Brake hose MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 207 of 1216

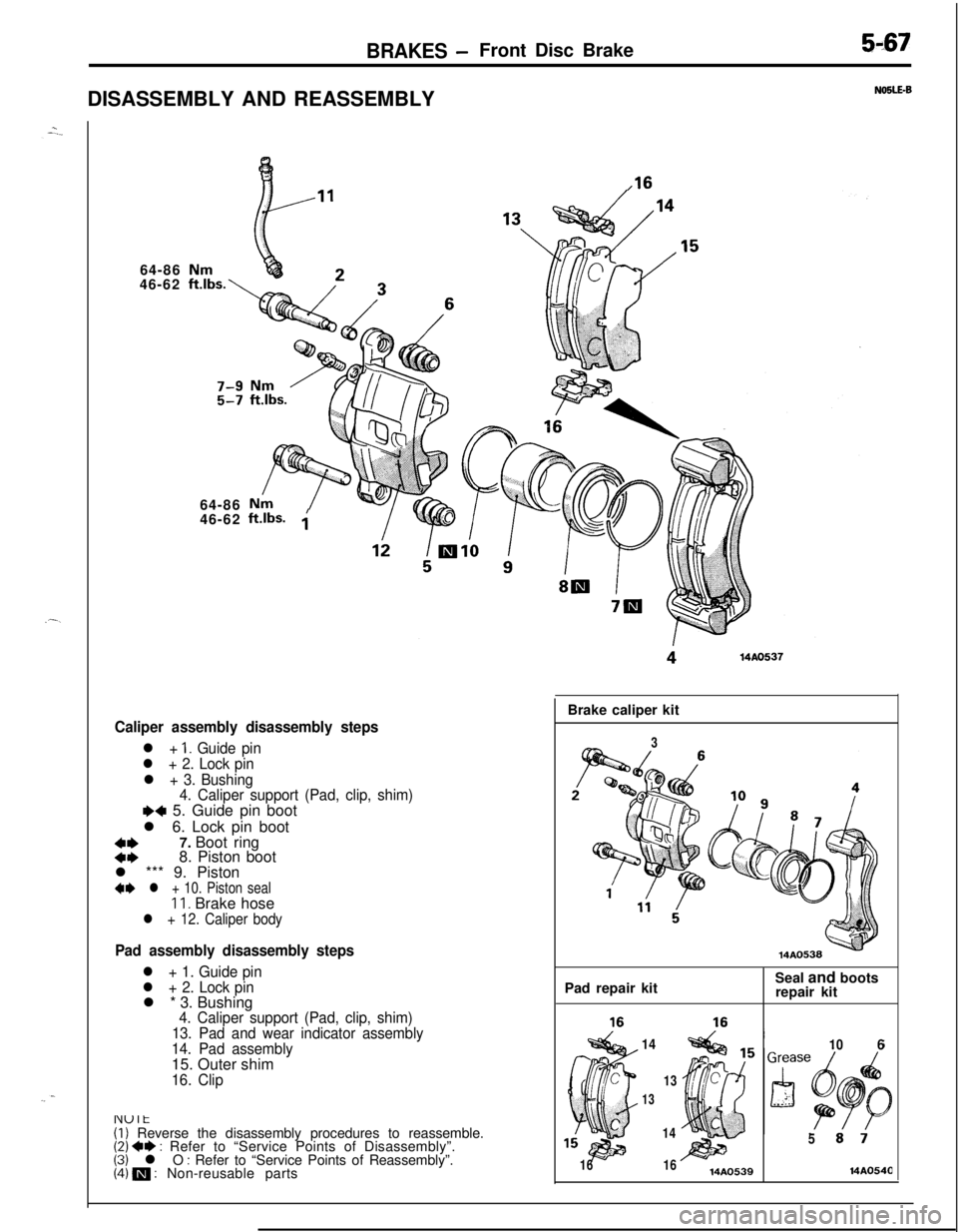

BRAKES -Front Disc Brake5-67DISASSEMBLY AND REASSEMBLY

64-86

46-62

64-86

46-62

ft.lbs. ;

Caliper assembly disassembly steps

l + 1. Guide pin

l + 2. Lock pin

l + 3. Bushing

4. Caliper support (Pad, clip, shim)

e+ 5. Guide pin boot

l 6. Lock pin boot

::7. Boot ring

8. Piston boot

l *** 9. Piston

4I) l + 10. Piston sealIl. Brake hosel + 12. Caliper body

Pad assembly disassembly steps

l + 1. Guide pin

l + 2. Lock pinl * 3. Bushing

4. Caliper support (Pad, clip, shim)

13. Pad and wear indicator assembly

14. Pad assembly15. Outer shim

16. Clip

NOSLE-B

.16

(1) Reverse the disassembly procedures to reassemble.(2) +e : Refer to “Service Points of Disassembly”.(3) l O : Refer to “Service Points of Reassembly”.(4) m : Non-reusable partsBrake caliper kit

3Pad repair kitSeal and boots

repair kit

14

106

13

13

1614

1614AO539

514A054(3

Page 208 of 1216

5-68BRAKES - Front Disc Brake

14KO5414GOO54

14K057

14UOO72

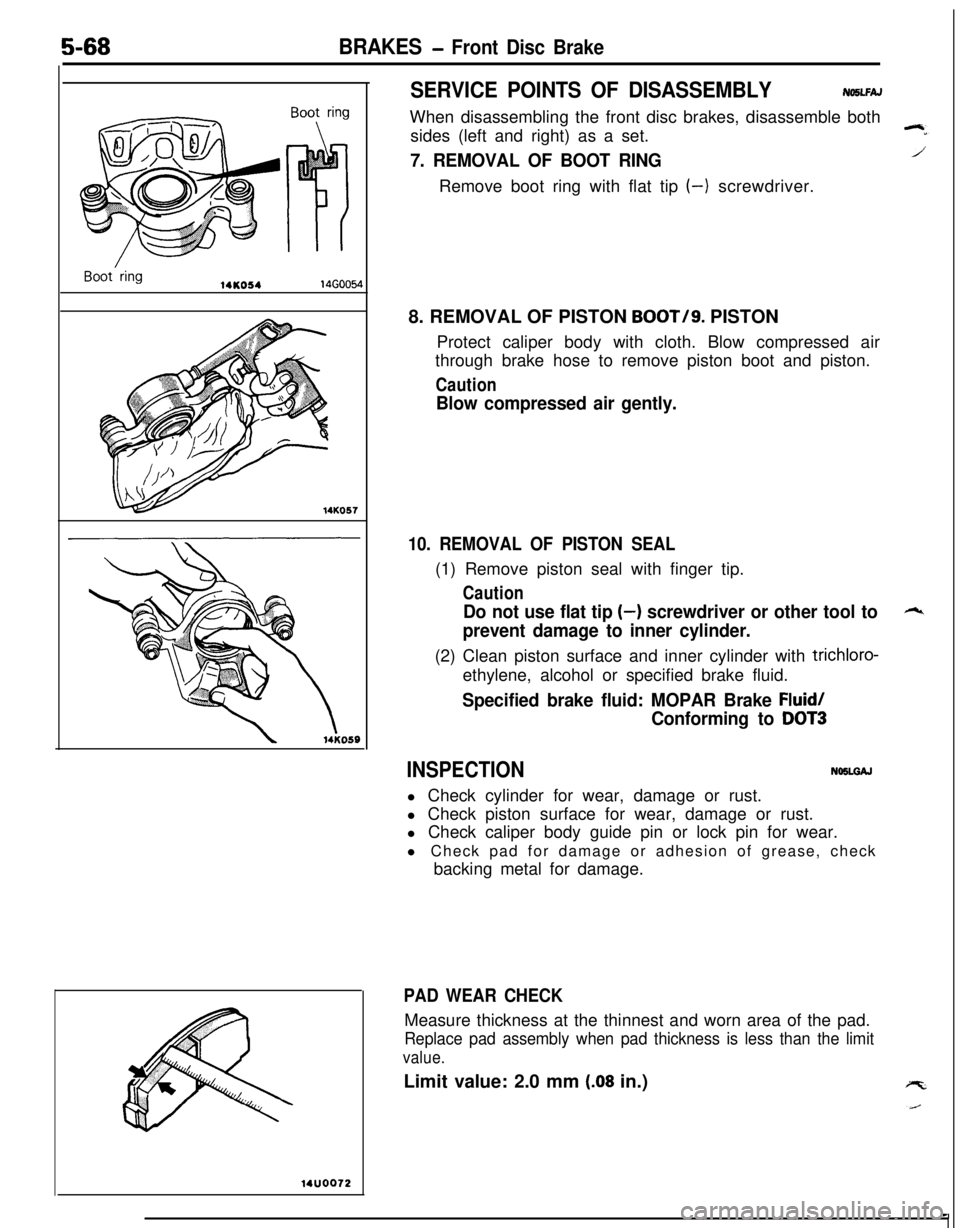

SERVICE POINTS OF DISASSEMBLYNO5LFAJWhen disassembling the front disc brakes, disassemble both

sides (left and right) as a set.

7. REMOVAL OF BOOT RINGRemove boot ring with flat tip

(-) screwdriver.

8. REMOVAL OF PISTON

BOOT/g. PISTON

Protect caliper body with cloth. Blow compressed air

through brake hose to remove piston boot and piston.

Caution

Blow compressed air gently.

10. REMOVAL OF PISTON SEAL(1) Remove piston seal with finger tip.

Caution

Do not use flat tip (-) screwdriver or other tool to

prevent damage to inner cylinder.(2) Clean piston surface and inner cylinder with

trichloro-ethylene, alcohol or specified brake fluid.

Specified brake fluid: MOPAR Brake Fluid/

Conforming to DOT3

INSPECTIONNOSLGAJl Check cylinder for wear, damage or rust.

l Check piston surface for wear, damage or rust.

l Check caliper body guide pin or lock pin for wear.

l Check pad for damage or adhesion of grease, check

backing metal for damage.

PAD WEAR CHECKMeasure thickness at the thinnest and worn area of the pad.

Replace pad assembly when pad thickness is less than the limit

value.Limit value: 2.0 mm

(.08 in.)

Page 210 of 1216

5-70

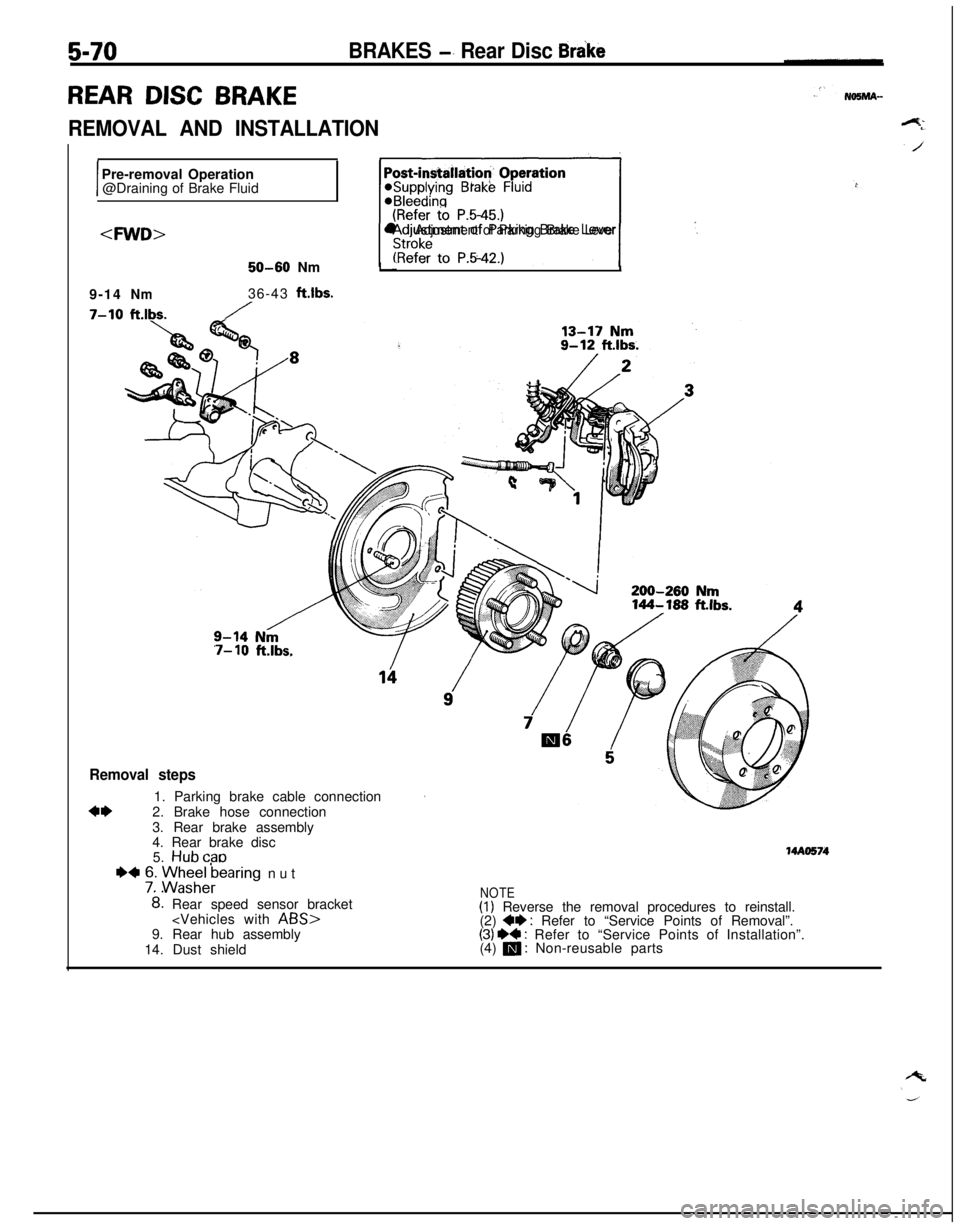

REAR DISC BRAKE

BRAKES -’ Rear Disc Brake

REMOVAL AND INSTALLATION

IPre-removal Operation

@Draining of Brake Fluid

~1 ,.

l Adjustment of Parking Brake Lever

1.150-60Nm

9-14

Nm36-43ft.lbs.

7-10ft.lbs./

7- 10ft.lbs.

Removal steps

4*1. Parking brake cable connection

2. Brake hose connection

3. Rear brake assembly

4. Rear brake disc

5.

Hubcab

+4 76. ME;AFearing nut

8: Rear speed sensor bracket

14. Dust shield

NOTE(1) Reverse the removal procedures to reinstall.

(2) +* : Refer to “Service Points of Removal”.(3) ** : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

MAO574

Page 211 of 1216

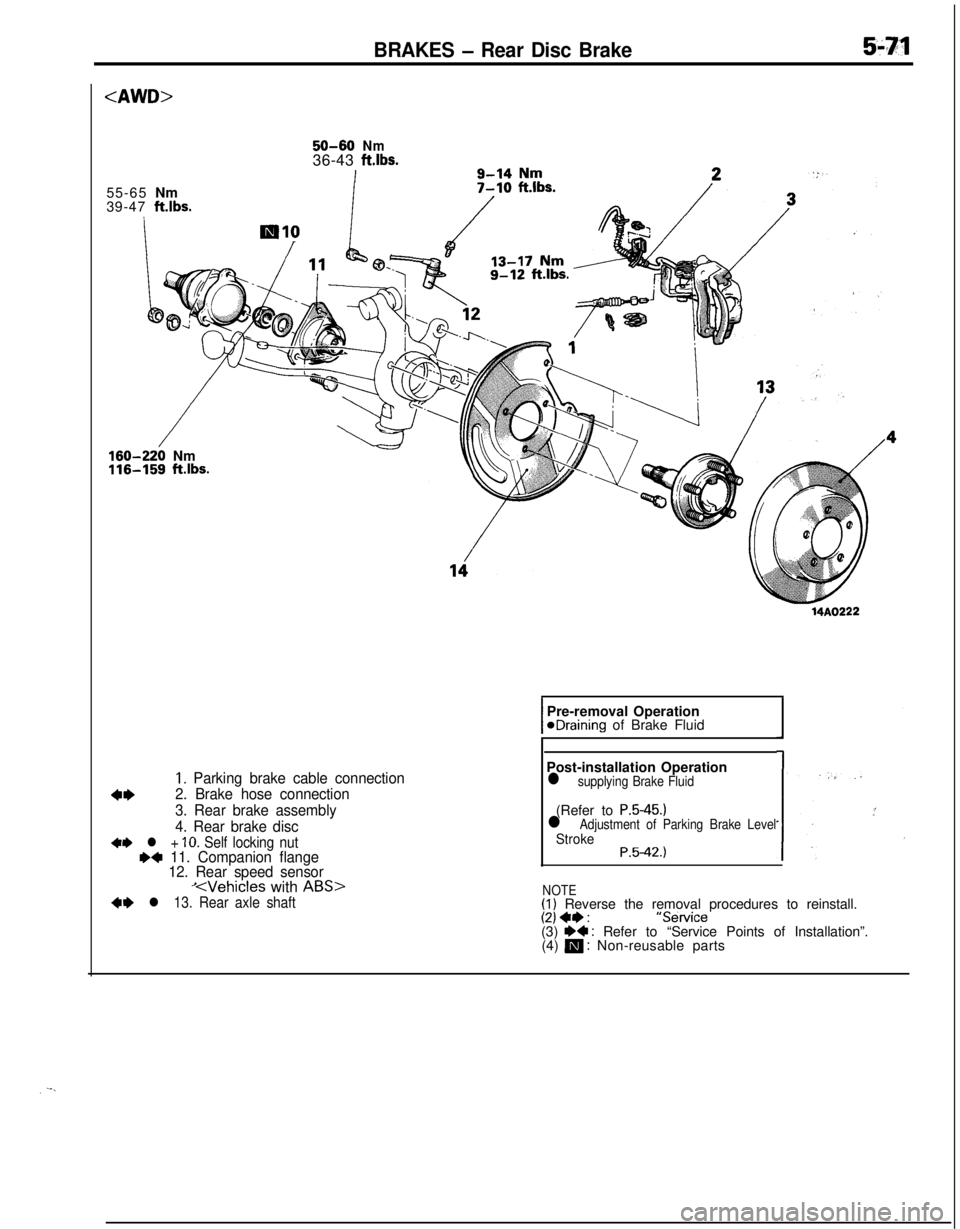

BRAKES - Rear Disc Brake59q!l

50-60Nm36-43ft.lbs.9-14Nm55-65Nm

39-47

klbs.

/160-220 Nm116-159 ft.lbs.14A0222

1. Parking brake cable connection

4*2. Brake hose connection

3. Rear brake assembly

4. Rear brake disc

+e l + IO. Self locking nutr)+ 11. Companion flange

12. Rear speed sensor

KVehicles with ABS>+e l 13. Rear axle shaftPre-removal Operation

@Draining of Brake Fluid

Post-installation Operation

l supplying Brake Fluid(Refer to

P.5-45.)l Adjustment of Parking Brake LevelStrokeP.5-42.)

NOTE

(1) Reverse the removal procedures to reinstall.(2) +e:“Service

(3) I)+ : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

Page 212 of 1216

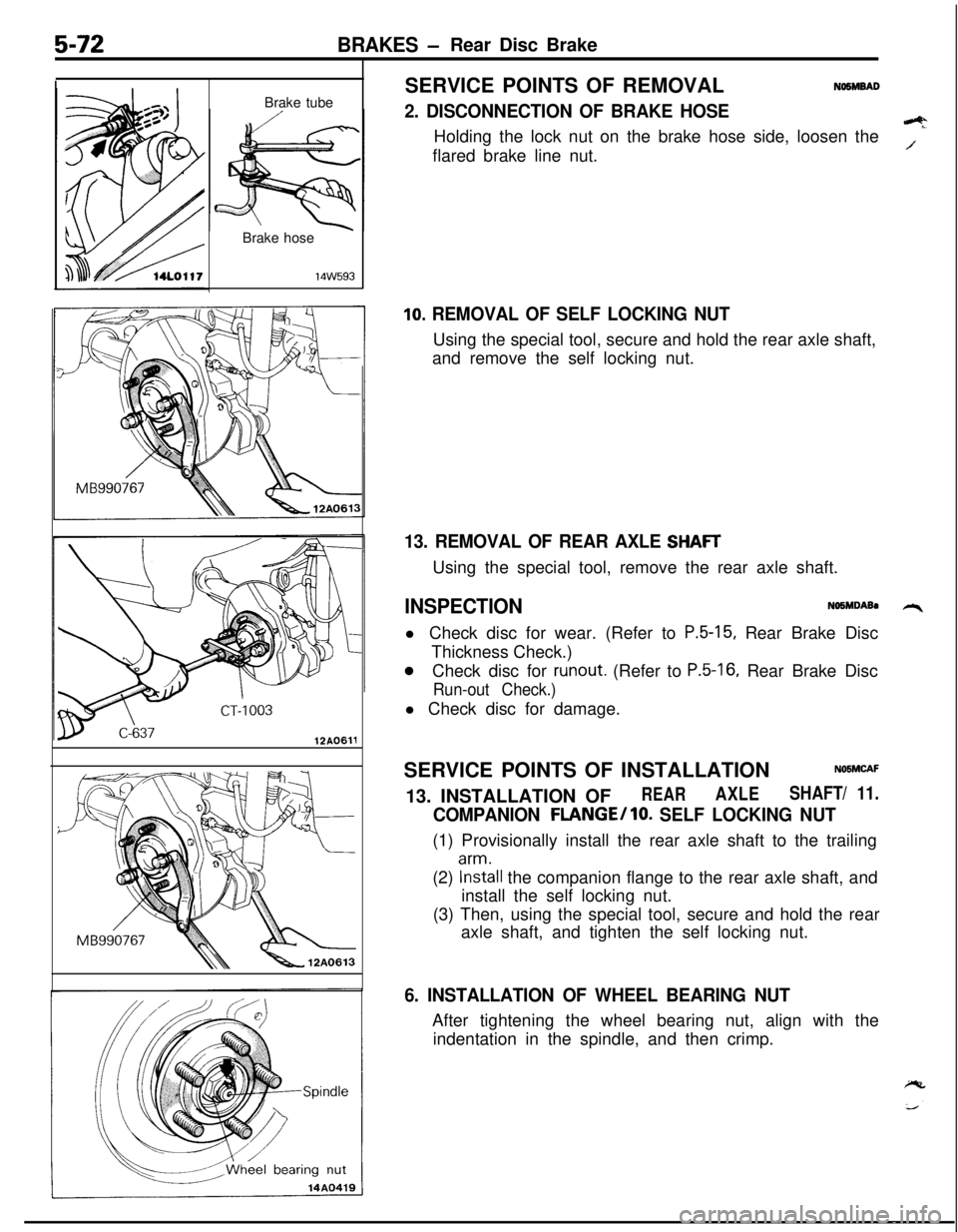

5-72BRAKES -Rear Disc Brake

Brake tube

Brake hose

14w593

12A0611SERVICE POINTS OF REMOVALNO5MBAD

2. DISCONNECTION OF BRAKE HOSEHolding the lock nut on the brake hose side, loosen theeflared brake line nut./

10. REMOVAL OF SELF LOCKING NUTUsing the special tool, secure and hold the rear axle shaft,

and remove the self locking nut.

13. REMOVAL OF REAR AXLE SHAFTUsing the special tool, remove the rear axle shaft.

INSPECTIONNO5MDABa rq.l Check disc for wear. (Refer to

P.5-15, Rear Brake Disc

Thickness Check.)

0Check disc for runout. (Refer to P.5-16, Rear Brake Disc

Run-out Check.)l Check disc for damage.

SERVICE POINTS OF INSTALLATION

NOSMCAF13. INSTALLATION OF

REARAXLESHAFT/ 11.

COMPANION FLANGE/IO. SELF LOCKING NUT(1) Provisionally install the rear axle shaft to the trailing

(2) ;‘,‘%I, the companion flange to the rear axle shaft, and

install the self locking nut.

(3) Then, using the special tool, secure and hold the rear

axle shaft, and tighten the self locking nut.

6. INSTALLATION OF WHEEL BEARING NUTAfter tightening the wheel bearing nut, align with the

indentation in the spindle, and then crimp.

Page 213 of 1216

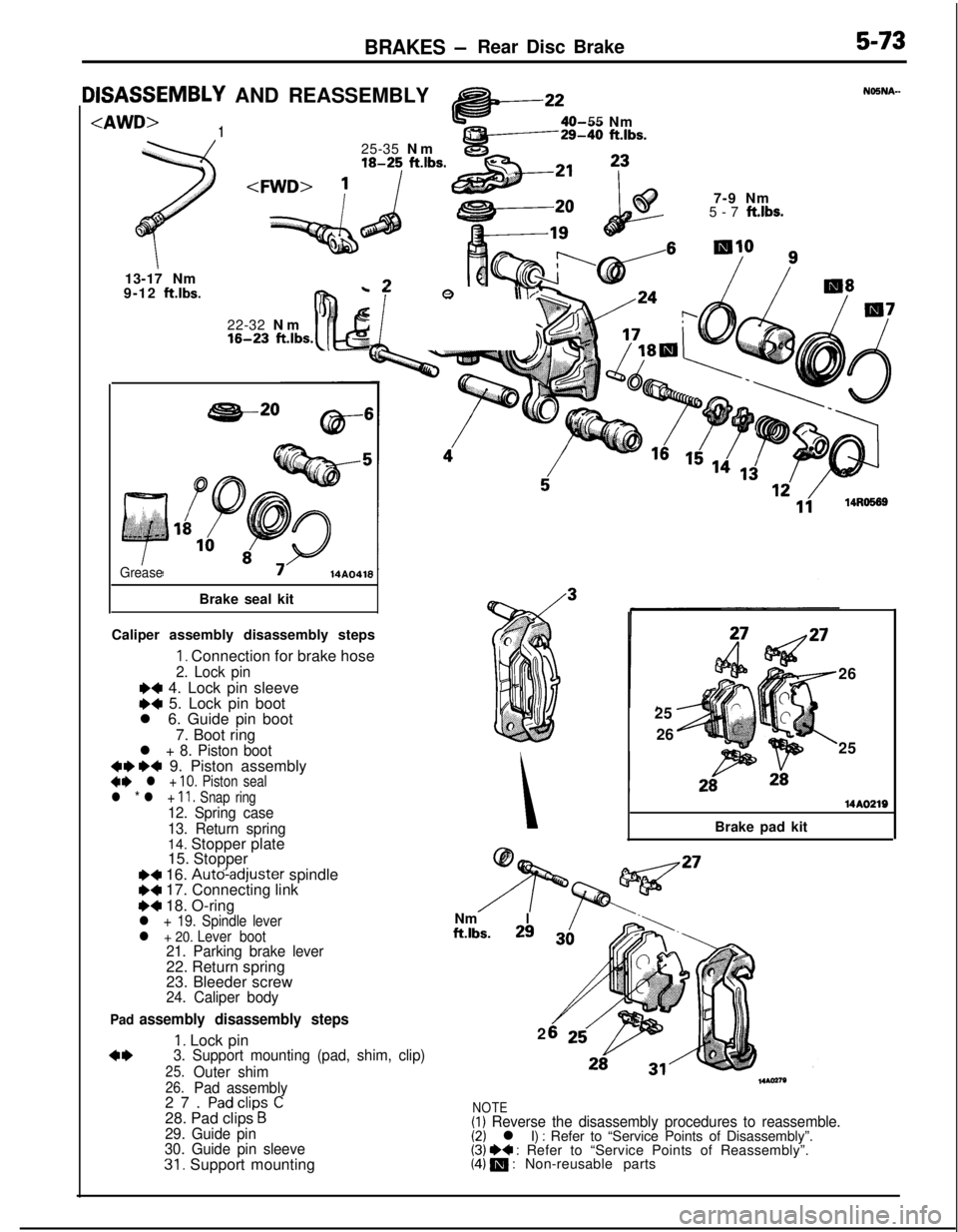

BRAKES -Rear Disc Brake5-73

IISASSEMBLY AND REASSEMBLY

125-35 Nm

18-25 ft.lbs.

;

I13-17 Nm

9-12

ftlbs.

c*:O55 Nm29-40 ft.lbs.22-32 Nm

16-23 fi.J,,s.b- Q \\T;17-9 Nm

5-7

ft.lbs.

GreaseBrake seal kit

Caliper assembly disassembly steps

1. Connection for brake hose

2. Lock pin

N 4. Lock pin sleeveM 5. Lock pin boot

l 6. Guide pin boot

7. Boot ring

l + 8. Piston boot+e W+ 9. Piston assembly** l + 10. Piston seal

l * l + Il. Snap ring12. Spring case

13. Return spring14. Stopper plate

15. Stopper

~~ 16. Auto-adjuster spindleI)+ 17. Connecting link

I)+ 18. O-ringl + 19. Spindle leverl + 20. Lever boot21. Parking brake lever22. Return spring

23. Bleeder screw

24. Caliper body

Pad

assembly disassembly steps

1. Lock pinNm

Iftlbs.293.2

*I)3. Support mounting (pad, shim, clip)

25.Outer shim26.Pad assembly27. Padclips C28. Pad clips BNOTE

29. Guide pin

30. Guide pin sleeve

31. Support mounting

(I) Reverse the disassembly procedures to reassemble.(2) l I) : Refer to “Service Points of Disassembly”.(3) H : Refer to “Service Points of Reassembly”.(4) 19 : Non-reusable parts26

25

26

25

Brake pad kit

14AO219

Page 236 of 1216

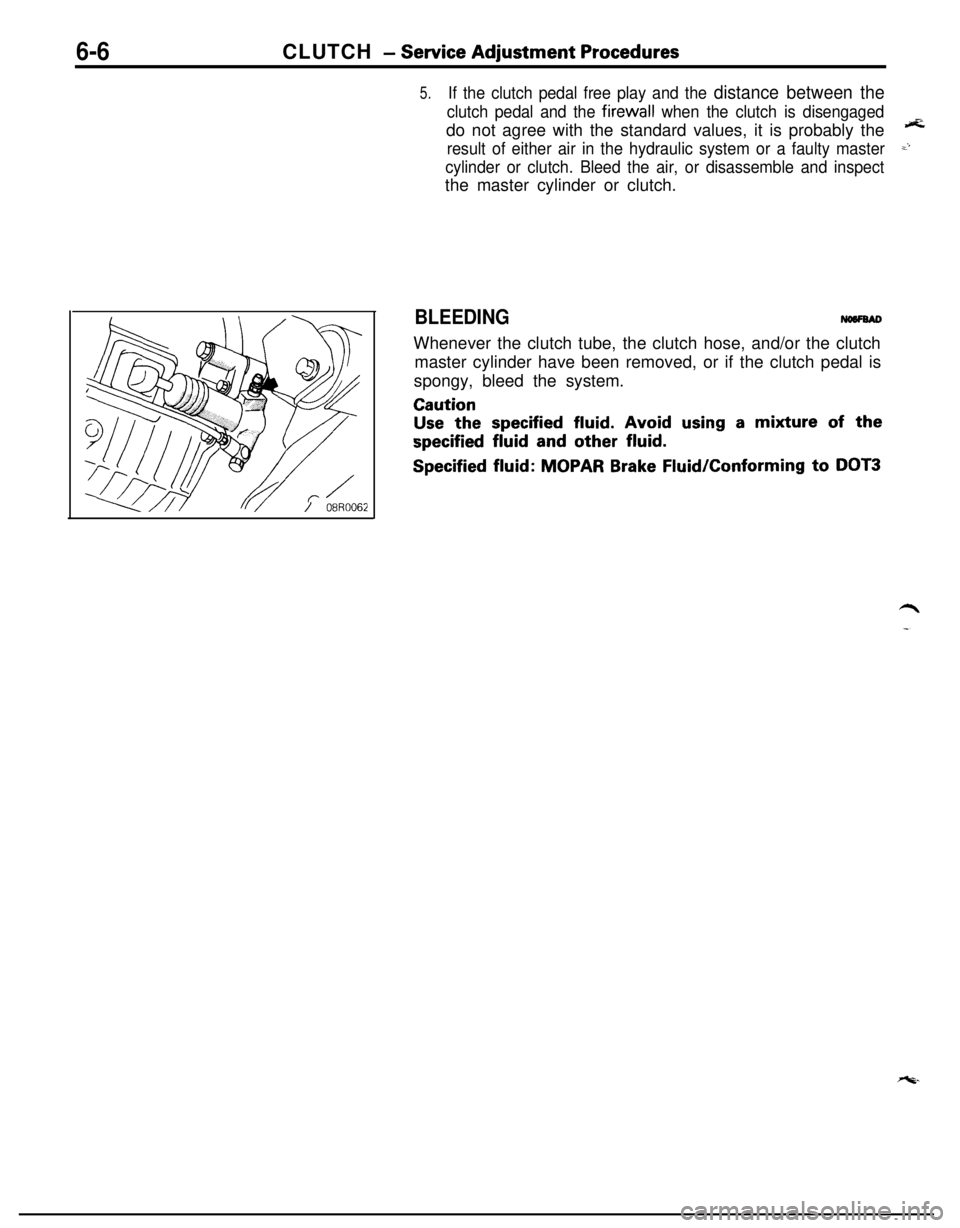

6-6CLUTCH - Service Adjustment Procedures

5.If the clutch pedal free play and the distance between the

clutch pedal and the firewall when the clutch is disengageddo not agree with the standard values, it is probably the

A

result of either air in the hydraulic system or a faulty master2

cylinder or clutch. Bleed the air, or disassemble and inspectthe master cylinder or clutch.

BLEEDINGWhenever the clutch tube, the clutch hose, and/or the clutch

master cylinder have been removed, or if the clutch pedal is

spongy, bleed the system.

Caution

Use the specified fluid. Avoid using a mixture of the

specified fluid and other fluid.

Specified fluid: MOPAR Brake Fluid/Conforming to DOT3

Page 315 of 1216

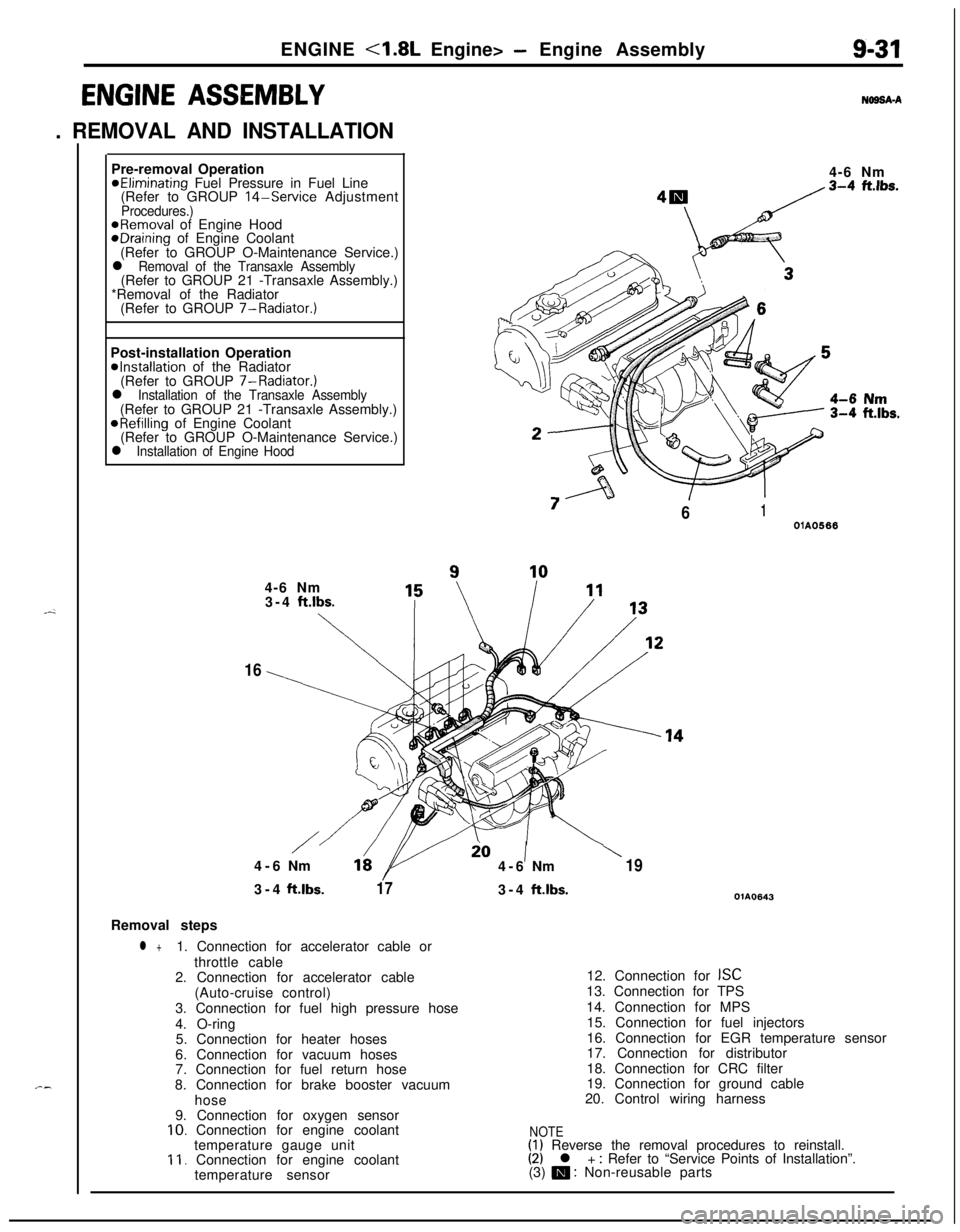

ENGINE <1.8L Engine> - Engine Assembly9-31

ENGINE ASSEMBLY

. REMOVAL AND INSTALLATION

N69SA-APre-removal Operation

@Eliminating Fuel Pressure in Fuel Line

(Refer to GROUP 14-Service AdjustmentProcedures.)@Removal of Engine HoodeDraining of Engine Coolant

(Refer to GROUP O-Maintenance Service.)

l Removal of the Transaxle Assembly(Refer to GROUP 21 -Transaxle Assembly.)

*Removal of the Radiator

(Refer to GROUP 7-Radiator.)

Post-installation Operation

@Installation of the Radiator

(Refer to GROUP 7-Radiator.)

l Installation of the Transaxle Assembly(Refer to GROUP 21 -Transaxle Assembly.)

@Refilling of Engine Coolant

(Refer to GROUP O-Maintenance Service.)

l Installation of Engine Hood4-6 Nm

“7

/61OlA05664-6 Nm

3-4

ft.lbs.

\

16

/io1\4-6Nm164-6Nm193-4ft.lbs.

173-4ft.lbs.OlA0643Removal steps

l +1. Connection for accelerator cable or

throttle cable

2. Connection for accelerator cable

(Auto-cruise control)

3. Connection for fuel high pressure hose

4. O-ring

5. Connection for heater hoses

6. Connection for vacuum hoses

7. Connection for fuel return hose

8. Connection for brake booster vacuum

hose

9. Connection for oxygen sensor

10. Connection for engine coolant

temperature gauge unit

11. Connection for engine coolant

temperature sensor12. Connection for

ISC13. Connection for TPS

14. Connection for MPS

15. Connection for fuel injectors

16. Connection for EGR temperature sensor

17. Connection for distributor

18. Connection for CRC filter

19. Connection for ground cable

20. Control wiring harness

NOTE(1) Reverse the removal procedures to reinstall.(2) l + : Refer to “Service Points of Installation”.

(3) m : Non-reusable parts

Page 320 of 1216

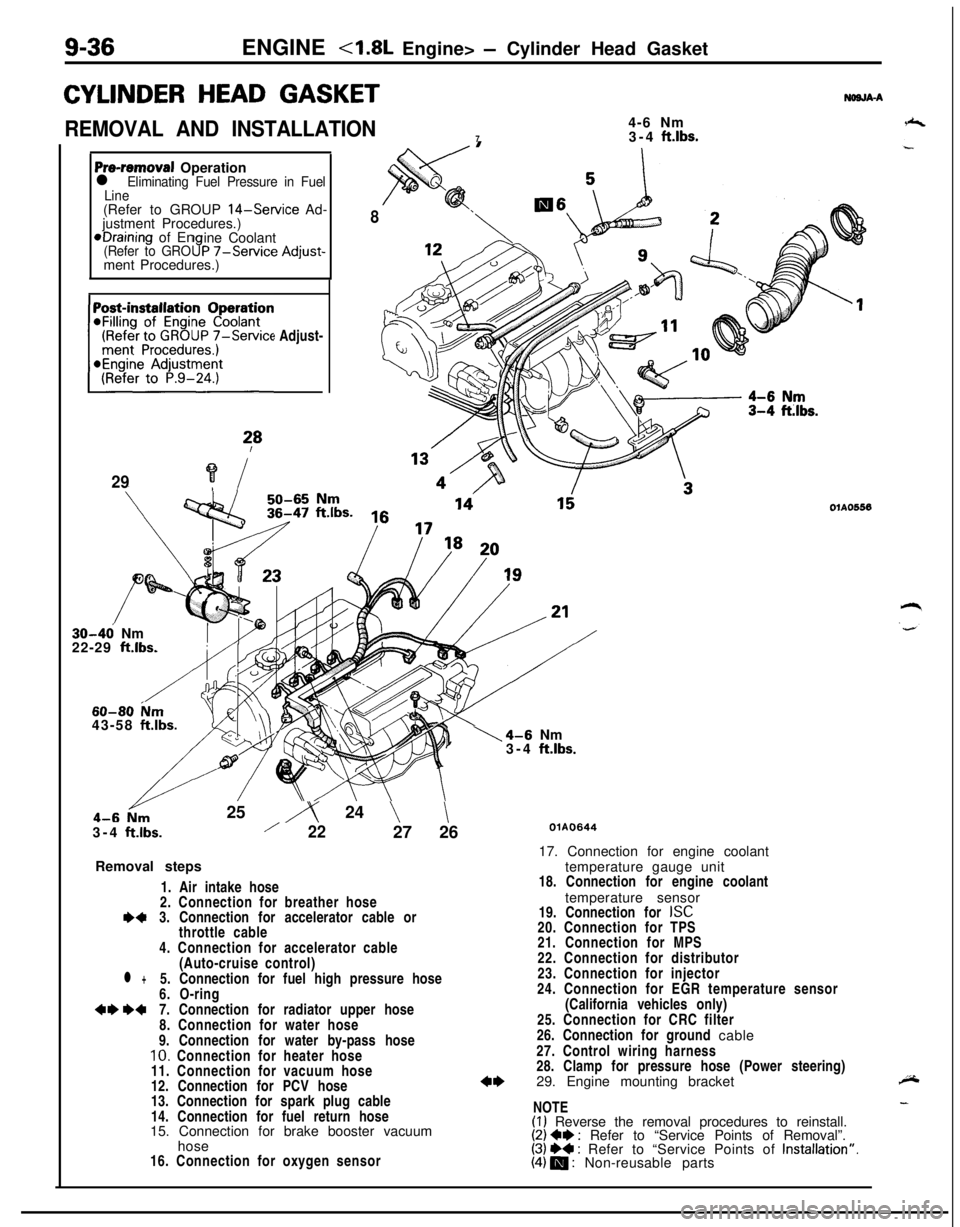

9-36ENGINE

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION4-6 Nm

73-4 ft.lbs.

NWJA-A

Pre-removal Operationl Eliminating Fuel Pressure in Fuel

Line(Refer to GROUP

14-Service Ad-

justment Procedures.)*Draining of En

ine Coolant

(Refer to GRO9P -/-Service Adjust-ment Procedures.)

(Refer to GROUP

7-Service Adjust-~~~~~~~n

?*

29?i

8

30-46 Nm

22-29 ft.lbs.

60-80 ium43-58 ftlbs.25

iy 24 \\3-4

ftlbs./2227 26

Removal steps

1. Air intake hose

2. Connection for breather hose

I)43. Connection for accelerator cable or

throttle cable

4. Connection for accelerator cable

(Auto-cruise control)

l +5. Connection for fuel high pressure hose

6. O-ring

+e W7. Connection for radiator upper hose

8. Connection for water hose

9. Connection for water by-pass hose

10. Connection for heater hose

11. Connection for vacuum hose

12. Connection for PCV hose

13. Connection for spark plug cable

14. Connection for fuel return hose

15. Connection for brake booster vacuum

hose

16. Connection for oxygen sensor

1\4-6 Nm

3-4 ftlbs.

OlAO556

QlAO64417. Connection for engine coolant

temperature gauge unit

18. Connection for engine coolant

temperature sensor

19. Connection for

ISC20. Connection for TPS

21. Connection for MPS

22. Connection for distributor

23. Connection for injector

24. Connection for EGR temperature sensor

(California vehicles only)

25. Connection for CRC filter

26. Connection for ground cable

27. Control wiring harness

28. Clamp for pressure hose (Power steering)

29. Engine mounting bracket

NOTE

(I) Reverse the removal procedures to reinstall.(2) Ce : Refer to “Service Points of Removal”.(3) ++ : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

Page 365 of 1216

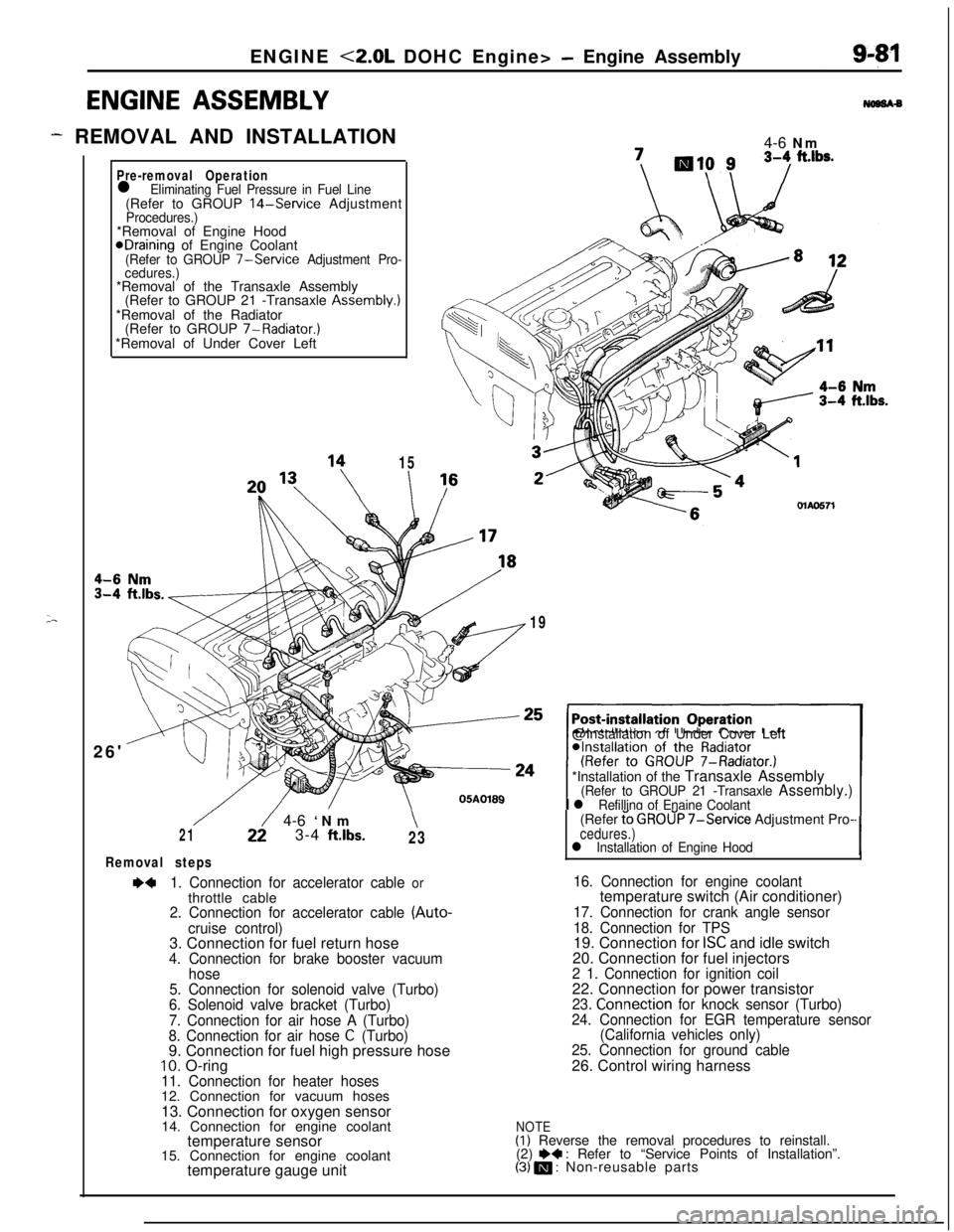

ENGINE <2.0L DOHC Engine> - Engine Assembly

ENGINE ASSEMBLY

- REMOVAL AND INSTALLATION

;-

Pre-removal Operationl Eliminating Fuel Pressure in Fuel Line(Refer to GROUP 14-Service AdjustmentProcedures.)*Removal of Engine Hood

@Draining of Engine Coolant(Refer to GROUP 7-Service Adjustment Pro-

cedures.)*Removal of the Transaxle Assembly

(Refer to GROUP 21 -Transaxle Assembly.)

*Removal of the Radiator

(Refer to GROUP 7-Radiator.)

*Removal of Under Cover Left

26'

15

I4-6 Nm\I /MAO571

19@Installation of Under Cover Left

*Installation of the Transaxle Assembly

(Refer to GROUP 21 -Transaxle Assembly.)

I l Refilling of Enaine Coolant

/22/ 4-6 ‘Nm\213-4 ftlbs.23

Removal steps

~~1. Connection for accelerator cable orthrottle cable

2. Connection for accelerator cable (Auto-

cruise control)3. Connection for fuel return hose

4. Connection for brake booster vacuum

hose

5. Connection for solenoid valve (Turbo)

6. Solenoid valve bracket (Turbo)

7. Connection for air hose A (Turbo)

8. Connection for air hose

C (Turbo)9. Connection for fuel high pressure hose

10. O-ring11. Connection for heater hoses12. Connection for vacuum hoses

13. Connection for oxygen sensor

14. Connection for engine coolant

temperature sensor

15. Connection for engine coolant

temperature gauge unit(Refer

t’o GROUP 7-Service Adjustment Pro-cedures.)l Installation of Engine Hood‘I

16. Connection for engine coolanttemperature switch (Air conditioner)

17. Connection for crank angle sensor

18. Connection for TPS19. Connection for

ISC and idle switch

20. Connection for fuel injectors

2 1. Connection for ignition coil22. Connection for power transistor

23. Connection for knock sensor (Turbo)

24. Connection for EGR temperature sensor

(California vehicles only)

25. Connection for ground cable26. Control wiring harness

NOTE(I) Reverse the removal procedures to reinstall.

(2) e+ : Refer to “Service Points of Installation”.(3) m : Non-reusable parts