mileage MITSUBISHI ECLIPSE 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 230 of 1216

5-90BRAKES - Parking Brakes

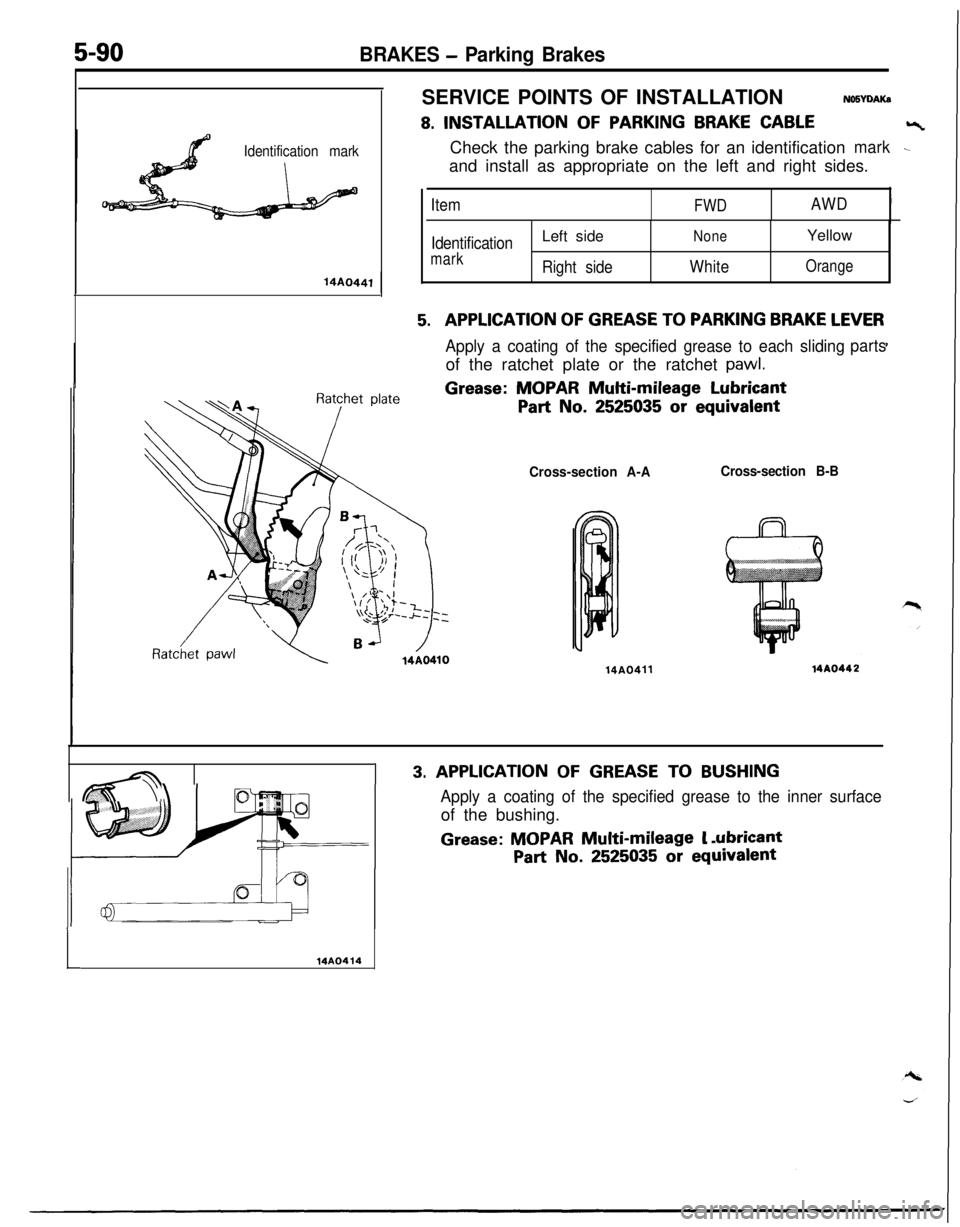

Identification markSERVICE POINTS OF INSTALLATION

NO!iYDAKa

8. INSTALLATION OF PARKING BRAKE CABLECheck the parking brake cables for an identification

markand install as appropriate on the left and right sides.

ItemFWDAWDI

IdentificationLeft sideNoneYellow

markRight sideWhiteOrange

5.APPLICATION OF GREASE TO PARKING BRAKE LEVER

Apply a coating of the specified grease to each slidingpartsof the ratchet plate or the ratchet

pawl.

Grease: MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

Cross-section A-ACross-section B-B

14A041114AO442

&=4--

13. APPLICATION OF GREASE TO BUSHING

Apply a coating of the specified grease to the inner surfaceof the bushing.

Grease: MOPAR Multi-mileage 1 lhifinnt

Part No. 2525035 or eq

._I. ..v-.--uivalent

114A0414

Page 233 of 1216

CLUTCH - Specifications/Special Tool6-3

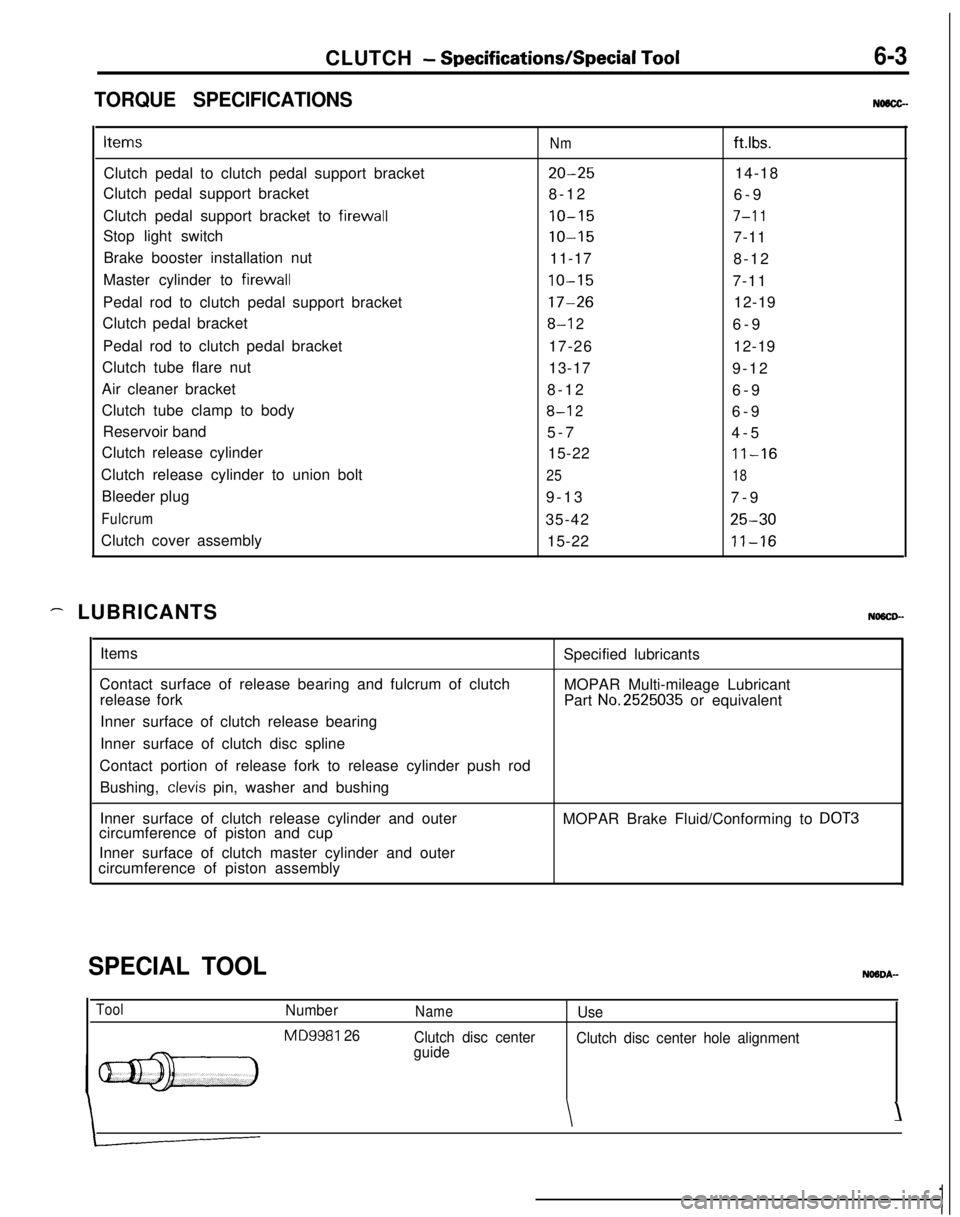

TORQUE SPECIFICATIONSNMCC-Items

Nmftlbs.Clutch pedal to clutch pedal support bracket

20-2514-18

Clutch pedal support bracket

8-12

6-9

Clutch pedal support bracket to firewall

10-157-l 1Stop light switch

10-157-11

Brake booster installation nut

11-17

8-12

Master cylinder to firewall

10-157-11

Pedal rod to clutch pedal support bracket

17-2612-19

Clutch pedal bracket

8-l 26-9

Pedal rod to clutch pedal bracket

17-2612-19

Clutch tube flare nut

13-17

9-12

Air cleaner bracket

8-12

6-9

Clutch tube clamp to body

8-l 26-9

Reservoir band

5-7

4-5

Clutch release cylinder

15-22

11-16Clutch release cylinder to union bolt

2518Bleeder plug

9-13

7-9

Fulcrum35-4225-30Clutch cover assembly

15-22

11-16

- LUBRICANTSNOSCD-Items

Contact surface of release bearing and fulcrum of clutch

release fork

Inner surface of clutch release bearing

Inner surface of clutch disc splineSpecified lubricants

MOPAR Multi-mileage Lubricant

Part

No.2525035 or equivalent

Contact portion of release fork to release cylinder push rod

Bushing,

clevis pin, washer and bushing

Inner surface of clutch release cylinder and outer

circumference of piston and cupMOPAR Brake Fluid/Conforming to

DOT3Inner surface of clutch master cylinder and outer

circumference of piston assembly

SPECIAL TOOL

ToolNumber

MD9981 26

NameUse

Clutch disc center

guideClutch disc center hole alignment

\\

Page 238 of 1216

6-8CLUTCH - Clutch PedalOhmmeter

OBAOO40OLIA0039

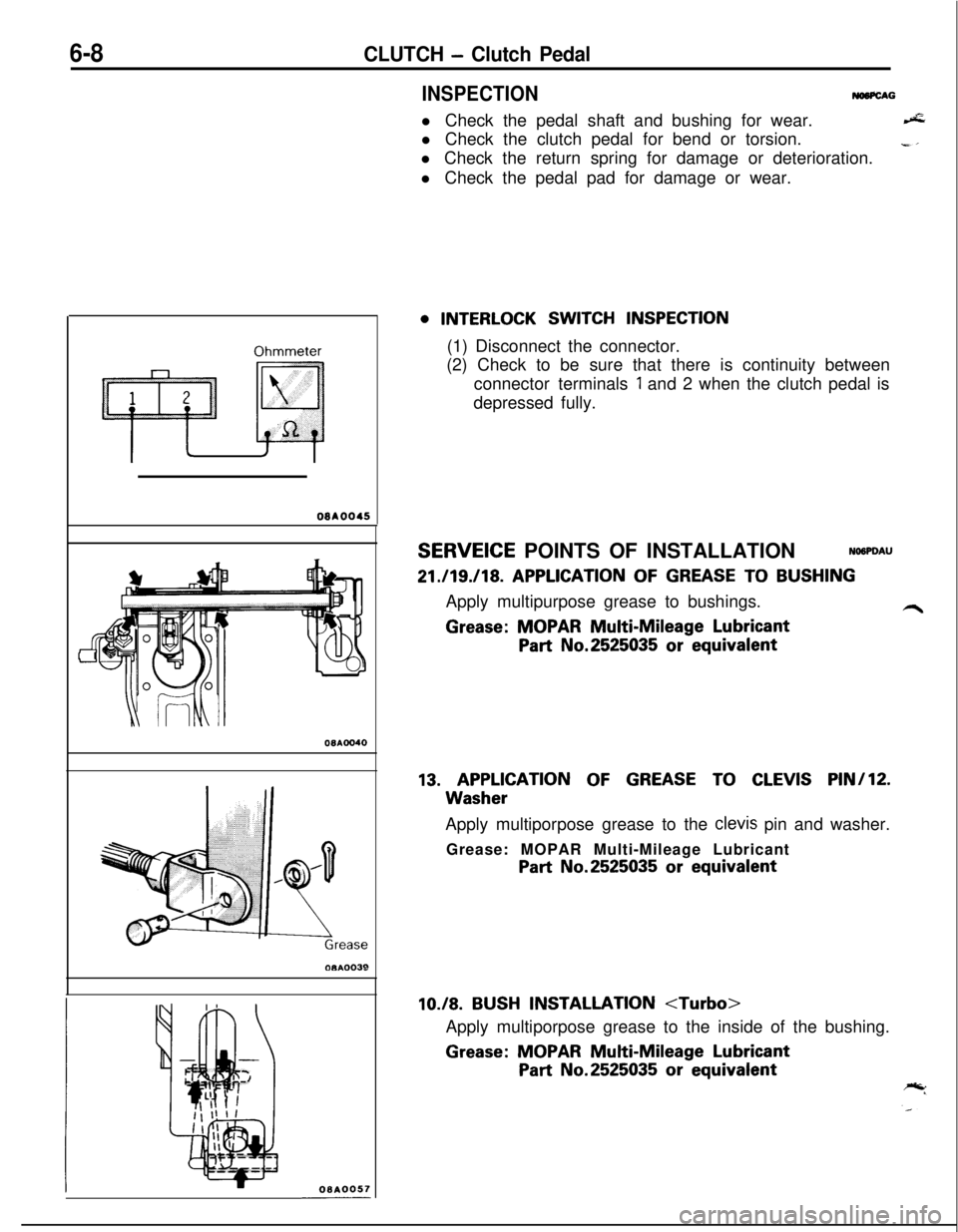

INSPECTIONNWFCAG

l Check the pedal shaft and bushing for wear.

Al Check the clutch pedal for bend or torsion.

-’l Check the return spring for damage or deterioration.

l Check the pedal pad for damage or wear.

. INTERLOCK SWITCH INSPECTION(1) Disconnect the connector.

(2) Check to be sure that there is continuity between

connector terminals

1 and 2 when the clutch pedal is

depressed fully.

SERVEICE POINTS OF INSTALLATIONNOWDAU21./19./18.

APPLICATION OF GREASE TO BUSHING

Apply multipurpose grease to bushings.

+%

Grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

13. APPLICATION OF GREASE TO CLEVIS PIN/12.

WasherApply multiporpose grease to the

clevis pin and washer.

Grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

10./8. BUSH INSTALLATION

Grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

Page 240 of 1216

640CLUTCH - Clutch Control

3

~~~ --Clutch tube

TI)

%5

/Hose clip

Clutch hose

Secure side

08W507

Grease09AOO39

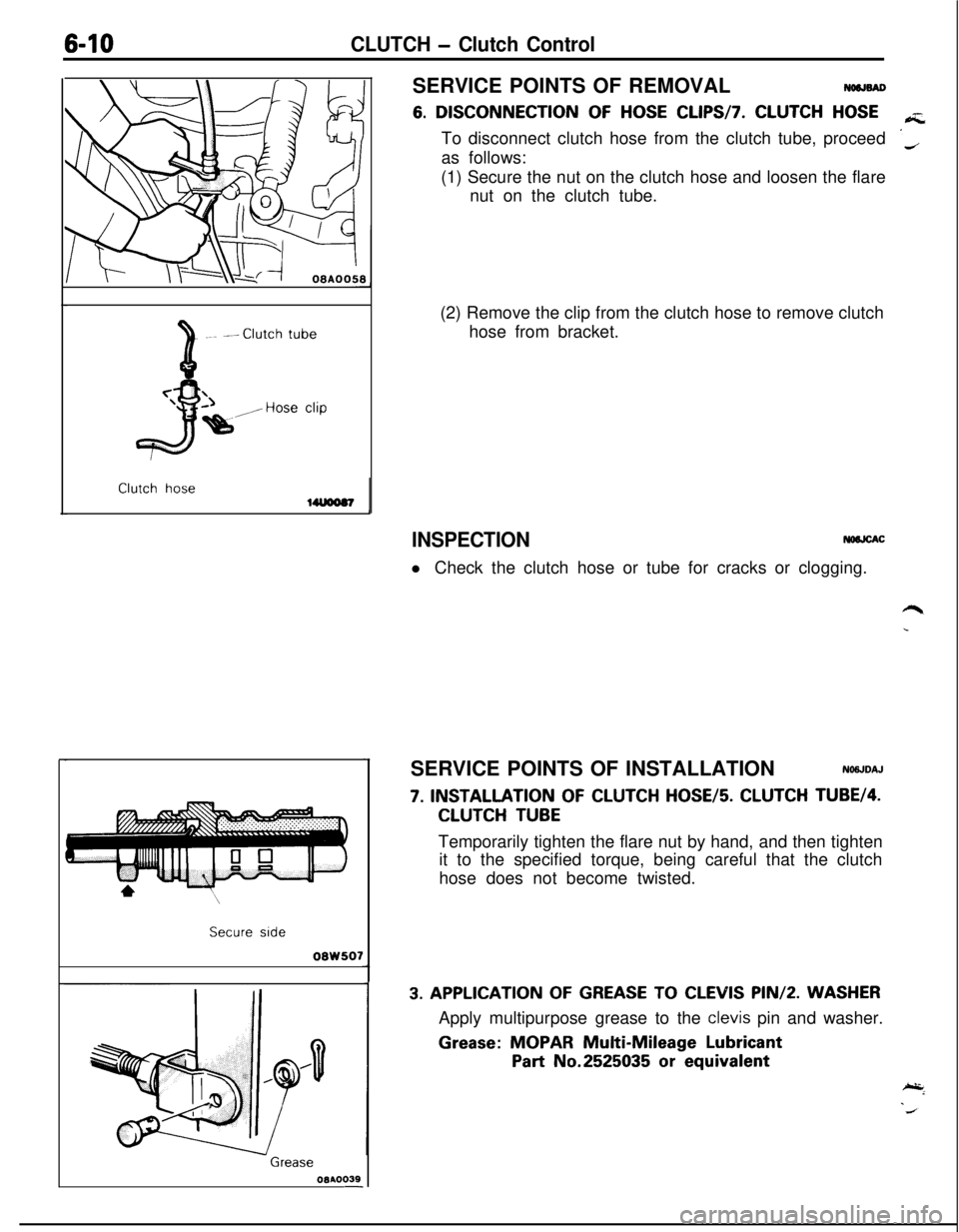

-SERVICE POINTS OF REMOVAL

Na9JMD

6. DISCONNECTION OF HOSE CLIPSI7. CLUTCH HOSETo disconnect clutch hose from the clutch tube, proceed

as follows:

(1) Secure the nut on the clutch hose and loosen the flare

nut on the clutch tube.

(2) Remove the clip from the clutch hose to remove clutch

hose from bracket.

INSPECTIONNO9JCACl Check the clutch hose or tube for cracks or clogging.

SERVICE POINTS OF INSTALLATIONNO6JDAJ

7. INSTALLATION OF CLUTCH HOSE/S. CLUTCH TUBE/4.

CLUTCH TUBETemporarily tighten the flare nut by hand, and then tighten

it to the specified torque, being careful that the clutch

hose does not become twisted.

3. APPLICATION OF GREASE TO CLEVIS PIN/2. WASHERApply multipurpose grease to the

clevis pin and washer.

Grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

Page 243 of 1216

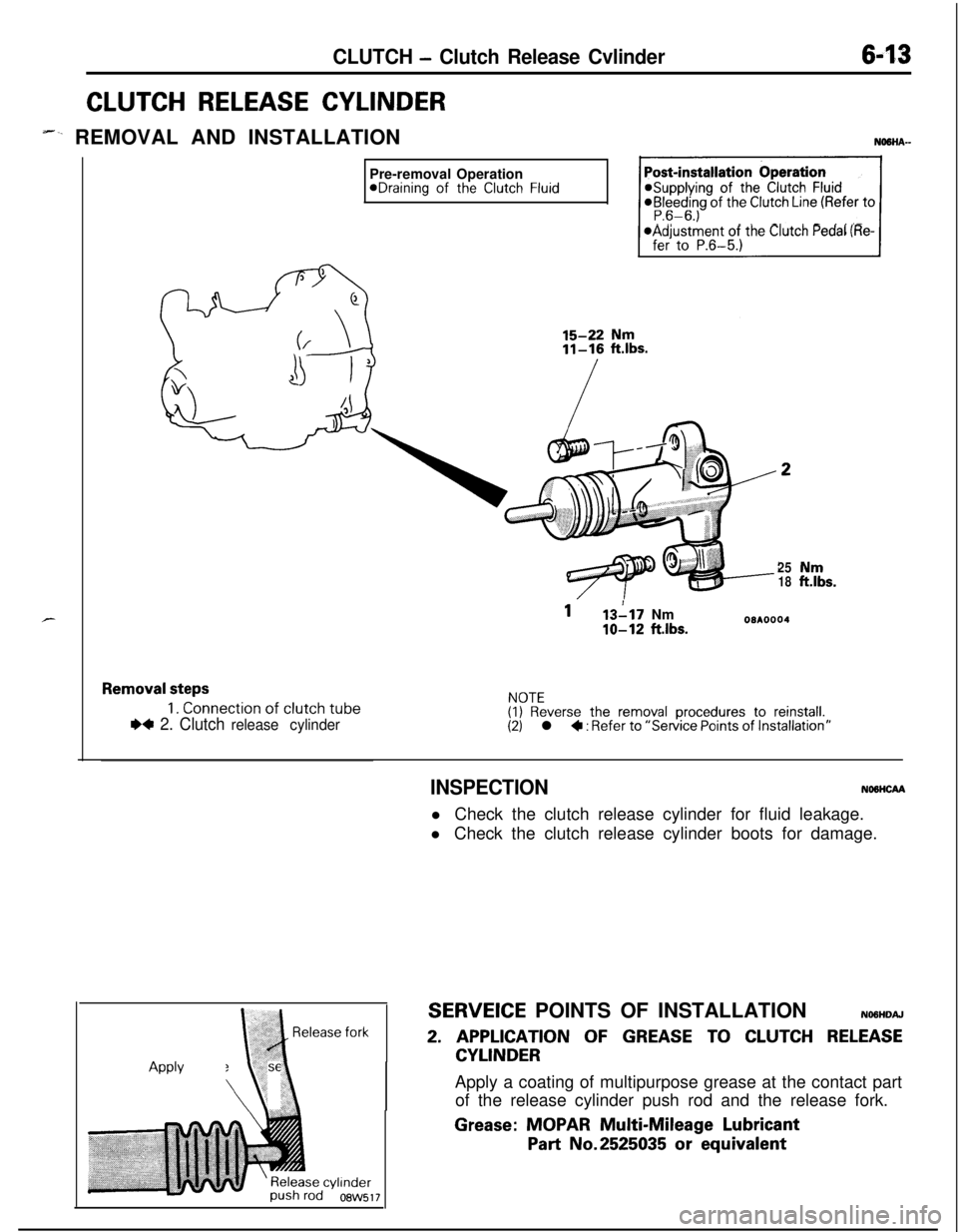

CLUTCH - Clutch Release Cvlinder6-13

CLUTCH RELEASE CYLINDER

-‘- REMOVAL AND INSTALLATIONNaaHA--Pre-removal Operation

@Draining of the Clutch Fluid@Supplying of the Clutch Fluid@Bleeding of the Clutch Line (Refer to

@Adjustment of the Clutch Pedal (Re-

2518EL.

113117 Nm

IO-12 ftlbs.08A0004

Removal steps

1. Connection of clutch tube

I)4 2. Clutch release cylinder

NOTE(I) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Installation”

INSPECTIONNOMCAAl Check the clutch release cylinder for fluid leakage.

l Check the clutch release cylinder boots for damage.

SERVEICE POINTS OF INSTALLATIONNO6HDAJ

2. APPLICATION OF GREASE TO CLUTCH RELEASE

CYLINDERApply grease

\\ :\Apply a coating of multipurpose grease at the contact part

of the release cylinder push rod and the release fork.

Grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

Page 248 of 1216

6-18CLUTCH - Clutch Cover and Disc

I6CLO33

Clutch disc

T& assemblyClutch cover

6CLO26

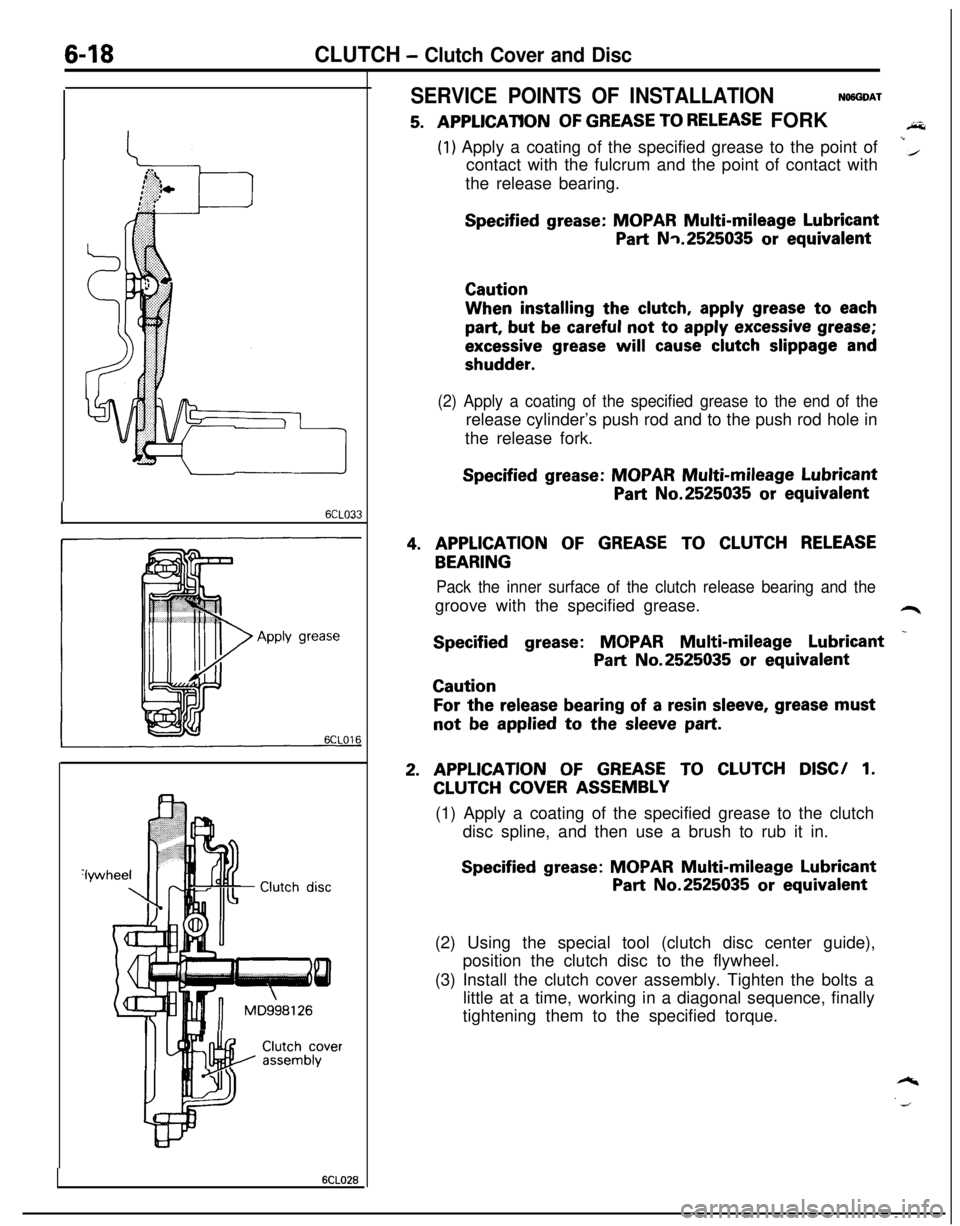

SERVICE POINTS OF INSTALLATIONNWGDAT

5. A,PPLlCATlONOF GREASE TO RELEASE FORKAi&

(1) Apply a coating of the specified grease to the point of

contact with the fulcrum and the point of contact withi(the release bearing.

Specified grease: MOPAR Multi-mileage Lubricant

Part Nq.2525035 or equivalentCautionWhen installing the

clutch, apply grease to each

part, but be careful not to apply excessive grease;

excessive grease will cause clutch slippage and

shudder.

(2) Apply a coating of the specified grease to the end of therelease cylinder’s push rod and to the push rod hole in

the release fork.

Specified grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

4. APPLICATION OF GREASE TO CLUTCH RELEASE

BEARING

Pack the inner surface of the clutch release bearing and thegroove with the specified grease.

L4r

Specified grease: MOPAR Multi-mileage Lubricant _

Part No.2525035 or equivalentCaution

For the release bearing of a resin sleeve, grease mustnot

be applied to the sleeve part.

2. APPLICATION OF GREASE TO CLUTCH DISC/ 1.

CLUTCH COVER ASSEMBLY

(1) Apply a coating of the specified grease to the clutch

disc spline, and then use a brush to rub it in.

Specified grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

(2) Using the special tool (clutch disc center guide),

position the clutch disc to the flywheel.

(3) Install the clutch cover assembly. Tighten the bolts a

little at a time, working in a diagonal sequence, finally

tightening them to the specified torque.

Page 463 of 1216

FUEL SYSTEM - Troubleshooting14-S

Symptom

Poor fuel mileage,

Probable cause

Trouble In the MPI system

Remedy

Check for output of self-diagnosis

code.Read the code with a voltmeter.Malfunction

of the sensorl Intake air temperature sensorl Engine coolant temperature sensorl Barometric pressure sensorl Ignition switchl Idle position switch

l Throttle position sensorl No. 1 cylinder TDC sensor, crank angle sensor

Check the sensor-related circuit.Check the sensor as a single unit.

l TDC sensor, crank angle sensor<2.0L DOHC Engine>

l Power steering oil pressure switch

l Air conditioner switch

l lnhrbrtor switch l Motor

position sensor

l Air flow sensor

0 Oxygen sensor

Malfunction of the engine control system

l Stepper motor <2.0L DOHC Engine>

0 Injector0 Power transistor

Check the actuator-related circurt.Check the actuator as a single unit.

The fuel pressure is not proper.Check the fuel pressure.

Page 559 of 1216

ENGINE CONTROL - SpecificatiodTroubleshooting

ENGINE CONTROL

-.

SPECIFICATIONS

SERVICE SPECIFICATIONSN14CEA

Items

Standard value

Accelerator cable playmm (in.)

dfi>

Accelerator switch switching pointmm (in.)Specifications

1-2 (.04-.08)

3-5 (.12-.20)

2-6 (.08-.24)

N14CkATORQUE SPECIFICATIONS

Items

Accelerator arm bracket to body

Throttle body side inner cable to air intake plenum

Accelerator arm side inner cable to body

Nmft.lbs.

8-126-9

4-63-4

4-63-4

I

: j,

LUBRICANTS_-

Items

Accelerator arm and return spring

Specified lubricants

MOPAR Multi-mileage Lubricant Part No.2525035

or equivalentQuantityAs required

SEALANTN14CE.-BItems

I-- ~Accelerator arm bracket

Specified sealant

I3M ATD Part No.8663 or equivalentI

-.

TROUBLESHOOTINGN14EGABa

ACCELERATOR CABLE AND ACCELERATOR PEDAL

Symptom

Throttle valve will notfully

open or close

Probable causeRemedyMisadjusted

accelerator cableMisadjusted automatic

speed-control cableAdjust

Broken return springThrottle

lever malfunctionReplace

Accelerator pedaloperation not smooth(over acceleration)

Accelerator pedal wrongly tightenedMisinstalled

accelerator cable

Accelerator cable requires lubrication

Repair

Lubricate or replace

Page 562 of 1216

14-108ENGINE CONTROL - Engine Control

INSPECTION

j N%PJCf@l Check the inner and outer cable for damage.

l Check the cable for smooth movement.$+

l Check the accelerator arm for bending.--

l Check the return spring for deterioration.

l Check the connection of bushing to end metal fitting.

l Check the accelerator switch for ON/OFF switching.

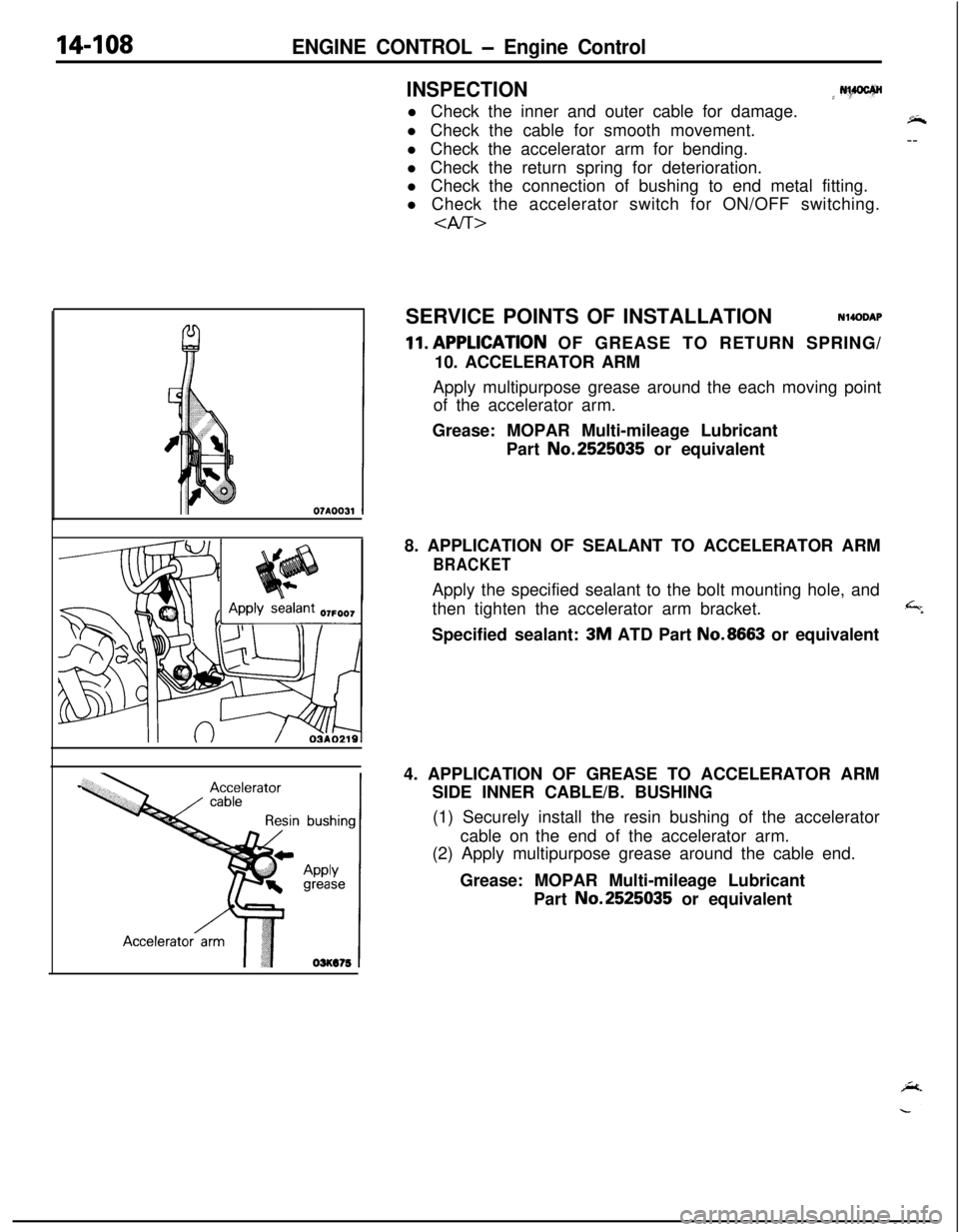

SERVICE POINTS OF INSTALLATIONN14DDAP

ll.APPLlCATlON OF GREASE TO RETURN SPRING/

10. ACCELERATOR ARM

Apply multipurpose grease around the each moving point

of the accelerator arm.

Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

8. APPLICATION OF SEALANT TO ACCELERATOR ARM

BRACKETApply the specified sealant to the bolt mounting hole, and

then tighten the accelerator arm bracket.

,%Specified sealant:

3M ATD Part No.8663 or equivalent

4. APPLICATION OF GREASE TO ACCELERATOR ARM

SIDE INNER CABLE/B. BUSHING

(1) Securely install the resin bushing of the accelerator

cable on the end of the accelerator arm.

(2) Apply multipurpose grease around the cable end.

Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

Page 599 of 1216

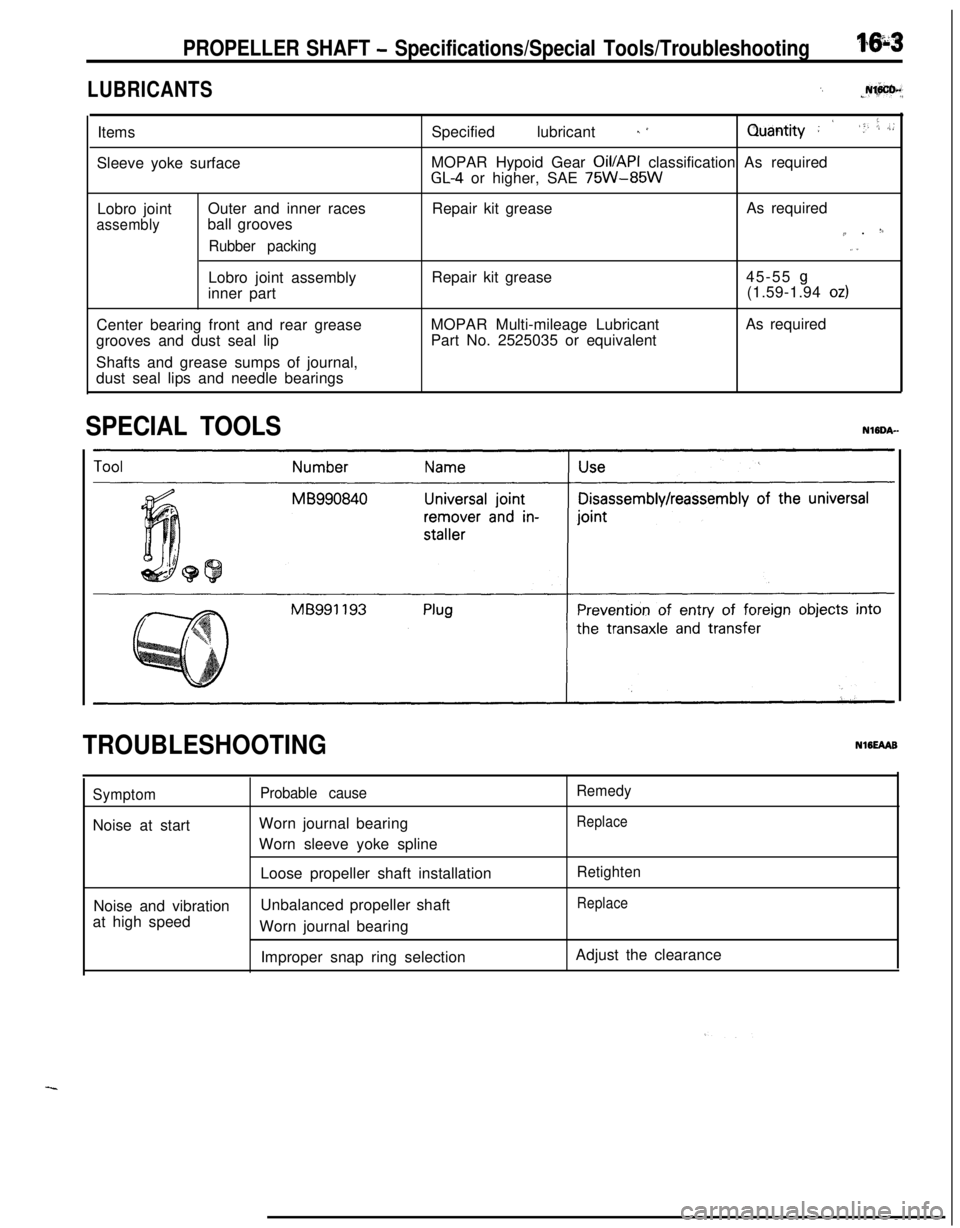

PROPELLER SHAFT - Specifications/Special Tools/Troubleshooting*(g&a

LUBRICANTS‘) wN$ii%.y,

Items

Sleeve yoke surfaceSpecified lubricant

h +Quafqtity ; ’‘I, ‘. ,b:MOPAR Hypoid Gear

Oil/API classification As required

GL-4 or higher, SAE 75W-85WLobro jointOuter and inner races

assemblyball grooves

Rubber packingLobro joint assembly

inner part

Center bearing front and rear grease

grooves and dust seal lip

Shafts and grease sumps of journal,

dust seal lips and needle bearingsRepair kit grease

Repair kit grease

MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalentAs required

,.. . ‘*

,^45-55

g(1.59-1.94 oz)As required

SPECIAL TOOLSNlBDA--

TROUBLESHOOTINGNWEAAB

SymptomNoise at start

Noise and vibration

at high speedProbable causeWorn journal bearing

Worn sleeve yoke spline

Loose propeller shaft installation

Unbalanced propeller shaft

Worn journal bearing

Improper snap ring selectionRemedy

Replace

Retighten

ReplaceAdjust the clearance