change wheel MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1 of 1216

BACKUPGROUP INDEX &ma

;r Service Manual

LASER

TALON

1991

Volume-l

Engine, Chassis

& Body

FOREWORDThis Service Manual has been prepared with the

latest service information available at the time of

‘* publication.It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliabilitydesigned into these outstanding vehicles.

This BACKUP DSM manual IS to be used ONLY as a BACKUP. Please DO NOT REDISTRIBUTEWHOLE SECTIONS. This BACKUP was sold to you under the fact that you do indeed OWNa GENUINE DSM MANUAL. It CANNOT BE considered a REPLACEMENT (Unless your originalmanual was lost or destroyed.)Please See

README.N or README.HTML for additional information

Thank you. G~mm~emymanual@hotma~l.com

1,

wA

CHRYSLER

CORPORATION

Chrysler Corporation reserves the right to make changes in design 0’: tomake additions to or improvements in its products without lmqoslngd ., . any obligations upon itself to install them on its products previouslymanufactured.

0 1990 Mitsubishi Motors CorporationPrinted in U.S.A.Introduction and

Master

Troubleshooting. . . . . .,. . . . . . . . . r...m,

Lubrication and Maintenance . . . . . . . . ‘-0‘8

; “. i,

.Front Suspension. . . . . . . . . . . . . . ..*............d...Rear Axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . ..‘.....................

/

ServiceBrakes-Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~......................‘t.

Cooling. . . . . . . . . . . . . . . . . ..i....................................

,., .‘,-,

Engine..i....~....r...............~....~.*,.~.~.~,‘~~...;..~~..Intake and Exhaust

. . . . . . ..L....................Fuel System

. . . . . . . . . . . ..ti.......r................~...Propeller Shaft

.......................................IRear

Suspensiori.............................y.f...

ManualSteering- Power.....................................Manual

I

transaxle-Automatic .............:;i...,;.....;Wheels

and Tires.................................

Body.............................................................Heater & Air Conditioning

..............Emission

Contr6l Systems..............

INOTE: For Electrical, refer toVolume-2 “Electrical”.

Page 20 of 1216

20INTRODUCTION AND MASTER TROUBLESHOOTING - Towing and Hoisting

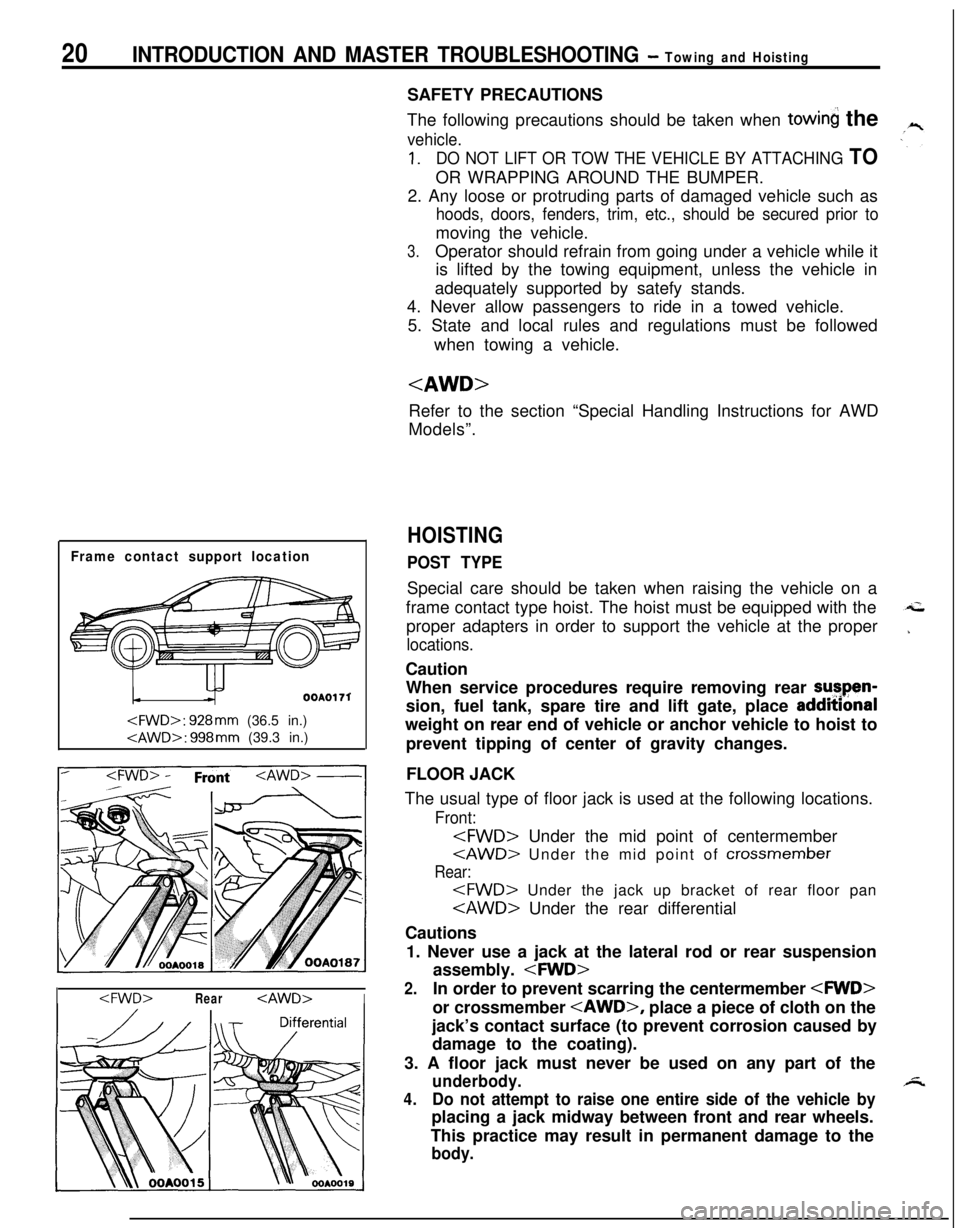

Frame contact support location

OOAOI 71

I

The following precautions should be taken when

towin the

vehicle.

1.DO NOT LIFT OR TOW THE VEHICLE BY ATTACHING TOOR WRAPPING AROUND THE BUMPER.

2. Any loose or protruding parts of damaged vehicle such as

hoods, doors, fenders, trim, etc., should be secured prior tomoving the vehicle.

3.Operator should refrain from going under a vehicle while it

is lifted by the towing equipment, unless the vehicle in

adequately supported by satefy stands.

4. Never allow passengers to ride in a towed vehicle.

5. State and local rules and regulations must be followed

when towing a vehicle.

Refer to the section “Special Handling Instructions for AWD

Models”.

HOISTING

POST TYPESpecial care should be taken when raising the vehicle on a

frame contact type hoist. The hoist must be equipped with the

proper adapters in order to support the vehicle at the proper

locations.Caution

When service procedures require removing rear sutpen-

sion, fuel tank, spare tire and lift gate, place addmonal

weight on rear end of vehicle or anchor vehicle to hoist to

prevent tipping of center of gravity changes.

FLOOR JACK

The usual type of floor jack is used at the following locations.

Front:

Rear:

Cautions

1. Never use a jack at the lateral rod or rear suspension

assembly.

2.In order to prevent scarring the centermember

jack’s contact surface (to prevent corrosion caused by

damage to the coating).

3. A floor jack must never be used on any part of the

underbody.

4.Do not attempt to raise one entire side of the vehicle byplacing a jack midway between front and rear wheels.

This practice may result in permanent damage to the

body.

Page 46 of 1216

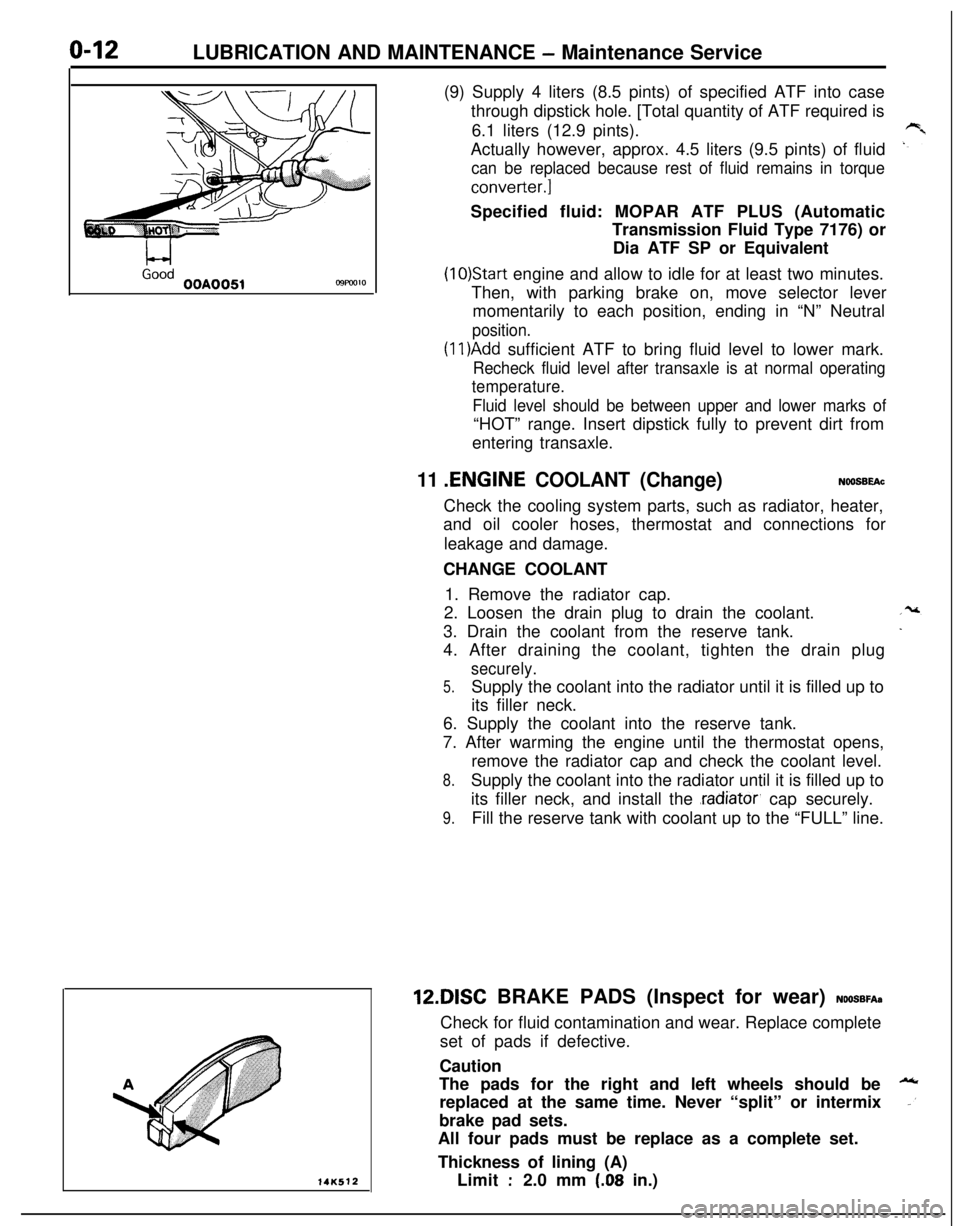

LUBRICATION AND MAINTENANCE - Maintenance Service

L-4GoodOOA0051C9FW1014K512(9) Supply 4 liters (8.5 pints) of specified ATF into case

through dipstick hole. [Total quantity of ATF required is

6.1 liters (12.9 pints).

Actually however, approx. 4.5 liters (9.5 pints) of fluid

can be replaced because rest of fluid remains in torque

converter.]Specified fluid: MOPAR ATF PLUS (Automatic

Transmission Fluid Type 7176) or

Dia ATF SP or Equivalent

(10)Start engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector lever

momentarily to each position, ending in “N” Neutral

position.

(1 l)Add sufficient ATF to bring fluid level to lower mark.

Recheck fluid level after transaxle is at normal operating

temperature.

Fluid level should be between upper and lower marks of“HOT” range. Insert dipstick fully to prevent dirt from

entering transaxle.

11 .ENGINE COOLANT (Change)NOOSBEAcCheck the cooling system parts, such as radiator, heater,

and oil cooler hoses, thermostat and connections for

leakage and damage.

CHANGE COOLANT

1. Remove the radiator cap.

2. Loosen the drain plug to drain the coolant.

3. Drain the coolant from the reserve tank.

4. After draining the coolant, tighten the drain plug

securely.

5.Supply the coolant into the radiator until it is filled up to

its filler neck.

6. Supply the coolant into the reserve tank.

7. After warming the engine until the thermostat opens,

remove the radiator cap and check the coolant level.

8.Supply the coolant into the radiator until it is filled up to

its filler neck, and install the

.radiator, cap securely.

9.Fill the reserve tank with coolant up to the “FULL” line.12DISC BRAKE PADS (Inspect for wear)

NOOSBFA~Check for fluid contamination and wear. Replace complete

set of pads if defective.

Caution

The pads for the right and left wheels should be

replaced at the same time. Never “split” or intermix

brake pad sets.

All four pads must be replace as a complete set.

Thickness of lining (A)

Limit

:2.0 mm (.08 in.)

Page 47 of 1216

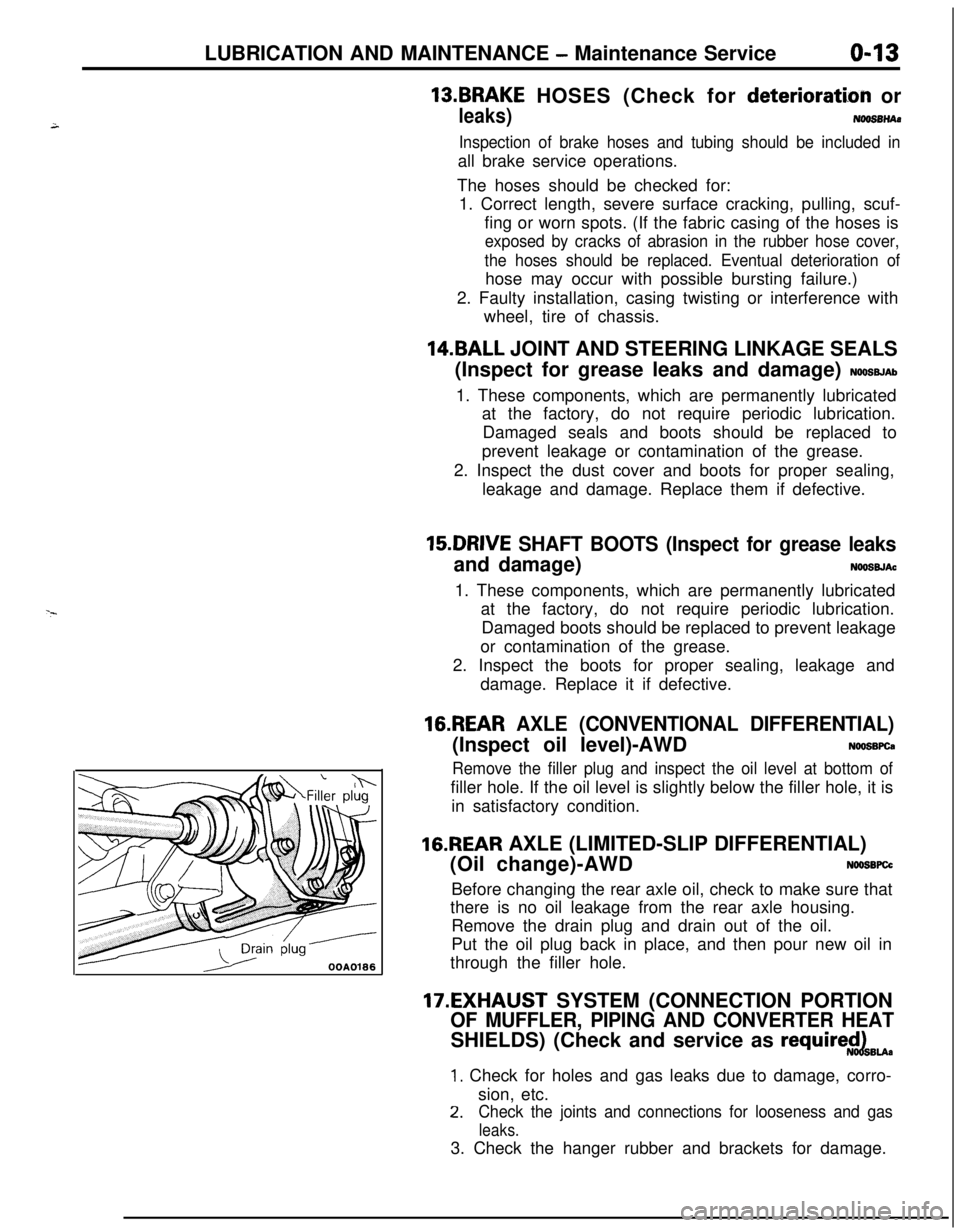

LUBRICATION AND MAINTENANCE - Maintenance Serviceo-13

OOAOlB6

13.BRAKE HOSES (Check for deteriorati.on or

leaks)NwBBnAs

Inspection of brake hoses and tubing should be included inall brake service operations.

The hoses should be checked for:

1. Correct length, severe surface cracking, pulling, scuf-

fing or worn spots. (If the fabric casing of the hoses is

exposed by cracks of abrasion in the rubber hose cover,

the hoses should be replaced. Eventual deterioration ofhose may occur with possible bursting failure.)

2. Faulty installation, casing twisting or interference with

wheel, tire of chassis.

14.BALL JOINT AND STEERING LINKAGE SEALS

(Inspect for grease leaks and damage)

NWSBJAb1. These components, which are permanently lubricated

at the factory, do not require periodic lubrication.

Damaged seals and boots should be replaced to

prevent leakage or contamination of the grease.

2. Inspect the dust cover and boots for proper sealing,

leakage and damage. Replace them if defective.

15.DRIVE SHAFT BOOTS (Inspect for grease leaksand damage)

NWSBJAc1. These components, which are permanently lubricated

at the factory, do not require periodic lubrication.

Damaged boots should be replaced to prevent leakage

or contamination of the grease.

2. Inspect the boots for proper sealing, leakage and

damage. Replace it if defective.

16.REAR AXLE (CONVENTIONAL DIFFERENTIAL)(Inspect oil level)-AWD

NWSBFCa

Remove the filler plug and inspect the oil level at bottom offiller hole. If the oil level is slightly below the filler hole, it is

in satisfactory condition.

16.REAR AXLE (LIMITED-SLIP DIFFERENTIAL)

(Oil change)-AWD

N66SBFCcBefore changing the rear axle oil, check to make sure that

there is no oil leakage from the rear axle housing.

Remove the drain plug and drain out of the oil.

Put the oil plug back in place, and then pour new oil in

through the filler hole.

17.EXHAUST SYSTEM (CONNECTION PORTION

OF MUFFLER, PIPING AND CONVERTER HEATSHIELDS) (Check and service as

require$dBu.

1. Check for holes and gas leaks due to damage, corro-

sion, etc.

2.Check the joints and connections for looseness and gas

leaks.3. Check the hanger rubber and brackets for damage.

Page 183 of 1216

BRAKES - Service Adjustment Procedures5-43When engine is

stoppedNo good

0

wtwo061

VV;Videngine is

t4uoo60

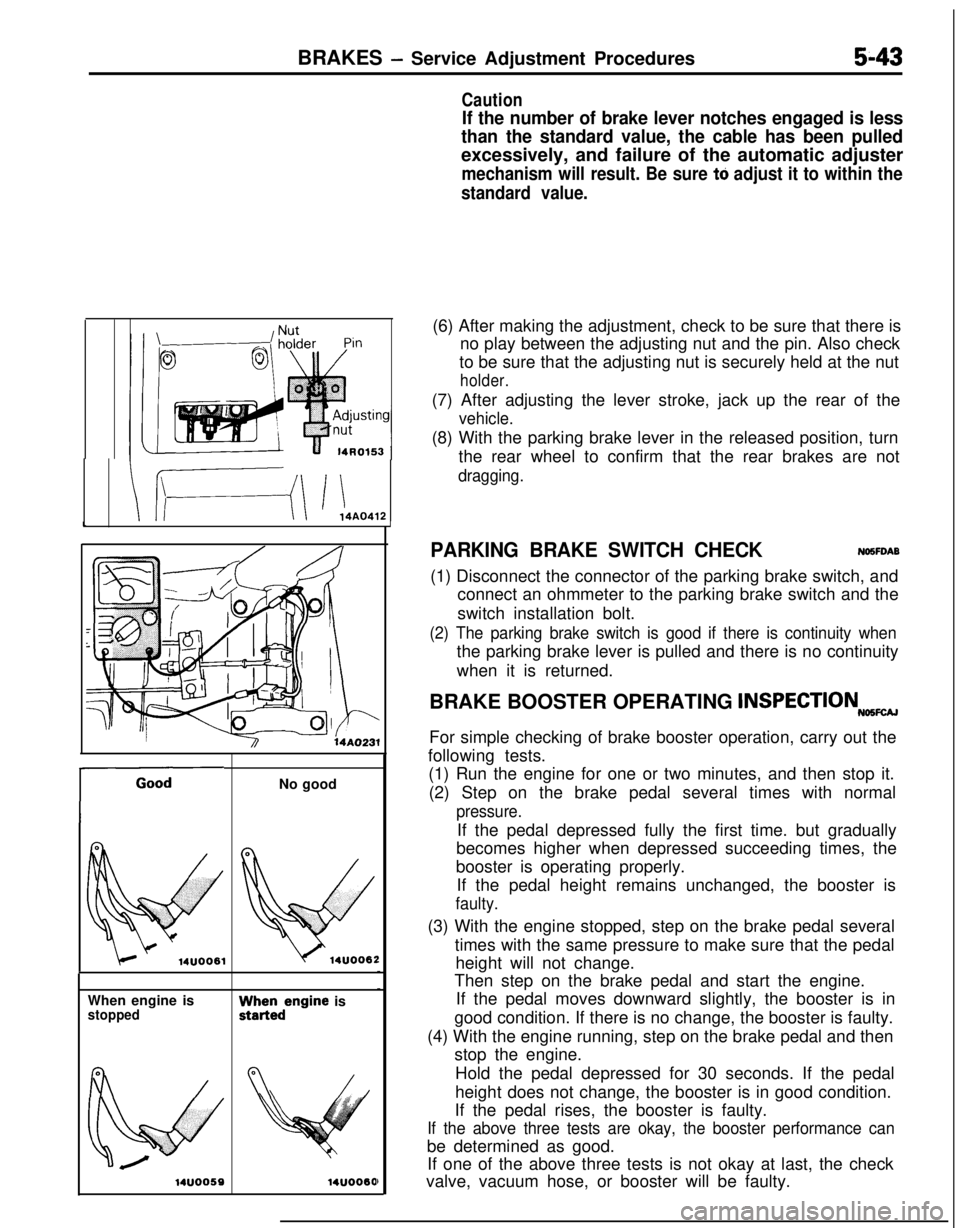

Caution

If the number of brake lever notches engaged is less

than the standard value, the cable has been pulledexcessively, and failure of the automatic adjuster

mechanism will result. Be sure tti adjust it to within the

standard value.(6) After making the adjustment, check to be sure that there is

no play between the adjusting nut and the pin. Also check

to be sure that the adjusting nut is securely held at the nut

holder.(7) After adjusting the lever stroke, jack up the rear of the

vehicle.(8) With the parking brake lever in the released position, turn

the rear wheel to confirm that the rear brakes are not

dragging.

PARKING BRAKE SWITCH CHECKN05FDAB

(1) Disconnect the connector of the parking brake switch, and

connect an ohmmeter to the parking brake switch and the

switch installation bolt.

(2) The parking brake switch is good if there is continuity whenthe parking brake lever is pulled and there is no continuity

when it is returned.

BRAKE BOOSTER OPERATING

lNSPECTIONNoSFcuFor simple checking of brake booster operation, carry out the

following tests.

(1) Run the engine for one or two minutes, and then stop it.

(2) Step on the brake pedal several times with normal

pressure.If the pedal depressed fully the first time. but gradually

becomes higher when depressed succeeding times, the

booster is operating properly.

If the pedal height remains unchanged, the booster is

faulty.(3) With the engine stopped, step on the brake pedal several

times with the same pressure to make sure that the pedal

height will not change.

Then step on the brake pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is faulty.

(4) With the engine running, step on the brake pedal and then

stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is faulty.

If the above three tests are okay, the booster performance canbe determined as good.

If one of the above three tests is not okay at last, the check

valve, vacuum hose, or booster will be faulty.

Page 188 of 1216

5-48BRAKES - Service Adjustment Procedures

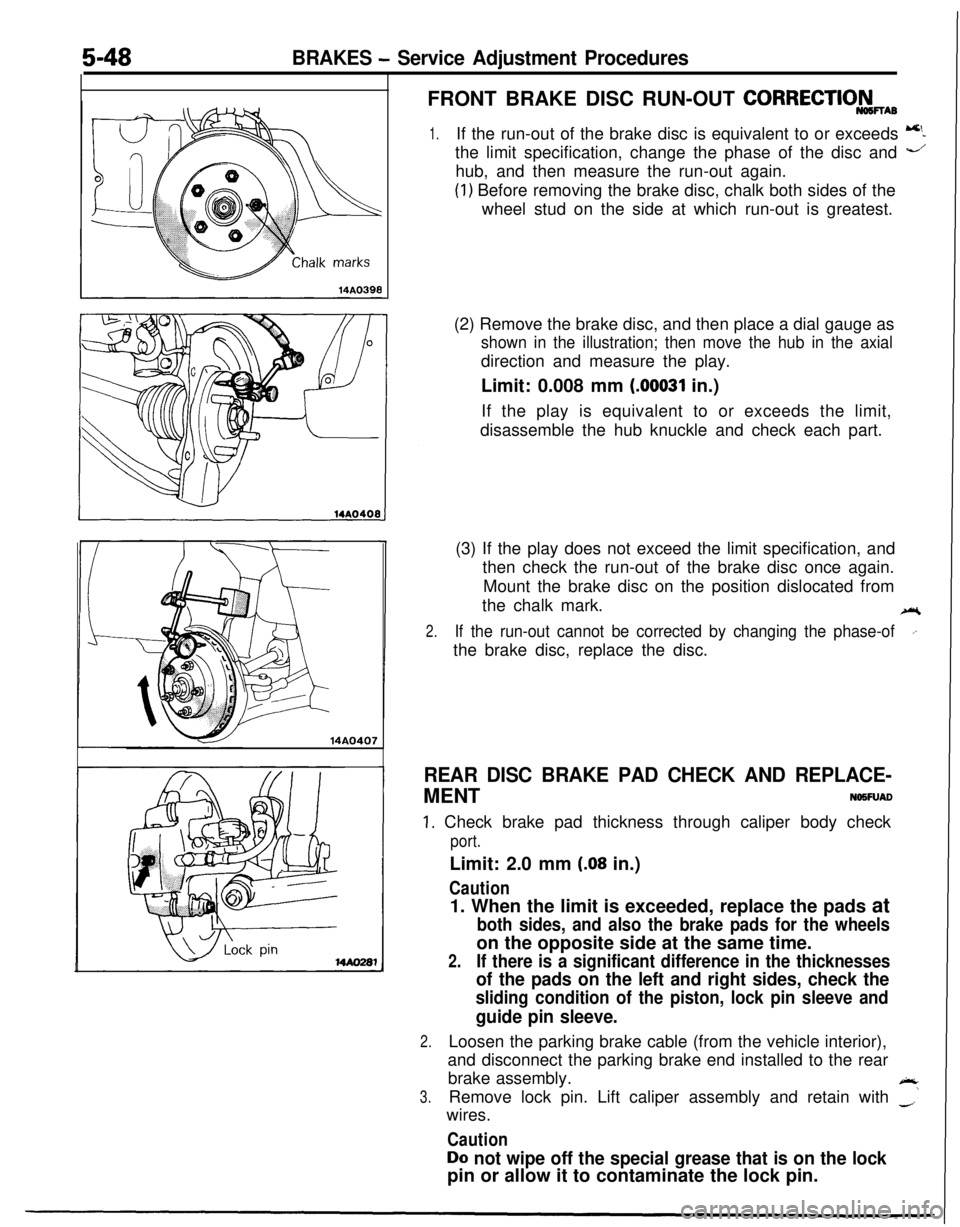

14A0407FRONT BRAKE DISC RUN-OUT

CORRECTIO&wAB

1.If the run-out of the brake disc is equivalent to or exceeds 5the limit specification, change the phase of the disc and

-’hub, and then measure the run-out again.

(1) Before removing the brake disc, chalk both sides of the

wheel stud on the side at which run-out is greatest.

(2) Remove the brake disc, and then place a dial gauge as

shown in the illustration; then move the hub in the axialdirection and measure the play.

Limit: 0.008 mm

(00031 in.)

If the play is equivalent to or exceeds the limit,

disassemble the hub knuckle and check each part.

(3) If the play does not exceed the limit specification, and

then check the run-out of the brake disc once again.

Mount the brake disc on the position dislocated from

the chalk mark.

ei

2.If the run-out cannot be corrected by changing the phase-ofI’the brake disc, replace the disc.

REAR DISC BRAKE PAD CHECK AND REPLACE-MENT

NO5FUAD

1. Check brake pad thickness through caliper body check

port.Limit: 2.0 mm

(.08 in.)

Caution1. When the limit is exceeded, replace the pads at

both sides, and also the brake pads for the wheelson the opposite side at the same time.

2.If there is a significant difference in the thicknesses

of the pads on the left and right sides, check the

sliding condition of the piston, lock pin sleeve and

guide pin sleeve.

2.Loosen the parking brake cable (from the vehicle interior),

and disconnect the parking brake end installed to the rear

brake assembly.

A

3.Remove lock pin. Lift caliper assembly and retain with -‘wires.

Caution

Do not wipe off the special grease that is on the lockpin or allow it to contaminate the lock pin.

Page 247 of 1216

CLUTCH - Clutch Cover and Disc647

08A0038

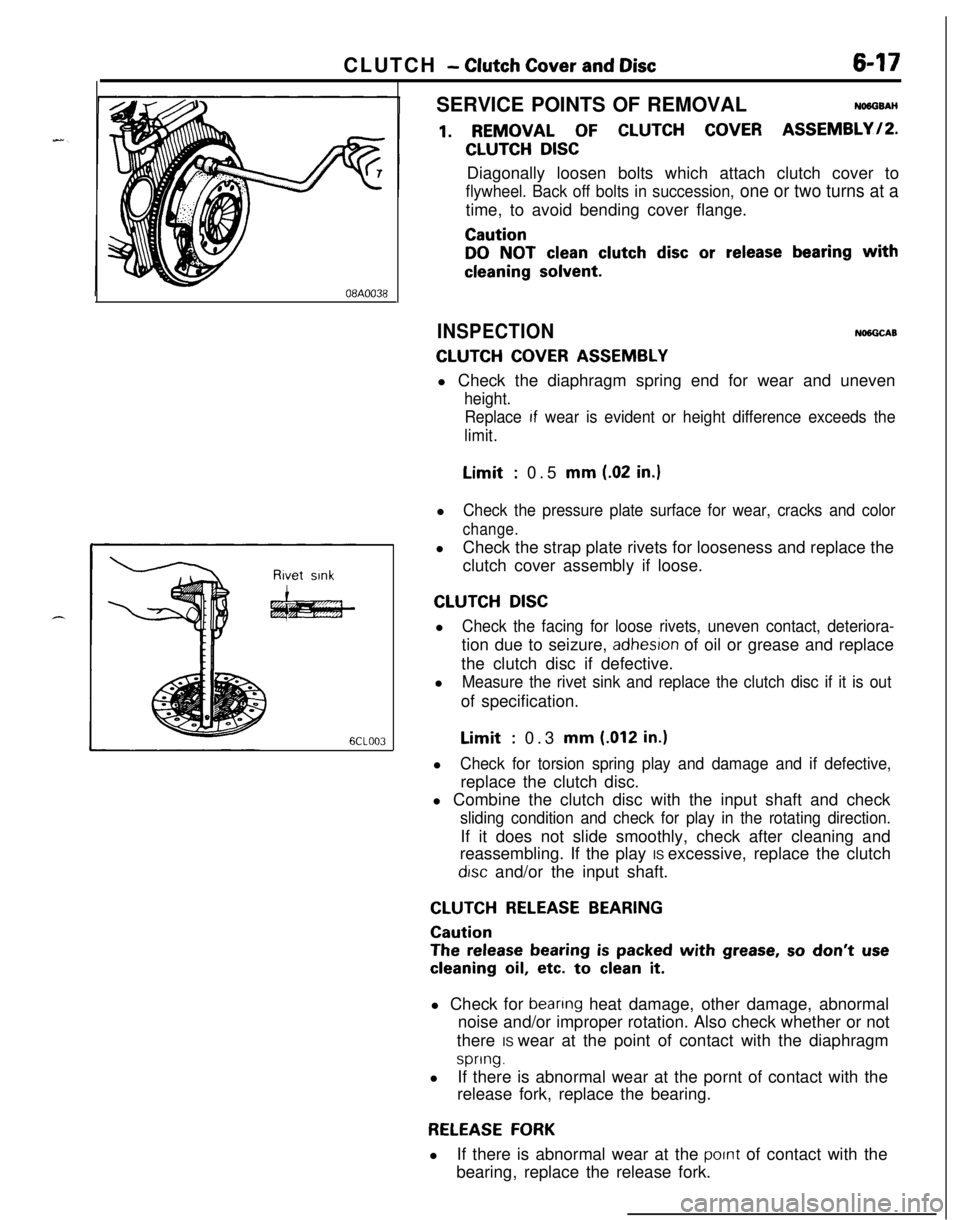

6CLOO3SERVICE POINTS OF REMOVAL

NO6OSAH

1. REMOVAL OF CLUTCH COVER ASSEMBLY/P.

CLUTCH DISCDiagonally loosen bolts which attach clutch cover to

flywheel. Back off bolts in succession, one or two turns at atime, to avoid bending cover flange.

Caution

DO NOT clean clutch disc or release bearing with

cleaning solvent.

INSPECTIONNlNGCAB

CLUTCH COVER ASSEMBLYl Check the diaphragm spring end for wear and uneven

height.

Replace

If wear is evident or height difference exceeds the

limit.Limit

: 0.5 mm (.02 in.)l

Check the pressure plate surface for wear, cracks and color

change.lCheck the strap plate rivets for looseness and replace the

clutch cover assembly if loose.

CLUTCH DISCl

Check the facing for loose rivets, uneven contact, deteriora-tion due to seizure,

adhesron of oil or grease and replace

the clutch disc if defective.

l

Measure the rivet sink and replace the clutch disc if it is outof specification.Limit

: 0.3 mm (.012 in.)l

Check for torsion spring play and damage and if defective,replace the clutch disc.

l Combine the clutch disc with the input shaft and check

sliding condition and check for play in the rotating direction.If it does not slide smoothly, check after cleaning and

reassembling. If the play IS excessive, replace the clutch

drsc and/or the input shaft.

CLUTCH RELEASE BEARING

Caution

The release bearing is packed with grease, so don’t use

cleaning oil, etc. to clean it.l Check for

beanng heat damage, other damage, abnormal

noise and/or improper rotation. Also check whether or not

there IS wear at the point of contact with the diaphragm

spring.lIf there is abnormal wear at the pornt of contact with the

release fork, replace the bearing.

RELEASE FORKlIf there is abnormal wear at the

pornt of contact with the

bearing, replace the release fork.

Page 660 of 1216

19-12STEERING - Service Adjustment Procedures

Pressure ofWater pump

pulleyOlA0059Fluid fluctuation

While engine

runningWhile enginestopped13uo139

Return hoseVinyl hose

x ,3Ao,42-

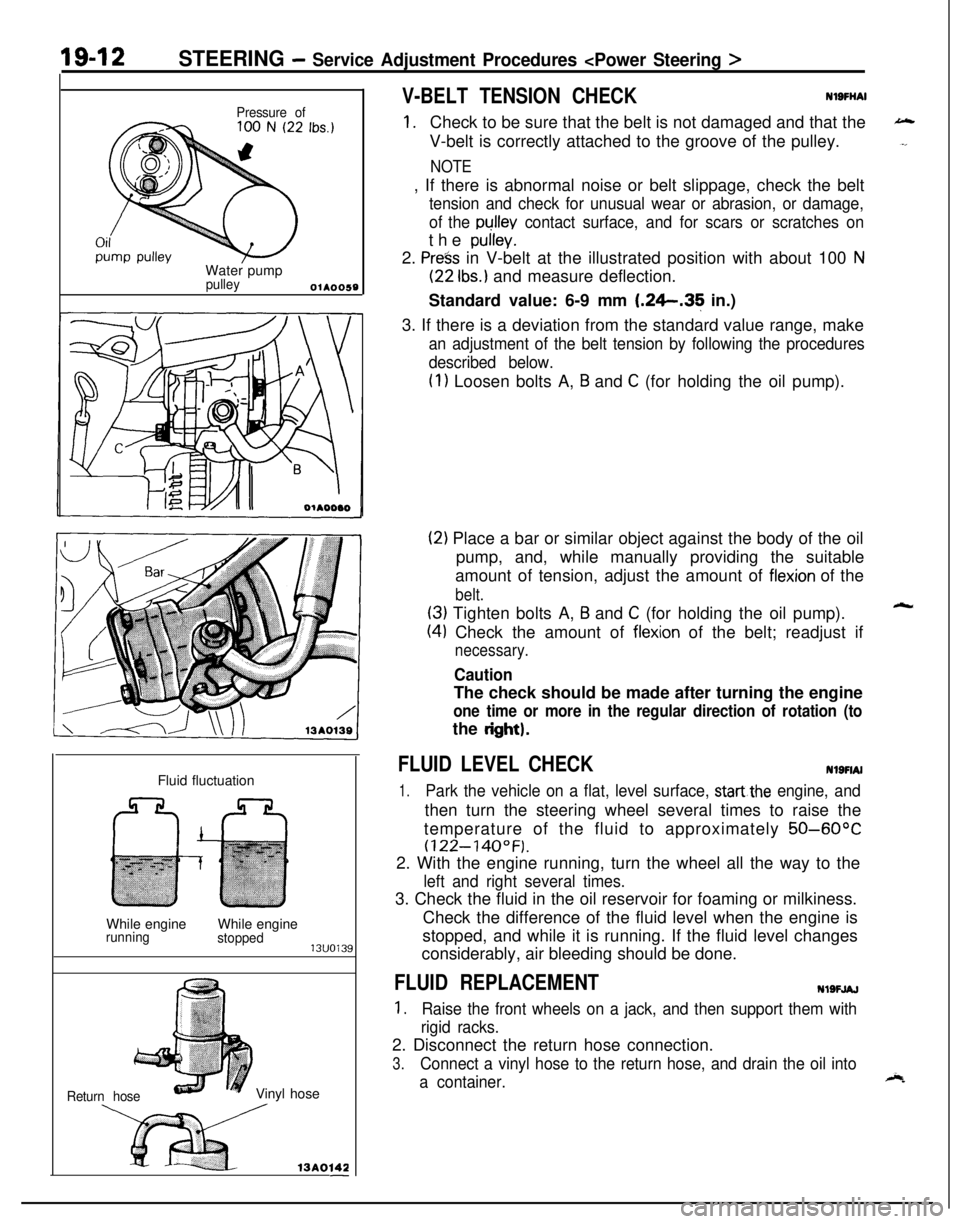

V-BELT TENSION CHECKNlSFliAl

1.Check to be sure that the belt is not damaged and that the

V-belt is correctly attached to the groove of the pulley.

NOTE, If there is abnormal noise or belt slippage, check the belt

tension and check for unusual wear or abrasion, or damage,

of the

pullev contact surface, and for scars or scratches onthe

pulley.2.

Press in V-belt at the illustrated position with about 100 N

(22 Ibs.) and measure deflection.

Standard value: 6-9 mm

1.26.35 in.)

3. If there is a deviation from the standard value range, make

an adjustment of the belt tension by following the procedures

described below.

(1) Loosen bolts A, B and C (for holding the oil pump).

(2) Place a bar or similar object against the body of the oil

pump, and, while manually providing the suitable

amount of tension, adjust the amount of

flexion of the

belt.

(3) Tighten bolts A, B and C (for holding the oil pump).

(4) Check the amount of flexion of the belt; readjust if

necessary.

CautionThe check should be made after turning the engine

one time or more in the regular direction of rotation (tothe

dght).

FLUID LEVEL CHECKNlSFIAI

1.Park the vehicle on a flat, level surface, startthe engine, andthen turn the steering wheel several times to raise the

temperature of the fluid to approximately

50-60°C

(122-140°F).2. With the engine running, turn the wheel all the way to the

left and right several times.3. Check the fluid in the oil reservoir for foaming or milkiness.

Check the difference of the fluid level when the engine is

stopped, and while it is running. If the fluid level changes

considerably, air bleeding should be done.

FLUID REPLACEMENTNlSFJAJ

1.Raise the front wheels on a jack, and then support them with

rigid racks.2. Disconnect the return hose connection.

3.Connect a vinyl hose to the return hose, and drain the oil into

a container.

Page 661 of 1216

STEERING - Service -Adjustment Procedures < Power Steering >IgJf~

4.Disconnect the high-tension cable, and then while operating

the starting motor intermittently, turn the steering wheel all;

the way to the left and right several times to drain all of the

fluid.

Caution, 35

Be careful not to position thq high-tension able ye&r the

carburetor or the delivery pipe.5. Connect the return hoses securely, and then

secur& it ,with

the clip.6. Fill the oil reservoir with the specified fluid up

td the Ibwerposition of the filter, and then bleed the air.

.’

Specified fluid:MOPAR ATF PLUS (Automatic Transmis-sion Fluid Type 7176)/Automatic trans-

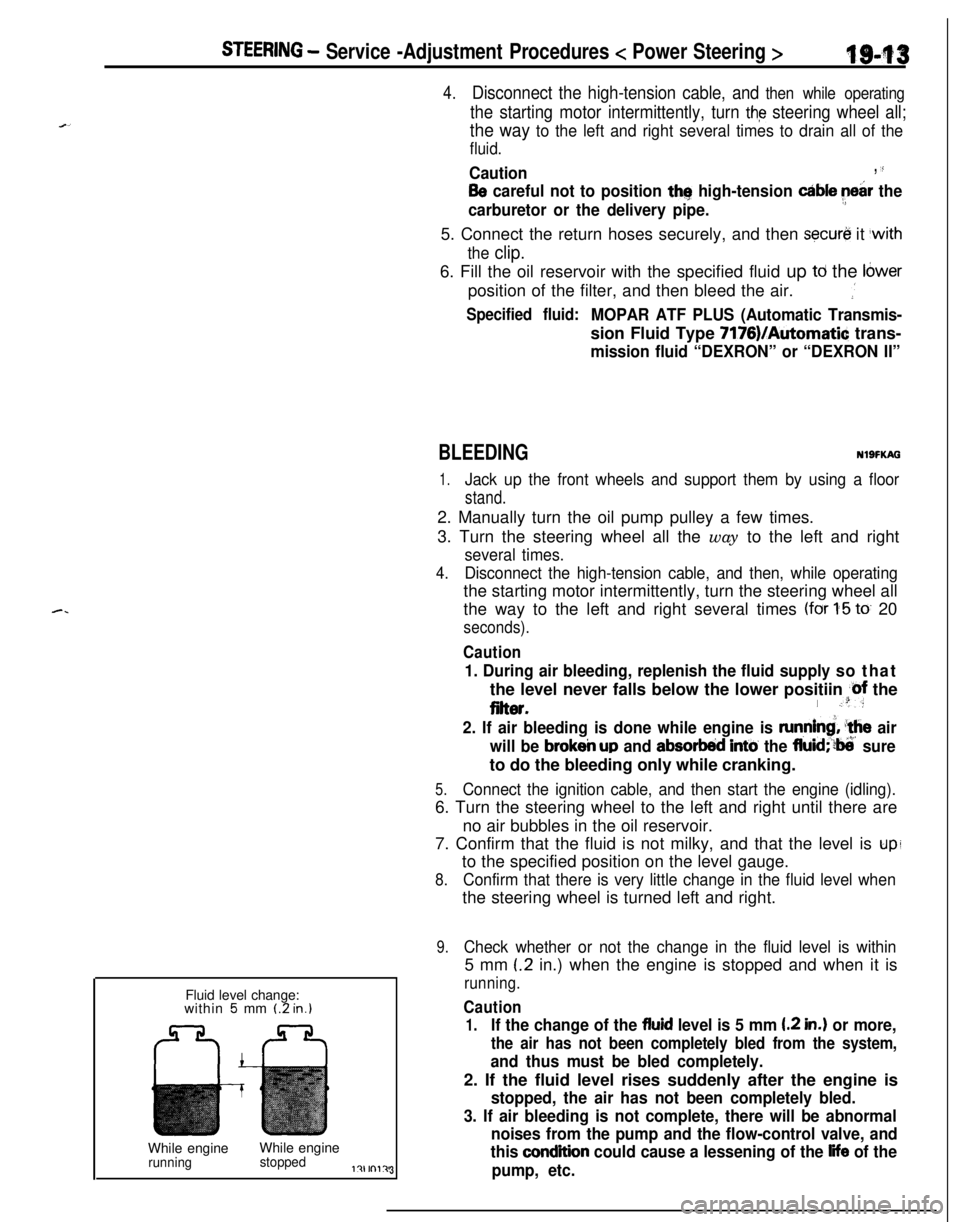

mission fluid “DEXRON” or “DEXRON II”Fluid level change:

within

5 mm (2 in.)While engineWhile engine

runningstoppedl?lrnl?J3

BLEEDINGNlSFKAG

1.Jack up the front wheels and support them by using a floor

stand.2. Manually turn the oil pump pulley a few times.

3. Turn the steering wheel all the way to the left and right

several times.

4.Disconnect the high-tension cable, and then, while operatingthe starting motor intermittently, turn the steering wheel all

the way to the left and right several times

(for 1-5 to 20

seconds).

Caution

1. During air bleeding, replenish the fluid supply so thatthe level never falls below the lower positiin

@f the

eiter.I .“:

2. If air bleeding is done while engine is runnind, ‘the air

will be

brokeir up and absorbed intti the fluid;‘?ti’ sureto do the bleeding only while cranking.

5.Connect the ignition cable, and then start the engine (idling).6. Turn the steering wheel to the left and right until there are

no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is

upito the specified position on the level gauge.

8.Confirm that there is very little change in the fluid level whenthe steering wheel is turned left and right.

9.Check whether or not the change in the fluid level is within5 mm

(.2 in.) when the engine is stopped and when it is

running.

Caution

1.If the change of the fluid level is 5 mm I.2 in.) or more,

the air has not been completely bled from the system,

and thus must be bled completely.2. If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled.

3. If air bleeding is not complete, there will be abnormal

noises from the pump and the flow-control valve, and

this

condition could cause a lessening of the life of the

pump, etc.