brake fluid MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 210 of 1216

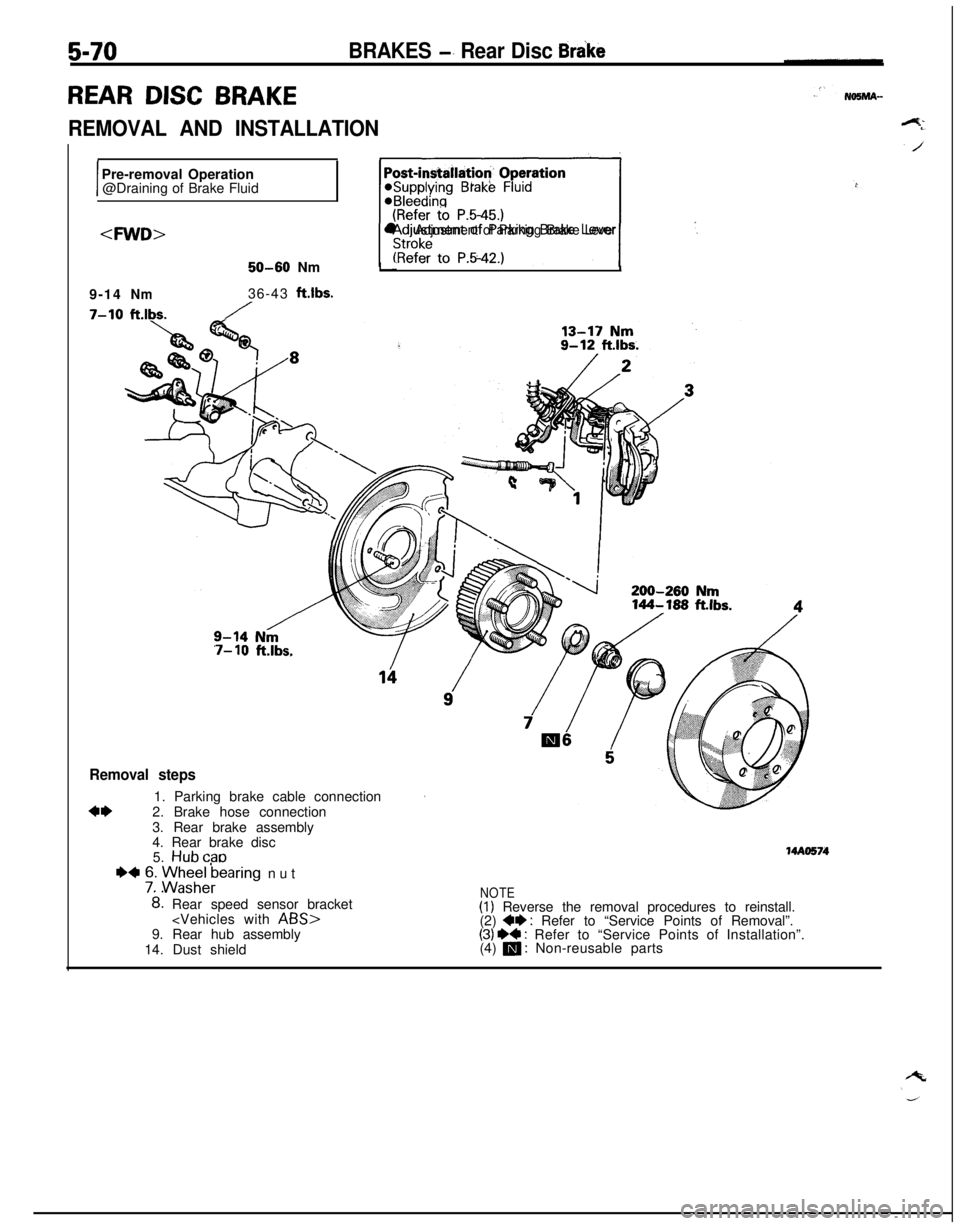

5-70

REAR DISC BRAKE

BRAKES -’ Rear Disc Brake

REMOVAL AND INSTALLATION

IPre-removal Operation

@Draining of Brake Fluid

~1 ,.

l Adjustment of Parking Brake Lever

1.150-60Nm

9-14

Nm36-43ft.lbs.

7-10ft.lbs./

7- 10ft.lbs.

Removal steps

4*1. Parking brake cable connection

2. Brake hose connection

3. Rear brake assembly

4. Rear brake disc

5.

Hubcab

+4 76. ME;AFearing nut

8: Rear speed sensor bracket

14. Dust shield

NOTE(1) Reverse the removal procedures to reinstall.

(2) +* : Refer to “Service Points of Removal”.(3) ** : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

MAO574

Page 211 of 1216

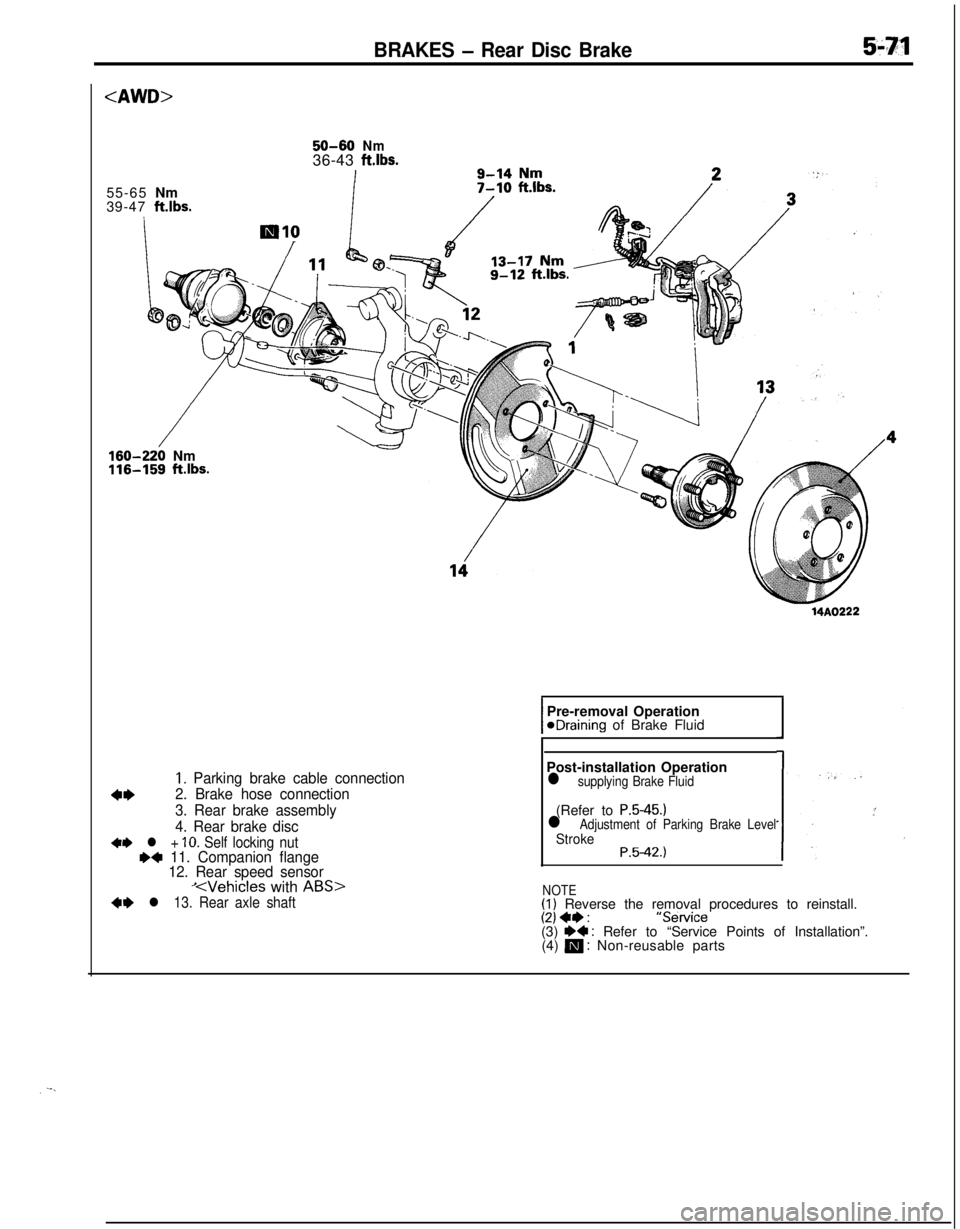

BRAKES - Rear Disc Brake59q!l

50-60Nm36-43ft.lbs.9-14Nm55-65Nm

39-47

klbs.

/160-220 Nm116-159 ft.lbs.14A0222

1. Parking brake cable connection

4*2. Brake hose connection

3. Rear brake assembly

4. Rear brake disc

+e l + IO. Self locking nutr)+ 11. Companion flange

12. Rear speed sensor

KVehicles with ABS>+e l 13. Rear axle shaftPre-removal Operation

@Draining of Brake Fluid

Post-installation Operation

l supplying Brake Fluid(Refer to

P.5-45.)l Adjustment of Parking Brake LevelStrokeP.5-42.)

NOTE

(1) Reverse the removal procedures to reinstall.(2) +e:“Service

(3) I)+ : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

Page 214 of 1216

5-74BRAKES -Rear Disc Brake

1410062

14R0050

14UOO72

SERVICE POINTS OF DISASSEMBLYNO5NBAEWhen disassembling the rear disc brakes, disassemble both

sides (left and right) as a set.

3. REMOVAL OF SUPPORT MOUNTINGWith the lock pin removed, pull the support mounting off

from the caliper body.

9. DISASSEMBLY OF PISTON ASSEMBLYUse the special tool to twist the piston out of the caliper

body.

10. DISASSEMBLY OF PISTON SEAL

(1) Remove piston seal with finger tip.

Caution

Do not use flat tip (-) screwdriver or other tool to

prevent damage to inner cylinder.(2) Clean piston surface and inner cylinder with

trichloro-ethylene, alcohol or specified brake fluid.

Specified brake fluid: MOPAR Brake Fluid/

Conforming to DOT3

11. DISASSEMBLY OF SNAP RINGWhile using a 19 mm

(75 in.) diameter steel pipe to press

the spring case into the caliper body, use the snap ring

pliers to remove the snap ring from the caliper body.

INSPECTIONN65NCAAa

e Check the connecting link and the spindle for wear or

damage.l

l Check the spindle lever shaft for rust.

l

l Check the piston for rust.

Check the piston seal for wear or deterioration.

l

piston

PAD WEAR CHECK(1) Measure the thickness of the pad at the thinnest place.

(.08(2) If the pad assemblies are worn beyond the limit, replace

them.

Page 217 of 1216

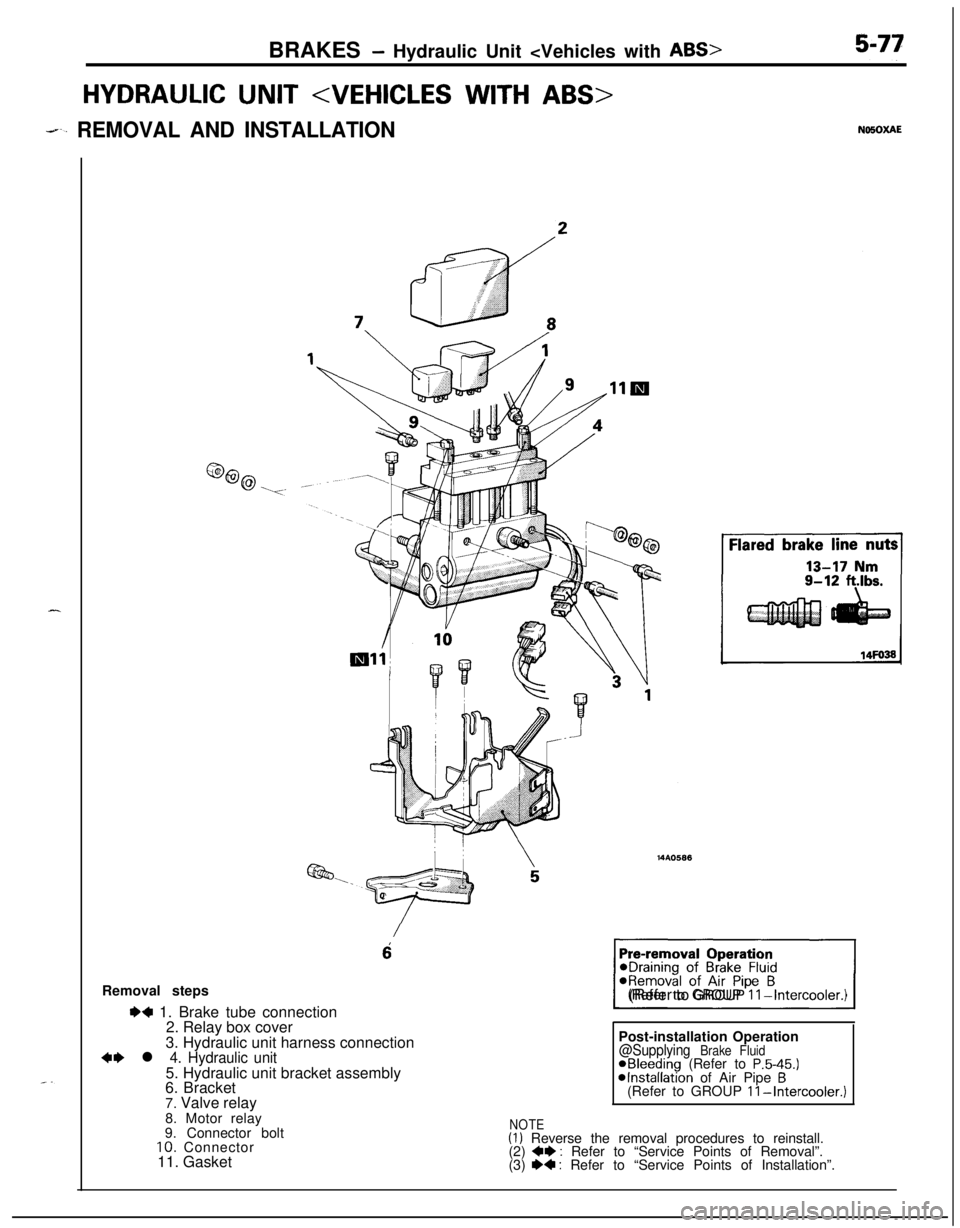

BRAKES - Hydraulic Unit

HYDRAULIC UNIT

--. REMOVAL AND INSTALLATION

6Removal steps

I)+ 1. Brake tube connection

2. Relay box cover

3. Hydraulic unit harness connection

~~ l 4. Hydraulic unit5. Hydraulic unit bracket assembly

6. Bracket

7. Valve relay

1(Refer to GROUP

II-Intercooler.)Post-installation Operation

@Supplying Brake FluidaBleeding (Refer to P.5-45.)@Installation of Air Pipe B(Refer to GROUP II-Intercooler.)8. Motor relay

9. Connector bolt

10. Connector

11. Gasket

NOTE(1) Reverse the removal procedures to reinstall.

(2) +e : Refer to “Service Points of Removal”.

(3) e+ : Refer to “Service Points of Installation”.

Page 233 of 1216

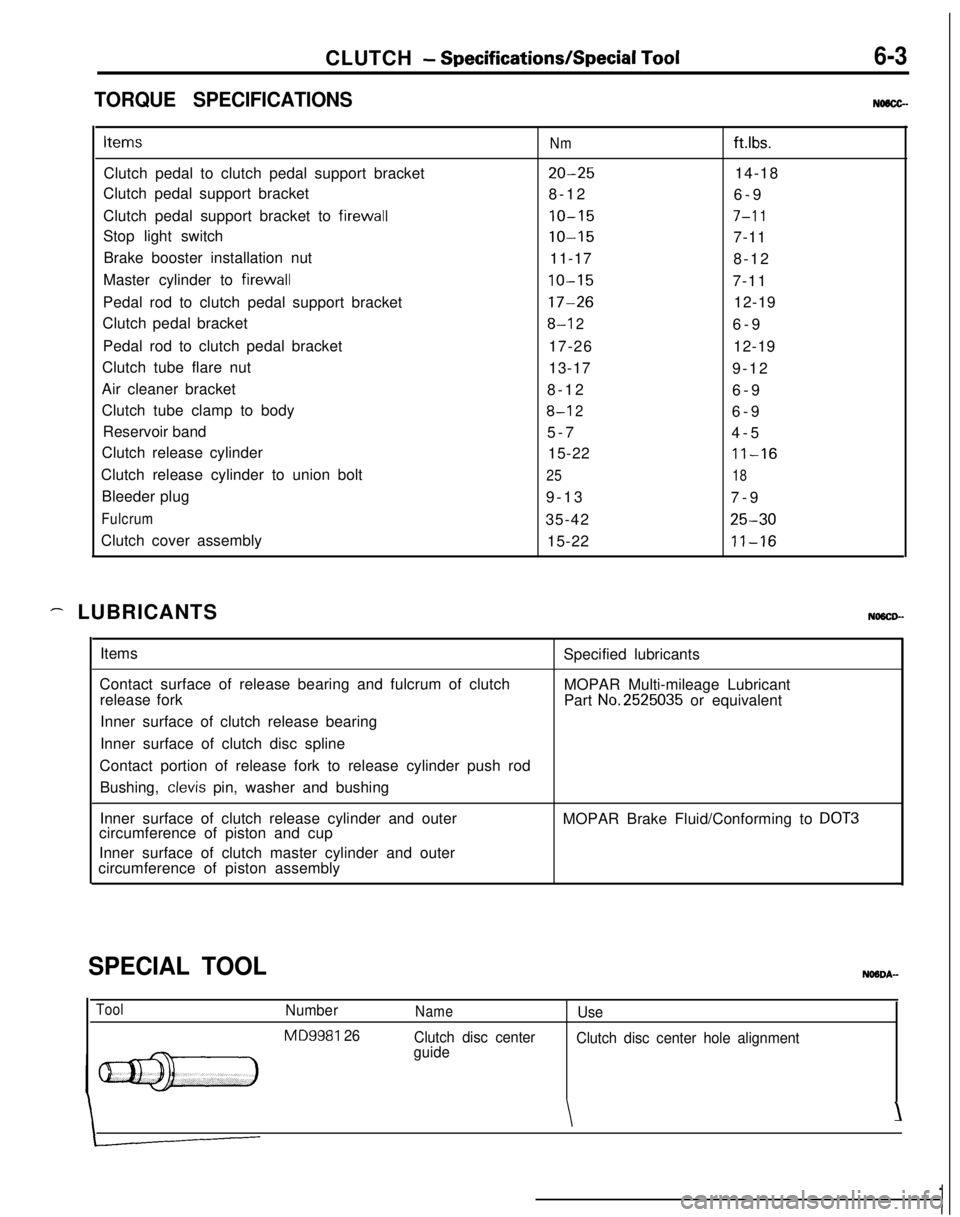

CLUTCH - Specifications/Special Tool6-3

TORQUE SPECIFICATIONSNMCC-Items

Nmftlbs.Clutch pedal to clutch pedal support bracket

20-2514-18

Clutch pedal support bracket

8-12

6-9

Clutch pedal support bracket to firewall

10-157-l 1Stop light switch

10-157-11

Brake booster installation nut

11-17

8-12

Master cylinder to firewall

10-157-11

Pedal rod to clutch pedal support bracket

17-2612-19

Clutch pedal bracket

8-l 26-9

Pedal rod to clutch pedal bracket

17-2612-19

Clutch tube flare nut

13-17

9-12

Air cleaner bracket

8-12

6-9

Clutch tube clamp to body

8-l 26-9

Reservoir band

5-7

4-5

Clutch release cylinder

15-22

11-16Clutch release cylinder to union bolt

2518Bleeder plug

9-13

7-9

Fulcrum35-4225-30Clutch cover assembly

15-22

11-16

- LUBRICANTSNOSCD-Items

Contact surface of release bearing and fulcrum of clutch

release fork

Inner surface of clutch release bearing

Inner surface of clutch disc splineSpecified lubricants

MOPAR Multi-mileage Lubricant

Part

No.2525035 or equivalent

Contact portion of release fork to release cylinder push rod

Bushing,

clevis pin, washer and bushing

Inner surface of clutch release cylinder and outer

circumference of piston and cupMOPAR Brake Fluid/Conforming to

DOT3Inner surface of clutch master cylinder and outer

circumference of piston assembly

SPECIAL TOOL

ToolNumber

MD9981 26

NameUse

Clutch disc center

guideClutch disc center hole alignment

\\

Page 236 of 1216

6-6CLUTCH - Service Adjustment Procedures

5.If the clutch pedal free play and the distance between the

clutch pedal and the firewall when the clutch is disengageddo not agree with the standard values, it is probably the

A

result of either air in the hydraulic system or a faulty master2

cylinder or clutch. Bleed the air, or disassemble and inspectthe master cylinder or clutch.

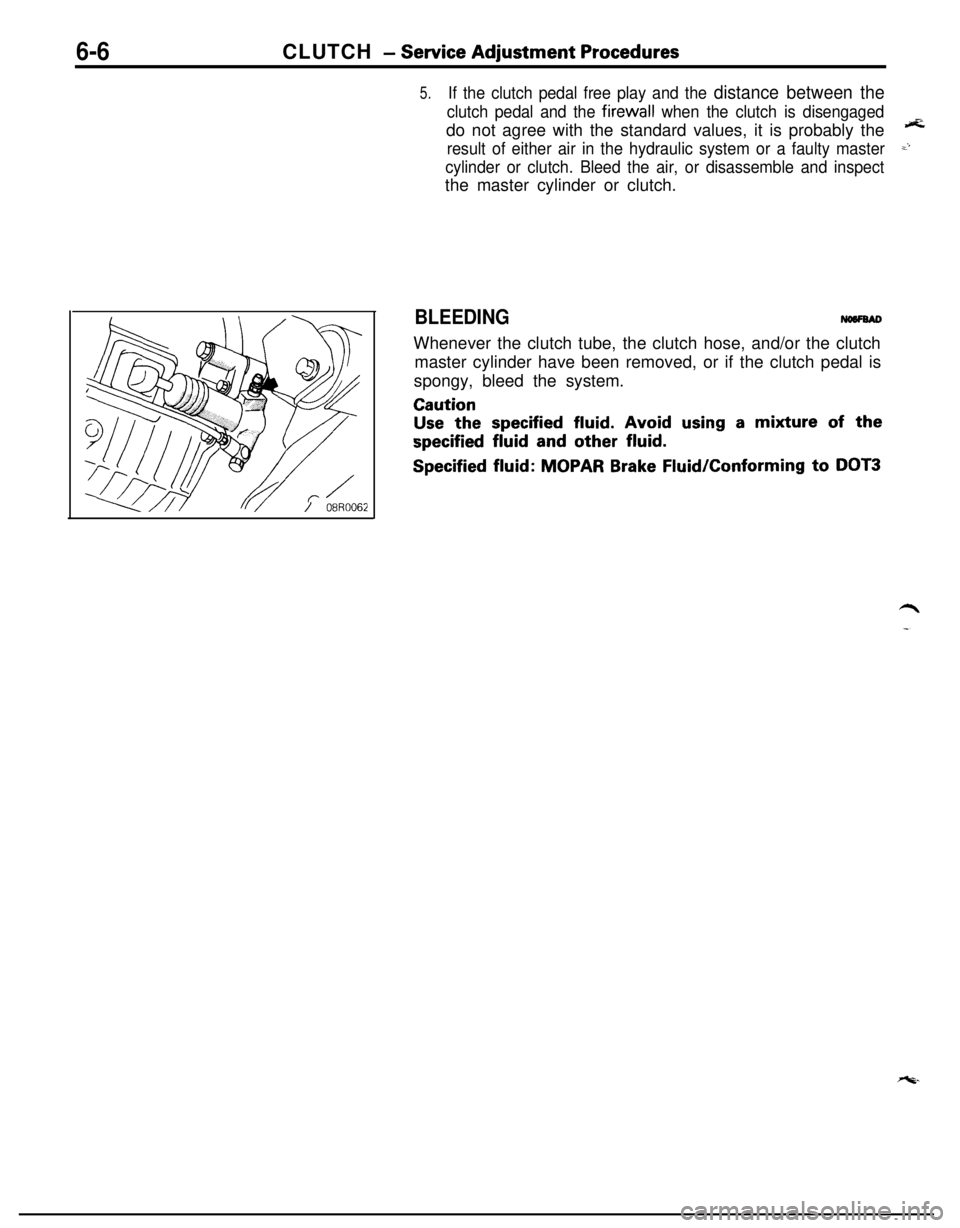

BLEEDINGWhenever the clutch tube, the clutch hose, and/or the clutch

master cylinder have been removed, or if the clutch pedal is

spongy, bleed the system.

Caution

Use the specified fluid. Avoid using a mixture of the

specified fluid and other fluid.

Specified fluid: MOPAR Brake Fluid/Conforming to DOT3

Page 242 of 1216

6-12CLUTCH - Clutch Master CylinderResew&r

bandk

oaA0058

08Y517

Grease

SERVICE POINTS OF REASSEMBLYNaaNciAN

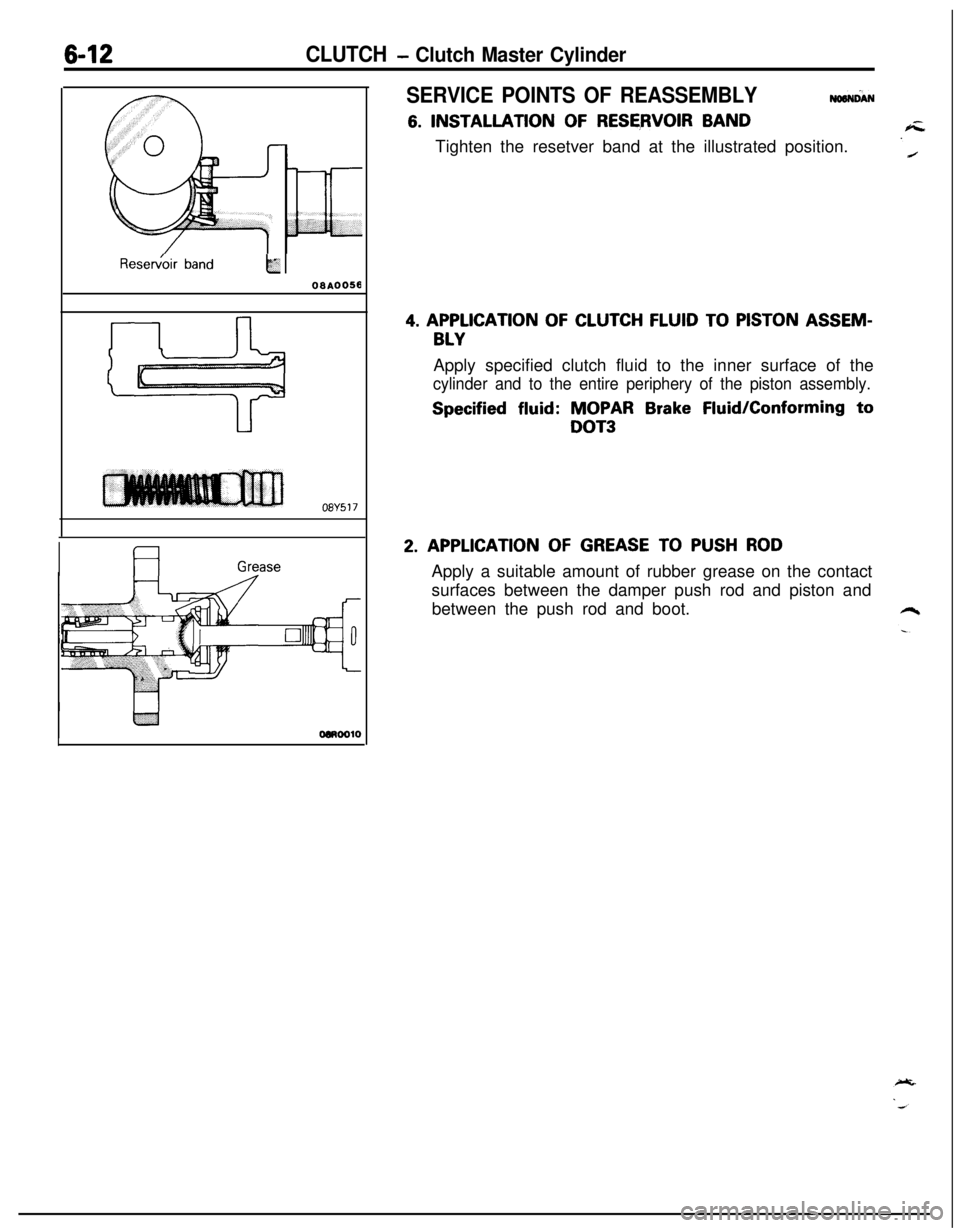

6. INSTALLATION OF RESERVOIR BAND

Tighten the resetver band at the illustrated position.

4. APPLICATION OF CLUTCH FLUID TO PISTON ASSEM-

BLYApply specified clutch fluid to the inner surface of the

cylinder and to the entire periphery of the piston assembly.

Specified fluid: MOPAR Brake Fluid/Conforming to

DOT3

2. APPLICATION OF GREASE TO PUSH RODApply a suitable amount of rubber grease on the contact

surfaces between the damper push rod and piston and

between the push rod and boot.

Page 244 of 1216

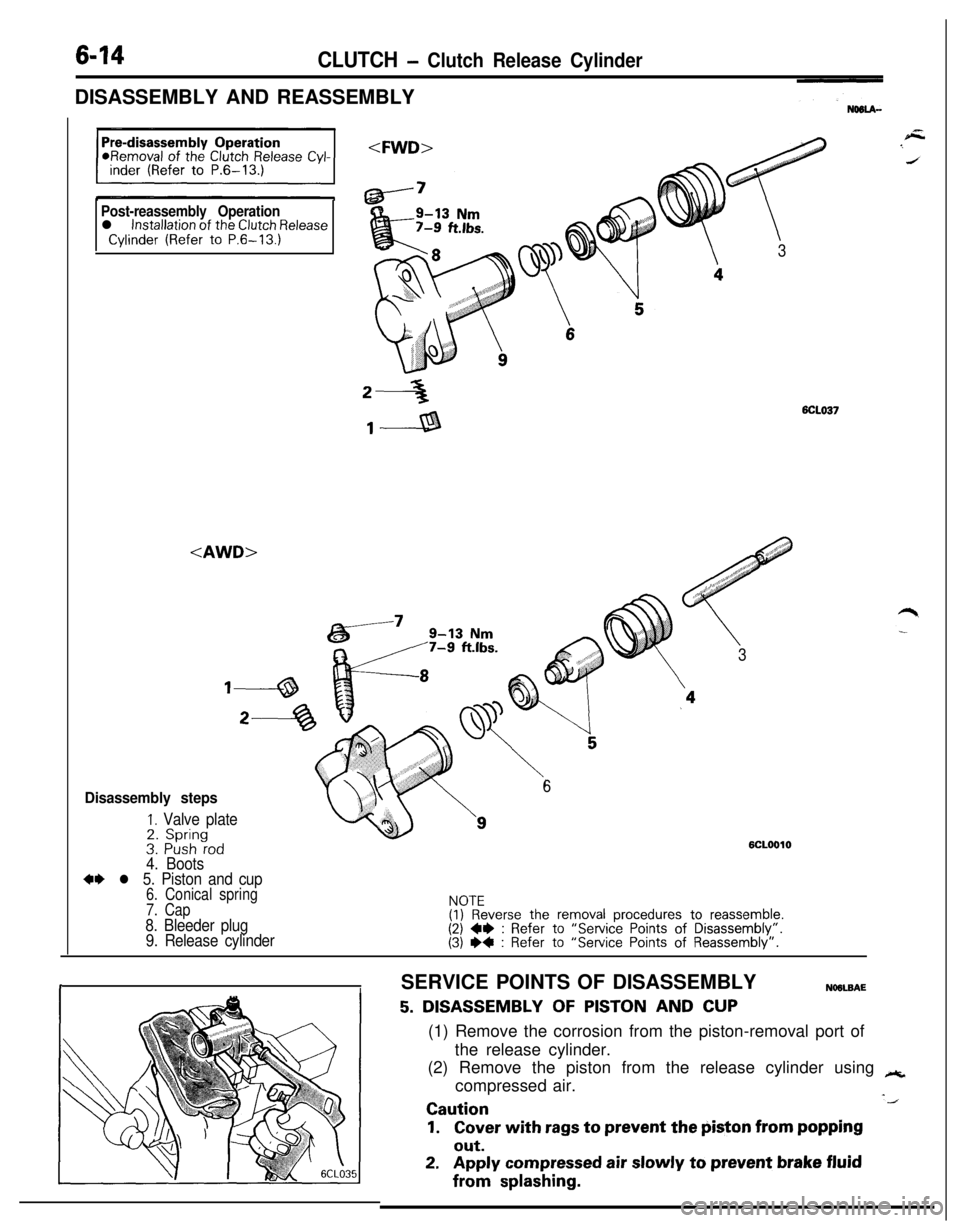

6-14CLUTCH - Clutch Release CylinderDISASSEMBLY AND REASSEMBLY

Post-reassembly Operationl installation of the Clutch ReleaseCylinder (Refer to P.6-13.)

,, #,,“”

7

3

2-36CLO37

,---a

#,J,,, ‘::.”/,,,,d$’ ’.,:..a

<

/ : i 01‘, ., 1

3

Disassembly steps

I. Valve plate2. Spring

6

3. Push rod4. Boots

6CLOOlO

*+ l 5. Piston and cup6. Conical spring

7. Cap

8. Bleeder plug

9. Release cylinder

NOTE(1) Reverse the removal procedures to reassemble.(2) W : Refer to “Service Points of Disassembly”.(3) I)4 : Refer to “Service Points of Reassembly”.

rISERVICE POINTS OF DISASSEMBLYNOOLBAE

5. DISASSEMBLY OF PISTON AND CUP(1) Remove the corrosion from the piston-removal port of

the release cylinder.

(2) Remove the piston from the release cylinder using

++,compressed air.

-JCaution

1.Cover with rags to prevent the piston from popping

out.

2.Apply compressed air slowly to prevent brake fluidfrom

splashing.

Page 245 of 1216

.-CLUTCH - Clutch Release Cvlinder6-15

\

Piston

@*

CUP6CLOOO3DCLOOE

,

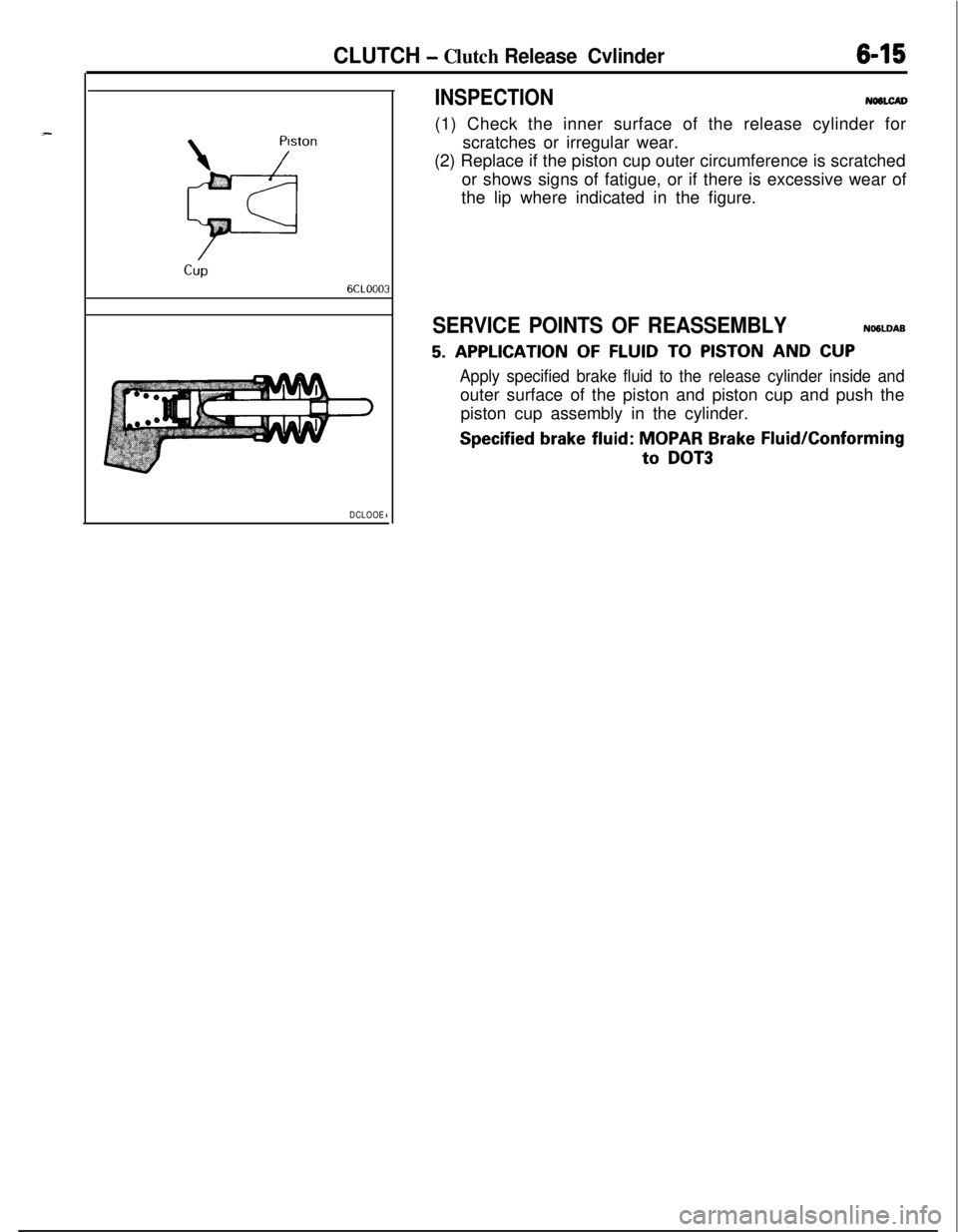

INSPECTIONNWLCAV(1) Check the inner surface of the release cylinder for

scratches or irregular wear.

(2) Replace if the piston cup outer circumference is scratched

or shows signs of fatigue, or if there is excessive wear of

the lip where indicated in the figure.

SERVICE POINTS OF REASSEMBLYNO6LDAB

5. APPLICATION OF FLUID TO PISTON AND CUP

Apply specified brake fluid to the release cylinder inside andouter surface of the piston and piston cup and push the

piston cup assembly in the cylinder.

Specified brake fluid: MOPAR Brake Fluid/Conforming

to DOT3

Page 695 of 1216

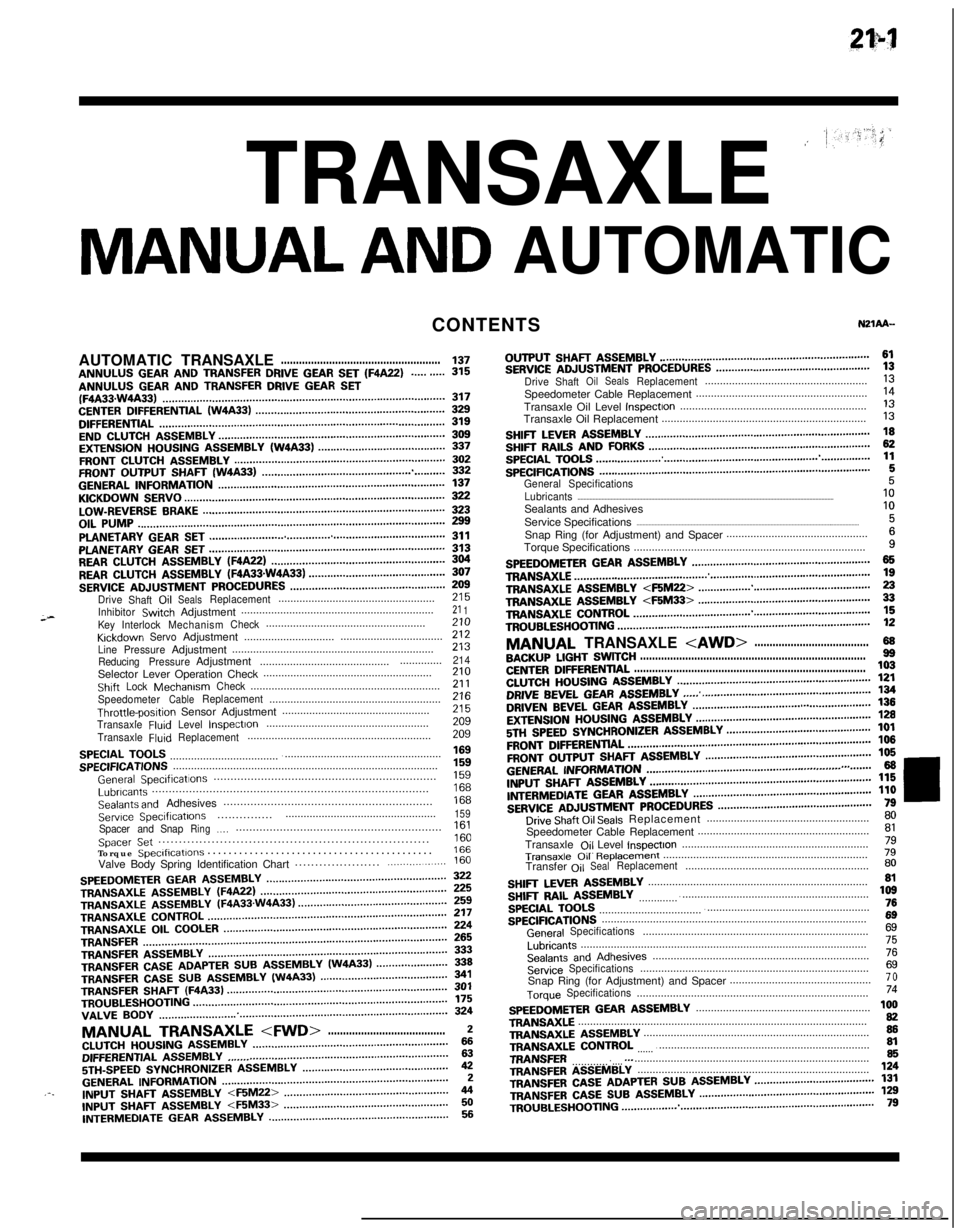

TRANSAXLE ’

MANUAL AND AUTOMATICCONTENTS

;-AUTOMATICTRANSAXLE

.....................................................137ANNULUS GEAR AND TRANSFER DRIVE GEAR SET (F4A22)..........315ANNULUS GEAR AND TRANSFER DRIVE GEAR SET(F4A33.W4A33)...........................................................................................317CENTERDIFFERENTIAL(W4A33).............................................................329DIFFERENTIAL............................................................................................319ENDCLUTCHASSEMBLY.........................................................................309EXTENSIONHOUSINGASSEMBLY(W4A33).........................................337FRONTCLUTCHASSEMBLY....................................................................302FRONTOUTPUTSHAFT(W4A33)...........................................................332GENERALINFORMATION.........................................................................137KICKDOWNSERVO....................................................................................322LOW-REVERSEBRAKE..............................................................................323OILPUMP...................................................................................................299PLANETARYGEARSET............................................................................311PLANETARYGEARSET............................................................................313REARCLUTCHASSEMBLY(F4A22)........................................................304REARCLUTCHASSEMBLY(FQA33sW4A33)............................................307SERVICEADJUSTMENTPROCEDURES..................................................Drive

Shaft,OilSealsReplacement....................................................;;;

InhibitorSwtchAdjustment................................................................21 1KeyInterlockMechanismCheck.....................................................KrckdownServoAdjustment..................................zii..............................

LinePressureAdjustment...................................................................213

ReducingPressureAdjustment.........................................................214Selector Lever Operation Check........................................................210ShiftLockMechanismCheck...............................................................21 1SpeedometerCableReplacement.........................................................Throttle-posltipn Sensor Adjustment.................................................z2:

TransaxleFluIdLevelInspectIon......................................................209

TransaxleFluidReplacement.............................................................209

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................;“5”9

GeneralSpeclficatlons..................................................................1%Lubricants..................................................................................Sealants and Adhesives..............................................................izi

Serwce Speclflcatlons..................................................159...............Spacer andSnapRing.,.,.............................................................Spacer Set..................................................................1::Torque Speclflcatlons...........................................166Valve Body Spring Identification Chart.....................

.................160

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLEASSEMBLY(WA22)............................................................zTRANSAXLE

ASSEMBLY(F4A33.W4A33)................................................TRANSAXLECONTROL.............................................................................;;;TRANSAXLE

OILCOOLER........................................................................TRANSFER..................................................................................................fg

TRANSFERASSEMBLY.............................................................................333TRANSFERCASEADAPTERSUBASSEMBLY(W4A33).......................339TRANSFER CASE SUB ASSEMBLY (W4A33)341TRANSFER SHAFT (F4A33)TROUBLESHOOTING..................................................................................................................................................................................................f;;VALVE

BODY.............................................................................................324

MANUAL TRANSAXLE

5TH-SPEEDSYNCHRONIZERASSEMBLY...............................................42GENERALINFORMATION.........................................................................2.-.INPUTfj,-,A,TASSEMBLY

INTERMEDIATE GEAR ASSEMBLY..........................................................56OUTPUT

SHAFT ASSEMBLY....................................................................61SERVICEADJUSTMENTPROCEDURES..................................................DriveShaftOilSealsReplacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle Oil Level

InspectIon..............................................................‘liTransaxle Oil Replacement....................................................................

I3

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILSANDFORKS........................................................................g

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................1:

General Specifications5Lubricants..........................................................................................................................................................................10Sealants and Adhesives

Service Specifications

....................................................................................................................................................1:Snap Ring (for Adjustment) and Spacer...............................................

Torque Specifications.............................................................................

i

SPEEDOMETERGEARASSEMBLY..........................................................TRANS&G.E................................................................................................zTRANSAXLEA!jSEMBLY

TROUBLESHOOTING..................................................................................12

MANUAL TRANSAXLE

CENTERDIFFERENTIAL.............................................................................103CLUTCHHOUSINGASSEMBLY...............................................................DRIVE BEVEL GEAR ASSEMBLY;g

...... .......................................................DRIVENBEVELGEARASSEMBLY...................................a......................EXTENSIONHOUSINGASSEMBLY.........................................................;g

5Tf.jSPEEDSYNCHRONIZERASSEMBLY...............................................101

FRONTDlFFERENTlAL...............................................................................106

FRONTOUTPUTSHAFTASSEMBLY......................................................106

GENERALI~~~~MATN)N...............................................................,.,.......66INPUTSHAFTASSEMBLY........................................................................l~ER,“,EDlATEGEARASSMBLY..........................................................;;i

SERVICEADJUSTMENTPROCEDURES..................................................Drive Shaft Oil Seals Replacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle

Ojl Level lnspectlon..............................................................;l

Transaxle 011 R~pb33ment....................................................................79Transfer

OilSealReplacement.............................................................80

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILASSEMBLY............................................................................,z

SPECIALTOOLS.........................................................................................76

SPECIFICATIONS........................................................................................6g

GeneralSpecifications...........................................................................6g

Lubricants...............................................................................................75

SealantsandAdhesives........................................................................76

ServiceSpecifications............................................................................6gSnap Ring (for Adjustment) and Spacer...............................................7 o

TorqueSpecifications.............................................................................74

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLE................................................................................................1:TRANSAXLEASSEMBLY...........................................................................86TRANSAXLE

CONTROL

.............................................................................TRANSFER...............................................................................................

g.._TRANSFERA!333lBLY.............................................................................,24

TRANSFERCASEADAPTERSUBASSEMBLY.......................................131TRANSFERCASESUBASSEMBLY.........................................................TR,,UBLES,,OO,,NG..................................................................................1;;