Brake hose MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 184 of 1216

BRAKES - Service Adjustment Procedures

WA041 7

Pressure

gaugePressure

PropG-tioning valve t4Lmt

,’

,Sdit point

outputpressure

Input pressure

14uoo55CHECK VALVE OPERATION CHECK

NOSFNAJ

When checking the check valve, keep the check valve fit in thevacuum hose.

1. Remove the vacuum hose.

Caution

The check valve is press-fit inside the vacuum hose and

do not remove the check valve from the vacuum hose.

2.Check the operation of the check valve by using a vacuum

pump.Vacuum pump connection Accept/reject criteria

Connection at the brake A negative pressure (vacuum) is

booster side

@Icreated and held.

Connection at the intake

manifold side

@A negative pressure (vacuum) is notcreated.

Caution

If the check valve is defective, replace it as an assembly

unit together with the vacuum hose.PROPORTIONING VALVE FUNCTION TEST

NOSFKAJ

1.Connect two pressure gauges, one each to the input side

and output side of the proportioning valve, as shown.

2. Air bleed the brake line and the pressure gauge.

3. While gradually depressing the brake pedal, make the

following measurements and check to be sure that the

measured values are within the allowable range.

(1) Output pressure begins to drop relative to input

pressure (split point).

Standard value:

MPa (561-633 psi)

MPa (491-561 psi)

(2) Output fluid pressure when input fluid pressure are as

follows.

Standard value:

tFVVD>5.15-5.65 MPa (732-804 psi)

[at 8.2

MPa (1,163 psi)]

MPa (661-732 psi)

[at 7.7

MPa (1,095 psi)],

(3) Output pressure difference between left and right

brake lines

Limit: 0.4

MPa (57 psi)

4. If the measured pressures are not within the

permissibleranges, replace the proportioning valve.

Page 190 of 1216

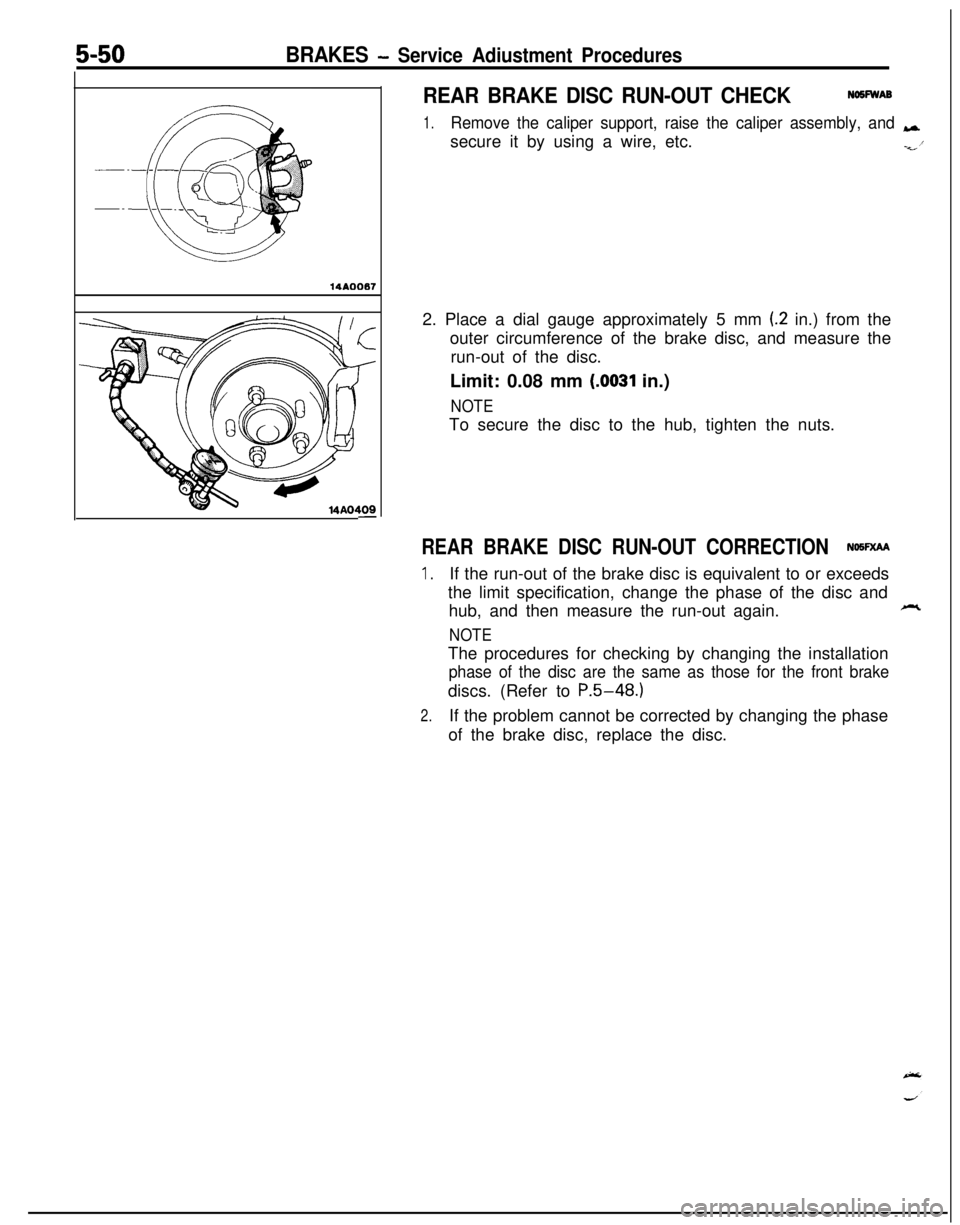

5-50BRAKES - Service Adiustment Procedures

14A.0067

MAO409-

REAR BRAKE DISC RUN-OUT CHECKNOSWAB

1.Remove the caliper support, raise the caliper assembly, and Ir.secure it by using a wire, etc.

-u/2. Place a dial gauge approximately 5 mm

(2 in.) from the

outer circumference of the brake disc, and measure the

run-out of the disc.

Limit: 0.08 mm

(.0031 in.)

NOTETo secure the disc to the hub, tighten the nuts.

REAR BRAKE DISC RUN-OUT CORRECTIONNWFXAA

1.If the run-out of the brake disc is equivalent to or exceeds

the limit specification, change the phase of the disc and

hub, and then measure the run-out again.

rc

NOTEThe procedures for checking by changing the installation

phase of the disc are the same as those for the front brakediscs. (Refer to

P.5-48.)

2.If the problem cannot be corrected by changing the phase

of the brake disc, replace the disc.

Page 196 of 1216

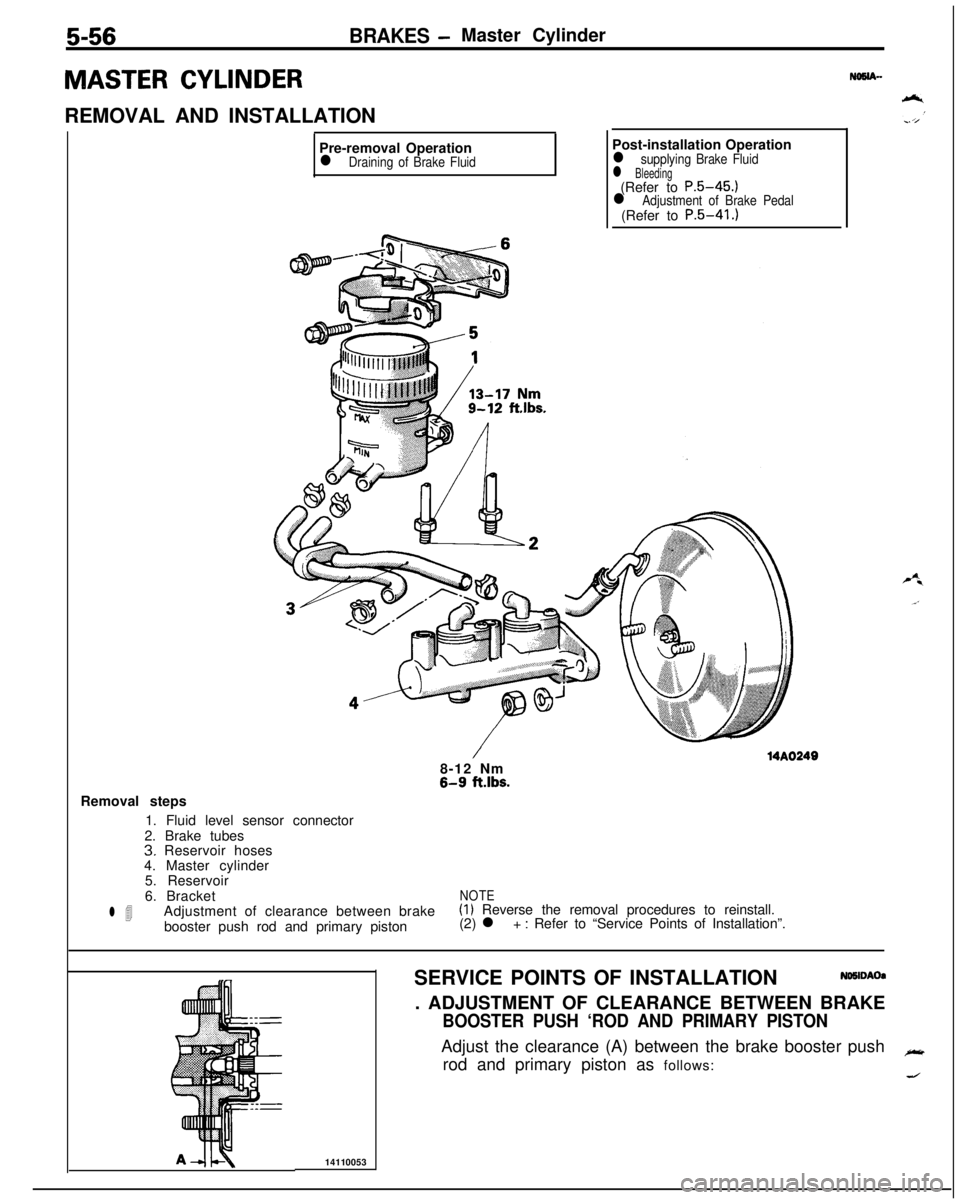

5-56BRAKES -Master Cylinder

MASTER CYLINDERREMOVAL AND INSTALLATION

Pre-removal Operation

l Draining of Brake FluidPost-installation Operationl supplying Brake Fluidl Bleeding(Refer to P.5-45.1l Adjustment of Brake Pedal(Refer to P.5-41.)

Removal steps

/8-12 Nm

6-S Mbs.

14A02491. Fluid level sensor connector

2. Brake tubes

3. Reservoir hoses

4. Master cylinder

5. Reservoir

6. Bracket

NOTE

l 4Adjustment of clearance between brake(I) Reverse the removal procedures to reinstall.

booster push rod and primary piston(2) l + : Refer to “Service Points of Installation”.

14110053SERVICE POINTS OF INSTALLATIONNWlDAOa

. ADJUSTMENT OF CLEARANCE BETWEEN BRAKE

BOOSTER PUSH ‘ROD AND PRIMARY PISTONAdjust the clearance (A) between the brake booster push

rod and primary piston as follows:

m

J

Page 200 of 1216

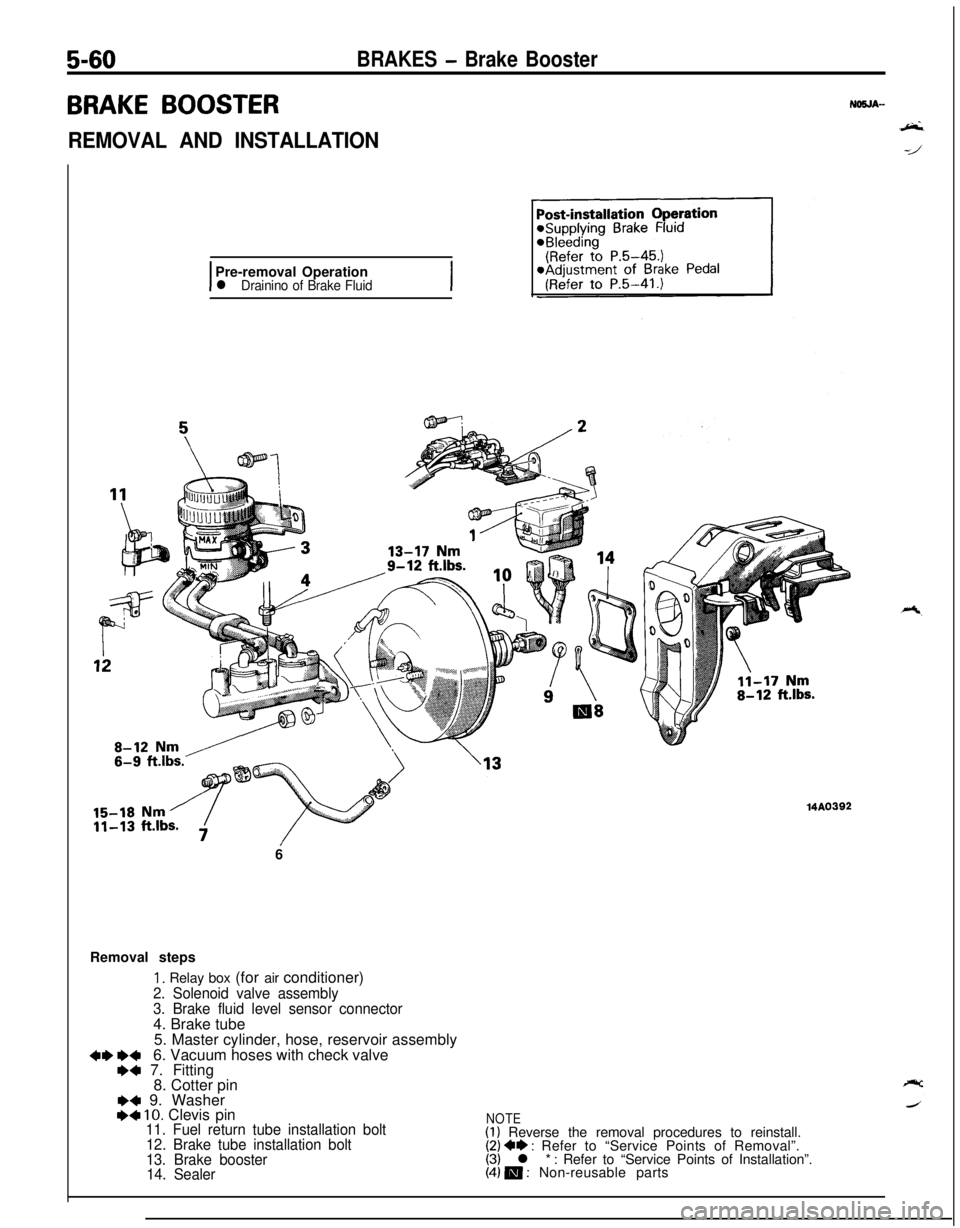

5-60BRAKES - Brake Booster

BRAKE BOOSTER

REMOVAL AND INSTALLATION

IPre-removal Operationl Drainino of Brake FluidI6

Removal steps

1. Relay box (for air conditioner)

2. Solenoid valve assembly

3. Brake fluid level sensor connector4. Brake tube

5. Master cylinder, hose, reservoir assembly

+I) e+6. Vacuum hoses with check valve+a 7. Fitting

8. Cotter pin

I)4 9. WasherI)4 10. Clevis pin11. Fuel return tube installation bolt

12. Brake tube installation bolt

13. Brake booster

14. Sealer

MA0392

NOTE(1) Reverse the removal procedures to reinstall.(2) ** : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

Page 201 of 1216

BRAKES - Brake Booster5-61Vacuum hose

MAO394

14uoo50

14Y626Vacuum hose

mm (in.)

14A0395

SERVICE POINTS OF REMOVALNow9Al

6. REMOVAL OF VACUUM HOSE WITH CHECK VALVE

NOTE

Since the check valve is fit to the vacuum hose, replace thecheck valve as an assembly unit together with the vacuum

hose if the check valve is defective.

SERVICE POINTS OF INSTALLATIONNOWDAV

10. APPLICATION OF GREASE TO CLEVIS PIN/g. WASHERAfter applying the specified grease to the

clevis pin and

washer, insert the clevis pin and bend the cotter pin tightly.

Grease: MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

7. APPLICATION OF SEALANT TO

FITTINGWhen installing the vacuum hose fitting, apply semi-drying

sealant to its threaded portion.

6. INSTALLATION OF VACUUM HOSE WITH CHECK

VALVE(1) Attach the vacuum hose so that it may be inserted to a

dimension illustrated.

Caution

Prevent interference between the check valve and

brake booster.(2) The vacuum hose at the engine should be securely

connected until it contacts the hexagonal edge of the

fitting, and then should be secured by the hose clip.

Page 202 of 1216

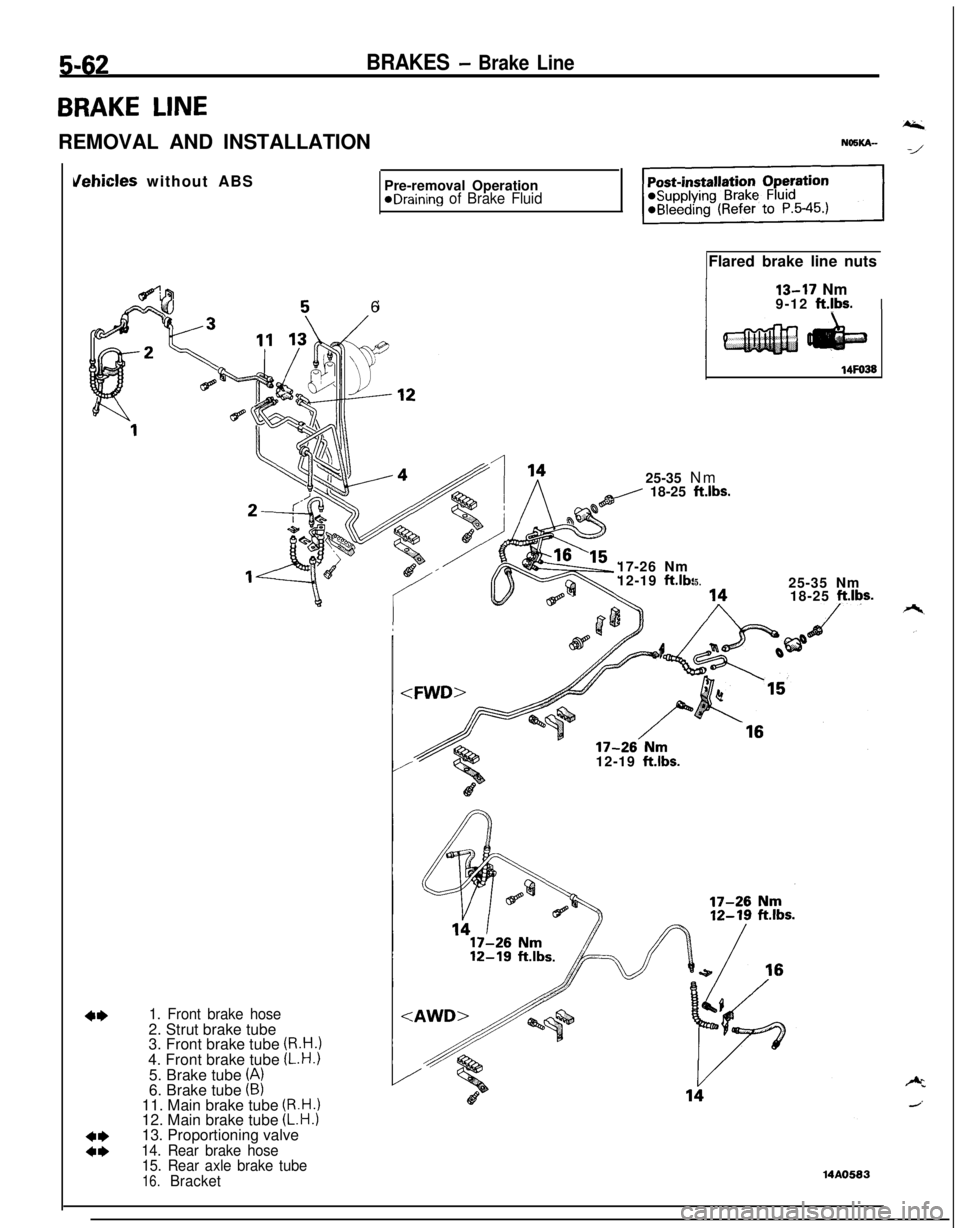

5-62BRAKES - Brake Line

BRAKE LINEREMOVAL AND INSTALLATIONr/ehicles without ABS

Pre-removal Operation

eDraining of Brake Fluid6

/

NOSKA-

>/Flared brake line nuts

13-17 Nm

9-12 ft.lbs.I

14FO3825-35 Nm

/ 18-25 ftlbs.17-26 Nm

12-19 ft.lb!

5.25-35 Nm

18-25 ftlbs.12-19

ft.lbs.

1. Front brake hose2. Strut brake tube

3. Front brake tube

(R.H.)4. Front brake tube (L.H.)5. Brake tube (A)6. Brake tube (9)11. Main brake tube (R.H.)12. Main brake tube (L.H.)13. Proportioning valve

14. Rear brake hose

15. Rear axle brake tube

16.BracketMAO583

Page 203 of 1216

--

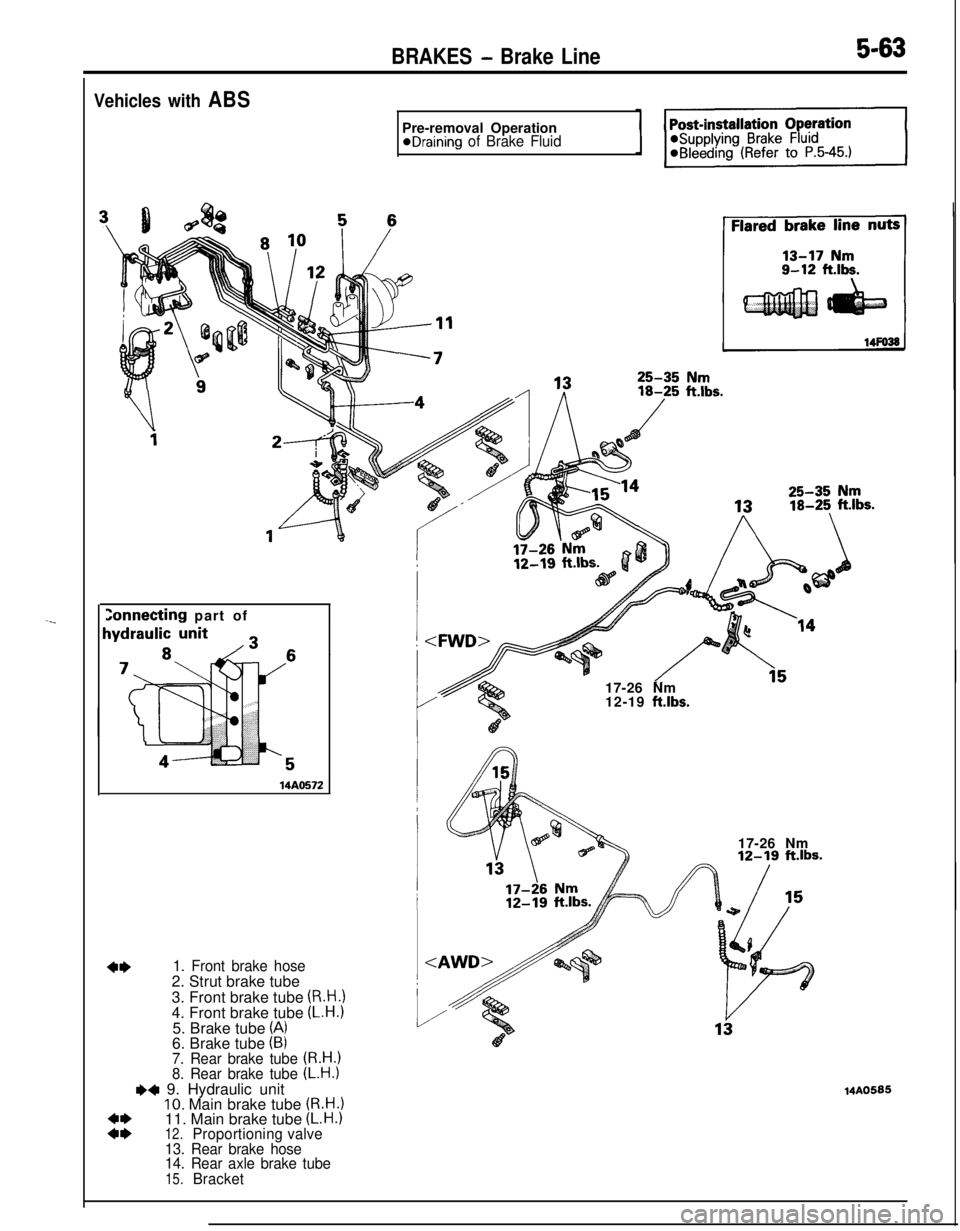

BRAKES - Brake Line5-63

Vehicles with ABSPre-removal Operation

*Draining of Brake FluidZonnecting part of14A057i

!

4*1. Front brake hose2. Strut brake tube

3. Front brake tube

(R.H.)4. Front brake tube (L.H.)5. Brake tube (A)6. Brake tube (9)7. Rear brake tube (R.H.)8. Rear brake tube (L.H.)~~ 9. Hydraulic unit10. Main brake tube (R.H.)11. Main brake tube (L.H.)2:12.Proportioningvalve

13. Rear brake hose

14. Rear axle brake tube

15.Bracket17-26 Nm

12-19

ftlbs.17-26 Nm

12-19 ft.lbs.14A0585

Page 204 of 1216

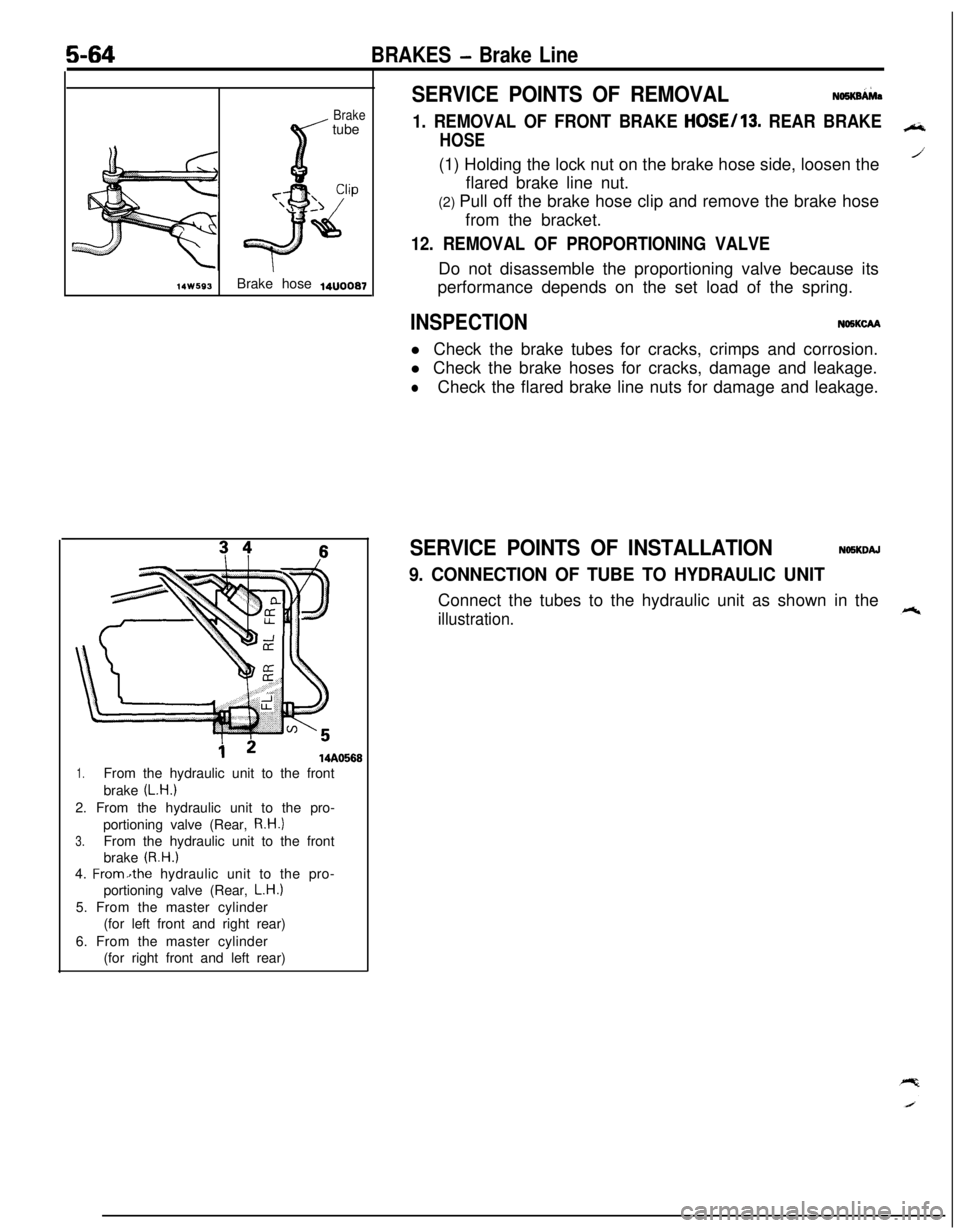

5-64BRAKES - Brake Line

Braketube

14w593Brake hose ,4”ooe~

1.From the hydraulic unit to the front

brake

(L.H.)2. From the hydraulic unit to the pro-

portioning valve (Rear,

R.H.)

3.From the hydraulic unit to the front

brake

(R.H.)4.

From.,the hydraulic unit to the pro-

portioning valve (Rear,

L.H.)5. From the master cylinder

(for left front and right rear)

6. From the master cylinder

(for right front and left rear)

SERVICE POINTS OF REMOVAL.m LN88K8AMll

1. REMOVAL OF FRONT BRAKE HOSE/13. REAR BRAKEr-e

HOSE(1) Holding the lock nut on the brake hose side, loosen the

iflared brake line nut.

(2) Pull off the brake hose clip and remove the brake hose

from the bracket.

12. REMOVAL OF PROPORTIONING VALVEDo not disassemble the proportioning valve because its

performance depends on the set load of the spring.

INSPECTIONNO5KCAhl Check the brake tubes for cracks, crimps and corrosion.

l Check the brake hoses for cracks, damage and leakage.

lCheck the flared brake line nuts for damage and leakage.

SERVICE POINTS OF INSTALLATIONNO5KDAJ

9. CONNECTION OF TUBE TO HYDRAULIC UNITConnect the tubes to the hydraulic unit as shown in the

illustration.

Page 205 of 1216

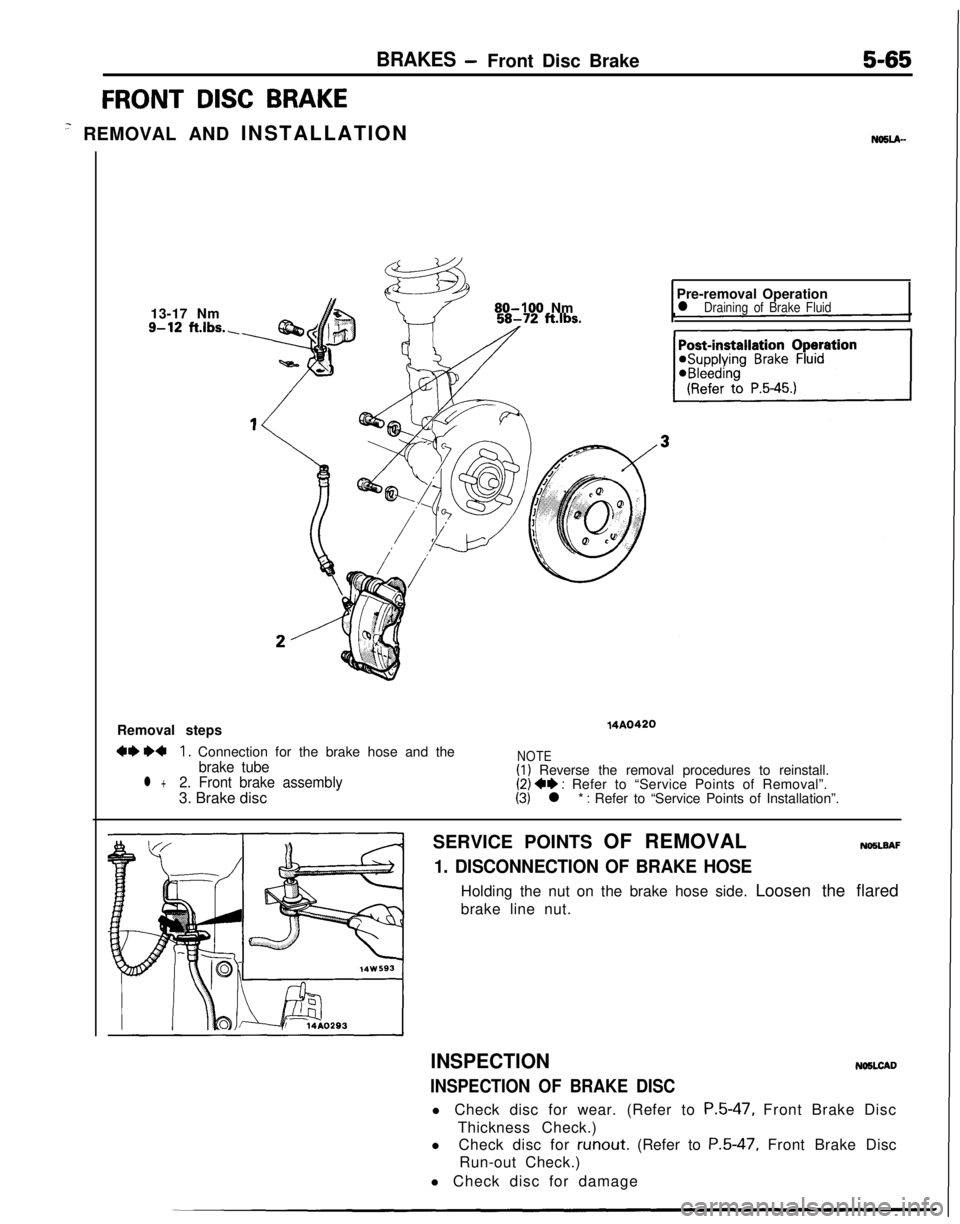

BRAKES -Front Disc Brake5-65

FRONT DISC BRAKE

’ REMOVAL AND INSTALLATIONNOSLA--13-17 Nm

9-12 ft.lbs.,

80-100 NmPre-removal Operationl Draining of Brake FluidRemoval steps

W M1. Connection for the brake hose and the

brake tubel +2. Front brake assembly3. Brake disc

14A0420

NOTE(I) Reverse the removal procedures to reinstall.(2) +I) : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL

N-LEAF

1. DISCONNECTION OF BRAKE HOSEHolding the nut on the brake hose side. Loosen the flared

brake line nut.

INSPECTIONNOSLCAD

INSPECTION OF BRAKE DISCl Check disc for wear. (Refer to P.5-47, Front Brake Disc

Thickness Check.)

lCheck disc for

runout. (Refer to P.5-47, Front Brake Disc

Run-out Check.)

l Check disc for damage

Page 206 of 1216

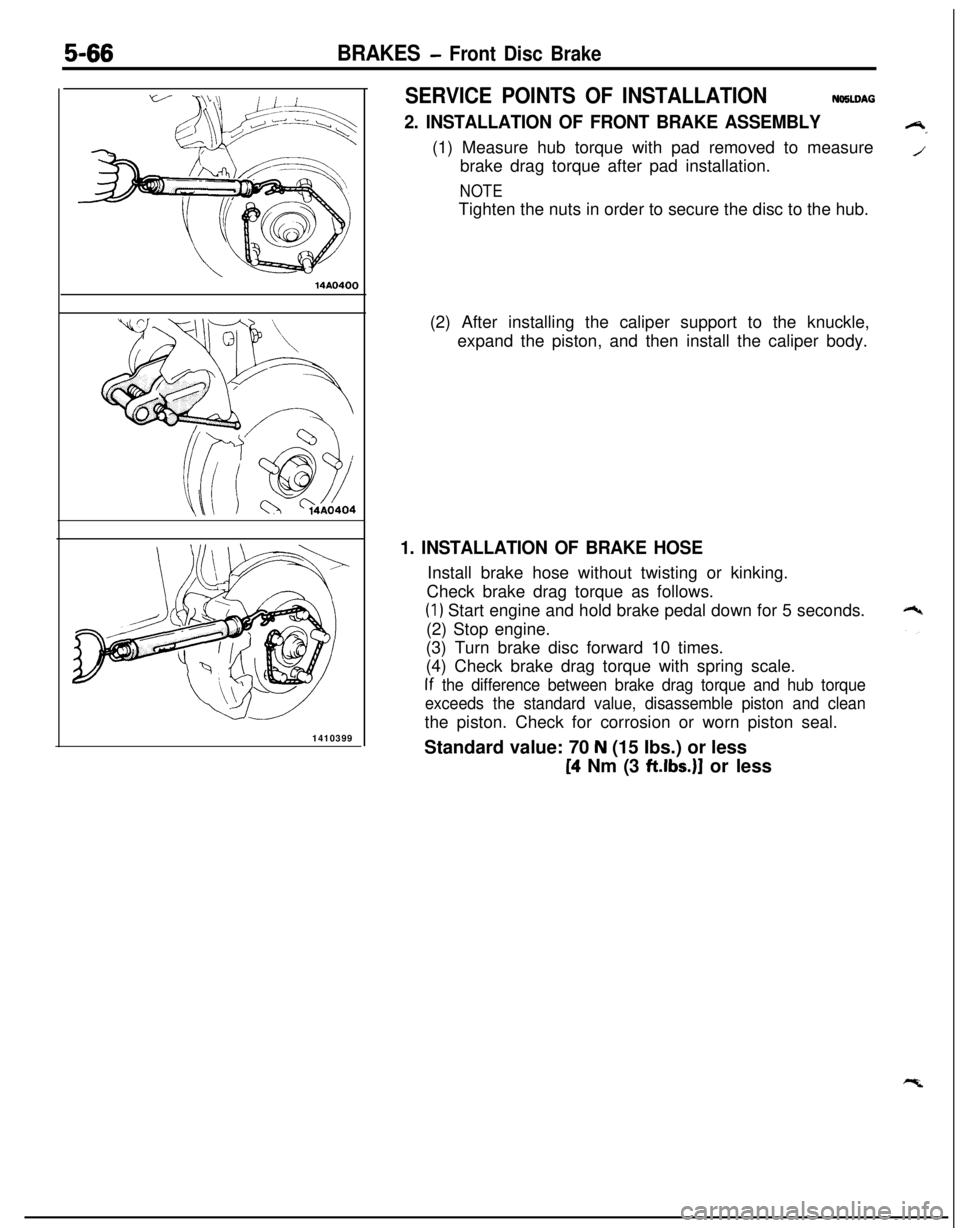

5,966BRAKES - Front Disc Brake

14A04001410399

SERVICE POINTS OF INSTALLATIONNO5LDAG

2. INSTALLATION OF FRONT BRAKE ASSEMBLY(1) Measure hub torque with pad removed to measure

brake drag torque after pad installation.

NOTETighten the nuts in order to secure the disc to the hub.

(2) After installing the caliper support to the knuckle,

expand the piston, and then install the caliper body.

1. INSTALLATION OF BRAKE HOSEInstall brake hose without twisting or kinking.

Check brake drag torque as follows.

(1) Start engine and hold brake pedal down for 5 seconds.

(2) Stop engine.

(3) Turn brake disc forward 10 times.

(4) Check brake drag torque with spring scale.

If the difference between brake drag torque and hub torque

exceeds the standard value, disassemble piston and cleanthe piston. Check for corrosion or worn piston seal.

Standard value: 70

N (15 Ibs.) or less[4 Nm (3

ft.lbs.)J or less