mileage MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 84 of 1216

2-36FRONT SUSPENSION - Lower Arm

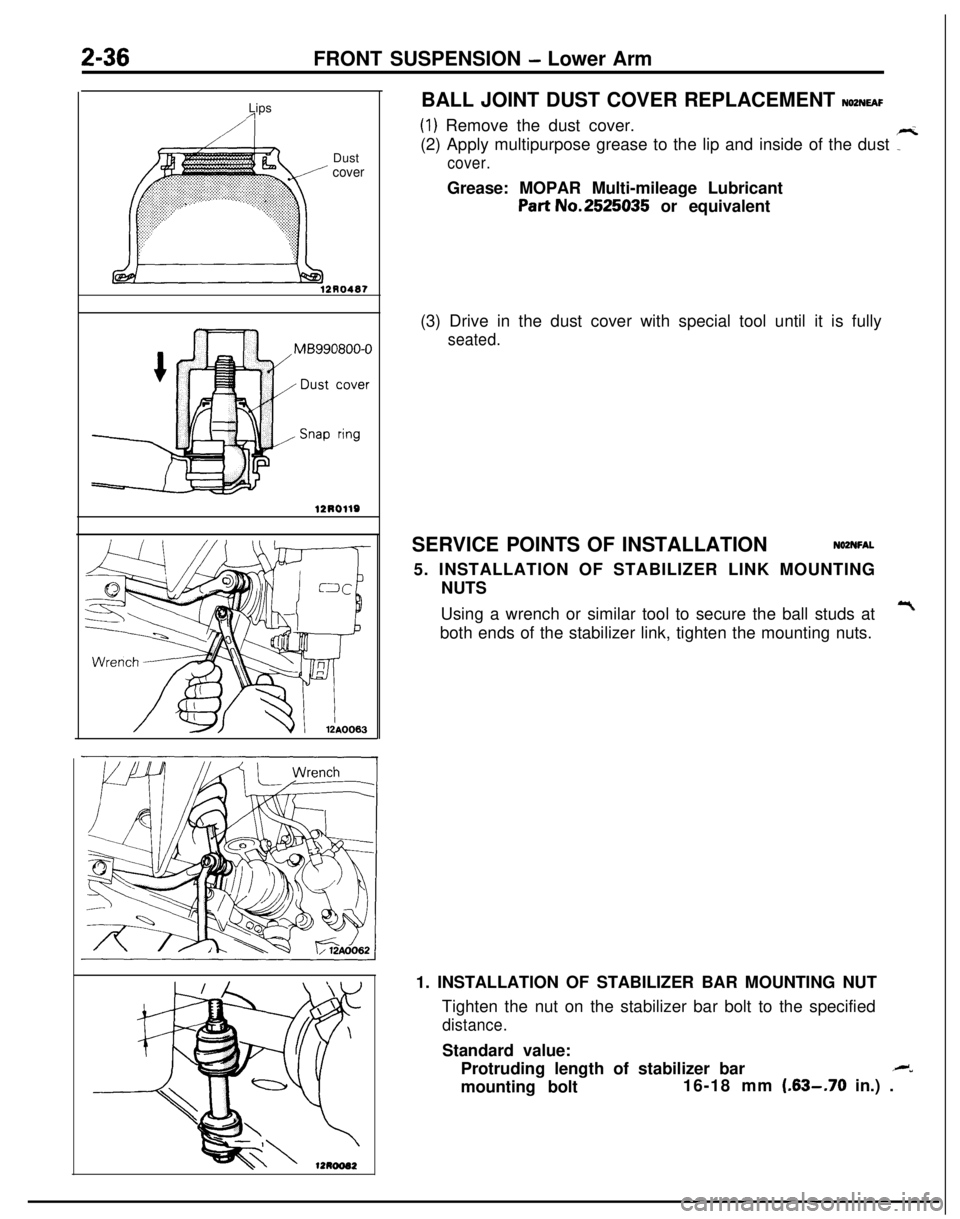

Lips

/IDust

cover

12R0487BALL JOINT DUST COVER REPLACEMENT

NOZNEAF

(1) Remove the dust cover.

(2) Apply multipurpose grease to the lip and inside of the dust

7

cover.Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

(3) Drive in the dust cover with special tool until it is fully

seated.SERVICE POINTS OF INSTALLATION

NOZNFAL5. INSTALLATION OF STABILIZER LINK MOUNTING

NUTS

Using a wrench or similar tool to secure the ball studs at

Tboth ends of the stabilizer link, tighten the mounting nuts.

1. INSTALLATION OF STABILIZER BAR MOUNTING NUT

Tighten the nut on the stabilizer bar bolt to the specified

distance.Standard value:

Protruding length of stabilizer bar

.M”mounting bolt16-18 mm

(.63-.70 in.) .

Page 88 of 1216

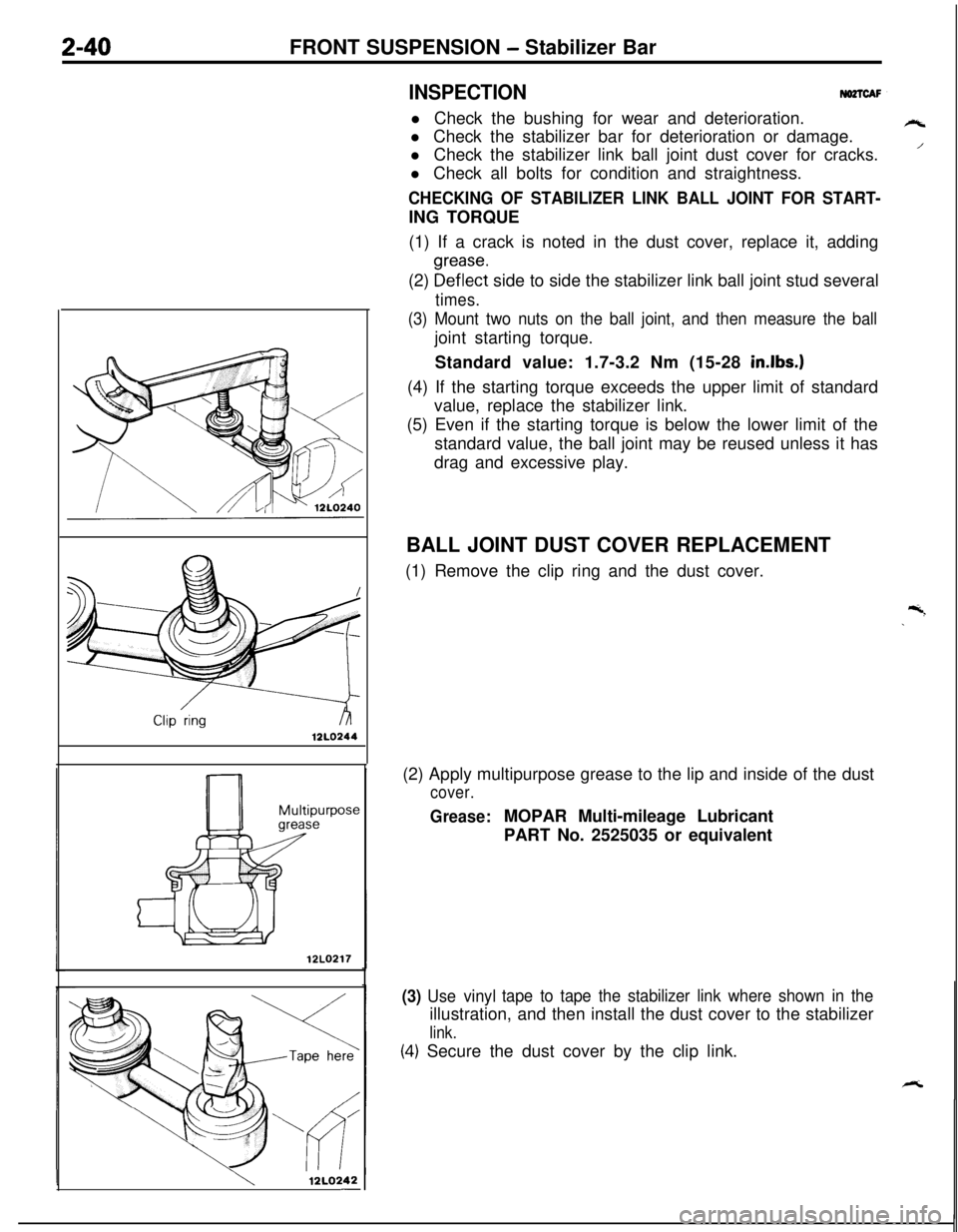

12LO244Z-40FRONT SUSPENSION - Stabilizer Bar

INSPECTIONNO2TCAFl Check the bushing for wear and deterioration.

l Check the stabilizer bar for deterioration or damage.

l Check the stabilizer link ball joint dust cover for cracks.

l Check all bolts for condition and straightness.

CHECKING OF STABILIZER LINK BALL JOINT FOR START-ING TORQUE

(1) If a crack is noted in the dust cover, replace it, adding

(2)

~~f~~~t side to side the stabilizer link ball joint stud several

times.

(3) Mount two nuts on the ball joint, and then measure the balljoint starting torque.

Standard value: 1.7-3.2 Nm (15-28

in.lbs.)(4) If the starting torque exceeds the upper limit of standard

value, replace the stabilizer link.

(5) Even if the starting torque is below the lower limit of the

standard value, the ball joint may be reused unless it has

drag and excessive play.

12LO217

12LQ242-BALL JOINT DUST COVER REPLACEMENT

(1) Remove the clip ring and the dust cover.

(2) Apply multipurpose grease to the lip and inside of the dust

cover.

Grease:MOPAR Multi-mileage Lubricant

PART No. 2525035 or equivalent

(3) Use vinyltape to tape the stabilizer link where shown in theillustration, and then install the dust cover to the stabilizer

link.

(4.) Secure the dust cover by the clip link.

rt

/

Page 105 of 1216

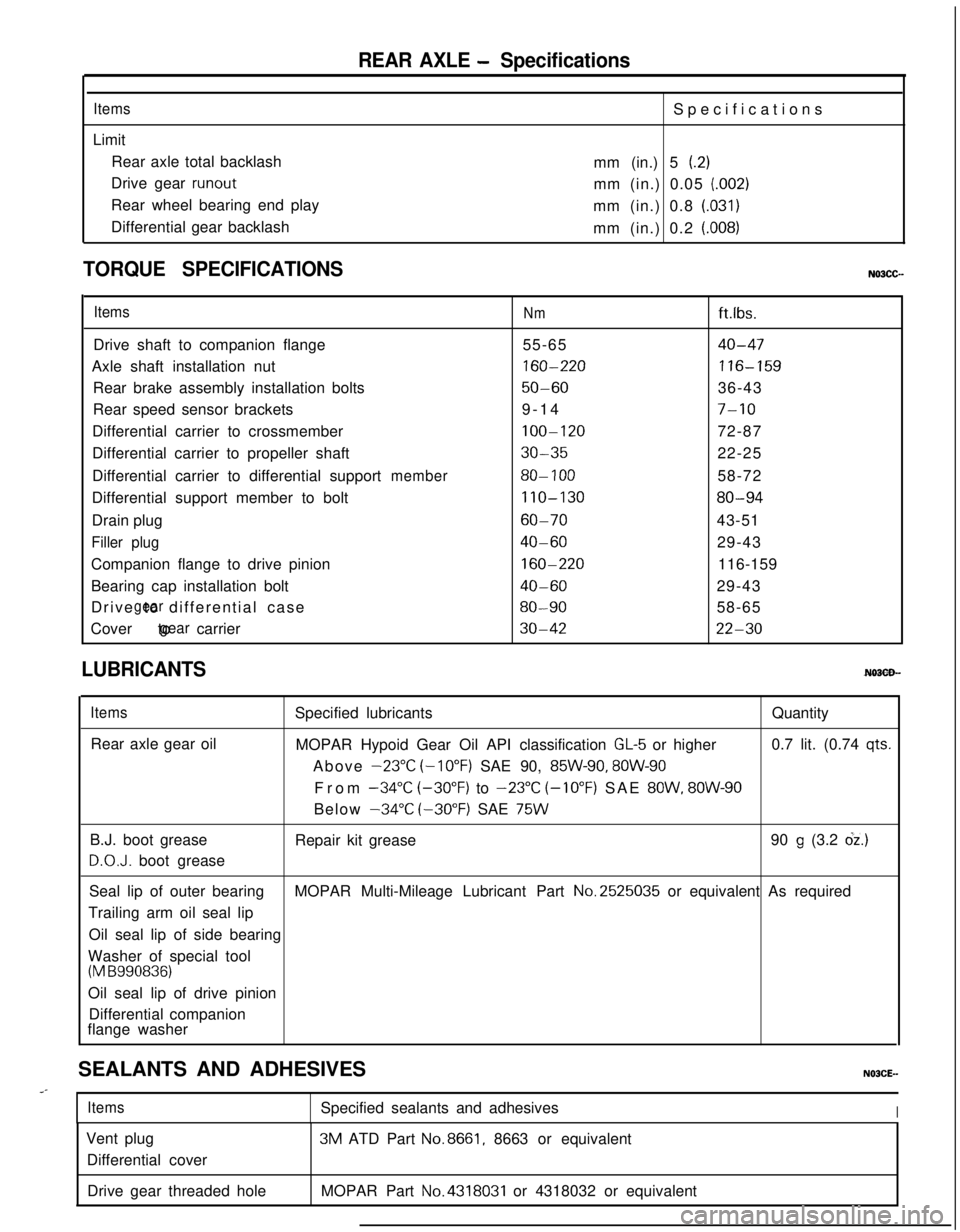

REAR AXLE - Specifications

ItemsLimit

Rear axle total backlash

Drive gear

runoutRear wheel bearing end play

Differential gear backlashSpecifications

mm (in.) 5

(.2)mm (in.) 0.05

(.002)mm (in.) 0.8

(.031)mm (in.) 0.2

(.008)

TORQUE SPECIFICATIONS

ItemsNmft.lbs.

Drive shaft to companion flange55-65

40-47Axle shaft installation nut

160-220116-159Rear brake assembly installation bolts

50-6036-43

Rear speed sensor brackets9-14

7-10Differential carrier to crossmember

100-12072-87

Differential carrier to propeller shaft

30-3522-25

Differential carrier to differential support

member80- 10058-72

Differential support member to bolt

110-13080-94Drain plug

60-7043-51

Filler plug40-6029-43

Companion flange to drive pinion

160-220116-159

Bearing cap installation bolt

40-6029-43

Drive to differential case

gear80-9058-65

Cover to carrier

gear30-4222-30

LUBRICANTS

ItemsRear axle gear oilSpecified lubricantsQuantity

MOPAR Hypoid Gear Oil API classification

GL-5 or higher0.7 lit. (0.74 qts.Above

-23°C (-10°F) SAE 90, 85W-90, 8OW-90From

-34°C (-30°F) to -23°C (-10°F) SAE 8OW, 8OW-90Below

-34°C (-30°F) SAE 75WB.J. boot grease

D.O.J. boot greaseRepair kit grease90

g (3.2 dz.)Seal lip of outer bearingMOPAR Multi-Mileage Lubricant Part No.2525035 or equivalent As required

Trailing arm oil seal lip

Oil seal lip of side bearing

Washer of special tool

(M B990836)Oil seal lip of drive pinion

Differential companion

flange washer

SEALANTS AND ADHESIVES

..-

ItemsSpecified sealants and adhesivesIVent plug

Differential cover3M ATD Part

No.8661, 8663 or equivalent

Drive gear threaded holeMOPAR Part

No.4318031 or 4318032 or equivalent

Page 114 of 1216

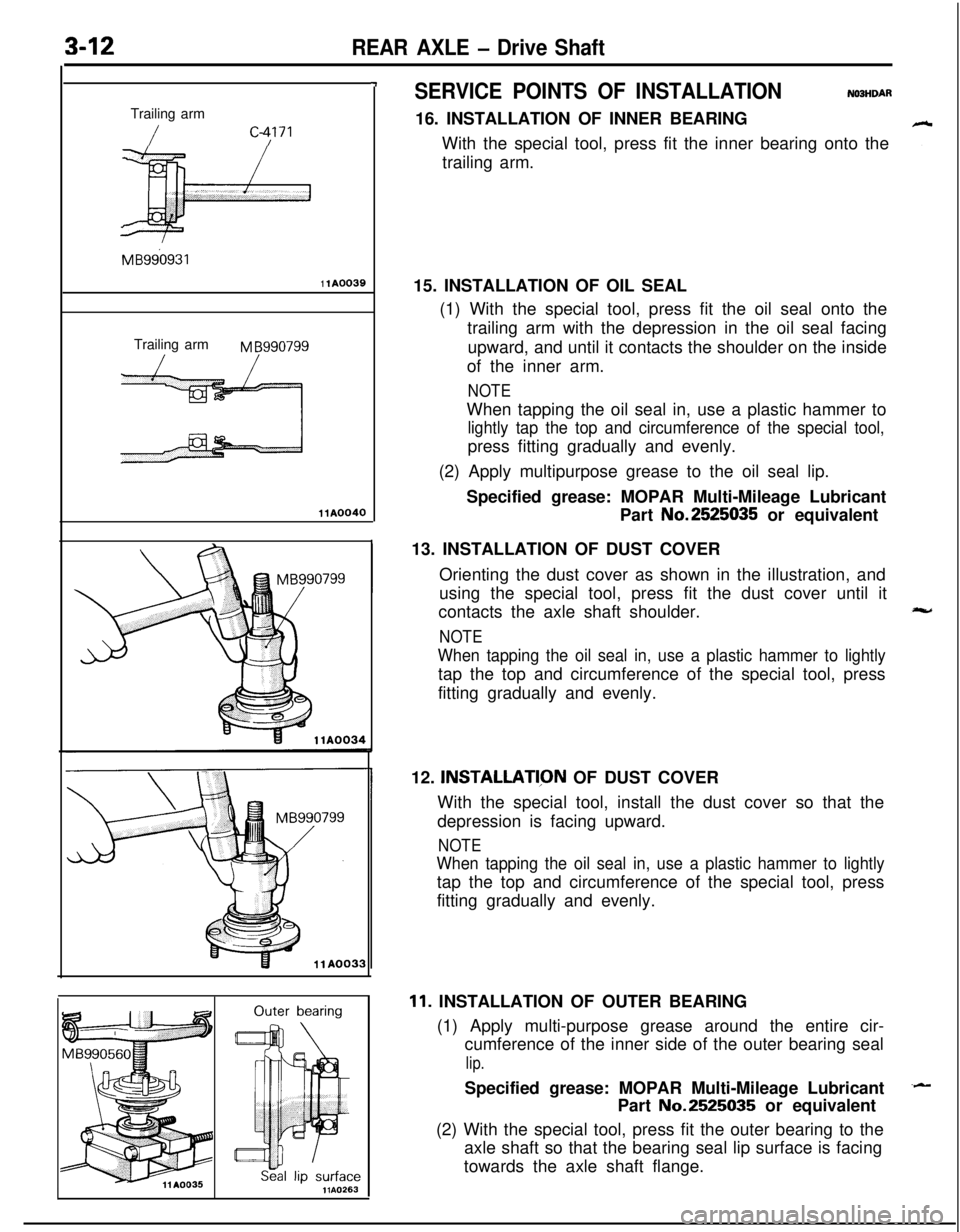

3-12REAR AXLE - Drive ShaftTrailing arm

/c-4171

F

MB960931

1 lA0039Trailing arm

M B990799

11 A0040

7

llAO263

SERVICE POINTS OF INSTALLATIONN03HDAR16. INSTALLATION OF INNER BEARING

With the special tool, press fit the inner bearing onto the

trailing arm.

15. INSTALLATION OF OIL SEAL

(1) With the special tool, press fit the oil seal onto the

trailing arm with the depression in the oil seal facing

upward, and until it contacts the shoulder on the inside

of the inner arm.

NOTEWhen tapping the oil seal in, use a plastic hammer to

lightly tap the top and circumference of the special tool,press fitting gradually and evenly.

(2) Apply multipurpose grease to the oil seal lip.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

13. INSTALLATION OF DUST COVER

Orienting the dust cover as shown in the illustration, and

using the special tool, press fit the dust cover until it

contacts the axle shaft shoulder.

NOTE

When tapping the oil seal in, use a plastic hammer to lightlytap the top and circumference of the special tool, press

fitting gradually and evenly.

12.

INSTALLATl,ON OF DUST COVER

With the special tool, install the dust cover so that the

depression is facing upward.

NOTE

When tapping the oil seal in, use a plastic hammer to lightlytap the top and circumference of the special tool, press

fitting gradually and evenly.

11. INSTALLATION OF OUTER BEARING

(1) Apply multi-purpose grease around the entire cir-

cumference of the inner side of the outer bearing seal

lip.Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

(2) With the special tool, press fit the outer bearing to the

axle shaft so that the bearing seal lip surface is facing

towards the axle shaft flange.

Page 116 of 1216

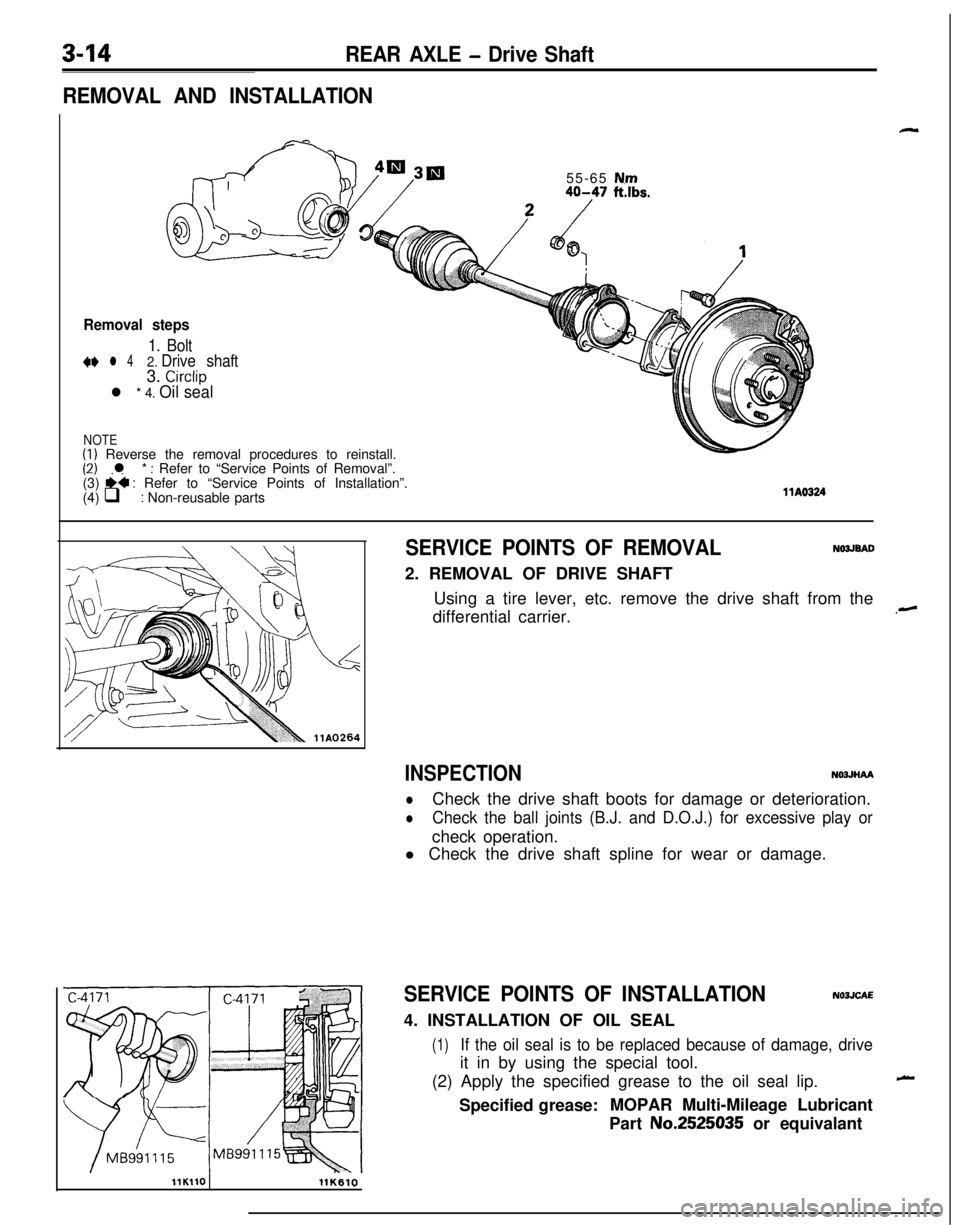

3-‘14REAR AXLE - Drive Shaft

REMOVAL AND INSTALLATION55-65

N.m40-47 ft.lbs.

Removal steps

1. Bolt+e l 42. Drive shaft3. Circlip

l * 4. Oil seal

NOTE(1) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”.<-,(3) ii : Refer to “Service Points of Installation”.

(4) q : Non-reusable partsllA0324

SERVICE POINTS OF REMOVALNO3JEAD2. REMOVAL OF DRIVE SHAFT

Using a tire lever, etc. remove the drive shaft from the

differential carrier.

INSPECTIONNOJJHAA

lCheck the drive shaft boots for damage or deterioration.

lCheck the ball joints (B.J. and D.O.J.) for excessive play orcheck operation.

l Check the drive shaft spline for wear or damage.

SERVICE POINTS OF INSTALLATIONN03JCAE4. INSTALLATION OF OIL SEAL

(1)If the oil seal is to be replaced because of damage, driveit in by using the special tool.

(2) Apply the specified grease to the oil seal lip.

Specified grease:MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalant

,-

-

llK110llK610

Page 129 of 1216

REAR AXLE - Differential Carrier3-27

llK010

71

llY181llY182

.MB990836(MB990835)

llrm3

V223

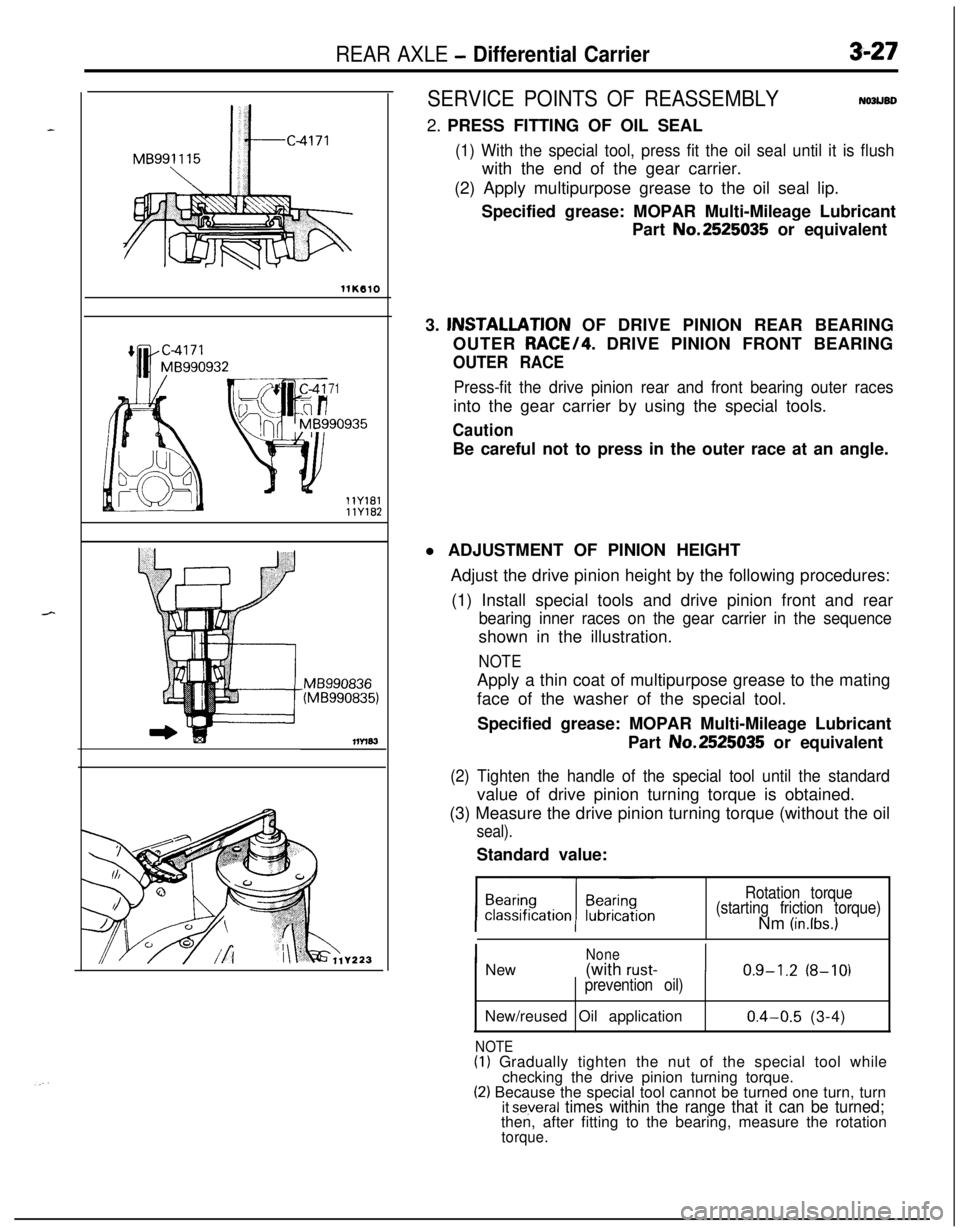

SERVICE POINTS OF REASSEMBLYNOJUBD2. PRESS FITTING OF OIL SEAL

(1) With the special tool, press fit the oil seal until it is flushwith the end of the gear carrier.

(2) Apply multipurpose grease to the oil seal lip.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

3. lNSTALLATlON OF DRIVE PINION REAR BEARING

OUTER RACE/4. DRIVE PINION FRONT BEARING

OUTER RACE

Press-fit the drive pinion rear and front bearing outer racesinto the gear carrier by using the special tools.

CautionBe careful not to press in the outer race at an angle.

l ADJUSTMENT OF PINION HEIGHT

Adjust the drive pinion height by the following procedures:

(1) Install special tools and drive pinion front and rear

bearing inner races on the gear carrier in the sequenceshown in the illustration.

NOTEApply a thin coat of multipurpose grease to the mating

face of the washer of the special tool.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

(2) Tighten the handle of the special tool until the standardvalue of drive pinion turning torque is obtained.

(3) Measure the drive pinion turning torque (without the oil

seal).Standard value:

Rotation torque

(starting friction torque)Nm

(in.lbs.)

I

NoneNew(with rust-I0.9-1.2 (8-10)prevention oil)New/reused Oil application

NOTE

0.4-0.5 (3-4)(I) Gradually tighten the nut of the special tool while

checking the drive pinion turning torque.

(2) Because the special tool cannot be turned one turn, turnit several times within the range that it can be turned;then, after fitting to the bearing, measure the rotation

torque.

Page 131 of 1216

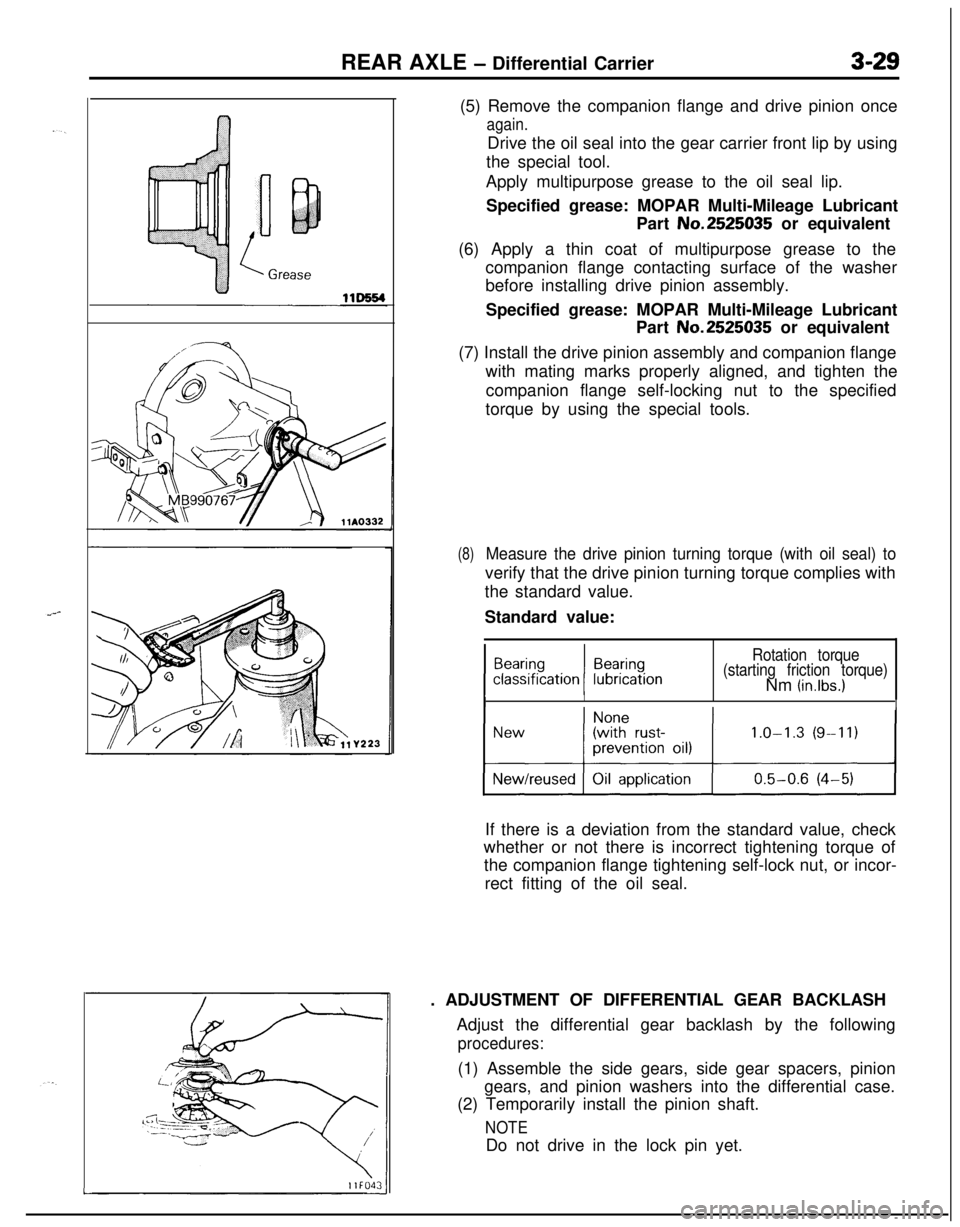

REAR AXLE - Differential Carrier3-29

Y223(5) Remove the companion flange and drive pinion once

again.Drive the oil seal into the gear carrier front lip by using

the special tool.

Apply multipurpose grease to the oil seal lip.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

(6) Apply a thin coat of multipurpose grease to the

companion flange contacting surface of the washer

before installing drive pinion assembly.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

(7) Install the drive pinion assembly and companion flange

with mating marks properly aligned, and tighten the

companion flange self-locking nut to the specified

torque by using the special tools.

(8)Measure the drive pinion turning torque (with oil seal) toverify that the drive pinion turning torque complies with

the standard value.

Standard value:

Rotation torque

(starting friction torque)Nm

(in.lbs.)

IIIIIf there is a deviation from the standard value, check

whether or not there is incorrect tightening torque of

the companion flange tightening self-lock nut, or incor-

rect fitting of the oil seal.

. ADJUSTMENT OF DIFFERENTIAL GEAR BACKLASH

Adjust the differential gear backlash by the following

procedures:(1) Assemble the side gears, side gear spacers, pinion

gears, and pinion washers into the differential case.

(2) Temporarily install the pinion shaft.

NOTEDo not drive in the lock pin yet.

L-

Page 145 of 1216

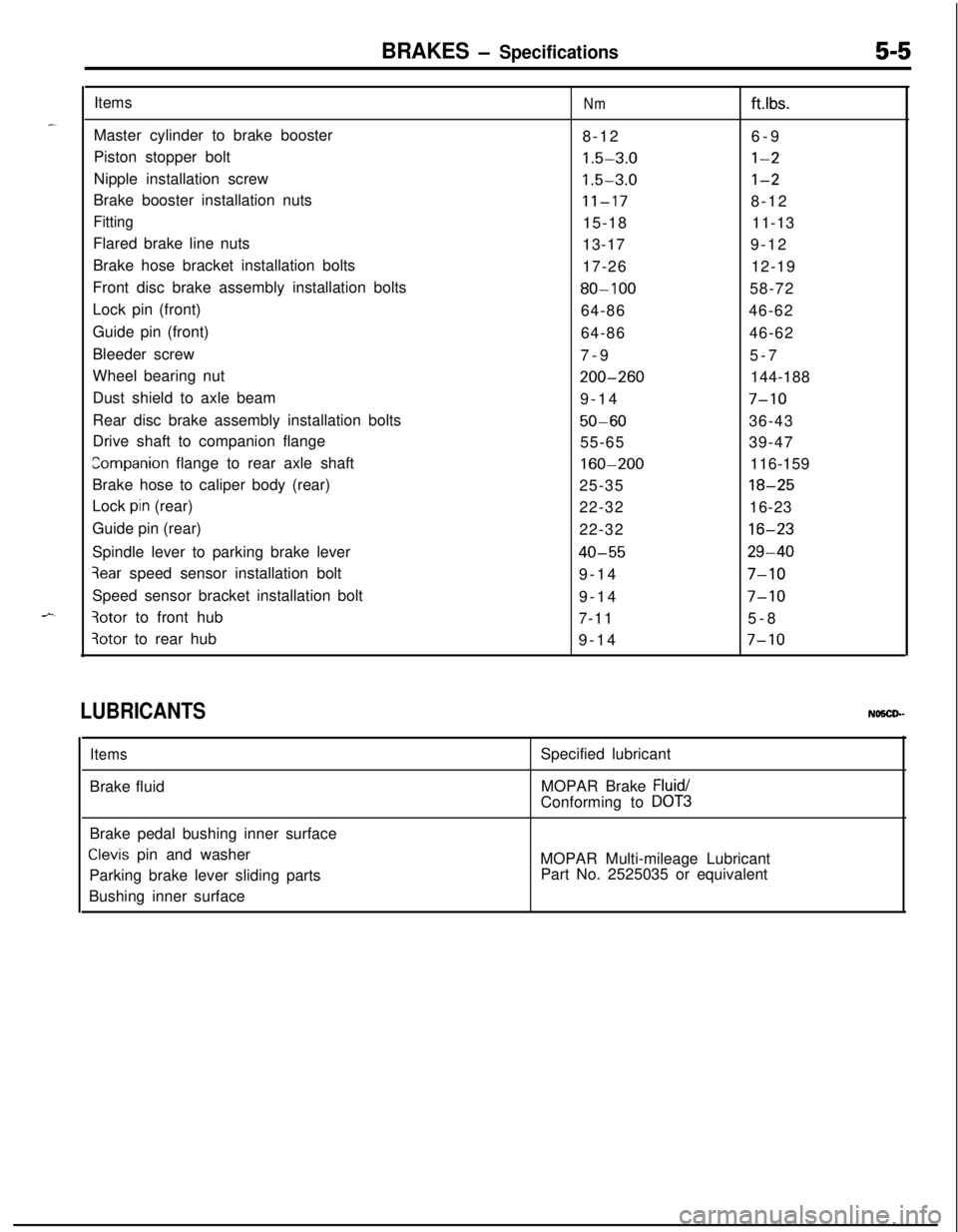

BRAKES - Specifications5-5Items

Nmftlbs.Master cylinder to brake booster

8-126-9

Piston stopper bolt

1.5-3.0l-2Nipple installation screw

1.5-3.0l-2Brake booster installation nuts

11-178-12

Fitting15-1811-13

Flared brake line nuts

13-179-12

Brake hose bracket installation bolts

17-2612-19

Front disc brake assembly installation bolts

80-10058-72

Lock pin (front)

64-8646-62

Guide pin (front)

64-8646-62

Bleeder screw

7-95-7

Wheel bearing nut

200-260144-188

Dust shield to axle beam

9-14

7-10Rear disc brake assembly installation bolts

50-6036-43

Drive shaft to companion flange

55-6539-47

companion flange to rear axle shaft160-200116-159

Brake hose to caliper body (rear)

25-35

18-25Lock

pin (rear)

22-3216-23

Guide pin (rear)

22-32

16-23Spindle lever to parking brake lever

40-5529-40

3ear speed sensor installation bolt

9-147-10Speed sensor bracket installation bolt

9-14

7-10

3otor to front hub

7-115-8

3otor to rear hub

9-147-10

LUBRICANTSNO5CP-

ItemsBrake fluidSpecified lubricant

MOPAR Brake

Fluid/Conforming to

DOT3Brake pedal bushing inner surface

Clevis pin and washer

Parking brake lever sliding parts

Bushing inner surfaceMOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

Page 195 of 1216

BRAKES - Brake Pedal5-55

14L0142No continuity

Continuity

mm

t.16 in.)

14LO171

:Vehicles with auto-cruiseontrol svstem>

14A0256

14ll0050

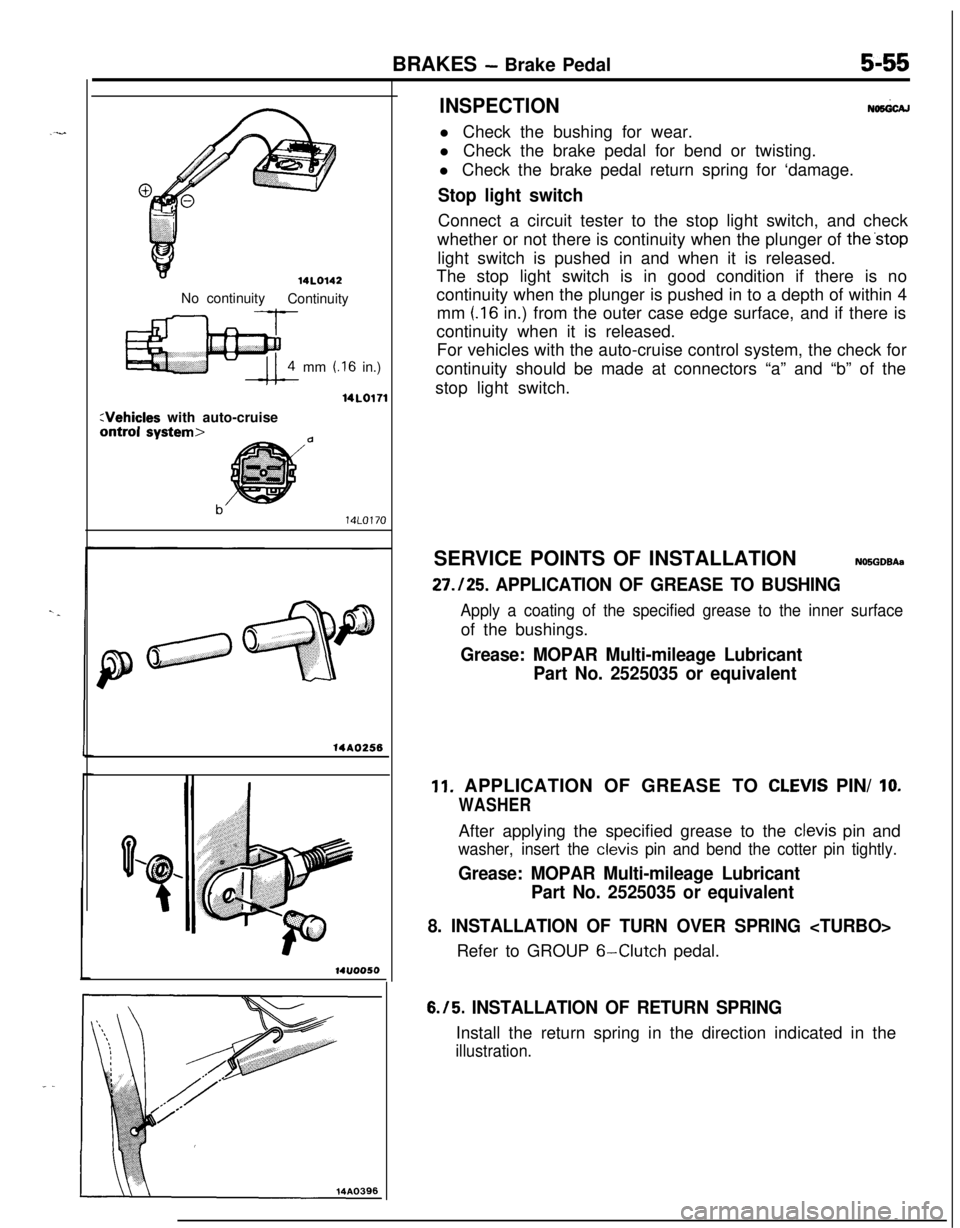

INSPECTIONNoMicAll Check the bushing for wear.

l Check the brake pedal for bend or twisting.

l Check the brake pedal return spring for ‘damage.

Stop light switchConnect a circuit tester to the stop light switch, and check

whether or not there is continuity when the plunger of the’stop

light switch is pushed in and when it is released.

The stop light switch is in good condition if there is no

continuity when the plunger is pushed in to a depth of within 4

mm

(.I6 in.) from the outer case edge surface, and if there is

continuity when it is released.

For vehicles with the auto-cruise control system, the check for

continuity should be made at connectors “a” and “b” of the

stop light switch.

SERVICE POINTS OF INSTALLATIONN05GDBAa

27.125. APPLICATION OF GREASE TO BUSHING

Apply a coating of the specified grease to the inner surfaceof the bushings.

Grease: MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

11. APPLICATION OF GREASE TO CLEVIS PIN/ IO.

WASHERAfter applying the specified grease to the

clevis pin and

washer, insert the clevis pin and bend the cotter pin tightly.

Grease: MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

8. INSTALLATION OF TURN OVER SPRING

6-Clutch pedal.

6.15. INSTALLATION OF RETURN SPRINGInstall the return spring in the direction indicated in the

illustration.

Page 201 of 1216

BRAKES - Brake Booster5-61Vacuum hose

MAO394

14uoo50

14Y626Vacuum hose

mm (in.)

14A0395

SERVICE POINTS OF REMOVALNow9Al

6. REMOVAL OF VACUUM HOSE WITH CHECK VALVE

NOTE

Since the check valve is fit to the vacuum hose, replace thecheck valve as an assembly unit together with the vacuum

hose if the check valve is defective.

SERVICE POINTS OF INSTALLATIONNOWDAV

10. APPLICATION OF GREASE TO CLEVIS PIN/g. WASHERAfter applying the specified grease to the

clevis pin and

washer, insert the clevis pin and bend the cotter pin tightly.

Grease: MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

7. APPLICATION OF SEALANT TO

FITTINGWhen installing the vacuum hose fitting, apply semi-drying

sealant to its threaded portion.

6. INSTALLATION OF VACUUM HOSE WITH CHECK

VALVE(1) Attach the vacuum hose so that it may be inserted to a

dimension illustrated.

Caution

Prevent interference between the check valve and

brake booster.(2) The vacuum hose at the engine should be securely

connected until it contacts the hexagonal edge of the

fitting, and then should be secured by the hose clip.