brakes MITSUBISHI ECLIPSE 1991 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 227 of 1216

BRAKES - G-sensor

I

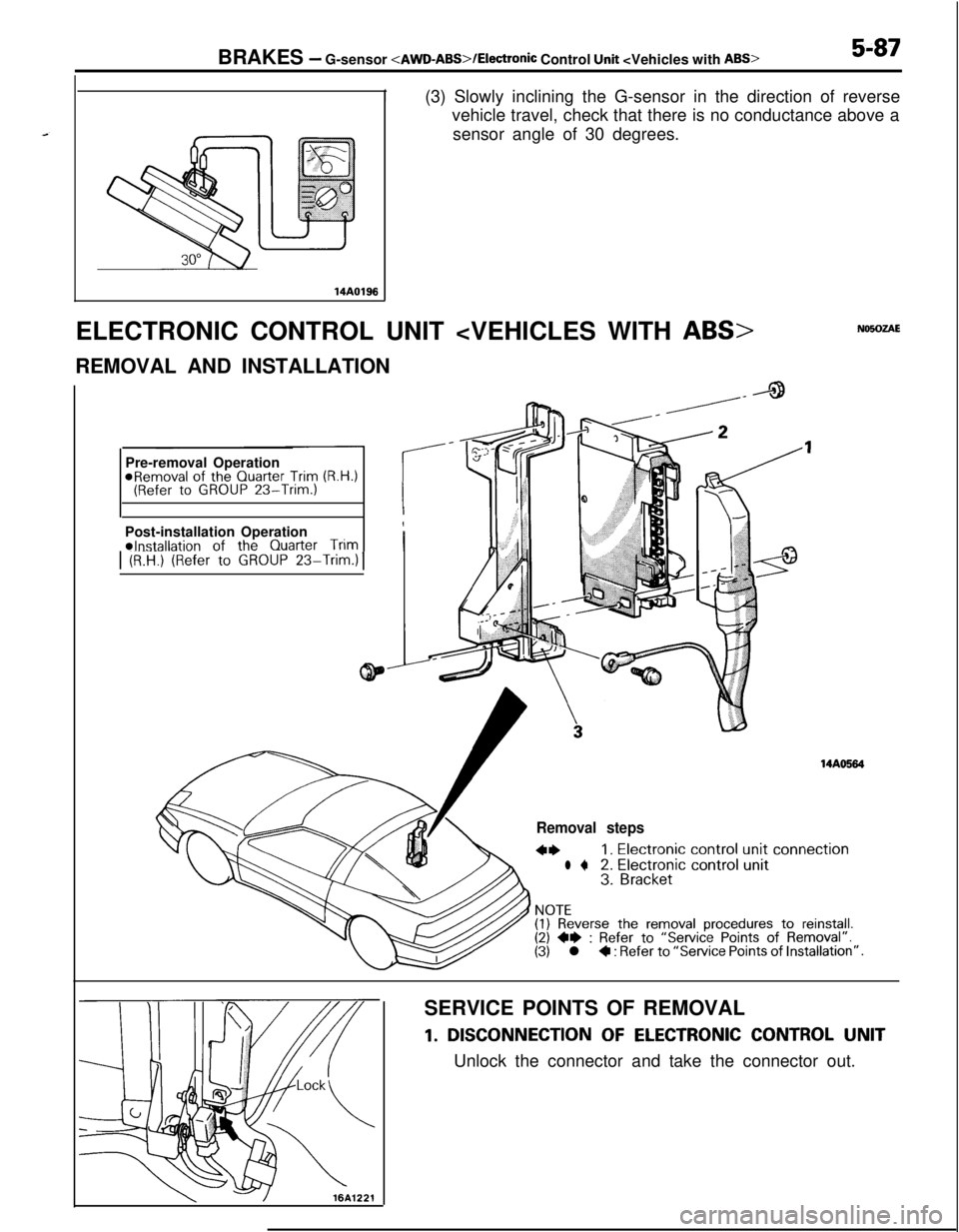

14AO198(3) Slowly inclining the G-sensor in the direction of reverse

vehicle travel, check that there is no conductance above a

sensor angle of 30 degrees.

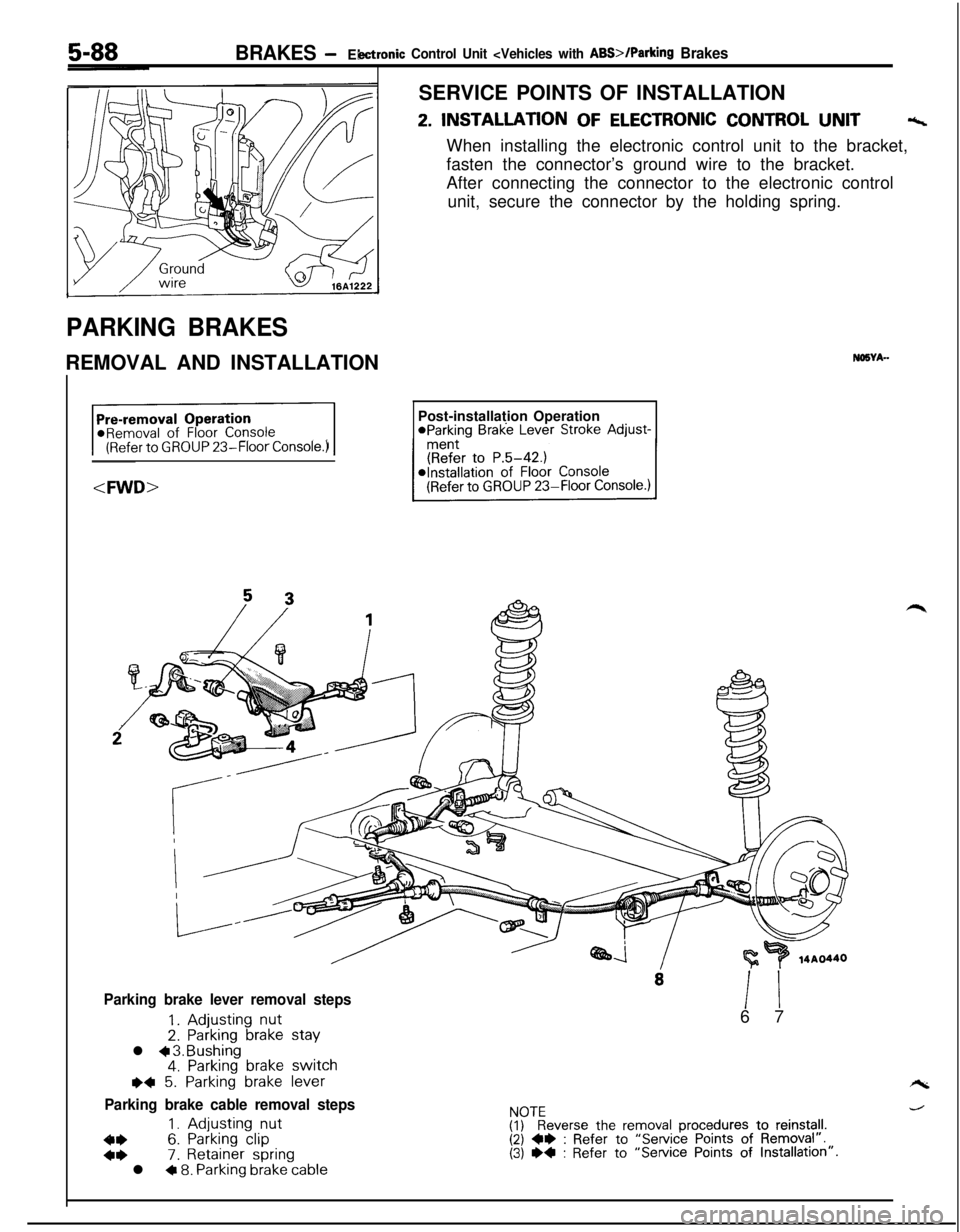

ELECTRONIC CONTROL UNIT

Pre-removal Operation

@Removal of the Quarter Trim (R.H.)(Refer to GROUP 23-Trim.)IPost-installation Operation

4*Installation of the

Quarter TrimI1 (RIt?.) (Refer to GROUP 23-Trim.)1

14AO584

Removal steps

4*1. Electronic control unit connection

l +2. Electronic control unit3. Bracket

NOTE(I) Reverse the removal procedures to reinstall.(2) 4e : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL

1. DISCONNECTION OF ELECTRONIC CONTROL UNIT

Unlock the connector and take the connector out.

Page 228 of 1216

BRAKES -El cteronic Control Unit

PARKING BRAKESREMOVAL AND INSTALLATION

*i(Refer to GROUP 23-Floor Console.)

2. INSTALLATION OF ELECTRONIC CONTROL UNIT%When installing the electronic control unit to the bracket,

fasten the connector’s ground wire to the bracket.

After connecting the connector to the electronic control

unit, secure the connector by the holding spring.

Post-installation Operation

aParking Brake Lever Stroke Adjust-

NOSYA-

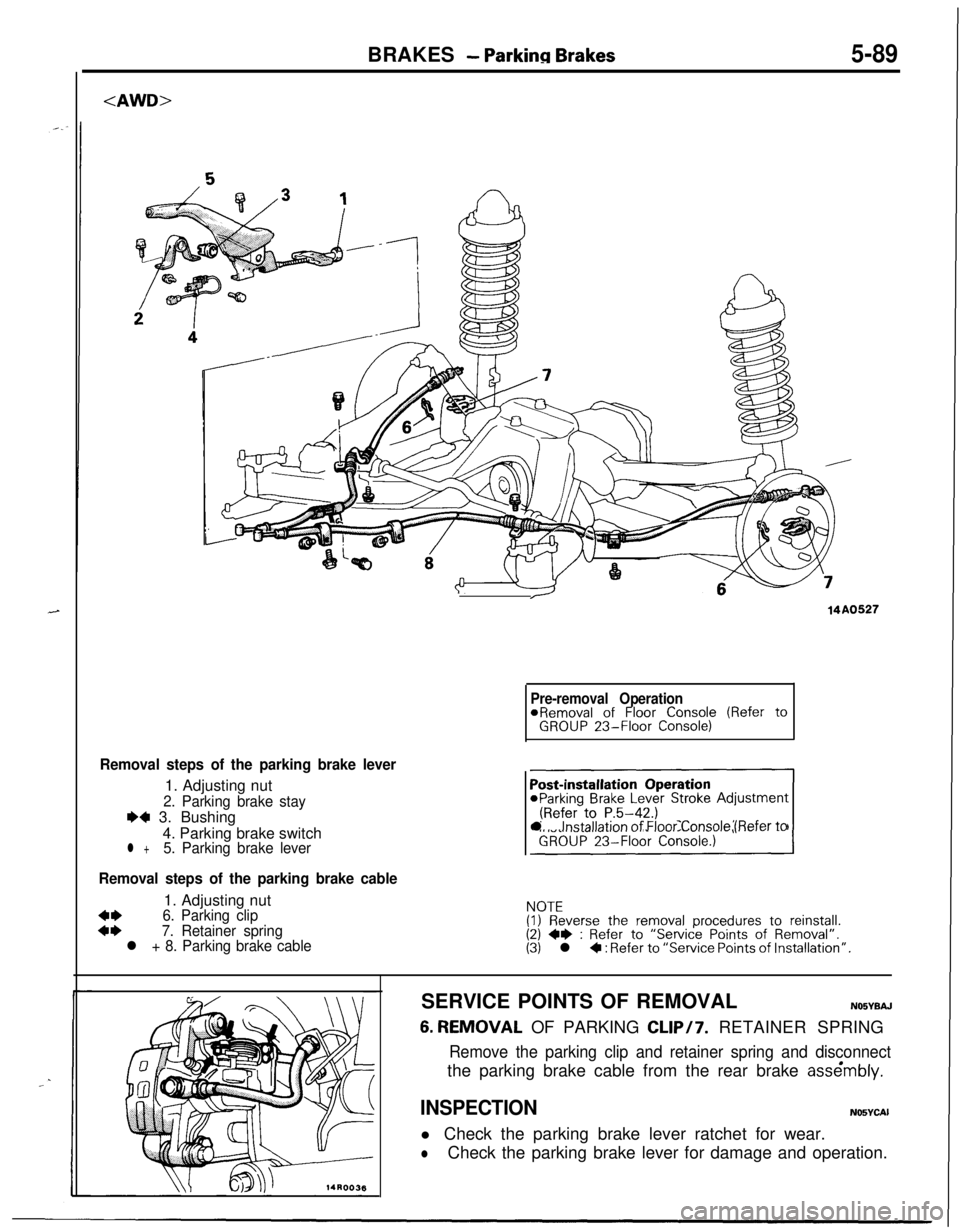

Parking brake lever removal steps

1. Adjusting nut2. Parking brake stayl + 3. Bushing4. Parking brake switchW 5. Parking brake lever

I I6 7

h

Parking brake cable removal steps

1. Adjusting nut6. Parking clip7. Retainer springl * 8. Parking brake cable

l?TFeverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) I)4 : Refer to “Service Points of Installation”.

4

Page 229 of 1216

BRAKES - Parking Brakes5-89

Removal steps of the parking brake lever1. Adjusting nut

2. Parking brake stay

W 3. Bushing

4. Parking brake switch

l +5. Parking brake lever

Removal steps of the parking brake cable1. Adjusting nut

::6. Parking clip

7. Retainer spring

l + 8. Parking brake cable

14A0527

Pre-removal OperationaRemoval of Floor Console (Refer toGROUP 23-Floor Console)

@Parking Brake Lever Stroke Adjustment

l installation of

Floor Console (Refer to

NOTE(1) Reverse the removal procedures to reinstall.(2) 4e : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL

N05YBAJ

6. REMOVAL OF PARKING CLIP/7. RETAINER SPRING

Remove the parking clip and retainer spring and disconnectthe parking brake cable from the rear brake

as&mbly.

INSPECTIONNO5YCAIl Check the parking brake lever ratchet for wear.

lCheck the parking brake lever for damage and operation.

Page 230 of 1216

5-90BRAKES - Parking Brakes

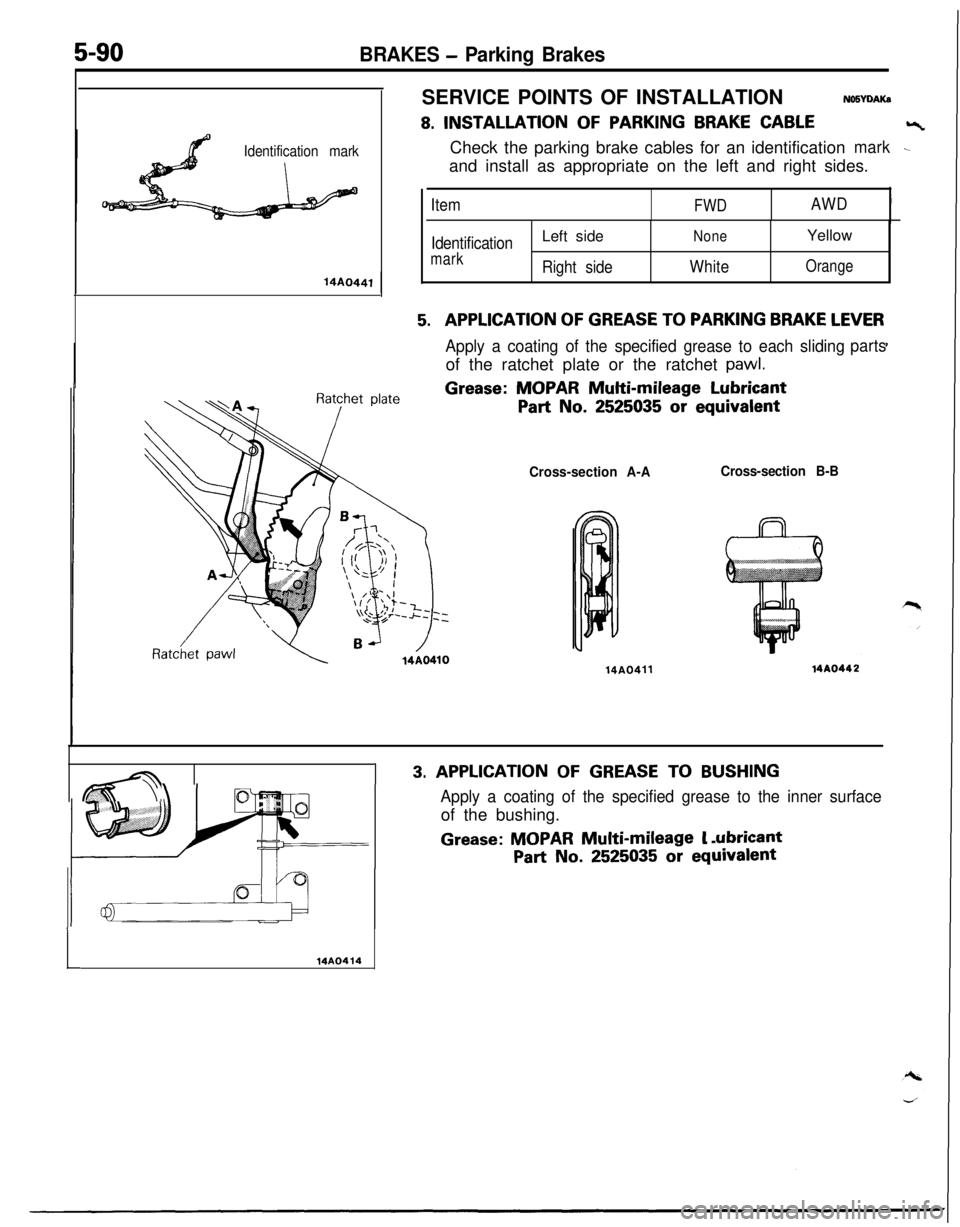

Identification markSERVICE POINTS OF INSTALLATION

NO!iYDAKa

8. INSTALLATION OF PARKING BRAKE CABLECheck the parking brake cables for an identification

markand install as appropriate on the left and right sides.

ItemFWDAWDI

IdentificationLeft sideNoneYellow

markRight sideWhiteOrange

5.APPLICATION OF GREASE TO PARKING BRAKE LEVER

Apply a coating of the specified grease to each slidingpartsof the ratchet plate or the ratchet

pawl.

Grease: MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

Cross-section A-ACross-section B-B

14A041114AO442

&=4--

13. APPLICATION OF GREASE TO BUSHING

Apply a coating of the specified grease to the inner surfaceof the bushing.

Grease: MOPAR Multi-mileage 1 lhifinnt

Part No. 2525035 or eq

._I. ..v-.--uivalent

114A0414

Page 847 of 1216

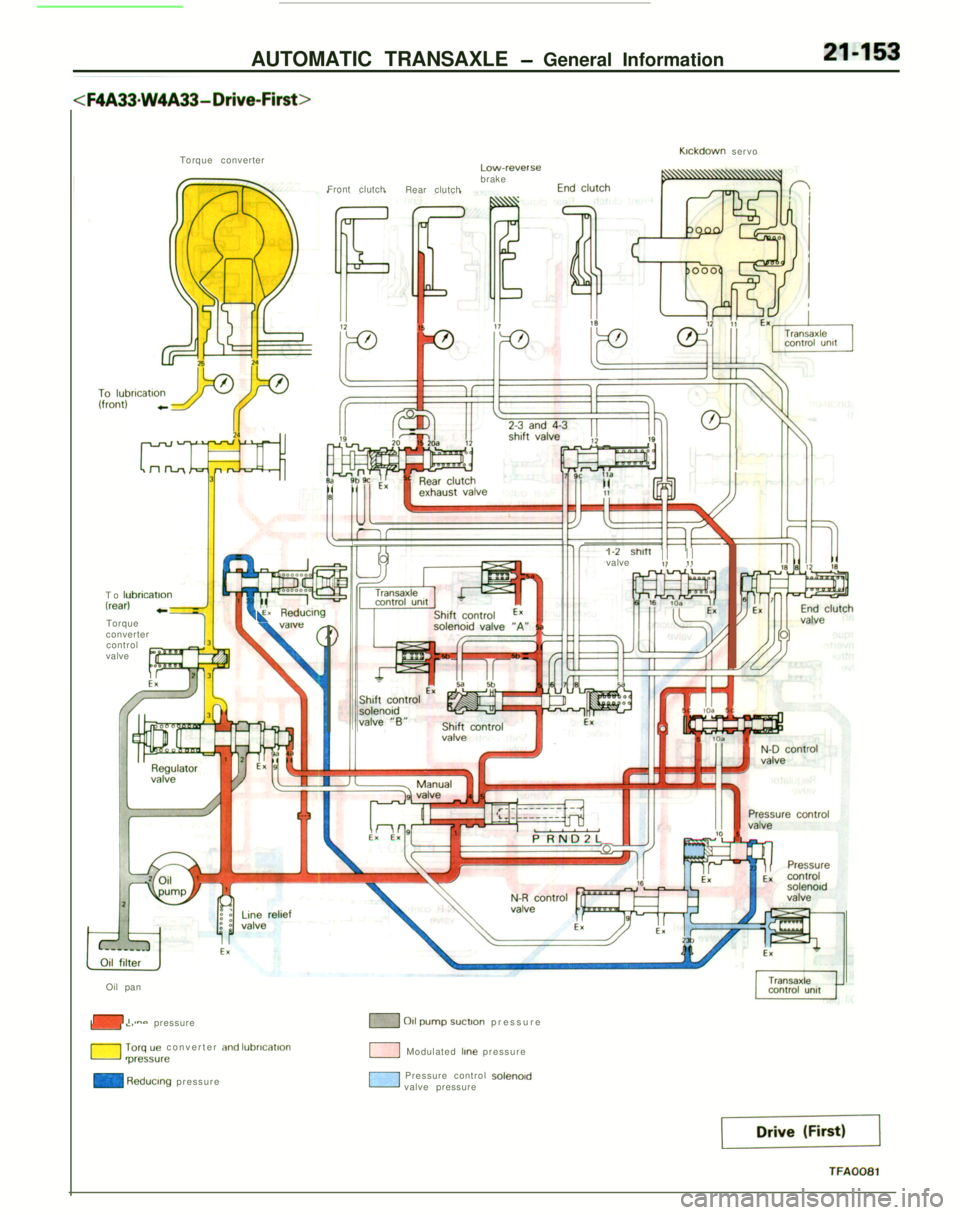

AUTOMATIC TRANSAXLE - General Information21453

Torque converter

To

lubn(rear)

Torquezatlon4-Zconverter

control

valveFront clutch

Rear clutch

Low-reverbrakese

Ktckdown servo

‘-2 sh’+f [;valve\I

& Reducmg

;\Oil pan

II1-0 pressureue converter and lubrfcataon

r.-z~re

m Reducmg pressure

0 011 pump suctm pressure

0 Modulated lme pressure

0Pressure control solenoidvalve pressure

TFA0081

Page 869 of 1216

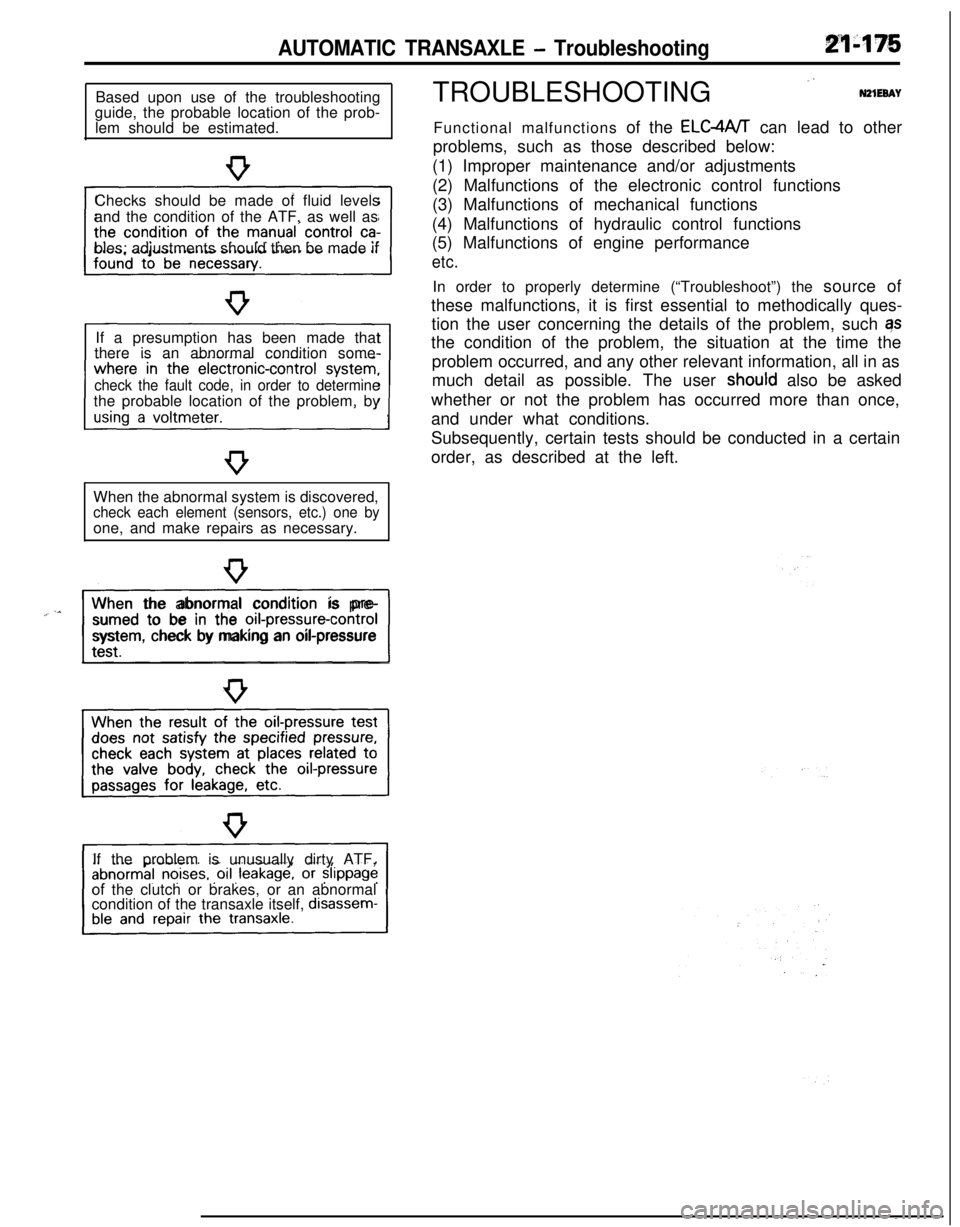

AUTOMATIC TRANSAXLE - TroubleshootingBased upon use of the troubleshooting

guide, the probable location of the prob-

lem should be estimated.

Checks should be made of fluid levels

and the condition of the ATF, as well as

bles; adjustments should then be made if

If a presumption has been made that

there is an abnormal condition some-

check the fault code, in order to determinethe probable location of the problem, by

When the abnormal system is discovered,

check each element (sensors, etc.) one byone, and make repairs as necessary.

“~^II_When the abnormal condition is pre-

sumed to be in the

orI-pressure-controlsystem, check by making an oil-pressure

If the problem is unusually dirty ATF,

of the clutch or brakes, or an abnormal

condition of the transaxle itself,

disassem-TROUBLESHOOTING

”N21EeAYFunctional malfunctions of the ELC4A/T can lead to other

problems, such as those described below:

(1) Improper maintenance and/or adjustments

(2) Malfunctions of the electronic control functions

(3) Malfunctions of mechanical functions

(4) Malfunctions of hydraulic control functions

(5) Malfunctions of engine performance

etc.In order to properly determine (“Troubleshoot”) the source of

these malfunctions, it is first essential to methodically ques-

tion the user concerning the details of the problem, such qs

the condition of the problem, the situation at the time the

problem occurred, and any other relevant information, all in as

much detail as possible. The user

shoutd also be asked

whether or not the problem has occurred more than once,

and under what conditions.

Subsequently, certain tests should be conducted in a certain

order, as described at the left.

Page 872 of 1216

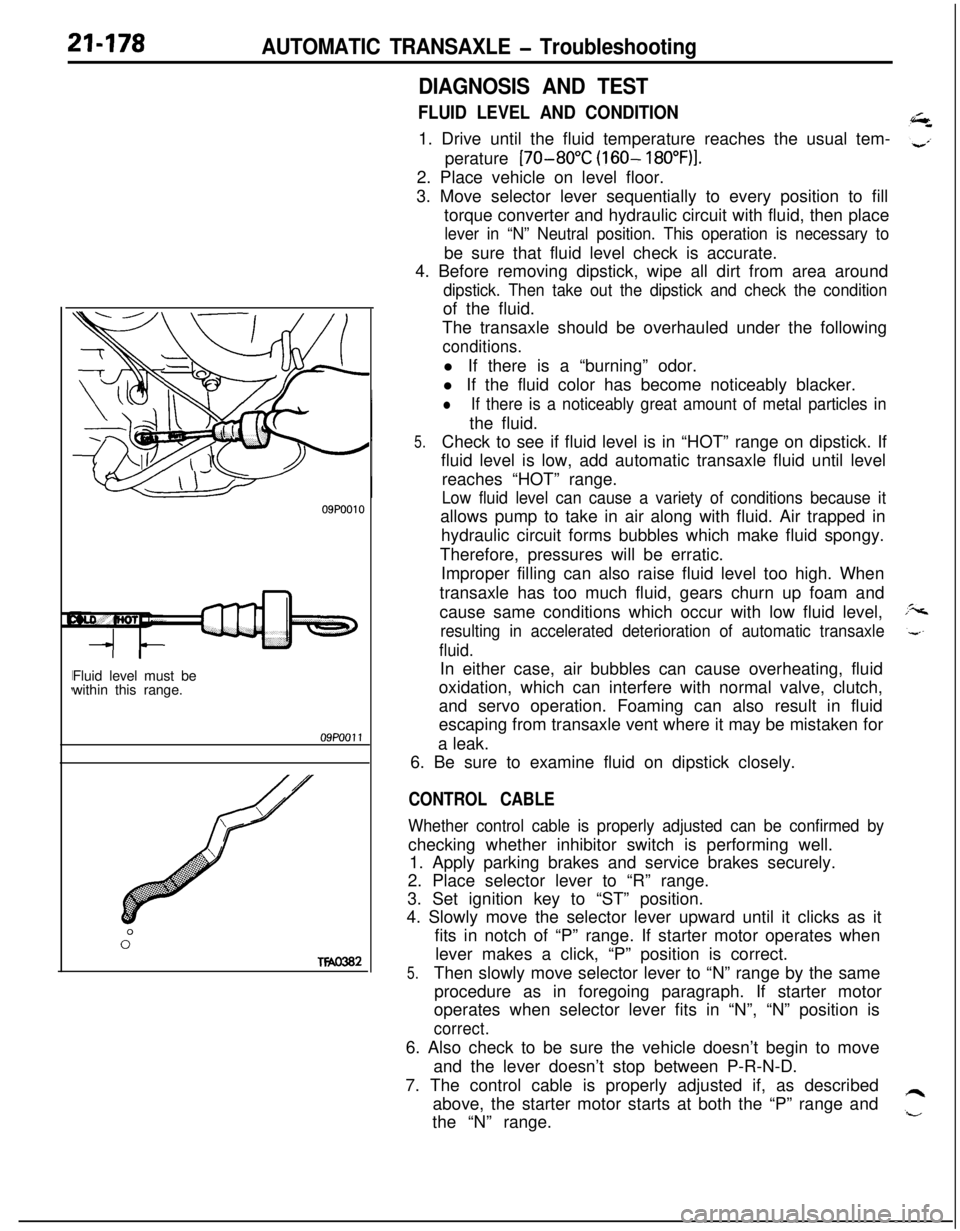

21-178AUTOMATIC TRANSAXLE - Troubleshooting

09P0010Fluid level must be

within this range.09PoOll

0”

Two302

DIAGNOSIS AND TEST

FLUID LEVEL AND CONDITION1. Drive until the fluid temperature reaches the usual tem-

perature

[70-80°C (160- 18O”F)I.2. Place vehicle on level floor.

3. Move selector lever sequentially to every position to fill

torque converter and hydraulic circuit with fluid, then place

lever in “N” Neutral position. This operation is necessary tobe sure that fluid level check is accurate.

4. Before removing dipstick, wipe all dirt from area around

dipstick. Then take out the dipstick and check the conditionof the fluid.

The transaxle should be overhauled under the following

conditions.l If there is a “burning” odor.

l If the fluid color has become noticeably blacker.

lIf there is a noticeably great amount of metal particles inthe fluid.

5.Check to see if fluid level is in “HOT” range on dipstick. If

fluid level is low, add automatic transaxle fluid until level

reaches “HOT” range.

Low fluid level can cause a variety of conditions because itallows pump to take in air along with fluid. Air trapped in

hydraulic circuit forms bubbles which make fluid spongy.

Therefore, pressures will be erratic.

Improper filling can also raise fluid level too high. When

transaxle has too much fluid, gears churn up foam and

cause same conditions which occur with low fluid level,

resulting in accelerated deterioration of automatic transaxle

fluid.In either case, air bubbles can cause overheating, fluid

oxidation, which can interfere with normal valve, clutch,

and servo operation. Foaming can also result in fluid

escaping from transaxle vent where it may be mistaken for

a leak.

6. Be sure to examine fluid on dipstick closely.

CONTROL CABLE

Whether control cable is properly adjusted can be confirmed bychecking whether inhibitor switch is performing well.

1. Apply parking brakes and service brakes securely.

2. Place selector lever to “R” range.

3. Set ignition key to “ST” position.

4. Slowly move the selector lever upward until it clicks as it

fits in notch of “P” range. If starter motor operates when

lever makes a click, “P” position is correct.

5.Then slowly move selector lever to “N” range by the same

procedure as in foregoing paragraph. If starter motor

operates when selector lever fits in “N”, “N” position is

correct.6. Also check to be sure the vehicle doesn’t begin to move

and the lever doesn’t stop between P-R-N-D.

7. The control cable is properly adjusted if, as described

above, the starter motor starts at both the “P” range and

the “N” range.

Page 878 of 1216

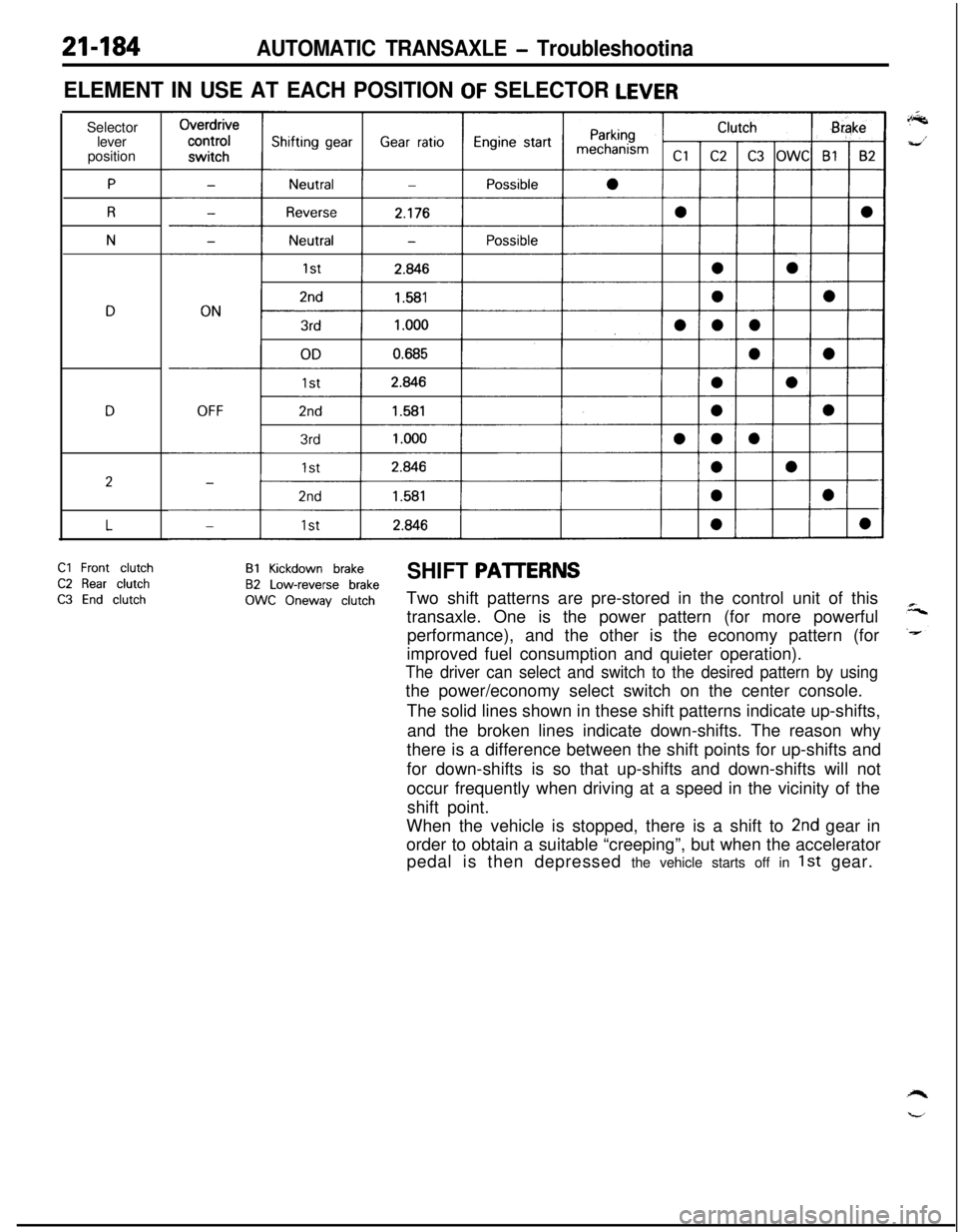

21-184AUTOMATIC TRANSAXLE - TroubleshootinaSelector

lever

position

P

R

N

ELEMENT IN USE AT EACH POSITION OF SELECTOR LEVER

2

LCl

Front clutch

C2 Rear clutch

C3 End clutch

Bl Kickdown brakeSHIFT PAlTERNS82 Low-reverse brake

OWC Oneway clutchTwo shift patterns are pre-stored in the control unit of this

transaxle. One is the power pattern (for more powerful

performance), and the other is the economy pattern (for

improved fuel consumption and quieter operation).

The driver can select and switch to the desired pattern by usingthe power/economy select switch on the center console.

The solid lines shown in these shift patterns indicate up-shifts,

and the broken lines indicate down-shifts. The reason why

there is a difference between the shift points for up-shifts and

for down-shifts is so that up-shifts and down-shifts will not

occur frequently when driving at a speed in the vicinity of the

shift point.

When the vehicle is stopped, there is a shift to

2nd gear in

order to obtain a suitable “creeping”, but when the accelerator

pedal is then depressed the vehicle starts off in

1st gear.

Page 888 of 1216

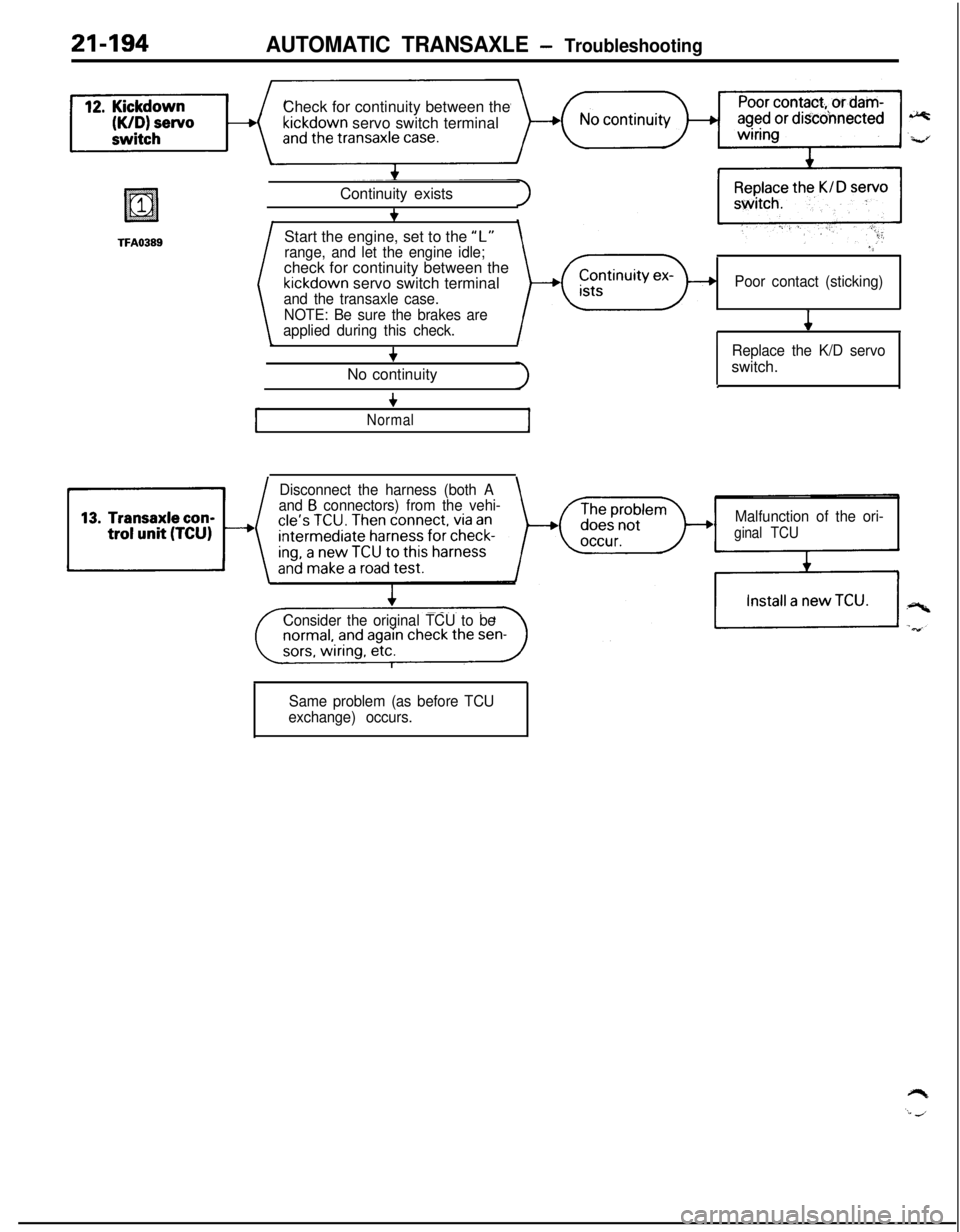

21-194AUTOMATIC TRANSAXLE - TroubleshootingCheck for continuity between the

kickdown servo switch terminal

TFA0389Start the engine, set to the “L”Continuity exists

+

range, and let the engine idle;check for continuity between the

kickdown servo switch terminaland the transaxle case.

NOTE: Be sure the brakes are

applied during this check.

+No continuity

“‘

Poor contact (sticking)

4

Replace the K/D servoswitch.

.

+

Normal

Disconnect the harness (both A

and B connectors) from the vehi-

Malfunction of the ori-

ginal TCU

Consider the original TCU to be

Same problem (as before TCU

exchange) occurs.

Page 896 of 1216

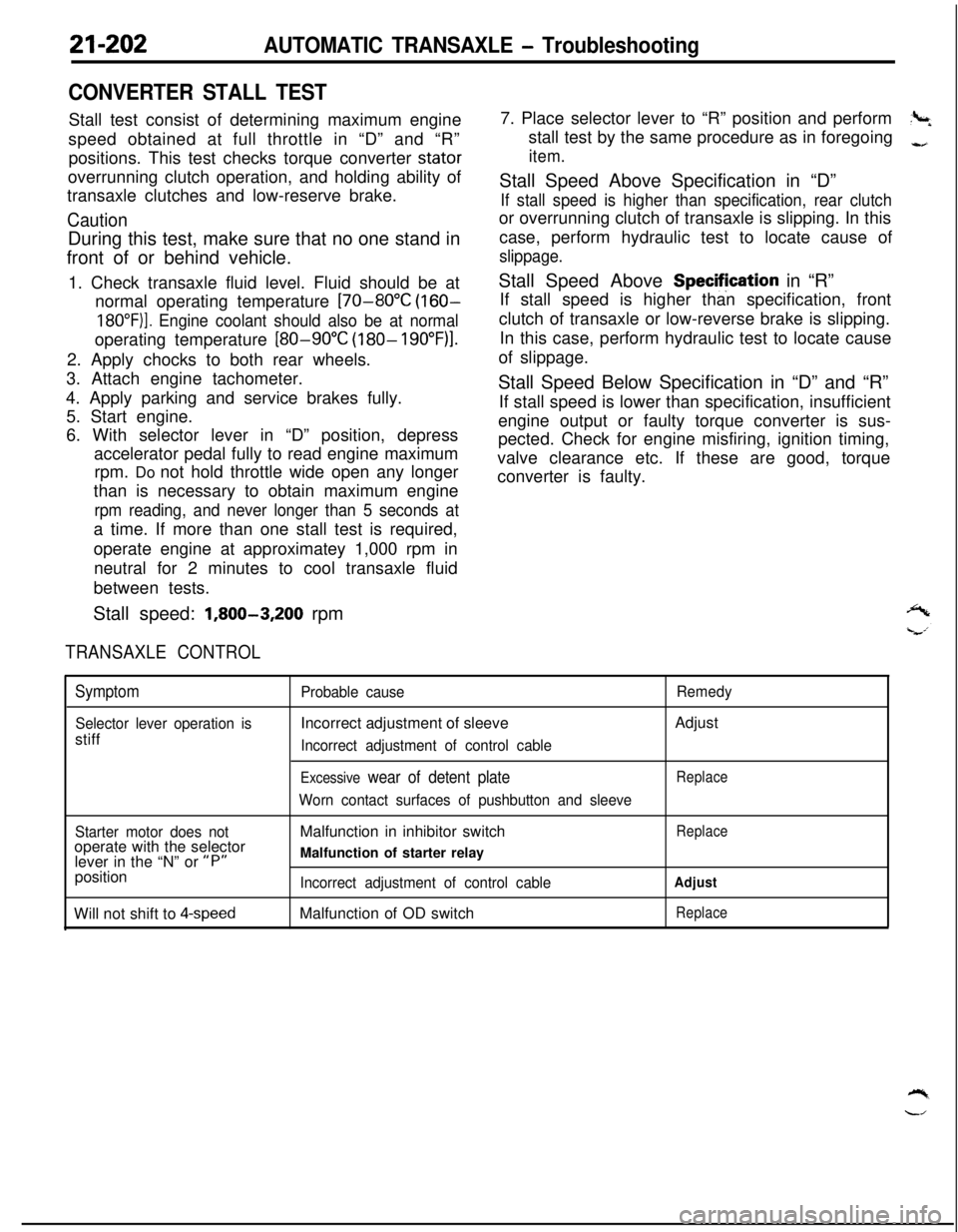

21-202AUTOMATIC TRANSAXLE - Troubleshooting

CONVERTER STALL TESTStall test consist of determining maximum engine

speed obtained at full throttle in “D” and “R”

positions. This test checks torque converter stator

overrunning clutch operation, and holding ability of

transaxle clutches and low-reserve brake.

CautionDuring this test, make sure that no one stand in

front of or behind vehicle.

1. Check transaxle fluid level. Fluid should be at

normal operating temperature

[70-80°C (160-

18O”F)]. Engine coolant should also be at normaloperating temperature

[80-90°C (180- 19O”F)l.2. Apply chocks to both rear wheels.

3. Attach engine tachometer.

4. Apply parking and service brakes fully.

5. Start engine.

6. With selector lever in “D” position, depress

accelerator pedal fully to read engine maximum

rpm. Do not hold throttle wide open any longer

than is necessary to obtain maximum engine

rpm reading, and never longer than 5 seconds ata time. If more than one stall test is required,

operate engine at approximatey 1,000 rpm in

neutral for 2 minutes to cool transaxle fluid

between tests.

Stall speed:

1,800-3,200 rpm

TRANSAXLE CONTROL7. Place selector lever to “R” position and perform

?+stall test by the same procedure as in foregoing

-,

item.Stall Speed Above Specification in “D”

If stall speed is higher than specification, rear clutchor overrunning clutch of transaxle is slipping. In this

case, perform hydraulic test to locate cause of

slippage.Stall Speed Above Specifjcation in “R”

If stall speed is higher than specification, front

clutch of transaxle or low-reverse brake is slipping.

In this case, perform hydraulic test to locate cause

of slippage.

Stall Speed Below Specification in “D” and “R”

If stall speed is lower than specification, insufficient

engine output or faulty torque converter is sus-

pected. Check for engine misfiring, ignition timing,

valve clearance etc. If these are good, torque

converter is faulty.

Symptom

Selector lever operation isstiff

Probable causeIncorrect adjustment of sleeve

Incorrect adjustment of control cable

Excessive wear of detent plate

Worn contact surfaces of pushbutton and sleeveRemedyAdjust

Replace

Starter motor does notoperate with the selector

lever in the “N” or

“P”position

Will not shift to

4-speedMalfunction in inhibitor switch

Malfunction of starter relay

Incorrect adjustment of control cableMalfunction of OD switch

Replace

Adjust

Replace