brake fluid MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 17 of 1216

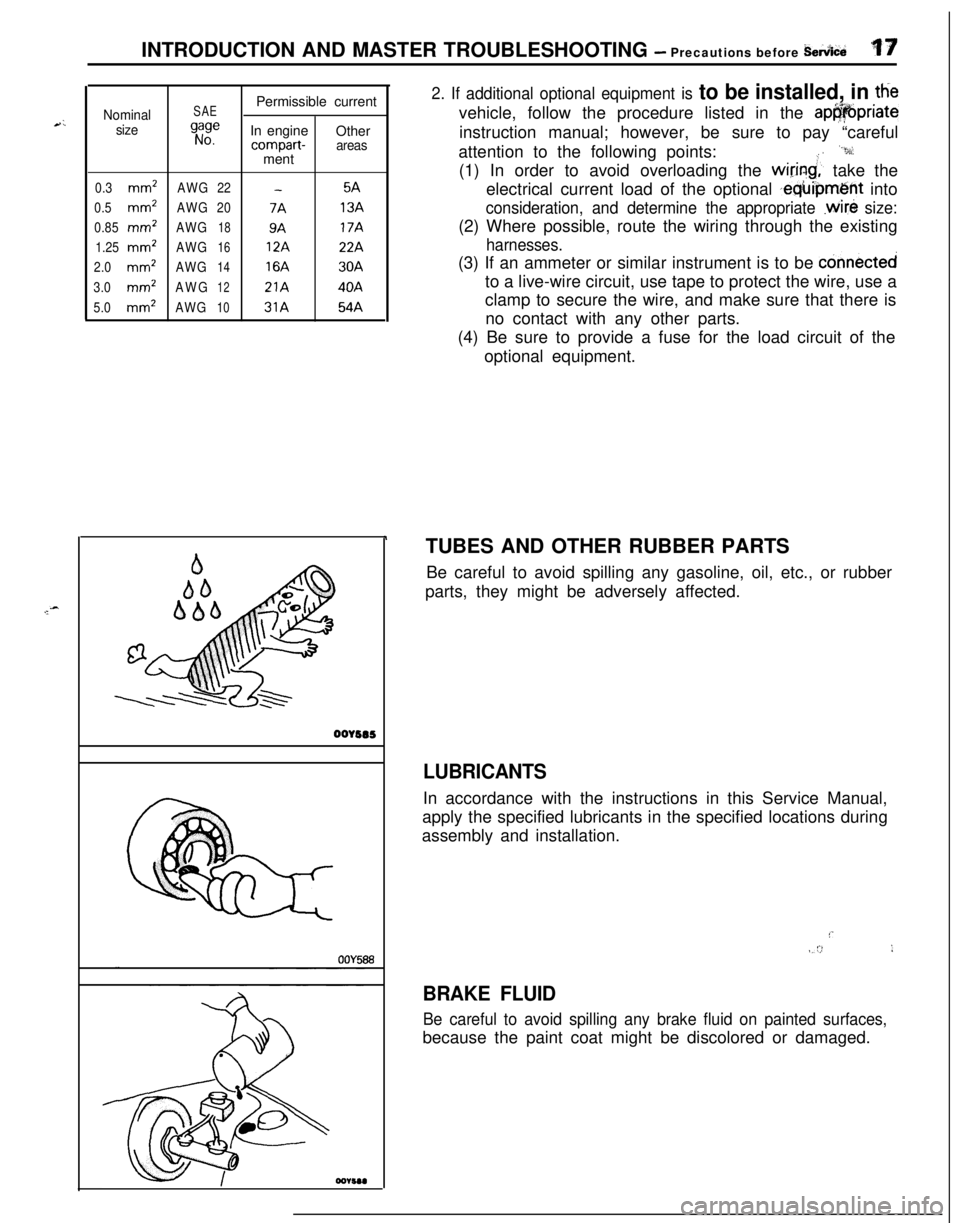

INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions before Sew&e‘37

Nominal

sizeSAE

gi:ePermissible current

In engine

Othercompart-areasment

0.3mm2AWG22-5A

0.5

mm2AWG207A13A

0.85

mm’AWG189A17A

1.25

mm2AWG1612A22A

2.0mm2AWG1416A30A

3.0mm’AWG1221A40A

5.0mm2AWG1031A54A

r ‘.

oorsas

2. If additional optional equipment is to be installed, in ttievehicle, follow the procedure listed in the

ap@@priateinstruction manual; however, be sure to pay “careful

attention to the following points:

“9:(1) In order to avoid overloading the

wiring;’ take the

electrical current load of the optional

,equipment into

consideration, and determine the appropriate .wire size:(2) Where possible, route the wiring through the existing

harnesses.(3) If an ammeter or similar instrument is to be

connectedto a live-wire circuit, use tape to protect the wire, use a

clamp to secure the wire, and make sure that there is

no contact with any other parts.

(4) Be sure to provide a fuse for the load circuit of the

optional equipment.

TUBES AND OTHER RUBBER PARTS

Be careful to avoid spilling any gasoline, oil, etc., or rubber

parts, they might be adversely affected.

LUBRICANTSIn accordance with the instructions in this Service Manual,

apply the specified lubricants in the specified locations during

assembly and installation.

!’IV/ :>,I

BRAKE FLUID

Be careful to avoid spilling any brake fluid on painted surfaces,because the paint coat might be discolored or damaged.

Page 31 of 1216

INTRODUCTION AND MASTER TROUBLESH’OOTING .- Master ~pAi&oOti~31POOR FUEL MILEAGE

../, *,, /S./..‘, _I, #_.a,‘.rr?

Symptom

Poor fuel mileageProbable cause

Fuel leak

Air cleaner clogged.Ignition system problems

Reference page or remedy”Repair as necessary.

-8-169

IFuel injection system problems.I-ICompression too low.9-23

Tires improperly inflated.22-3

Clutch slips.6-4

Brakes drag.5-7I

NOISE

Symptom

NoiseProbable cause

Loose bolts and nuts.

Engine noiseReference page or remedy

Retighten as necessary

9-23

’

HARD STEERING

Symptom

Hard steeringProbable causeLoose power steering oil pump belt

Low fluid levelAir in power steering system

Low tire pressure

Reference page or remedy19-12

Replenish19-13

22-3

Excessive turning resistance of lower arm ballExcessively tightened of steering gear box

IImproper front wheel alignment2-8

Excessive turning resistance of tie-rod ballioint2-35

1 i-23.30

19-8.10Sticky flow control valve

Bent rack in steering gear box‘.19-4119-23.30

POOR RETURN OF STEERING WHEEL TO CENTERSymptom

1Probable causeIReference pageI

Poor return of steering wheel tocenterImproper front wheel alignment

2-8

Improper tire pressure22-3

Excessive tightened rack support cover19-23.30

I-- ~~~Damaged front wheel bearingI2-12I

Page 37 of 1216

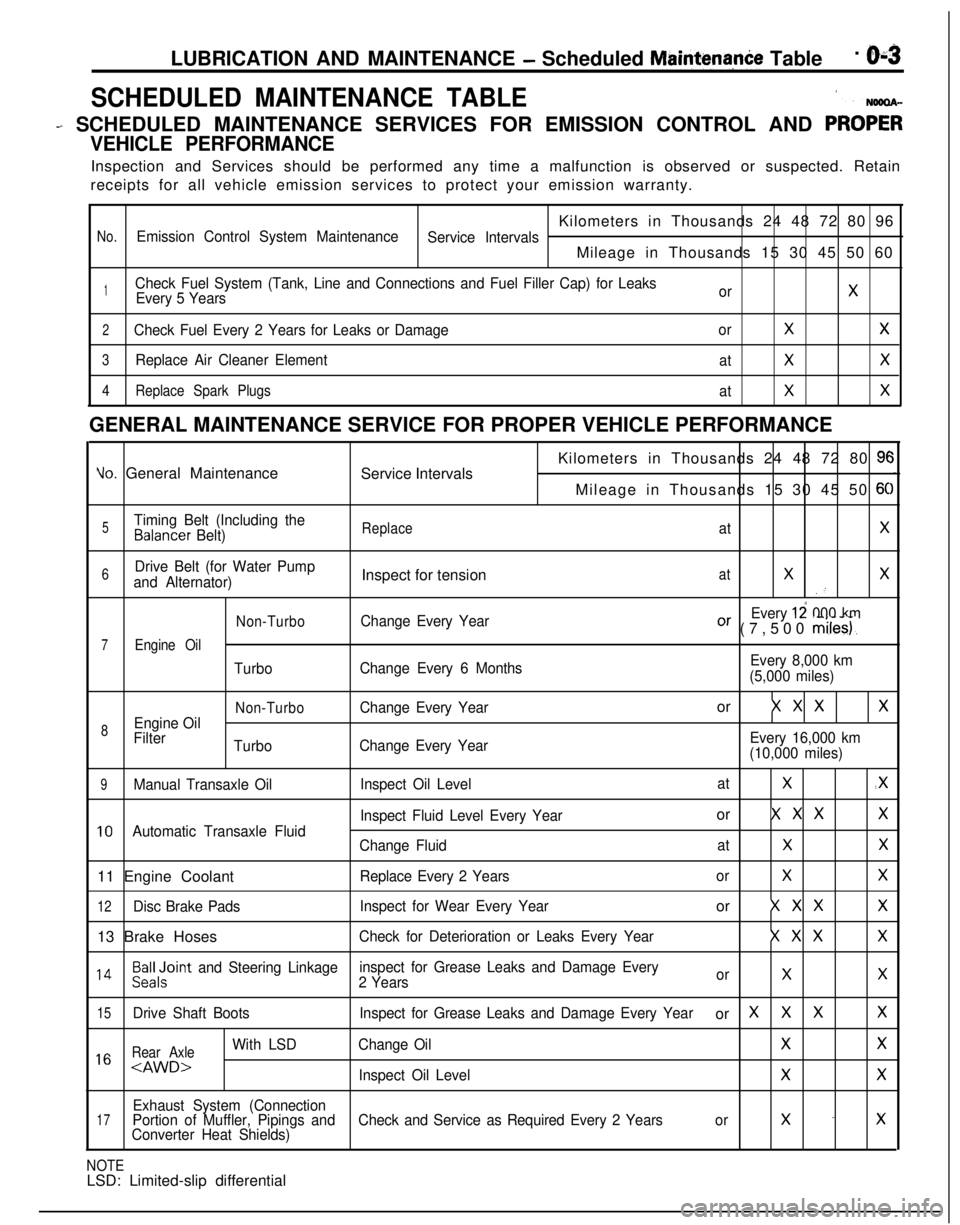

LUBRICATION AND MAINTENANCE - Scheduled MaintenanCe Table. &3

SCHEDULED MAINTENANCE TABLE1

- SCHEDULED MAINTENANCE SERVICES FOR EMISSION CONTROL AND PRO;;

VEHICLE PERFORMANCEInspection and Services should be performed any time a malfunction is observed or suspected. Retain

receipts for all vehicle emission services to protect your emission warranty.

Kilometers in Thousands 24 48 72 80 96

No.Emission Control System Maintenance

Service IntervalsMileage in Thousands 15 30 45 50 60

1Check Fuel System (Tank, Line and Connections and Fuel Filler Cap) for Leaks

Every 5 YearsorX

2Check Fuel Every 2 Years for Leaks or DamageorXX

3Replace Air Cleaner Element

atXX

4Replace Spark Plugs

atXXGENERAL MAINTENANCE SERVICE FOR PROPER VEHICLE PERFORMANCE

Yo. General Maintenance

Service IntervalsKilometers in Thousands 24 48 72 80 9cMileage in Thousands 15 30 45 50

6C

5Timing Belt (Including theBalancer Belt)ReplaceatX

6Drive Belt (for Water Pump

and Alternator)Inspect for tensionatXX.’

Non-TurboChange Every YearEvery 12 000 kmOr (7,500 miles).

7Engine Oil

TurboChange Every 6 MonthsEvery 8,000 km

(5,000 miles)

Non-TurboChange Every Yearor X X XX

8Engine Oil

Filter

TurboChange Every YearEvery 16,000 km

(10,000 miles)

9Manual Transaxle OilInspect Oil LevelatX.X

Inspect Fluid Level Every Yearor X X XX

10Automatic Transaxle Fluid

Change FluidatXX11 Engine Coolant

Replace Every 2 YearsorXX

12Disc Brake PadsInspect for Wear Every Yearor X X XX13 Brake Hoses

Check for Deterioration or Leaks Every YearX X XX

l 4Beiloint and Steering Linkageinspect for Grease Leaks and Damage Every

2 YearsorXX

15Drive Shaft BootsInspect for Grease Leaks and Damage Every Yearor XXXX

Rear Axle

With LSDChange OilXX1 6

Exhaust System (Connection17Portion of Muffler, Pipings andCheck and Service as Required Every 2 Yearsorx -xConverter Heat Shields)

NOTELSD: Limited-slip differential

Page 38 of 1216

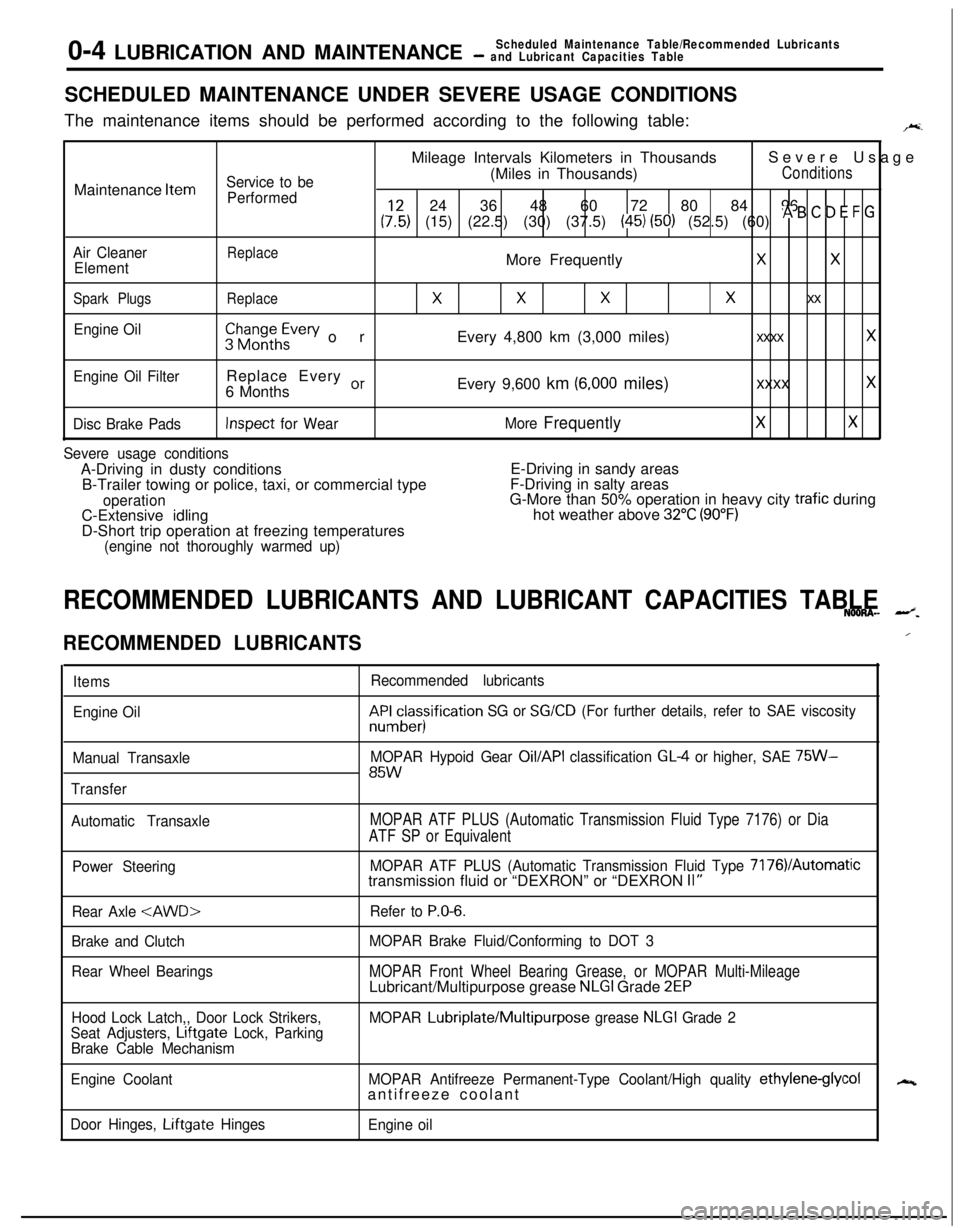

0-4 LUBRICATION AND MAINTENANCEScheduled Maintenance Table/Recommended Lubricants- and Lubricant Capacities TableSCHEDULED MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The maintenance items should be performed according to the following table:

F.Mileage Intervals Kilometers in ThousandsSevere Usage

Service to be(Miles in Thousands)ConditionsMaintenance

Item

Performed24 36 48 60 72 80 84 96

(:,:) (15) (22.5) (30) (37.5) (45) (50) (52.5) (60) * B ’ D E F G

Air CleanerReplaceElementMore FrequentlyXX

Spark PlugsReplace

XXXx xx

Engine Oil$$~~~h~vev orEvery 4,800 km (3,000 miles)xxxx x

Engine Oil FilterReplace Every or6 MonthsEvery 9,600 km (6,000 miles)xxxx x

Disc Brake PadsInspect for WearMore FrequentlyXX

Severe usage conditionsA-Driving in dusty conditionsE-Driving in sandy areas

B-Trailer towing or police, taxi, or commercial typeF-Driving in salty areas

operationG-More than 50% operation in heavy city trafic during

C-Extensive idlinghot weather above 32°C (90°F)D-Short trip operation at freezing temperatures

(engine not thoroughly warmed up)

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLENOONA- --z.

RECOMMENDED LUBRICANTS

Items

Engine Oil

Manual Transaxle

TransferRecommended lubricantskF&cesisification

SG or SG/CD (For further details, refer to SAE viscosity

MOPAR Hypoid Gear

Oil/API classification GL4 or higher, SAE 75W-85W

Automatic TransaxleMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176) or Dia

ATF SP or Equivalent

Power SteeringMOPAR ATF PLUS (Automatic Transmission Fluid Type 7176VAutomatictransmission fluid or “DEXRON” or “DEXRON II”

Rear Axle

Brake and Clutch

Rear Wheel BearingsRefer to

P.O-6.

MOPAR Brake Fluid/Conforming to DOT 3

MOPAR Front Wheel Bearing Grease, or MOPAR Multi-MileageLubricant/Multipurpose grease NLGI Grade 2EP

Hood Lock Latch,, Door Lock Strikers,

Seat Adjusters, Lrftgate Lock, Parking

Brake Cable MechanismMOPAR Lubriplate/Multipurpose grease NLGI Grade 2

Engine CoolantMOPAR Antifreeze Permanent-Type Coolant/High quality

ethylene-glycolantifreeze coolant

Door Hinges, Liftgate Hinges

Engine oil

/

N

Page 46 of 1216

LUBRICATION AND MAINTENANCE - Maintenance Service

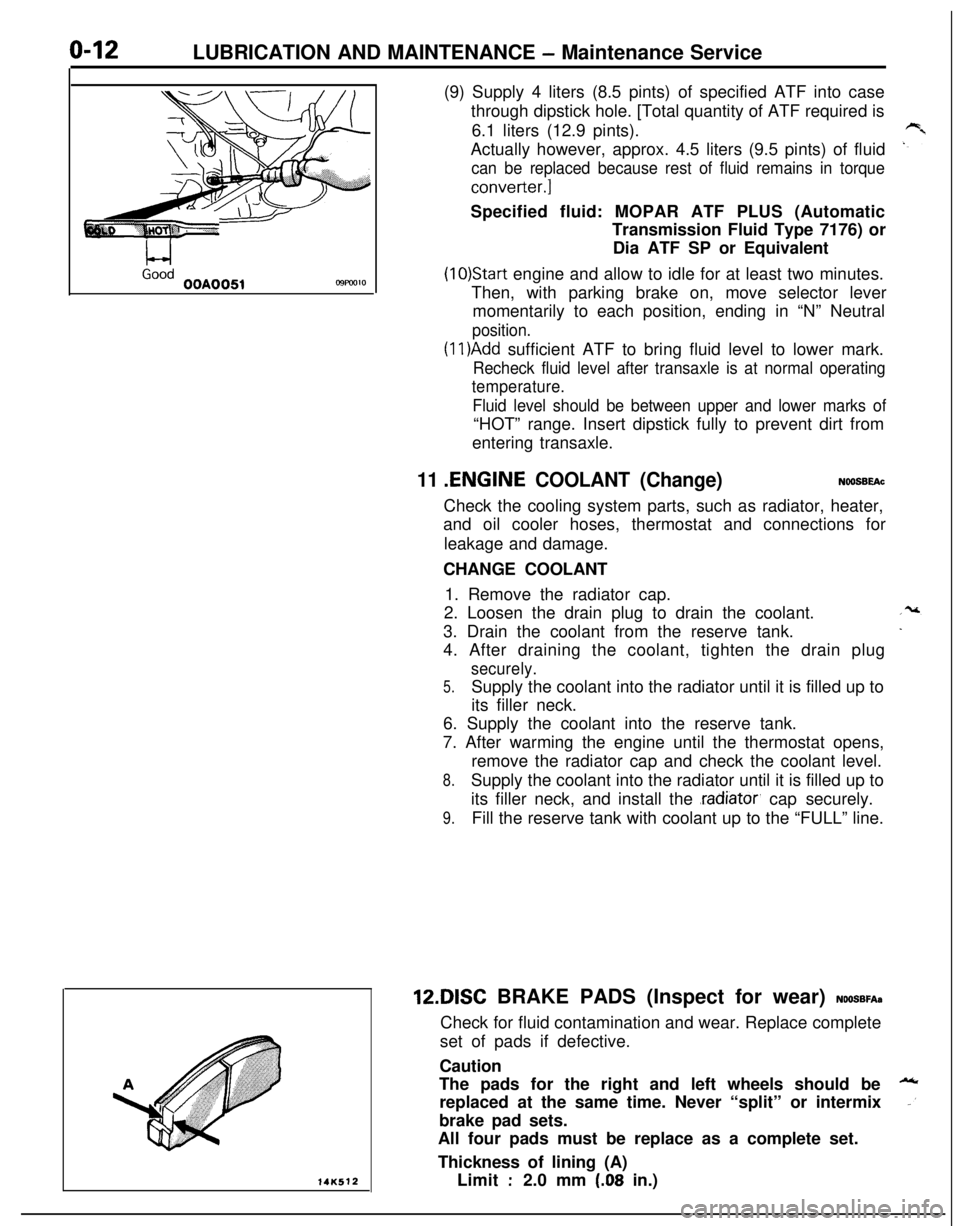

L-4GoodOOA0051C9FW1014K512(9) Supply 4 liters (8.5 pints) of specified ATF into case

through dipstick hole. [Total quantity of ATF required is

6.1 liters (12.9 pints).

Actually however, approx. 4.5 liters (9.5 pints) of fluid

can be replaced because rest of fluid remains in torque

converter.]Specified fluid: MOPAR ATF PLUS (Automatic

Transmission Fluid Type 7176) or

Dia ATF SP or Equivalent

(10)Start engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector lever

momentarily to each position, ending in “N” Neutral

position.

(1 l)Add sufficient ATF to bring fluid level to lower mark.

Recheck fluid level after transaxle is at normal operating

temperature.

Fluid level should be between upper and lower marks of“HOT” range. Insert dipstick fully to prevent dirt from

entering transaxle.

11 .ENGINE COOLANT (Change)NOOSBEAcCheck the cooling system parts, such as radiator, heater,

and oil cooler hoses, thermostat and connections for

leakage and damage.

CHANGE COOLANT

1. Remove the radiator cap.

2. Loosen the drain plug to drain the coolant.

3. Drain the coolant from the reserve tank.

4. After draining the coolant, tighten the drain plug

securely.

5.Supply the coolant into the radiator until it is filled up to

its filler neck.

6. Supply the coolant into the reserve tank.

7. After warming the engine until the thermostat opens,

remove the radiator cap and check the coolant level.

8.Supply the coolant into the radiator until it is filled up to

its filler neck, and install the

.radiator, cap securely.

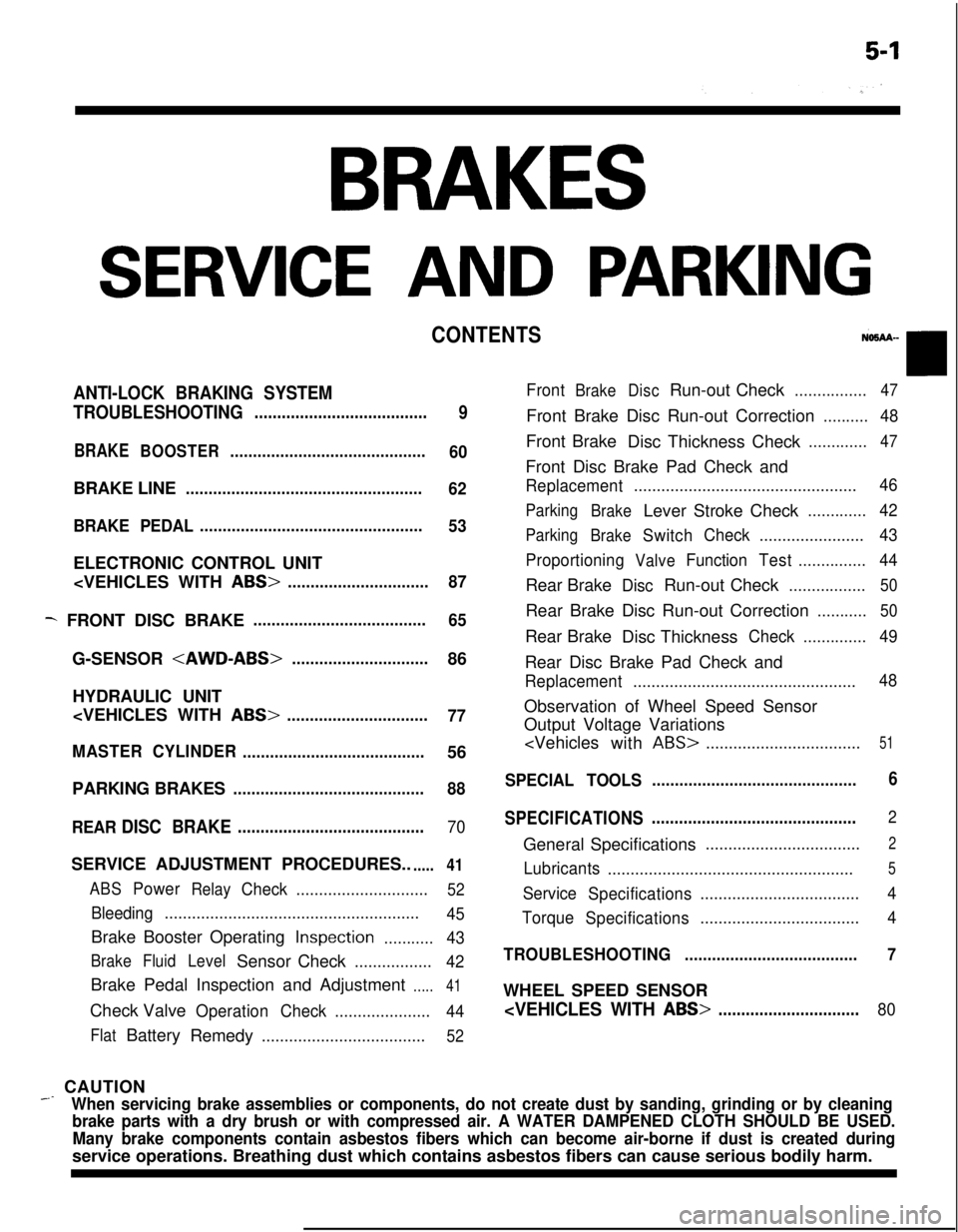

9.Fill the reserve tank with coolant up to the “FULL” line.12DISC BRAKE PADS (Inspect for wear)

NOOSBFA~Check for fluid contamination and wear. Replace complete

set of pads if defective.

Caution

The pads for the right and left wheels should be

replaced at the same time. Never “split” or intermix

brake pad sets.

All four pads must be replace as a complete set.

Thickness of lining (A)

Limit

:2.0 mm (.08 in.)

Page 141 of 1216

BRAKES

SERVICE AND PARKING

CONTENTS

ANTI-LOCK BRAKING SYSTEM

TROUBLESHOOTING

......................................

9

BRAKEBOOSTER...........................................

60BRAKE LINE

....................................................

62

BRAKE PEDAL.................................................

53ELECTRONIC CONTROL UNIT

- FRONT DISC BRAKE......................................

65G-SENSOR

HYDRAULIC UNIT

77

MASTERCYLINDER

........................................56

PARKING BRAKES

..........................................88

REAR

DISC BRAKE.........................................70SERVICE ADJUSTMENT PROCEDURES..

.....41

ABSPowerRelayCheck.............................52

Bleeding........................................................

45Brake Booster Operating

Inspection...........43

BrakeFluidLevelSensor Check.................

42Brake Pedal Inspection and Adjustment

.....41Check Valve

OperationCheck.....................

44

FlatBattery

Remedy....................................52

FrontBrakeDiscRun-out Check................47Front Brake Disc Run-out Correction

..........48Front Brake

Disc Thickness Check

.............47Front Disc Brake Pad Check and

Replacement.................................................46

Parking

BrakeLever Stroke Check.............42

Parking

BrakeSwitchCheck.......................43

Proportioning

ValveFunctionTest...............44Rear Brake

DiscRun-out Check.................50Rear Brake Disc Run-out Correction

...........50Rear Brake

Disc Thickness

Check..............49Rear Disc Brake Pad Check and

Replacement.................................................48Observation of Wheel Speed Sensor

Output Voltage Variations

ABS>..................................51

SPECIAL TOOLS.............................................6

SPECIFICATIONS.............................................

2General Specifications

..................................2

Lubricants

......................................................5

Service

Specifications...................................4

Torque

Specifications...................................4

TROUBLESHOOTING......................................7WHEEL SPEED SENSOR

_ CAUTION

When servicing brake assemblies or components, do not create dust by sanding, grinding or by cleaning

brake parts with a dry brush or with compressed air. A WATER DAMPENED CLOTH SHOULD BE USED.

Many brake components contain asbestos fibers which can become air-borne if dust is created duringservice operations. Breathing dust which contains asbestos fibers can cause serious bodily harm.

Page 145 of 1216

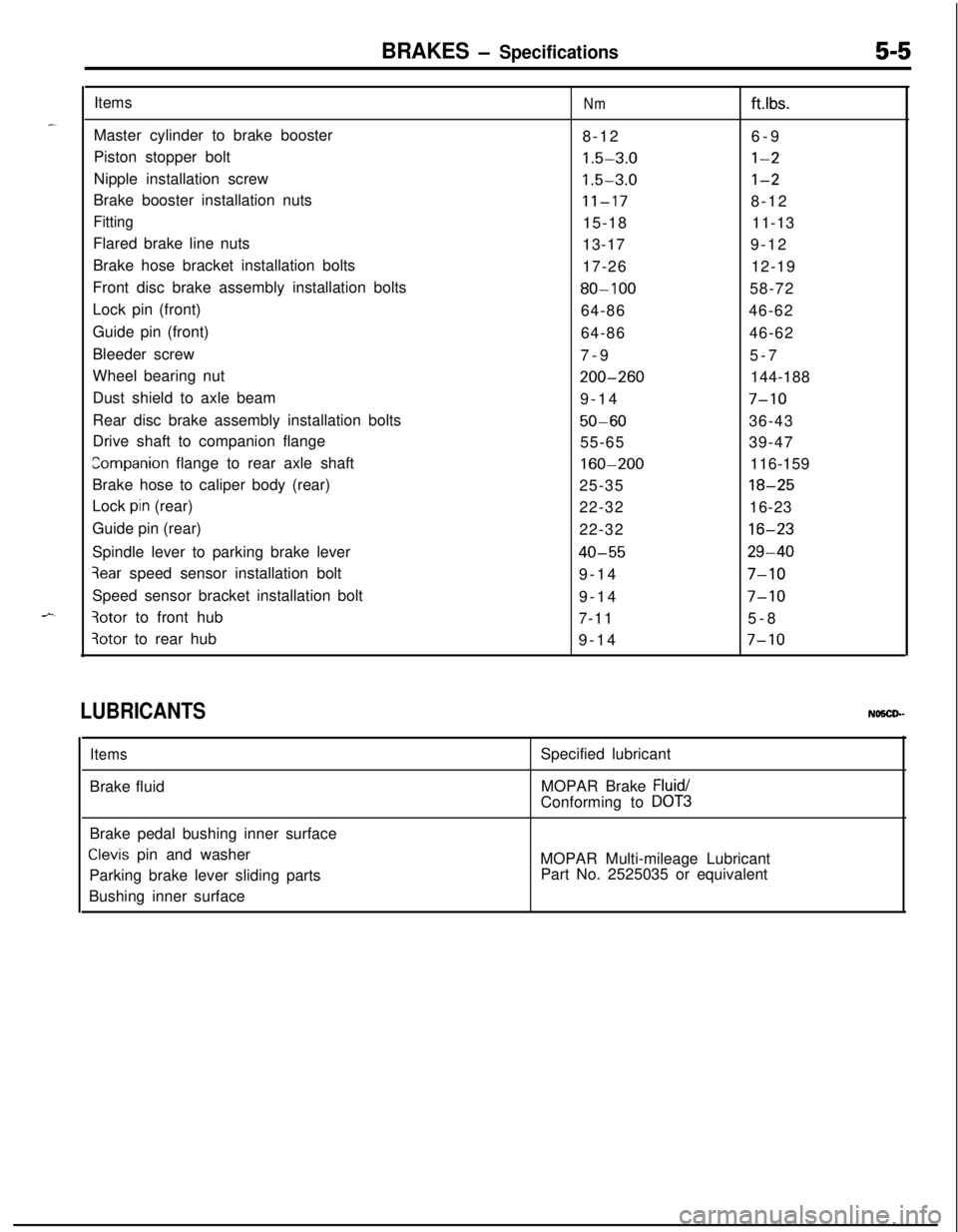

BRAKES - Specifications5-5Items

Nmftlbs.Master cylinder to brake booster

8-126-9

Piston stopper bolt

1.5-3.0l-2Nipple installation screw

1.5-3.0l-2Brake booster installation nuts

11-178-12

Fitting15-1811-13

Flared brake line nuts

13-179-12

Brake hose bracket installation bolts

17-2612-19

Front disc brake assembly installation bolts

80-10058-72

Lock pin (front)

64-8646-62

Guide pin (front)

64-8646-62

Bleeder screw

7-95-7

Wheel bearing nut

200-260144-188

Dust shield to axle beam

9-14

7-10Rear disc brake assembly installation bolts

50-6036-43

Drive shaft to companion flange

55-6539-47

companion flange to rear axle shaft160-200116-159

Brake hose to caliper body (rear)

25-35

18-25Lock

pin (rear)

22-3216-23

Guide pin (rear)

22-32

16-23Spindle lever to parking brake lever

40-5529-40

3ear speed sensor installation bolt

9-147-10Speed sensor bracket installation bolt

9-14

7-10

3otor to front hub

7-115-8

3otor to rear hub

9-147-10

LUBRICANTSNO5CP-

ItemsBrake fluidSpecified lubricant

MOPAR Brake

Fluid/Conforming to

DOT3Brake pedal bushing inner surface

Clevis pin and washer

Parking brake lever sliding parts

Bushing inner surfaceMOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

Page 181 of 1216

BRAKES - Service Adjustment Procedures5-47switch

switch

v14F516

Idown ,./

F14517

F14518

F14519

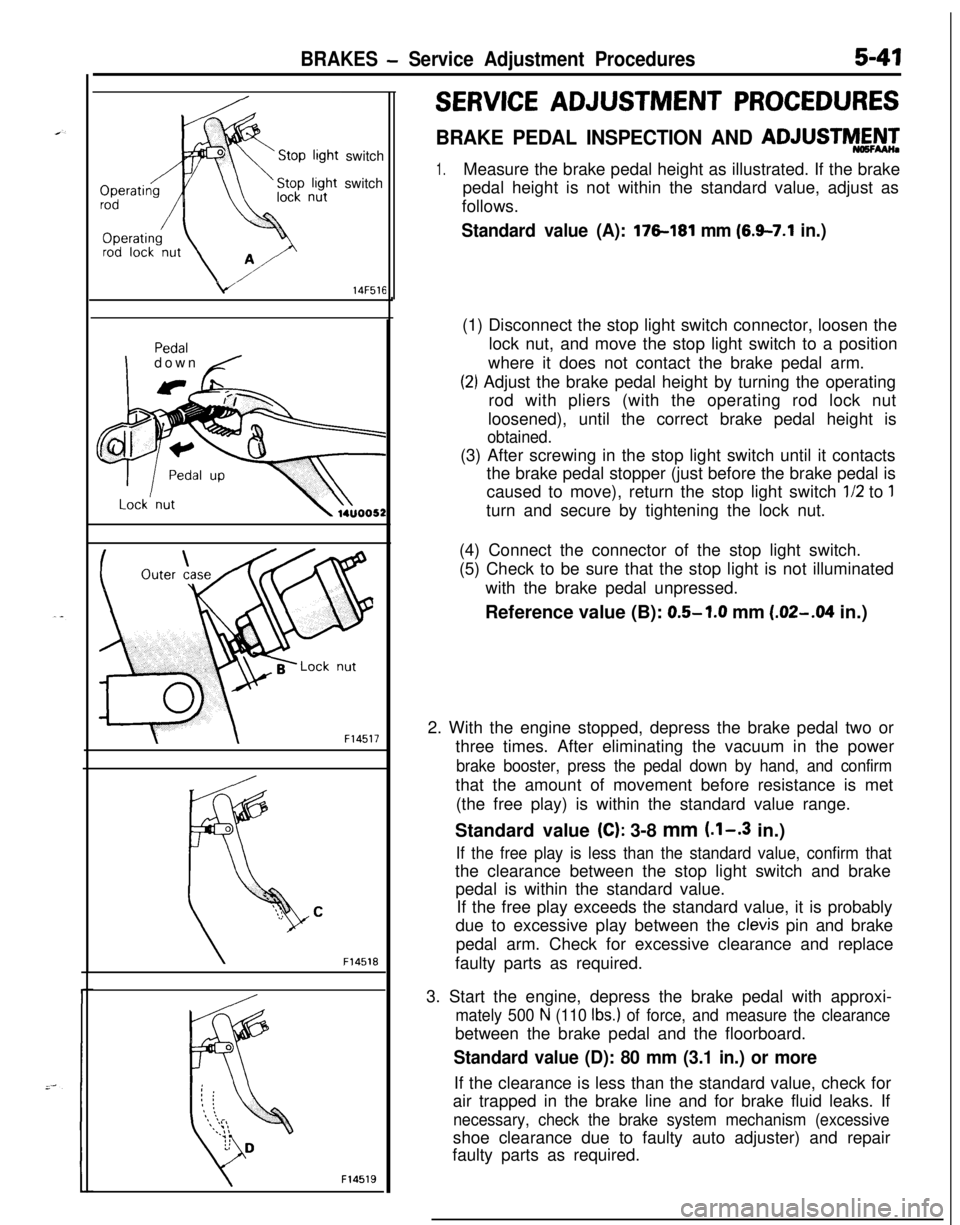

SERVICE ADJUSTMENT PROCEDURES

BRAKE PEDAL INSPECTION AND ADJUSTM&g

1.Measure the brake pedal height as illustrated. If the brake

pedal height is not within the standard value, adjust as

follows.

Standard value (A): 176181 mm (6.9-7.1 in.)(1) Disconnect the stop light switch connector, loosen the

lock nut, and move the stop light switch to a position

where it does not contact the brake pedal arm.

(2) Adjust the brake pedal height by turning the operating

rod with pliers (with the operating rod lock nut

loosened), until the correct brake pedal height is

obtained.(3) After screwing in the stop light switch until it contacts

the brake pedal stopper (just before the brake pedal is

caused to move), return the stop light switch

l/2 to 1turn and secure by tightening the lock nut.

(4) Connect the connector of the stop light switch.

(5) Check to be sure that the stop light is not illuminated

with the brake pedal unpressed.

Reference value (B): 0.5-1.0 mm

(.02-M in.)

2. With the engine stopped, depress the brake pedal two or

three times. After eliminating the vacuum in the power

brake booster, press the pedal down by hand, and confirmthat the amount of movement before resistance is met

(the free play) is within the standard value range.

Standard value

(C): 3-8 mm (.l-.3 in.)

If the free play is less than the standard value, confirm thatthe clearance between the stop light switch and brake

pedal is within the standard value.

If the free play exceeds the standard value, it is probably

due to excessive play between the

clevis pin and brake

pedal arm. Check for excessive clearance and replace

faulty parts as required.

3. Start the engine, depress the brake pedal with approxi-

mately 500 N (110 Ibs.) of force, and measure the clearancebetween the brake pedal and the floorboard.

Standard value (D): 80 mm (3.1 in.) or moreIf the clearance is less than the standard value, check for

air trapped in the brake line and for brake fluid leaks. If

necessary, check the brake system mechanism (excessiveshoe clearance due to faulty auto adjuster) and repair

faulty parts as required.

Page 182 of 1216

5-42BRAKES - Service Adjustment Procedures

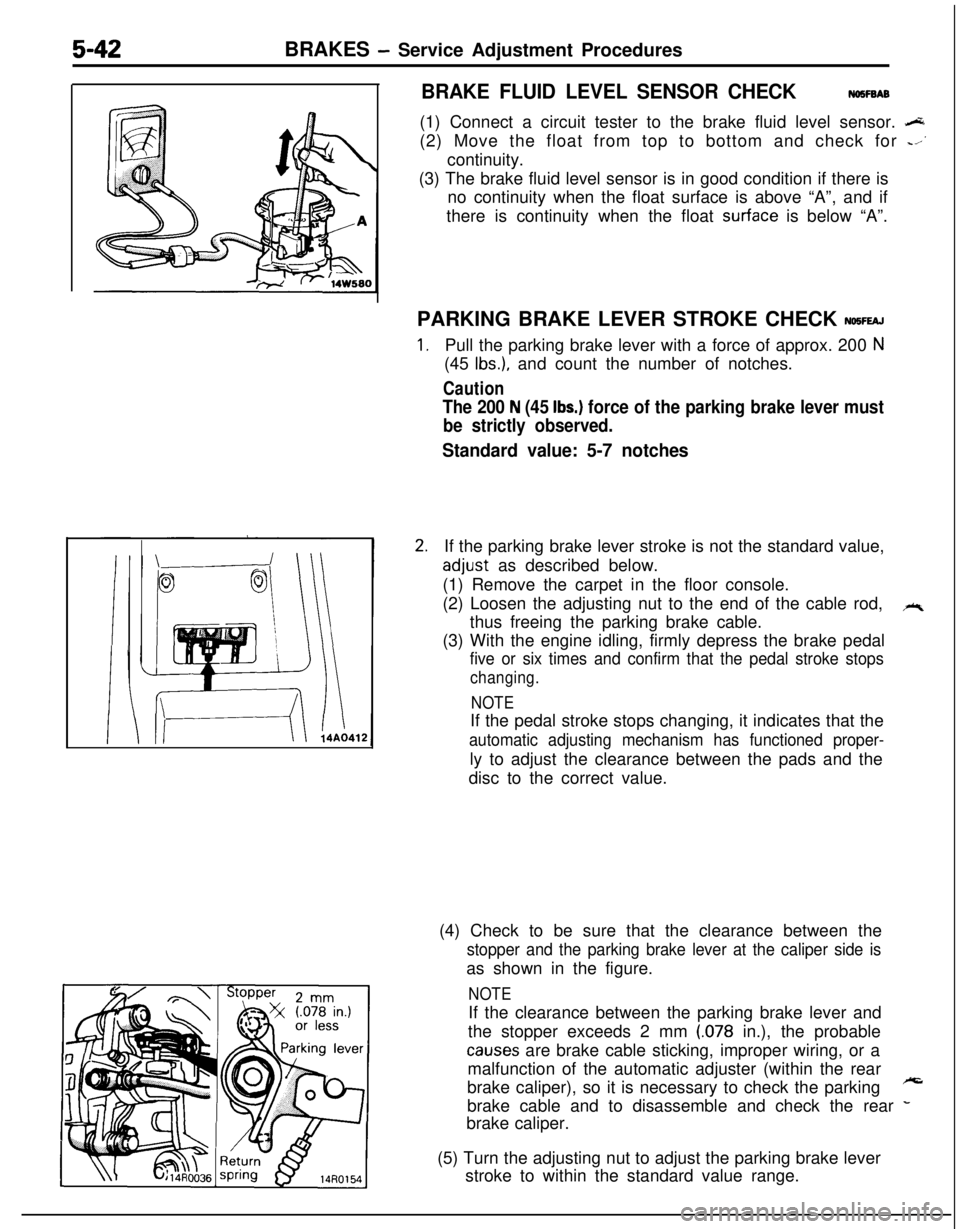

BRAKE FLUID LEVEL SENSOR CHECKNO5FBAB(1) Connect a circuit tester to the brake fluid level sensor.

4(2) Move the float from top to bottom and check for

.-,’continuity.

(3) The brake fluid level sensor is in good condition if there is

no continuity when the float surface is above “A”, and if

there is continuity when the float

surface is below “A”.

PARKING BRAKE LEVER STROKE CHECK NWFEAJ

1.Pull the parking brake lever with a force of approx. 200 N(45

Ibs.), and count the number of notches.

Caution

The 200 N (45 Ibs.) force of the parking brake lever must

be strictly observed.

Standard value: 5-7 notches

2.If the parking brake lever stroke is not the standard value,

adjust as described below.

(1) Remove the carpet in the floor console.

(2) Loosen the adjusting nut to the end of the cable rod,

fithus freeing the parking brake cable.

(3) With the engine idling, firmly depress the brake pedal

five or six times and confirm that the pedal stroke stops

changing.

NOTEIf the pedal stroke stops changing, it indicates that the

automatic adjusting mechanism has functioned proper-ly to adjust the clearance between the pads and the

disc to the correct value.

(4) Check to be sure that the clearance between the

stopper and the parking brake lever at the caliper side isas shown in the figure.

NOTEIf the clearance between the parking brake lever and

the stopper exceeds 2 mm

(078 in.), the probable

causes are brake cable sticking, improper wiring, or a

malfunction of the automatic adjuster (within the rear

brake caliper), so it is necessary to check the parking

-brake cable and to disassemble and check the rear

-brake caliper.

(5) Turn the adjusting nut to adjust the parking brake lever

stroke to within the standard value range.

Page 184 of 1216

BRAKES - Service Adjustment Procedures

WA041 7

Pressure

gaugePressure

PropG-tioning valve t4Lmt

,’

,Sdit point

outputpressure

Input pressure

14uoo55CHECK VALVE OPERATION CHECK

NOSFNAJ

When checking the check valve, keep the check valve fit in thevacuum hose.

1. Remove the vacuum hose.

Caution

The check valve is press-fit inside the vacuum hose and

do not remove the check valve from the vacuum hose.

2.Check the operation of the check valve by using a vacuum

pump.Vacuum pump connection Accept/reject criteria

Connection at the brake A negative pressure (vacuum) is

booster side

@Icreated and held.

Connection at the intake

manifold side

@A negative pressure (vacuum) is notcreated.

Caution

If the check valve is defective, replace it as an assembly

unit together with the vacuum hose.PROPORTIONING VALVE FUNCTION TEST

NOSFKAJ

1.Connect two pressure gauges, one each to the input side

and output side of the proportioning valve, as shown.

2. Air bleed the brake line and the pressure gauge.

3. While gradually depressing the brake pedal, make the

following measurements and check to be sure that the

measured values are within the allowable range.

(1) Output pressure begins to drop relative to input

pressure (split point).

Standard value:

MPa (561-633 psi)

MPa (491-561 psi)

(2) Output fluid pressure when input fluid pressure are as

follows.

Standard value:

tFVVD>5.15-5.65 MPa (732-804 psi)

[at 8.2

MPa (1,163 psi)]

MPa (661-732 psi)

[at 7.7

MPa (1,095 psi)],

(3) Output pressure difference between left and right

brake lines

Limit: 0.4

MPa (57 psi)

4. If the measured pressures are not within the

permissibleranges, replace the proportioning valve.