drain bolt MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 860 of 1216

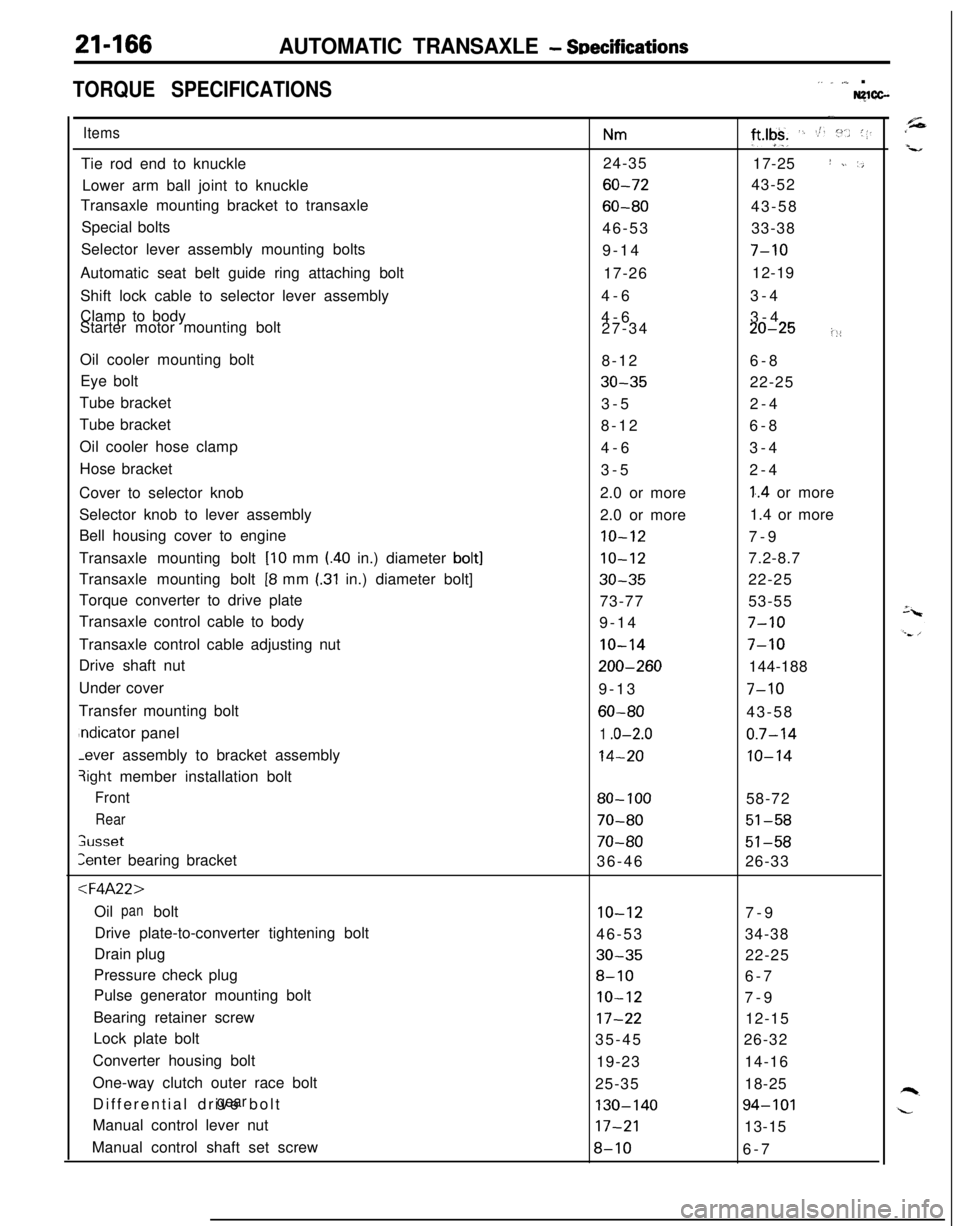

21-166AUTOMATIC TRANSAXLE - SDecifications

TORQUE SPECIFICATIONS,. _ ,,,_ .Nglcc-

ItemsTie rod end to knuckle

Lower arm ball joint to knuckle

Transaxle mounting bracket to transaxle

Special bolts

Selector lever assembly mounting bolts

Automatic seat belt guide ring attaching bolt

Shift lock cable to selector lever assembly

Clamp to body

Starter motor mounting bolt

Oil cooler mounting bolt

Eye bolt

Tube bracket

Tube bracket

Oil cooler hose clamp

Hose bracket

Cover to selector knob

Selector knob to lever assembly

Bell housing cover to engine

Transaxle mounting bolt

[lo mm l.40 in.) diameter bolt]Transaxle mounting bolt

[8 mm I.31 in.) diameter bolt]

Torque converter to drive plate

Transaxle control cable to body

Transaxle control cable adjusting nut

Drive shaft nut

Under cover

Transfer mounting boltndicator panel-ever assembly to bracket assembly

3ight member installation bolt

Front

Rear

;usset

Zenter bearing bracket

:l=4A22>Oil bolt

panDrive plate-to-converter tightening bolt

Drain plug

Pressure check plug

Pulse generator mounting bolt

Bearing retainer screw

Lock plate bolt

Converter housing bolt

One-way clutch outer race bolt

Differential drive bolt

gearManual control lever nut

Manual control shaft set screw

Nm24-35

60-72

60-8046-53

9-14

17-26

4-6

4-6

27-34

8-12

30-353-5

8-12

4-6

3-5

2.0 or more

2.0 or more

10-12

10-12

30-3573-77

9-14

IO-14

200-2609-13

60-80

1 .o-2.0

14-20

80- 100

70-80

70-8036-46

10-1246-53

30-35

8-10

IO-12

17-2235-45

19-23

25-35

130-14017-21

8-10

-.

ft*lgk+ ‘. St. :“.. (1.17-25

I ~. ‘,43-52

43-58

33-38

7-1012-19

3-4

3-4

20-25i::6-8

22-25

2-4

6-8

3-4

2-4

1..4 or more

1.4 or more

7-9

7.2-8.7

22-25

53-55

7-10

7-10144-188

7-1043-58

0.7-14

10-1458-72

51-58

51-5826-33

7-9

34-38

22-25

6-7

7-9

12-15

26-32

14-16

18-25

94-10113-15

6-7

Page 861 of 1216

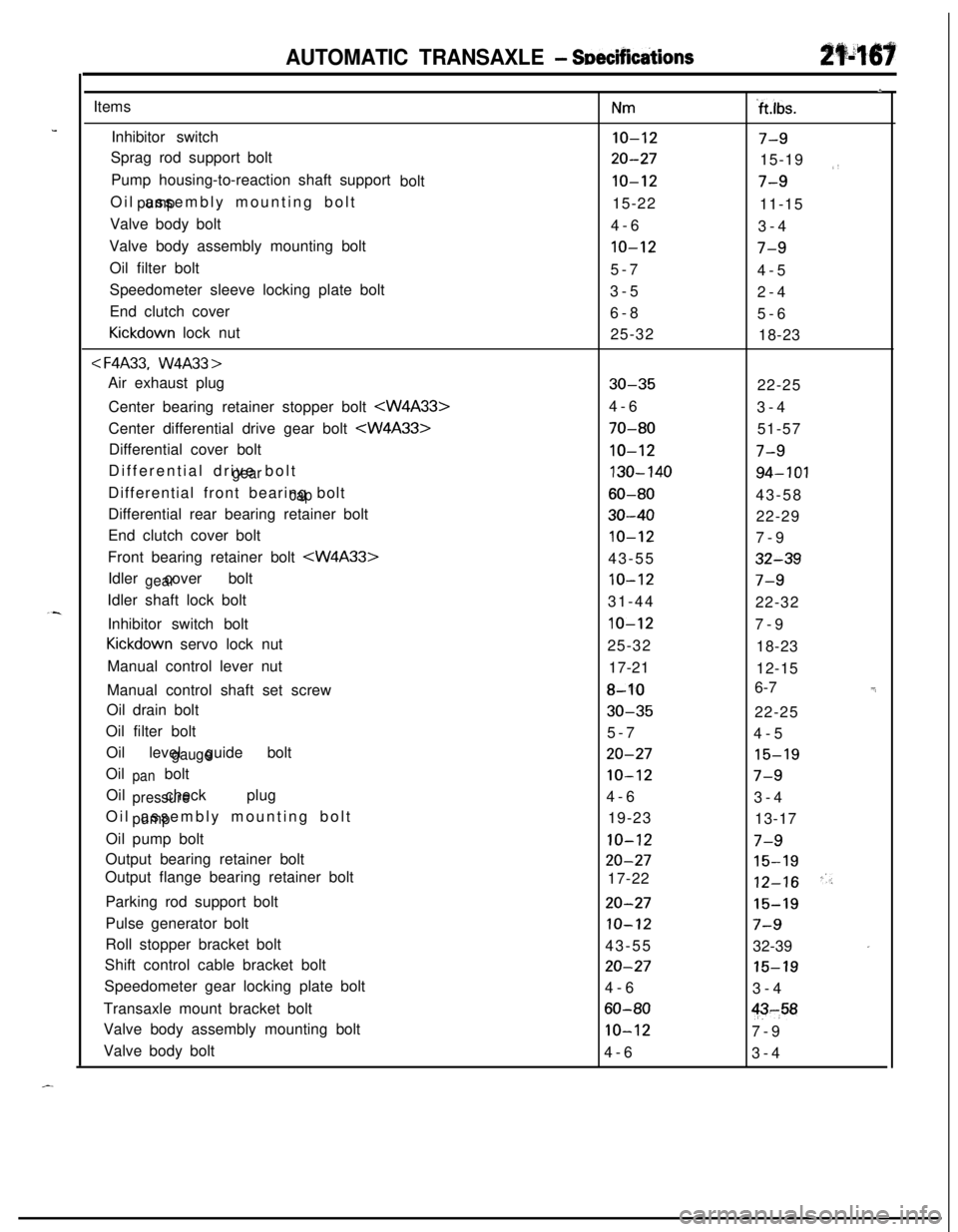

AUTOMATIC TRANSAXLE - SeecificdionsItems

Inhibitor switch

Sprag rod support bolt

Pump housing-to-reaction shaft support

bolt

Oil assembly mounting bolt

pumpValve body bolt

Valve body assembly mounting bolt

Oil filter bolt

Speedometer sleeve locking plate bolt

End clutch cover

Kickdown lock nut

< F4A33.W4A33 >Air exhaust plug

Center bearing retainer stopper bolt

Differential drive bolt

gearDifferential front bearing bolt

capDifferential rear bearing retainer bolt

End clutch cover bolt

Front bearing retainer bolt

gearIdler shaft lock bolt

Inhibitor switch bolt

Kickdown servo lock nut

Manual control lever nut

Manual control shaft set screw

Oil drain bolt

Oil filter bolt

Oil level guide bolt

gaugeOil bolt

panOil check plug

pressureOil assembly mounting bolt

pumpOil pump bolt

Output bearing retainer bolt

Output flange bearing retainer bolt

Nm

IO-12

20-27

10-1215-22

4-6

10-125-7

3-5

6-8

25-32

30-354-6

70-80

10-12

130-140

60-80

30-40

10-1243-55

10-1231-44

IO-1225-32

17-21

8-10

30-355-7

20-27

10-124-6

19-23

10-12

20-2717-22

,I

‘ft.lbs.

7-915-19

,,

7-911-15

3-4

7-94-5

2-4

5-6

18-23

22-25

3-4

51-57

7-9

94-10143-58

22-29

7-9

32-39

7-922-32

7-9

18-23

12-15

6-7

-_22-25

4-5

15-19

7-93-4

13-17

7-9

15-19

12-16"/Parking rod support bolt

20-2715-19Pulse generator bolt

IO-127-9Roll stopper bracket bolt

43-55

32-39

'Shift control cable bracket bolt

20-2715-19Speedometer gear locking plate bolt

4-6

3-4

Transaxle mount bracket bolt

60-80$-,58Valve body assembly mounting bolt

10-127-9

Valve body bolt

4-6

3-4

-.

Page 862 of 1216

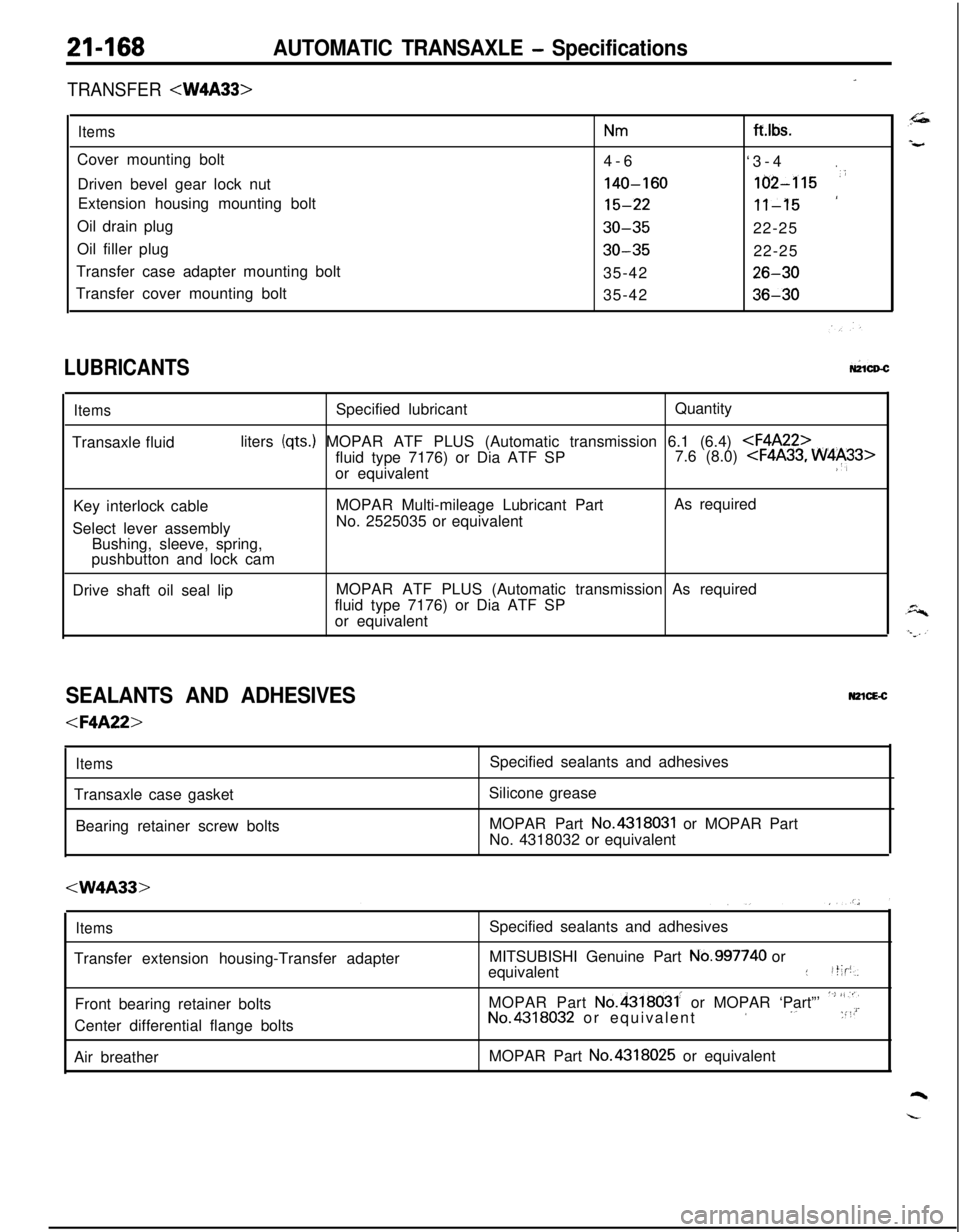

21-168AUTOMATIC TRANSAXLE - Specifications

-TRANSFER

ItemsNmCover mounting bolt

4-6

Driven bevel gear lock nut

140-160Extension housing mounting bolt

15-22Oil drain plug

30-35Oil filler plug

30-35Transfer case adapter mounting bolt

35-42

Transfer cover mounting bolt

35-42ft.lbs.

‘3-4

.

162-115 ‘i

‘11-1522-25

22-25

26-30

36-30

LUBRICANTSW1CD-C

ItemsSpecified lubricantQuantity

Transaxle fluidliters

(qts.) MOPAR ATF PLUS (Automatic transmission 6.1 (6.4)

or equivalent

:‘,Key interlock cableMOPAR Multi-mileage Lubricant PartAs required

Select lever assemblyNo. 2525035 or equivalent

Bushing, sleeve, spring,

pushbutton and lock cam

Drive shaft oil seal lipMOPAR ATF PLUS (Automatic transmission As required

fluid type 7176) or Dia ATF SP

or equivalent

SEALANTS AND ADHESIVESN2lcE-c

ItemsTransaxle case gasket

Bearing retainer screw bolts

Silicone grease

MOPAR Part

No.4318031 or MOPAR Part

No. 4318032 or equivalent

ItemsTransfer extension housing-Transfer adapter

Front bearing retainer bolts

Center differential flange bolts

Air breatherSpecified sealants and adhesives

MITSUBISHI Genuine Part

No.997740 or

equivalent::t;p,

MOPAR Part

No.4318031. or MOPAR ‘Part”’ ‘~’ “,“iNo.4318032 or equivalent’ ‘. :“’MOPAR Part No.4318025 or equivalent

Page 918 of 1216

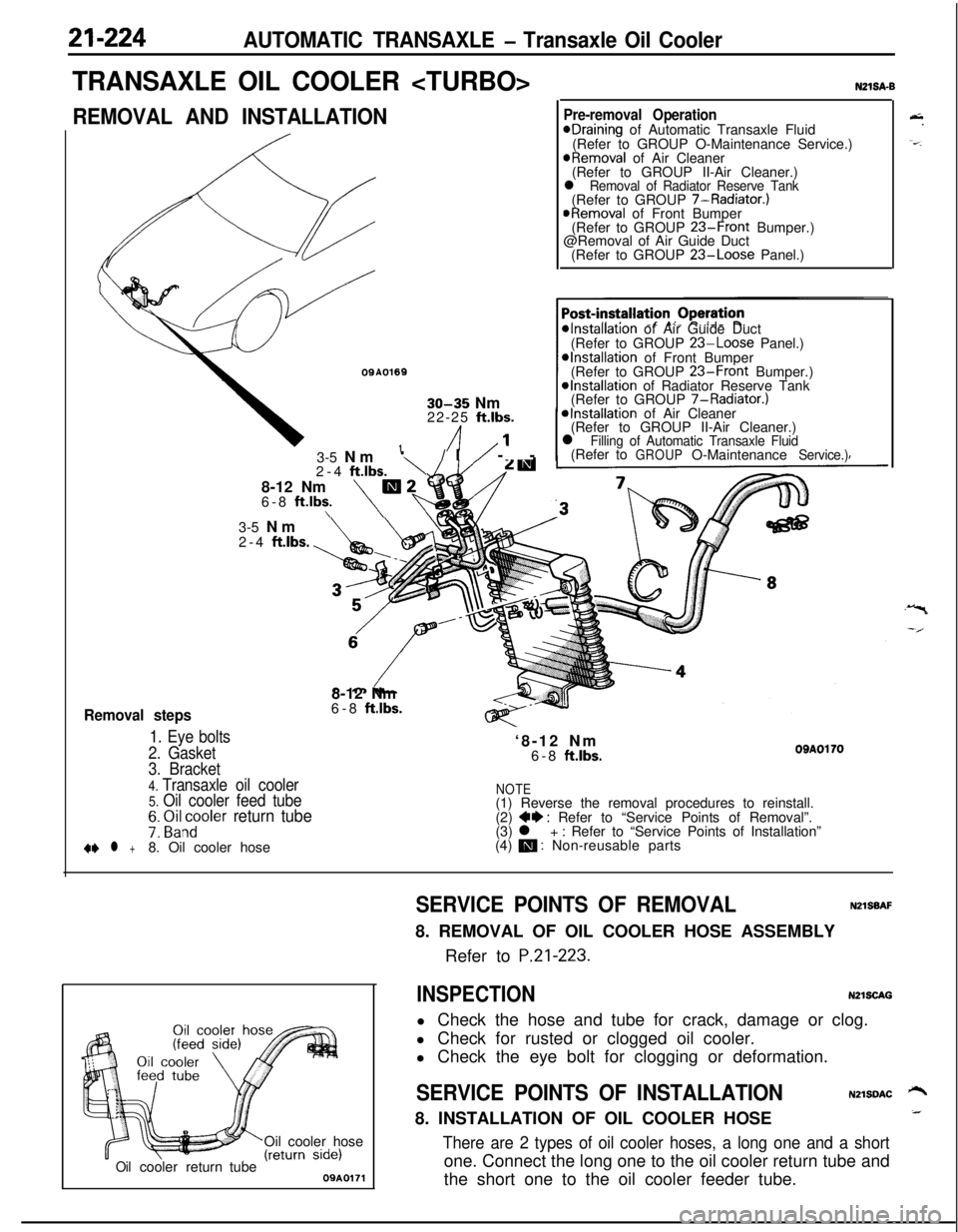

21-224AUTOMATIC TRANSAXLE - Transaxle Oil Cooler

TRANSAXLE OIL COOLER

REMOVAL AND INSTALLATION

OQA01691

30-35 Nm

22-25 ft.lbs.

/I1’

Removal steps

1. Eye bolts

2. Gasket3-5 Nm

‘\/I/ --

2-4

ftlbs.8-12 Nm

m26-8 ft.lbs.\\

N21SA-B

Pre-removal OperationeDraining of Automatic Transaxle Fluid

(Refer to GROUP O-Maintenance Service.)

@Removal of Air Cleaner

(Refer to GROUP II-Air Cleaner.)

l Removal of Radiator Reserve Tank(Refer to GROUP 7-Radiator.)

@Removal of Front Bumper

(Refer to GROUP 23-Front Bumper.)

@Removal of Air Guide Duct

(Refer to GROUP

23-Loose Panel.)

*Installation of Air Guide Duct

(Refer to GROUP 23-Loose Panel.)*Installation of Front Bumper

(Refer to GROUP 23-Front Bumper.)@Installation of Radiator Reserve Tank

(Refer to GROUP 7-Radiator.)

*Installation of Air Cleaner

(Refer to GROUP II-Air Cleaner.)

l Filling of Automatic Transaxle Fluid(Refer toGROUPO-MaintenanceService.)3-5 Nm

2-4

ftlbs.8-12 Nm

6-8

ft.lbs.‘8-12 Nm

6-8

ftlbs.OBAOl703. Bracket

4. Transaxle oil cooler5. Oil cooler feed tubeNOTE(1) Reverse the removal procedures to reinstall.

7: ~i&~oler return tube(2) ++ : Refer to “Service Points of Removal”.

(3) l + : Refer to “Service Points of Installation”

+e l +8. Oil cooler hose(4) m : Non-reusable parts

Oil cooler hose

Oilcoolerreturn tube09A0171

&.

-=-.

SERVICE POINTS OF REMOVALNZlSBAF8. REMOVAL OF OIL COOLER HOSE ASSEMBLY

Refer to

P.21-223.

INSPECTIONN2lSCAGl Check the hose and tube for crack, damage or clog.

l Check for rusted or clogged oil cooler.

l Check the eye bolt for clogging or deformation.

SERVICE POINTS OF INSTALLATIONN2lSDAC ‘-+8. INSTALLATION OF OIL COOLER HOSE_

There are 2 types of oil cooler hoses, a long one and a shortone. Connect the long one to the oil cooler return tube and

the short one to the oil cooler feeder tube.

Page 919 of 1216

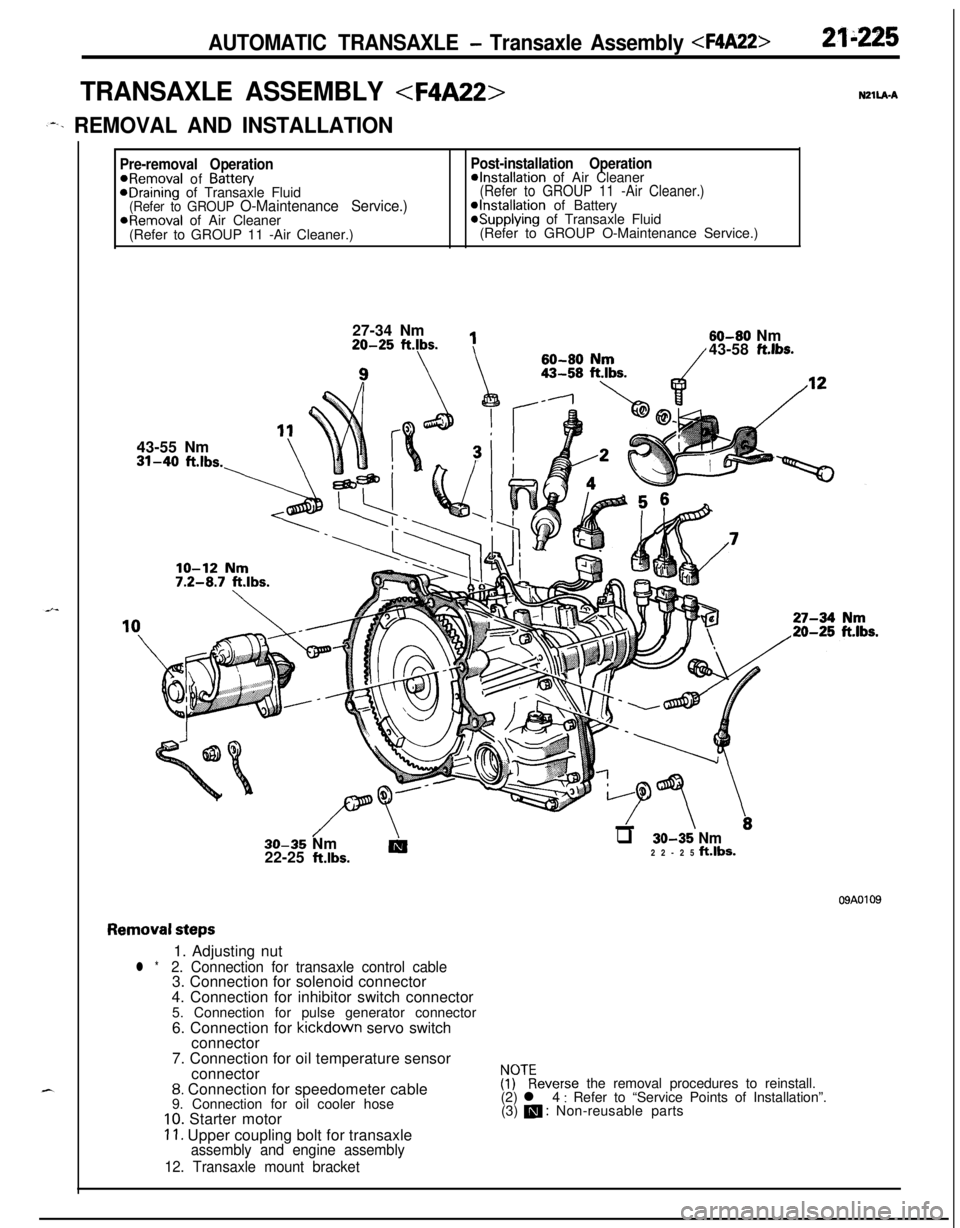

AUTOMATIC TRANSAXLE - Transaxle Assembly

TRANSAXLE ASSEMBLY

,--. REMOVAL AND INSTALLATION

Pre-removal OperationPost-installation Operation@Removal of Battew@Installation of Air CleaneraDraining of Transaxle Fluid(Refer to GROUP 11 -Air Cleaner.)(Refer to GROUP O-Maintenance Service.)@Installation of BatteryaRemoval of Air Cleaner*Supplying of Transaxle Fluid

(Refer to GROUP 11 -Air Cleaner.)(Refer to GROUP O-Maintenance Service.)

27-34 Nm20-25

ftlbs.

1143-55 Nm31-40

ft.lbs.-\60-80

flrn60-80 Nm/43-58 ft.lbs.

//\-LTT \.30-35 Nm

AIq 30-35 Nm22-25 klbs.22-25 ft.lbs.

09A0109

Removal steps1. Adjusting nut

l *2. Connection for transaxle control cable3. Connection for solenoid connector

4. Connection for inhibitor switch connector

5. Connection for pulse generator connector

6. Connection for kickdown servo switch

connector

7. Connection for oil temperature sensor

connector

8. Connection for speedometer cable

9. Connection for oil cooler hose

10. Starter motor

11. Upper coupling bolt for transaxleassembly and engine assembly

12. Transaxle mount bracket

$?everse the removal procedures to reinstall.

(2) l 4 : Refer to “Service Points of Installation”.

(3) m : Non-reusable parts

Page 953 of 1216

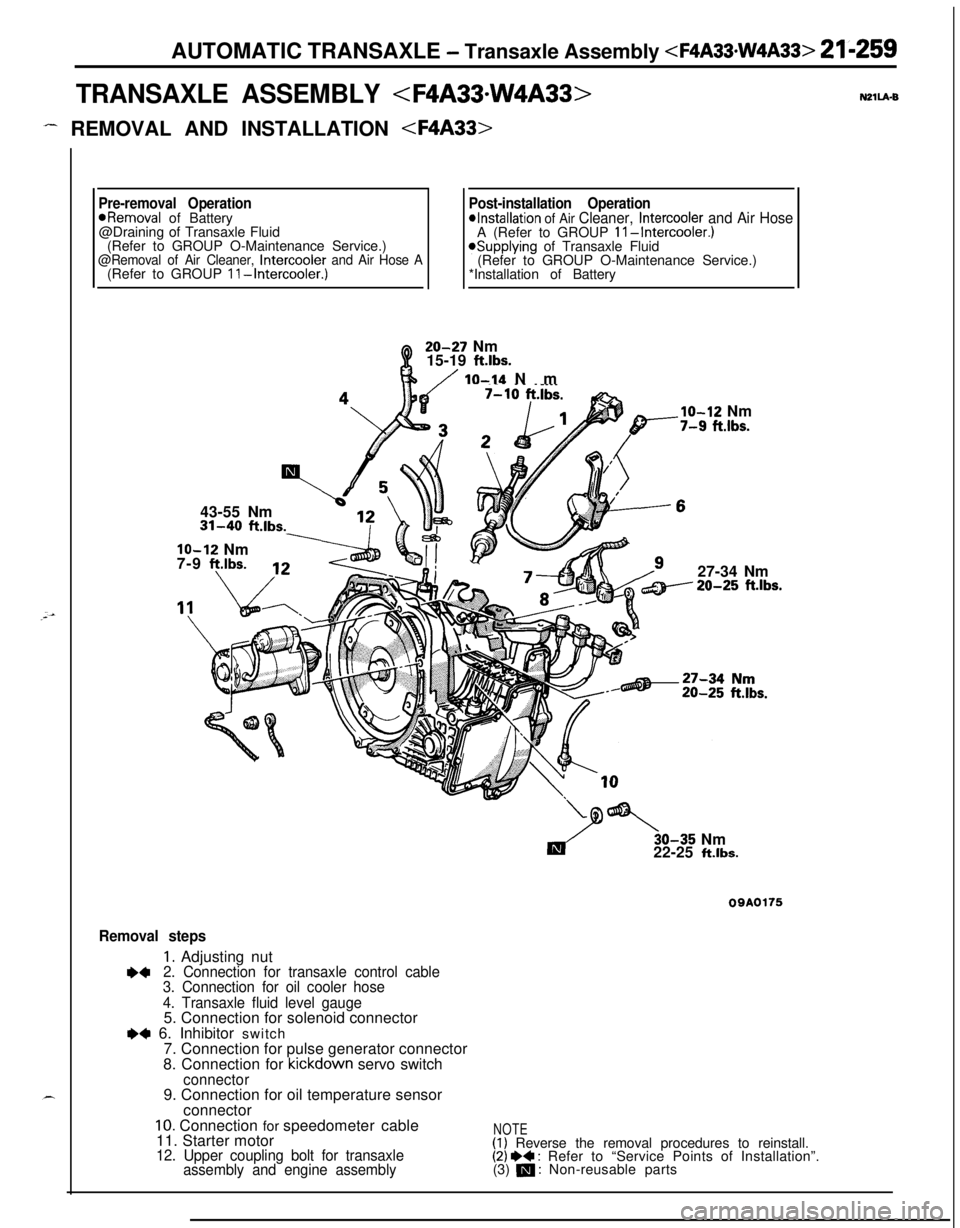

AUTOMATIC TRANSAXLE - Transaxle Assembly

TRANSAXLE ASSEMBLY

- REMOVAL AND INSTALLATION

Pre-removal OperationPost-installation Operation*Removal of Battery*Installation of Air Cleaner, Intercooler and Air Hose@Draining of Transaxle Fluid

A (Refer to GROUP II-Intercooler.)(Refer to GROUP O-Maintenance Service.)

@Removal of Air Cleaner, Intercooler and Air Hose A*Supplying of Transaxle Fluid

(Refer to GROUP O-Maintenance Service.)

(Refer to GROUP II-Intercooler.)*Installation of Battery20-27 Nm

15-19

ft.lbs.

/ IO-14 Nm

43-55 Nm31-40

ft.lbs.

lo-12 Nm

7-9 f?.lbs.

___.Ibs.

lo-12 Nm-7-9 fi.lbs.27-34 Nm20-25

ft.lbs.30-35 Nm

22-25

ft.lbs.

09A0175

Removal steps

1. Adjusting nut+42. Connection for transaxle control cable

3. Connection for oil cooler hose

4. Transaxle fluid level gauge5. Connection for solenoid connector

e+ 6. Inhibitor switch

7. Connection for pulse generator connector

8. Connection for kickdown servo switch

connector9. Connection for oil temperature sensor

connector

10. Connection for speedometer cable

11. Starter motor

12. Upper coupling bolt for transaxle

assembly and engine assembly

NOTE(1) Reverse the removal procedures to reinstall.(2) I)+ : Refer to “Service Points of Installation”.

(3) m : Non-reusable parts