charging MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 423 of 1216

11-l

INTAKE AND

EXHAUSTAIR CLEANER

. . . . . . . ..*........................................8

EXHAUST MANIFOLD <1.8L Engine> . . . . . . . .26

EXHAUST MANIFOLD

<2.0L DOHC Engine

(Non-Turbo)>

. . . . . . ..*.*.......................................27EXHAUST MANIFOLD

<2.0L DOHC Engine

(Turbo)>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .*...........................28

CONTENTSNllAA--

-EXHAUST PIPE AND MAIN MUFFLER<1.8L Engine,

2.0L DOHC Engine

(Non-Turbo)>

. . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .30EXHAUST PIPE AND MAIN MUFFLER<2.0L

DOHCEngine(Turbo)>. . . . . . . . . . . . . . . . . . . . .31INTAKE MANIFOLD

<1.8LEngine> . . . . . . . . . . . .13INTAKE MANIFOLD

<2.0L DOHC Engine> 17

INTERCOOLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11SERVICE ADJUSTMENT PROCEDURES..

.....5Air

Bypass ValveInspection........................7Air Cleaner Element Inspection and

Replacement . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5Supercharging Pressure Control System

Inspection

.,...... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . .6Supercharging Pressure Relief Solenoid

Valve Inspection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7Turbocharger Supercharging Pressure

Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6SPECIAL TOOL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..#................4

SPECIFICATIONS.............................................2General Specifications

..................................2Service Specifications

...................................2Torque Specifications

...................................2

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Abnormal Noise

Exhaust Gas Leakage

TURBOCHARGER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Page 424 of 1216

11-2INTAKE AND EXHAUST - Specifications

SPECIFICATIONS

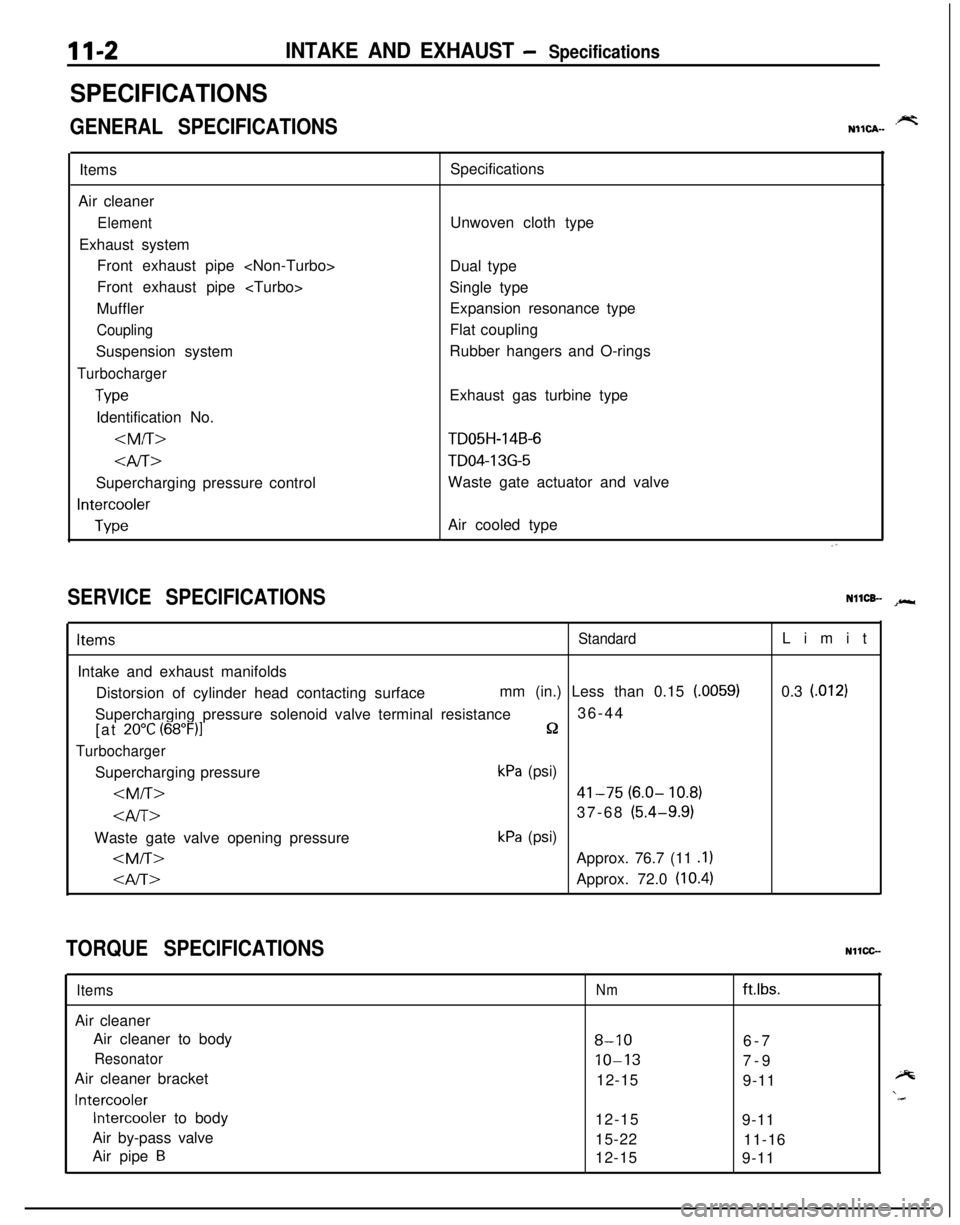

GENERAL SPECIFICATIONS.prtNIICA-Items

Air cleaner

ElementExhaust system

Front exhaust pipe

Front exhaust pipe

Muffler

CouplingSuspension system

Turbocharger

TypeIdentification No.

4iT>Supercharging pressure control

Intercooler

TypeSpecifications

Unwoven cloth type

Dual type

Single type

Expansion resonance type

Flat coupling

Rubber hangers and O-rings

Exhaust gas turbine type

TD05H-14B-6

TD04-13G-5Waste gate actuator and valve

Air cooled type

SERVICE SPECIFICATIONSNllCB- spr*

ItemsStandardIntake and exhaust manifolds

Distorsion of cylinder head contacting surfacemm (in.) Less than 0.15

(.0059)Supercharging pressure solenoid valve terminal resistance36-44

[at

20°C (68”F)lQ

TurbochargerSupercharging pressure

kPa (psi)

kPa (psi)

0.3

l.0121

TORQUE SPECIFICATIONSNllCC-

ItemsAir cleaner

Air cleaner to body

ResonatorAir cleaner bracket

Intercooler

Intercooler to body

Air by-pass valve

Air pipe

B

Nmftlbs.

8-106-7

10-137-9

12-15

9-11

12-15

9-11

15-22

11-16

12-15

9-11

Page 428 of 1216

11-6INTAKE AND EXHAUST - Service Adjustment Procedwes

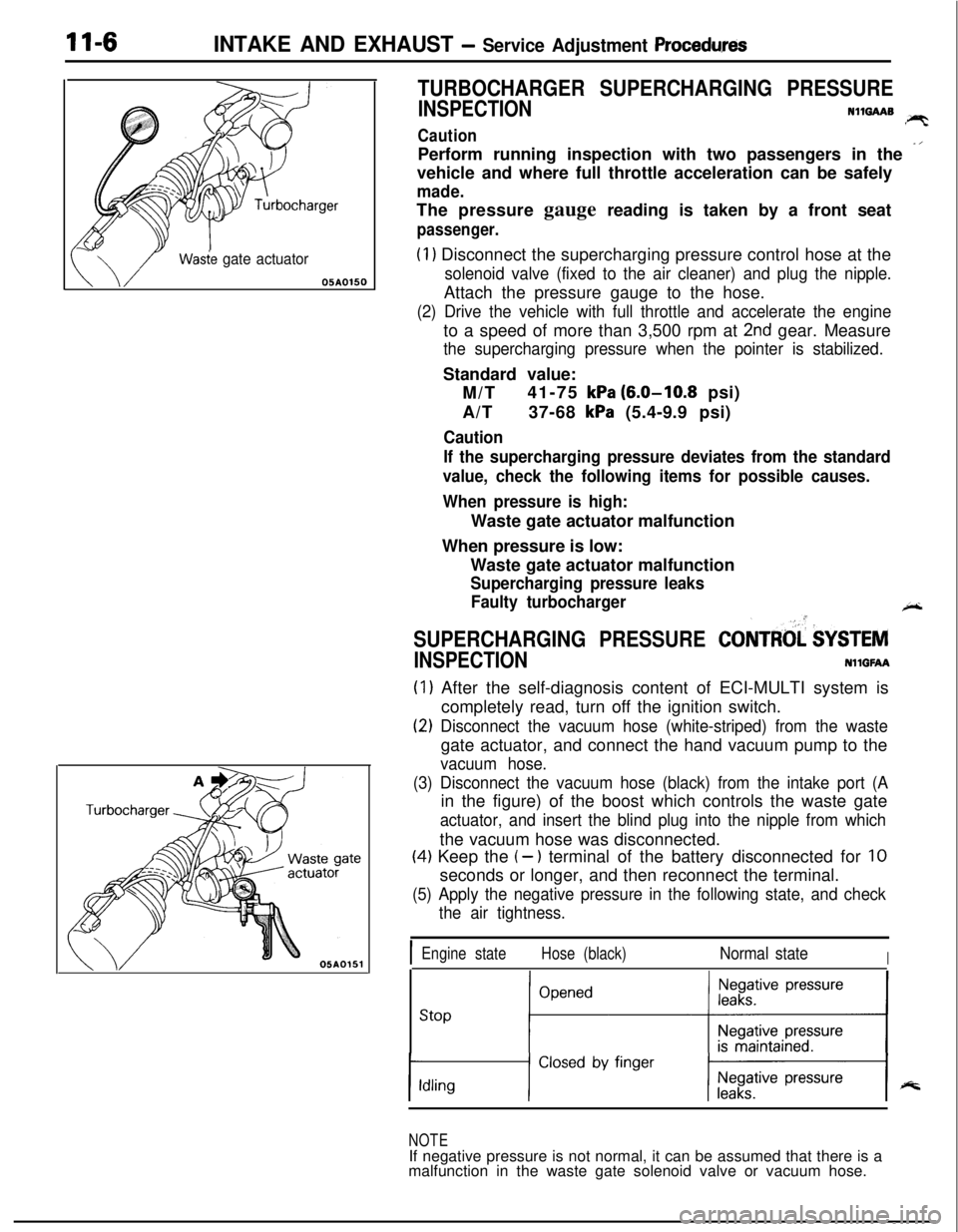

Wasie gate actuator05AOlSO

TURBOCHARGER SUPERCHARGING PRESSURE

INSPECTIONN1mAAB!PTCautionPerform running inspection with two passengers in the

-’vehicle and where full throttle acceleration can be safely

made.The pressure gauge reading is taken by a front seat

passenger.

(1) Disconnect the supercharging pressure control hose at the

solenoid valve (fixed to the air cleaner) and plug the nipple.Attach the pressure gauge to the hose.

(2) Drive the vehicle with full throttle and accelerate the engineto a speed of more than 3,500 rpm at

2nd gear. Measure

the supercharging pressure when the pointer is stabilized.Standard value:

M/T41-75

kPa (6.0-10.8 psi)

A/T37-68

kPa (5.4-9.9 psi)

Caution

If the supercharging pressure deviates from the standard

value, check the following items for possible causes.

When pressure is high:Waste gate actuator malfunction

When pressure is low:

Waste gate actuator malfunction

Supercharging pressure leaks

Faulty turbocharger

+-

SUPERCHARGING PRESSURE CONTRtd $YSTEM

INSPECTIONNllGFAA

(1) After the self-diagnosis content of ECI-MULTI system is

completely read, turn off the ignition switch.

(2) Disconnect the vacuum hose (white-striped) from the wastegate actuator, and connect the hand vacuum pump to the

vacuum hose.

(3) Disconnect the vacuum hose (black) from the intake port (Ain the figure) of the boost which controls the waste gate

actuator, and insert the blind plug into the nipple from whichthe vacuum hose was disconnected.

(4) Keep the (- ) terminal of the battery disconnected for 10seconds or longer, and then reconnect the terminal.

(5) Apply the negative pressure in the following state, and check

the air tightness.

IEngine stateHose (black)Normal stateI

stop ;“““*I

NOTEIf negative pressure is not normal, it can be assumed that there is a

malfunction in the waste gate solenoid valve or vacuum hose.

Page 429 of 1216

INTAKE AND EXHAUST - Service Adjustment ProceduresII-7

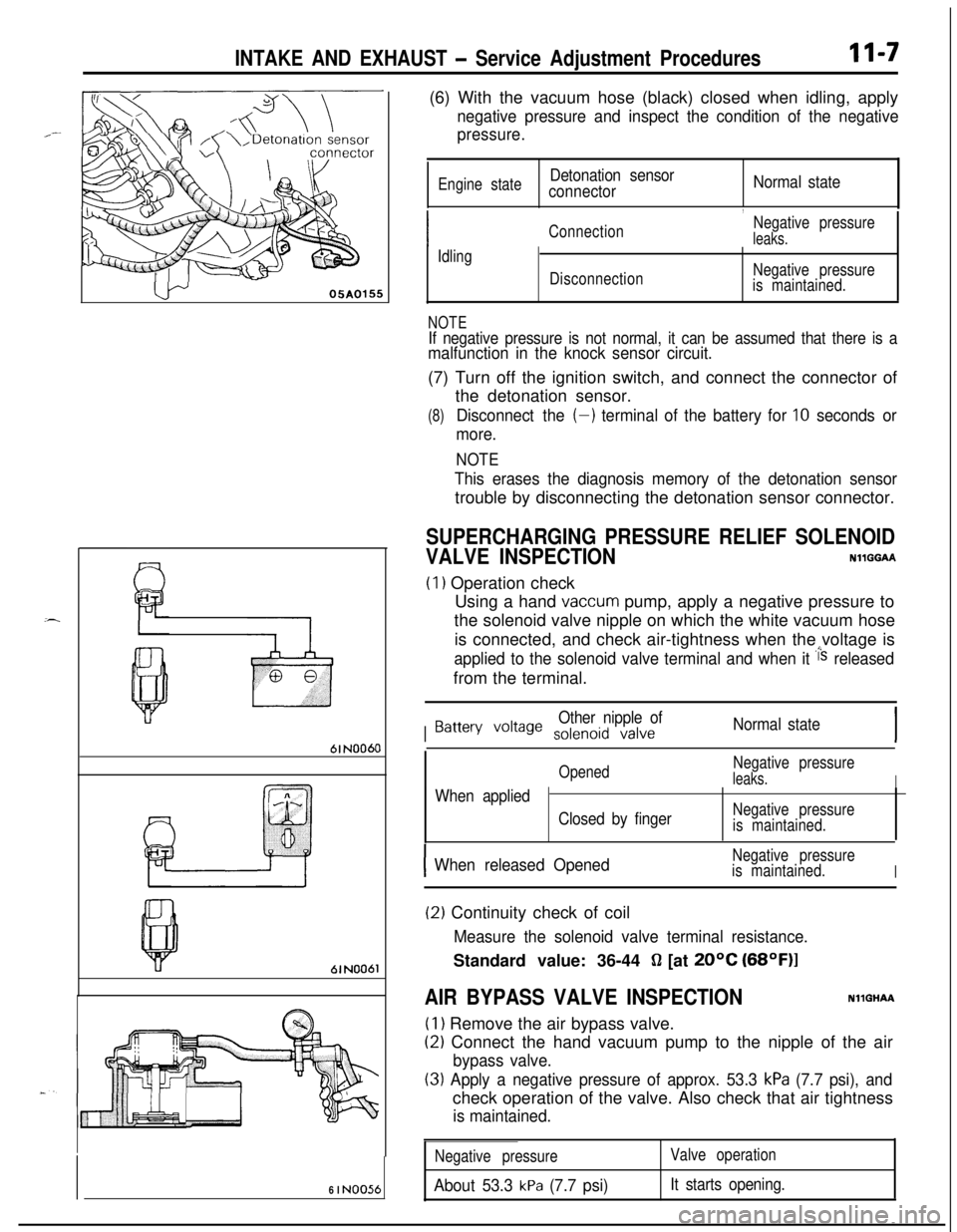

w05A0155

h61

NO06061

NO0616 I

NO056(6) With the vacuum hose (black) closed when idling, apply

negative pressure and inspect the condition of the negative

pressure.

Engine stateDetonation sensor

connectorNormal state

,

ConnectionNegative pressureleaks.

Idling

DisconnectionNegative pressure

is maintained.

NOTEIf negative pressure is not normal, it can be assumed that there is amalfunction in the knock sensor circuit.(7) Turn off the ignition switch, and connect the connector of

the detonation sensor.

(8)Disconnect the (-) terminal of the battery for 10 seconds or

more.

NOTE

This erases the diagnosis memory of the detonation sensortrouble by disconnecting the detonation sensor connector.

SUPERCHARGING PRESSURE RELIEF SOLENOID

VALVE INSPECTIONNllGGAA

(1) Operation check

Using a hand

vaccum pump, apply a negative pressure to

the solenoid valve nipple on which the white vacuum hose

is connected, and check air-tightness when the voltage is

applied to the solenoid valve terminal and when it i‘s releasedfrom the terminal.

I

Other nipple ofBattery voile solenoid valveNormal state

OpenedNegative pressureleaks.IWhen applied

Closed by fingerNegative pressure

is maintained.

IWhen released OpenedNegative pressure

is maintained.

I

(2) Continuity check of coil

Measure the solenoid valve terminal resistance.Standard value: 36-44

fl [at 20°C (68OF)l

AIR BYPASS VALVE INSPECTIONNllGHAA

(1) Remove the air bypass valve.

(2) Connect the hand vacuum pump to the nipple of the air

bypass valve.

(3) Apply a negative pressure of approx. 53.3 kPa (7.7 psi), andcheck operation of the valve. Also check that air tightness

is maintained.

Negative pressure

About 53.3 kPa (7.7 psi)

Valve operation

It starts opening.

Page 1154 of 1216

24-10HEATERS AND AIR CONDITIONING - Safety Precautions

SAFETY PRECAUTIONSN24PAAD

The refrigerant used in all air conditioner is R-l 2. It istransparent and colorless in both the liquid and

vapor state. Since it has a boiling point of

-29.8”C(-85.6”F).

at atmospheric pressure, it will be a vapor

at all normal temperatures and pressures. The vaporis heavier than air, non-flammable, and nonexplo-

sive. It is nonpoisonous except when it is in direct

contact with open flame. It

ia noncorrosive except

when combined with water. The following precau-

tions must be observed when handling

R-12.Caution

Wear safety goggles when servicing the refriger-ation system.

R-12 evaporates so rapidly at normal atmospheric

pressures and temperatures that it tends to freeze

anything it contacts. For this reason, extreme care

must be taken to prevent any liquid refrigerant from

contacting the skin and especially the eyes. Always

wear safety goggles when servicing the refrigera-

tion part of the air conditioning system. Keep a

bottle of sterile mineral oil handy when working on

the refrigeration system. Should any liquid re-

frigerant get into the eyes, use a few drops of

mineral oil to wash them out.

R-12 is rapidly

absorbed by the oil. Next splash the eyes with

plenty of cold water. Call your doctor immediately

even though irritation has ceased after treatment.

Caution

Do not heat

R-12 above 40°C (104°F).In most instances, moderate heat is required to

bring the pressure of the refrigerant in its container

above the pressure of the system when charging or

adding refrigerant. A bucket or large pan of hot

water not over

40°C (104°F) is all the heat required

for this purpose. Do not heat the refrigerant contain-

er with a blow torch or any other means that would

raise temperature and pressure above this tempera-ture. Do not weld or steam clean on or near the

system components or refrigerant lines.

Caution

Keep

R-12 containers upright when charging the

system.When metering

R-12 into the refrigeration system,

keep the supply tank or cans in an upright position. Ifthe refrigerant container is on its side or upside

down, liquid refrigerant will enter the system and

damage the compressor.Caution

Always work in a well-ventilated room.

‘irrGood ventilation is vital in the working area. Always

discharge the refrigerant into the service bay ex-

haust system or outside the building. Large quanti-

ties of refrigerant vapor in a small, poorly ventilated

room can displace the air and cause suffocation.

Although

R-12 vapor is normally nonpoisonous,

contact with an open flame can cause the vapor to

become very poisonous. Do not discharge large

quantities of refrigerant in an area having an open

flame. A poisonous gas is produced when using theflame-type leak detector. Avoid inhaling the fumes

from the leak detector.

Caution

Do not allow liquid refrigerant to touch bright

metal.

Refrigerant will tarnish bright metal and chrome

surfaces, and in combination with moisture can

severely corrode all metal surfaces.

R-12 Refrigerant Bundling

Refrigerant Recycling

R-12 refrigerant is a chloro-floro-carbon (CFC) that

can contribute to the depletion of the ozone layer in

the upper atmosphere.A

Ozone filters out harmful radiation from the sun.

- -/.To assist in protecting the ozone layer, Mitsubishi

Motors Corporation

recomends that a R-12 re-

frigerant recycling device that meets SAE standard

J1991 be used.

Contact an automotive service equipment supplier

for refrigerant recycling equipment that is available

in your area.

Refer to the operating instructions provided with therecycling equipment for proper operation.

Page 1155 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-I 1

SERVICE ADJUSTMENT PROCEDURES

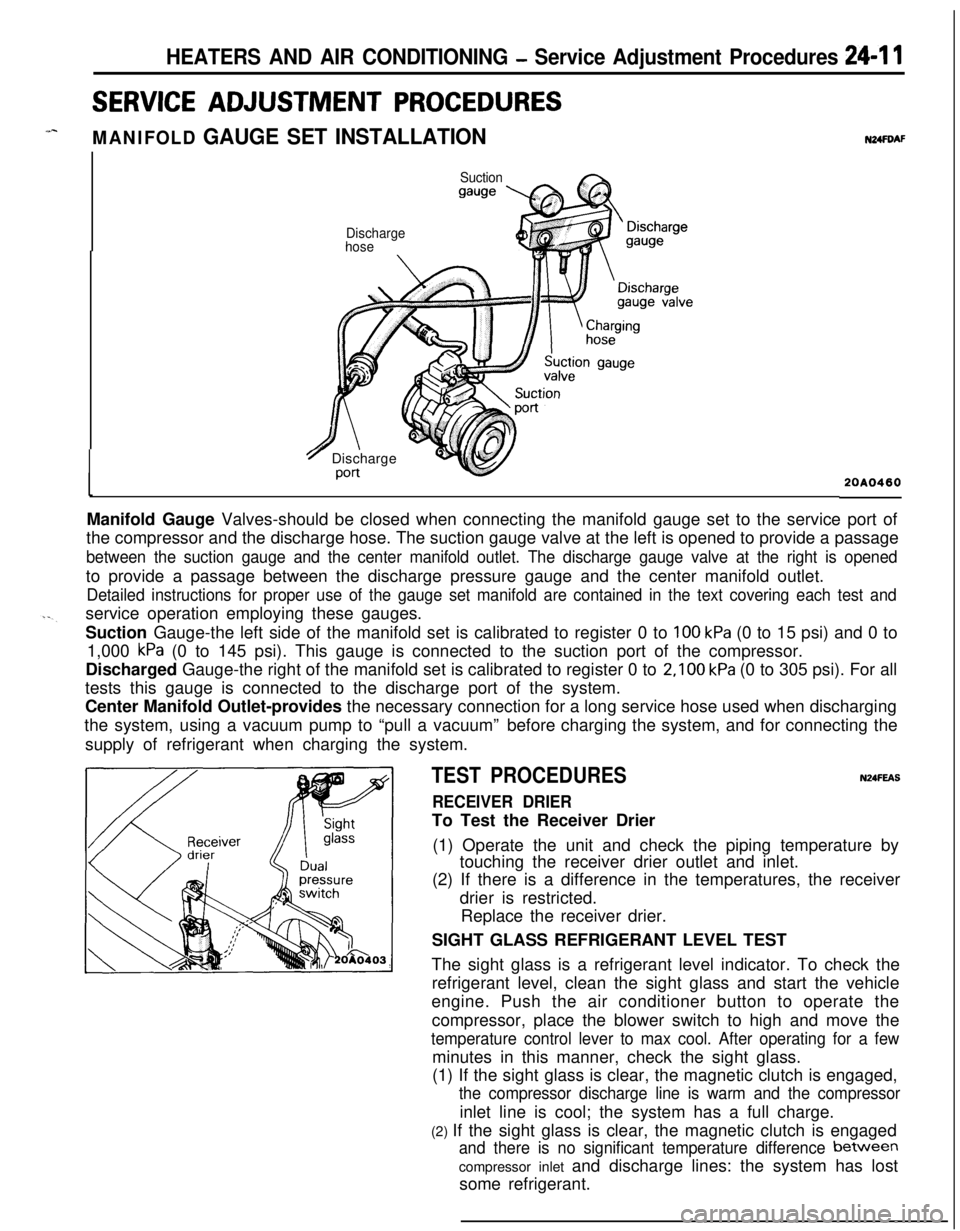

MANIFOLD GAUGE SET INSTALLATION

Suction

gauge

N24FDAF

Discharge

hose

7 Discharge

Port20A0460Manifold Gauge Valves-should be closed when connecting the manifold gauge set to the service port of

the compressor and the discharge hose. The suction gauge valve at the left is opened to provide a passage

between the suction gauge and the center manifold outlet. The discharge gauge valve at the right is openedto provide a passage between the discharge pressure gauge and the center manifold outlet.

Detailed instructions for proper use of the gauge set manifold are contained in the text covering each test andservice operation employing these gauges.

Suction Gauge-the left side of the manifold set is calibrated to register 0 to

100 kPa (0 to 15 psi) and 0 to

1,000

kPa (0 to 145 psi). This gauge is connected to the suction port of the compressor.

Discharged Gauge-the right of the manifold set is calibrated to register 0 to

2,100 kPa (0 to 305 psi). For all

tests this gauge is connected to the discharge port of the system.

Center Manifold Outlet-provides the necessary connection for a long service hose used when discharging

the system, using a vacuum pump to “pull a vacuum”before charging the system, and for connecting the

supply of refrigerant when charging the system.

TEST PROCEDURESN24FEAS

RECEIVER DRIERTo Test the Receiver Drier

(1) Operate the unit and check the piping temperature by

touching the receiver drier outlet and inlet.

(2) If there is a difference in the temperatures, the receiver

drier is restricted.

Replace the receiver drier.

SIGHT GLASS REFRIGERANT LEVEL TEST

The sight glass is a refrigerant level indicator. To check the

refrigerant level, clean the sight glass and start the vehicle

engine. Push the air conditioner button to operate the

compressor, place the blower switch to high and move the

temperature control lever to max cool. After operating for a fewminutes in this manner, check the sight glass.

(1) If the sight glass is clear, the magnetic clutch is engaged,

the compressor discharge line is warm and the compressorinlet line is cool; the system has a full charge.

(2) If the sight glass is clear, the magnetic clutch is engaged

and there is no significant temperature difference between

compressor inlet and discharge lines: the system has lost

some refrigerant.

Page 1156 of 1216

24-12 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

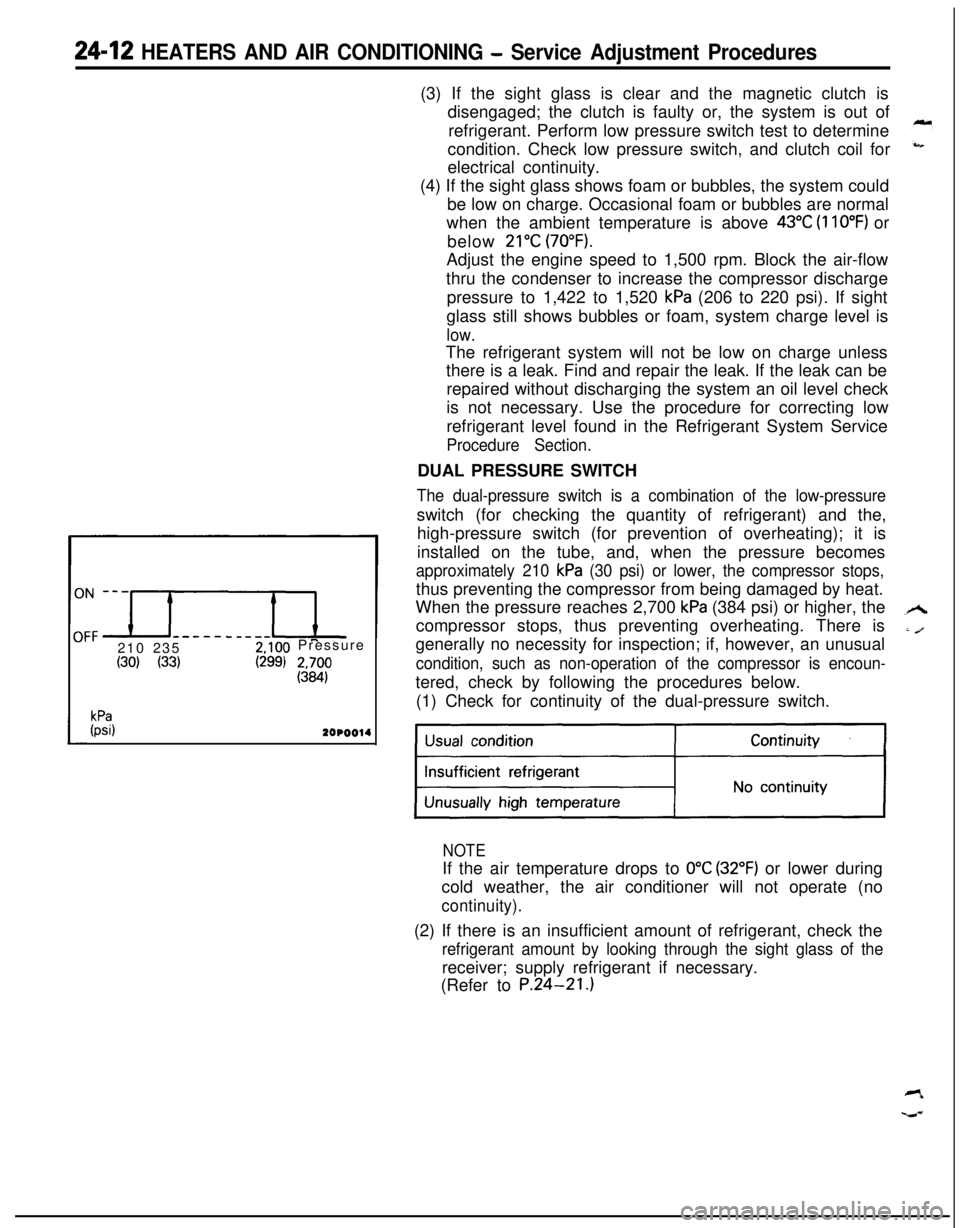

------__--210 2352,100 Pressure

(30) (33)(299) 2&

kPa(psi)2OPOO14(3) If the sight glass is clear and the magnetic clutch is

disengaged; the clutch is faulty or, the system is out of

refrigerant. Perform low pressure switch test to determine

condition. Check low pressure switch, and clutch coil for

electrical continuity.

(4) If the sight glass shows foam or bubbles, the system could

be low on charge. Occasional foam or bubbles are normal

when the ambient temperature is above

43°C (110°F) or

below

21°C (70°F).Adjust the engine speed to 1,500 rpm. Block the air-flow

thru the condenser to increase the compressor discharge

pressure to 1,422 to 1,520

kPa (206 to 220 psi). If sight

glass still shows bubbles or foam, system charge level is

low.The refrigerant system will not be low on charge unless

there is a leak. Find and repair the leak. If the leak can be

repaired without discharging the system an oil level check

is not necessary. Use the procedure for correcting low

refrigerant level found in the Refrigerant System Service

Procedure Section.DUAL PRESSURE SWITCH

The dual-pressure switch is a combination of the low-pressureswitch (for checking the quantity of refrigerant) and the,

high-pressure switch (for prevention of overheating); it is

installed on the tube, and, when the pressure becomes

approximately 210 kPa (30 psi) or lower, the compressor stops,thus preventing the compressor from being damaged by heat.

When the pressure reaches 2,700

kPa (384 psi) or higher, the

compressor stops, thus preventing overheating. There is

generally no necessity for inspection; if, however, an unusual

condition, such as non-operation of the compressor is encoun-tered, check by following the procedures below.

(1) Check for continuity of the dual-pressure switch.

NOTEIf the air temperature drops to

0°C (32°F) or lower during

cold weather, the air conditioner will not operate (no

continuity).(2) If there is an insufficient amount of refrigerant, check the

refrigerant amount by looking through the sight glass of thereceiver; supply refrigerant if necessary.

(Refer to P.24-21.)

Page 1161 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-Q

ilectric leakletector tester

2OUO333

40°C(I 04°F)20A0463

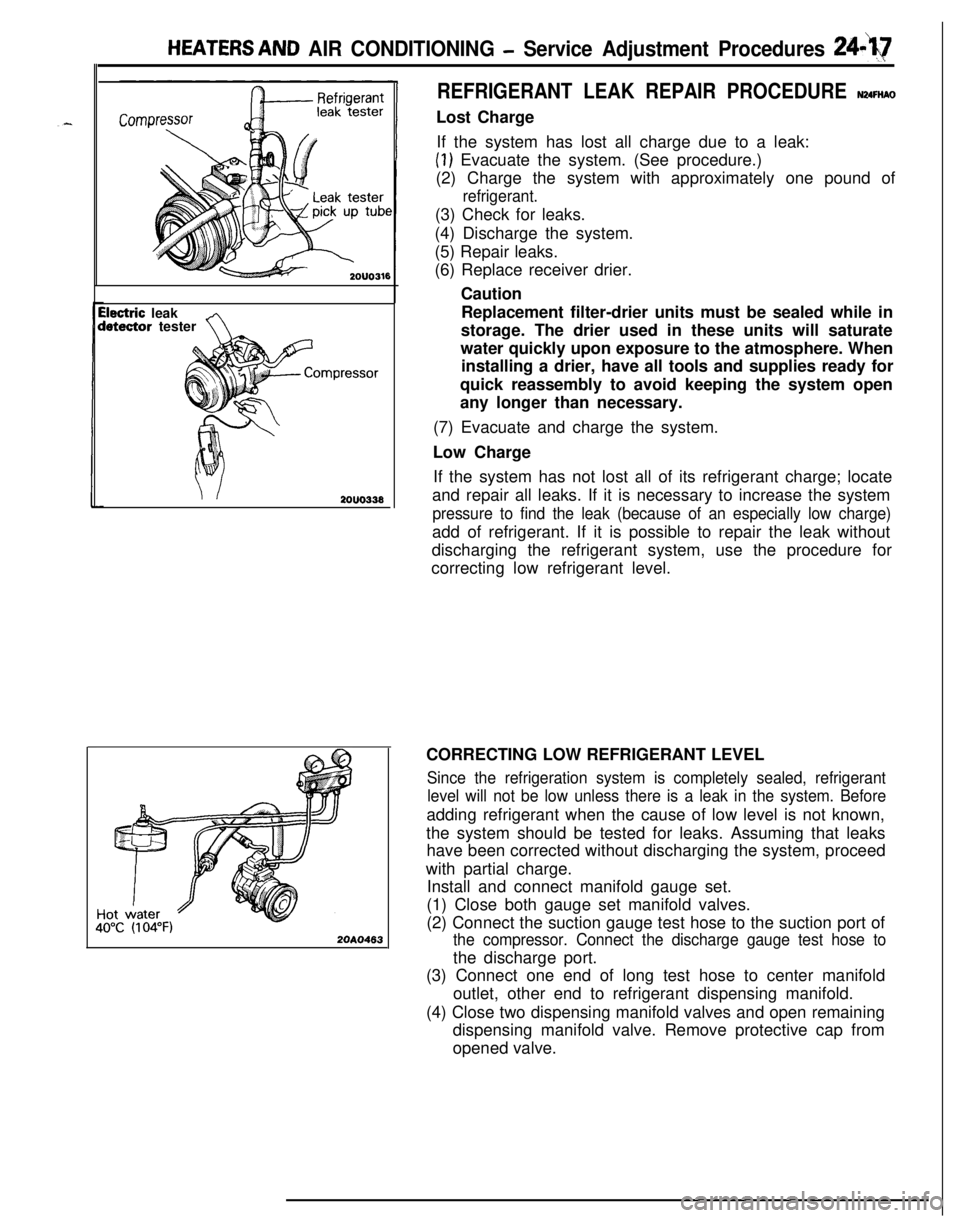

REFRIGERANT LEAK REPAIR PROCEDURE N24FtiAOLost Charge

If the system has lost all charge due to a leak:

(1) Evacuate the system. (See procedure.)

(2) Charge the system with approximately one pound of

refrigerant.(3) Check for leaks.

(4) Discharge the system.

(5) Repair leaks.

(6) Replace receiver drier.

Caution

Replacement filter-drier units must be sealed while in

storage. The drier used in these units will saturate

water quickly upon exposure to the atmosphere. When

installing a drier, have all tools and supplies ready for

quick reassembly to avoid keeping the system open

any longer than necessary.

(7) Evacuate and charge the system.

Low Charge

If the system has not lost all of its refrigerant charge; locate

and repair all leaks. If it is necessary to increase the system

pressure to find the leak (because of an especially low charge)add of refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the procedure for

correcting low refrigerant level.

CORRECTING LOW REFRIGERANT LEVEL

Since the refrigeration system is completely sealed, refrigerant

level will not be low unless there is a leak in the system. Beforeadding refrigerant when the cause of low level is not known,

the system should be tested for leaks. Assuming that leaks

have been corrected without discharging the system, proceed

with partial charge.

Install and connect manifold gauge set.

(1) Close both gauge set manifold valves.

(2) Connect the suction gauge test hose to the suction port of

the compressor. Connect the discharge gauge test hose tothe discharge port.

(3) Connect one end of long test hose to center manifold

outlet, other end to refrigerant dispensing manifold.

(4) Close two dispensing manifold valves and open remaining

dispensing manifold valve. Remove protective cap from

opened valve.

Page 1162 of 1216

24-18 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

(5) Screw a can of R-12 to the opened manifold valve. Be sure

gasket is in place and in good condition. Tighten refrigerantcan and manifold locking nut to insure a good seal. Do not

overtighten 8 to

11 Nm (6 to 8 ft.lbs.) is sufficient if gasket

is in good condition.

(6) Turn manifold valve (above the refrigerant can) completely

clockwise to puncture the can. This closes the valve and

seals the refrigerant in the can.

Caution

Never heat small cans of refrigerant over

40°C (104°F)as they may explode.

(7) Place the refrigerant in a large pan of water heated to 52°C

(104°F). Place pan of water containing the refrigerant can

on an accurate scale so the amount of refrigerant added

can be weighed. Open the refrigerant manifold valve.

(8) Purge all air from test hoses. Air in the system will be

trapped in the condenser causing abnormally high dis-

charge pressures and interfering with condensing of the

refrigerant.(9) Slightly loosen both test hoses at the gauge set manifold.

Tighten the hoses as soon as the air is purged.

(10)Slightly loosen charging hose connection at gauge set

manifold. This will purge air from the charging hose.

Tighten connection as soon as air is purged.

(I l)With vehicle windows open and hood up, operate engine at1,500 rpm and jump the low pressure switch terminals

located on the receiver drier so the clutch will remain

engaged.

(12)Place air conditioner control on air conditioner and place theblower switch on high.

(13)lf necessary, block the condenser to maintain a discharge

pressure of 1,422 to 1,520

kPa (206 to 220 psi). System

must be charged through the evaporator suction service

ports as follows:

(a) Slowly open the suction service gauge valve.

Meter flow of refrigerant by adjusting, the suciton

service gauge valve so that pressure registered at the

suction service gauge does not exceed 345 kPa (50 psi).Keep refrigerant container upright.

(b) Add refrigerant gas until there is no foam visible at the

sight glass.

Add an additional

170 g (6 oz.)

(c) Close the suction gauge valve.

CautionToo much refrigerant in the system can cause

abnormally high discharge pressures. Care must beused so that the exact recommended amount or

refrigerant is added after foam clears in the sight

glass.(d) Close dispensing manifold valve. Remove test hoses

and adapters from the service ports of compressor,

install protective caps at service ports and reconnect

wiring.(e) Check system performance.

(P.24- 16.)

e

. i”

A

i-4

Page 1163 of 1216

-.

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 241$19Oil collector can

2OAO464DISCHARGING SYSTEM

Since the air conditioning refrigerant system is pressurized, it

will be necessary to completely discharge the system (in a wellventilated area) before replacing any refrigerant component.

The procedure is as follows:

(1) Install manifold gauge set. Make sure the gauge set valves

are closed before attaching the hoses to the refrigerant

system.(2) Install a long hose to the manifold gauge set connector.

Run this hose to the oil collector can near a shop exhaust

system.A good oil collector can may be made from a large empty

coffee can with a plastic top. Slit the plastic top in the formof a

Y to make an entrance for the refrigerant hose and an

exit for the gas.

(3) Open the compressor discharge and suction line pressure

valves and blow the refrigerant into the oil collector can.

Watch to make sure the hose does not blow out of the

collector can.

(4) When the system has been completely discharged, mea-

sure the amount of oil collected in the can. The amount of

oil measured should be added to the refrigerant system

before it is re-charged. Add new oil-discard the used oil.

CautionIt is important to have the correct amount of oil in the

refrigerant system.

Too little oil will provide inadequate compressor lubrication

and cause a compressor failure. Too much oil will increasedischarge air temperature.

When a IOPAI 7 compressor is installed at the factory, it

contains 80 cc (4.8

cu.in.) of refrigerant oil. While the air

conditioning system is in operation, the oil is carried

through the entire system by the refrigerant.

Some of this oil will be trapped and retained in various partsof the system.

When the following system components are changed, it is

necessary to add oil to the system to replace the oil being

removed with the component.

Compressor:30 cc (1.8 cu.in.1

Condenser:20 cc (1.2 cu.in.1

Evaporator:30 cc (1.8 cu.in.)

Piping:10 cc (.6 cu.in.1Receiver drier: 10 cc

(.6 cu.in.1