width MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 25 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - :;k%ii::& and25

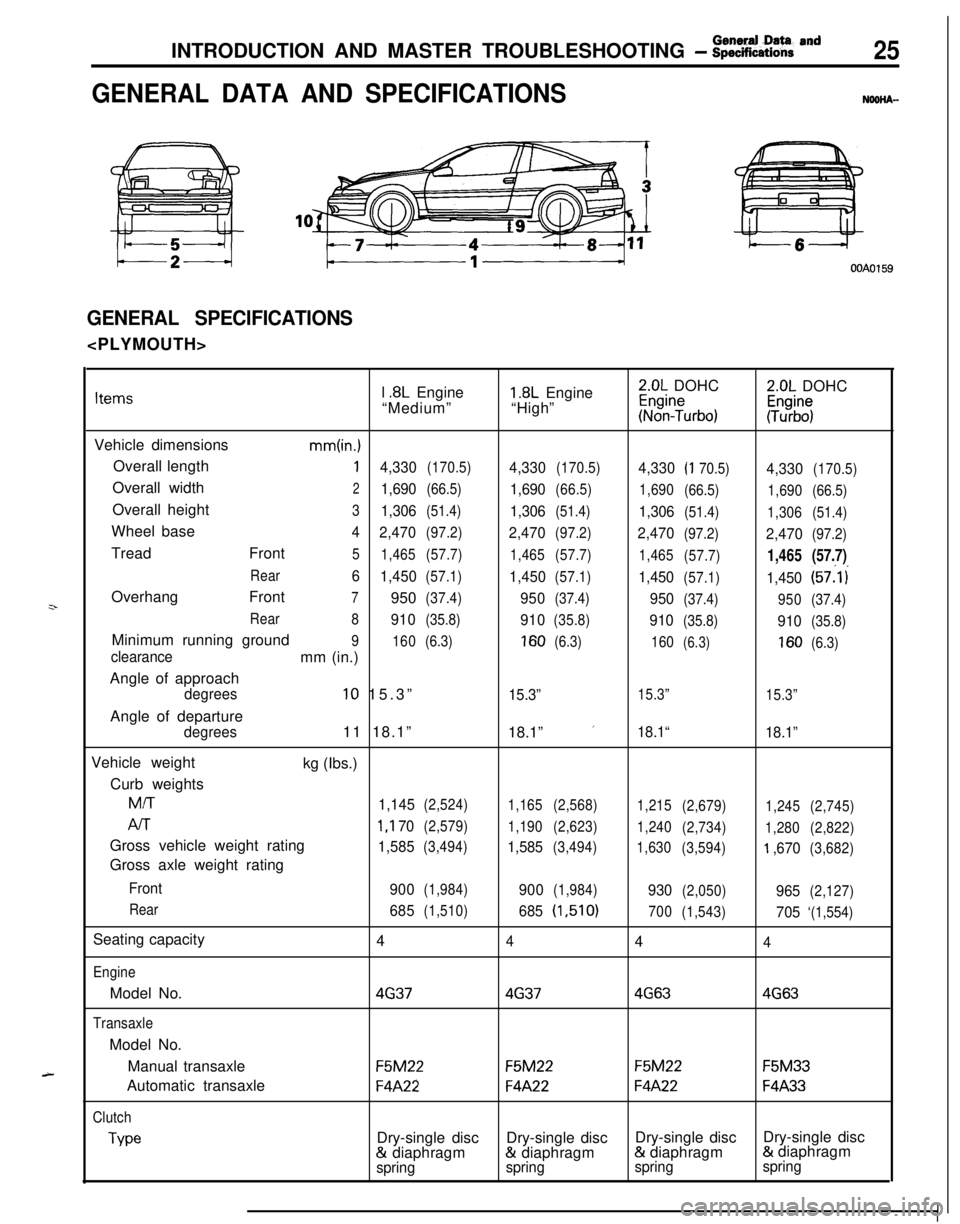

GENERAL DATA AND SPECIFICATIONSNOOHA-

OOAOl59

GENERAL SPECIFICATIONS

z-

A-l

.8L Engine1.8L Engine2.0L DOHC2.0L DOHCItems“Medium”“High”~%n?urbo):Tz%$

Vehicle dimensions

mm(in.)Overall length

14,330(170.5)4,330(170.5)4,330(I 70.5)4,330(170.5)Overall width

21,690(66.5)1,690(66.5)

1,690

(66.5)

1,690(66.5)Overall height

31,306(51.4)1,306(51.4)1,306(51.4)

1,306(51.4)Wheel base

4

2,470(97.2)2,470(97.2)2,470(97.2)2,470(97.2)Tread Front

5

1,465(57.7)

1,465(57.7)

1,465

(57.7)1,465(57.7)

Rear6

1,450(57.1)1,450(57.1)1,450(57.1)1,450(57:l i

Overhang Front

7950(37.4)950(37.4)950(37.4)

950(37.4)

Rear

8

910(35.8)910(35.8)910(35.8)910(35.8)Minimum running ground

9

160(6.3)160(6.3)

160(6.3)160(6.3)clearancemm (in.)

Angle of approach

degrees10 15.3”15.3”15.3”

15.3”Angle of departure

degrees11 18.1”

18.1” ’18.1“

18.1”Vehicle weight

kg (Ibs.)

Curb weights

M/T

1,145(2,524)

1,165(2,568)

1,215

(2,679)

1,245(2,745)

AIT1 ,I 70(2,579)

1,190(2,623)

1,240

(2,734)

1,280(2,822)Gross vehicle weight rating

1,585(3,494)1,585(3,494)

1,630

(3,594)‘I ,670(3,682)Gross axle weight rating

Front

900(1,984)900(1,984)930(2,050)965(2,127)

Rear

685(1,510)685(1,510)

700

(1,543)705‘(1,554)Seating capacity

4

444

EngineModel No.

4G3746374G634G63

TransaxleModel No.

Manual transaxle

F5M22F5M22F5M22F5M33Automatic transaxle

F4A22F4A22F4A22F4A33

Clutch

TypeDry-single discDry-single discDry-single discDry-single disc& diaphragm& diaphragm& diaphragm& diaphragm

springspringspringspring

Page 26 of 1216

26INTRODUCTION AND MASTER TROUBLESHOOTING - :;:%:a=and

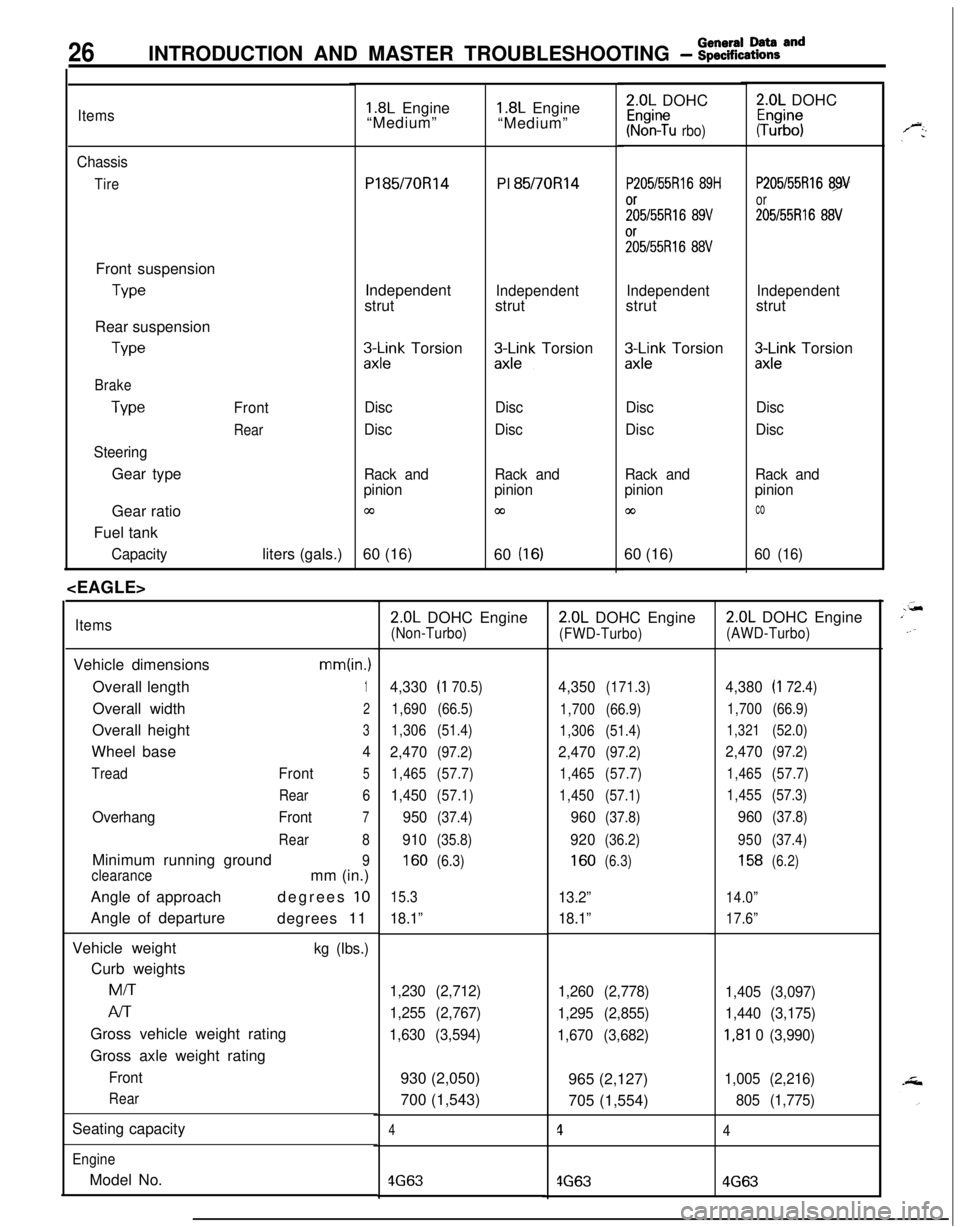

Items

Chassis

TireFront suspension

TypeRear suspension

We

Brake

Type

SteeringGear typeFront

RearGear ratio

Fuel tank

Capacityliters (gals.)

1.8L Engine

“Medium”Pl85/70R14

PI 85/70Rl4

Independent

strut

Independentstrut

3l\Fk Torsion&k-k Torsion

Disc

DiscDisc

Disc

Rack and

pinion

03

Rack and

pinion

cn60 (16)

60

(16)

ItemsVehicle dimensions

mm(in.)Overall length

1Overall width

2Overall height

3Wheel base

4

TreadFront5

Rear6

OverhangFront7

Rear8Minimum running ground

9

clearancemm (in.)

Angle of approachdegrees

10Angle of departure

degrees 11

Vehicle weight

kg (Ibs.)Curb weightsMiT

Al-rGross vehicle weight rating

Gross axle weight rating

Front

RearSeating capacity

EngineModel No.

1.8L Engine

“Medium”2.0L DOHC

Kr%n?u rbo)

P205/55Rl6 89H

;;5/55R16 89V%55R16

88V

Independentstrut

zx;;k Torsion

Disc

Disc

Rack and

pinion

co60 (16)

2.0L DOHC

#b”;

P205/55Rl6 89

or

205155R16 88V

Independentstrut

3Lnk Torsion

Disc

Disc

Rack and

pinion

co

60 (16)

2.0L DOHC Engine(Non-Turbo)

4,330(I 70.5)

1,690(66.5)

1,306(51.4)

2,470(97.2)

1,465(57.7)

1,450(57.1)

950(37.4)

910(35.8)

160(6.3)

15.3

18.1”

1,230 (2,712)

1,255 (2,767)

1,630 (3,594)930 (2,050)

700 (1,543)

4

4G63

2.0L DOHC Engine

(FWD-Turbo)

4,350(171.3)

1,700(66.9)

1,306(51.4)

2,470(97.2)

1,465(57.7)

1,450(57.1)

960(37.8)

920(36.2)

160(6.3)

13.2”

18.1”

1,260 (2,778)

1,295 (2,855)

1,670 (3,682)965 (2,127)

705 (1,554)

1

4G63

2.0L DOHC Engine

(AWD-Turbo)

4,380(I 72.4)

1,700(66.9)

1,321(52.0)

2,470(97.2)

1,465(57.7)

1,455(57.3)

960(37.8)

950(37.4)

158(6.2)

14.0”

17.6”

1,405 (3,097)

1,440 (3,175)

I,81 0 (3,990)

1,005 (2,216)

805 (1,775)

4

4G63

Page 293 of 1216

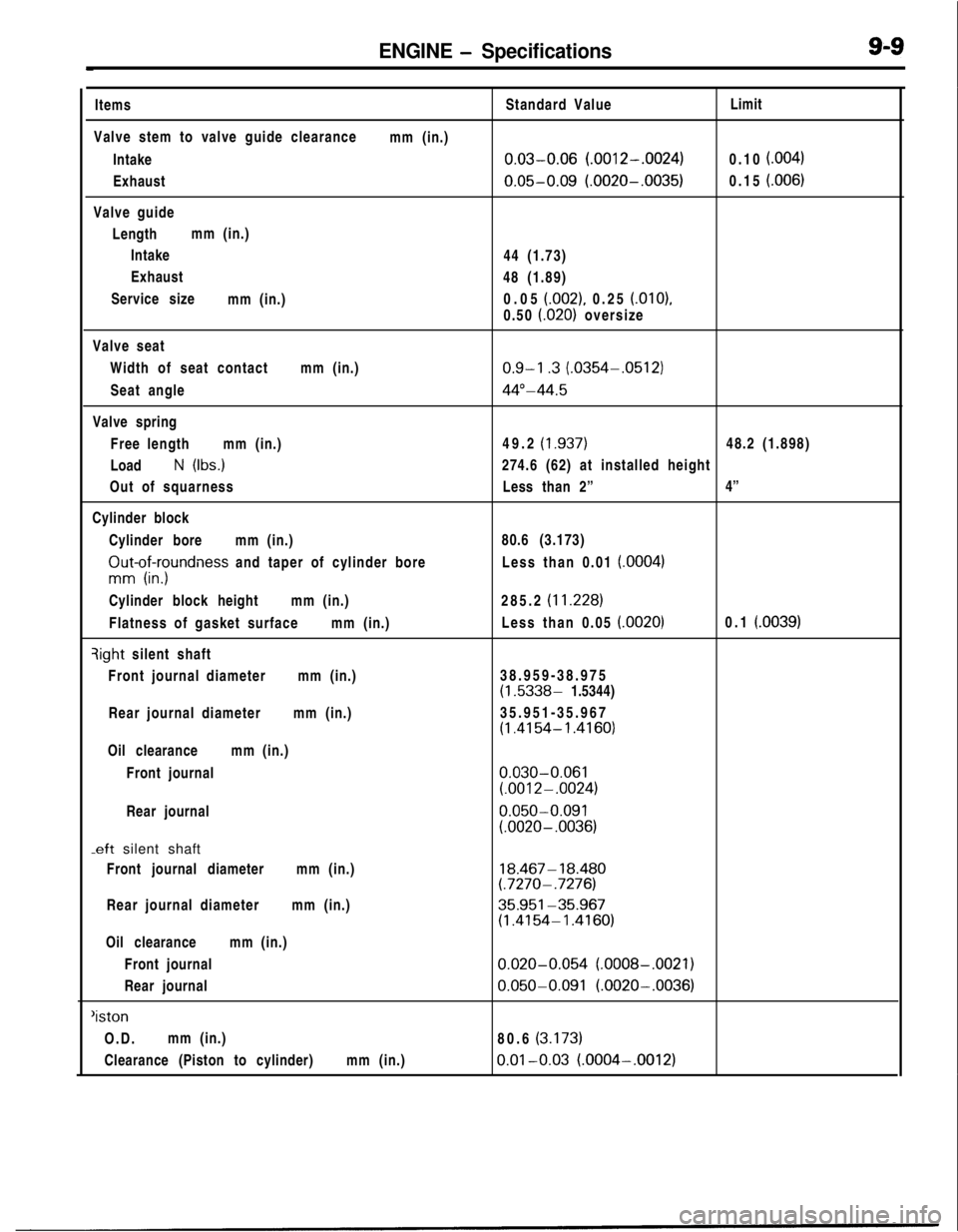

ENGINE - SpecificationsItems

Valve stem to valve guide clearance

Intake

Exhaust

Valve guide

Lengthmm (in.)

Intake

Exhaust

Service size

mm (in.)mm (in.)Standard Value

0.03-0.06 (.0012-.0024)

0.05-0.09 (.0020-.0035)44 (1.73)

48 (1.89)

0.05

(.002), 0.25 (.OlO),

0.50

i.020) oversizeLimit

0.10

f.004)0.15

i.006)Valve seat

Width of seat contactmm (in.)

Seat angle

Valve spring

Free lengthmm (in.)

Load

N (Ibs.)

Out of squarness

Cylinder block

Cylinder boremm (in.)

ZIut-of;yundness and taper of cylinder bore

Cylinder block heightmm (in.)

Flatness of gasket surfacemm (in.)qight silent shaft

Front journal diametermm (in.)

Rear journal diametermm (in.)

Oil clearancemm (in.)

Front journal

Rear journal

-eft silent shaft

Front journal diametermm (in.)

Rear journal diametermm (in.)

Oil clearancemm (in.)

Front journal

Rear journal

‘istonO.D.mm (in.)

Clearance (Piston to cylinder)mm (in.)

0.9-l .3 (.0354-.0512)

44”-44.549.2

(1.937)48.2 (1.898)

274.6 (62) at installed height

Less than 2”4”

80.6 (3.173)

Less than 0.01

(.0004)285.2

(11.228)Less than 0.05

(.0020)0.1 (.0039)38.959-38.975

(1.5338- 1.5344)

35.951-35.967

(1.4154- 1.4160)

0.030-0.061(.0012-.0024)

0.050-0.091(.0020- .0036)

18.467- 18.480(.7270- .7276)

35.951-35.967(1.4154-1.4160)

0.020-0.054 (.0008-.0021)

0.050-0.091 (.0020-.0036)80.6

(3.173)

0.01-0.03 (.0004-.0012)

Page 295 of 1216

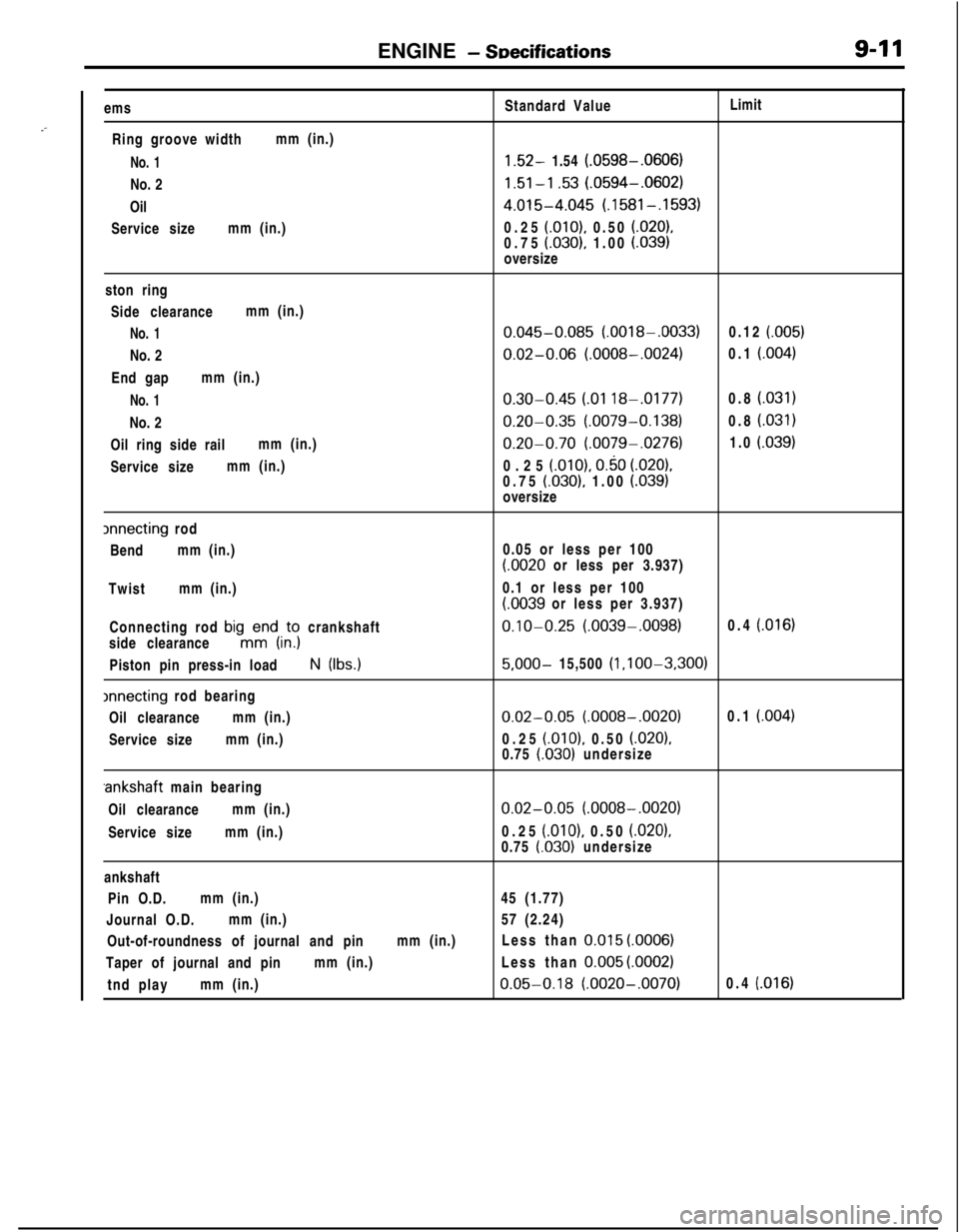

ENGINE - SDecifications9-11

.-ems

Ring groove widthmm (in.)

No. 1No. 2

Oil

Service sizemm (in.)Standard ValueLimit1.52- 1.54 (.0598-.0606)

1.51-l .53 (.0594-.0602)

4.015-4.045 (.1581-.1593)0.25

(.OlO), 0.50 (.020),0.75 (.030), 1.00 (.039)oversize

ston ring

Side clearancemm (in.)

No. 1No. 2

End gapmm (in.)

No. 1No. 2

Oil ring side railmm (in.)

Service sizemm (in.)

0.045-0.085 (.0018-.0033)0.12 (.005)

0.02-0.06 (.0008-.0024)0.1 (.004)

0.30-0.45 LO1 188.0177)0.8 (.031)

0.20-0.35 (.0079-0.138)0.8 i.031)

0.20-0.70 (.0079-.0276)1.0 (.039)0.25

(.OlO), 0.50 (.020).0.75 (.030), 1.00 LO391oversize

lnnecting rod

Bendmm (in.)

Twistmm (in.)

Connecting rod

bigmKdi,;; crankshaft

side clearance

Piston pin press-in loadN (Ibs.)

xrnecting rod bearing

Oil clearancemm (in.)

Service sizemm (in.)0.05 or less per 100

(.0020 or less per 3.937)

0.1 or less per 100

LOO39 or less per 3.937)

0.10-0.25 (.0039-.0098)0.4 (.016)

5,000- 15,500 (l ,l OO-3,300)

0.02-0.05 (.0008-.0020)0.1 (.004)0.25

(.OlO), 0.50 (.020),0.75 (.030) undersize.ankshaft main bearing

Oil clearancemm (in.)

Service sizemm (in.)

0.02-0.05 (.0008-.0020)0.25

(.OlO), 0.50 i.0201,

0.75 l.030) undersize

ankshaft

Pin O.D.mm (in.)45 (1.77)

Journal O.D.mm (in.)57 (2.24)

Out-of-roundness of journal and pinmm (in.)Less than

0.015 (.OOOS)Taper of journal and pinmm (in.)Less than

0.005 (.0002)tnd playmm (in.)

0.05-0.18 (.0020-.0070)0.4 (.016)

Page 298 of 1216

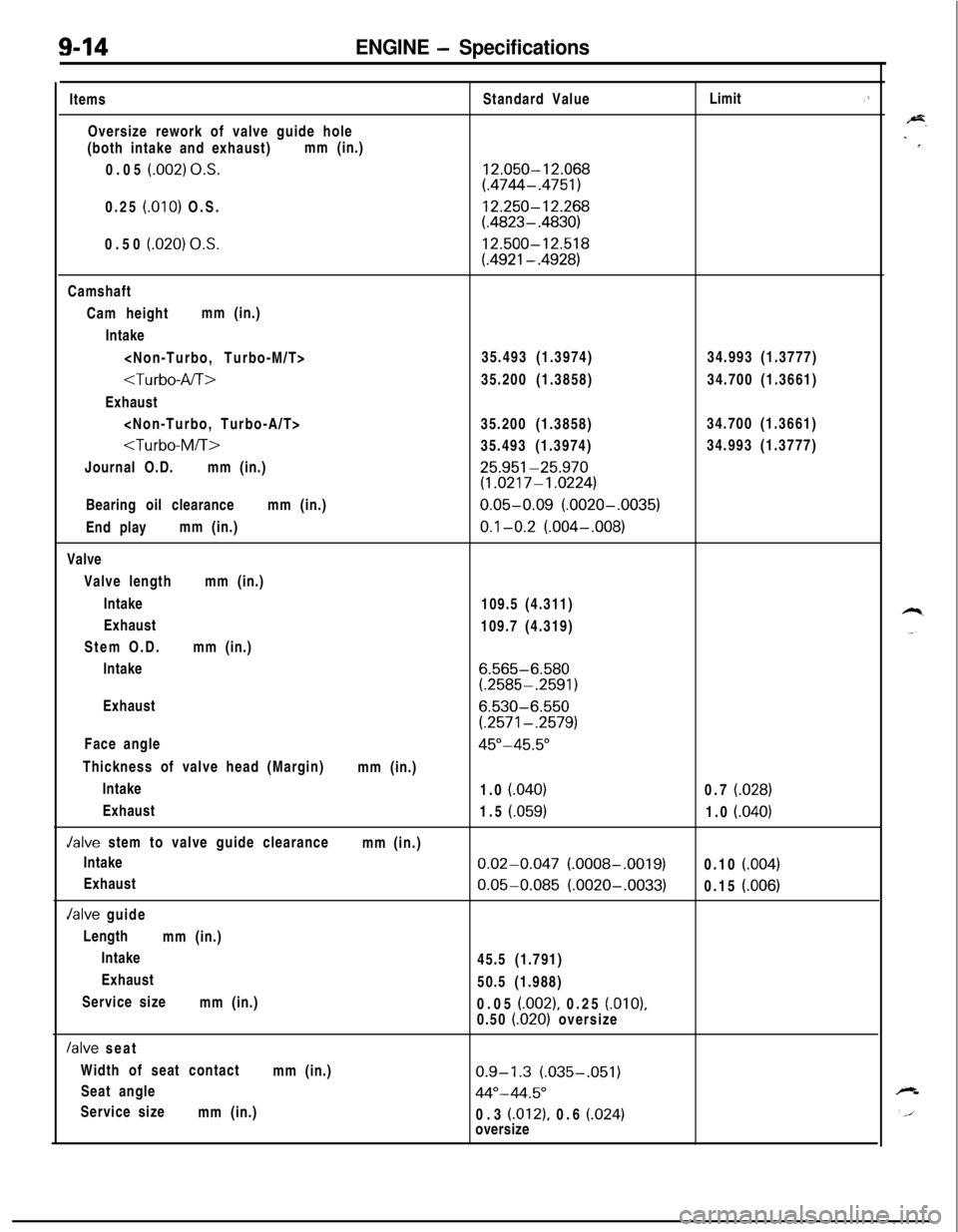

9-14ENGINE - SpecificationsItems

Oversize rework of valve guide hole

(both intake and exhaust)mm (in.)

0.05

(.002) O.S.0.25

(.OlO) O.S.

0.50

(.020) 0,s.Standard Value

12.050-12.068(.4744-.4751)

12.250-12.268(.4823-.4830)

12.500-12.518

(.4921-.4928)Limit

,’Camshaft

Cam heightmm (in.)

Intake

Exhaust

Journal O.D.mm (in.)

25.951-25.970(1.0217-1.0224)Bearing oil clearancemm (in.)

0.05-0.09 (.0020-.0035)End playmm (in.)

0.1-0.2 (.004-,008)Valve

Valve lengthmm (in.)

Intake

109.5 (4.311)

Exhaust

109.7 (4.319)

Stem O.D.mm (in.)

Intake

6.565-6.580(.2585-.2591)Exhaust

6.530-6.550

(.2571-.2579)Face angle

45"-45.5"Thickness of valve head (Margin)

mm (in.)

Intake

1.0

(.040)0.7 (.028)Exhaust

1.5

(.059)1.0 (.040)Jalve stem to valve guide clearance

mm (in.)

Intake

0.02-0.047 (.0008-.0019)0.10 (.004)Exhaust

0.05-0.085 (.0020-.0033)0.15 (.006)Jalve guide

Length

mm (in.)

Intake

45.5 (1.791)

Exhaust

50.5 (1.988)

Service size

mm (in.)

0.05

(.002), 0.25 (.OlO),0.50 (.020) oversize

/alve seat

Width of seat contact

mm (in.)

0.9-1.3 (.035-.051)Seat angle

44"-44.5"Service size

mm (in.)

0.3

(.012), 0.6 (.024)oversize

Page 299 of 1216

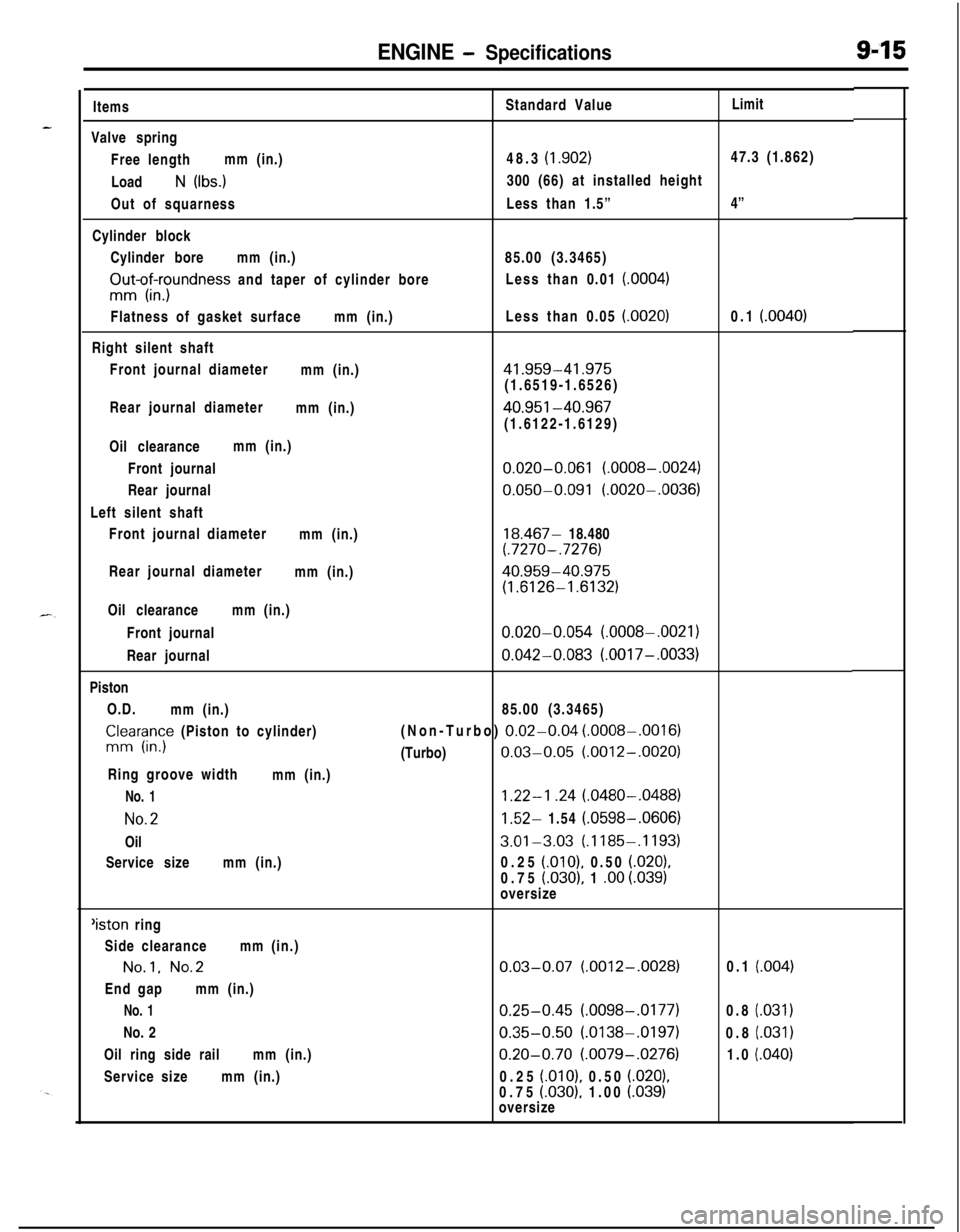

ENGINE - Specifications9-15ItemsStandard ValueLimit

Valve spring

Free lengthmm (in.)48.3

(1.902)47.3 (1.862)

Load

N (Ibs.)300 (66) at installed height

Out of squarnessLess than 1.5”4”

Cylinder block

Cylinder boremm (in.)85.00 (3.3465)

FIu-o$xrndness and taper of cylinder boreLess than 0.01 (0004)Flatness of gasket surfacemm (in.)Less than 0.05

(.0020)0.1 (.0040)Right silent shaft

Front journal diameter

mm (in.)

41.959-41.975(1.6519-1.6526)

Rear journal diameter

mm (in.)

40.951-40.967(1.6122-1.6129)

Oil clearancemm (in.)

Front journal

0.020-0.061 (.0008-.0024)Rear journal

0.050-0.091 (.0020-.0036)Left silent shaft

Front journal diameter

mm (in.)

18.467- 18.480(.7270-.7276)Rear journal diameter

mm (in.)

40.959-40.975

(1.6126-1.6132)Oil clearancemm (in.)

Front journal

0.020-0.054 (.0008-.0021)Rear journal

0.042-0.083 (.0017-.0033)Piston

O.D.

mm (in.)85.00 (3.3465)

CnlIr;;y (Piston to cylinder)(Non-Turbo) 0.02-0.04 (.0008-.0016)(Turbo)

0.03-0.05 (.0012-.0020)Ring groove width

mm (in.)

No. 11.22-l .24 (.0480-.0488)

No.21.52- 1.54 (.0598-.0606)Oil

3.01-3.03 (.1185-.1193)Service sizemm (in.)0.25

(.OlO), 0.50 (.020),0.75

(.030), 1 .oo i.039)oversize‘iston ring

Side clearancemm (in.)

No.1. No.2End gapmm (in.)

No. 1No. 2

Oil ring side railmm (in.)

Service sizemm (in.)

0.03-0.07 (.0012-.0028)

0.25-0.45 (.0098-.0177)

0.35-0.50 (.0138-.0197)

0.20-0.70 (.0079-.0276)0.25

(.OlO), 0.50 (.020),0.75 (030). 1.00 i.039)oversize0.1

(.004)0.8

(.031)0.8

(.031)1.0

(.040)

Page 328 of 1216

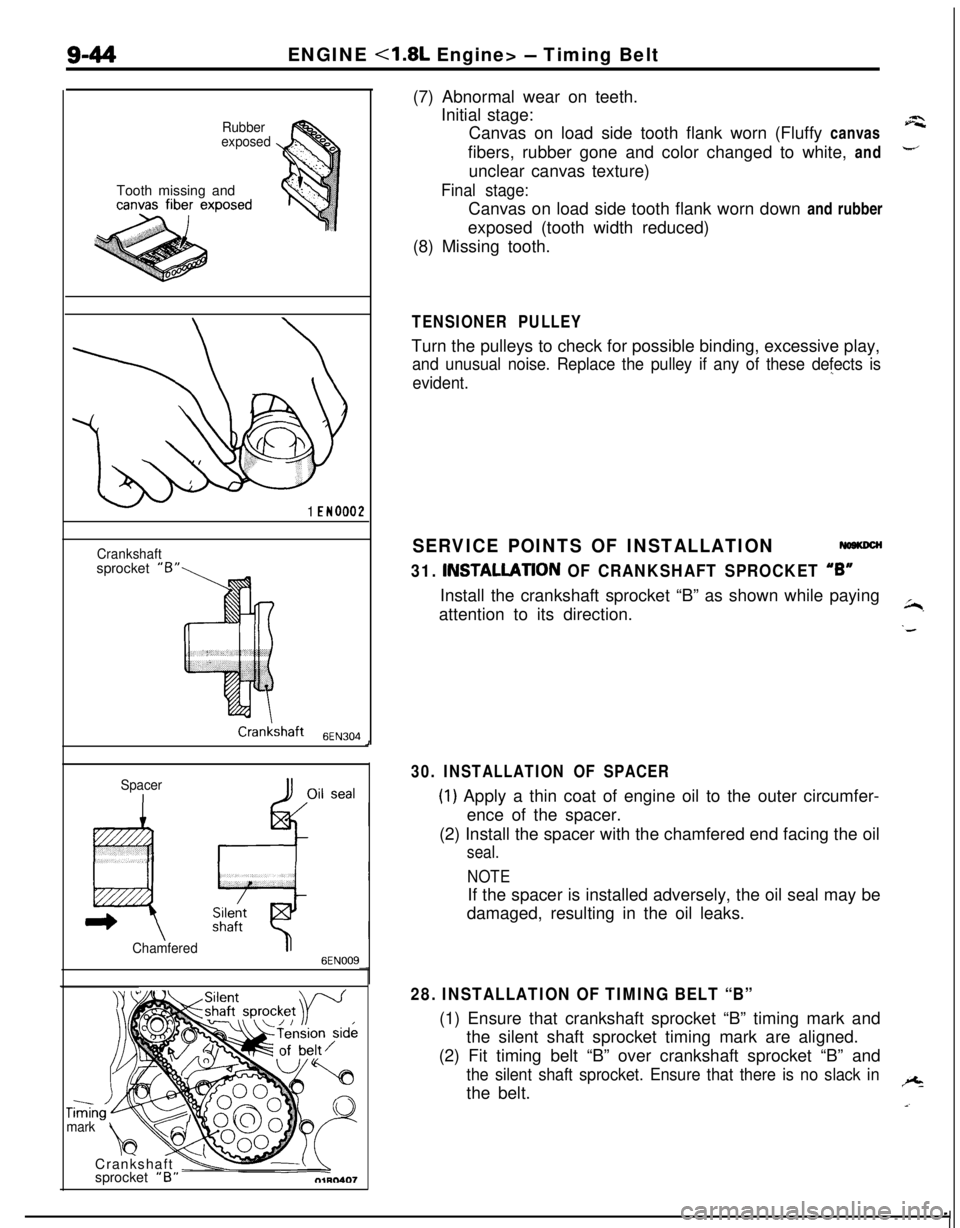

9-44ENGINE <1.8L Engine> - Timing Belt

Rubber

exposedTooth missing and

1 EN0002

Crankshaftsprocket “6

Crankshaft 6EN304

Spacer

Chamfered

6EN009

J

TiGGrnmarkCrankshaft

\vsprocket “B”(7) Abnormal wear on teeth.

Initial stage:

Canvas on load side tooth flank worn (Fluffy canvas

afibers, rubber gone and color changed to white, and

-unclear canvas texture)

Final stage:Canvas on load side tooth flank worn down and rubber

exposed (tooth width reduced)

(8) Missing tooth.

TENSIONER PULLEYTurn the pulleys to check for possible binding, excessive play,

and unusual noise. Replace the pulley if any of these defects is

evident.”

SERVICE POINTS OF INSTALLATION

31. INSTALLATlON OF CRANKSHAFT SPROCKET “6”Install the crankshaft sprocket “B” as shown while paying

attention to its direction.

~,

‘d

30. INSTALLATION OF SPACER

(1) Apply a thin coat of engine oil to the outer circumfer-

ence of the spacer.

(2) Install the spacer with the chamfered end facing the oil

seal.

NOTEIf the spacer is installed adversely, the oil seal may be

damaged, resulting in the oil leaks.

28. INSTALLATION OF TIMING BELT “B”(1) Ensure that crankshaft sprocket “B” timing mark and

the silent shaft sprocket timing mark are aligned.

(2) Fit timing belt “B” over crankshaft sprocket “B” and

the silent shaft sprocket. Ensure that there is no slack inthe belt.+

a.

Page 348 of 1216

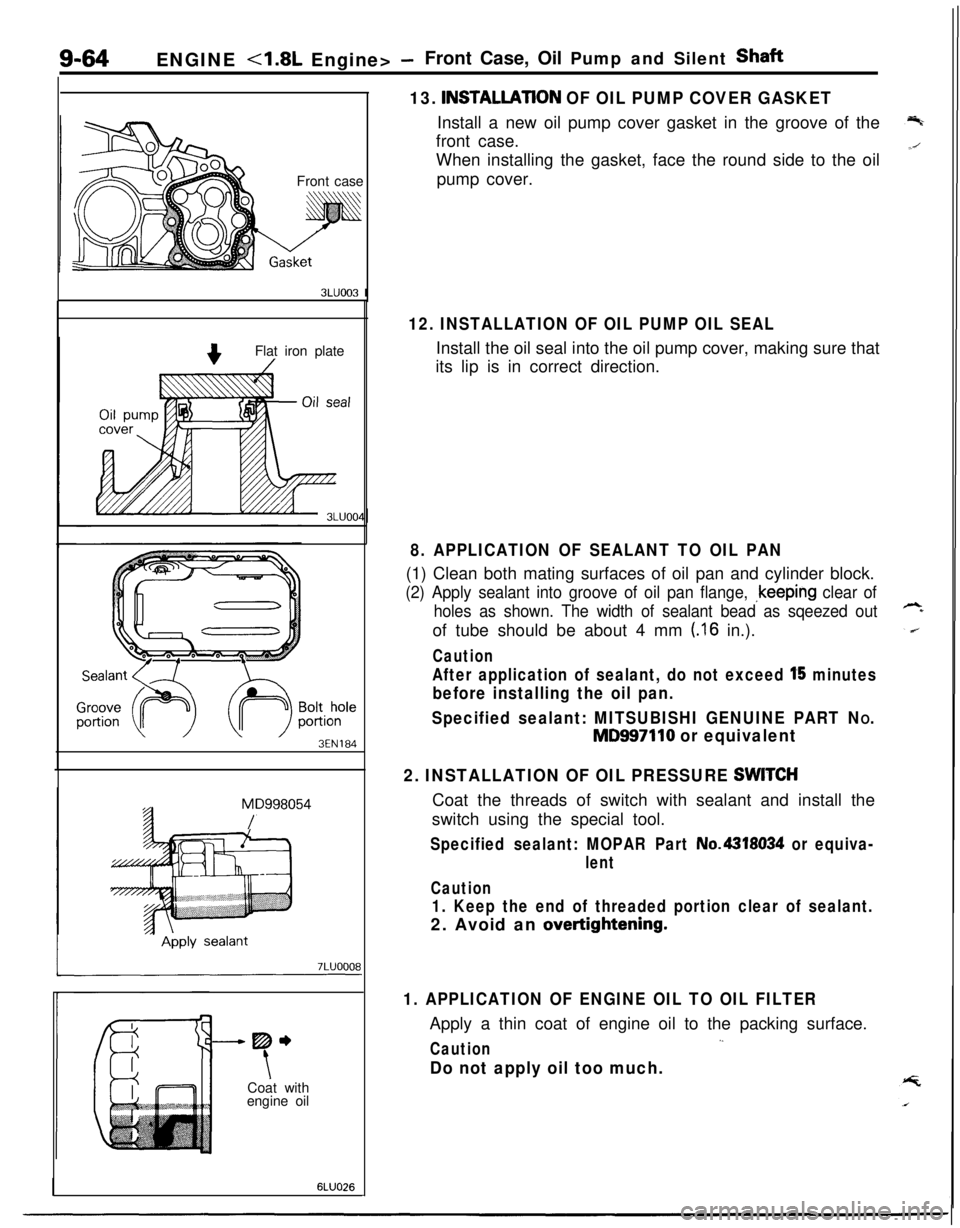

9-64ENGINE 4.8L Engine> -Front Case, Oil Pump and Silent Shaft

13.

INSTALLATlON OF OIL PUMP COVER GASKETInstall a new oil pump cover gasket in the groove of the

front case.

Front caseWhen installing the gasket, face the round side to the oil

pump cover.

3LUOO3 I

Flat iron plate

3EN184

MD998054

/

-----me

tCoat with

engine oil

6LUO26

12. INSTALLATION OF OIL PUMP OIL SEALInstall the oil seal into the oil pump cover, making sure that

its lip is in correct direction.

8. APPLICATION OF SEALANT TO OIL PAN(1) Clean both mating surfaces of oil pan and cylinder block.

(2) Apply sealant into groove of oil pan flange, ~keeping clear of

holes as shown. The width of sealant bead as sqeezed outof tube should be about 4 mm

(.I6 in.).

Caution

After application of sealant, do not exceed l’5 minutes

before installing the oil pan.

Specified sealant: MITSUBISHI GENUINE PART N

O.

MD997110 or equivalent

2. INSTALLATION OF OIL PRESSURE

SWlTCHCoat the threads of switch with sealant and install the

switch using the special tool.

Specified sealant: MOPAR Part No.4318034 or equiva-

lent

Caution

1. Keep the end of threaded portion clear of sealant.2. Avoid an

overtightening.

1. APPLICATION OF ENGINE OIL TO OIL FILTERApply a thin coat of engine oil to the packing surface.

,.Caution

Do not apply oil too much.

Page 354 of 1216

ENGINE <1.8L Engine> -Crankshaft, Flywheel and Drive Plate

3EN055

6EN043

1 EN067

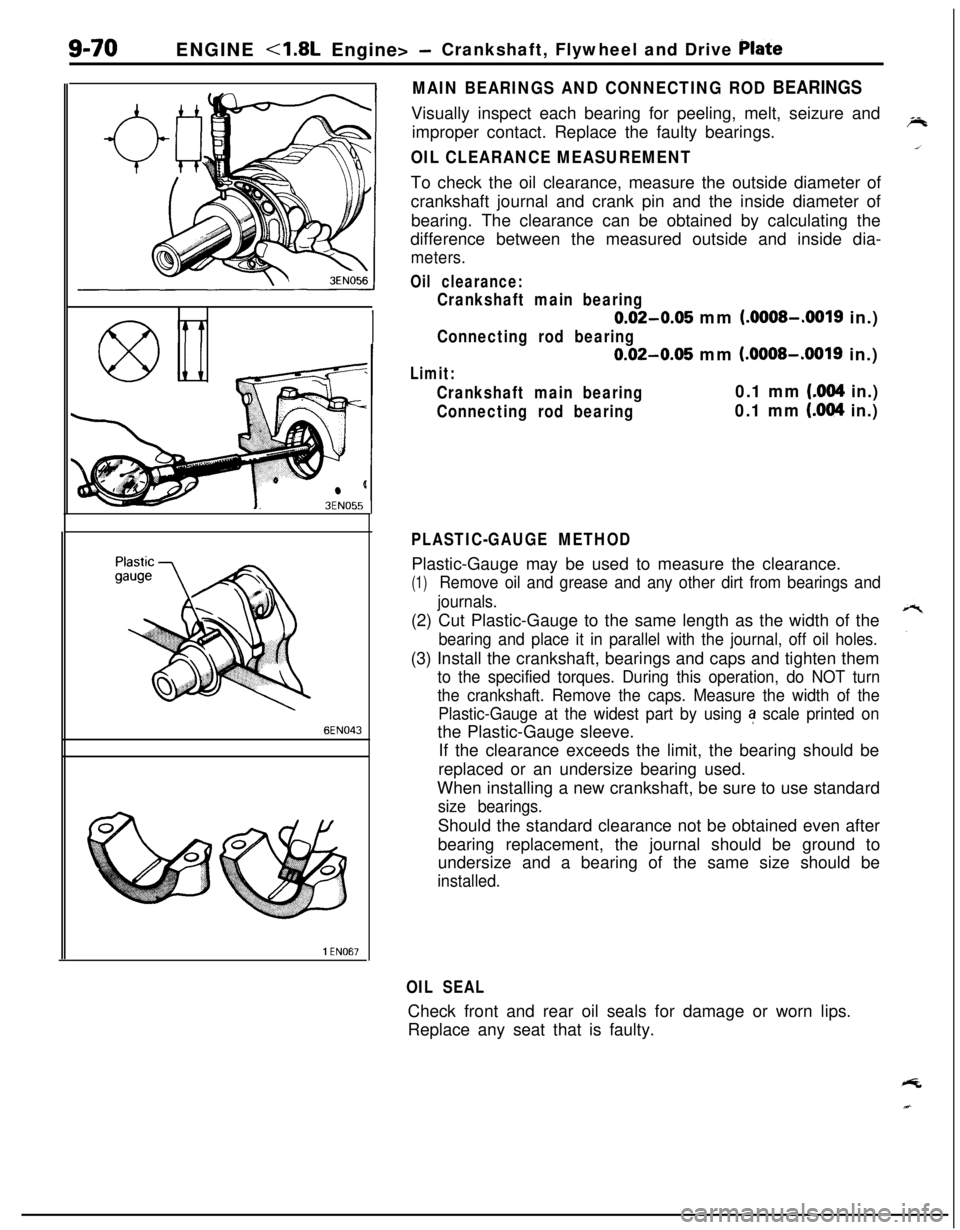

MAIN BEARINGS AND CONNECTING ROD BEARINGSVisually inspect each bearing for peeling, melt, seizure and

improper contact. Replace the faulty bearings.

OIL CLEARANCE MEASUREMENTTo check the oil clearance, measure the outside diameter of

crankshaft journal and crank pin and the inside diameter of

bearing. The clearance can be obtained by calculating the

difference between the measured outside and inside dia-

meters.

Oil clearance:

Crankshaft main bearing

0.02-0.05 mm (.OOOS-.0019 in.)

Connecting rod bearing

0.02-0.05 mm (.OOOS-.0019 in.)

Limit:

Crankshaft main bearing0.1 mm (.004 in.)

Connecting rod bearing0.1 mm (.004 in.)

PLASTIC-GAUGE METHODPlastic-Gauge may be used to measure the clearance.

(1)Remove oil and grease and any other dirt from bearings and

journals.(2) Cut Plastic-Gauge to the same length as the width of the

bearing and place it in parallel with the journal, off oil holes.(3) Install the crankshaft, bearings and caps and tighten them

to the specified torques. During this operation, do NOT turn

the crankshaft. Remove the caps. Measure the width of the

Plastic-Gauge at the widest part by using

a scale printed onthe Plastic-Gauge sleeve.

If the clearance exceeds the limit, the bearing should be

replaced or an undersize bearing used.

When installing a new crankshaft, be sure to use standard

size bearings.Should the standard clearance not be obtained even after

bearing replacement, the journal should be ground to

undersize and a bearing of the same size should be

installed.

OIL SEALCheck front and rear oil seals for damage or worn lips.

Replace any seat that is faulty.

Page 383 of 1216

ENGINE <2.0L DOHC Engine> - Timing Belt9-99

-

\

Q+i!il

008ooo

rackCrack

7EN207

SeparationRounded belt side

Abnormal wear

(fluffy canvas fiber)

7EN208

Rubber

exposedTooth missing and

canvas fiber

exoosed

7EN2096EN0159

-

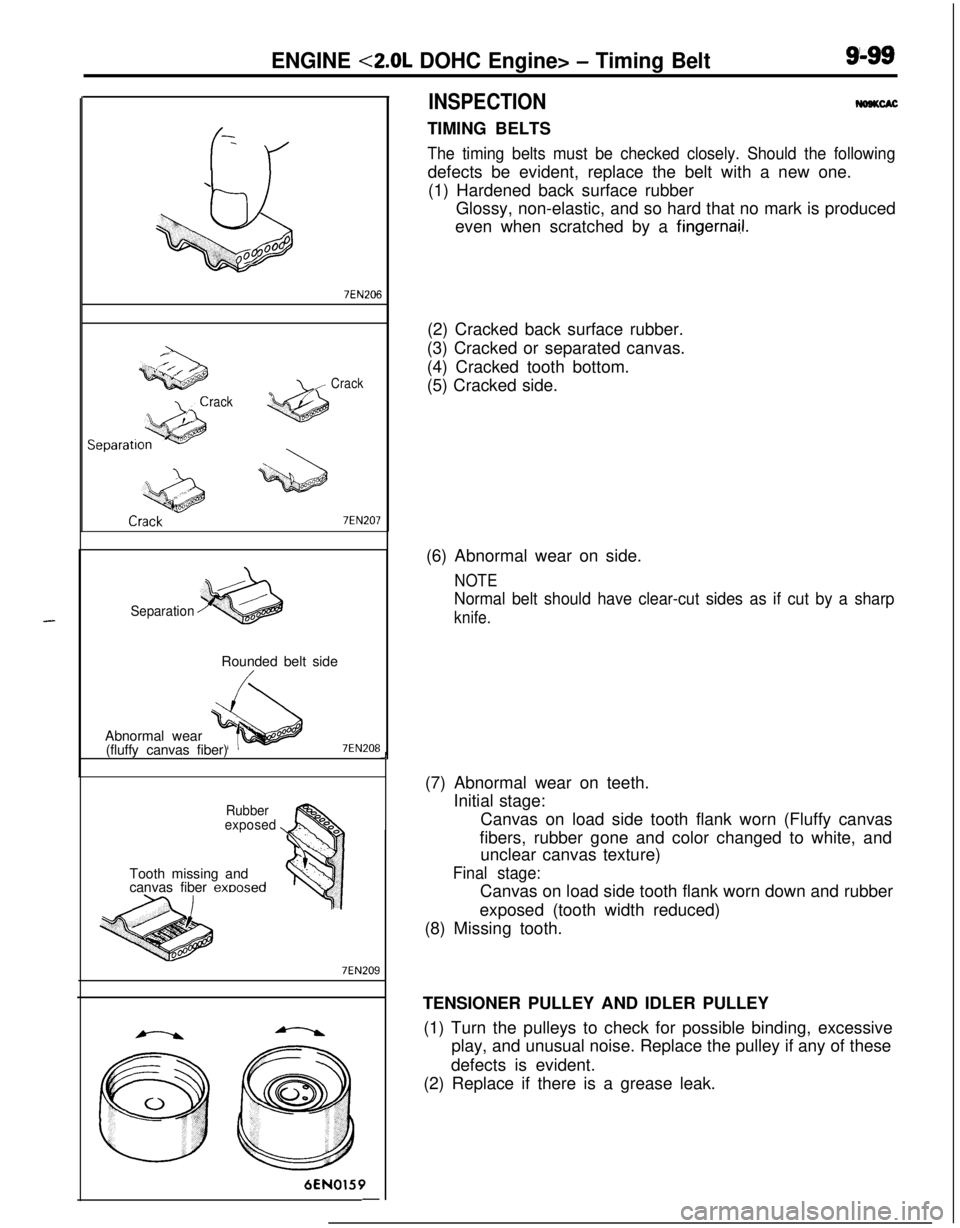

INSPECTIONWSKCACTIMING BELTS

The timing belts must be checked closely. Should the followingdefects be evident, replace the belt with a new one.

(1) Hardened back surface rubber

Glossy, non-elastic, and so hard that no mark is produced

even when scratched by a

fingernai.1.(2) Cracked back surface rubber.

(3) Cracked or separated canvas.

(4) Cracked tooth bottom.

(5) Cracked side.J(6) Abnormal wear on side.

NOTE

Normal belt should have clear-cut sides as if cut by a sharp

knife.(7) Abnormal wear on teeth.

Initial stage:

Canvas on load side tooth flank worn (Fluffy canvas

fibers, rubber gone and color changed to white, and

unclear canvas texture)

Final stage:Canvas on load side tooth flank worn down and rubber

exposed (tooth width reduced)

(8) Missing tooth.

TENSIONER PULLEY AND IDLER PULLEY

(1) Turn the pulleys to check for possible binding, excessive

play, and unusual noise. Replace the pulley if any of these

defects is evident.

(2) Replace if there is a grease leak.