service MITSUBISHI ECLIPSE 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 62 of 1216

2-14FRONT SUSPENSION - Hub and Knuckle

llR0032

llK012SERVICE POINTS OF REASSEMBLY

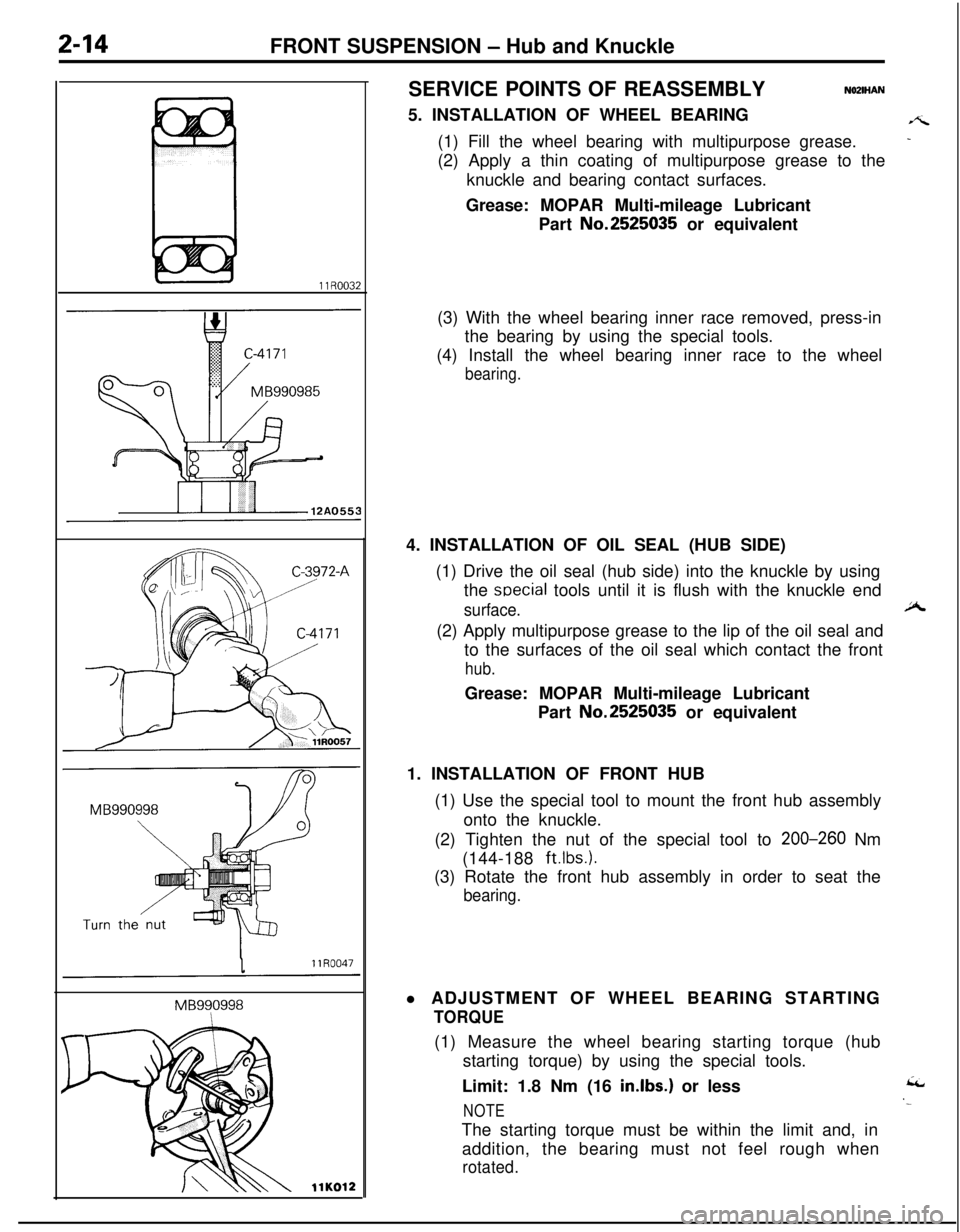

NOZIHAN5. INSTALLATION OF WHEEL BEARING

A(1) Fill the wheel bearing with multipurpose grease.

-(2) Apply a thin coating of multipurpose grease to the

knuckle and bearing contact surfaces.

Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

(3) With the wheel bearing inner race removed, press-in

the bearing by using the special tools.

(4) Install the wheel bearing inner race to the wheel

bearing.4. INSTALLATION OF OIL SEAL (HUB SIDE)

(1) Drive the oil seal (hub side) into the knuckle by using

the

soecial tools until it is flush with the knuckle end

surface.A(2) Apply multipurpose grease to the lip of the oil seal and

to the surfaces of the oil seal which contact the front

hub.Grease: MOPAR Multi-mileage Lubricant

Part No.2525035 or equivalent

1. INSTALLATION OF FRONT HUB

(1) Use the special tool to mount the front hub assembly

onto the knuckle.

(2) Tighten the nut of the special tool to 200-260 Nm

(144-188

ft.lbs.).(3) Rotate the front hub assembly in order to seat the

bearing.l ADJUSTMENT OF WHEEL BEARING STARTING

TORQUE(1) Measure the wheel bearing starting torque (hub

starting torque) by using the special tools.

Limit: 1.8 Nm (16

in.lbs.) or lessic

‘-NOTEThe starting torque must be within the limit and, in

addition, the bearing must not feel rough when

rotated.

Page 64 of 1216

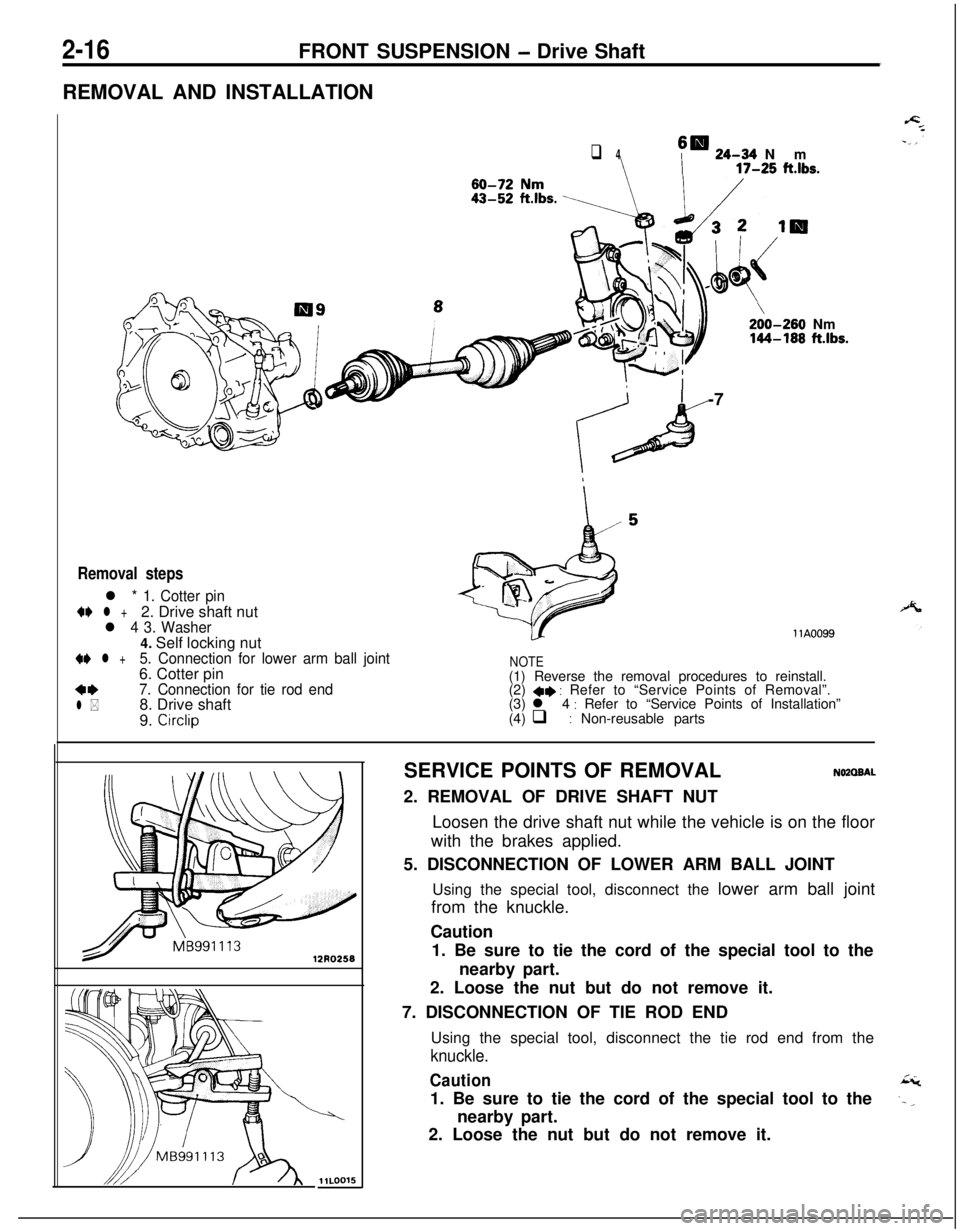

2-16FRONT SUSPENSION - Drive Shaft

REMOVAL AND INSTALLATION

q 4sm 24-34 Nm

\ I17-25 ft.lbs.

/I200-260 Nm144-168 ftlbs.-7

Removal steps

l * 1. Cotter pin

4e l +2. Drive shaft nutl 4 3. Washer4. Self locking nut

+e l +5. Connection for lower arm ball joint6. Cotter pin

**7. Connection for tie rod end

l *8. Drive shaft

9. Circlip

llA0099

NOTE(1) Reverse the removal procedures to reinstall.

(2)

4* : Refer to “Service Points of Removal”.

(3) l 4 : Refer to “Service Points of Installation”

(4) q : Non-reusable parts

12130255

w

llLOO15SERVICE POINTS OF REMOVAL

NOZOBAL2. REMOVAL OF DRIVE SHAFT NUT

Loosen the drive shaft nut while the vehicle is on the floor

with the brakes applied.

5. DISCONNECTION OF LOWER ARM BALL JOINT

Using the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loose the nut but do not remove it.

7. DISCONNECTION OF TIE ROD END

Using the special tool, disconnect the tie rod end from the

knuckle.

Caution1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loose the nut but do not remove it.

Page 65 of 1216

FRONT SUSPENSION - Drive Shaft247Pry bar

13E526

12RO426Cotter pin

/

/HubllR0015

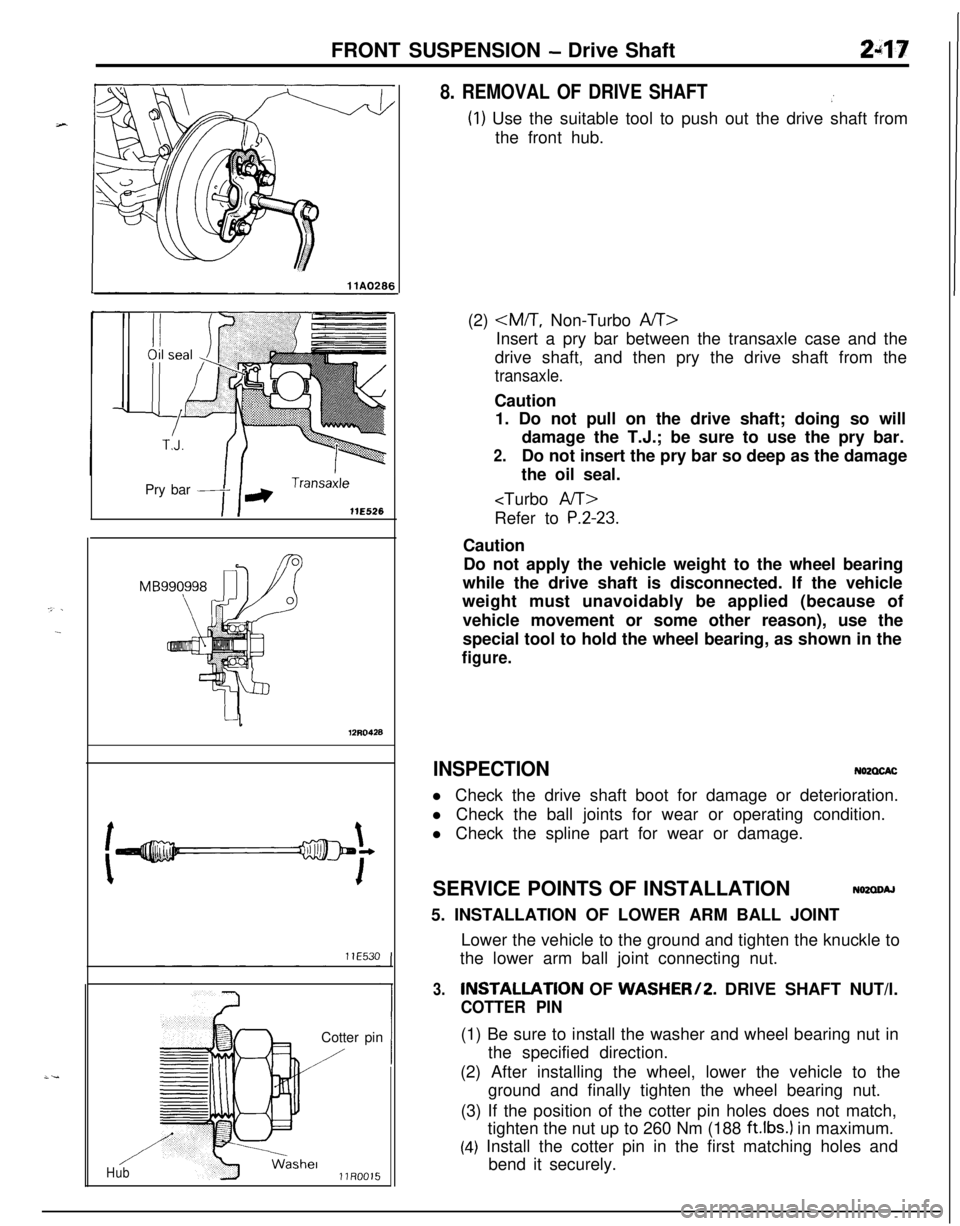

8. REMOVAL OF DRIVE SHAFT.’

(1) Use the suitable tool to push out the drive shaft from

the front hub.

(2)

Insert a pry bar between the transaxle case and the

drive shaft, and then pry the drive shaft from the

transaxle.Caution

1. Do not pull on the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

2.Do not insert the pry bar so deep as the damage

the oil seal.

P.2-23.Caution

Do not apply the vehicle weight to the wheel bearing

while the drive shaft is disconnected. If the vehicle

weight must unavoidably be applied (because of

vehicle movement or some other reason), use the

special tool to hold the wheel bearing, as shown in the

figure.

INSPECTIONN62CXACl Check the drive shaft boot for damage or deterioration.

l Check the ball joints for wear or operating condition.

l Check the spline part for wear or damage.

SERVICE POINTS OF INSTALLATION

N62aoAJ5. INSTALLATION OF LOWER ARM BALL JOINT

Lower the vehicle to the ground and tighten the knuckle to

the lower arm ball joint connecting nut.

3.INSTALLATlON OF WASHER/2. DRIVE SHAFT NUT/l.

COTTER PIN(1) Be sure to install the washer and wheel bearing nut in

the specified direction.

(2) After installing the wheel, lower the vehicle to the

ground and finally tighten the wheel bearing nut.

(3) If the position of the cotter pin holes does not match,

tighten the nut up to 260 Nm (188

ft.lbs.) in maximum.

(4) Install the cotter pin in the first matching holes and

bend it securely.

Page 66 of 1216

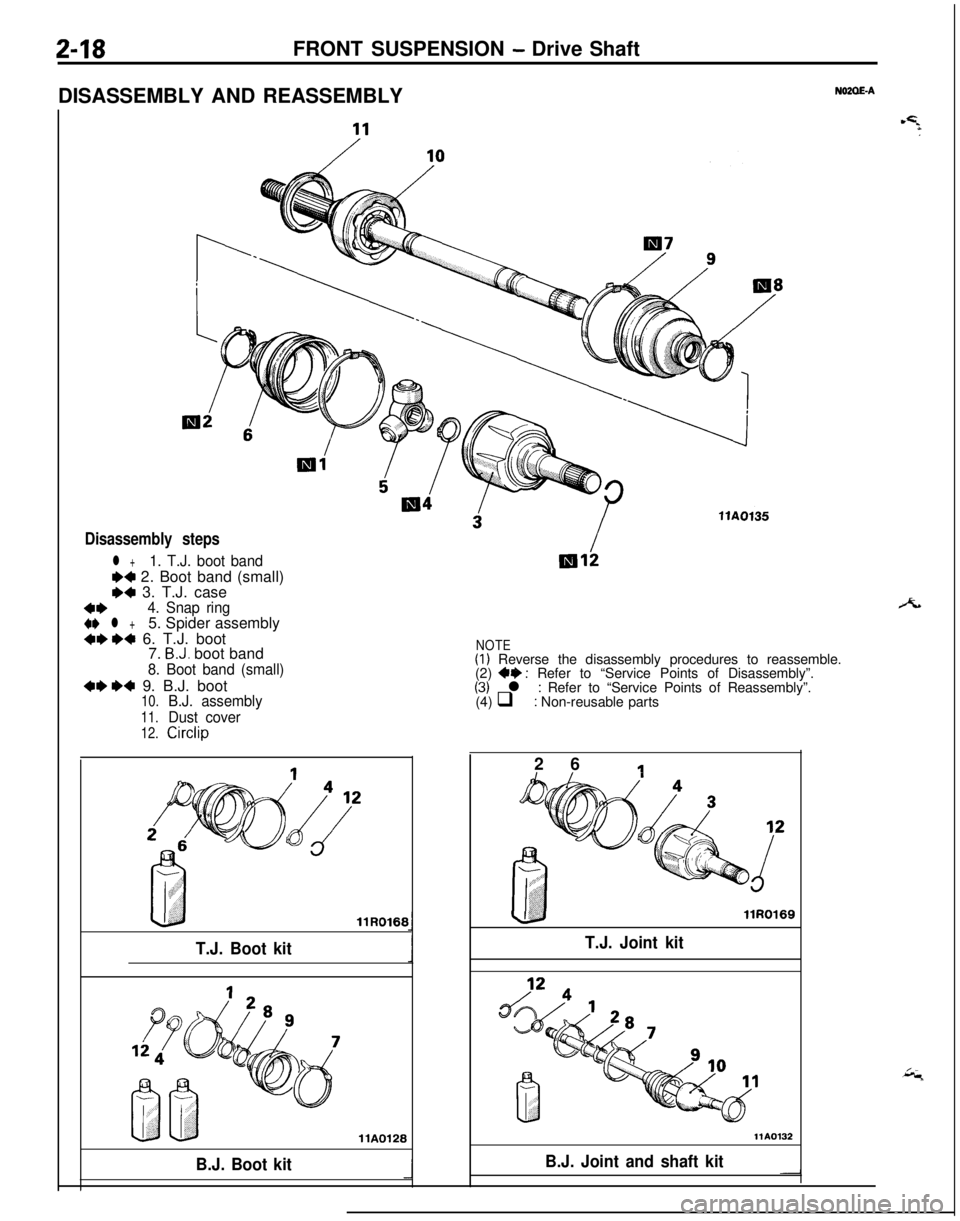

Z-18FRONT SUSPENSION - Drive Shaft

DISASSEMBLY AND REASSEMBLY

NOZOE-A

Disassembly steps

l +1. T.J. boot band

W 2. Boot band (small)e4 3. T.J. case

4*4. Snap ring

4I) l +5. Spider assembly4ee4 6. T.J. boot

7. B.J. boot band

8. Boot band (small)

4ee4 9. B.J. boot10.B.J. assembly

11.Dust cover

12.Circlip

T.J. Boot kitllR0166

llA0128

B.J. Boot kitllAOf35

NOTE(I) Reverse the disassembly procedures to reassemble.

(2) 4+ : Refer to “Service Points of Disassembly”.(3) l : Refer to “Service Points of Reassembly”.

(4) q : Non-reusable parts

2 6

1

llR0169

T.J. Joint kit

-IB.J. Joint and shaft kit

Page 67 of 1216

FRONT SUSPENSION - Drive Shaft249'

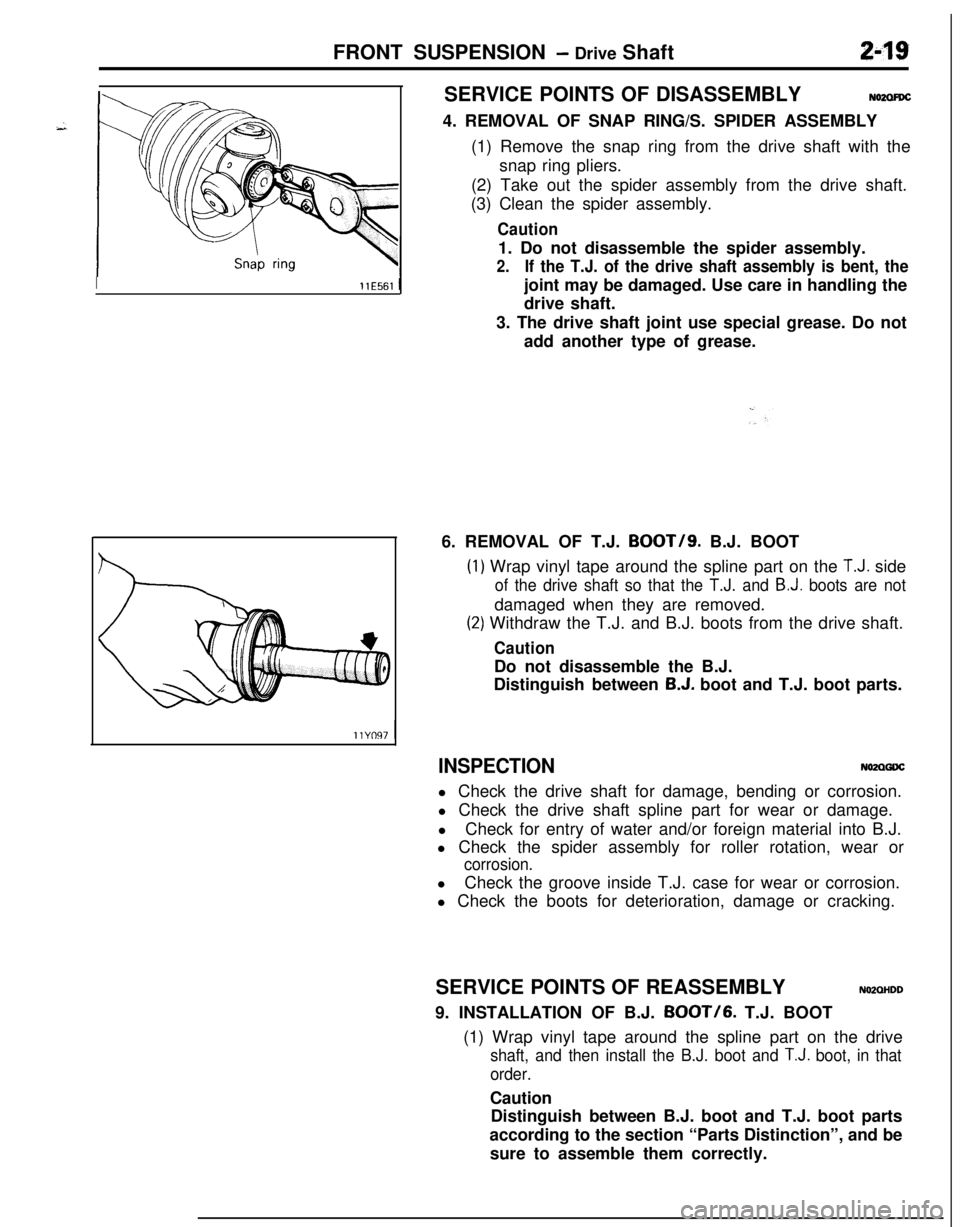

IllE561 ISERVICE POINTS OF DISASSEMBLY

NO2ClFDC4. REMOVAL OF SNAP RING/S. SPIDER ASSEMBLY

(1) Remove the snap ring from the drive shaft with the

snap ring pliers.

(2) Take out the spider assembly from the drive shaft.

(3) Clean the spider assembly.

Caution1. Do not disassemble the spider assembly.

2.If the T.J. of the drive shaft assembly is bent, thejoint may be damaged. Use care in handling the

drive shaft.

3. The drive shaft joint use special grease. Do not

add another type of grease.

6. REMOVAL OF T.J. BOOT/g. B.J. BOOT

(1

(2

) Wrap vinyl tape around the spline part on the T.J. side

of the drive shaft so that the T.J. and B.J. boots are notdamaged when they are removed.

‘) Withdraw the T.J. and B.J. boots from the drive shaft.

CautionDo not disassemble the B.J.

Distinguish between

B.J. boot and T.J. boot parts.

INSPECTIONNO2QGDCl Check the drive shaft for damage, bending or corrosion.

l Check the drive shaft spline part for wear or damage.

lCheck for entry of water and/or foreign material into B.J.

l Check the spider assembly for roller rotation, wear or

corrosion.lCheck the groove inside T.J. case for wear or corrosion.

l Check the boots for deterioration, damage or cracking.

SERVICE POINTS OF REASSEMBLY

NMOHDD9. INSTALLATION OF B.J.

BOOT/6. T.J. BOOT

(1) Wrap vinyl tape around the spline part on the drive

shaft, and then install the B.J. boot and T.J. boot, in that

order.Caution

Distinguish between B.J. boot and T.J. boot parts

according to the section “Parts Distinction”, and be

sure to assemble them correctly.

Page 70 of 1216

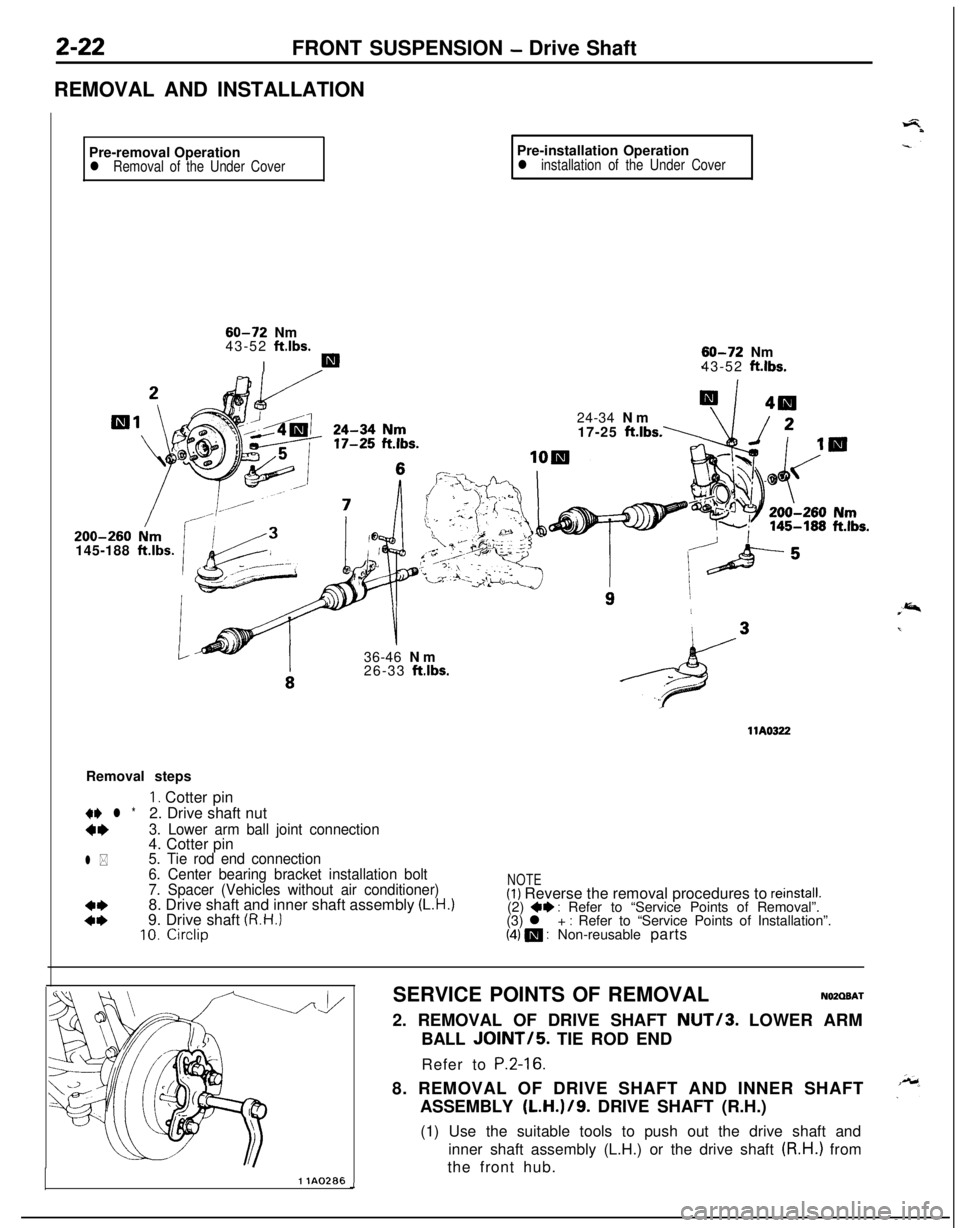

2-22FRONT SUSPENSION - Drive Shaft

REMOVAL AND INSTALLATION

Pre-removal OperationPre-installation Operation

l Removal of the Under Coverl installation of the Under Cover

60-72 Nm

43-52 ftlbs.

I60-72 Nm

43-52 ftlbs.

200-260 irn145-188 ft.lbs.

I24-34 Nm

17-25 ft.lbs.

Y36-46 Nm

26-33

ft.lbs.

llAO322Removal steps

I. Cotter pin

+I) l *2. Drive shaft nut

4*3. Lower arm ball joint connection4. Cotter pin

l *5. Tie rod end connection

6. Center bearing bracket installation bolt

7. Spacer (Vehicles without air conditioner)

::8. Drive shaft and inner shaft assembly

(L.H.)9. Drive shaft (R.H.)10. Circlip

NOTE(1) Reverse the removal procedures to reinstall.(2) 4* : Refer to “Service Points of Removal”.

(3) l + : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

1 lA0266SERVICE POINTS OF REMOVAL

NOZQBAT2. REMOVAL OF DRIVE SHAFT

NUT/3. LOWER ARM

BALL

JOINT/5. TIE ROD END

Refer to P.2-16.

8. REMOVAL OF DRIVE SHAFT AND INNER SHAFT

ASSEMBLY

(L.H.)/9. DRIVE SHAFT (R.H.)

(1) Use the suitable tools to push out the drive shaft and

inner shaft assembly (L.H.) or the drive shaft

(R.H.) from

the front hub.

1

Page 71 of 1216

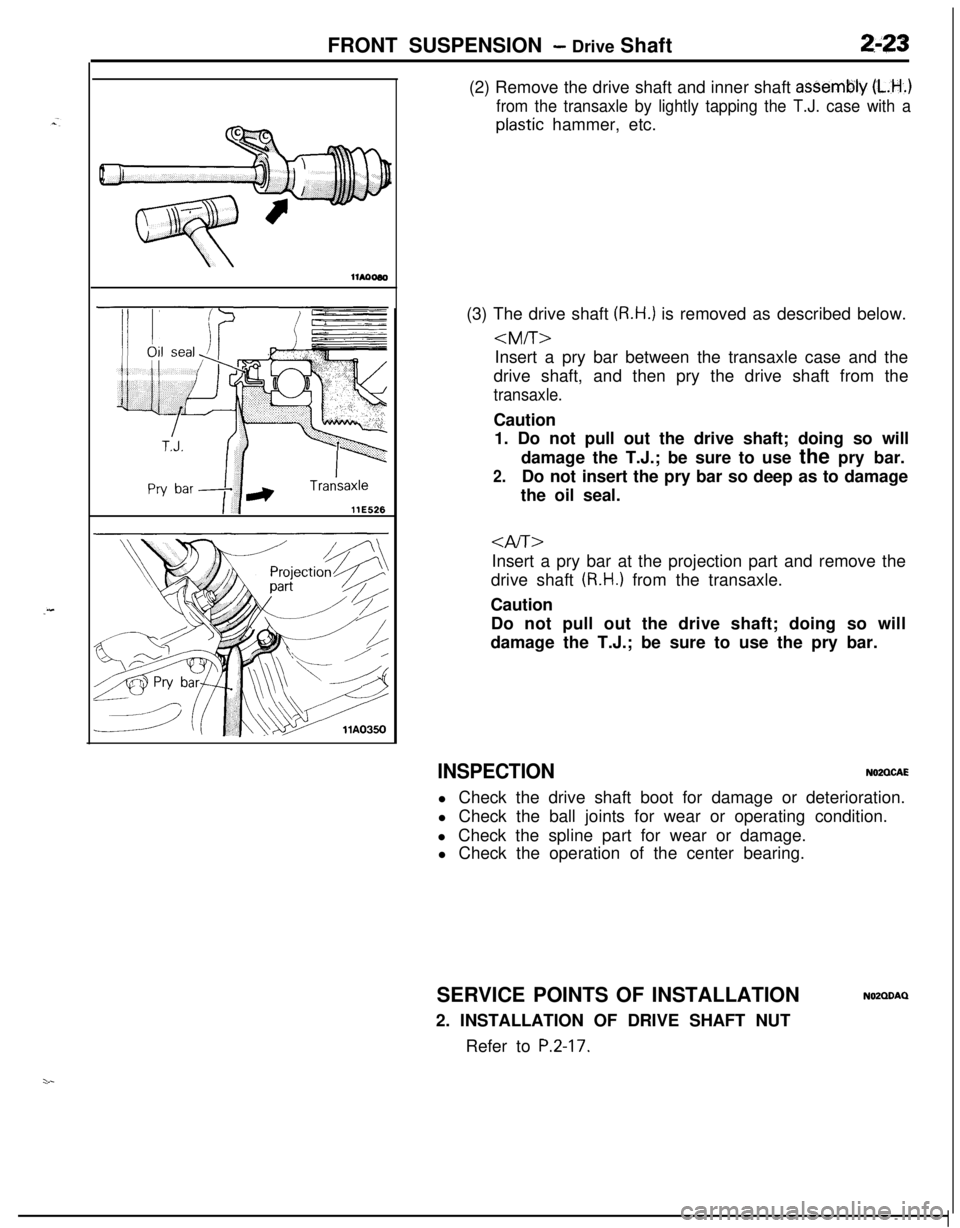

FRONT SUSPENSION - Drive Shaft2-23

llE526(2) Remove the drive shaft and inner shaft

asSembly (L.H..)

from the transaxle by lightly tapping the T.J. case with a

plastic hammer, etc.

(3) The drive shaft

(R.H.) is removed as described below.

drive shaft, and then pry the drive shaft from the

transaxle.Caution

1. Do not pull out the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

2.Do not insert the pry bar so deep as to damage

the oil seal.

Insert a pry bar at the projection part and remove the

drive shaft

(R.H.) from the transaxle.

Caution

Do not pull out the drive shaft; doing so will

damage the T.J.; be sure to use the pry bar.

INSPECTIONN02QCAEl Check the drive shaft boot for damage or deterioration.

l Check the ball joints for wear or operating condition.

l Check the spline part for wear or damage.

l Check the operation of the center bearing.

SERVICE POINTS OF INSTALLATION

2. INSTALLATION OF DRIVE SHAFT NUT

Refer to

P.2-17.

NOZQDAQ

Page 72 of 1216

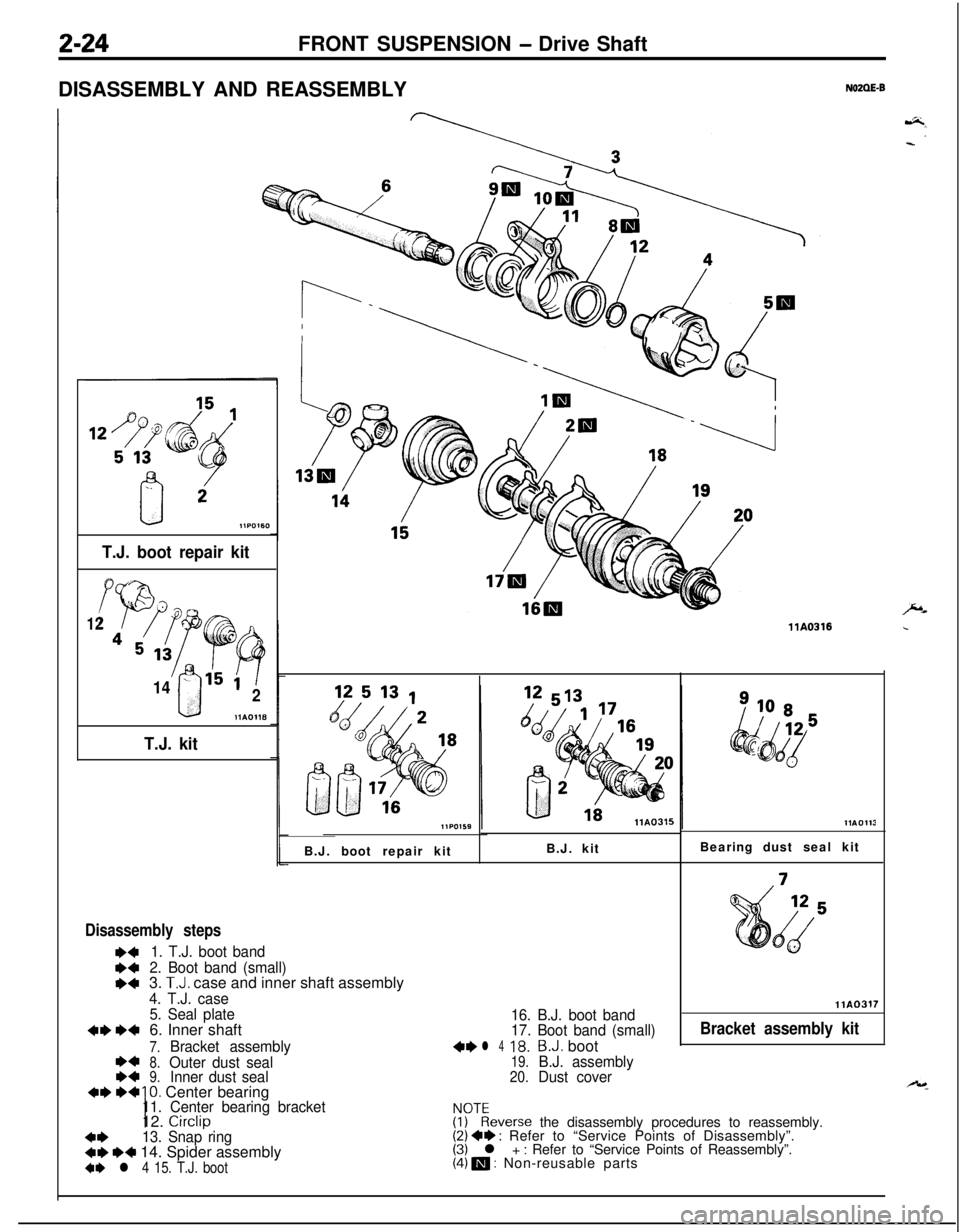

2-24FRONT SUSPENSION - Drive Shaft

DISASSEMBLY AND REASSEMBLY

NOZQE-B

T.J. boot repair kit

d-

‘Pr12

45,3 ;c

!'F?

14- 151

0

92

11AOH8

T.J. kit

llA0316B.J. boot repair kitB.J. kit

Disassembly steps

1. T.J. boot band

2. Boot band (small)3.

T.J. case and inner shaft assembly

4. T.J. case

5. Seal plate6. Inner shaft

16. B.J. boot band

17. Boot band (small)

7.Bracket assembly+I)l 418.B.J. boot

8.Outer dust seal19.B.J. assembly9.Inner dust seal20.Dust coverBearing dust seal kit

llA0317

Bracket assembly kit

10. Center bearing11. Center bearing bracket12. Circlip

4*13. Snap ring+e e+ 14. Spider assembly4I) l 4 15. T.J. boot

FJ)TEeverse the disassembly procedures to reassembly.(2) +e : Refer to “Service Points of Disassembly”.(3) l + : Refer to “Service Points of Reassembly”.(4) m : Non-reusable parts

Page 73 of 1216

FRONT SUSPENSION - Drive Shaft2-25

T.J. caseI

\ \It/P-

IllA0092

-/ MB990938

11E561llYO97SERVICE POINTS OF DISASSEMBLY

NOZOFED6. REMOVAL OF INNER

SHAFT(1) Using the special tool, remove the inner shaft assem-

bly, together with the seal plate, from the T.J. case.

from

(2) Use the suitable puller to remove the inner shaft

the center bearing bracket.

10. REMOVAL OF CENTER BEARING

Use the special tools to remove the center bearing from thecenter bearing bracket.

ix13. REMOVAL OF SNAP

RING/l4. SPIDER ASSEMBLY

(1) Remove the snap ring from the drive shaft with the

snap ring pliers.

(2) Take out the spider assembly from the drive shaft.

(3) Clean the spider assembly.

Caution

1. Do not disassemble the spider assembly.

2.If the T.J. of the drive shaft assembly is bent, thejoint may be damaged. Use care in handling the

drive shaft.

3. The drive shaft joint use special grease. Do not

add another type of grease.

15. REMOVAL OF T.J.

BOOT/l8. B.J. BOOT

(1) Wrap vinyl tape around the spline part on the T.J. side

of the drive shaft so that the T.J. and B.J. boots are notdamaged when they are removed.

(2) Withdraw the T.J. and

B.J. boots from the drive shaft.

Caution

Do not disassemble the B.J.

Distinguish between B.J. boot and T.J. boot parts.

Page 74 of 1216

2-26FRONT SUSPENSION - Drive Shaft

llE560

INSPECTIONN02QGEB

0

0

0

0Check the dust cover for damage or deterioration.Check the drive shaft for damage, bending or corrosion.

Check the inner shaft for damage, bending or corrosion.

-Check the drive shaft spline part for wear or damage.

=-Check the inner shaft spline for wear or damage.

Check for entry of water and/or foreign material into

B-J..Check the spider assembly for roller rotation, wear or

corrosion.Check the groove inside T.J. case for wear of corrosion.

Check the boots for deterioration, damage or cracking.

Check the center bearing for seizure, discoloration or

roughness of rolling surface.

SERVICE POINTS OF REASSEMBLY

NOZQHEEa

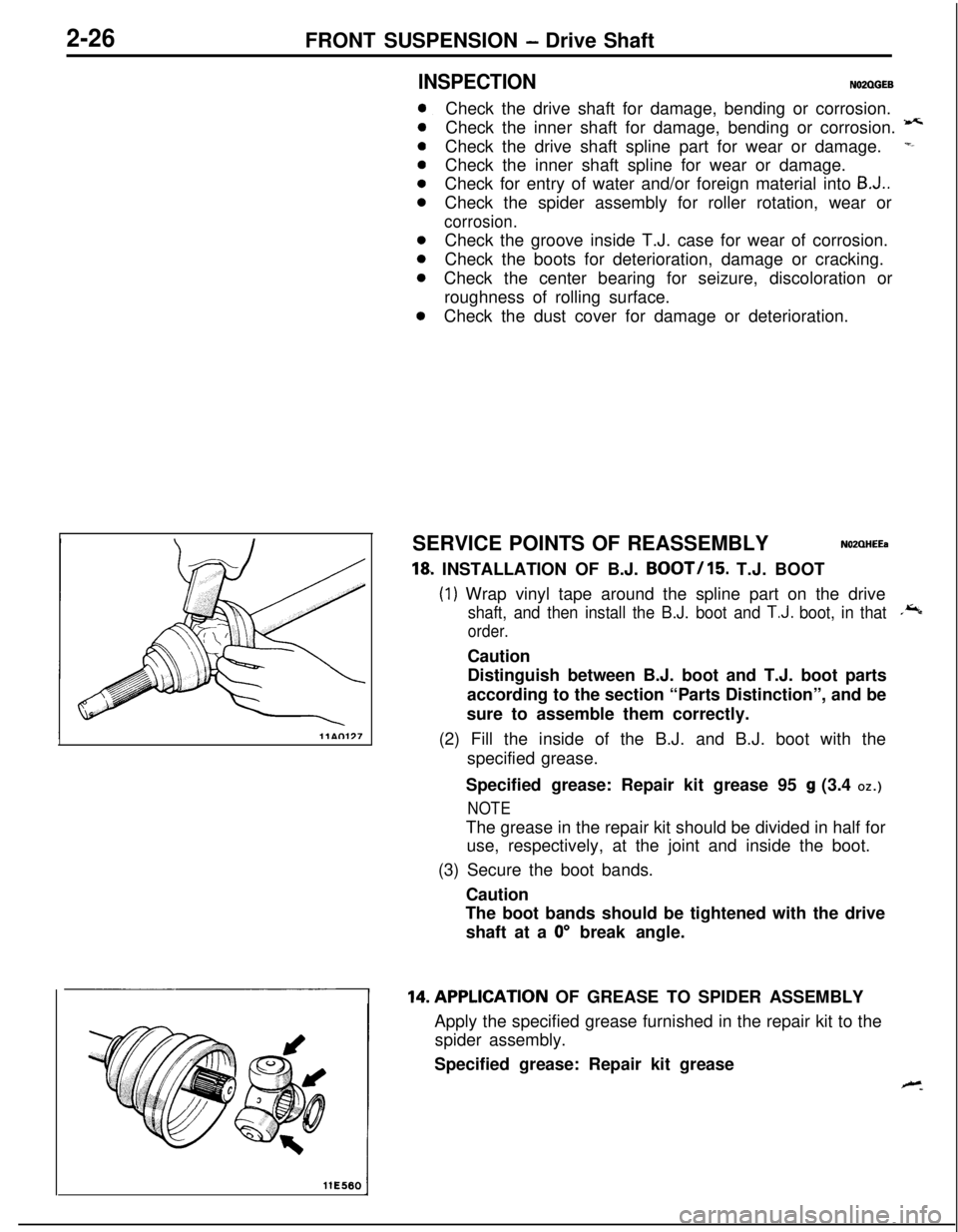

18, INSTALLATION OF B.J. BOOT/15. T.J. BOOT

(1) Wrap vinyl tape around the spline part on the drive

shaft, and then install the B.J. boot and T.J. boot, in that.*

order.Caution

Distinguish between B.J. boot and T.J. boot parts

according to the section “Parts Distinction”, and be

sure to assemble them correctly.

(2) Fill the inside of the B.J. and B.J. boot with the

specified grease.

Specified grease: Repair kit grease 95

g (3.4 OZ.)

NOTEThe grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

(3) Secure the boot bands.

Caution

The boot bands should be tightened with the drive

shaft at a

0” break angle.14.APPLlCATlON OF GREASE TO SPIDER ASSEMBLY

Apply the specified grease furnished in the repair kit to the

spider assembly.

Specified grease: Repair kit grease