heater MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 3 of 391

TALON

BACKUP

README.N or for additional information

PreViOUSlVmanufactured.a *-a- .I._..-1-L,.* _____ #Q ^_^__ l L.-Orintul in U.S.A.

GROUP INDEXROSA. - -

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . .

Front Suspensio n................................

.

Brakes - Eir$rii. . . . . . . . . . . . . . . . . . . . . . . . . . ..s...

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling. . . . . . :. . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . ..-..................

Engine....................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Shaft and Universal. . . . . . . .

ml

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power steeringCD

ManualTransaxl e - Automatic....................

m

Bodym

Heaters and Air ConditioningRI

A

Emission Control Systems

Page 48 of 391

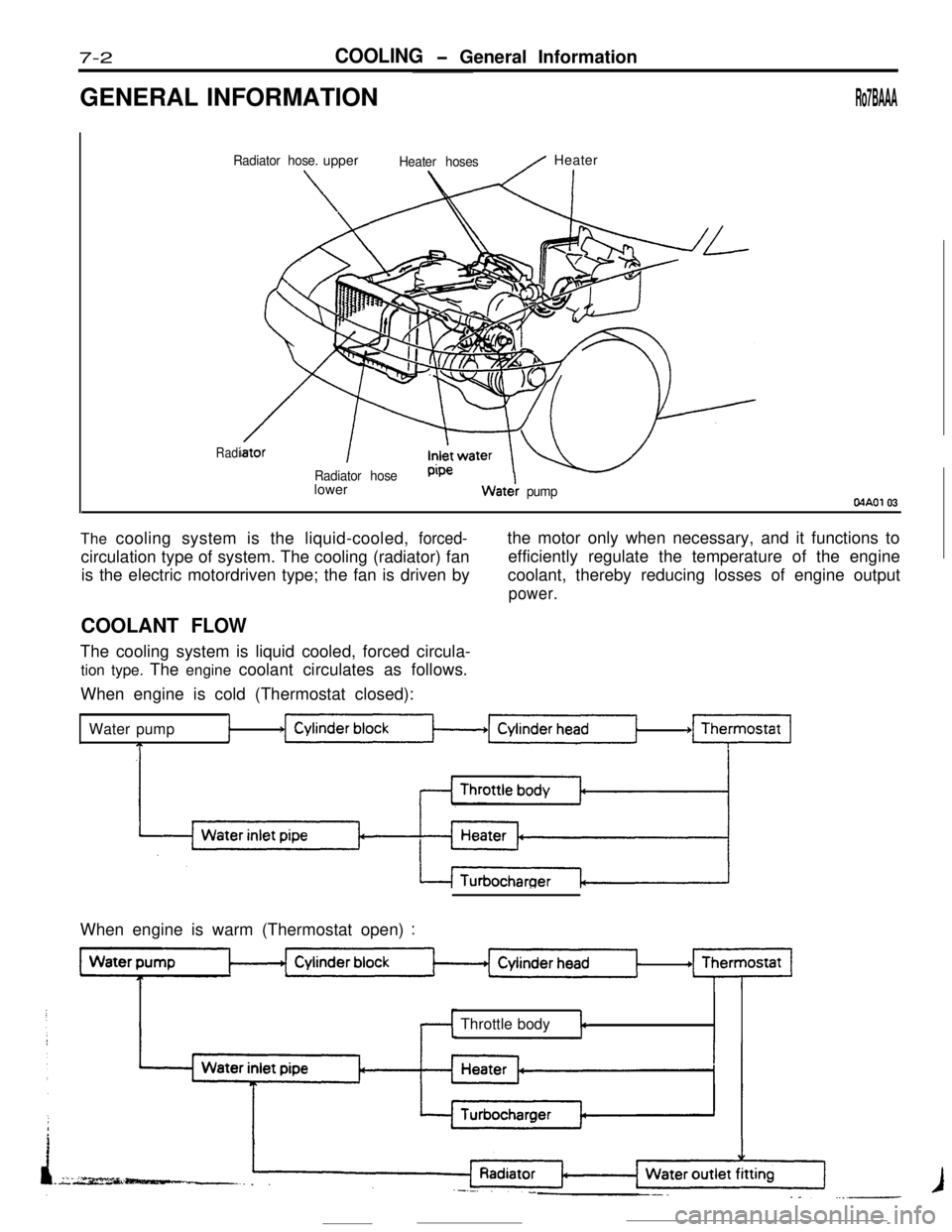

7-2 COOLIN G- General Information

/ Heater

Radi

Watei pumpMAO1 03

The cooling system is the liquid-cooled , forced-

1

T

+m

I

When engine is warm (Thermostat open) :

Throttle bodyt

Page 55 of 391

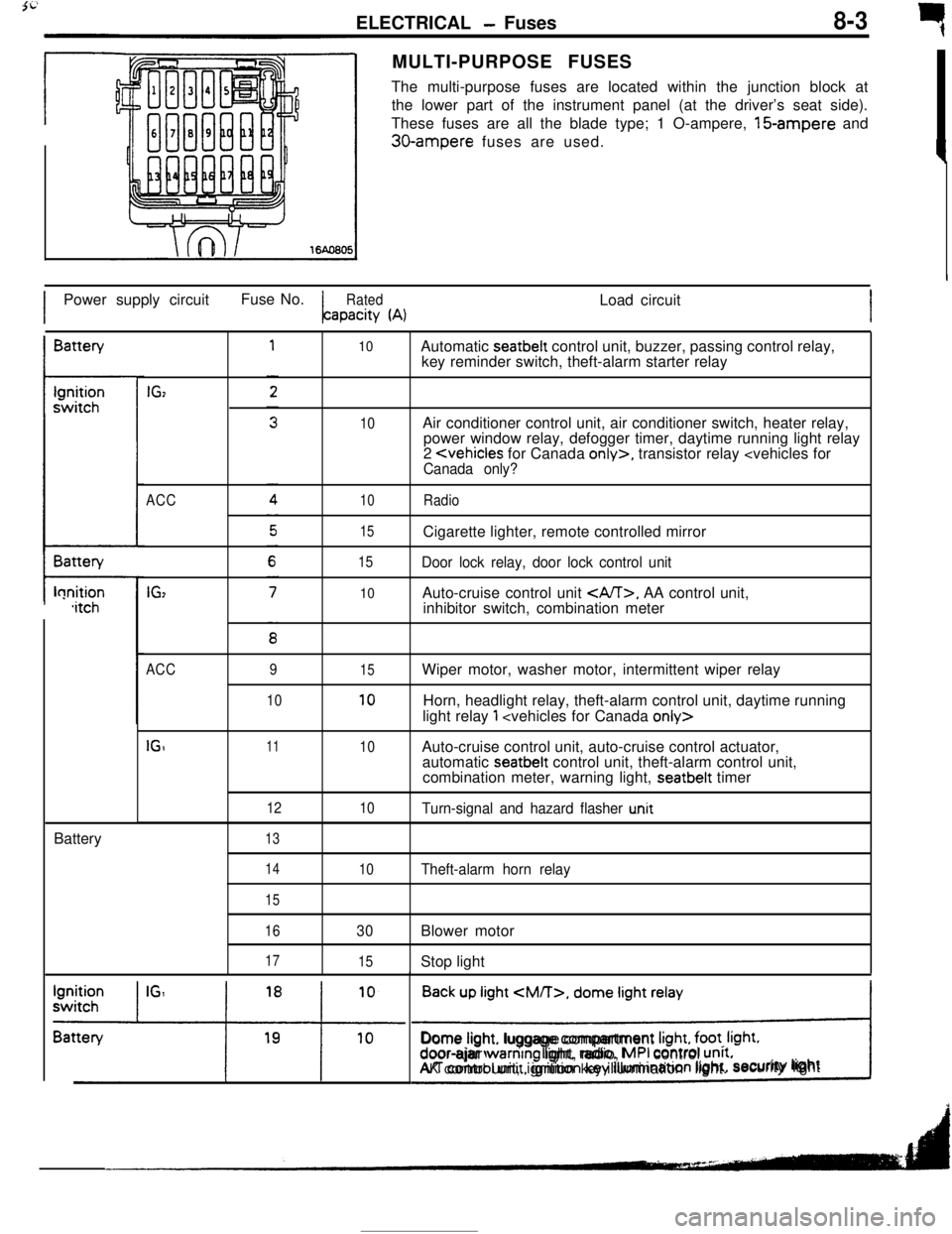

ELECTRICAL - Fuses8-3q

rMULTI-PURPOSE FUSES

The multi-purpose fuses are located within the junction block at

the lower part of the instrument panel (at the driver’s seat side).

These fuses are all the blade type; 1 O-ampere, 15-ampere and

30-ampere fuses are used.

IPower supply circuitFuse No.

RatedLoad circuitapacity

(A)IBattery

t-lonition,itchBattery

IGz

ACC

IG,

10

10

10

15

15

10Automatic seatbelt control unit, buzzer, passing control relay,

key reminder switch, theft-alarm starter relay

Air conditioner control unit, air conditioner switch, heater relay,

power window relay, defogger timer, daytime running light relay

2

Door lock relay, door lock control unitAuto-cruise control unit

, AA control unit,

inhibitor switch, combination meter

ACC

IGI9

1011

12

1315

10

10

10Wiper motor, washer motor, intermittent wiper relay

Horn, headlight relay, theft-alarm control unit, daytime running

light relay

1

automatic seatbelt control unit, theft-alarm control unit,

combination meter, warning light, seatbelt timer

Turn-signal and hazard flasher u.nit

14

15

16

17

10Theft-alarm horn relay

30Blower motor

15Stop light

Back up light

CM/T>, dome light relay

!Dome light. luggage compartment

Irght, foot. Irght.door-ajar warntng light, radio, MPI control unrt.AK control unit, ignition key illumination light.security lightI

Page 57 of 391

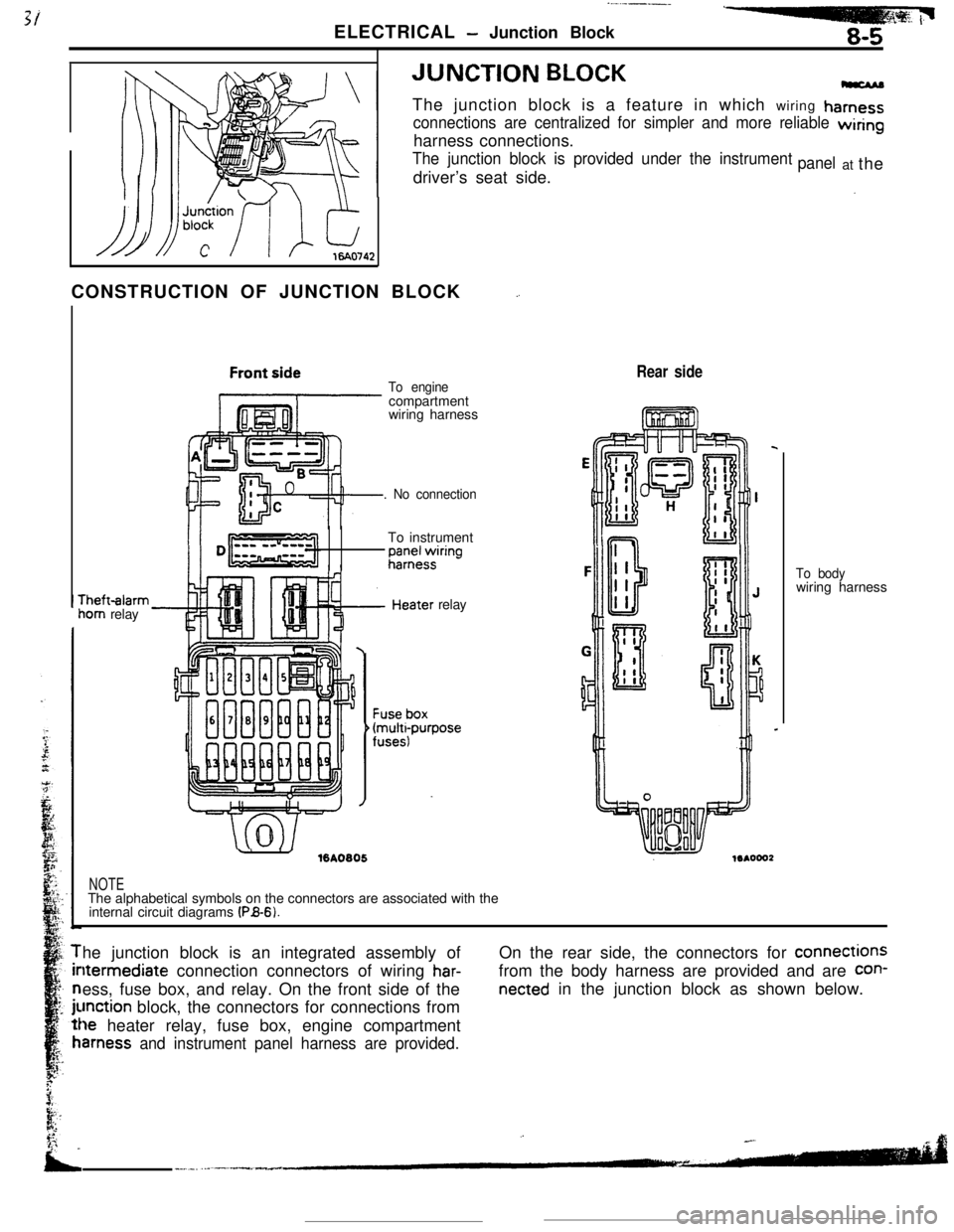

3i

ELECTRICAL - Junction Block8-5JUNCTION

BLOCKThe junction block is a feature in which wiring

hamess

connections are centralized for simpler and more reliable wiringharness connections.

The junction block is provided under the instrumentdriver’s seat side.panelat the

CONSTRUCTION OF JUNCTION BLOCK

_.rheft-alarm

iom relay

To enginecompartment

wiring harness

. No connectionTo instrument

;;;+$ring

.’ ./%A0805relay

Rear side

NOTEThe alphabetical symbols on the connectors are associated with the

internal circuit diagrams

(PB-6).To bodywiring harness

he junction block is an integrated assembly ofltermediate connection connectors of wiring

har-ess, fuse box, and relay. On the front side of the

unction block, the connectors for connections from

le heater relay, fuse box, engine compartment

amess and instrument panel harness are provided.On the rear side, the connectors for connections

from the body harness are provided and are

con-

netted in the junction block as shown below.

Page 63 of 391

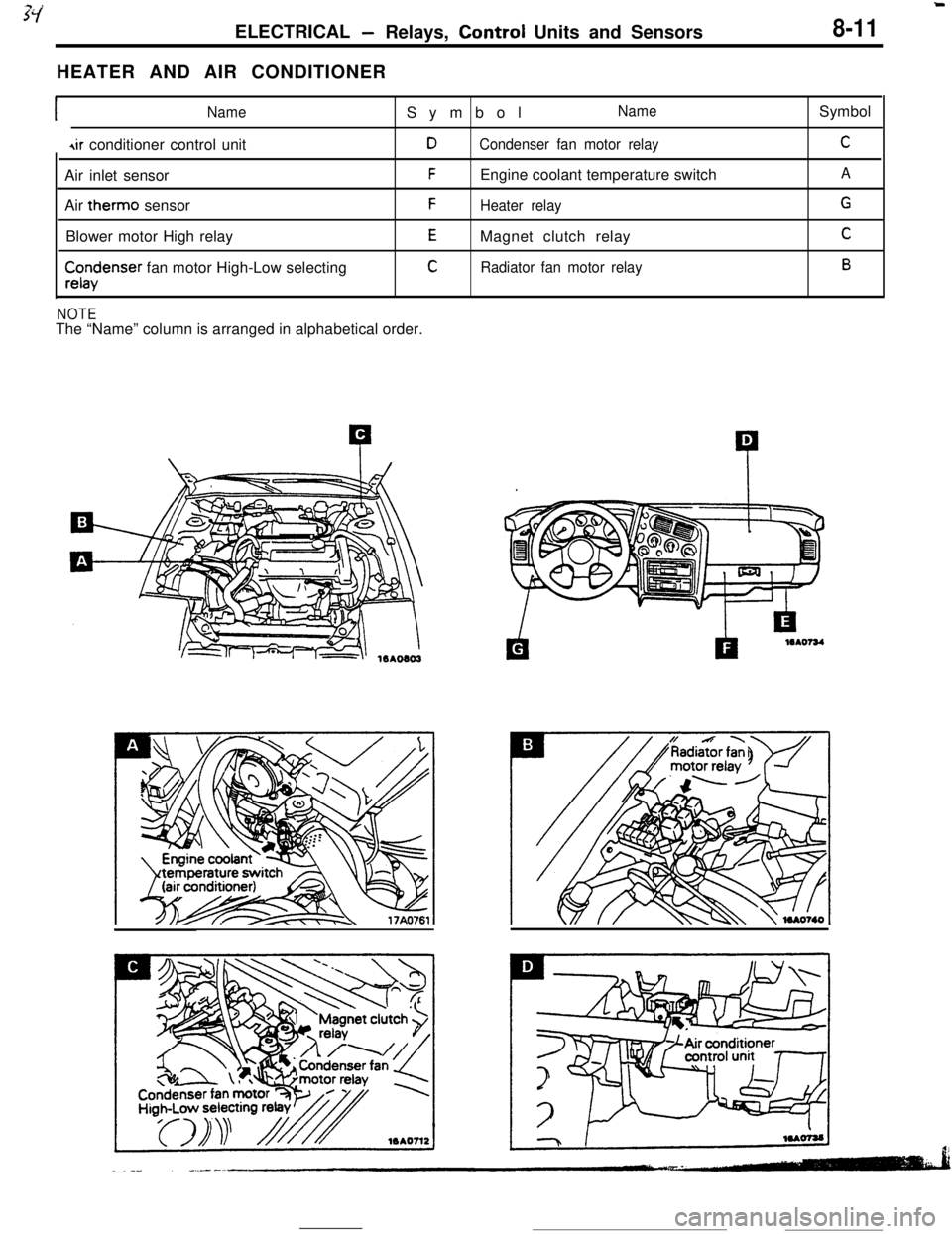

1ELECTRICAL

-Relays, Control Units and Sensors8-11HEATER AND AIR CONDITIONER

INameSymbolName

4ir conditioner control unitDCondenser fan motor relayAir inlet sensor

FEngine coolant temperature switch

Air therm0 sensor

FHeater relayBlower motor High relay

EMagnet clutch relay

$x$enser fan motor High-Low selectingCRadiator fan motor relay

NOTEThe “Name” column is arranged in alphabetical order.Symbol

C

A

G

C

B

Page 133 of 391

FUEL SYSTEM - Sensors14-21When exposed to light, the photo diode conducts

urrent in a direction opposite to an ordinary diode.

.s a result, current flows in the direction indicated

by the arrow and dotted line and a voltage (5 volts) isapplied to the comparator of the sensor unit so that

the terminal voltage of the engine control unit

becomes 5 volts. When the disc rotates further andthe slit moves beyond the space between the

LED/photo diode pair, the light can no longer reach

the photo diode, thus the current indicated by the

dotted line ceases to flow and the terminal voltage

of the engine control unit becomes 0 volt.

tn this

way, pulse signals are sent to the engine control

unit from the sensor unit.

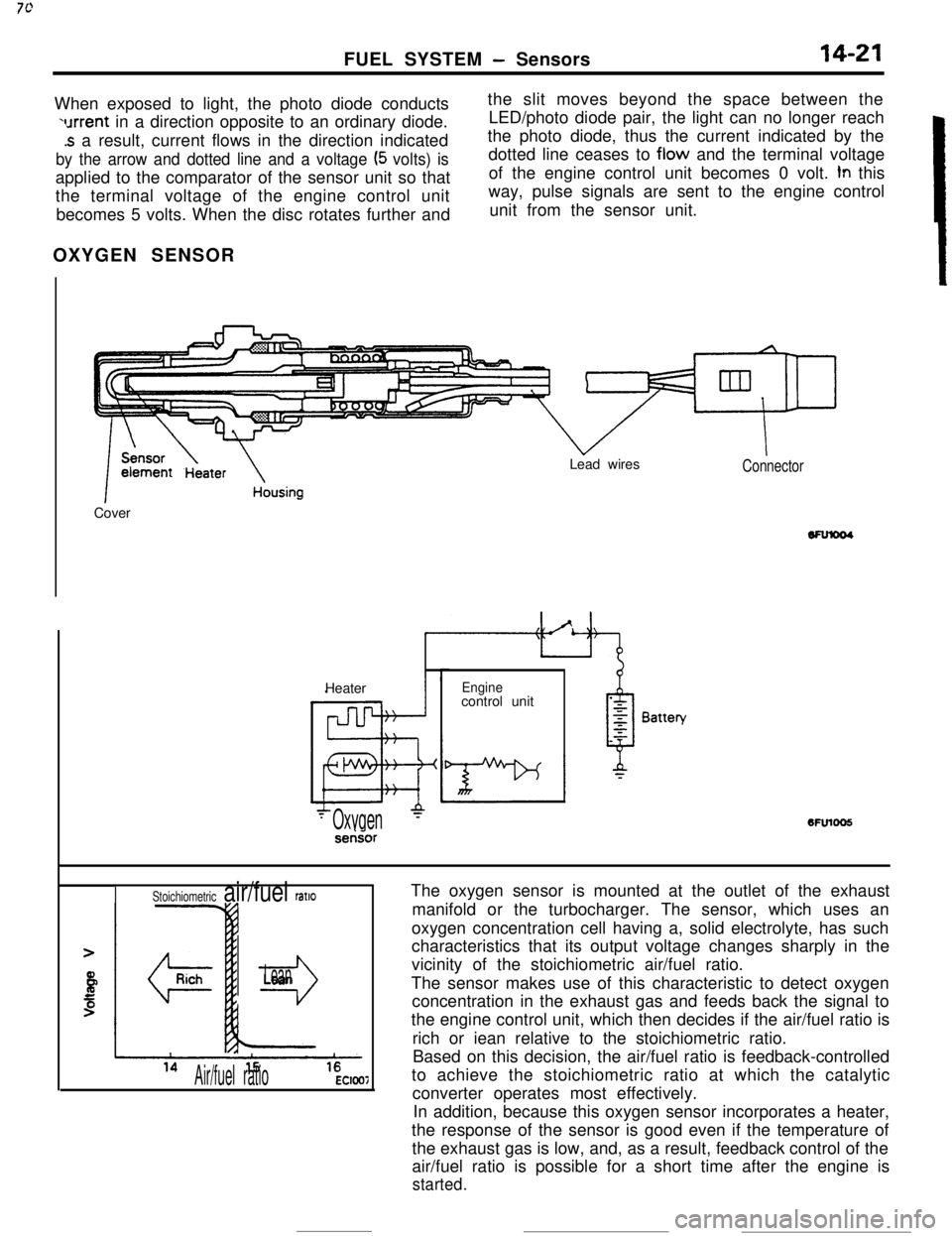

OXYGEN SENSOR

k

1 ~~~~t13ate~ousingCoverLead wiresConnectorHeater

Enginecontrol unit6FUlOO5

- Oxygen‘-serisor

The oxygen sensor is mounted at the outlet of the exhaust

manifold or the turbocharger. The sensor, which uses an

oxygen concentration cell having a, solid electrolyte, has such

characteristics that its output voltage changes sharply in the

vicinity of the stoichiometric air/fuel ratio.

The sensor makes use of this characteristic to detect oxygen

concentration in the exhaust gas and feeds back the signal to

the engine control unit, which then decides if the air/fuel ratio is

rich or iean relative to the stoichiometric ratio.

Based on this decision, the air/fuel ratio is feedback-controlled

to achieve the stoichiometric ratio at which the catalytic

converter operates most effectively.

In addition, because this oxygen sensor incorporates a heater,

the response of the sensor is good even if the temperature of

the exhaust gas is low, and, as a result, feedback control of the

air/fuel ratio is possible for a short time after the engine is

started.

Stoichiometric air/fuel ratlo

r3

Lean

Air/fuel ratioEC1007

Page 271 of 391

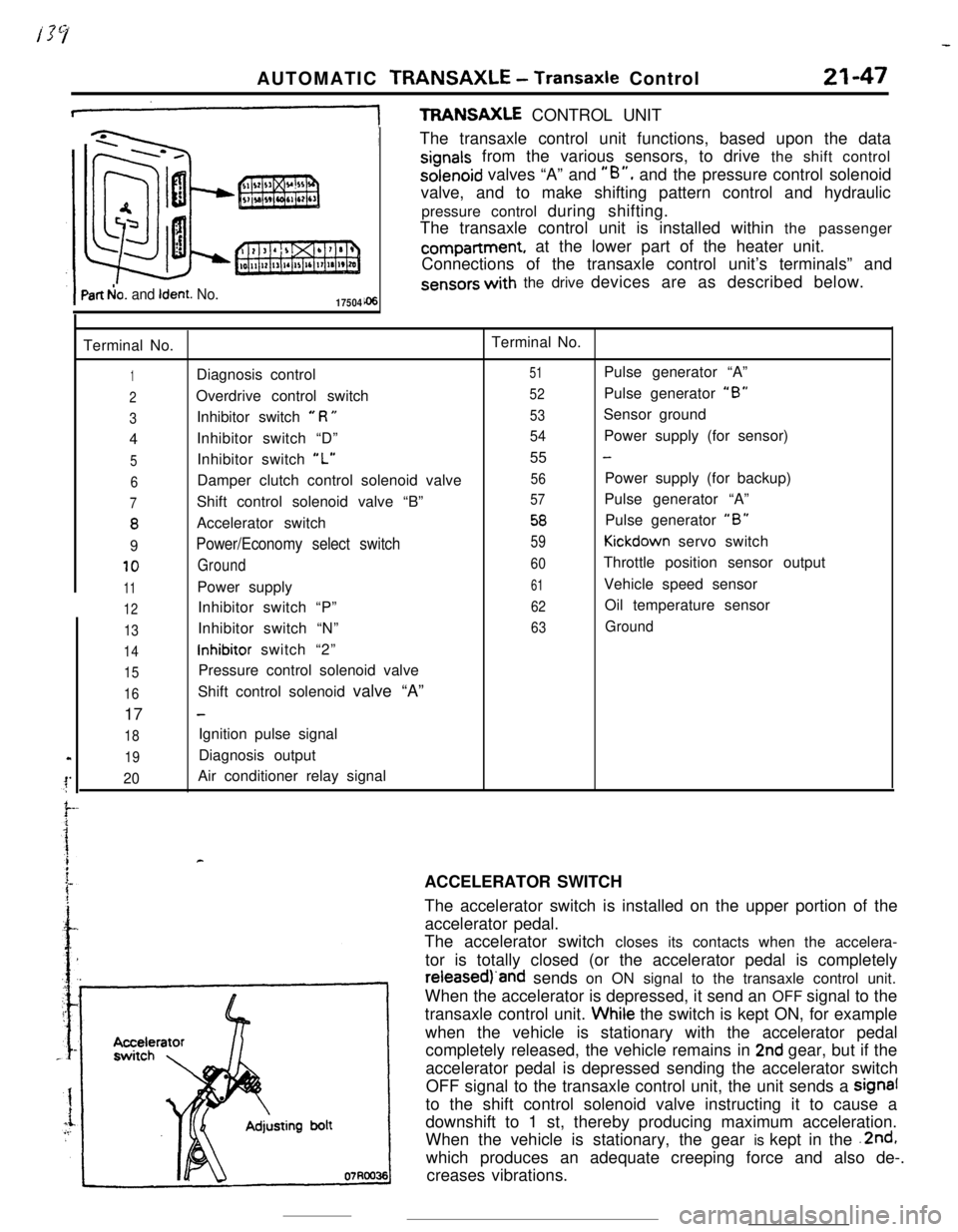

AUTOMATIC TRANSAXLE - Transaxle Control21-47

+TFWNSAXLE CONTROL UNIT

Part b!o. and Ident. No.17504The transaxle control unit functions, based upon the data

signals from the various sensors, to drive the shift controlsolenoid valves “A” and

“B”, and the pressure control solenoid

valve, and to make shifting pattern control and hydraulic

pressure control during shifting.

The transaxle control unit is installed within the passengercompartment, at the lower part of the heater unit.

Connections of the transaxle control unit’s terminals” and

sensors with the drive devices are as described below.

Terminal No.Terminal No.

1Diagnosis control51Pulse generator “A”

2Overdrive control switch52Pulse generator “B”

3Inhibitor switch e R U53Sensor ground

4Inhibitor switch “D”

54Power supply (for sensor)

5Inhibitor switch “L”55 -

6Damper clutch control solenoid valve56Power supply (for backup)

7Shift control solenoid valve “B”57Pulse generator “A”

8Accelerator switch58Pulse generator “B”

9Power/Economy select switch59Kickdown servo switch

10Ground60Throttle position sensor output

11Power supply61Vehicle speed sensor

12Inhibitor switch “P”62Oil temperature sensor

13Inhibitor switch “N”63Ground

14inhibitor switch “2”

15Pressure control solenoid valve

16Shift control solenoid valve “A”

17

-

18Ignition pulse signal

19Diagnosis output

20Air conditioner relay signal

rACCELERATOR SWITCH

The accelerator switch is installed on the upper portion of the

accelerator pedal.

The accelerator switch closes its contacts when the accelera-

tor is totally closed (or the accelerator pedal is completelyreieasedj‘and sends on ON signal to the transaxle control unit.

When the accelerator is depressed, it send an OFF signal to the

transaxle control unit. Whiie the switch is kept ON, for example

when the vehicle is stationary with the accelerator pedal

completely released, the vehicle remains in

2nd gear, but if the

accelerator pedal is depressed sending the accelerator switch

OFF signal to the transaxle control unit, the unit sends a signal

to the shift control solenoid valve instructing it to cause a

downshift to 1 st, thereby producing maximum acceleration.

When the vehicle is stationary, the gear is kept in the .2nd,

which produces an adequate creeping force and also de-.

creases vibrations.

Page 337 of 391

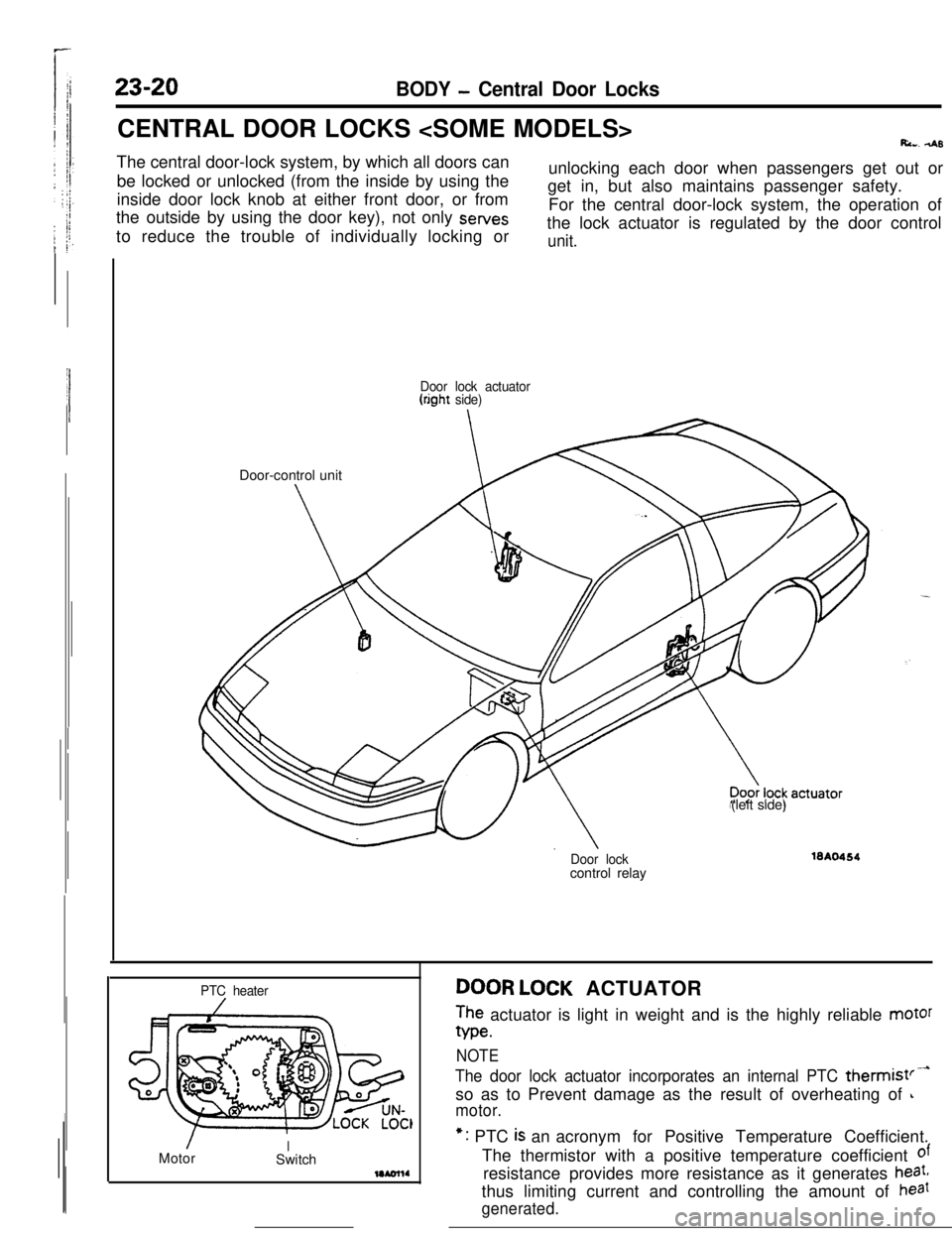

23-20BODY - Central Door LocksCENTRAL DOOR LOCKS

Ri... 4sThe central door-lock system, by which all doors can

be locked or unlocked (from the inside by using the

inside door lock knob at either front door, or from

the outside by using the door key), not only sewes

to reduce the trouble of individually locking orunlocking each door when passengers get out or

get in, but also maintains passenger safety.

For the central door-lock system, the operation of

the lock actuator is regulated by the door control

unit.

Door lock actuator(right side)Door-control unit

(left side)

Door lockcontrol relay16A0464

PTC heater

/MotorISwitchDOOR LOCK ACTUATOR

The actuator is light in weight and is the highly reliable motor

We.

NOTE

The door lock actuator incorporates an internal PTC thermist’-so as to Prevent damage as the result of overheating of

L

motor.*: PTC

is an acronym for Positive Temperature Coefficient.

The thermistor with a positive temperature coefficient

ofresistance provides more resistance as it generates

heat,thus limiting current and controlling the amount of

haat

generated.

Page 364 of 391

24-1

HEATERS

CONDITIONING

CONTENTS Rx&--

.._.........I............................... 8 HEATER CONSTRUCTIO N. . . . . . . . .._..................... 5

Compressor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . _ . . . . . . .._.. 8IDLE SPEED CONTRO L. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . 9

tNFORMATt0N. . . . . . .._................_......2

Page 365 of 391

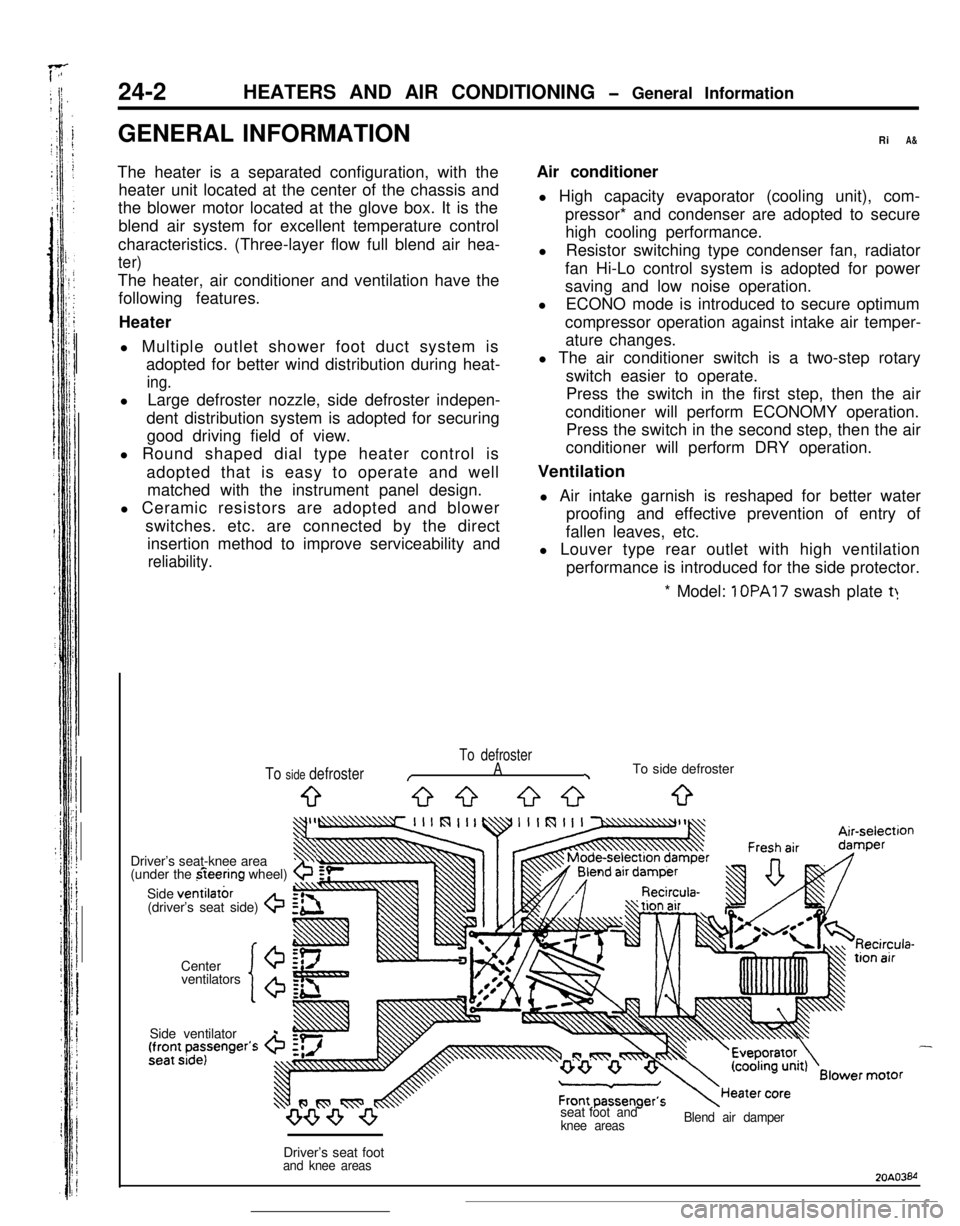

24-2 HEATERS AND AIR CONDITIONING

1 OPA17 swash plate t:

To defroster

/A\To side defroster

9G-3 53033

ventilators

‘lo’

Driver’s seat-knee area3$

(under the fieering wheel)b

Side ventilatbr(driver’s seat side) G

Center

20A03M