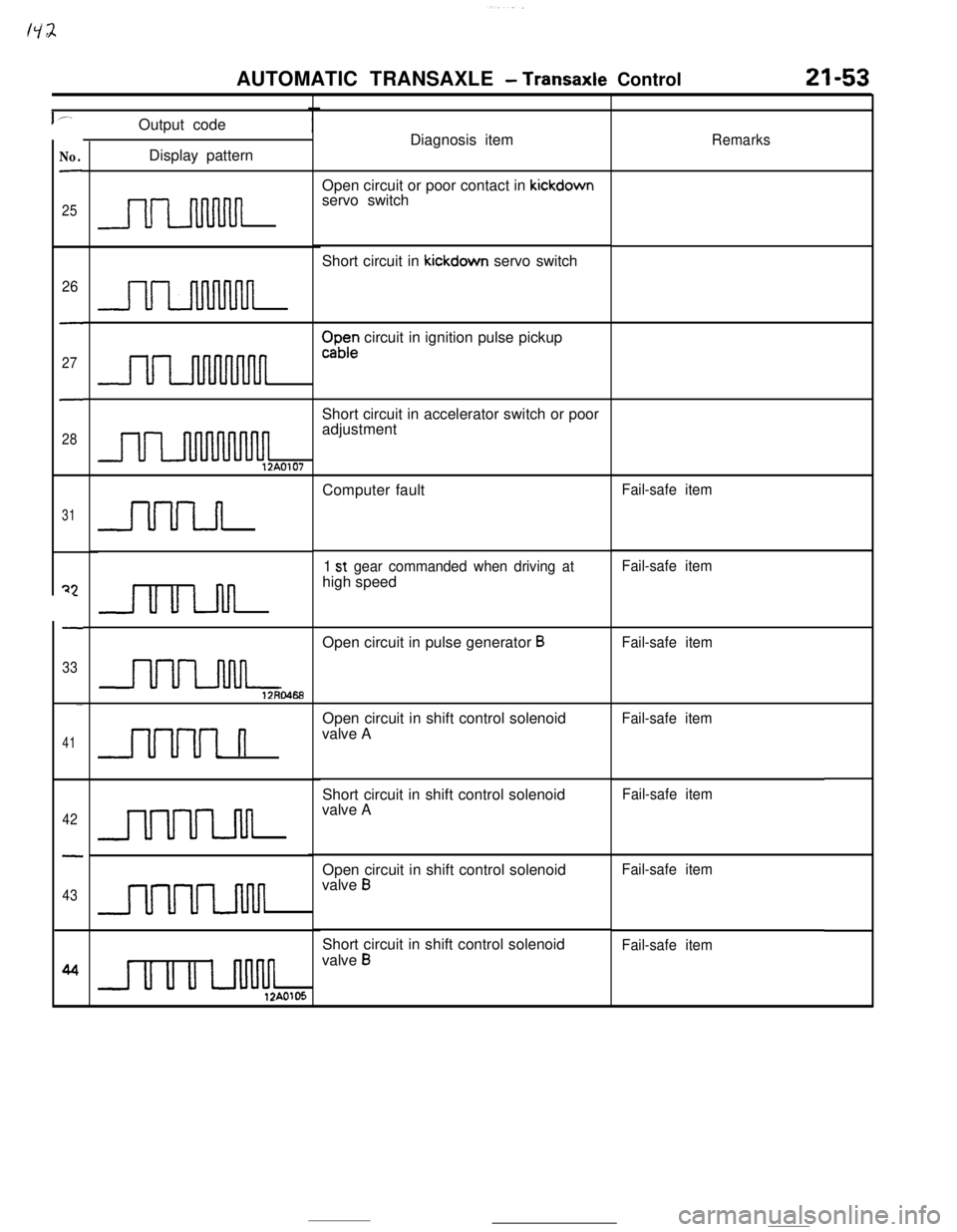

AUTOMATIC TRANSAXLE - Transaxle Control21-53

I-.

No.-

25Output code

Diagnosis item

RemarksDisplay pattern

Open circuit or poor contact in kickdown

servo switch

IJLluuul~Short circuit in kickdown servo switch

26

-

27

-

28

u1n

CIaD; circuit in ignition pulse pickup

U1Short circuit in accelerator switch or poor

adjustment

UI12A0107

31Computer fault

Fail-safe item

uu-ln

Fail-safe item

1 st gear commanded when driving athigh speed

22

-

33

II u LnnOpen circuit in pulse generator

BFail-safe item

-

41Open circuit in shift control solenoid

valve A

Fail-safe item

nShort circuit in shift control solenoid

valve A

Fail-safe item

42

-

43

UUULMOpen circuit in shift control solenoid

valve

B

Fail-safe item

UULJMShort circuit in shift control solenoid

valve

BFail-safe item

u II II LJM12A0105

Page 278 of 391

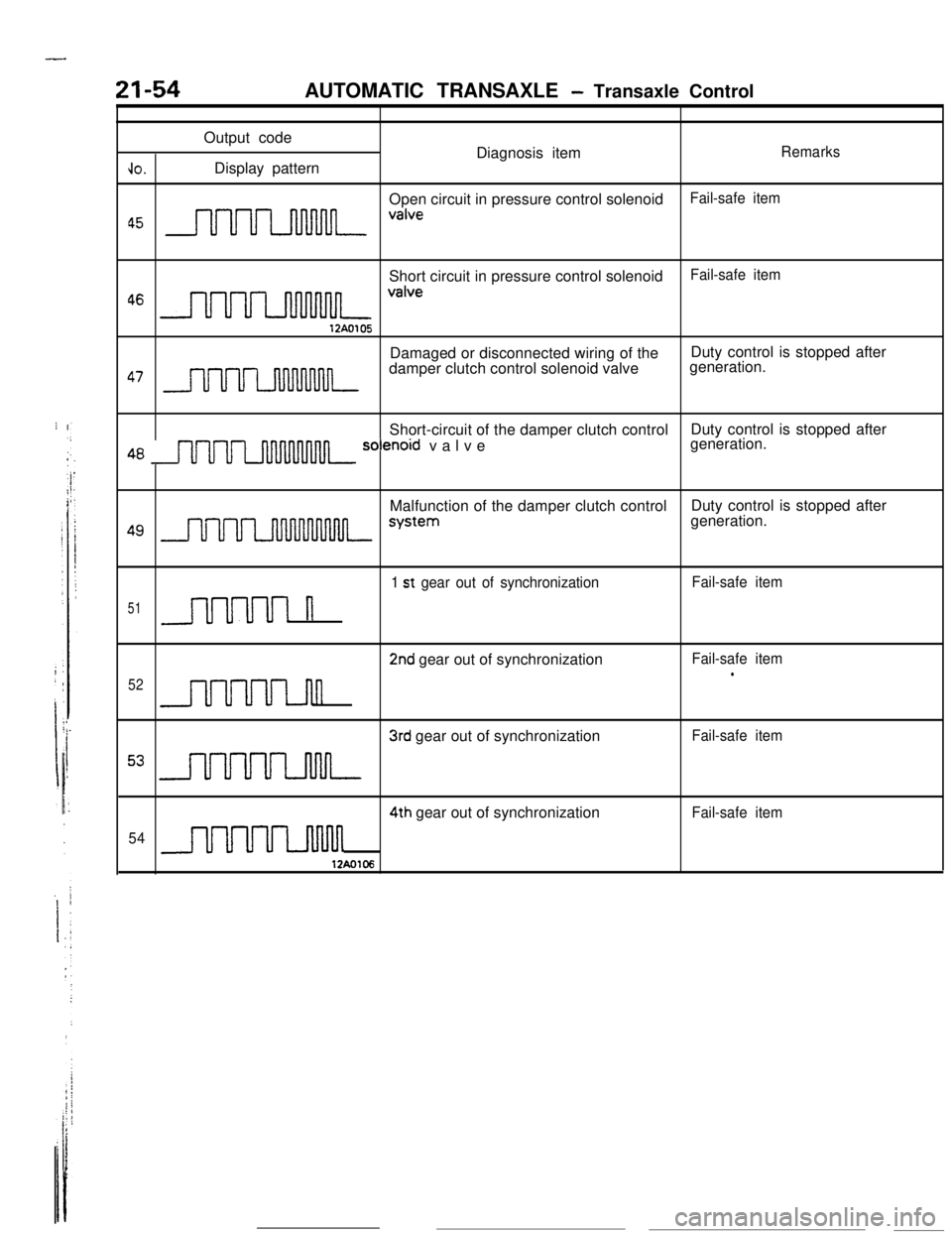

-21-54AUTOMATIC TRANSAXLE

- Transaxle Control

Output code

Diagnosis item

Remarks

JO.Display pattern

Open circuit in pressure control solenoid

Fail-safe item

a5 nnnn valveShort circuit in pressure control solenoid

Fail-safe item

46 m valve12A0105Damaged or disconnected wiring of theDuty control is stopped after

47 nnru7_nnnnnnndamper clutch control solenoid valvegeneration.

Short-circuit of the damper clutch controlDuty control is stopped after

48 m solenord valvegeneration.

Malfunction of the damper clutch controlDuty control is stopped after

49 J- systemgeneration.

1 st gear out of synchronizationFail-safe item

51n

2nd gear out of synchronizationFail-safe iteml52n

3rd gear out of synchronizationFail-safe item

53 m4th gear out of synchronization

Fail-safe item

54

uuum12Ao106