weight MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 8 of 391

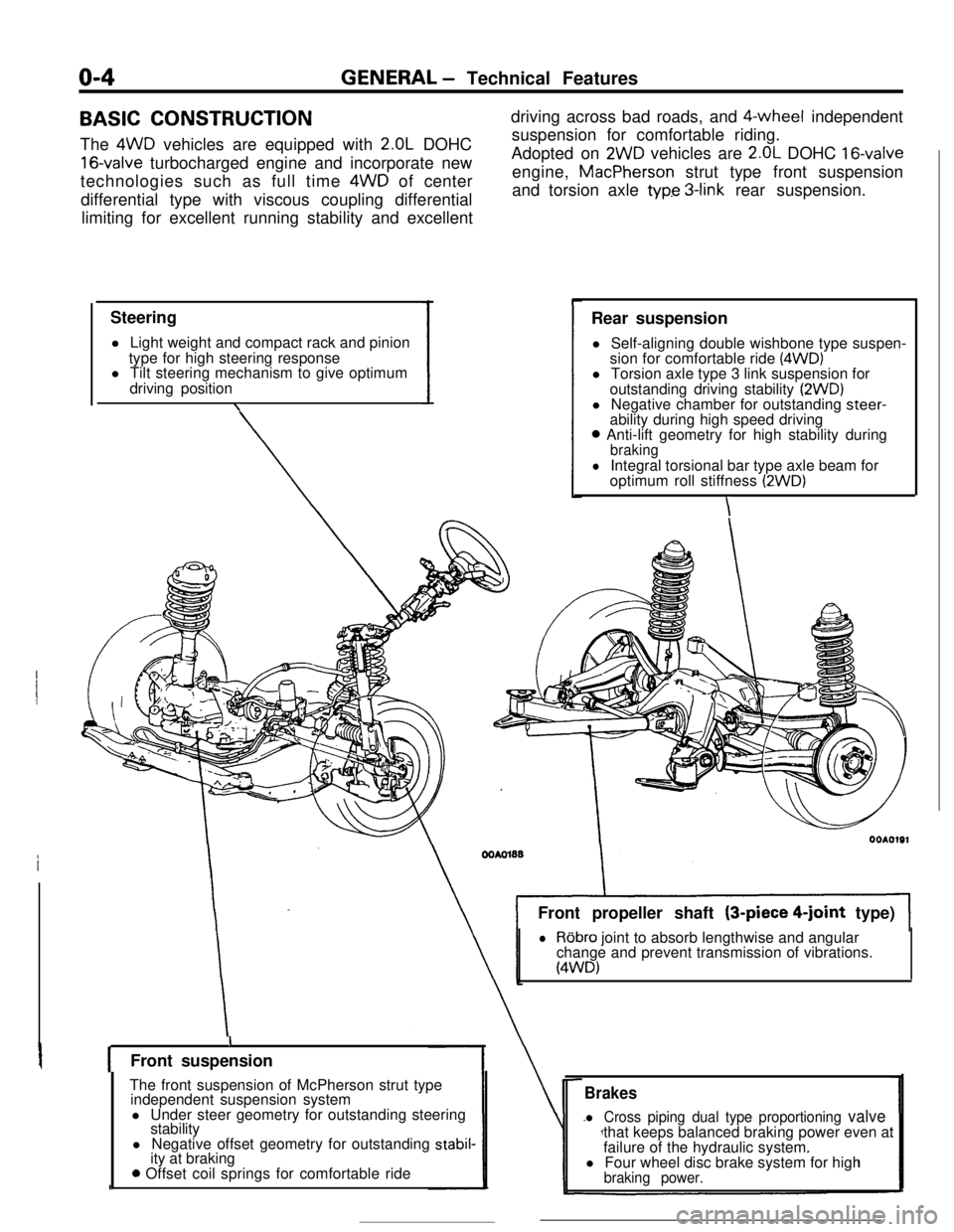

o-4GENERAL - Technical Features

BASIC CONSTRUCTION

The 4WD vehicles are equipped with

2.OL DOHC

16-valve turbocharged engine and incorporate new

technologies such as full time 4WD of center

differential type with viscous coupling differential

limiting for excellent running stability and excellent

Steering

l Light weight and compact rack and pinion

type for high steering response

l Tilt steering mechanism to give optimum

driving position

\driving across bad roads, and $-wheel independent

suspension for comfortable riding.

Adopted on

2WD vehicles are 2.OL DOHC 16-valveengine, MacPherson strut type front suspension

and torsion axle

typ.e 3-link rear suspension.

Rear suspension

l Self-aligning double wishbone type suspen-

sion for comfortable ride

(4WD)l Torsion axle type 3 link suspension for

outstanding driving stability

(2WD)l Negative chamber for outstanding steer-

ability during high speed driving

0 Anti-lift geometry for high stability duringbraking

lIntegral torsional bar type axle beam for

optimum roll stiffness (2WD)

\Front propeller shaft (3-piece

4-joint type)

lRobro joint to absorb lengthwise and angular

change and prevent transmission of vibrations.

(4WD)

IFront suspension

The front suspension of McPherson strut type

independent suspension system

l Under steer geometry for outstanding steering

stability

l Negative offset geometry for outstanding

stabil-ity at braking

0 Offset coil springs for comfortable ride

Brakes

l Cross piping dual type proportioning valvethat keeps balanced braking power even at

failure of the hydraulic system.

l Four wheel disc brake system for high

braking power.

Page 16 of 391

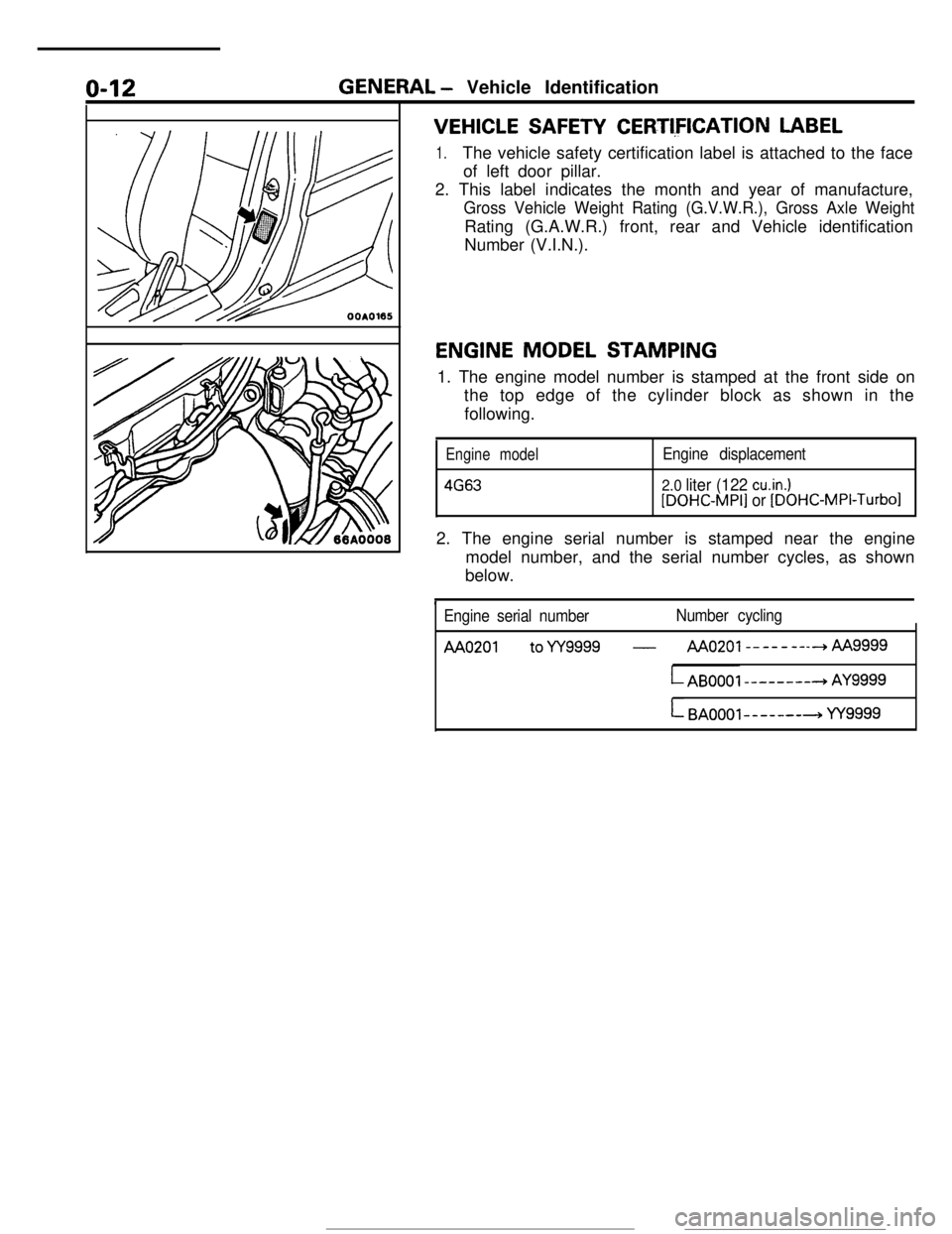

o-12GENERAL - Vehicle Identification

VEHICLE SAFETY CERTI,FICATION LABEL

1.The vehicle safety certification label is attached to the face

of left door pillar.

2. This label indicates the month and year of manufacture,

Gross Vehicle Weight Rating (G.V.W.R.), Gross Axle WeightRating (G.A.W.R.) front, rear and Vehicle identification

Number (V.I.N.).

ENGINE MODEL STAMPING

1. The engine model number is stamped at the front side on

the top edge of the cylinder block as shown in the

following.

Engine model

4663

Engine displacement

2.0 liter (122 cu.in.)[DOHC-MPI] or [DOHC-MPI-Turbo12. The engine serial number is stamped near the engine

model number, and the serial number cycles, as shown

below.

Engine serial numberNumber cycling

AA0201 toYY9999 -AAo201--------hAA

LAB0001 --------+ AY9999

L BAOOOl-------+ YY9999

Page 17 of 391

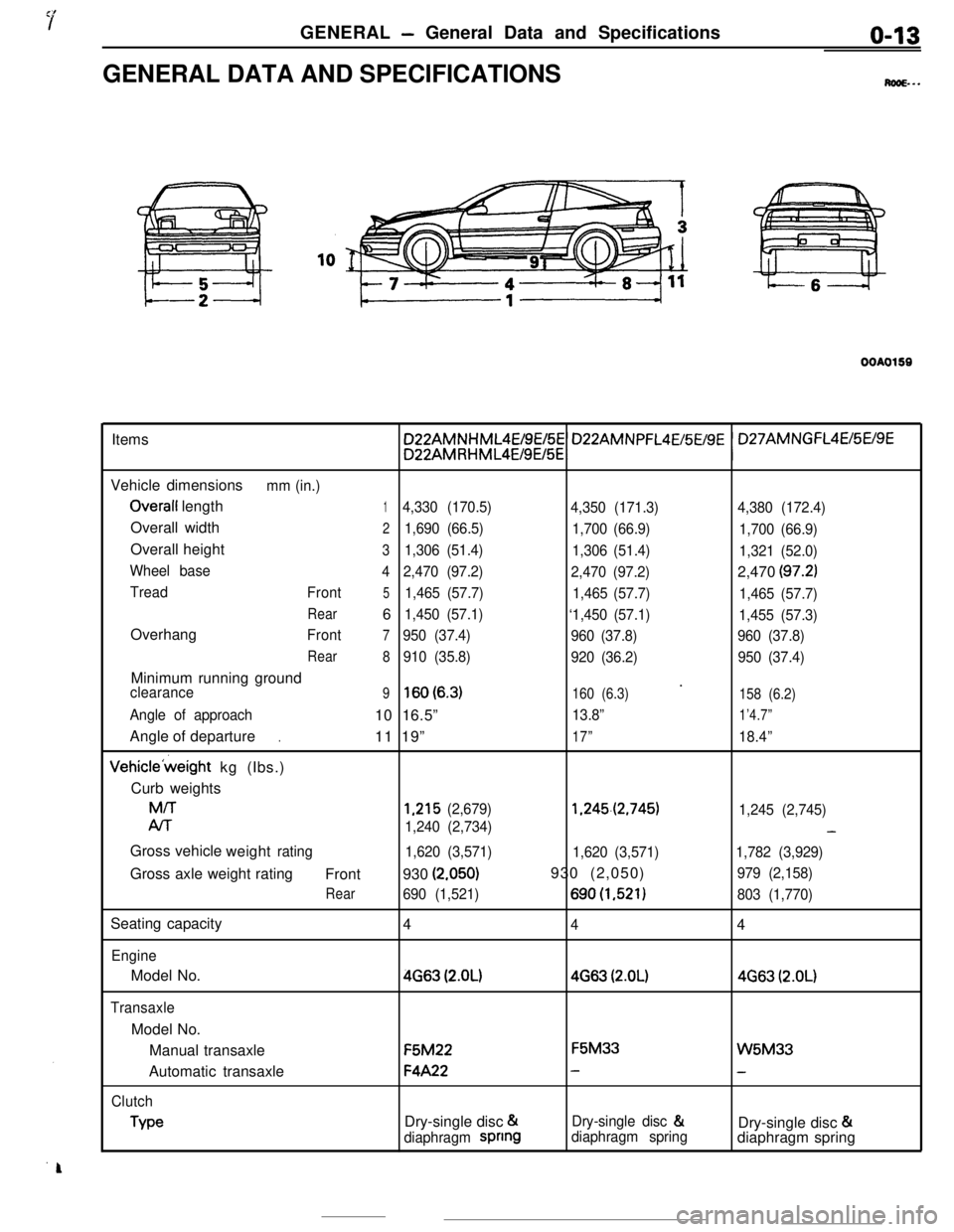

GENERAL - General Data and Specificationso-13GENERAL DATA AND SPECIFICATIONS

M...

OOAO159Items

Vehicle dimensions

mm (in.)

Overall length14,330 (170.5)

4,350 (171.3)4,380 (172.4)Overall width

21,690 (66.5)

1,700 (66.9)

1,700 (66.9)Overall height

31,306 (51.4)

1,306 (51.4)

1,321 (52.0)

Wheel base

42,470 (97.2)

2,470 (97.2)2,470

(97.2)

Tread

Front51,465 (57.7)

1,465 (57.7)

1,465 (57.7)

Rear61,450 (57.1)

‘1,450 (57.1)

1,455 (57.3)Overhang

Front7950 (37.4)

960 (37.8)960 (37.8)

Rear

8910 (35.8)

920 (36.2)950 (37.4)Minimum running ground

’clearance9lsO(6.3)160 (6.3)

158 (6.2)

Angle of approach10 16.5”13.8”1’4.7”Angle of departure

11 19”

17”18.4”.Vehicle’weight kg (Ibs.)

Curb weightsM/T

1,215 (2,679)1.245.(2,745)

1,245 (2,745)

Al-r

1,240 (2,734)-Gross vehicle

weight

rating

1,620 (3,571)

1,620 (3,571)1,782 (3,929)Gross axle weight rating

Front930

(2.050)930 (2,050)979 (2,158)

Rear690 (1,521)690(1,521)803 (1,770)Seating capacity

4

44

EngineModel No.

4663 (2.OL)4663 (2.OL)4663 (2.OL)

TransaxleModel No.

Manual transaxleF5M22F5M33

W5M33Automatic transaxle

F4A22--

Clutch

TypeDry-single disc &Dry-single disc &

Dry-single disc &

diaphragm spnngdiaphragm springdiaphragm spring

Page 20 of 391

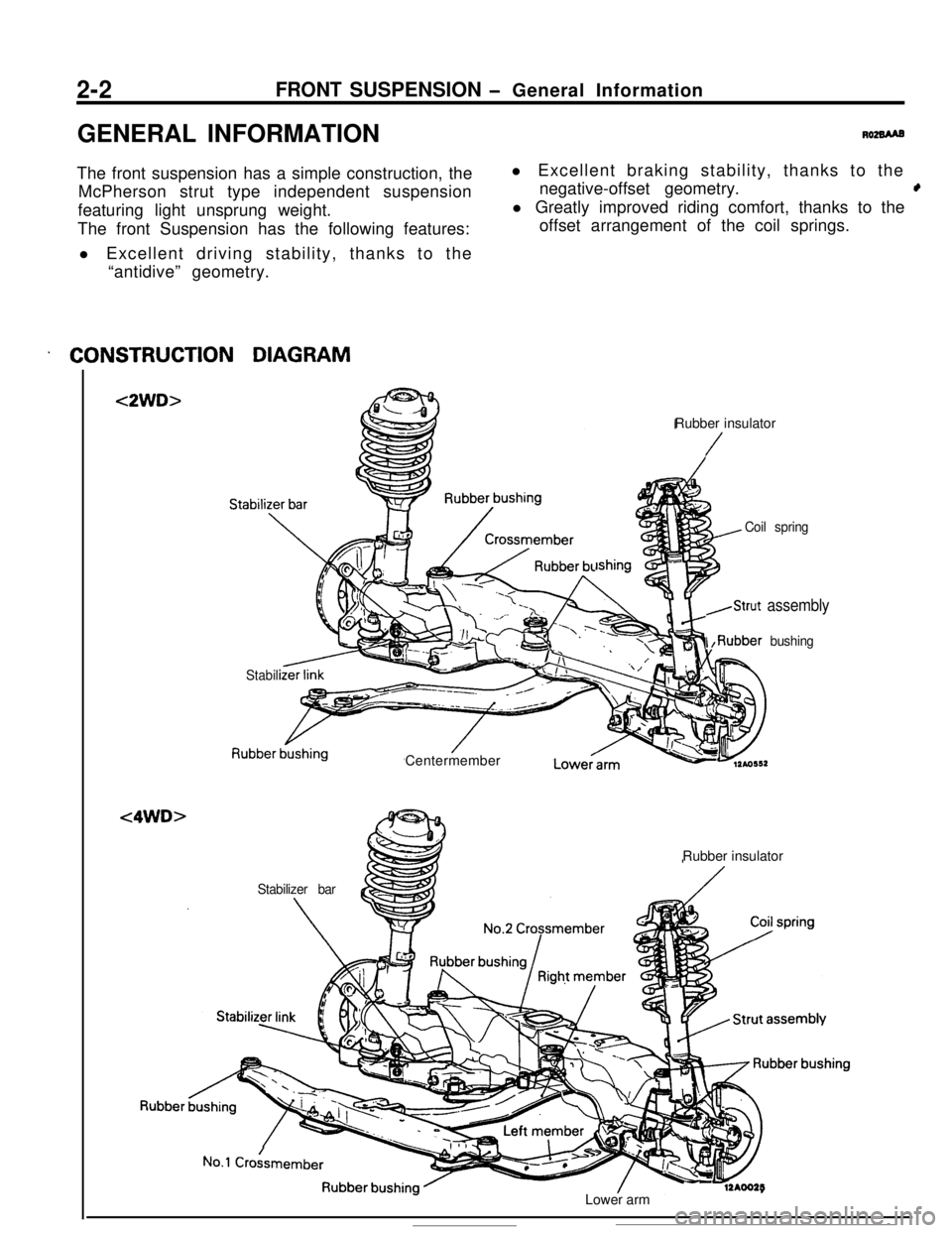

2-2

t

featuring light unsprung weight.

. CONSTRUCTION DIAGRAM

<2WD>

<4WD>

Rubber insulator

/

lshing

Coil spring

,Strut assembly

I ,Rubber bushing

Stabili

Lowecarm

Rubber insulator

No.1 Crokmember

- -12AOO25Lower arm

Page 152 of 391

14-40FUEL SYSTEM - Fuel Injection Control

BASIC INJECTOR ACTIVATION DURATION

In sequential injection under normal operating conditions, fuel

is injected into each cylinder once every cycle (i.e., two

crankshaft revolutions).

The injector activation duration required to inject the amount of

fuel that achieves the stoichiometric air-fuel ratio

(15 times as

much air, by weight, as gasoline, by weight) with regard to the

amount of air admitted during one cycle in each cylinder is

called the “basic injector activation duration”.

The amount of air admitted to each cylinder during one cycle is

calculated by the engine control unit based on the signals

provided by the air flow sensor and crank angle sensor.

FOR YOUR INFORMATION:

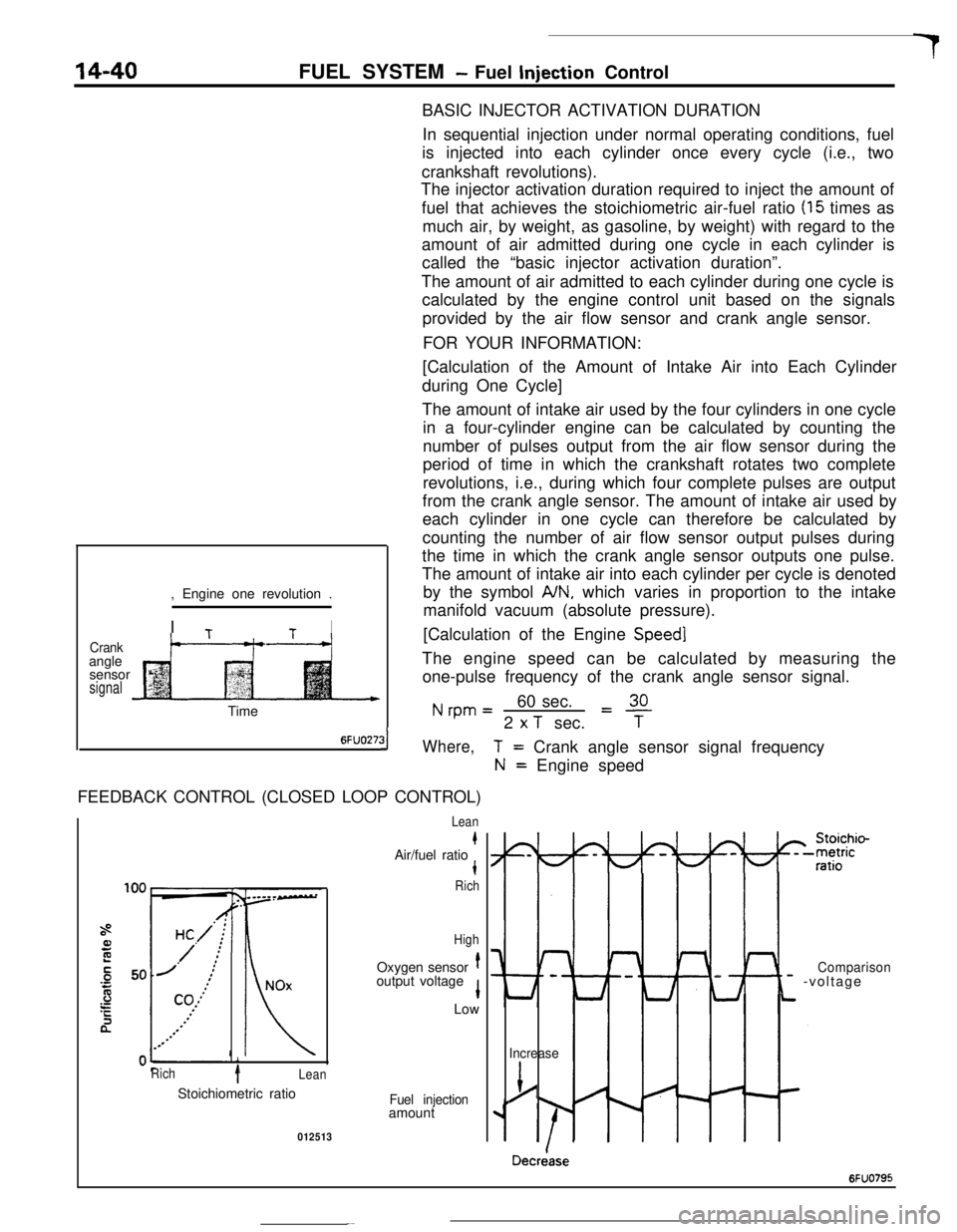

Crankangle

sensor

signal, Engine one revolution .

I

TtI

t--“---t-+[Calculation of the Amount of Intake Air into Each Cylinder

during One Cycle]

The amount of intake air used by the four cylinders in one cycle

in a four-cylinder engine can be calculated by counting the

number of pulses output from the air flow sensor during the

period of time in which the crankshaft rotates two complete

revolutions, i.e., during which four complete pulses are output

from the crank angle sensor. The amount of intake air used by

each cylinder in one cycle can therefore be calculated by

counting the number of air flow sensor output pulses during

the time in which the crank angle sensor outputs one pulse.

The amount of intake air into each cylinder per cycle is denoted

by the symbol

A/N, which varies in proportion to the intake

manifold vacuum (absolute pressure).

[Calculation of the Engine

Speed]The engine speed can be calculated by measuring the

one-pulse frequency of the crank angle sensor signal.

Nrpm=60 sec.L!!L2

x T sec.TTime

6FUO27:31Where,FEEDBACK CONTROL (CLOSED LOOP CONTROL)

i

Rich1Lean

T= Crank angle sensor signal frequency

N= Engine speed

Lean

kAir/fuel ratiot

Rich

HighOxygen sensor

toutput voltage

1Low

Stoichiometric ratio

Fuel injectionamount

012513

I-

Lt

Comparison- -voltage

Increase

j/

Decriase

6FUO795

Page 163 of 391

FUEL SYSTEM -Idle Speed Control14-51

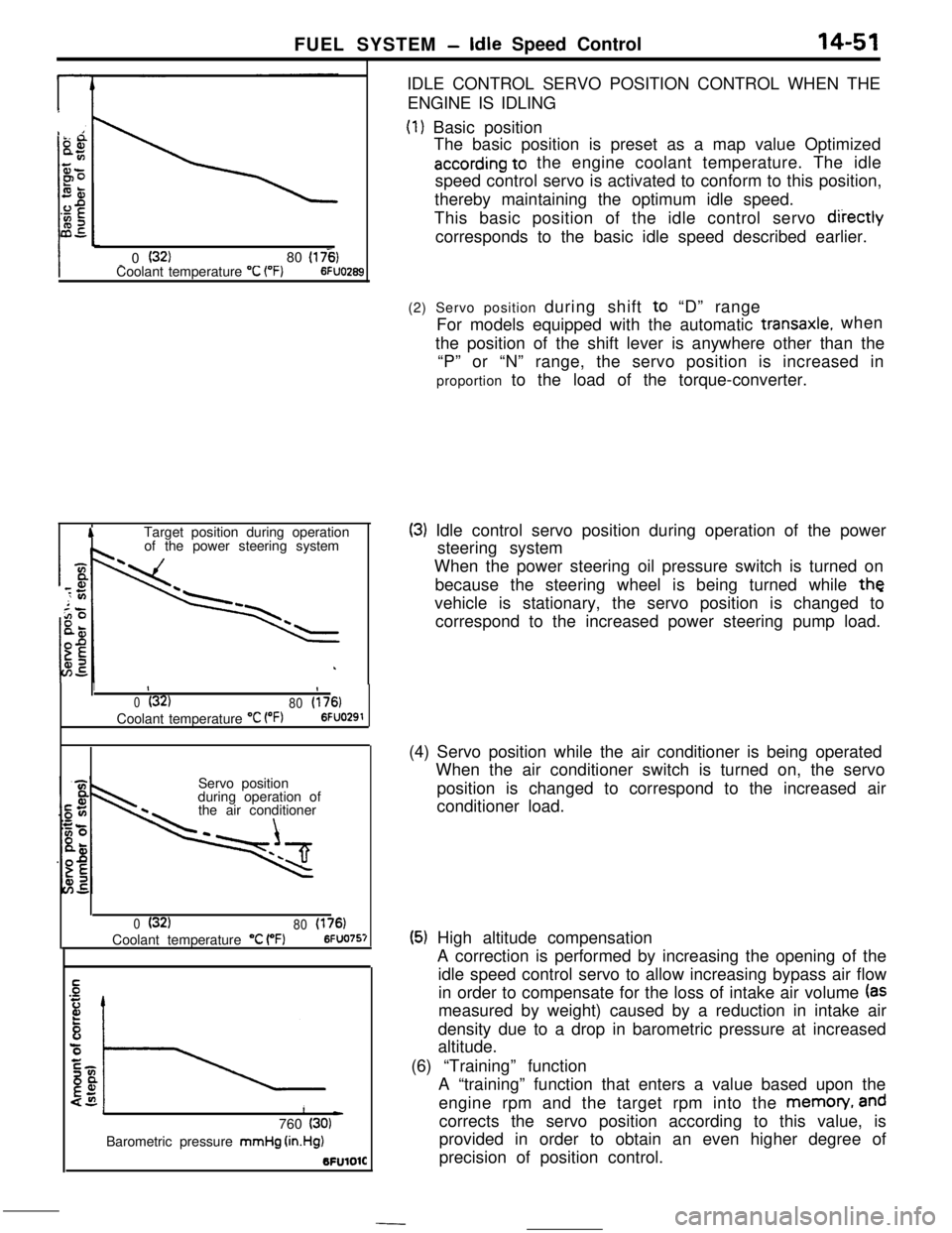

_ 0 (32)80 (175)Coolant temperature “C (“F)6FUO2653

ATarget position during operation

of the power steering systemIDLE CONTROL SERVO POSITION CONTROL WHEN THE

ENGINE IS IDLING

(1) Basic position

The basic position is preset as a map value Optimized

according to the engine coolant temperature. The idle

speed control servo is activated to conform to this position,

thereby maintaining the optimum idle speed.

This basic position of the idle control servo

diiectlycorresponds to the basic idle speed described earlier.

1II

0(32)

80(176)Coolant temperature

“C VW6FUO291Servo position

during operation of

the air conditioner

0(32)

80(176)Coolant temperature “C (“F)6FUO757

1L)760 (30)Barometric pressure mmHg

(in.Hg)BFUlOlC(2) Servo position during shift to “D” range

For models equipped with the automatic

transaxle.when

the position of the shift lever is anywhere other than the

“P” or “N” range, the servo position is increased in

proportion to the load of the torque-converter.

(3) Idle control servo position during operation of the power

steering system

When the power steering oil pressure switch is turned on

because the steering wheel is being turned while

thevehicle is stationary, the servo position is changed to

correspond to the increased power steering pump load.

(4) Servo position while the air conditioner is being operated

When the air conditioner switch is turned on, the servo

position is changed to correspond to the increased air

conditioner load.

(5) High altitude compensation

A correction is performed by increasing the opening of the

idle speed control servo to allow increasing bypass air flow

in order to compensate for the loss of intake air volume

(asmeasured by weight) caused by a reduction in intake air

density due to a drop in barometric pressure at increased

altitude.

(6) “Training” function

A “training” function that enters a value based upon the

engine rpm and the target rpm into the memon/,

andcorrects the servo position according to this value, is

provided in order to obtain an even higher degree of

precision of position control.

Page 211 of 391

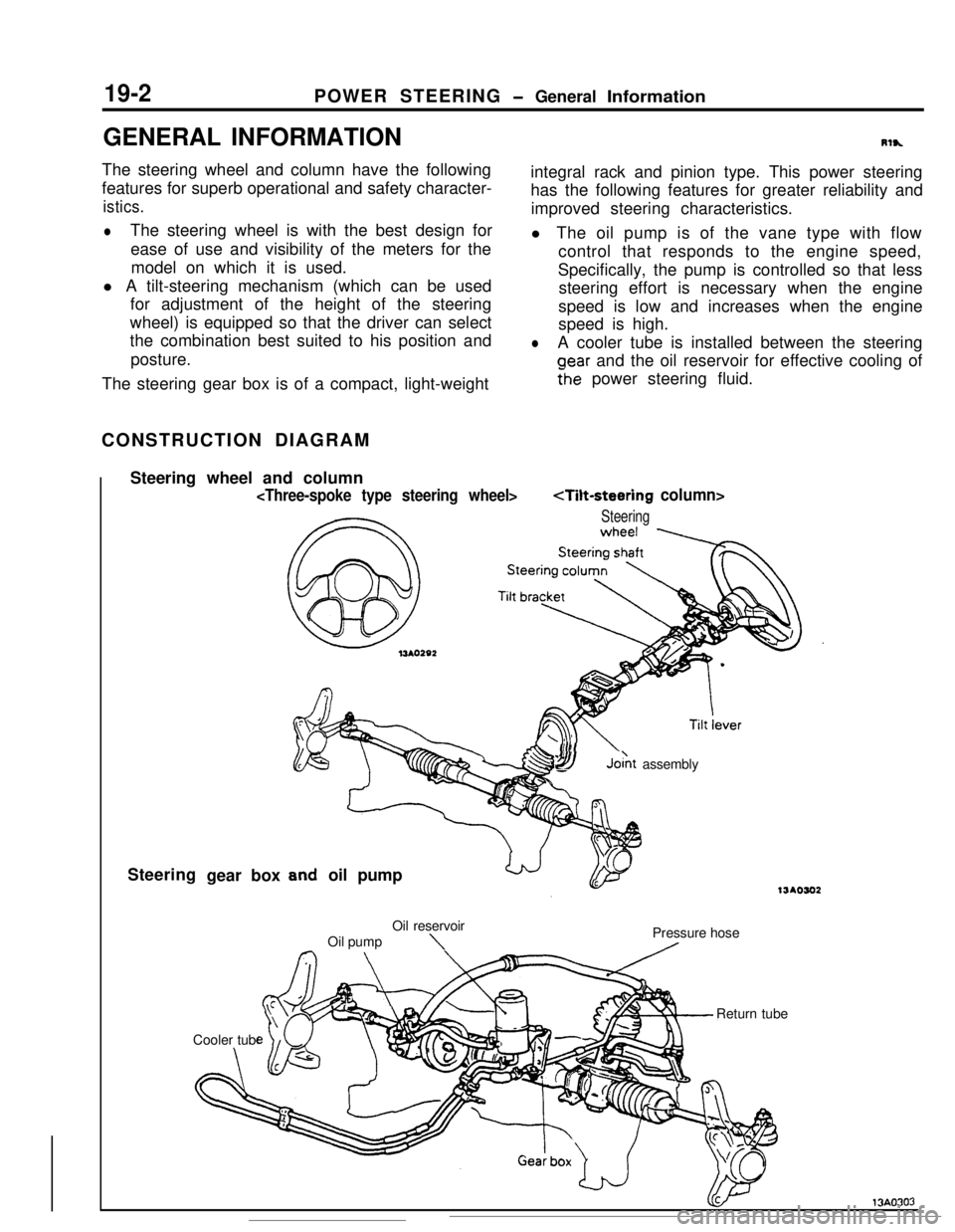

19-2 POWER STEERING

Rlh

integral rack and pinion type. This power steering

oear and the oil reservoir for effective cooling of

Fhe power steering fluid.The steering gear box is of a compact, light-weight

Steering

SYJo& assembly

oil pump

\Pressure hose

A

Page 230 of 391

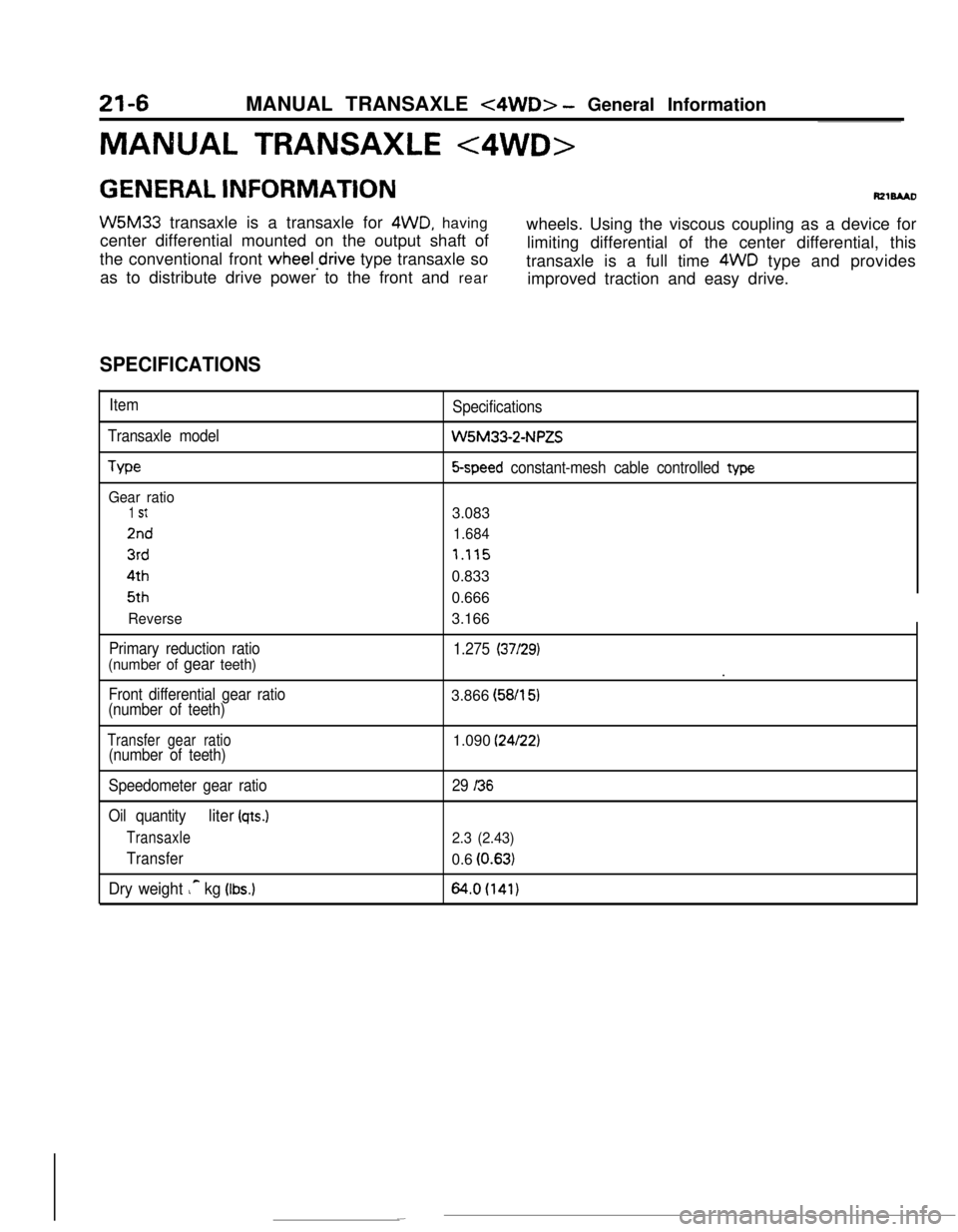

MANUAL TRANSAXLE <4WD> - General Information

MANUAL TRANSAXLE <4WD>

GENERAL INFORMATION

W5M33 transaxle is a transaxle for 4WD, having

center differential mounted on the output shaft ofwheels. Using the viscous coupling as a device for

the conventional front

wheeledrive type transaxle solimiting differential of the center differential, this

as to distribute drive power to the front and reartransaxle is a full time 4WD type and provides

improved traction and easy drive.

SPECIFICATIONS

Item

Transaxle model

We

Gear ratio

1 St

2nd

3rd4th5th

Reverse

Primary reduction ratio

(number of gear teeth)

Front differential gear ratio

(number of teeth)Specifications

W5M33-2-NPZS

5-speed constant-mesh cable controlled type3.083

1.684

7.1150.833

0.666

3.166

1.275 (37/29).

3.866 (58/l

51

Transfer gear ratio(number of teeth)1.090 (24/22)

Speedometer gear ratio

Oil quantity

liter (qts.)

Transaxle

Transfer

Dry weight ic kg (Ibs.)

29 I36

2.3 (2.43)0.6

(0.63)

64.0(141)

Page 336 of 391

i73BODY

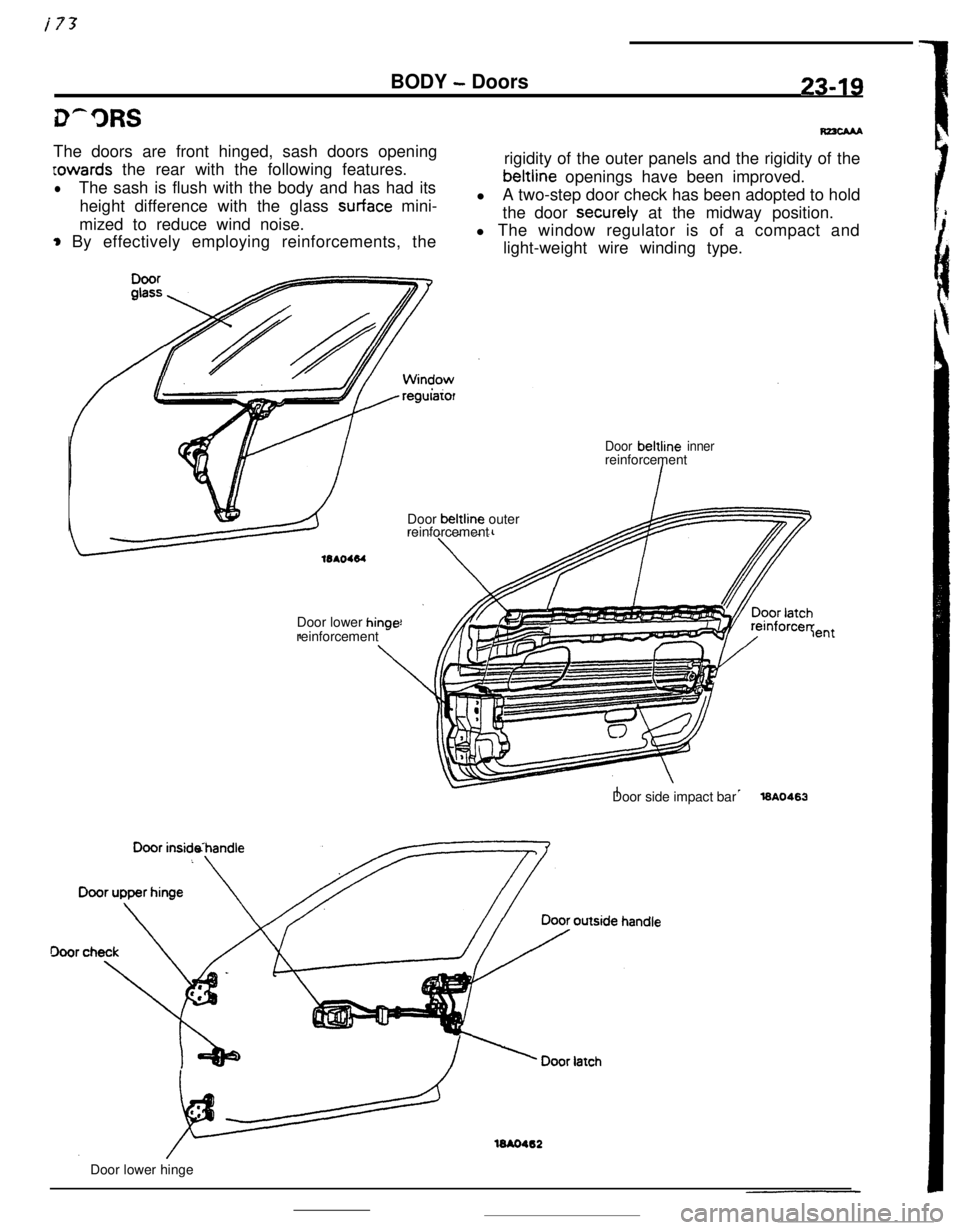

- Doors23-19The doors are front hinged, sash doors opening

Lowards the rear with the following features.

lThe sash is flush with the body and has had its

height difference with the glass

surface mini-

mized to reduce wind noise.

* By effectively employing reinforcements, the

regularorrigidity of the outer panels and the rigidity of thebeltline openings have been improved.

lA two-step door check has been adopted to hold

the door securely at the midway position.

l The window regulator is of a compact and

light-weight wire winding type.

Door beltline innerreinforcement

Door beltline outer

reinforcement

Door lower

hinr-reinforcement *-lentDoor side impact bar

l6A0463

16AO462Door lower hinge

Page 337 of 391

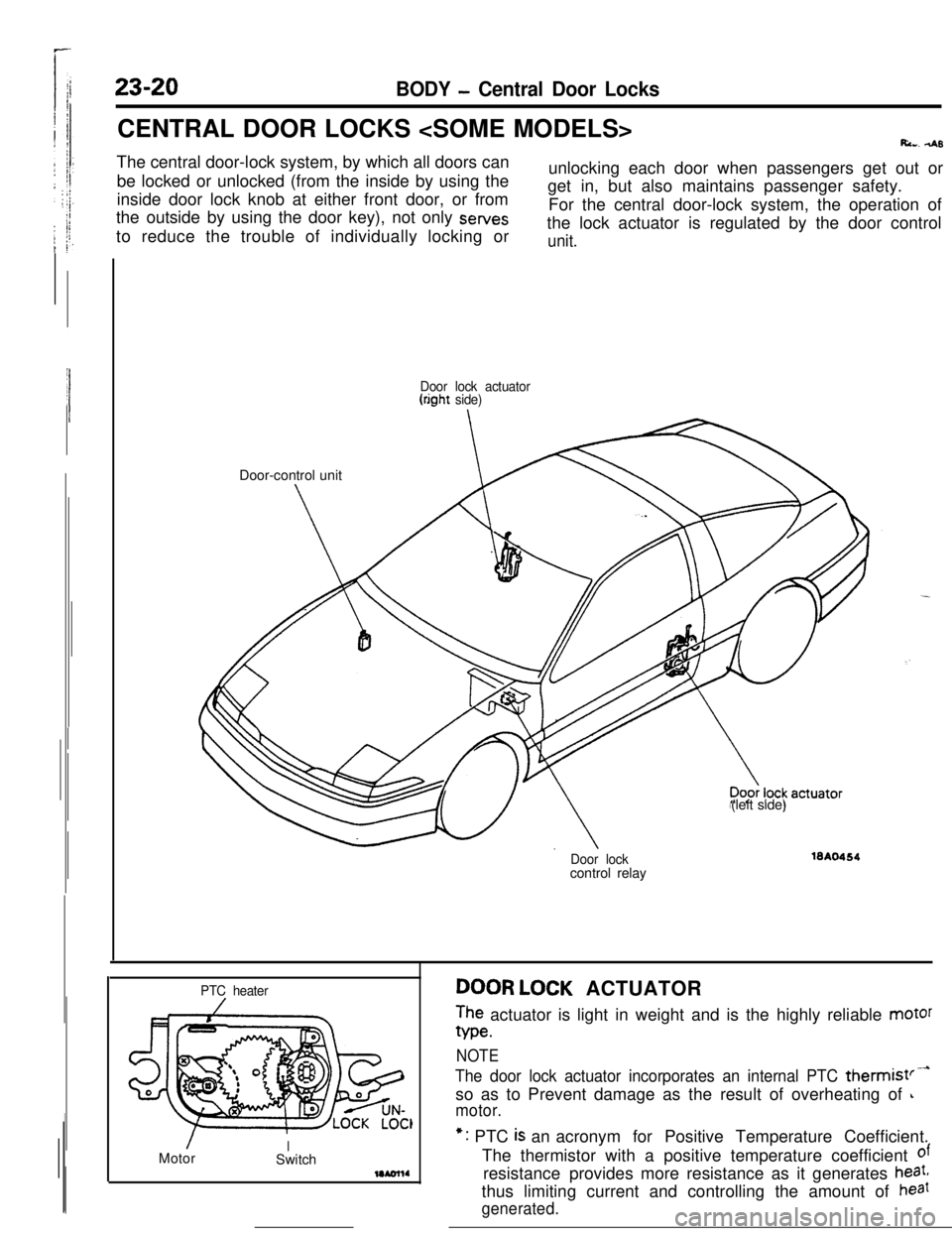

23-20BODY - Central Door LocksCENTRAL DOOR LOCKS

Ri... 4sThe central door-lock system, by which all doors can

be locked or unlocked (from the inside by using the

inside door lock knob at either front door, or from

the outside by using the door key), not only sewes

to reduce the trouble of individually locking orunlocking each door when passengers get out or

get in, but also maintains passenger safety.

For the central door-lock system, the operation of

the lock actuator is regulated by the door control

unit.

Door lock actuator(right side)Door-control unit

(left side)

Door lockcontrol relay16A0464

PTC heater

/MotorISwitchDOOR LOCK ACTUATOR

The actuator is light in weight and is the highly reliable motor

We.

NOTE

The door lock actuator incorporates an internal PTC thermist’-so as to Prevent damage as the result of overheating of

L

motor.*: PTC

is an acronym for Positive Temperature Coefficient.

The thermistor with a positive temperature coefficient

ofresistance provides more resistance as it generates

heat,thus limiting current and controlling the amount of

haat

generated.