air conditioner MITSUBISHI ECLIPSE 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1149 of 1216

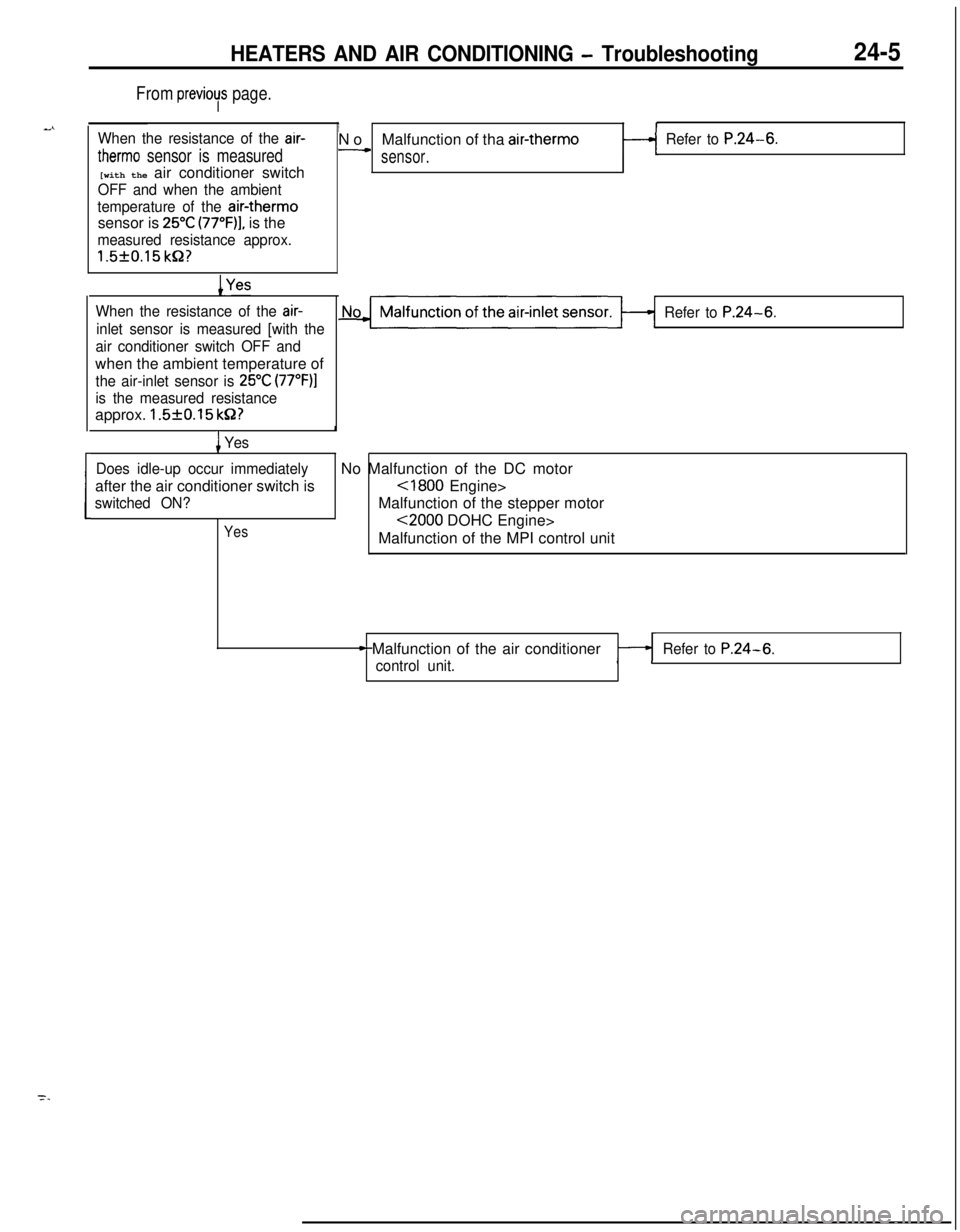

HEATERS AND AIR CONDITIONING - Troubleshooting24-5

From previoys page.

When the resistance of the air-

therm0 sensor is measured[with the air conditioner switch

OFF and when the ambient

temperature of the

air-therm0sensor is

25°C (77“F)], is the

measured resistance approx.

1.5f0.15 kP?

INoMalfunction of tha air-therm0Refer to P.24-6.-sensor.

Refer to P.24-6.

1Yes

When the resistance of the air-

inlet sensor is measured [with the

air conditioner switch OFF andwhen the ambient temperature of

the air-inlet sensor is 25°C (77”F)l

is the measured resistanceapprox.

1.5f0.15 k&2?I

1 Yes

Does idle-up occur immediatelyNo Malfunction of the DC motor

after the air conditioner switch is

cl800 Engine>

switched ON?Malfunction of the stepper motor

Yes~2000 DOHC Engine>

Malfunction of the MPI control unit

* Malfunction of the air conditioner

control unit.Refer to P.24-6.

Page 1150 of 1216

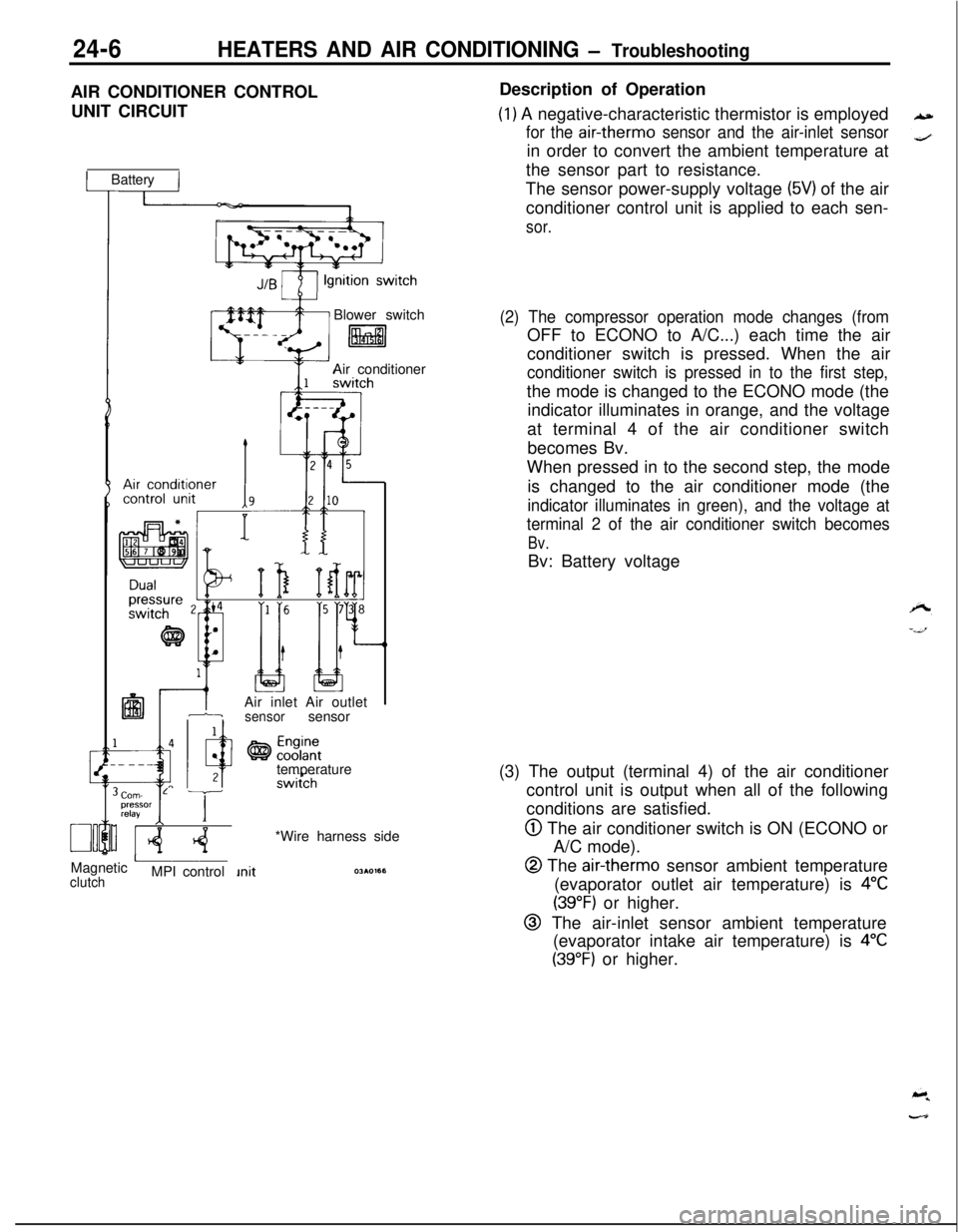

24-6HEATERS AND AIR CONDITIONING - TroubleshootingAIR CONDITIONER CONTROL

UNIT CIRCUIT

1 Battery IBlower switch

litalAir conditioner

IAir inlet Air outlet1-isensorsensor

temperature

Corn- L Tpressor

relayI IMagnetic

AclutchMPI control*Wire harness sideDescription of Operation

(1) A negative-characteristic thermistor is employed

for the air-therm0 sensor and the air-inlet sensorin order to convert the ambient temperature at

the sensor part to resistance.

The sensor power-supply voltage

(5V) of the air

conditioner control unit is applied to each sen-

sor.

(2) The compressor operation mode changes (fromOFF to ECONO to A/C...) each time the air

conditioner switch is pressed. When the air

conditioner switch is pressed in to the first step,the mode is changed to the ECONO mode (the

indicator illuminates in orange, and the voltage

at terminal 4 of the air conditioner switch

becomes Bv.

When pressed in to the second step, the mode

is changed to the air conditioner mode (the

indicator illuminates in green), and the voltage at

terminal 2 of the air conditioner switch becomes

Bv.Bv: Battery voltage

(3) The output (terminal 4) of the air conditioner

control unit is output when all of the following

conditions are satisfied.

@ The air conditioner switch is ON (ECONO or

A/C mode).

@ The air-therm0 sensor ambient temperature

(evaporator outlet air temperature) is

4°C

(39°F) or higher.

@ The air-inlet sensor ambient temperature

(evaporator intake air temperature) is

4°C

(39°F) or higher.

Page 1151 of 1216

HEATERS AND AIR CONDITIONING - Troubleshootinq

-.

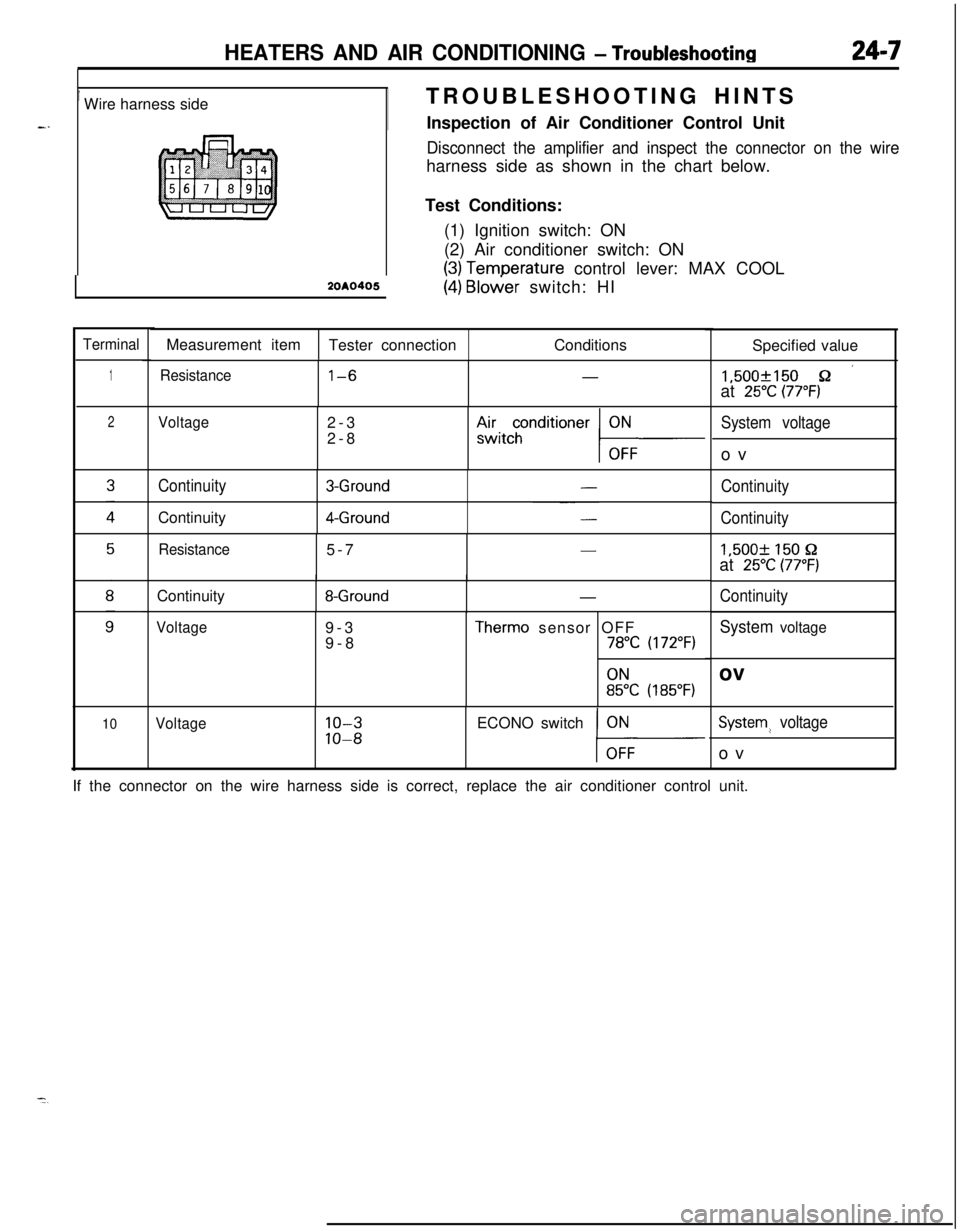

’ Wire harness sideTROUBLESHOOTING HINTS

Inspection of Air Conditioner Control Unit

Disconnect the amplifier and inspect the connector on the wireharness side as shown in the chart below.

Test Conditions:

(1) Ignition switch: ON

(2) Air conditioner switch: ON

(3) Temoerature control lever: MAX COOL2OAO405

(4j Bloier switch: HI

TerminalMeasurement item

Tester connectionConditions

Specified value

1Resistancel-6-1,500f150 sz ’at 25°C (77°F)

2

10

Voltage2-3

2-8Airtcchonditioner

ContinuityContinuity3-Ground

4-Ground

Resistance5-7

-ContinuityII

8-Ground-

Voltage9-3

9-8Therm0 sensor OFF78°C (172°F)

:5k (185°F)

Voltage10-3ECONO switch

10-8

System voltageov

Continuity

Continuity1,500+

150 s-2at 25°C (77’F)

Continuity

System voltageov

System? voltageov

If the connector on the wire harness side is correct, replace the air conditioner control unit.

Page 1152 of 1216

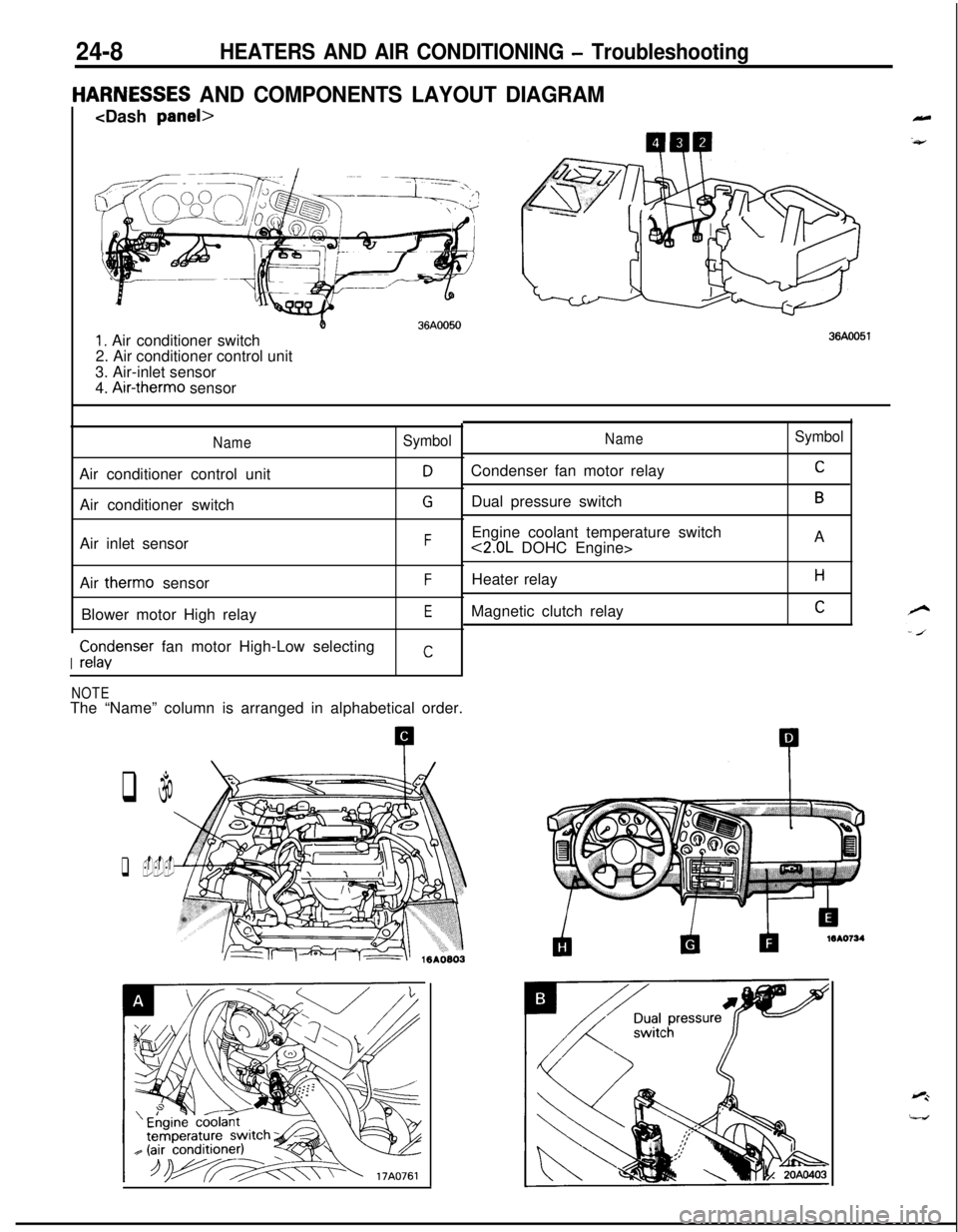

24-8HEATERS AND AIR CONDITIONING - Troubleshooting

IARNESSES AND COMPONENTS LAYOUT DIAGRAM

1. Air conditioner switch

2. Air conditioner control unit

3. Air-inlet sensor

4.

Air-therm0 sensor

36AOO51

NameSymbolAir conditioner control unit

DAir conditioner switch

GAir inlet sensor

FAir

therm0 sensorFBlower motor High relay

E

IrrIor:enser fan motor High-Low selecting

C

NameCondenser fan motor relay

Dual pressure switch

Engine coolant temperature switch

<2.0L DOHC Engine>

Heater relay

Magnetic clutch relay

Symbol

C

BA

H

C

NOTEThe “Name” column is arranged in alphabetical order.

q \

q ---

Page 1154 of 1216

24-10HEATERS AND AIR CONDITIONING - Safety Precautions

SAFETY PRECAUTIONSN24PAAD

The refrigerant used in all air conditioner is R-l 2. It istransparent and colorless in both the liquid and

vapor state. Since it has a boiling point of

-29.8”C(-85.6”F).

at atmospheric pressure, it will be a vapor

at all normal temperatures and pressures. The vaporis heavier than air, non-flammable, and nonexplo-

sive. It is nonpoisonous except when it is in direct

contact with open flame. It

ia noncorrosive except

when combined with water. The following precau-

tions must be observed when handling

R-12.Caution

Wear safety goggles when servicing the refriger-ation system.

R-12 evaporates so rapidly at normal atmospheric

pressures and temperatures that it tends to freeze

anything it contacts. For this reason, extreme care

must be taken to prevent any liquid refrigerant from

contacting the skin and especially the eyes. Always

wear safety goggles when servicing the refrigera-

tion part of the air conditioning system. Keep a

bottle of sterile mineral oil handy when working on

the refrigeration system. Should any liquid re-

frigerant get into the eyes, use a few drops of

mineral oil to wash them out.

R-12 is rapidly

absorbed by the oil. Next splash the eyes with

plenty of cold water. Call your doctor immediately

even though irritation has ceased after treatment.

Caution

Do not heat

R-12 above 40°C (104°F).In most instances, moderate heat is required to

bring the pressure of the refrigerant in its container

above the pressure of the system when charging or

adding refrigerant. A bucket or large pan of hot

water not over

40°C (104°F) is all the heat required

for this purpose. Do not heat the refrigerant contain-

er with a blow torch or any other means that would

raise temperature and pressure above this tempera-ture. Do not weld or steam clean on or near the

system components or refrigerant lines.

Caution

Keep

R-12 containers upright when charging the

system.When metering

R-12 into the refrigeration system,

keep the supply tank or cans in an upright position. Ifthe refrigerant container is on its side or upside

down, liquid refrigerant will enter the system and

damage the compressor.Caution

Always work in a well-ventilated room.

‘irrGood ventilation is vital in the working area. Always

discharge the refrigerant into the service bay ex-

haust system or outside the building. Large quanti-

ties of refrigerant vapor in a small, poorly ventilated

room can displace the air and cause suffocation.

Although

R-12 vapor is normally nonpoisonous,

contact with an open flame can cause the vapor to

become very poisonous. Do not discharge large

quantities of refrigerant in an area having an open

flame. A poisonous gas is produced when using theflame-type leak detector. Avoid inhaling the fumes

from the leak detector.

Caution

Do not allow liquid refrigerant to touch bright

metal.

Refrigerant will tarnish bright metal and chrome

surfaces, and in combination with moisture can

severely corrode all metal surfaces.

R-12 Refrigerant Bundling

Refrigerant Recycling

R-12 refrigerant is a chloro-floro-carbon (CFC) that

can contribute to the depletion of the ozone layer in

the upper atmosphere.A

Ozone filters out harmful radiation from the sun.

- -/.To assist in protecting the ozone layer, Mitsubishi

Motors Corporation

recomends that a R-12 re-

frigerant recycling device that meets SAE standard

J1991 be used.

Contact an automotive service equipment supplier

for refrigerant recycling equipment that is available

in your area.

Refer to the operating instructions provided with therecycling equipment for proper operation.

Page 1155 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-I 1

SERVICE ADJUSTMENT PROCEDURES

MANIFOLD GAUGE SET INSTALLATION

Suction

gauge

N24FDAF

Discharge

hose

7 Discharge

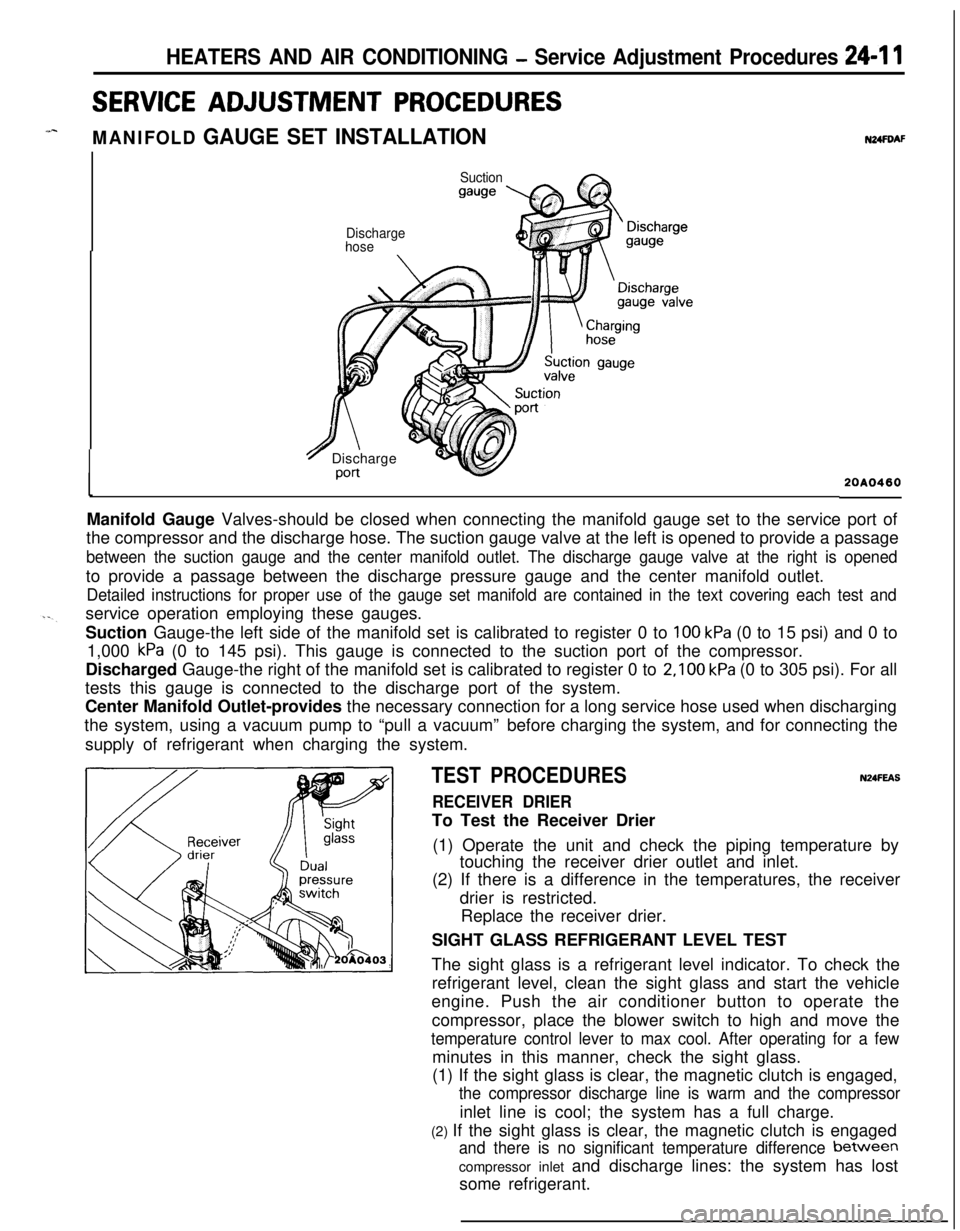

Port20A0460Manifold Gauge Valves-should be closed when connecting the manifold gauge set to the service port of

the compressor and the discharge hose. The suction gauge valve at the left is opened to provide a passage

between the suction gauge and the center manifold outlet. The discharge gauge valve at the right is openedto provide a passage between the discharge pressure gauge and the center manifold outlet.

Detailed instructions for proper use of the gauge set manifold are contained in the text covering each test andservice operation employing these gauges.

Suction Gauge-the left side of the manifold set is calibrated to register 0 to

100 kPa (0 to 15 psi) and 0 to

1,000

kPa (0 to 145 psi). This gauge is connected to the suction port of the compressor.

Discharged Gauge-the right of the manifold set is calibrated to register 0 to

2,100 kPa (0 to 305 psi). For all

tests this gauge is connected to the discharge port of the system.

Center Manifold Outlet-provides the necessary connection for a long service hose used when discharging

the system, using a vacuum pump to “pull a vacuum”before charging the system, and for connecting the

supply of refrigerant when charging the system.

TEST PROCEDURESN24FEAS

RECEIVER DRIERTo Test the Receiver Drier

(1) Operate the unit and check the piping temperature by

touching the receiver drier outlet and inlet.

(2) If there is a difference in the temperatures, the receiver

drier is restricted.

Replace the receiver drier.

SIGHT GLASS REFRIGERANT LEVEL TEST

The sight glass is a refrigerant level indicator. To check the

refrigerant level, clean the sight glass and start the vehicle

engine. Push the air conditioner button to operate the

compressor, place the blower switch to high and move the

temperature control lever to max cool. After operating for a fewminutes in this manner, check the sight glass.

(1) If the sight glass is clear, the magnetic clutch is engaged,

the compressor discharge line is warm and the compressorinlet line is cool; the system has a full charge.

(2) If the sight glass is clear, the magnetic clutch is engaged

and there is no significant temperature difference between

compressor inlet and discharge lines: the system has lost

some refrigerant.

Page 1156 of 1216

24-12 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

------__--210 2352,100 Pressure

(30) (33)(299) 2&

kPa(psi)2OPOO14(3) If the sight glass is clear and the magnetic clutch is

disengaged; the clutch is faulty or, the system is out of

refrigerant. Perform low pressure switch test to determine

condition. Check low pressure switch, and clutch coil for

electrical continuity.

(4) If the sight glass shows foam or bubbles, the system could

be low on charge. Occasional foam or bubbles are normal

when the ambient temperature is above

43°C (110°F) or

below

21°C (70°F).Adjust the engine speed to 1,500 rpm. Block the air-flow

thru the condenser to increase the compressor discharge

pressure to 1,422 to 1,520

kPa (206 to 220 psi). If sight

glass still shows bubbles or foam, system charge level is

low.The refrigerant system will not be low on charge unless

there is a leak. Find and repair the leak. If the leak can be

repaired without discharging the system an oil level check

is not necessary. Use the procedure for correcting low

refrigerant level found in the Refrigerant System Service

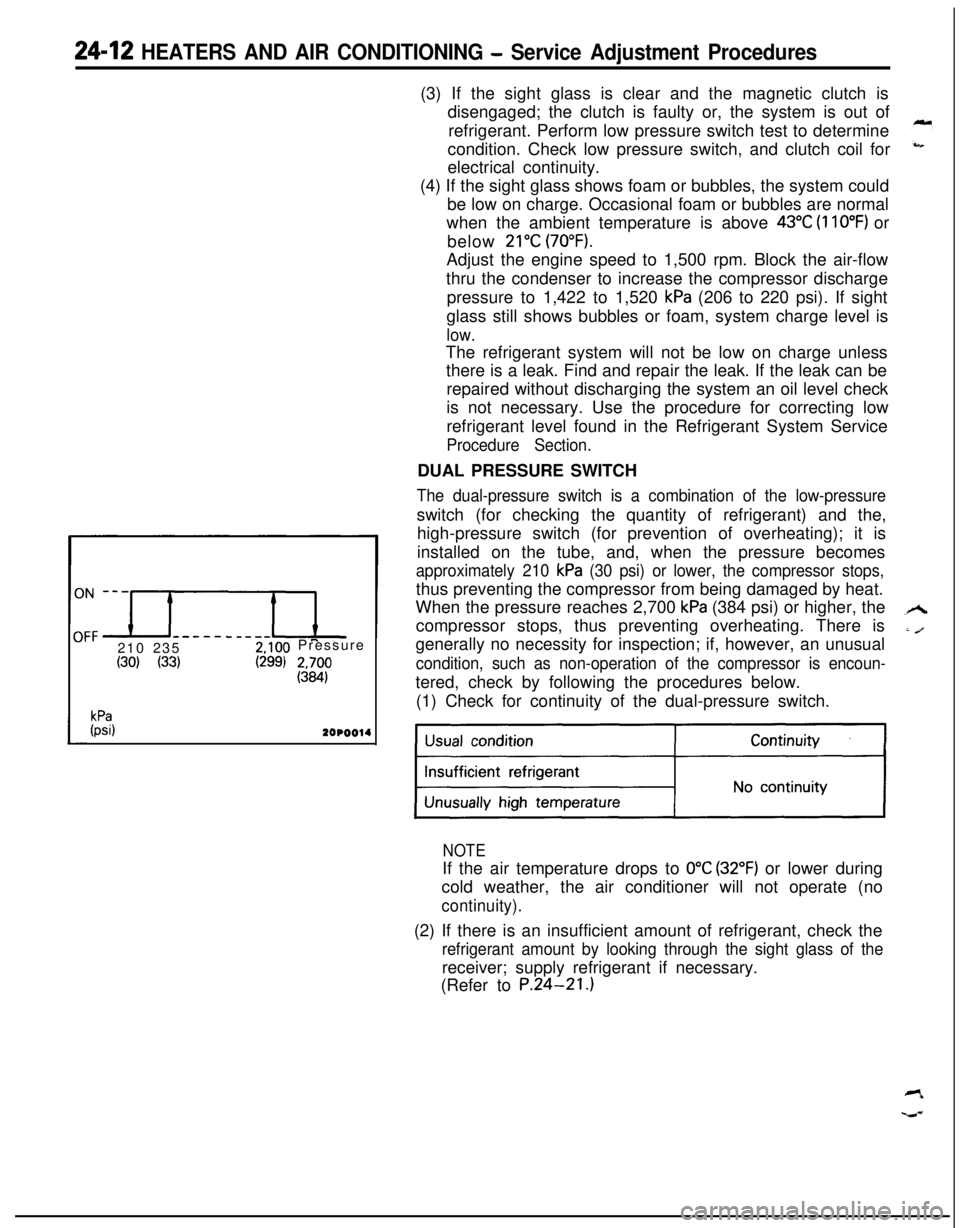

Procedure Section.DUAL PRESSURE SWITCH

The dual-pressure switch is a combination of the low-pressureswitch (for checking the quantity of refrigerant) and the,

high-pressure switch (for prevention of overheating); it is

installed on the tube, and, when the pressure becomes

approximately 210 kPa (30 psi) or lower, the compressor stops,thus preventing the compressor from being damaged by heat.

When the pressure reaches 2,700

kPa (384 psi) or higher, the

compressor stops, thus preventing overheating. There is

generally no necessity for inspection; if, however, an unusual

condition, such as non-operation of the compressor is encoun-tered, check by following the procedures below.

(1) Check for continuity of the dual-pressure switch.

NOTEIf the air temperature drops to

0°C (32°F) or lower during

cold weather, the air conditioner will not operate (no

continuity).(2) If there is an insufficient amount of refrigerant, check the

refrigerant amount by looking through the sight glass of thereceiver; supply refrigerant if necessary.

(Refer to P.24-21.)

Page 1157 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 249*I3

--Air-therm0

sensor

Air inlet

sensor

E>aporator(3)

Set the gauge manifold in place and check whether or not

the pressure at the high-pressure side has become the

dual-pressure switch activation pressure.

(4) Replace the switch if, under ordinary conditions, there is no

continuity.Caution

The condition can be considered to be satisfactory if

there is continuity.

Never increase the pressure in a deliberate attempt to

obtain an abnormally high temperature, because to do

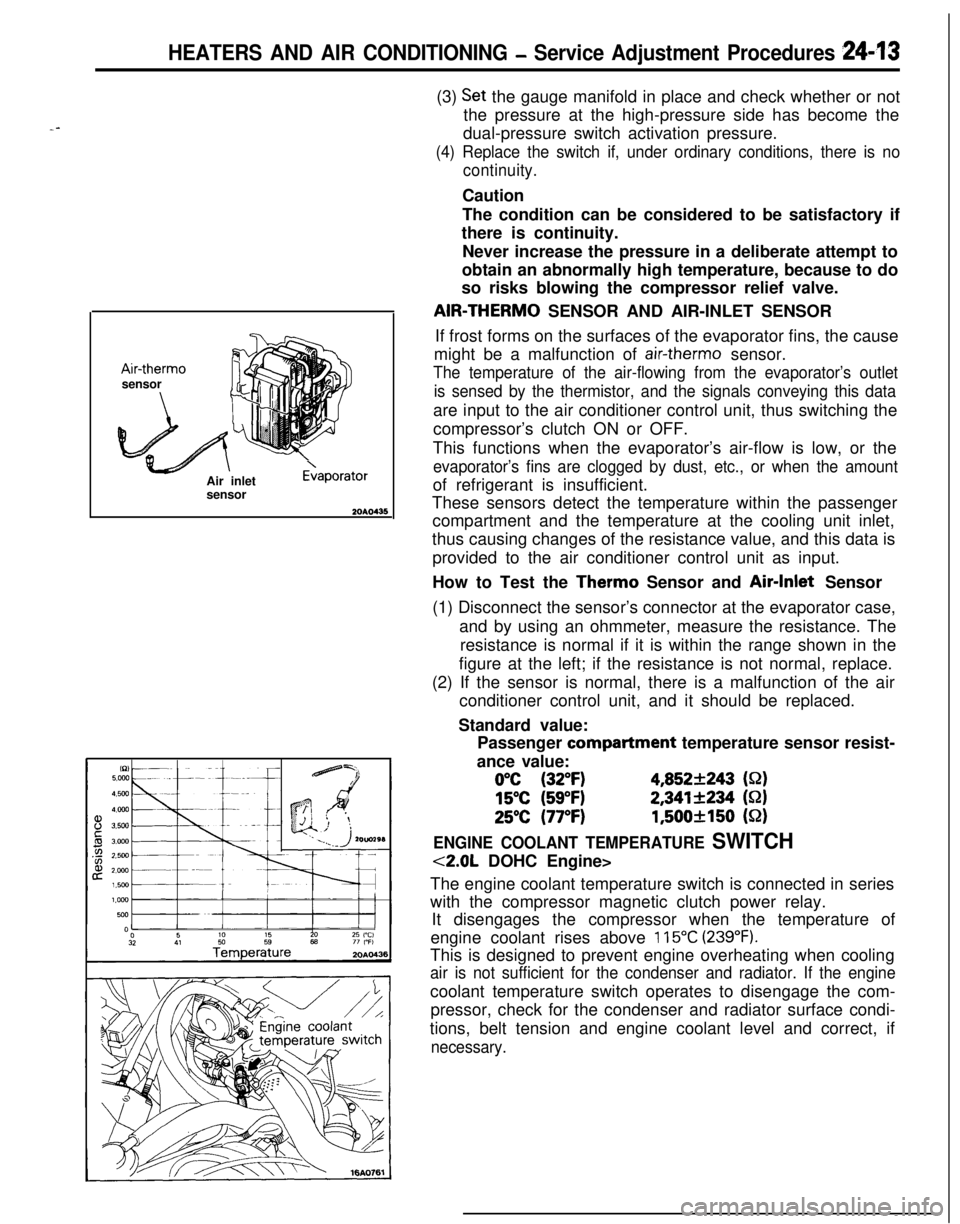

so risks blowing the compressor relief valve.AIR-THERM0 SENSOR AND AIR-INLET SENSOR

If frost forms on the surfaces of the evaporator fins, the cause

might be a malfunction of

air-therm0 sensor.

The temperature of the air-flowing from the evaporator’s outlet

is sensed by the thermistor, and the signals conveying this dataare input to the air conditioner control unit, thus switching the

compressor’s clutch ON or OFF.

This functions when the evaporator’s air-flow is low, or the

evaporator’s fins are clogged by dust, etc., or when the amountof refrigerant is insufficient.

These sensors detect the temperature within the passenger

compartment and the temperature at the cooling unit inlet,

thus causing changes of the resistance value, and this data is

provided to the air conditioner control unit as input.

How to Test the Therm0 Sensor and Air-Inlet Sensor

(1) Disconnect the sensor’s connector at the evaporator case,

and by using an ohmmeter, measure the resistance. The

resistance is normal if it is within the range shown in the

figure at the left; if the resistance is not normal, replace.

(2) If the sensor is normal, there is a malfunction of the air

conditioner control unit, and it should be replaced.

Standard value:

Passenger compartment temperature sensor resist-

ance value:

0°C (32°F)4,852+243 (S-2)

15°C (59°F)2,341+234 (S-2)

25°C (77°F)1,500+150 (52)

ENGINE COOLANT TEMPERATURE SWITCH

<2.0L DOHC Engine>

The engine coolant temperature switch is connected in series

with the compressor magnetic clutch power relay.

It disengages the compressor when the temperature of

engine coolant rises above

115°C (239°F).This is designed to prevent engine overheating when cooling

air is not sufficient for the condenser and radiator. If the enginecoolant temperature switch operates to disengage the com-

pressor, check for the condenser and radiator surface condi-

tions, belt tension and engine coolant level and correct, if

necessary.

Page 1158 of 1216

24-14 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

-Discharge

w-w

SuctiongaugeDischalgauge

2OUO306

SuctiongaugeDischargegauge

2OUO307--

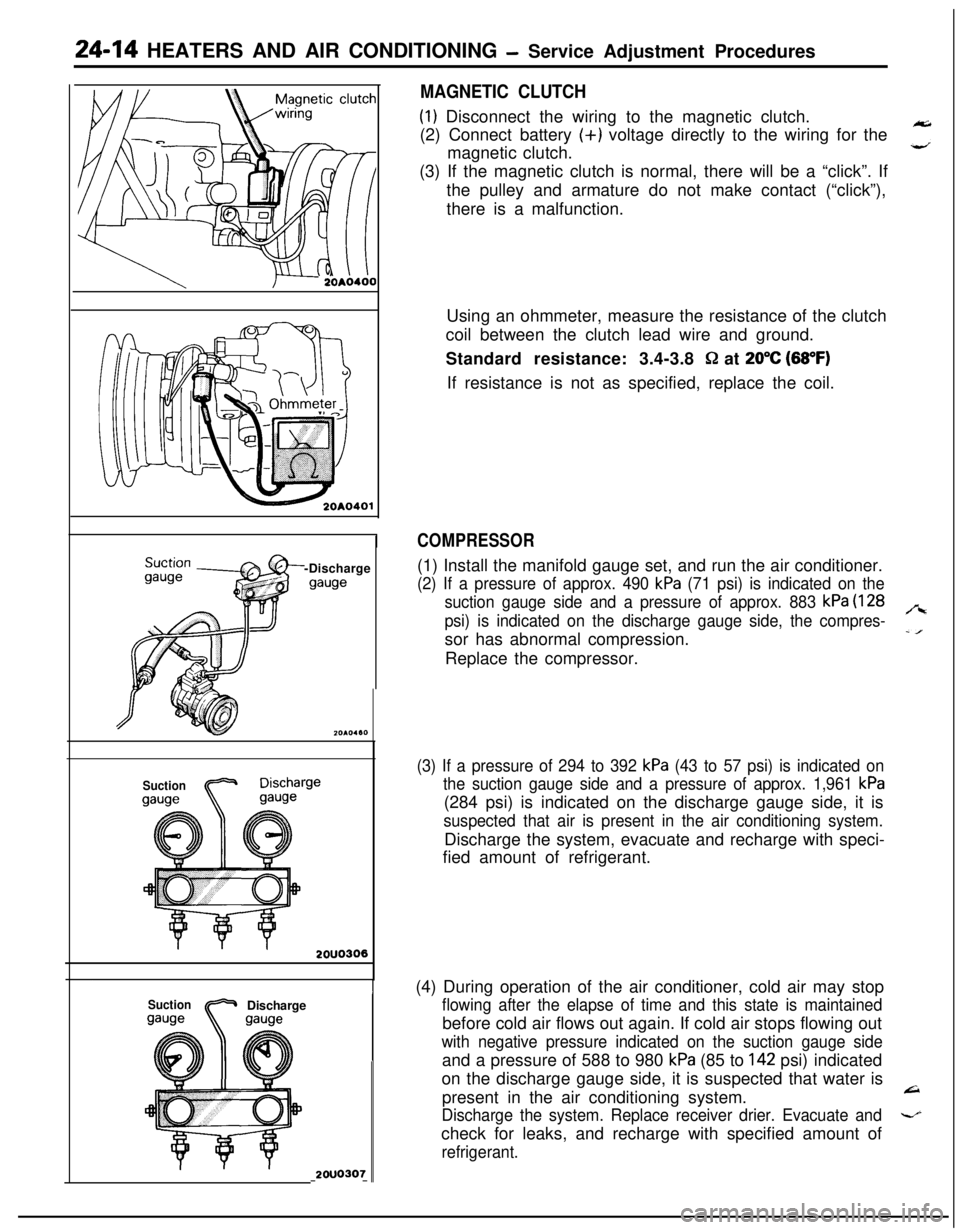

MAGNETIC CLUTCH(I) Disconnect the wiring to the magnetic clutch.

(2) Connect battery (+) voltage directly to the wiring for the

magnetic clutch.

,”(3) If the magnetic clutch is normal, there will be a “click”. If

the pulley and armature do not make contact (“click”),

there is a malfunction.

Using an ohmmeter, measure the resistance of the clutch

coil between the clutch lead wire and ground.

Standard resistance: 3.4-3.8

Q at 20°C (88°F)If resistance is not as specified, replace the coil.

COMPRESSOR(1) Install the manifold gauge set, and run the air conditioner.

(2) If a pressure of approx. 490 kPa (71 psi) is indicated on the

suction gauge side and a pressure of approx. 883

kPa (128

psi) is indicated on the discharge gauge side, the compres-

,“ssor has abnormal compression.

-IReplace the compressor.

(3) If a pressure of 294 to 392 kPa (43 to 57 psi) is indicated on

the suction gauge side and a pressure of approx. 1,961

kPa(284 psi) is indicated on the discharge gauge side, it is

suspected that air is present in the air conditioning system.Discharge the system, evacuate and recharge with speci-

fied amount of refrigerant.

(4) During operation of the air conditioner, cold air may stop

flowing after the elapse of time and this state is maintainedbefore cold air flows out again. If cold air stops flowing out

with negative pressure indicated on the suction gauge sideand a pressure of 588 to 980

kPa (85 to 142 psi) indicated

on the discharge gauge side, it is suspected that water is

present in the air conditioning system.

L=I

Discharge the system. Replace receiver drier. Evacuate and-check for leaks, and recharge with specified amount of

refrigerant.

Page 1160 of 1216

24-16 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

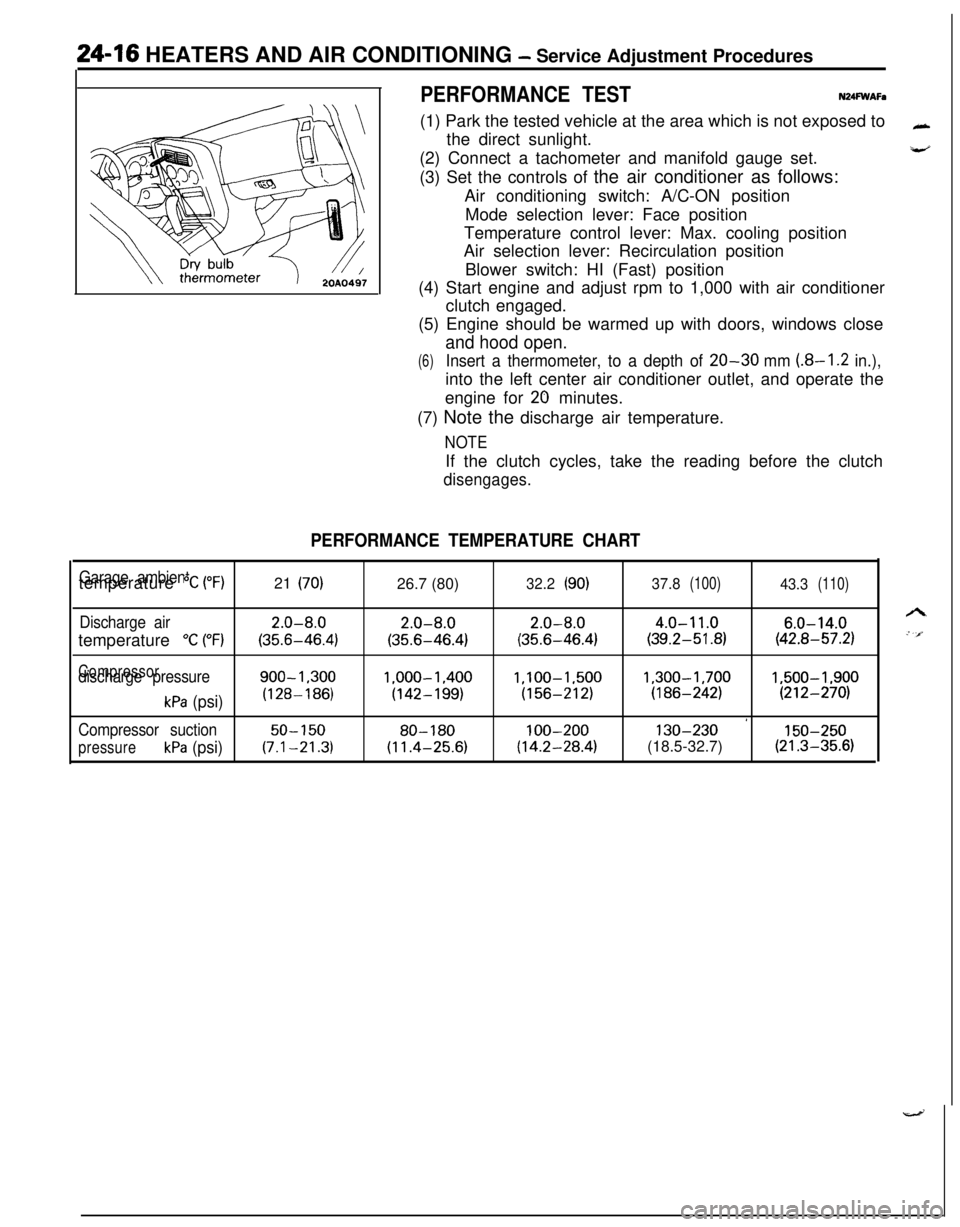

PERFORMANCE TESTN24FWAFa(1) Park the tested vehicle at the area which is not exposed to

the direct sunlight.

(2) Connect a tachometer and manifold gauge set.

(3) Set the controls of the air conditioner as follows:

Air conditioning switch: A/C-ON position

Mode selection lever: Face position

Temperature control lever: Max. cooling position

Air selection lever: Recirculation position

Blower switch: HI (Fast) position

(4) Start engine and adjust rpm to 1,000 with air conditioner

clutch engaged.

(5) Engine should be warmed up with doors, windows close

and hood open.

(6)Insert a thermometer, to a depth of 20-30 mm (8-I .2 in.),into the left center air conditioner outlet, and operate the

engine for

20 minutes.

(7) Note the discharge air temperature.

NOTEIf the clutch cycles, take the reading before the clutch

disengages.

PERFORMANCE TEMPERATURE CHART

Garage ambienttemperature “C (“F)21 (70)26.7 (80)32.2(90)37.8(100)43.3(110)

Discharge air2.0-8.02.0-8.02.0-8.04.0-11.06.0-14.0temperature

“C (“F)(35.6-46.4)(35.6-46.4)(35.6-46.4)(39.2-51.8)(42.8-57.2)

Compressordischarge pressure900-1.3001.000-1.400l,lOO-1,5001,300-1,7001,500-1,900

kPa (psi)(128-186)(142-199)(156-212)(186-242)(212-270)

’Compressor suction50-15080-180100-200130-230150-250

pressurekPa (psi)(7.1-21.3)(11.4-25.6)(14.2-28.4)(18.5-32.7)(21.3-35.6)