warning light MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 55 of 391

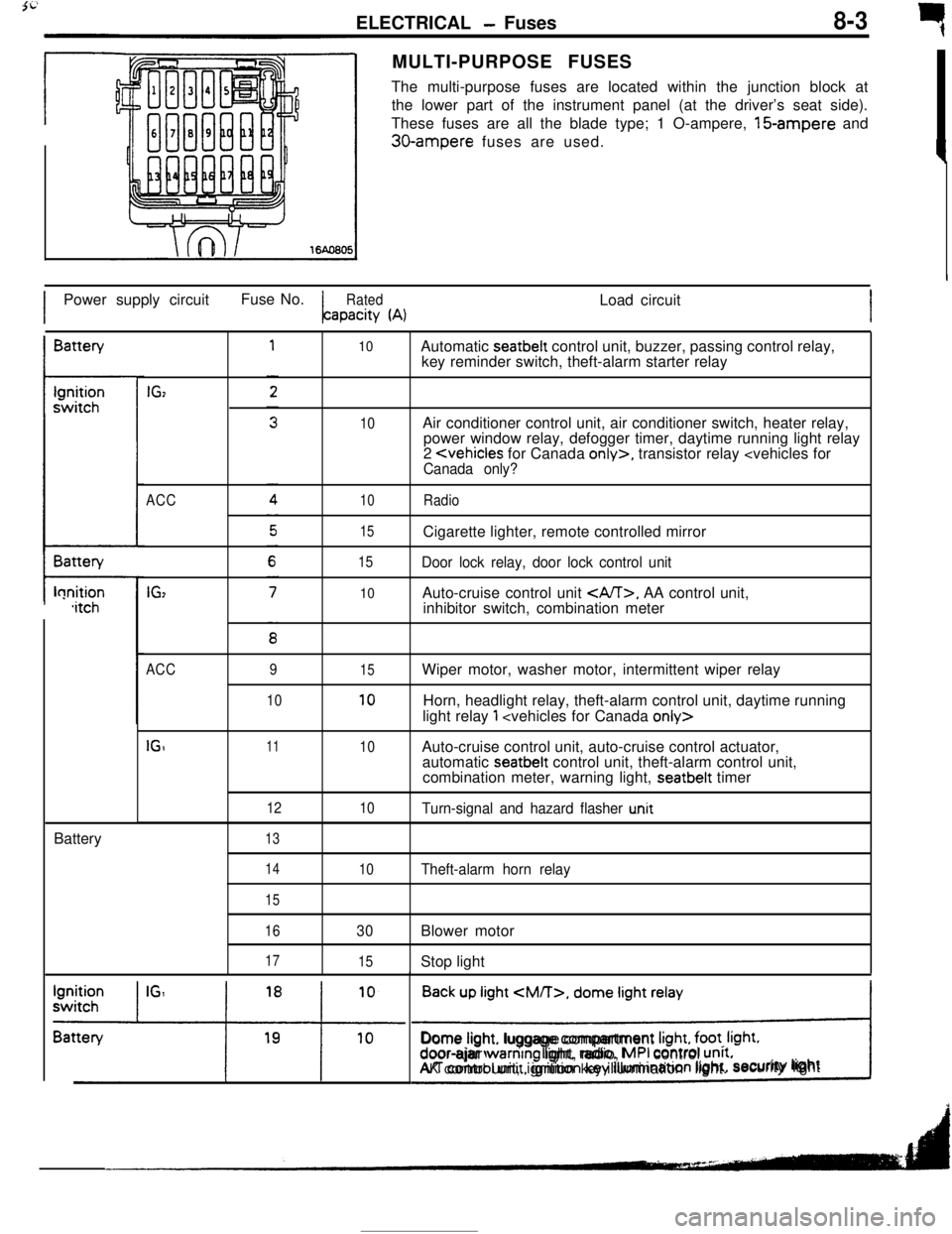

ELECTRICAL - Fuses8-3q

rMULTI-PURPOSE FUSES

The multi-purpose fuses are located within the junction block at

the lower part of the instrument panel (at the driver’s seat side).

These fuses are all the blade type; 1 O-ampere, 15-ampere and

30-ampere fuses are used.

IPower supply circuitFuse No.

RatedLoad circuitapacity

(A)IBattery

t-lonition,itchBattery

IGz

ACC

IG,

10

10

10

15

15

10Automatic seatbelt control unit, buzzer, passing control relay,

key reminder switch, theft-alarm starter relay

Air conditioner control unit, air conditioner switch, heater relay,

power window relay, defogger timer, daytime running light relay

2

Door lock relay, door lock control unitAuto-cruise control unit

, AA control unit,

inhibitor switch, combination meter

ACC

IGI9

1011

12

1315

10

10

10Wiper motor, washer motor, intermittent wiper relay

Horn, headlight relay, theft-alarm control unit, daytime running

light relay

1

automatic seatbelt control unit, theft-alarm control unit,

combination meter, warning light, seatbelt timer

Turn-signal and hazard flasher u.nit

14

15

16

17

10Theft-alarm horn relay

30Blower motor

15Stop light

Back up light

CM/T>, dome light relay

!Dome light. luggage compartment

Irght, foot. Irght.door-ajar warntng light, radio, MPI control unrt.AK control unit, ignition key illumination light.security lightI

Page 56 of 391

_--

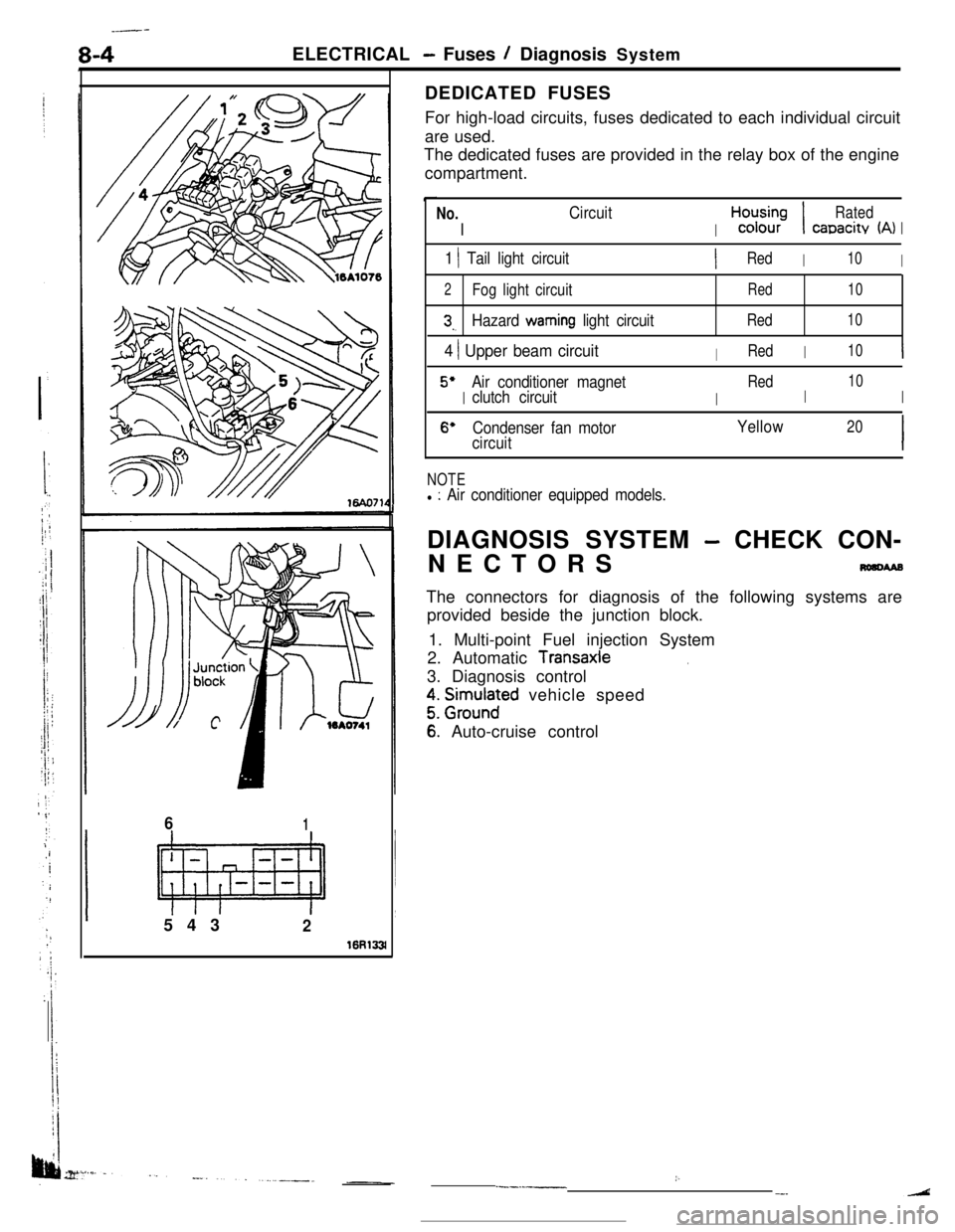

8-4ELECTRICAL - Fuses / Diagnosis System

61543

2

16R133lDEDICATED FUSES

For high-load circuits, fuses dedicated to each individual circuit

are used.

The dedicated fuses are provided in the relay box of the engine

compartment.

No.

I

Circuit

I

H,“d;;-;I

Rated

canacitv (A)I

1 1 Tail light circuitIRedI10I

2Fog light circuitRed10

3,.Hazard warning light circuitRed10

4 ) Upper beam circuitIRedI10I

5’

I

Air conditioner magnet

I

Red

I

10

clutch circuitI

6’Condenser fan motorYellow20

circuitI

NOTEl : Air conditioner equipped models.DIAGNOSIS SYSTEM

- CHECK CON-

NECTORS

nmcwaBThe connectors for diagnosis of the following systems are

provided beside the junction block.

1. Multi-point Fuel injection System

2. Automatic

Transaxle.3. Diagnosis control

z. grm.rlnaFd vehicle speed

6: Auto-cruise control

:..--.-__-.

Page 84 of 391

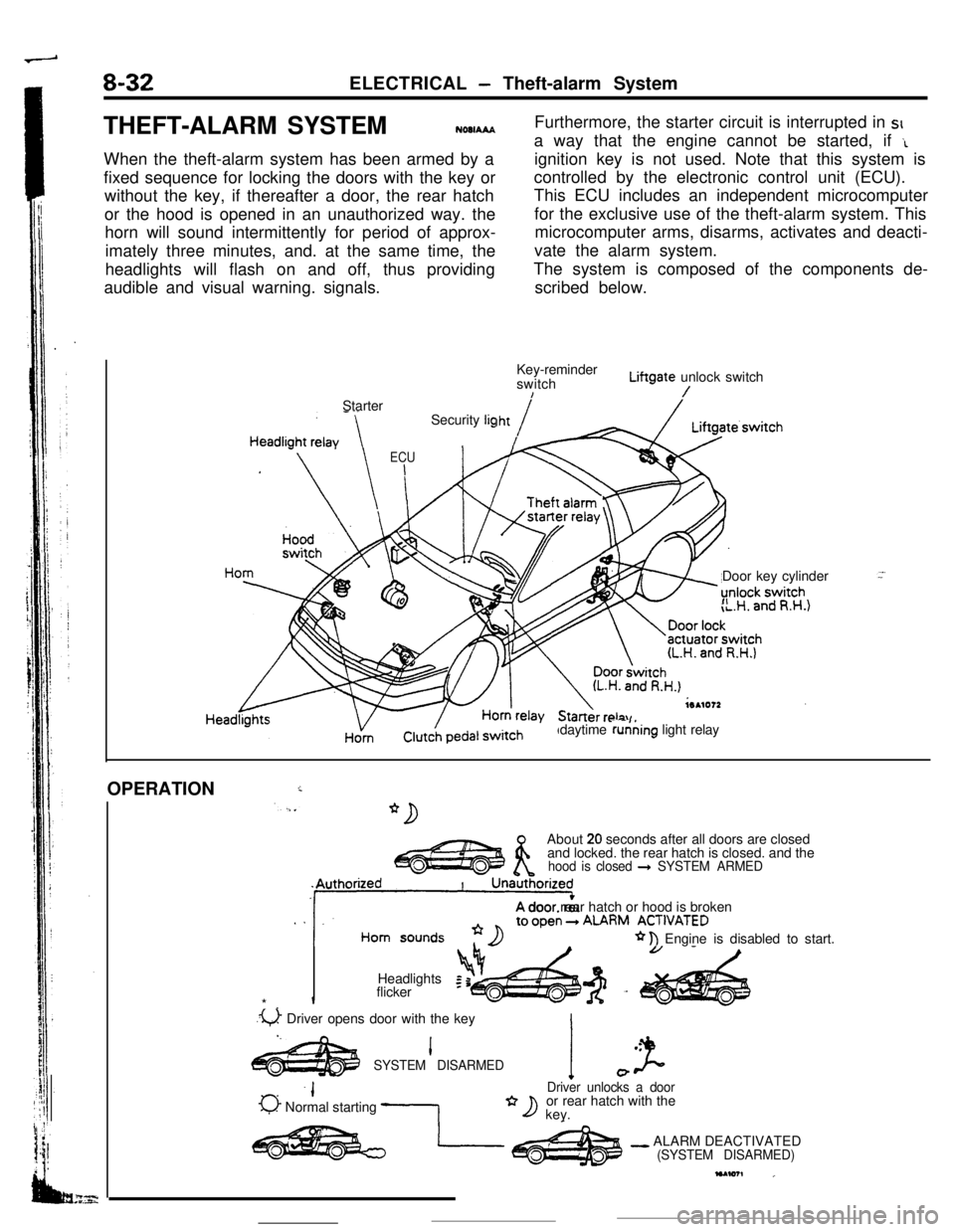

8-32ELECTRICAL - Theft-alarm System

THEFT-ALARM SYSTEM

NOOIAAAWhen the theft-alarm system has been armed by a

fixed sequence for locking the doors with the key or

without the key, if thereafter a door, the rear hatch

or the hood is opened in an unauthorized way. the

horn will sound intermittently for period of approx-

imately three minutes, and. at the same time, the

headlights will flash on and off, thus providing

audible and visual warning. signals.Furthermore, the starter circuit is interrupted in SIa way that the engine cannot be started, if

‘Lignition key is not used. Note that this system is

controlled by the electronic control unit (ECU).

This ECU includes an independent microcomputer

for the exclusive use of the theft-alarm system. This

microcomputer arms, disarms, activates and deacti-

vate the alarm system.

The system is composed of the components de-

scribed below.

Key-reminder

switchLiftgate unlock switch

!/Starter

Door key cylinder

”daytime running light relay Security

lig

ECU

I

HornOPERATION

iAbout

20 seconds after all doors are closed

and locked. the rear hatch is closed. and the

hood is closed + SYSTEM ARMED

. .‘11A door rear hatch or hood is brokenALARM ACT,“ATED

* n Engine is disabled to start.

Headlights

Iflicker

*.

.u Driver opens door with the key

I.l .

SYSTEM DISARMEDI J-0

-IDriver unlocks a door

0 Normal starting -1or rear hatch with the*D key.

- ALARM DEACTIVATED(SYSTEM DISARMED)

Page 119 of 391

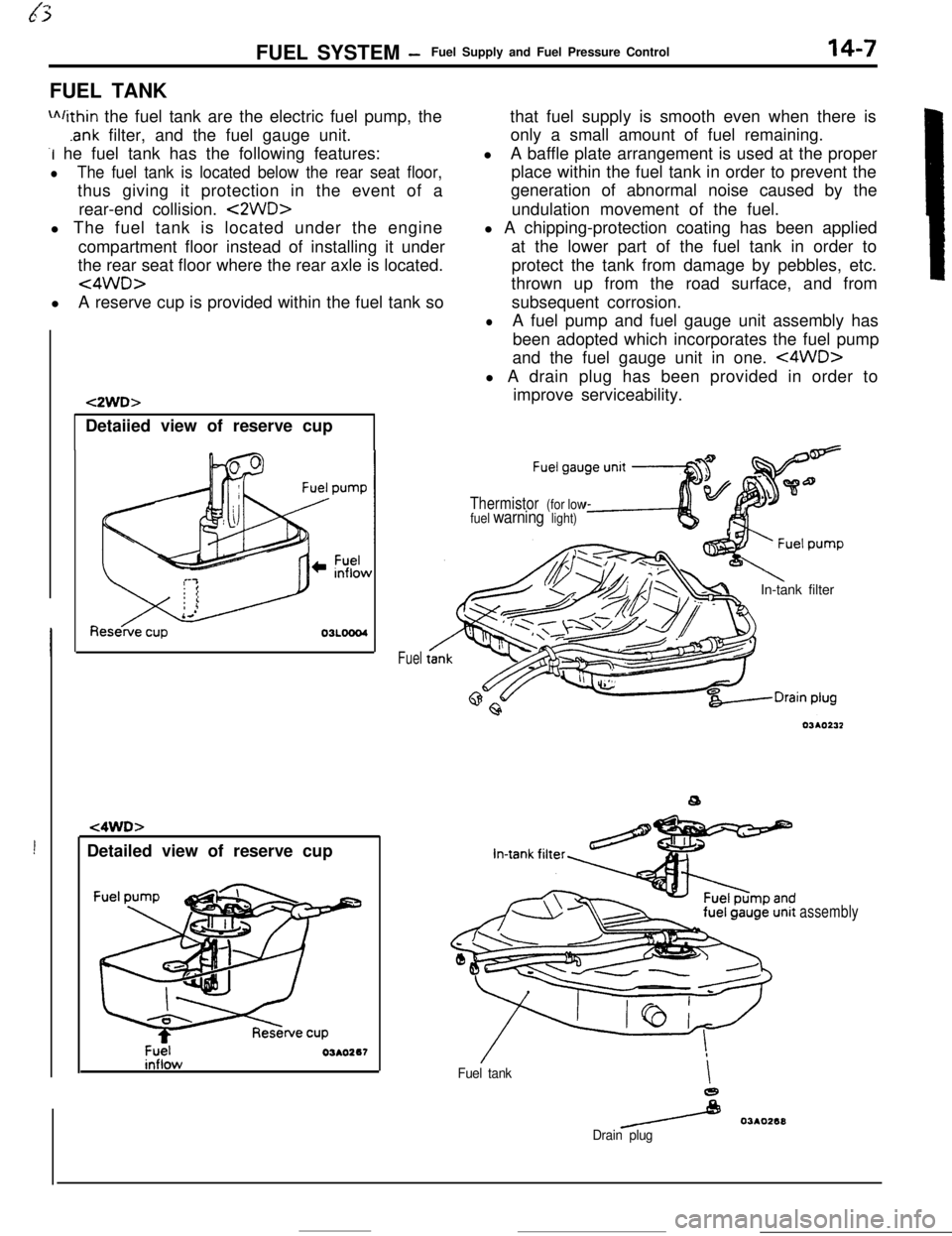

FUEL SYSTEM -Fuel Supply and Fuel Pressure Control14-7FUEL TANK

m/ithin the fuel tank are the electric fuel pump, the

.ank filter, and the fuel gauge unit.

-I he fuel tank has the following features:

lThe fuel tank is located below the rear seat floor,thus giving it protection in the event of a

rear-end collision.

<2WD>l The fuel tank is located under the engine

compartment floor instead of installing it under

the rear seat floor where the rear axle is located.

<4WD>lA reserve cup is provided within the fuel tank so

!Detailed view of reserve cup

t2WD>Detaiied view of reserve cup

t4WD>

Fuel03AO267

Fuelthat fuel supply is smooth even when there is

only a small amount of fuel remaining.

lA baffle plate arrangement is used at the proper

place within the fuel tank in order to prevent the

generation of abnormal noise caused by the

undulation movement of the fuel.

l A chipping-protection coating has been applied

at the lower part of the fuel tank in order to

protect the tank from damage by pebbles, etc.

thrown up from the road surface, and from

subsequent corrosion.

lA fuel pump and fuel gauge unit assembly has

been adopted which incorporates the fuel pump

and the fuel gauge unit in one.

<4WD>l A drain plug has been provided in order to

improve serviceability.

Thermistor (for low

fuel warning light)In-tank filter

Fuel tankI

e

/ 03AO268

Drain plug

assembly

Page 140 of 391

---_-

14-28FUEL SYSTEM- Ennine Control Unit

The engine control unit has an

onboard diagnosis

function, which is used mainly to diagnose the

sensors, thus facilitating system checks and troub-leshooting. It also has a fail-safe/backup function tc

ensure passenger and vehicle safety.

Onboard self-

diagnosisMainly for detecting failure of sensors

and foroutputting diagnosis code.

for detecting failure of sensors, etc. related

toemission control and to turn ON warning light

(Malfunction indicator light).

> Codes can be read by voltmeter.

ENGINE CHECK light is turned

2 ON.

The engine control unit is mounted in the passenger compart-

ment, at the location indicated in the illustration.,

Page 141 of 391

FUEL SYSTEM- Engine Control Unit14-29

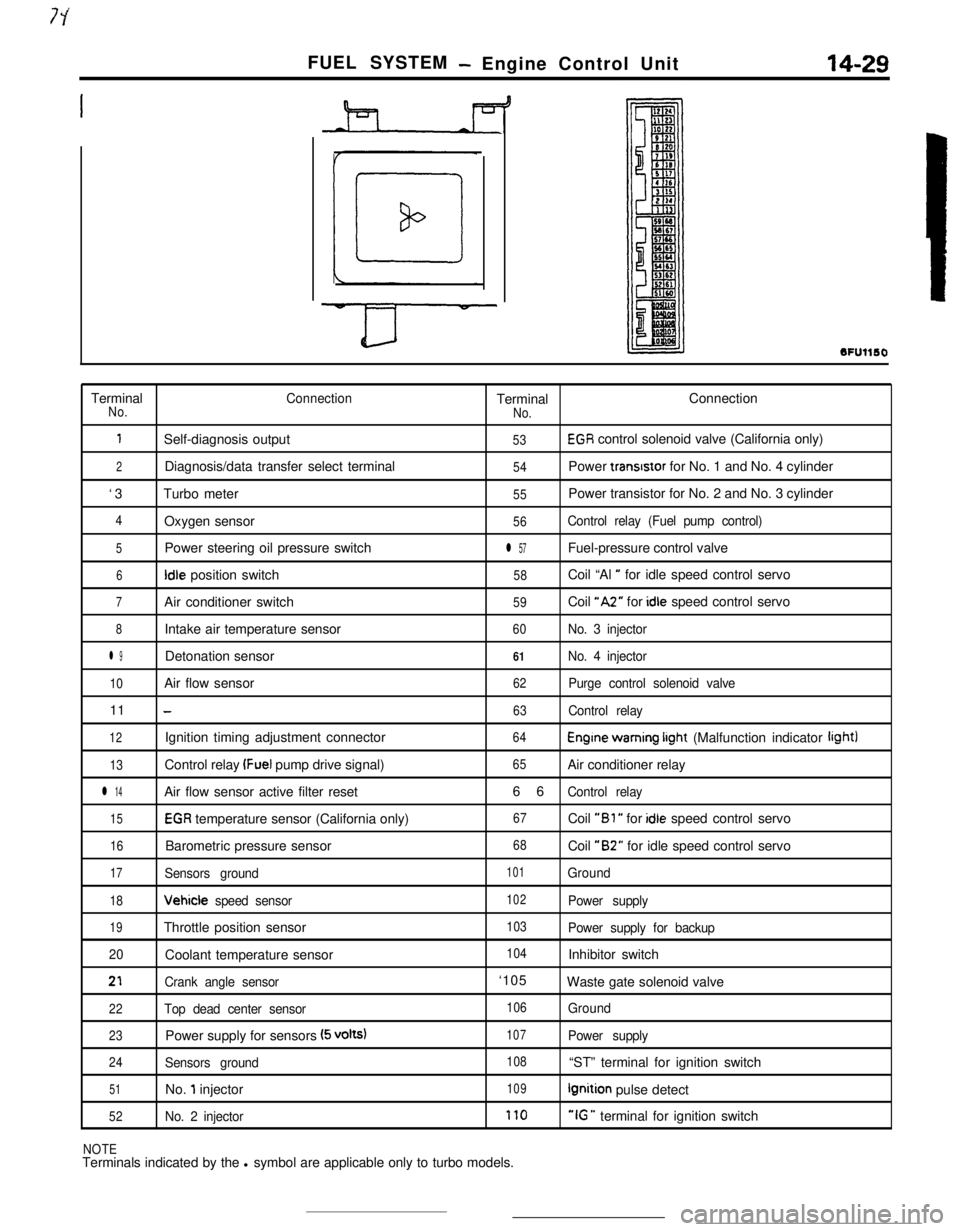

SFUllSOTerminal

ConnectionTerminalConnectionNo.

No.

1Self-diagnosis output53EGR control solenoid valve (California only)

2Diagnosis/data transfer select terminal54Power transrstor for No. 1 and No. 4 cylinder

‘3Turbo meter

55Power transistor for No. 2 and No. 3 cylinder

4Oxygen sensor56Control relay (Fuel pump control)

5Power steering oil pressure switchl 57Fuel-pressure control valve

6Idle position switch58Coil “Al ” for idle speed control servo

7Air conditioner switch59Coil “A2” for idle speed control servo

8Intake air temperature sensor60No. 3 injector

l 9Detonation sensor61No. 4 injector

10Air flow sensor62Purge control solenoid valve11

-63Control relay

12Ignition timing adjustment connector64Engine warning irght (Malfunction indicator light)

13Control relay (Fuel pump drive signal)65Air conditioner relay

l 14Air flow sensor active filter reset66Control relay

15EGR temperature sensor (California only)67Coil “Bl ” for idle speed control servo

16Barometric pressure sensor68Coil “B2” for idle speed control servo

17Sensors ground101Ground

18Vehicle speed sensor102Power supply

19Throttle position sensor103Power supply for backup

20Coolant temperature sensor

104Inhibitor switch

21Crank angle sensor‘105

Waste gate solenoid valve

22Top dead center sensor106Ground

23Power supply for sensors (5 volts)107Power supply

24Sensors ground108“ST” terminal for ignition switch

51No. 1 injector109Ignition pulse detect

52No. 2 injector170“IG ” terminal for ignition switch

NOTETerminals indicated by the l symbol are applicable only to turbo models.

Page 142 of 391

14-30SELF-DIAGNOSISFUEL SYSTEM- Engine Control Unit

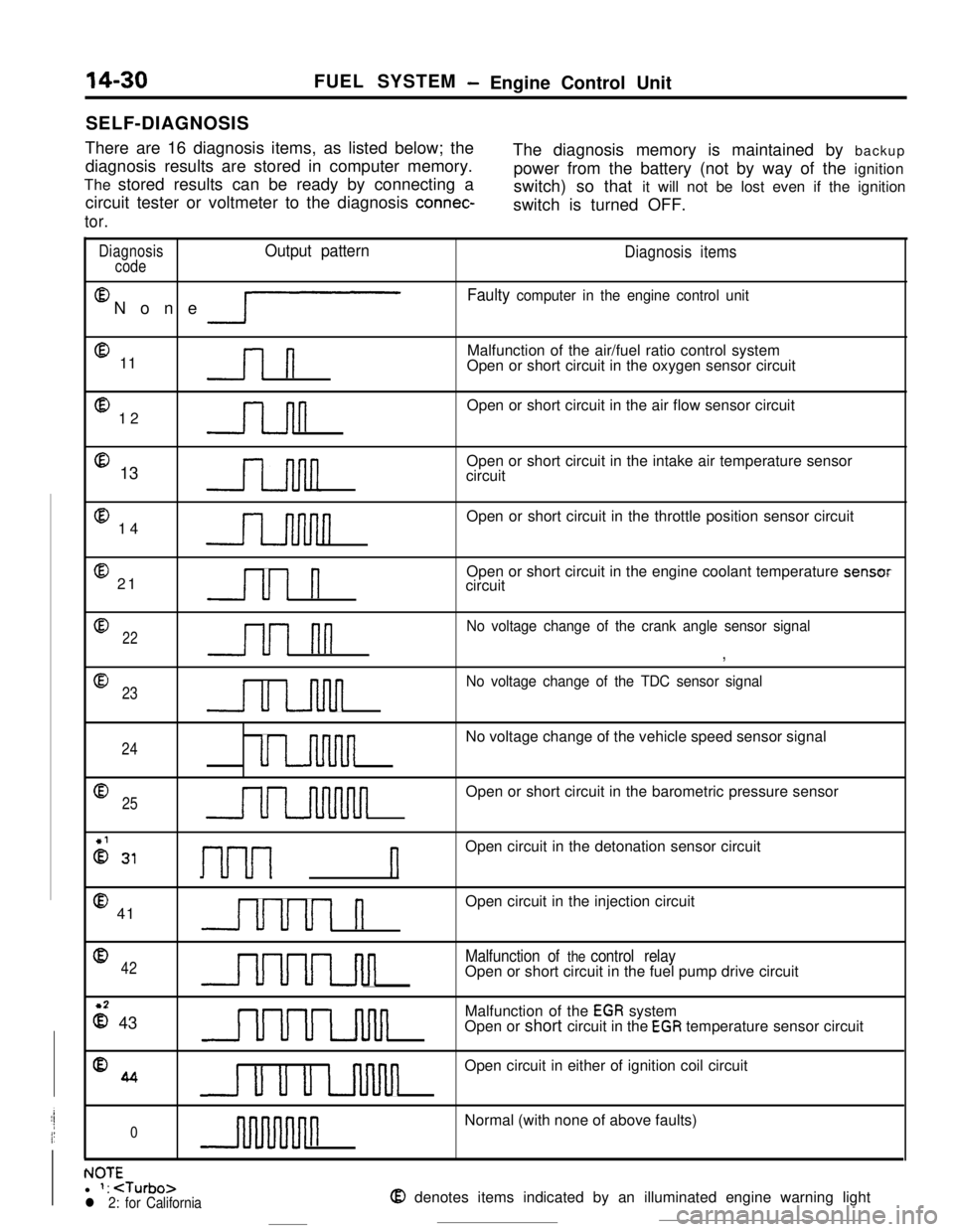

There are 16 diagnosis items, as listed below; the

diagnosis results are stored in computer memory.The diagnosis memory is maintained by backup

The stored results can be ready by connecting apower from the battery (not by way of the ignition

circuit tester or voltmeter to the diagnosis

connec-switch) so that it will not be lost even if the ignition

switch is turned OFF.

tor.

DiagnosisOutput pattern

codeEl

None

lP

@ 11l-l

@ 12n@ 13

@ 14

@ 21Ul n

Diagnosis items

Faulty computer in the engine control unitMalfunction of the air/fuel ratio control system

Open or short circuit in the oxygen sensor circuit

Open or short circuit in the air flow sensor circuit

Open or short circuit in the intake air temperature sensor

circuit

Open or short circuit in the throttle position sensor circuit

Open or short circuit in the engine coolant temperature sensor

circuit

022u1 nn

No voltage change of the crank angle sensor signal

,

@

23

u u-inn

No voltage change of the TDC sensor signal

24uu-uvinnnnNo voltage change of the vehicle speed sensor signal

Q25uuuuuunnnnnOpen or short circuit in the barometric pressure sensor

2 31I-~-~---~ nOpen circuit in the detonation sensor circuit

@ 41uuul nOpen circuit in the injection circuit

042UUuLJul

Malfunction of the control relayOpen or short circuit in the fuel pump drive circuit

z 43UUULnlulMalfunction of the

EGR system

Open or short circuit in the EGR temperature sensor circuit

%4u u u uvinnOpen circuit in either of ignition coil circuit

0nNormal (with none of above faults)

. IA-r-NUltl 1:

Page 143 of 391

FUEL SYSTEM - Engine Control Unit14-31

r

L

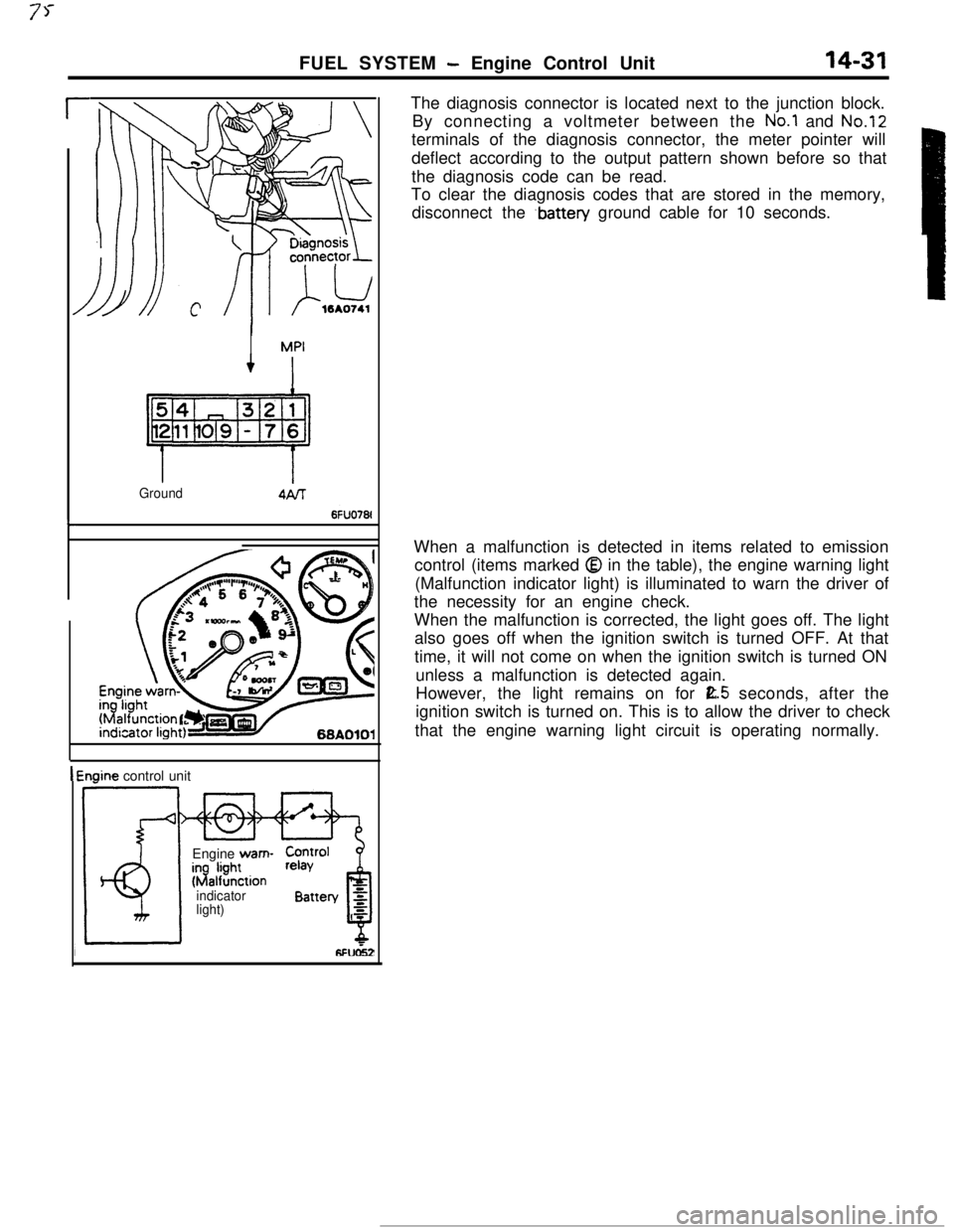

IMPI

Ground

1 Engine control unit

Engine wam-

$b?Stionindicator

light)The diagnosis connector is located next to the junction block.

By connecting a voltmeter between the

No.1 and No.12terminals of the diagnosis connector, the meter pointer will

deflect according to the output pattern shown before so that

the diagnosis code can be read.

To clear the diagnosis codes that are stored in the memory,

disconnect the

.battery ground cable for 10 seconds.

When a malfunction is detected in items related to emission

control (items marked

Q in the table), the engine warning light

(Malfunction indicator light) is illuminated to warn the driver of

the necessity for an engine check.

When the malfunction is corrected, the light goes off. The light

also goes off when the ignition switch is turned OFF. At that

time, it will not come on when the ignition switch is turned ON

unless a malfunction is detected again.

However, the light remains on for

E.5 seconds, after the

ignition switch is turned on. This is to allow the driver to check

that the engine warning light circuit is operating normally.

Page 350 of 391

BODY - Seat Belts23-33

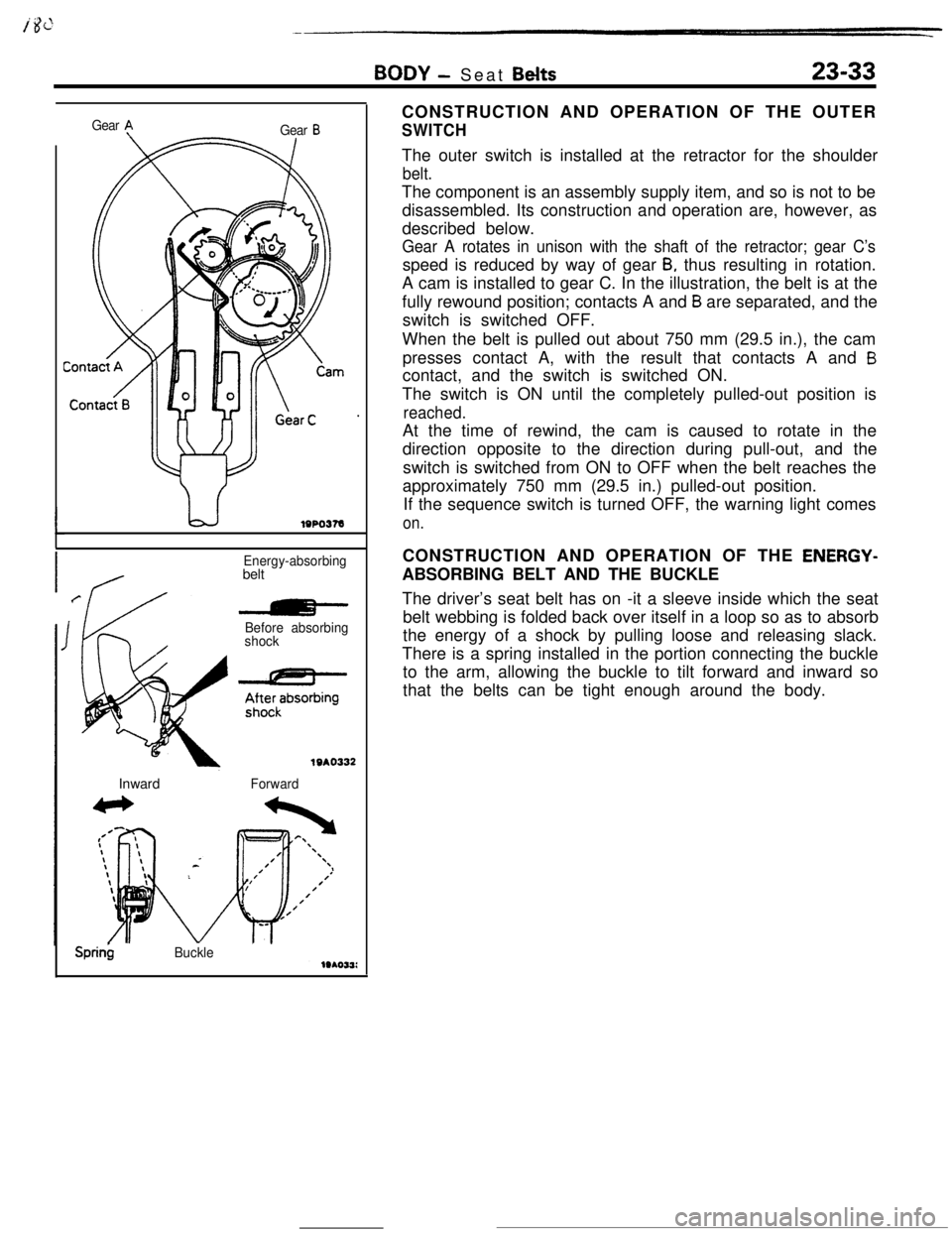

Gear eGear B

Energy-absorbingbelt

Before absorbing

shock

19AO332Inward

Forward

Sprin$BuckleCONSTRUCTION AND OPERATION OF THE OUTER

SWITCHThe outer switch is installed at the retractor for the shoulder

belt.The component is an assembly supply item, and so is not to be

disassembled. Its construction and operation are, however, as

described below.

Gear A rotates in unison with the shaft of the retractor; gear C’sspeed is reduced by way of gear

B, thus resulting in rotation.

A cam is installed to gear C. In the illustration, the belt is at the

fully rewound position; contacts A and

B are separated, and the

switch is switched OFF.

When the belt is pulled out about 750 mm (29.5 in.), the cam

presses contact A, with the result that contacts A and

Bcontact, and the switch is switched ON.

The switch is ON until the completely pulled-out position is

reached.At the time of rewind, the cam is caused to rotate in the

direction opposite to the direction during pull-out, and the

switch is switched from ON to OFF when the belt reaches the

approximately 750 mm (29.5 in.) pulled-out position.

If the sequence switch is turned OFF, the warning light comes

on.CONSTRUCTION AND OPERATION OF THE

ENERGY-ABSORBING BELT AND THE BUCKLE

The driver’s seat belt has on -it a sleeve inside which the seat

belt webbing is folded back over itself in a loop so as to absorb

the energy of a shock by pulling loose and releasing slack.

There is a spring installed in the portion connecting the buckle

to the arm, allowing the buckle to tilt forward and inward so

that the belts can be tight enough around the body.

Page 354 of 391

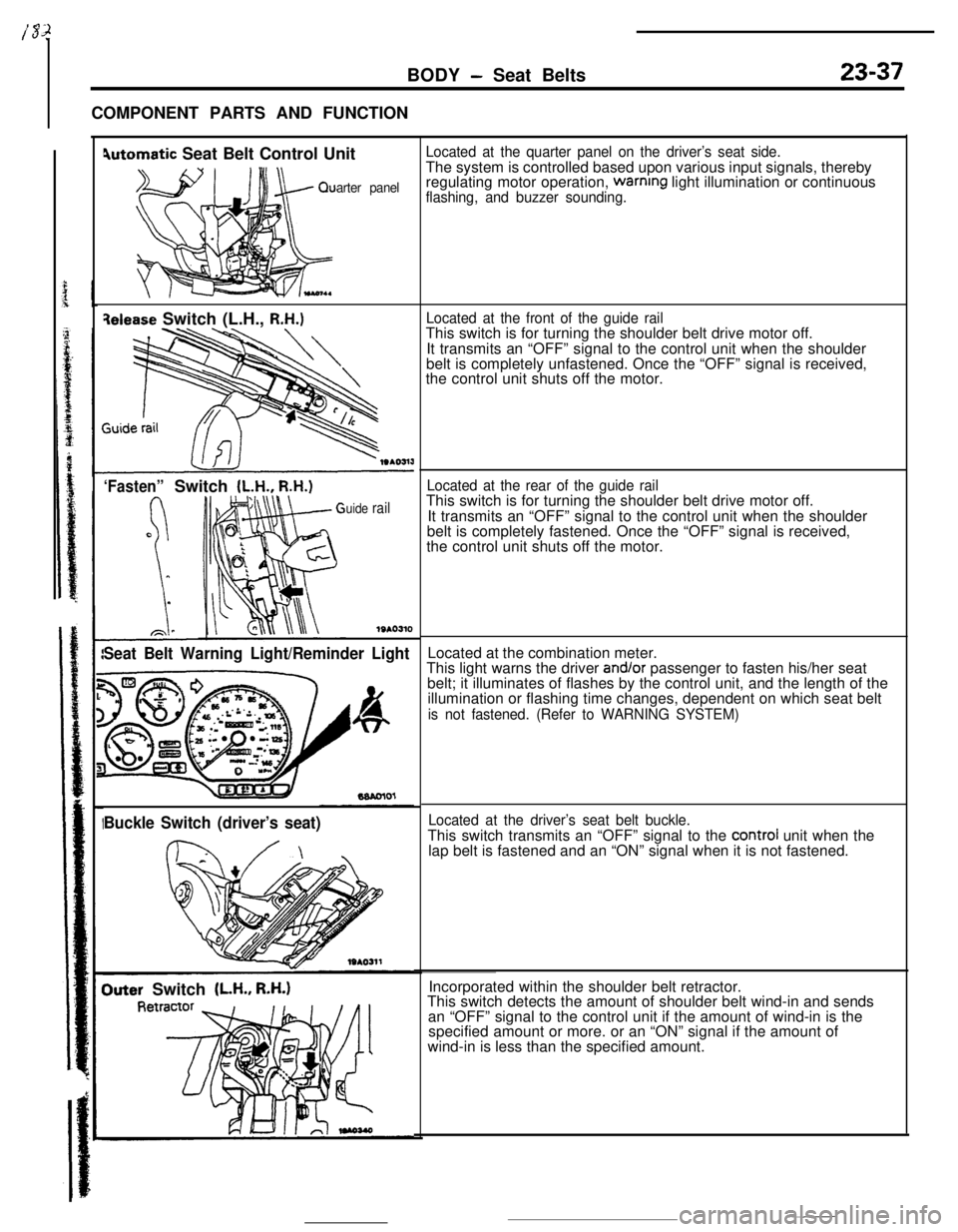

BODY - Seat Belts23-37COMPONENT PARTS AND FUNCTION

4utomatic Seat Belt Control Unit

arter panel

qelease Switch (L.H., R.H.)

‘Fasten”Switch (L.H., R.H.)

uide rail

1SAO310

Seat Belt Warning Light/Reminder Light

Buckle Switch (driver’s seat)

Outer Switch (LH., R.H.)

Located at the quarter panel on the driver’s seat side.The system is controlled based upon various input signals, thereby

regulating motor operation,

warnrng light illumination or continuousflashing, and buzzer sounding.

Located at the front of the guide railThis switch is for turning the shoulder belt drive motor off.

It transmits an “OFF” signal to the control unit when the shoulder

belt is completely unfastened. Once the “OFF” signal is received,

the control unit shuts off the motor.

Located at the rear of the guide railThis switch is for turning the shoulder belt drive motor off.

It transmits an “OFF” signal to the control unit when the shoulder

belt is completely fastened. Once the “OFF” signal is received,

the control unit shuts off the motor.

Located at the combination meter.

This light warns the driver

and/or passenger to fasten his/her seat

belt; it illuminates of flashes by the control unit, and the length of the

illumination or flashing time changes, dependent on which seat belt

is not fastened. (Refer to WARNING SYSTEM)

Located at the driver’s seat belt buckle.This switch transmits an “OFF” signal to the

control unit when the

lap belt is fastened and an “ON” signal when it is not fastened.

Incorporated within the shoulder belt retractor.

This switch detects the amount of shoulder belt wind-in and sends

an “OFF” signal to the control unit if the amount of wind-in is the

specified amount or more. or an “ON” signal if the amount of

wind-in is less than the specified amount.