engine coolant MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 59 of 391

ELECTRICAL -Relavs, Control Units and Sensors

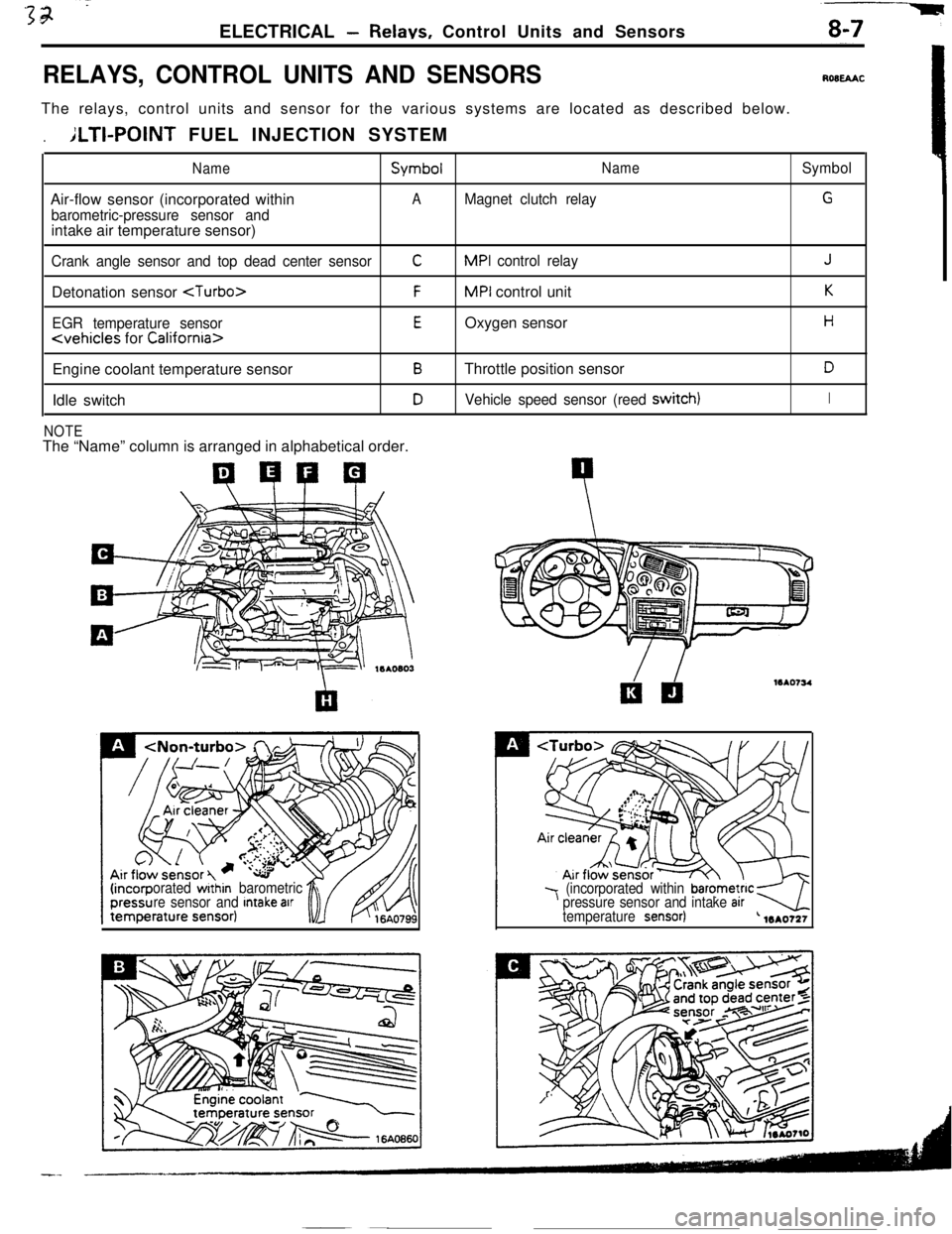

RELAYS, CONTROL UNITS AND SENSORSROBEAACThe relays, control units and sensor for the various systems are located as described below.

.ILTI-POINT FUEL INJECTION SYSTEM

NameSymbolNameSymbolAir-flow sensor (incorporated within

AMagnet clutch relayG

barometric-pressure sensor andintake air temperature sensor)

Crank angle sensor and top dead center sensorCMPI control relayJDetonation sensor

EGR temperature sensorEOxygen sensorH

Engine coolant temperature sensor

BThrottle position sensorDIdle switch

DVehicle speed sensor (reed switch)I

NOTEThe “Name” column is arranged in alphabetical order.

orated within barometric

re sensor and Intake arr7 (incorporated within barometnc kpressure sensor and intake arrtemperature sensor)-4L 1mo721

Page 63 of 391

1ELECTRICAL

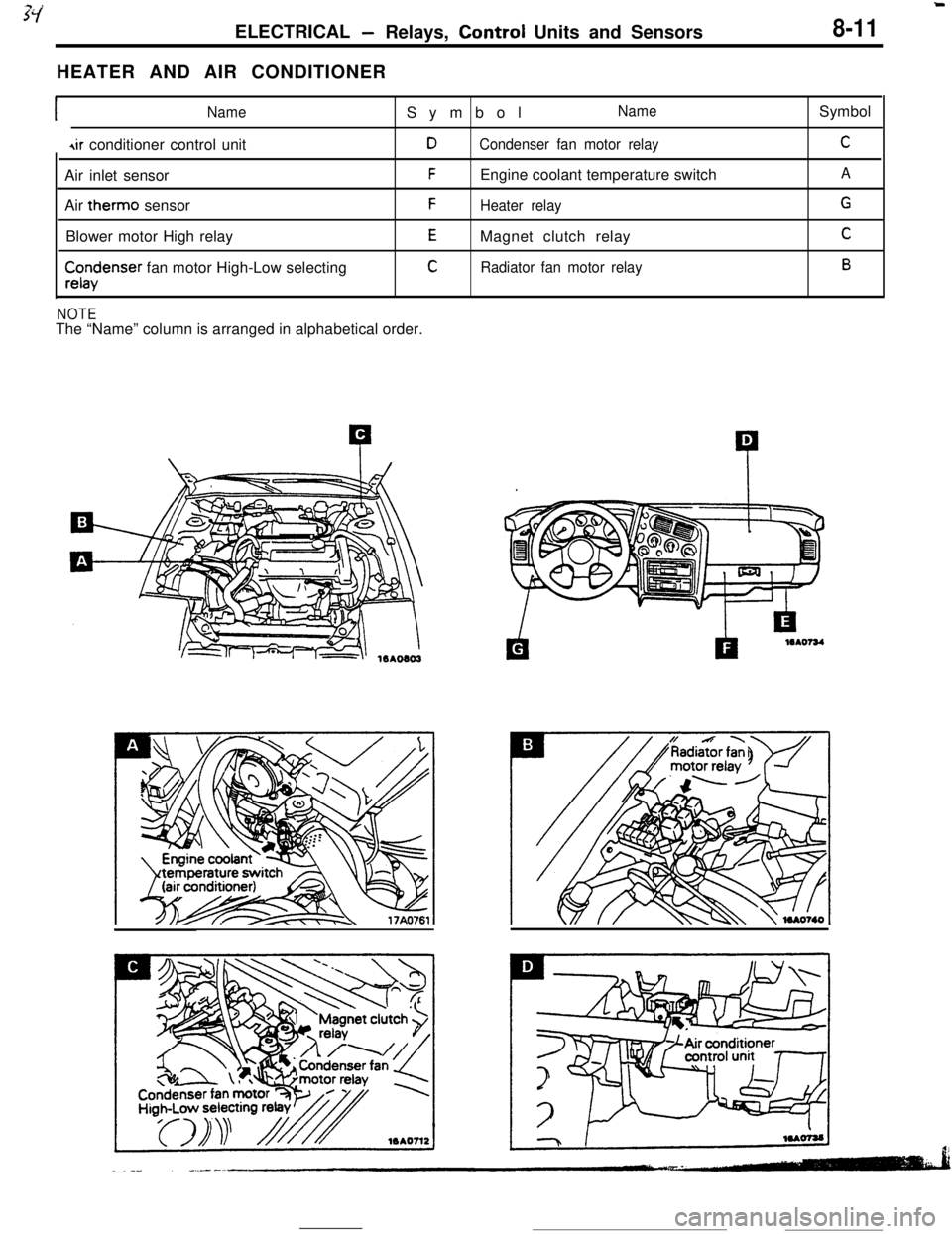

-Relays, Control Units and Sensors8-11HEATER AND AIR CONDITIONER

INameSymbolName

4ir conditioner control unitDCondenser fan motor relayAir inlet sensor

FEngine coolant temperature switch

Air therm0 sensor

FHeater relayBlower motor High relay

EMagnet clutch relay

$x$enser fan motor High-Low selectingCRadiator fan motor relay

NOTEThe “Name” column is arranged in alphabetical order.Symbol

C

A

G

C

B

Page 79 of 391

-----. _-- ___ELECTRICAL

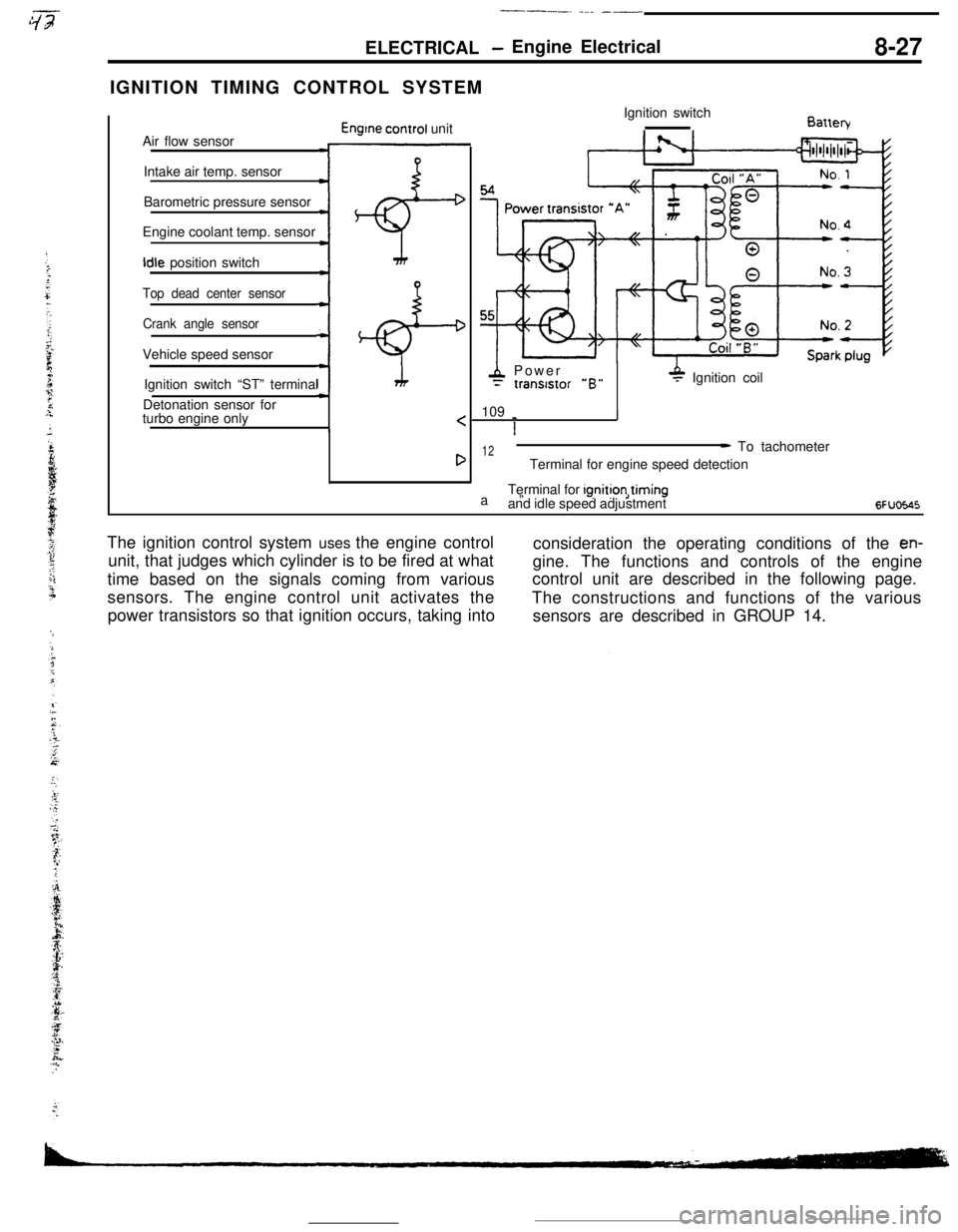

- Engine Electrical8-27IGNITION TIMING CONTROL SYSTEM

Air flow sensor

Engtne control unit

Intake air temp. sensor

Barometric pressure sensor

Engine coolant temp. sensorIdle position switch

:+

Top dead center sensor

Crank angle sensorVehicle speed sensor

;+Ignition switch “ST” terminal

Detonation sensor for

turbo engine only

4 Power= tranststor “B”P Ignition coil

109

_

I

1

12a”- To tachometer

Terminal for engine speed detection

Terminal for ignition,timing

and idle speed adjustment

6FUoE.45The ignition control system uses the engine control

consideration the operating conditions of the

en-unit, that judges which cylinder is to be fired at what

gine. The functions and controls of the engine

time based on the signals coming from variouscontrol unit are described in the following page.

sensors. The engine control unit activates the

The constructions and functions of the various

power transistors so that ignition occurs, taking into

sensors are described in GROUP 14.

Page 80 of 391

8-28ELECTRICAL- Engine Electrical

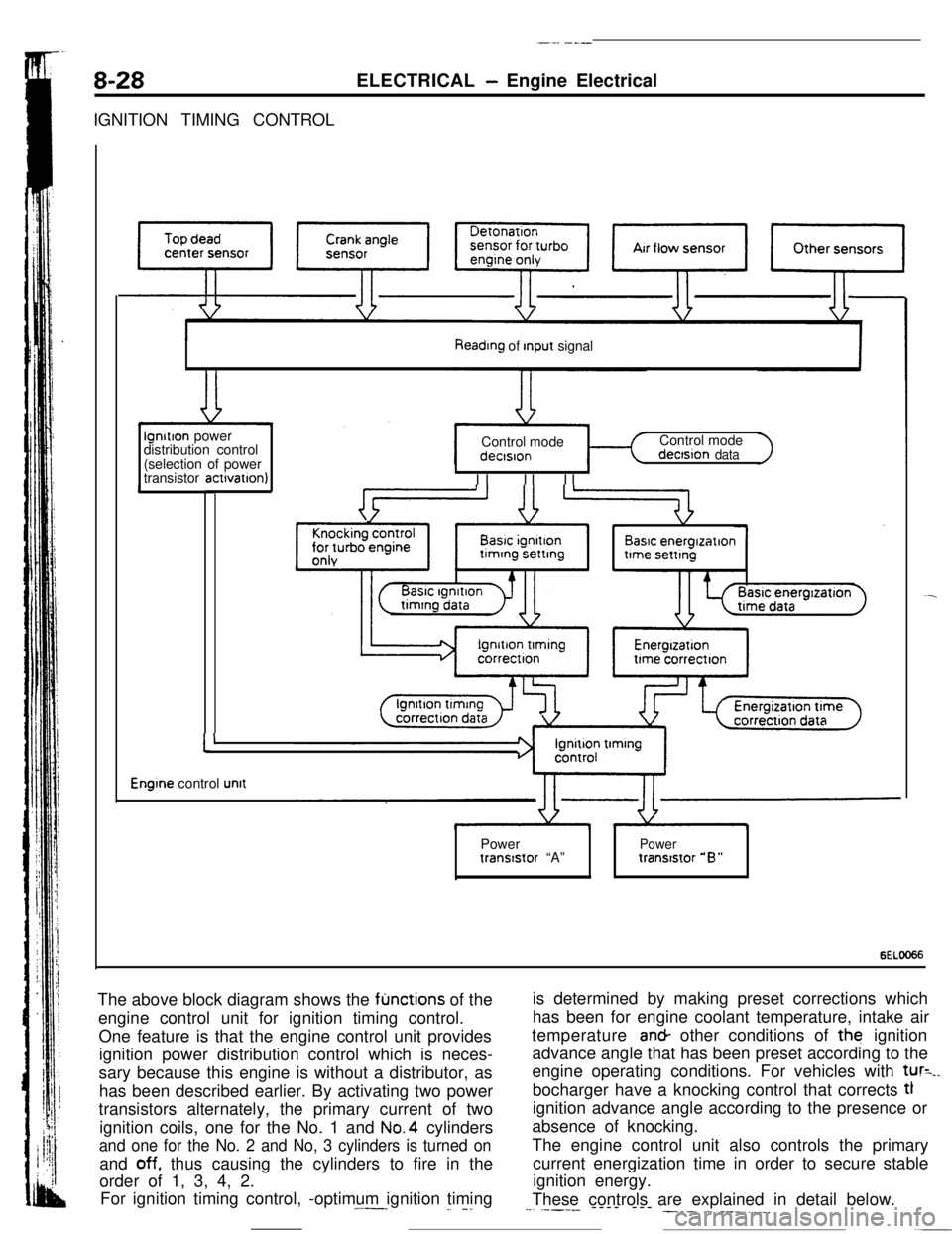

IGNITION TIMING CONTROL

Reading of Input signallgnitlon power

distribution control

(selection of power

transistor actlvatlon)Control mode

I II II IControl mode

dectsion data

Basic energlzatlon

I’

Engine control unitPower

Powertranststor “A”tranststor “B”

6ELOO66The above block diagram shows the

fljnctions of the

engine control unit for ignition timing control.

One feature is that the engine control unit provides

ignition power distribution control which is neces-

sary because this engine is without a distributor, as

has been described earlier. By activating two power

transistors alternately, the primary current of two

ignition coils, one for the No. 1 and No.4 cylinders

and one for the No. 2 and No, 3 cylinders is turned onand

off. thus causing the cylinders to fire in the

order of 1, 3, 4, 2.

For ignition timing control, -optimum ignition timing.^--_

_. -.is determined by making preset corrections which

has been for engine coolant temperature, intake air

temperature an& other conditions of the ignition

advance angle that has been preset according to the

engine operating conditions. For vehicles with

tur=_.bocharger have a knocking control that corrects tl

ignition advance angle according to the presence or

absence of knocking.

The engine control unit also controls the primary

current energization time in order to secure stable

ignition energy.

These controls are explained in detail below.

--. .----- ---- --- ___. .-. ___.,.__

Page 82 of 391

8-30ELECTRICAL - Engine Electrical

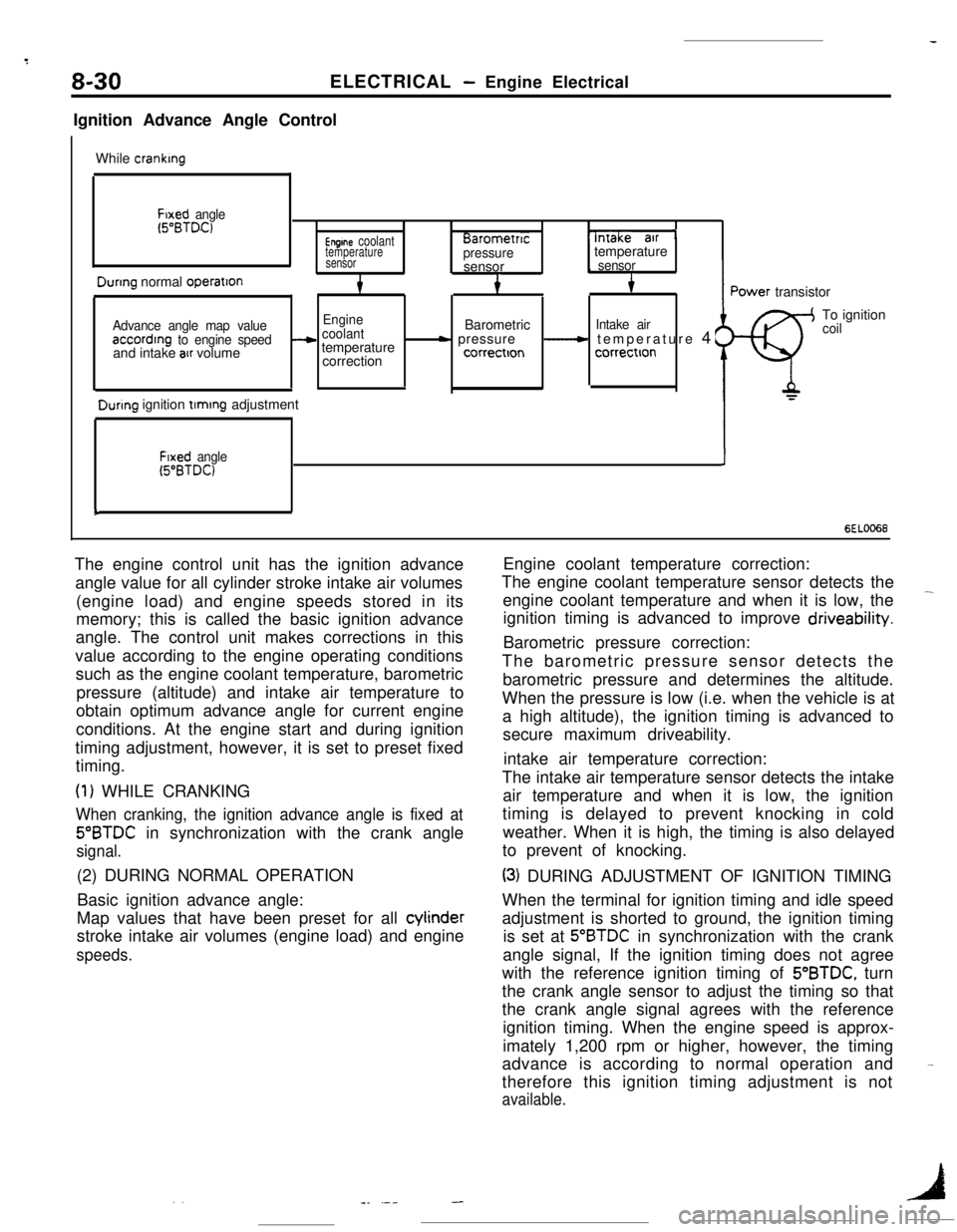

Ignition Advance Angle Control

While

cranking

Fixed angle(5”BTD.C)Engme coolantBarometnc‘-Intake air 1temperaturepressuretemperaturesensorsensor, sensor

Dunng normal operatlon4i+

Advance angle map valueEngine

coolantBarometricIntake airaccording to engine speed4and intake air volumetemperature- pressure__c temperature 4

correctioncorrectloncorrectton

Durtng ignition tlmmg adjustment

Fixed angle(5”BTDC)

c

=ower transistor

-$To ignition

coil

s

6EL0066The engine control unit has the ignition advance

angle value for all cylinder stroke intake air volumes

(engine load) and engine speeds stored in its

memory; this is called the basic ignition advance

angle. The control unit makes corrections in this

value according to the engine operating conditions

such as the engine coolant temperature, barometric

pressure (altitude) and intake air temperature to

obtain optimum advance angle for current engine

conditions. At the engine start and during ignition

timing adjustment, however, it is set to preset fixed

timing.

(1) WHILE CRANKING

When cranking, the ignition advance angle is fixed at

5”BTDC in synchronization with the crank angle

signal.(2) DURING NORMAL OPERATION

Basic ignition advance angle:

Map values that have been preset for all cylinder

stroke intake air volumes (engine load) and engine

speeds.Engine coolant temperature correction:

The engine coolant temperature sensor detects the

engine coolant temperature and when it is low, the

-ignition timing is advanced to improve driveability.

Barometric pressure correction:

The barometric pressure sensor detects the

barometric pressure and determines the altitude.

When the pressure is low (i.e. when the vehicle is at

a high altitude), the ignition timing is advanced to

secure maximum driveability.

intake air temperature correction:

The intake air temperature sensor detects the intake

air temperature and when it is low, the ignition

timing is delayed to prevent knocking in cold

weather. When it is high, the timing is also delayed

to prevent of knocking.

(3) DURING ADJUSTMENT OF IGNITION TIMING

When the terminal for ignition timing and idle speed

adjustment is shorted to ground, the ignition timing

is set at

5”BTDC in synchronization with the crank

angle signal, If the ignition timing does not agree

with the reference ignition timing of 5’BTDC, turn

the crank angle sensor to adjust the timing so that

the crank angle signal agrees with the reference

ignition timing. When the engine speed is approx-

imately 1,200 rpm or higher, however, the timing

advance is according to normal operation and

therefore this ignition timing adjustment is not

available.

-

. .1-_ .---

Page 83 of 391

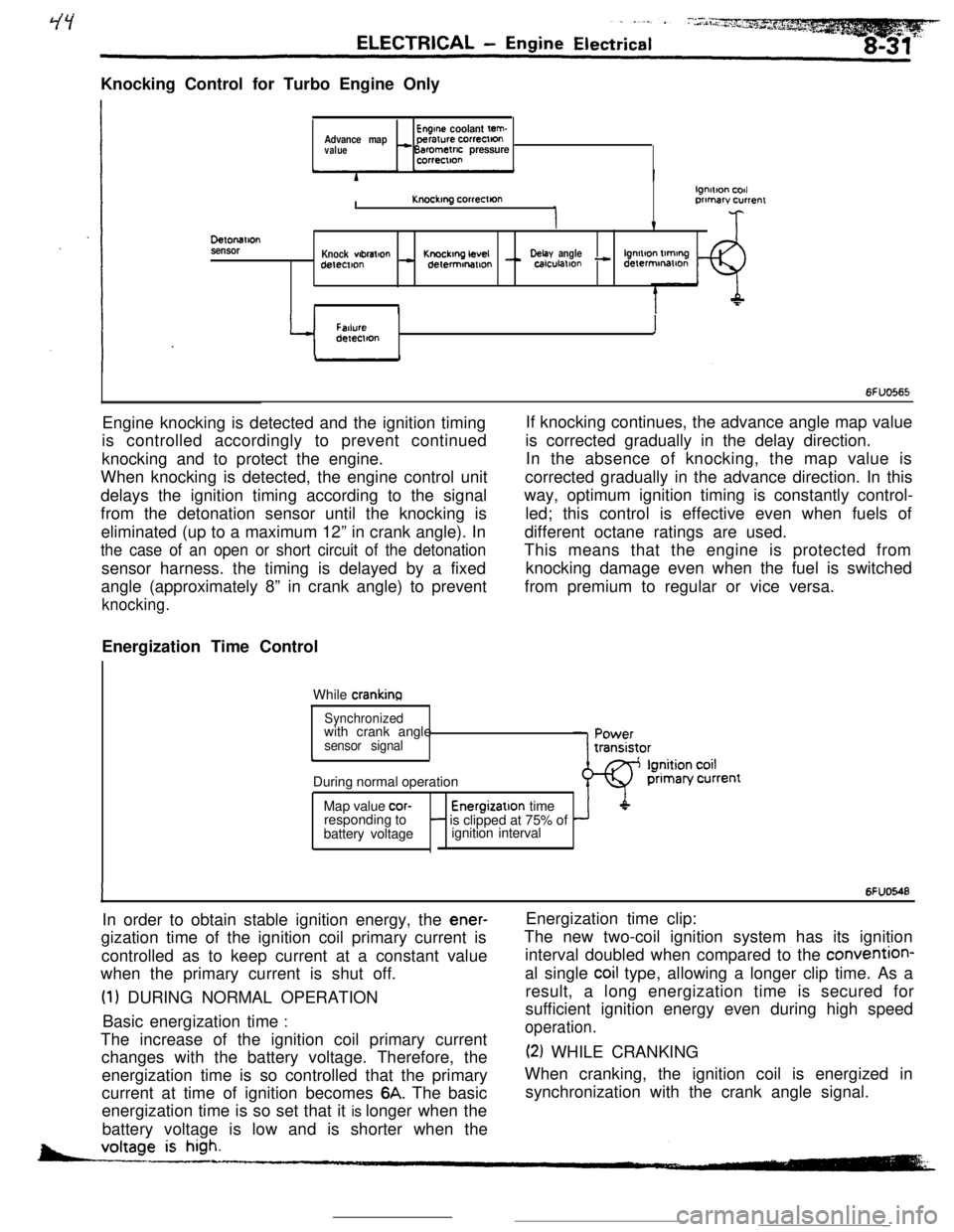

Knocking Control for Turbo Engine OnlyEngine coolant tern.Advance mapperarure correctton

value- Barometric pressurecorrectton

DelonaIlon

sensorI

lgnmon codKnockmg correcllonprimary currenr

v

Knock wbral+onKnockmg LevelDelay anglelgnmon tlmtngdetemon- delermonmon - calculallon - derermmatlon

II

Y

FatlureIdeIeclton

6FUO565Engine knocking is detected and the ignition timing

is controlled accordingly to prevent continued

knocking and to protect the engine.

When knocking is detected, the engine control unit

delays the ignition timing according to the signal

from the detonation sensor until the knocking is

eliminated (up to a maximum 12” in crank angle). In

the case of an open or short circuit of the detonationsensor harness. the timing is delayed by a fixed

angle (approximately 8” in crank angle) to prevent

knocking.Energization Time Control

While

crankinaIf knocking continues, the advance angle map value

is corrected gradually in the delay direction.

In the absence of knocking, the map value is

corrected gradually in the advance direction. In this

way, optimum ignition timing is constantly control-

led; this control is effective even when fuels of

different octane ratings are used.

This means that the engine is protected from

knocking damage even when the fuel is switched

from premium to regular or vice versa.

Synchronizedwith crank angle

sensor signalcDuring normal operation

Map value

cor-Energizatlon time

responding to- is clipped at 75% of

battery voltageignition interval

IIn order to obtain stable ignition energy, the

ener-gization time of the ignition coil primary current is

controlled as to keep current at a constant value

when the primary current is shut off.

(1) DURING NORMAL OPERATION

Basic energization time

:The increase of the ignition coil primary current

changes with the battery voltage. Therefore, the

energization time is so controlled that the primary

current at time of ignition becomes

6A. The basic

energization time is so set that it is longer when the

battery voltage is low and is shorter when the

6FUO548Energization time clip:

The new two-coil ignition system has its ignition

interval doubled when compared to the convention-

al single

coil type, allowing a longer clip time. As a

result, a long energization time is secured for

sufficient ignition energy even during high speed

operation.

(2) WHILE CRANKING

When cranking, the ignition coil is energized in

synchronization with the crank angle signal.

-

Page 94 of 391

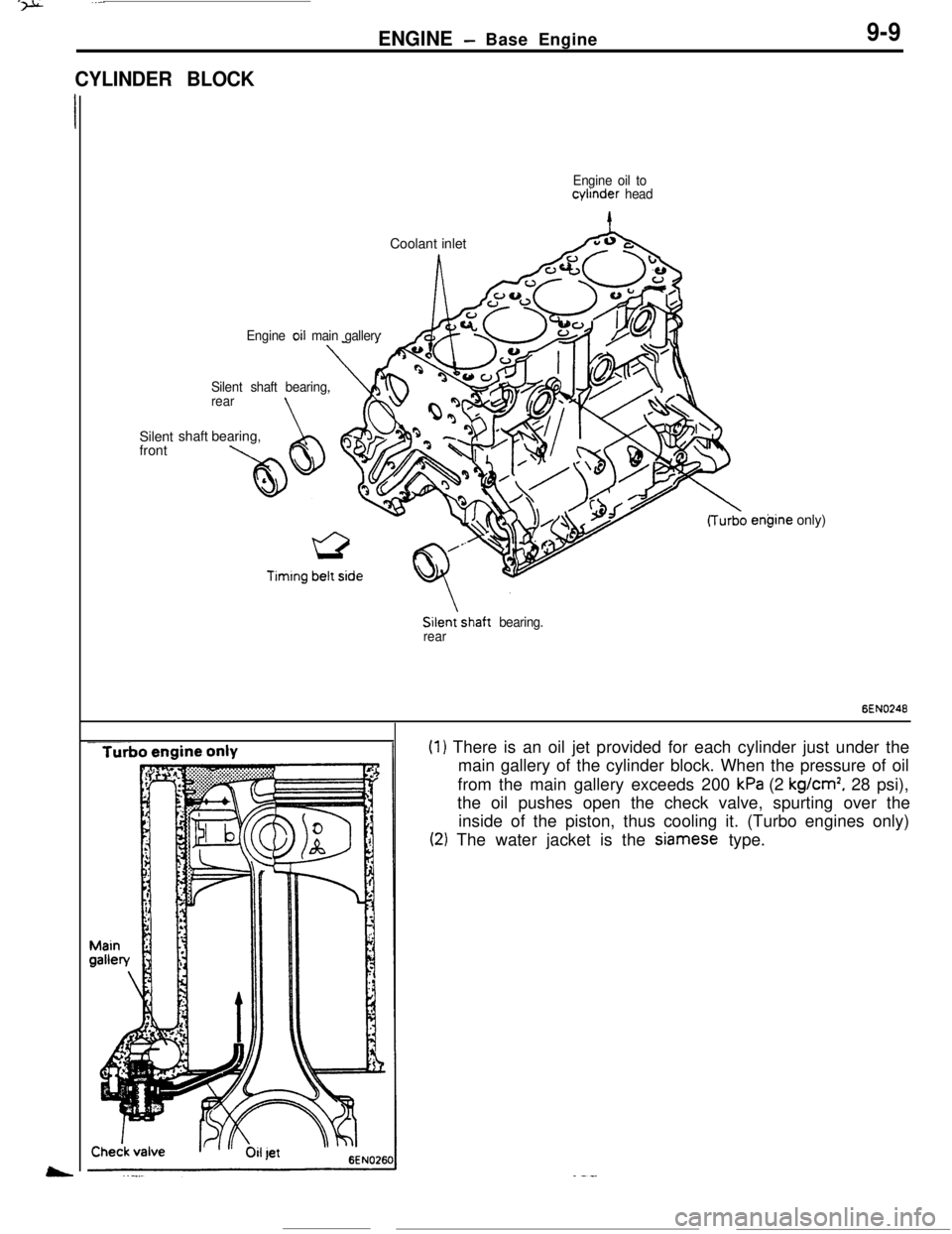

CYLINDER BLOCKENGINE

- Base Engine9-9

Engine oil tocylinder

headCoolant inlet

ASilent

front

Engine oil main gallery

Silent shaft bearing,

rear

\shaft bearing,

A taw

Silenishaft bearing.

rearengine only)

6EN0246

(1) There is an oil jet provided for each cylinder just under the

main gallery of the cylinder block. When the pressure of oil

from the main gallery exceeds 200

kPa (2 kg/cm’, 28 psi),

the oil pushes open the check valve, spurting over the

inside of the piston, thus cooling it. (Turbo engines only)

(2) The water jacket is the Siamese type.

Page 115 of 391

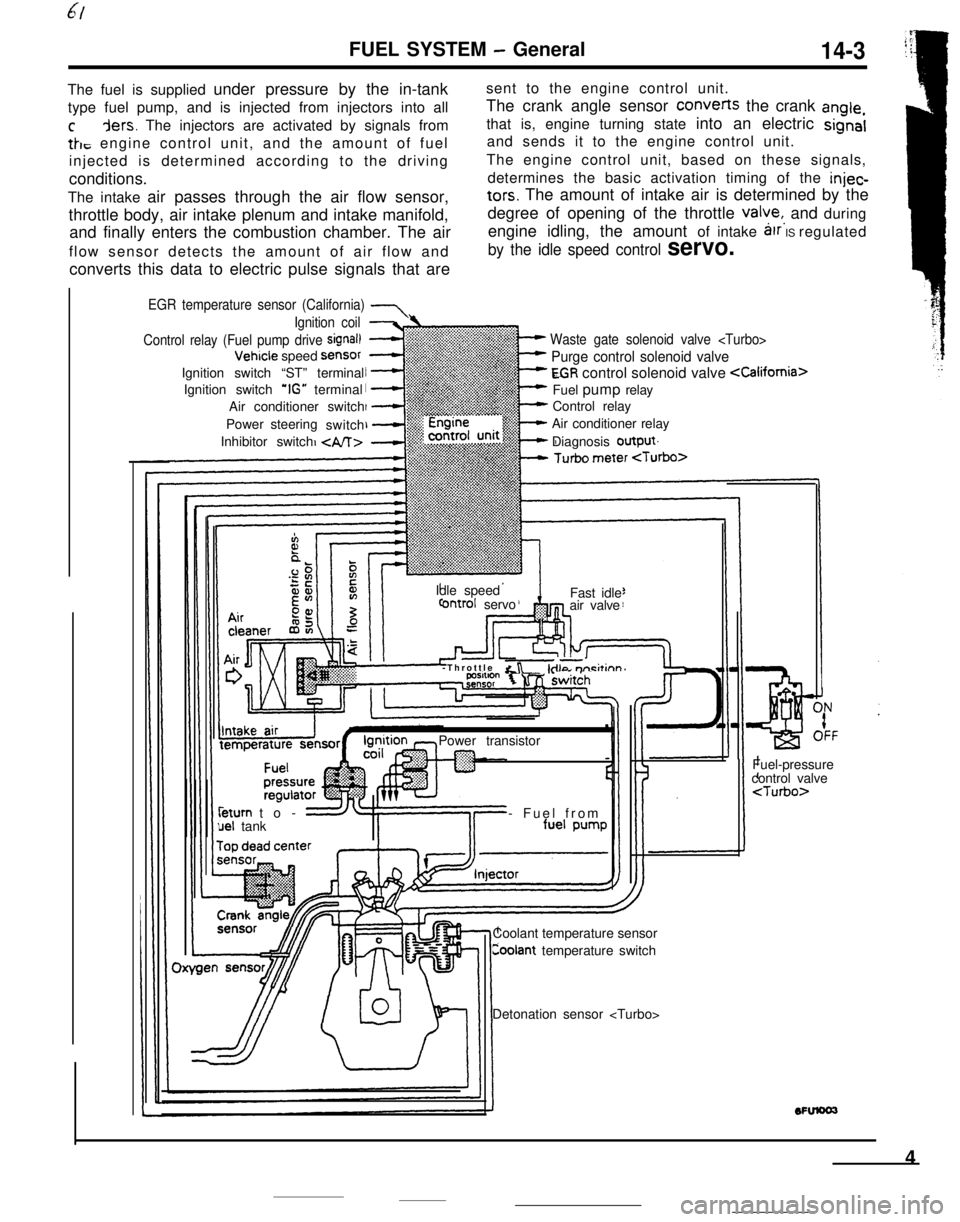

FUEL SYSTEM - General14-3The fuel is supplied under pressure by the in-tanksent to the engine control unit.

type fuel pump, and is injected from injectors into allThe crank angle sensor converts the crank

angle,

cders. The injectors are activated by signals fromthat is, engine turning state into an electric signal

tk, engine control unit, and the amount of fueland sends it to the engine control unit.

injected is determined according to the drivingThe engine control unit, based on these signals,

conditions.determines the basic activation timing of the

injec-The intake air passes through the air flow sensor,

tars. The amount of intake air is determined by the

throttle body, air intake plenum and intake manifold,degree of opening of the throttle

valye,, and during

and finally enters the combustion chamber. The airengine idling, the amount of intake

arr IS regulated

flow sensor detects the amount of air flow and

by the idle speed control servo.converts this data to electric pulse signals that are

EGR temperature sensor (California) 7

Waste gate solenoid valve

Purge control solenoid valve

EGR control solenoid valve

Control relay

Air conditioner relay

Diagnosis output

Ignition coil

Control relay (Fuel pump drive

signal)Vehicle speed

SensorIgnition switch “ST” terminal

Ignition switch

‘IG” terminal

Air conditioner switch

Power steering

switch

Inhibitor switch

Idle speed

ontrol servoFast idle

air valve

-Throttle

&r -kilo m-i&inn’Power transistorleturn to-

uel tank- Fuel from

Coolant temperature sensor

Coolant temperature switchFuel-pressure

control valve

4

Page 123 of 391

FUEL SYSTEM -Fuel Supply and Fuel Pressure Control

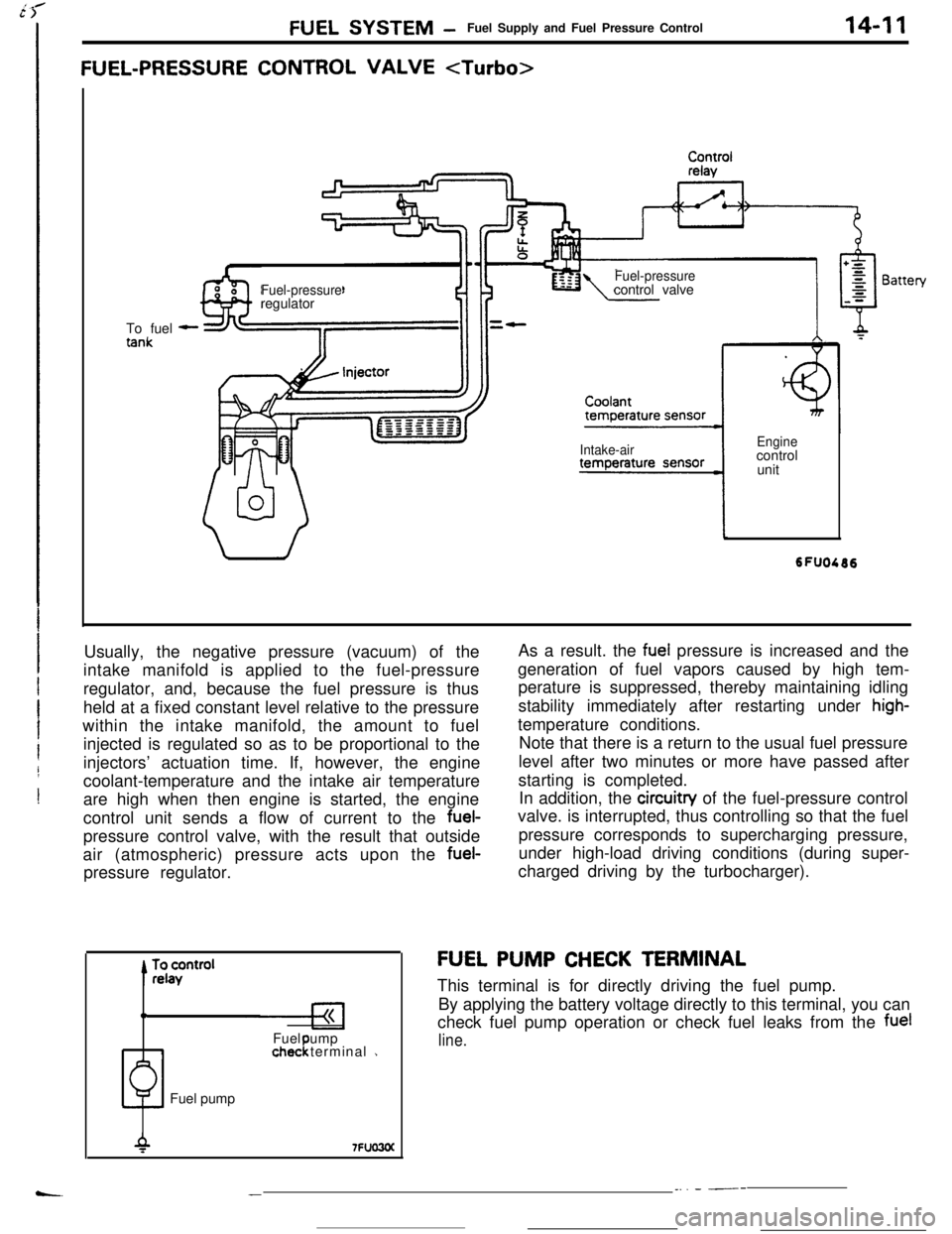

FUEL-PRESSURE CONTROL VALVE

14-11To fuel

-

Fuel-pressureregulatorFuel-pressurecontrol valve

Intake-airEnginecontrol

unit

Usually, the negative pressure (vacuum) of the

intake manifold is applied to the fuel-pressure

regulator, and, because the fuel pressure is thus

held at a fixed constant level relative to the pressure

within the intake manifold, the amount to fuel

injected is regulated so as to be proportional to the

injectors’ actuation time. If, however, the engine

coolant-temperature and the intake air temperature

are high when then engine is started, the engine

control unit sends a flow of current to the fuel-

pressure control valve, with the result that outside

air (atmospheric) pressure acts upon the fuel-

pressure regulator.

0Fuel ump

1chec terminal 1!Fuel pumpAs a result. the

fuel pressure is increased and the

generation of fuel vapors caused by high tem-

perature is suppressed, thereby maintaining idling

stability immediately after restarting under

high-temperature conditions.

Note that there is a return to the usual fuel pressure

level after two minutes or more have passed after

starting is completed.

In addition, the circuitry of the fuel-pressure control

valve. is interrupted, thus controlling so that the fuel

pressure corresponds to supercharging pressure,

under high-load driving conditions (during super-

charged driving by the turbocharger).

FU,EL PUMP CHECK TERMINAL

This terminal is for directly driving the fuel pump.

By applying the battery voltage directly to this terminal, you can

check fuel pump operation or check fuel leaks from the

fuel

line.

__. - ---

Page 124 of 391

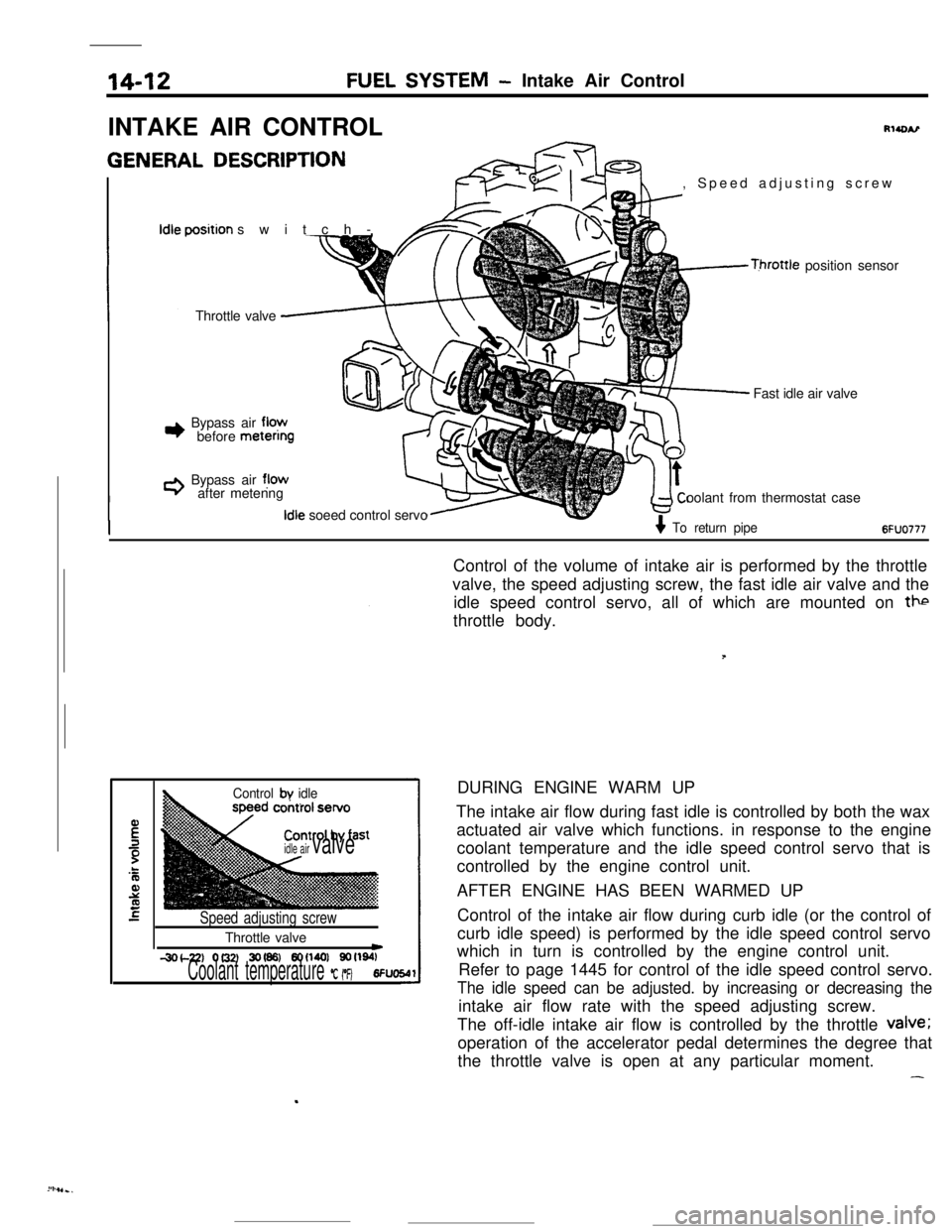

140’I2FUEL SYSTEM- Intake Air Control

INTAKE AIR CONTROL

GENERAL DESCRIPTION

Rl4oA?, Speed adjusting screwIdle oositionswitch-

Throttle valve

0

+ Bypass air flow

before metenng

Q Bypass air fjow

Iafter metenng

Idle soeed control servo

-?hrottle position sensor

Fast idle air valve

oolant from thermostat case

ITo return pipe6FUO777Control of the volume of intake air is performed by the throttle

valve, the speed adjusting screw, the fast idle air valve and the

idle speed control servo, all of which are mounted on

ttithrottle body.

iControl by idle

w/d c;zk;;fast

hhidle air valve

Speed adjusting screwThrottle valve

m-30~22) of321 sofm 6of140~ 901164

Coolant temperature ‘C (OF)6Fuo!DURING ENGINE WARM UP

The intake air flow during fast idle is controlled by both the wax

actuated air valve which functions. in response to the engine

coolant temperature and the idle speed control servo that is

controlled by the engine control unit.

AFTER ENGINE HAS BEEN WARMED UP

Control of the intake air flow during curb idle (or the control of

curb idle speed) is performed by the idle speed control servo

which in turn is controlled by the engine control unit.

Refer to page 1445 for control of the idle speed control servo.The idle speed can be adjusted. by increasing or decreasing theintake air flow rate with the speed adjusting screw.

The off-idle intake air flow is controlled by the throttle

valve;operation of the accelerator pedal determines the degree that

the throttle valve is open at any particular moment.

-

.?‘h,

. .