brake MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 578 of 1216

14-124AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

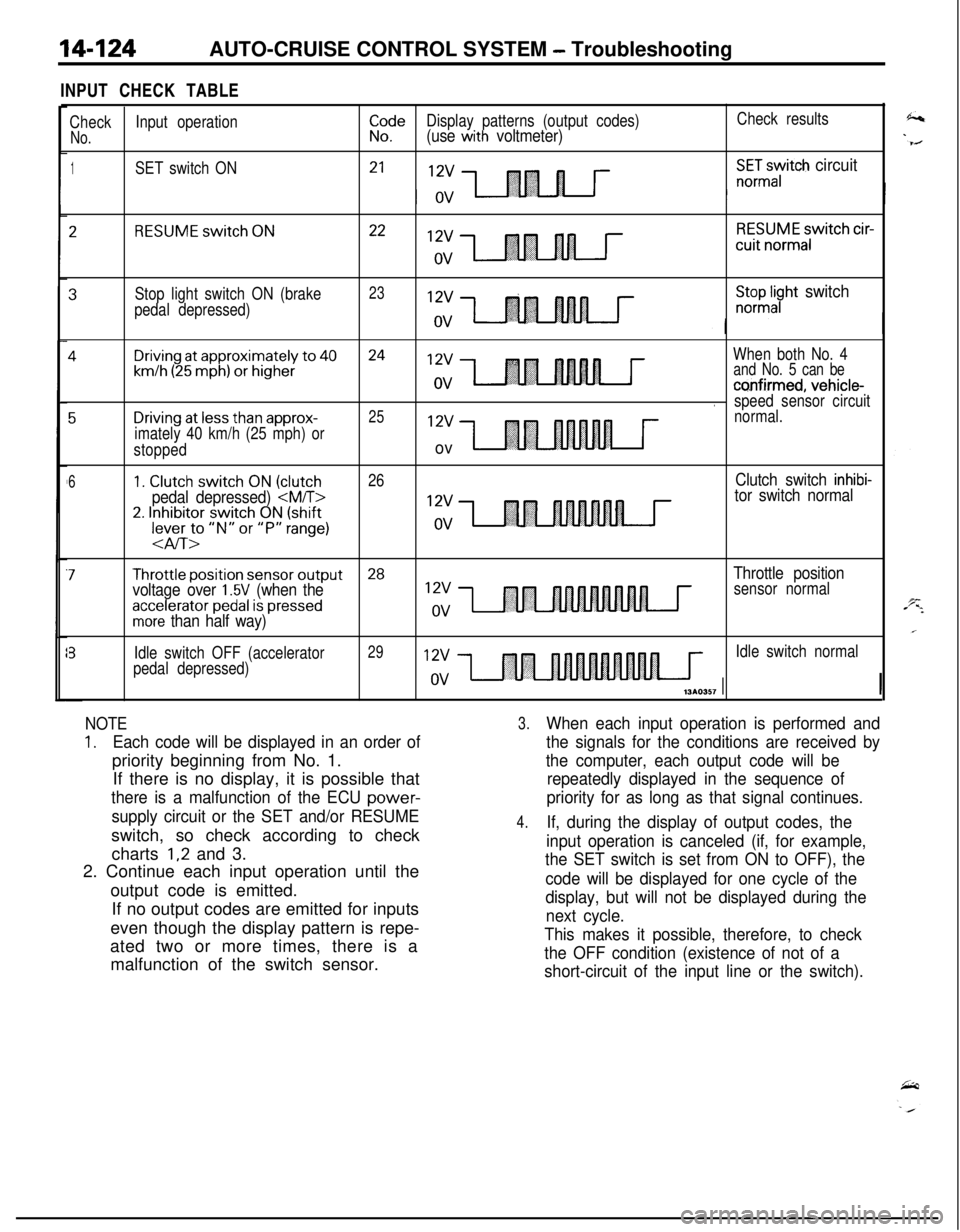

INPUT CHECK TABLE

CheckInput operationiI!eDisplay patterns (output codes)Check results

No.(use with voltmeter)

1SET switch ON21X:Gayitch circuit

2RESUME switch ON2212vRESUME switch cir-cuit

normalov

3Stop light switch ON (brake23

pedal depressed)

;;pl;yht switch

4Driving at approximately to 4024When both No. 4

km/h (25 mph) or higherand No. 5 can be

co,nfirmed, vehicle-.speed sensor circuit

5Driving at less than approx-2512vnormal.

imately 40 km/h (25 mph) or

stopped

ov

61. Clutch switch ON (clutch26Clutch switch inhibi-

pedal depressed)

2. Inhibitor switch ON (shift12vlever to “N” or “P” range)ov

-aIT>

7Throttle position sensor output28

voltage over 1.5V (when theThrottle positionsensor normal

accelerator pedal is pressedmore than half way)

?Idle switch OFF (accelerator29Idle switch normal

pedal depressed)

NOTE

1.Each code will be displayed in an order ofpriority beginning from No. 1.

If there is no display, it is possible that

there is a malfunction of the ECU power-

supply circuit or the SET and/or RESUMEswitch, so check according to check

charts

1,2 and 3.

2. Continue each input operation until the

output code is emitted.

If no output codes are emitted for inputs

even though the display pattern is repe-

ated two or more times, there is a

malfunction of the switch sensor.

3.When each input operation is performed and

the signals for the conditions are received by

the computer, each output code will be

repeatedly displayed in the sequence of

priority for as long as that signal continues.

4.If, during the display of output codes, the

input operation is canceled (if, for example,

the SET switch is set from ON to OFF), the

code will be displayed for one cycle of the

display, but will not be displayed during the

next cycle.

This makes it possible, therefore, to check

the OFF condition (existence of not of a

short-circuit of the input line or the switch).

Page 590 of 1216

14-136AUTO-CRUISE CONTROL SYSTEM- Service Adjustment Procedures03AQ250

rdjusting

03A0281

AUTO-CRUISE CONTROL CANCELLATION CHECK(1) Set the auto-cruise control.

”(2) Check to be sure that there is a return to ordinary driving,

and that the illumination of the auto-cruise indicator stops,

‘cwhen either of the operations below is performed.

@ The brake pedal is depressed.

@ The clutch pedal is depressed.

@ The shift lever is moved to the “N” or “P” range.

aIT>

@ The auto-cruise control main switch is switched OFF.

@ The ignition switch is turned to OFF.

CHECK OF RETURN TO THE SET SPEED BEFORE

CANCELLATION(1) Set the auto-cruise control.

(2) Check to be sure that the auto-cruise control is

cancelledwhen either of the operations below is performed.

@ The brake pedal is depressed.

@ The clutch pedal is depressed.

@I The shift lever is moved to the “N” range. (3) Turn the control switch to RESUME position and release

(RESUME switch

ONdOFF) while driving at a vehicle

speed of approximately 40 km/h (25 mph) or higher.

(4) After switching RESUME switch to OFF, check to be sure

that there is a return to the auto-cruise control speed before

it will be

cancelled and the vehicle will travel at the constant

speed.

A

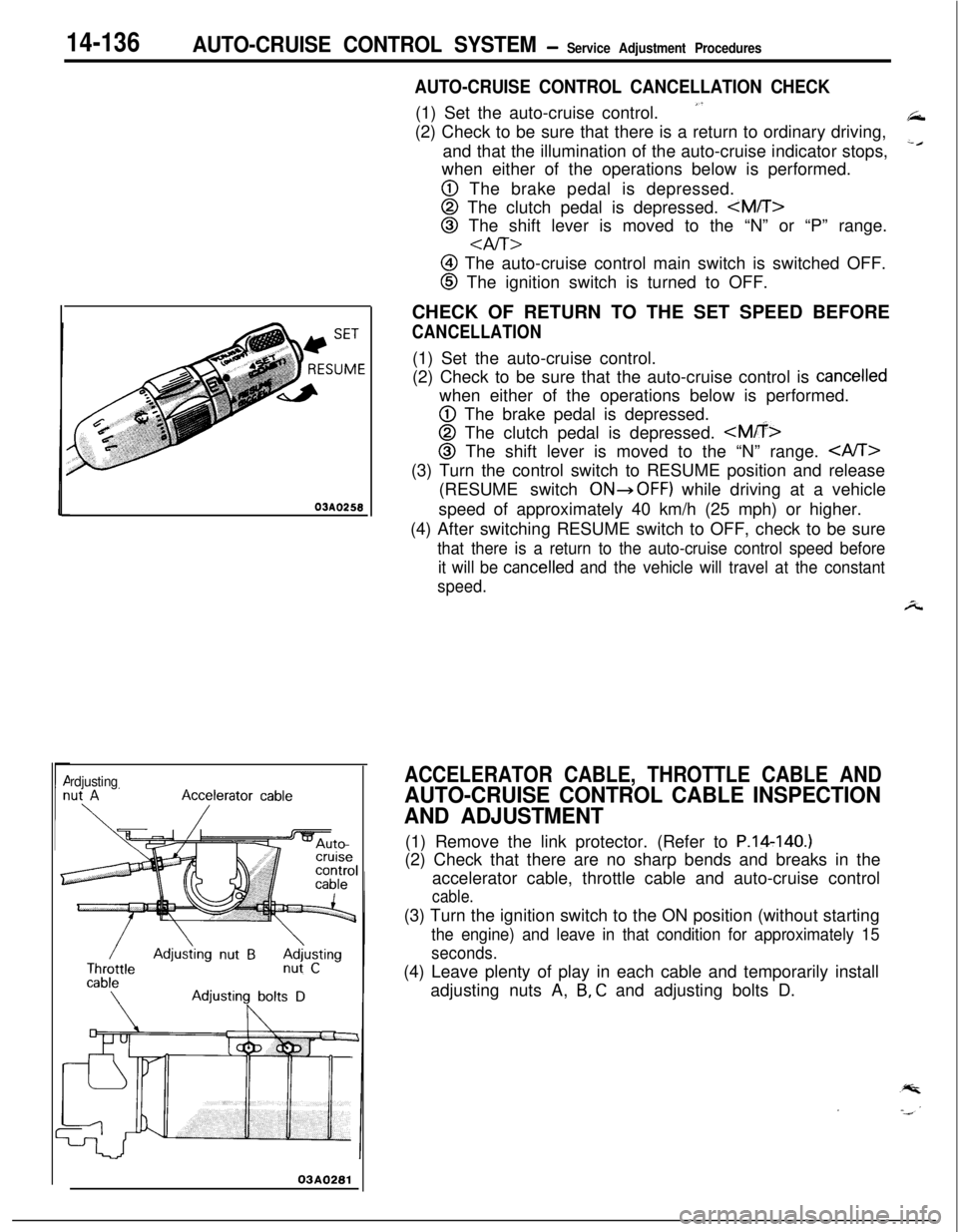

ACCELERATOR CABLE, THROTTLE CABLE AND

AUTO-CRUISE CONTROL CABLE INSPECTION

AND ADJUSTMENT(1) Remove the link protector. (Refer to P.14140.)

(2) Check that there are no sharp bends and breaks in the

accelerator cable, throttle cable and auto-cruise control

cable.(3) Turn the ignition switch to the ON position (without starting

the engine) and leave in that condition for approximately 15

seconds.(4) Leave plenty of play in each cable and temporarily install

adjusting nuts A,

B, C and adjusting bolts D.

Page 592 of 1216

14-138AUTO-CRUISE CONTROL SYSTEM - Service Adjustment Procedures

07A0051

07AOO50

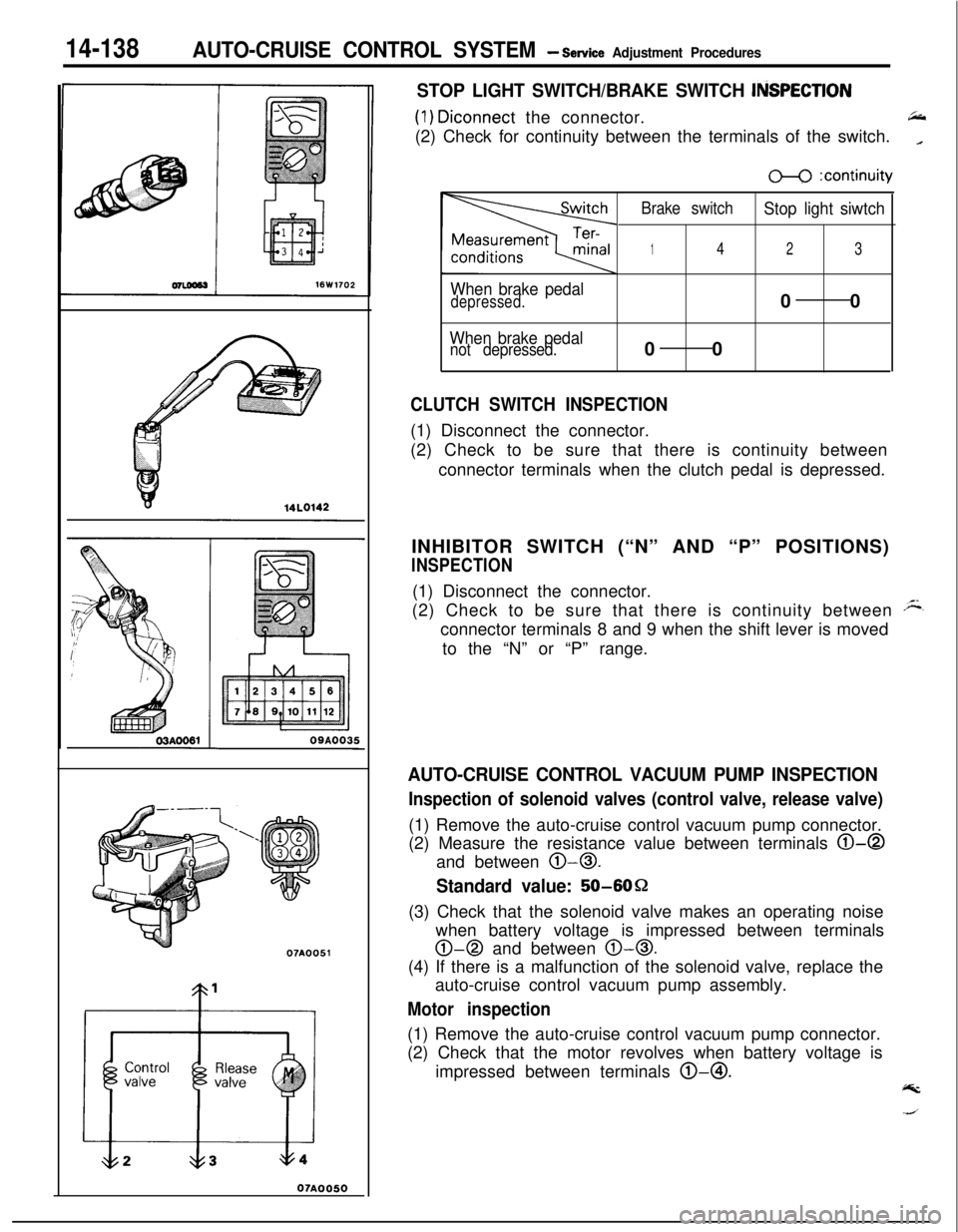

STOP LIGHT SWITCH/BRAKE SWITCH ItiSPECTlON

(1) Diconnect the connector.66(2) Check for continuity between the terminals of the switch.

_

When brake pedaldepressed.

When brake pedalnot depressed.

m :continuity

Brake switch

Stop light siwtch

142300

00

CLUTCH SWITCH INSPECTION(1) Disconnect the connector.

(2) Check to be sure that there is continuity between

connector terminals when the clutch pedal is depressed.

INHIBITOR SWITCH (“N” AND “P” POSITIONS)

INSPECTION(1) Disconnect the connector.

(2) Check to be sure that there is continuity between

Aconnector terminals 8 and 9 when the shift lever is moved

to the “N” or “P” range.

AUTO-CRUISE CONTROL VACUUM PUMP INSPECTION

Inspection of solenoid valves (control valve, release valve)(1) Remove the auto-cruise control vacuum pump connector.

(2) Measure the resistance value between terminals

0-0and between

0-0.

Standard value: 50-6OQ

(3) Check that the solenoid valve makes an operating noise

when battery voltage is impressed between terminals

0-0 and between 0-0.(4) If there is a malfunction of the solenoid valve, replace the

auto-cruise control vacuum pump assembly.

Motor inspection(1) Remove the auto-cruise control vacuum pump connector.

(2) Check that the motor revolves when battery voltage is

impressed between terminals @-@I.

@k

Page 612 of 1216

17-2REAR SUSPENSION

GENERAL SPECIFICATIONS

LN17CAA

ItemsVehicles with 1.8L EngineVehicles with 2.0L DOHC

Engine

jSuspension system

3-link, torsion axle with coil spring type

Coil spring

Wire dia.

x O.D. x free length

mm (in.) 10.1 x 105.1 x 336.510.2 x 105.2 x 316.5

(40 x 4.14 x 13.25)(40 x 4.14 x 12.46)

[Coil spring identification color]

[Light Blue

x 11[Orange x 11Spring constant

N/mm

(Ibs./in.) 20 (112.0)23 (128.8)

Shock absorber

TypeHydraulic, cylindrical, double-acting type

Max. length

mm (in.) 495 (19.5)485 (19.1)

Min. length

mm (in.) 315 (12.4)315 (12.4)

Strokemm (in.) 180 (7.1)170 (6.7)Damping force [at 0.3 m/set. (0.9

ft./set.)]

ExpansionN (Ibs.)800 (176)

ContractionN (Ibs.)300 (66)

Wheel bearing

TypeUnit ball bearing

SERVICE SPECIFICATIONS

Items

Standard valueToe-in (Left-right difference)

Camber

LimitWheel bearing end play

Rear hub rotary-sliding resistance

Rear hub rotary-sliding torque

NOTEToe-in and camber cannot be adjusted.mm (in.)

mm (in.)

N (Ibs.)

Nm

(ftlbs.)

TORQUE SPECIFICATIONS

Specifications

0+3 (Of.1 18)

-45’

f 30’

0.01 (004) or less

31

(7) or less

1.8

(1.30) or lessNI’ICB-A

ItemsNmft.lbs.

Wheel bearing nut

Shock absorber upper mounting nut

Shock absorber lower mounting nut

Lateral rod mounting nut (body side)

Lateral rod mounting bolt (axle beam side)

Trailing arm mounting bolt

Piston rod tightening nut

Brake hose and tube bracket mounting bolt

Caliper assembly mounting nut

Rear speed sensor mounting bolt

200-260

40-50

80- 100

80-100

100-120

100-120

20-2517-26

50-609-14144-188

29-36

58-72

58-72

72-87

72-87

14-18

12-19

36-43

I7-10

Nl7CGA

Page 613 of 1216

Special Tools/Troubleshooting/REAR SUSPENSION

SPECIAL TOOLN17DA.A

ToolNumberName1 Use1

L-451 4

Spring compressorRemoval and installation of the coil spring

bodyTROUBLESHOOTINGNI’IEA-A

Symptom

Squeaks or other

abnormal noiseProbable cause

Loose rear suspension installation bolts and nuts

Malfunction of shock absorber

Worn bushings

Remedy

Retighten

Replace

Poor rideExcessive tire inflation pressure

Malfunction of shock absorberWeak or broken springs

Adjust the pressure

Replace

Body tiltingWeak or deteriorated bushings

Weak or broken springs

Replace

SERVICE ADJUSTMENT PROCEDURES

REAR WHEEL ALIGNMENT INSPECTIONN17FAAC

The rear suspension assembly must be free of worn, loosen or

damaged parts prior to measurement of rear wheel alignment.

Standard value:

Toe-in (Left-right difference)

Of3 mm (Of.118 in.)

Camber-45’ + 30’

NOTEThe rear wheel alignment is set at the factory and cannot be

adjusted.If toe-in or camber is not within the standard value, replace

bent or damaged parts.

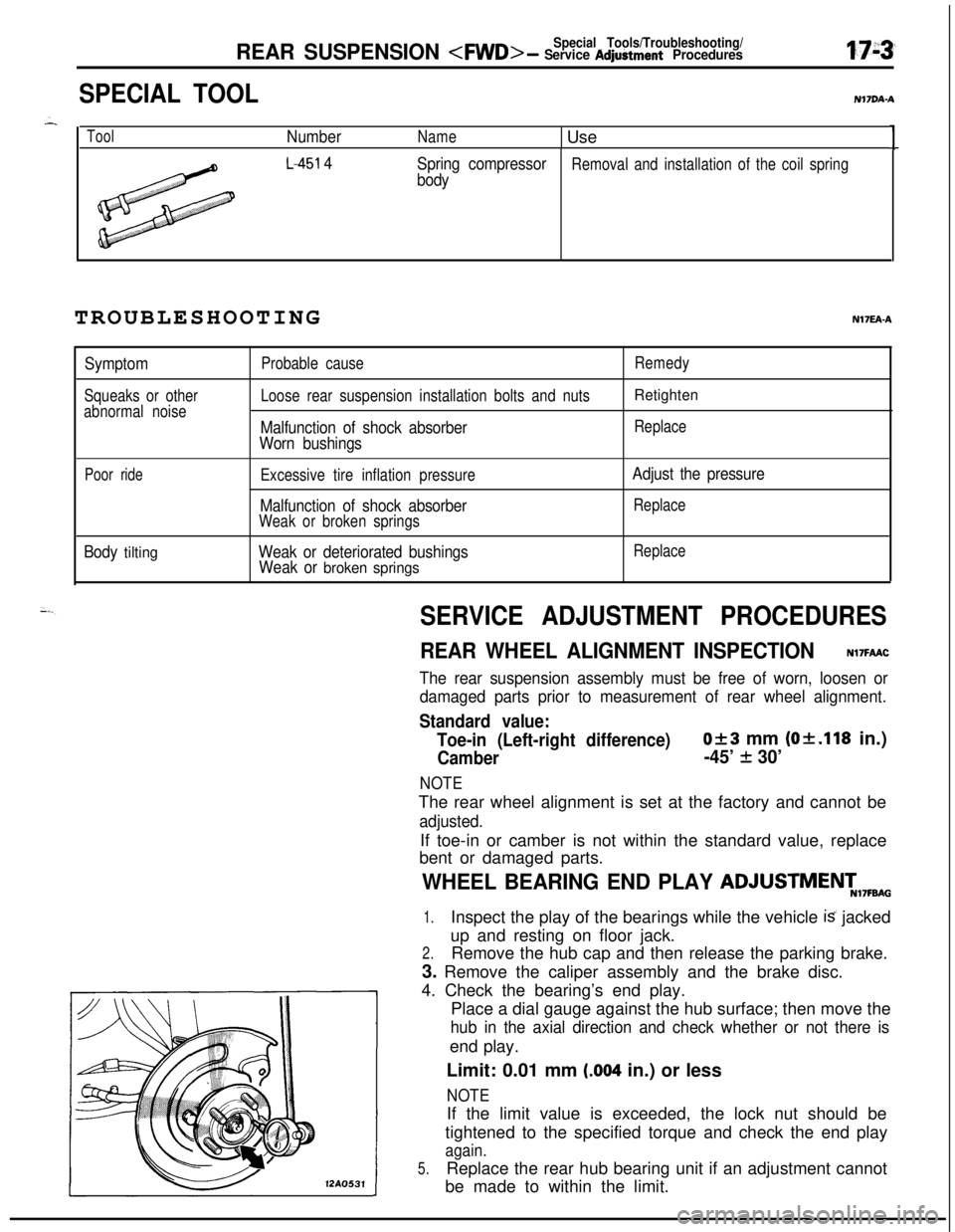

WHEEL BEARING END PLAY ADJUSTMENT,7FBA0

1.Inspect the play of the bearings while the vehicle is jacked

up and resting on floor jack.

2.Remove the hub cap and then release the parking brake.

3. Remove the caliper assembly and the brake disc.

4. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there isend play.

Limit: 0.01 mm

(.004 in.) or less

NOTE12AO531If the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.

5.Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

Page 614 of 1216

17-4REAR SUSPENSION

12A0533

3REAR HUB ROTARY-SLIDING

RESISTANCE

(TORQUE) ADJUSTMENTN17FCAC -

1.Inspect the play of the bearings while the vehicle is jacked.

up and resting on floor jack.

2. Release the parking brake.

3. Remove the caliper assembly and the brake disc.

4. After turnina the hub a few times to seat the bearing,

attach a spriig balance to the hub bolt, and, pulling at a 9@angle from the hub bolt, measure to determine whether or

not the rotary-sliding resistance of the rear hub (the

rotary-sliding torque of the rear hub) is the standard value.

Limit:

Rear hub rotary-sliding resistance

31N (7 Ibs.) or less

Rear hub rotary-sliding torque1.8 Nm (1.30

ft.lbs.) or less

NOTEIf the limit value is exceed, loosen the nut and then tighten

it to the specified torque, and check the rear hub

rotary-sliding torque again.

5. Replace the rear hub bearing unit if an adjustment cannot

+.be made to within the limit.

A

Page 615 of 1216

REAR SUSPENSION

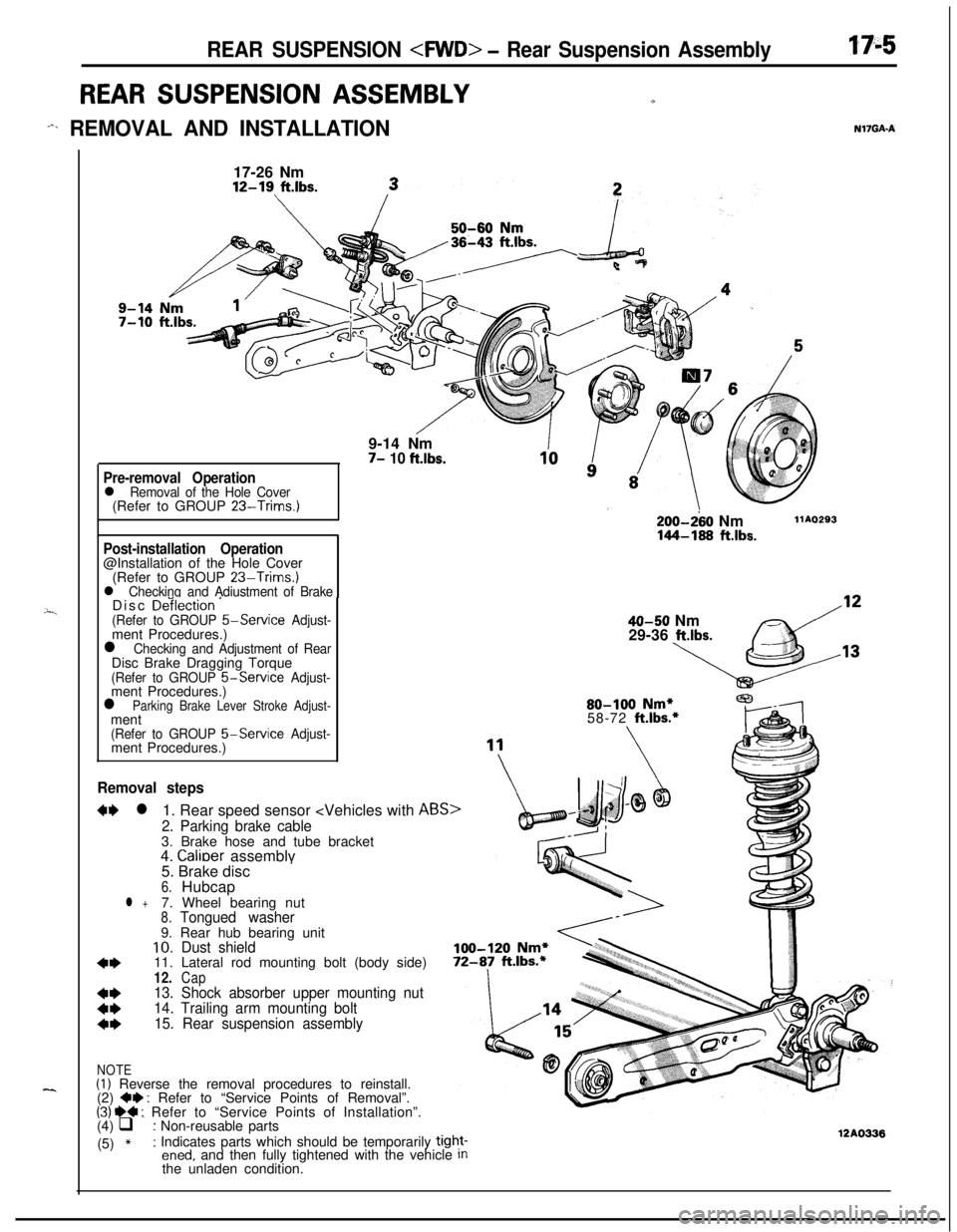

REAR SUSPENSION ASSEMBLYu

-%. REMOVAL AND INSTALLATIONN17GAA

---i

--..17-26 Nm12-19

ft.lbs.9-14 Nm

7- 10 ft.lbs.

Pre-removal Operationl Removal of the Hole Cover(Refer to GROUP 23-Trims.)

Post-installation Operation@Installation of the Hole Cover

(Refer to GROUP

23-Trims.)l Checking and Adiustment of BrakeDisc De‘ilection ’(Refer to GROUP 5-Service Adjust-ment Procedures.)

l Checking and Adjustment of RearDisc Brake Dragging Torque

(Refer to GROUP &Service Adjust-ment Procedures.)

l Parking Brake Lever Stroke Adjust-ment

(Refer to GROUP 5-Service Adjust-ment Procedures.)

Removal steps

W l1. Rear speed sensor

2. Parking brake cable3. Brake hose and tube bracket

4.

Calioer assemblv

200-280 Nm144-168 ftlbs.

llAO293

40-50 Nm

29-36 ltlbs.80-100

Nm*58-72 ft.lbs.*5. Brake disc

’6.Hubcapl +7. Wheel bearing nut8.Tongued washer9. Rear hub bearing unit

10.Dust shield

4*11. Lateral rod mounting bolt (body side)12.Cap

t:

13. Shock absorber upper mounting nut

14. Trailing arm mounting bolt

4*15. Rear suspension assembly

NOTE(I) Reverse the removal procedures to reinstall.

(2) +e : Refer to “Service Points of Removal”.(31 ~~ : Refer to “Service Points of Installation”.

(4) q : Non-reusable parts

(5)

*: Indicates parts which should be temporarily tight-ened, and then fully tightened with the vehicle Inthe unladen condition.12AO336

Page 622 of 1216

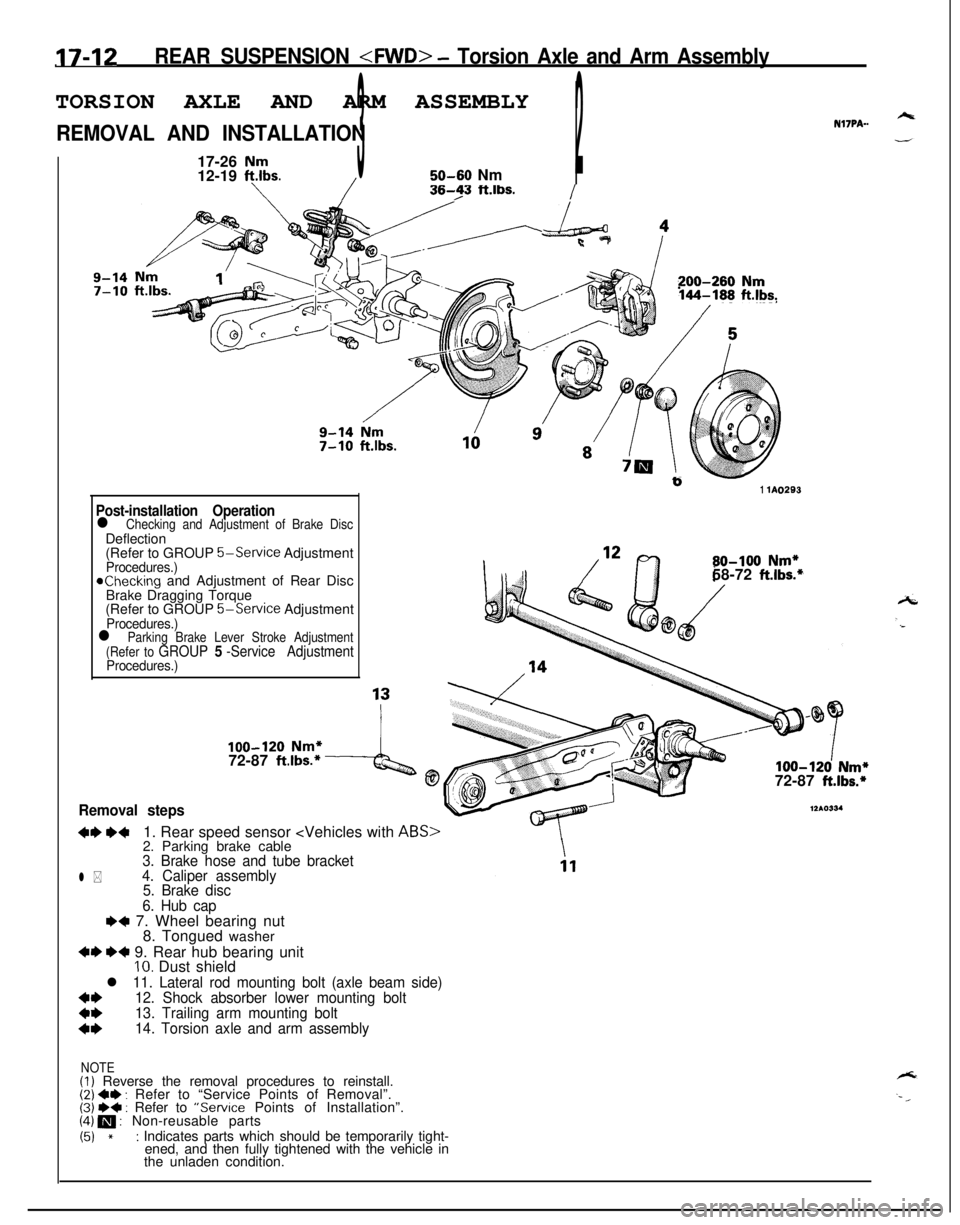

17-12REAR SUSPENSION

REMOVAL AND INSTALLATIONNl’IPA-.

17-26

Nm12-19 ft.lbs.350-60 Nm2/I

/36-23 ft.lbs./

Nm1’200-260 Nm144-188 ft.lbs.

b1 lA0293

Post-installation Operationl Checking and Adjustment of Brake DiscDeflection

(Refer to GROUP

5-Service AdjustmentProcedures.)achecking and Adjustment of Rear Disc

Brake Dragging Torque

(Refer to GROUP

5-Service AdjustmentProcedures.)

80-100 Nm*58-72 ft.lbs.*

l Parking Brake Lever Stroke Adjustment

(Refer to GROUP 5 -Service AdjustmentProcedures.)

100-120 Nm*72-87 ft.lbs.*4@100-120 Nm*72-87 ft.lbs.*

Removal steps

+I) ++1. Rear speed sensor

12*0334

l *

3. Brake hose and tube bracket

4. Caliper assembly

5. Brake disc

6. Hub cap

e+ 7. Wheel bearing nut

8. Tongued washer

+I) *+ 9. Rear hub bearing unitIO. Dust shield

l 11. Lateral rod mounting bolt (axle beam side)

*I)12. Shock absorber lower mounting bolt

13. Trailing arm mounting bolt

14. Torsion axle and arm assembly

NOTE(I) Reverse the removal procedures to reinstall.(2) ~~ : Refer to “Service Points of Removal”.(3j W+ : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

(51 *: Indicates parts which should be temporarily tight-

ened, and then fully tightened with the vehicle in

the unladen condition.

Page 624 of 1216

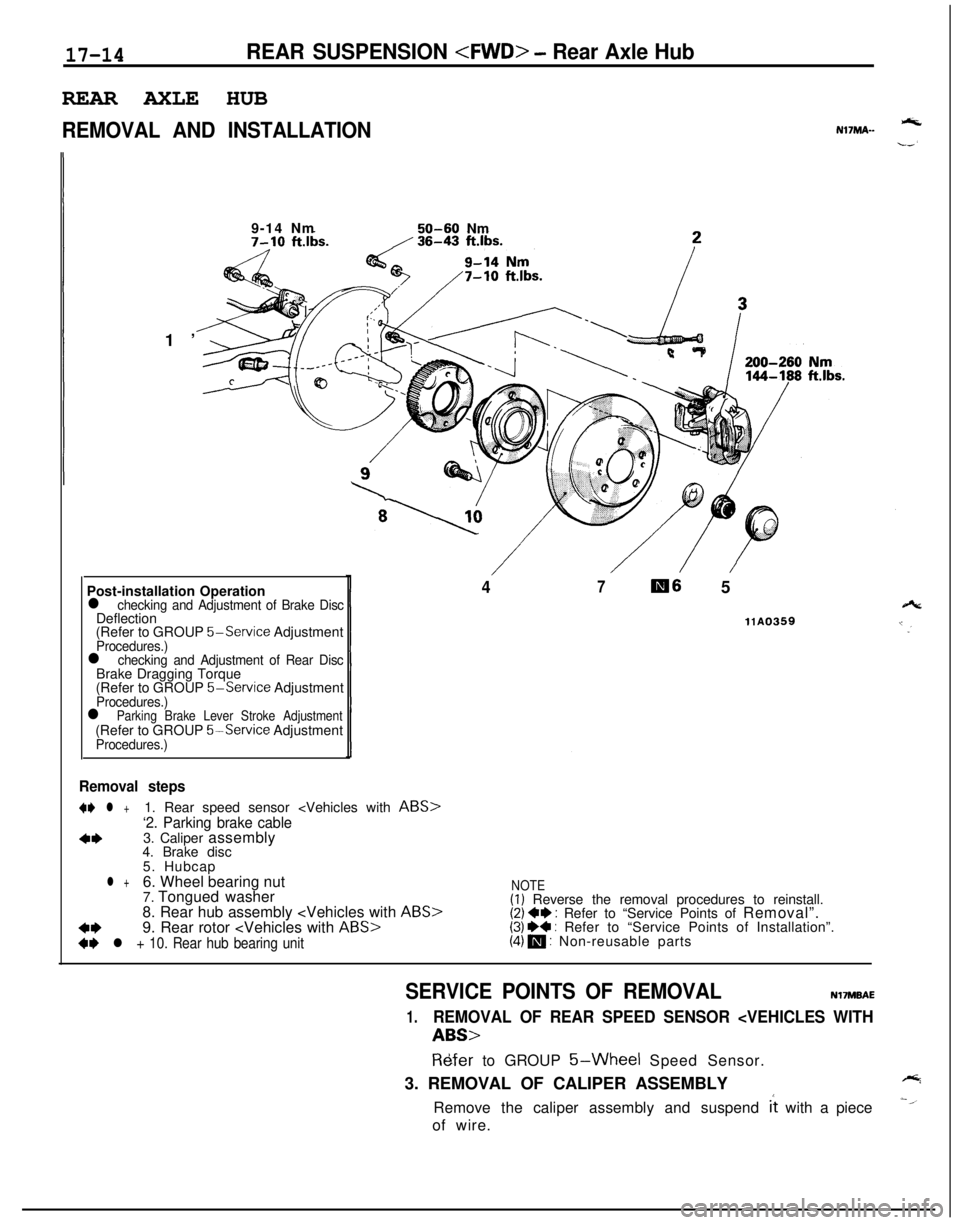

17-14REAR SUSPENSION

REMOVAL AND INSTALLATIONNl’IMA--1’9-14 Nm

50-60 Nm

Post-installation Operation

l checking and Adjustment of Brake DiscDeflection

(Refer to GROUP

5-Service AdjustmentProcedures.)l checking and Adjustment of Rear DiscBrake Dragging Torque

(Refer to GROUP

5-Service AdjustmentProcedures.)l Parking Brake Lever Stroke Adjustment(Refer to GROUP 5%Service AdjustmentProcedures.)

47m6 5

llA0359

Removal steps

+* l +1. Rear speed sensor

‘2. Parking brake cable

4*3. Caliper assembly

4. Brake disc

5. Hubcap

l +6. Wheel bearing nut

7. Tongued washer

8. Rear hub assembly

4*9. Rear rotor

+I) l + 10. Rear hub bearing unit

NOTE(I) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) I)+ : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

SERVICE POINTS OF REMOVALNVMBAE

1.REMOVAL OF REAR SPEED SENSOR

R6fer to GROUP 5-Wheel Speed Sensor.

3. REMOVAL OF CALIPER ASSEMBLY

Remove the caliper assembly and suspend

it with a piece

of wire.

Page 627 of 1216

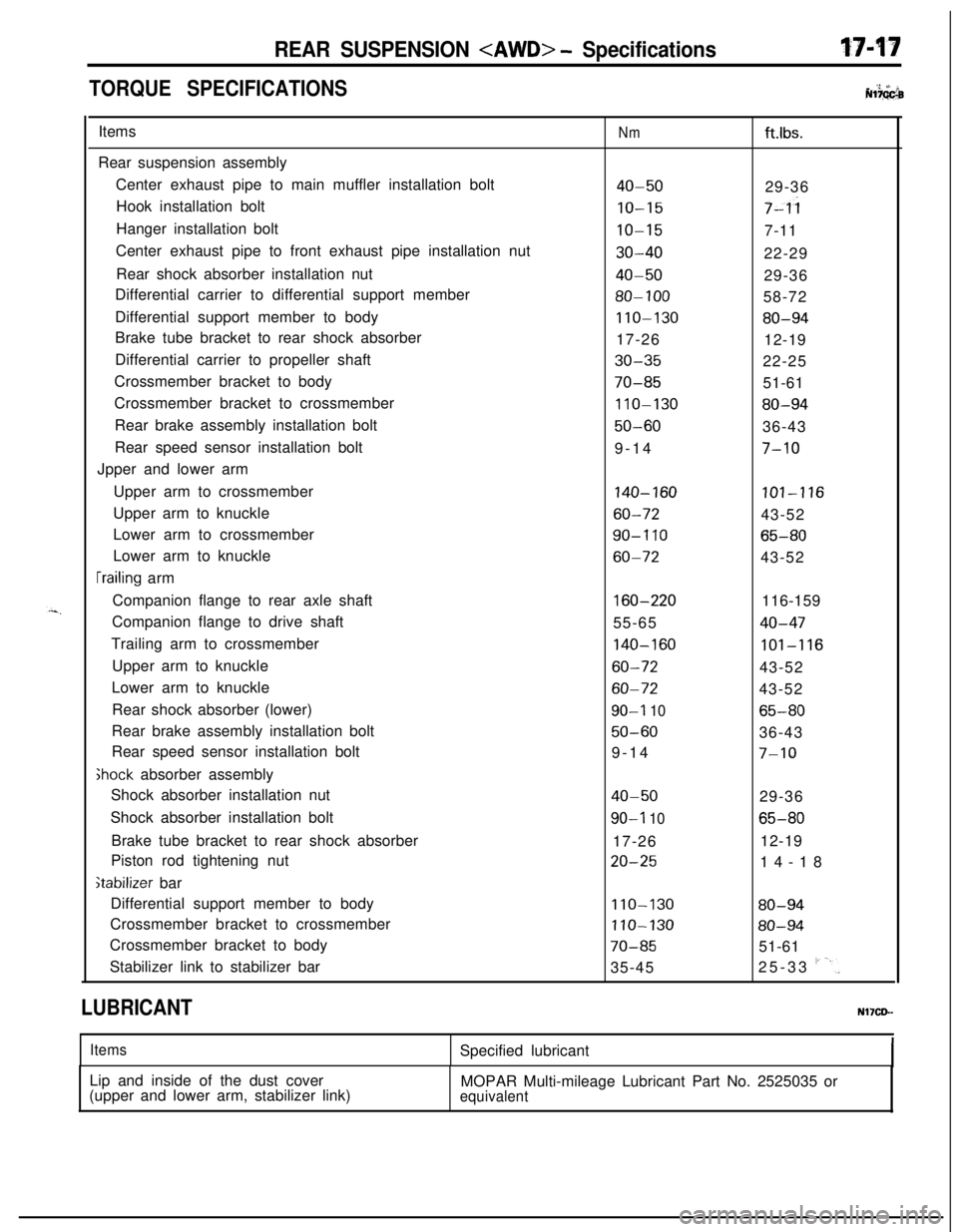

REAR SUSPENSION

TORQUE SPECIFICATIONS. ‘2 +’ iiNl?GGbItems

Rear suspension assembly

Center exhaust pipe to main muffler installation bolt

Hook installation bolt

Hanger installation bolt

Center exhaust pipe to front exhaust pipe installation nut

Rear shock absorber installation nut

Differential carrier to differential support member

Differential support member to body

Brake tube bracket to rear shock absorber

Differential carrier to propeller shaft

Crossmember bracket to body

Crossmember bracket to crossmember

Rear brake assembly installation bolt

Rear speed sensor installation bolt

Jpper and lower arm

Upper arm to crossmember

Upper arm to knuckle

Lower arm to crossmember

Lower arm to knuckle

[railing arm

Companion flange to rear axle shaft

Companion flange to drive shaft

Trailing arm to crossmember

Upper arm to knuckle

Lower arm to knuckle

Rear shock absorber (lower)

Rear brake assembly installation bolt

Rear speed sensor installation bolt

Ghock absorber assembly

Shock absorber installation nut

Shock absorber installation bolt

Brake tube bracket to rear shock absorber

Piston rod tightening nut

stabilizer bar

Differential support member to body

Crossmember bracket to crossmember

Crossmember bracket to body

Stabilizer link to stabilizer bar

Nmft.lbs.

40-5029-36

IO-157-ii

IO-157-11

30-4022-29

40-5029-36

80-10058-72

110-13080-9417-26

12-19

30-3522-25

70-8551-61

110-13080-94

50-6036-43

9-14

7-10

140-160101-116

60-7243-52

90-I 1065-80

60-7243-52

160-220116-159

55-65

40-47

140-160101-116

60-7243-52

60-7243-52

90-I 1065-80

50-6036-43

9-14

7-10

40-5029-36

90-l 1065-8017-2612-19

20-2514-18

110-13080-94

110-13080-94

70-8551-61

35-4525-33

I'-'.

LUBRICANTNl’ICD-

ItemsSpecified lubricant

Lip and inside of the dust cover

(upper and lower arm, stabilizer link)MOPAR Multi-mileage Lubricant Part No. 2525035 or

equivalent