oil pressure MITSUBISHI ECLIPSE 1991 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 695 of 1216

TRANSAXLE ’

MANUAL AND AUTOMATICCONTENTS

;-AUTOMATICTRANSAXLE

.....................................................137ANNULUS GEAR AND TRANSFER DRIVE GEAR SET (F4A22)..........315ANNULUS GEAR AND TRANSFER DRIVE GEAR SET(F4A33.W4A33)...........................................................................................317CENTERDIFFERENTIAL(W4A33).............................................................329DIFFERENTIAL............................................................................................319ENDCLUTCHASSEMBLY.........................................................................309EXTENSIONHOUSINGASSEMBLY(W4A33).........................................337FRONTCLUTCHASSEMBLY....................................................................302FRONTOUTPUTSHAFT(W4A33)...........................................................332GENERALINFORMATION.........................................................................137KICKDOWNSERVO....................................................................................322LOW-REVERSEBRAKE..............................................................................323OILPUMP...................................................................................................299PLANETARYGEARSET............................................................................311PLANETARYGEARSET............................................................................313REARCLUTCHASSEMBLY(F4A22)........................................................304REARCLUTCHASSEMBLY(FQA33sW4A33)............................................307SERVICEADJUSTMENTPROCEDURES..................................................Drive

Shaft,OilSealsReplacement....................................................;;;

InhibitorSwtchAdjustment................................................................21 1KeyInterlockMechanismCheck.....................................................KrckdownServoAdjustment..................................zii..............................

LinePressureAdjustment...................................................................213

ReducingPressureAdjustment.........................................................214Selector Lever Operation Check........................................................210ShiftLockMechanismCheck...............................................................21 1SpeedometerCableReplacement.........................................................Throttle-posltipn Sensor Adjustment.................................................z2:

TransaxleFluIdLevelInspectIon......................................................209

TransaxleFluidReplacement.............................................................209

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................;“5”9

GeneralSpeclficatlons..................................................................1%Lubricants..................................................................................Sealants and Adhesives..............................................................izi

Serwce Speclflcatlons..................................................159...............Spacer andSnapRing.,.,.............................................................Spacer Set..................................................................1::Torque Speclflcatlons...........................................166Valve Body Spring Identification Chart.....................

.................160

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLEASSEMBLY(WA22)............................................................zTRANSAXLE

ASSEMBLY(F4A33.W4A33)................................................TRANSAXLECONTROL.............................................................................;;;TRANSAXLE

OILCOOLER........................................................................TRANSFER..................................................................................................fg

TRANSFERASSEMBLY.............................................................................333TRANSFERCASEADAPTERSUBASSEMBLY(W4A33).......................339TRANSFER CASE SUB ASSEMBLY (W4A33)341TRANSFER SHAFT (F4A33)TROUBLESHOOTING..................................................................................................................................................................................................f;;VALVE

BODY.............................................................................................324

MANUAL TRANSAXLE

5TH-SPEEDSYNCHRONIZERASSEMBLY...............................................42GENERALINFORMATION.........................................................................2.-.INPUTfj,-,A,TASSEMBLY

INTERMEDIATE GEAR ASSEMBLY..........................................................56OUTPUT

SHAFT ASSEMBLY....................................................................61SERVICEADJUSTMENTPROCEDURES..................................................DriveShaftOilSealsReplacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle Oil Level

InspectIon..............................................................‘liTransaxle Oil Replacement....................................................................

I3

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILSANDFORKS........................................................................g

SPECIALTOOLS.........................................................................................SPECIFICATIONS........................................................................................1:

General Specifications5Lubricants..........................................................................................................................................................................10Sealants and Adhesives

Service Specifications

....................................................................................................................................................1:Snap Ring (for Adjustment) and Spacer...............................................

Torque Specifications.............................................................................

i

SPEEDOMETERGEARASSEMBLY..........................................................TRANS&G.E................................................................................................zTRANSAXLEA!jSEMBLY

TROUBLESHOOTING..................................................................................12

MANUAL TRANSAXLE

CENTERDIFFERENTIAL.............................................................................103CLUTCHHOUSINGASSEMBLY...............................................................DRIVE BEVEL GEAR ASSEMBLY;g

...... .......................................................DRIVENBEVELGEARASSEMBLY...................................a......................EXTENSIONHOUSINGASSEMBLY.........................................................;g

5Tf.jSPEEDSYNCHRONIZERASSEMBLY...............................................101

FRONTDlFFERENTlAL...............................................................................106

FRONTOUTPUTSHAFTASSEMBLY......................................................106

GENERALI~~~~MATN)N...............................................................,.,.......66INPUTSHAFTASSEMBLY........................................................................l~ER,“,EDlATEGEARASSMBLY..........................................................;;i

SERVICEADJUSTMENTPROCEDURES..................................................Drive Shaft Oil Seals Replacement......................................................;;Speedometer Cable Replacement.........................................................

Transaxle

Ojl Level lnspectlon..............................................................;l

Transaxle 011 R~pb33ment....................................................................79Transfer

OilSealReplacement.............................................................80

SHIFTLEVERASSEMBLY.........................................................................SHIFTRAILASSEMBLY............................................................................,z

SPECIALTOOLS.........................................................................................76

SPECIFICATIONS........................................................................................6g

GeneralSpecifications...........................................................................6g

Lubricants...............................................................................................75

SealantsandAdhesives........................................................................76

ServiceSpecifications............................................................................6gSnap Ring (for Adjustment) and Spacer...............................................7 o

TorqueSpecifications.............................................................................74

SPEEDOMETERGEARASSEMBLY..........................................................TRANSAXLE................................................................................................1:TRANSAXLEASSEMBLY...........................................................................86TRANSAXLE

CONTROL

.............................................................................TRANSFER...............................................................................................

g.._TRANSFERA!333lBLY.............................................................................,24

TRANSFERCASEADAPTERSUBASSEMBLY.......................................131TRANSFERCASESUBASSEMBLY.........................................................TR,,UBLES,,OO,,NG..................................................................................1;;

Page 846 of 1216

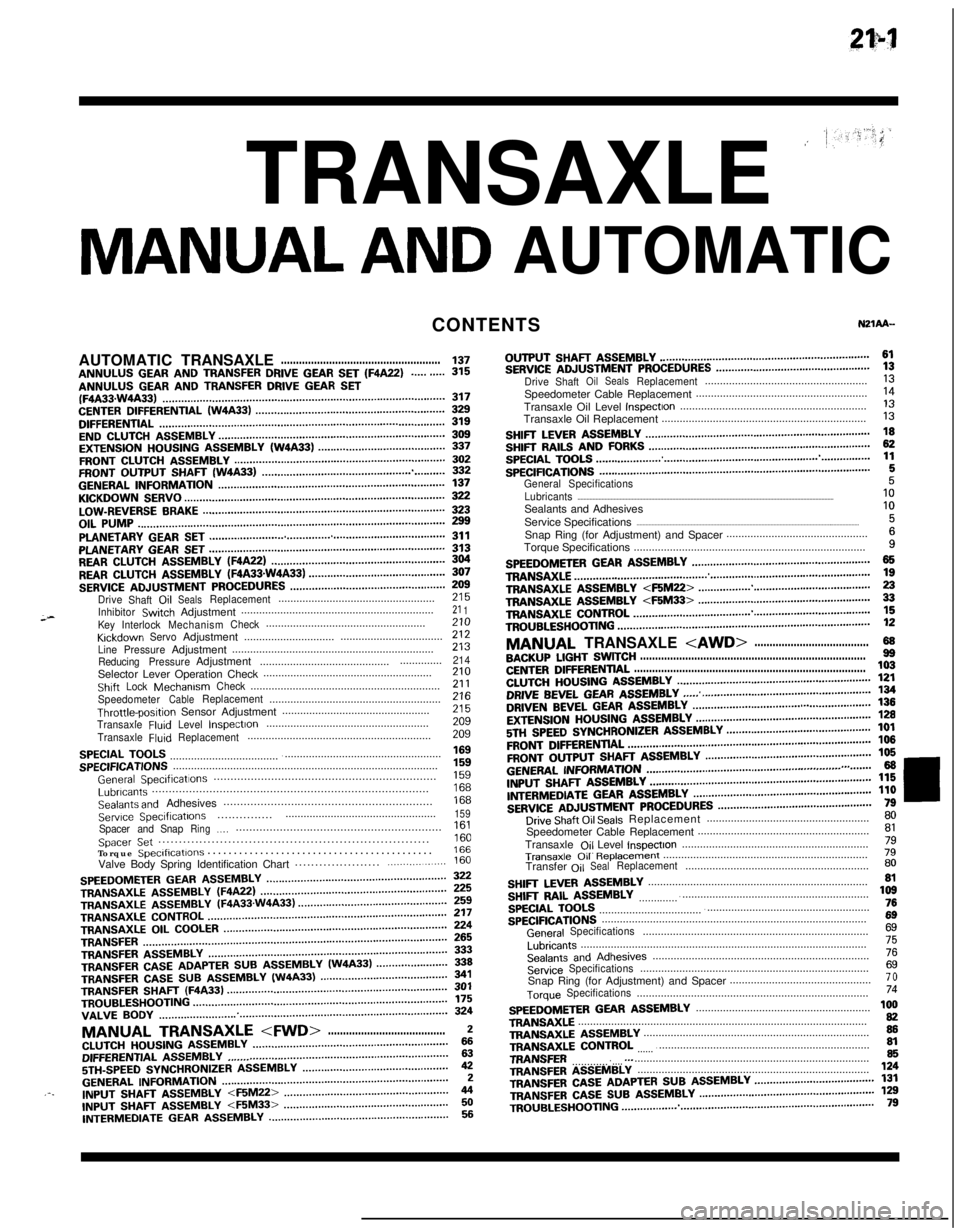

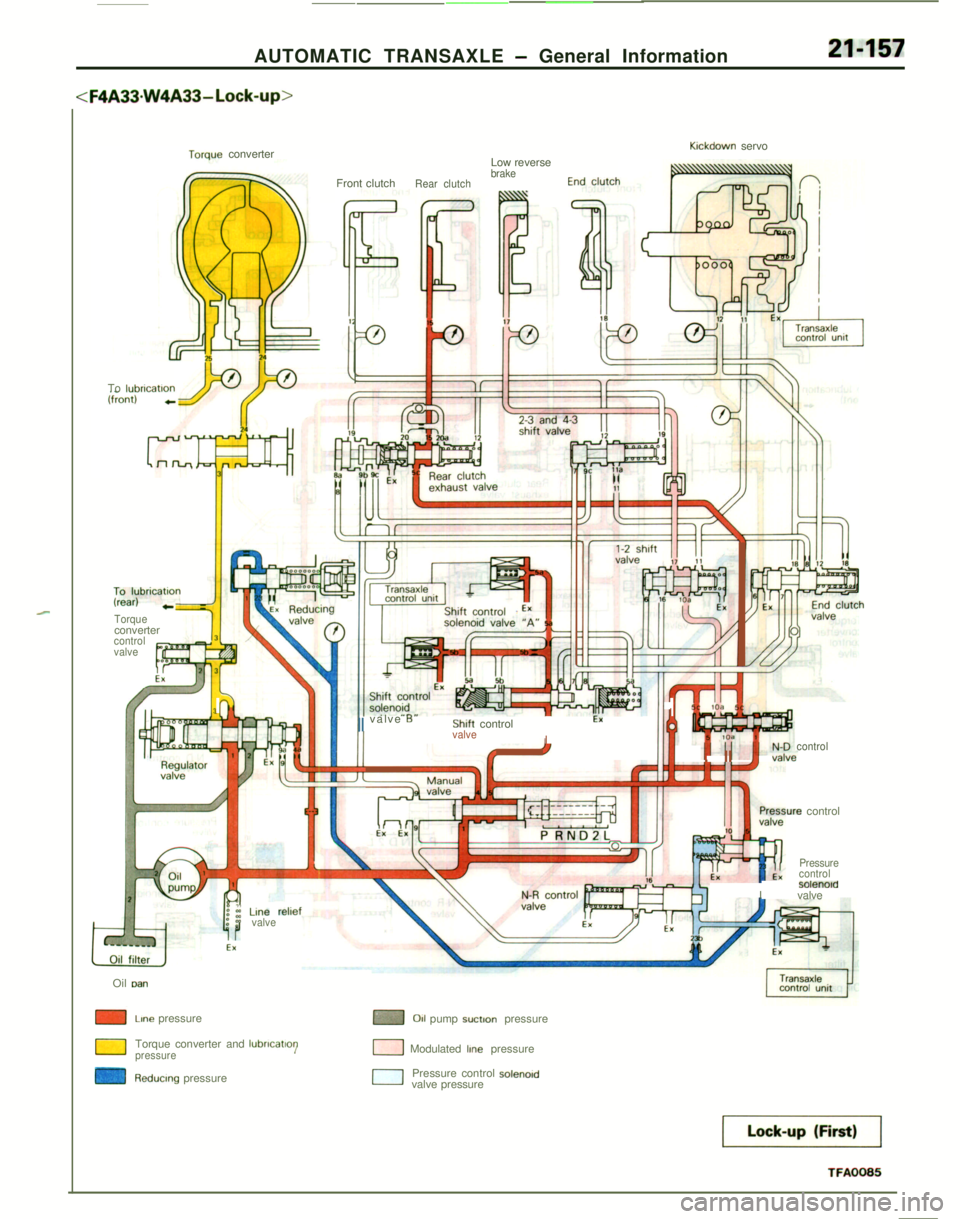

21-152AUTOMATIC TRANSAXLE - General Information

Klckdown servo

Torque converterLow-reversebrake

Front clutch

FEnd clutch

Rear clutch

To

lubncatlon

2-3 and 4-3

l-2sh1ft I 11Torque

h-_\E .Reducmgconverter

control

valve

N-D control

essure controllive

nPre%%lreIII I !!n i” controlFl --solmoldvalve

Transaxle

control

““ltOil pan

0 Lane pressure

Torque converter and

lubrlcatmssure

juclng pressure

011 pump suction pressure

IModulated Ime pressure

ElPressure control solenoidvalve oressure

Drive (Stopping)

TFA0080

Page 847 of 1216

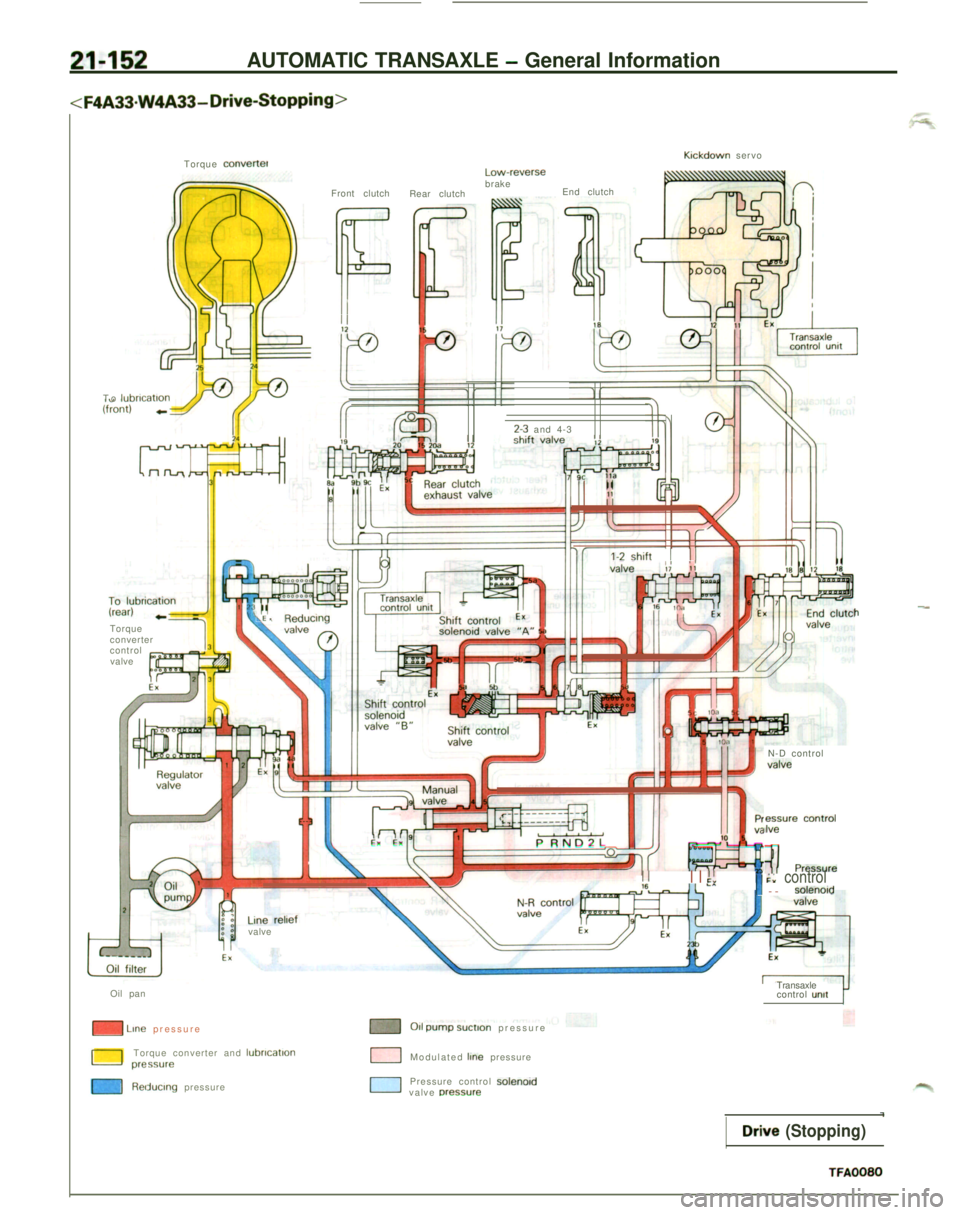

AUTOMATIC TRANSAXLE - General Information21453

Torque converter

To

lubn(rear)

Torquezatlon4-Zconverter

control

valveFront clutch

Rear clutch

Low-reverbrakese

Ktckdown servo

‘-2 sh’+f [;valve\I

& Reducmg

;\Oil pan

II1-0 pressureue converter and lubrfcataon

r.-z~re

m Reducmg pressure

0 011 pump suctm pressure

0 Modulated lme pressure

0Pressure control solenoidvalve pressure

TFA0081

Page 850 of 1216

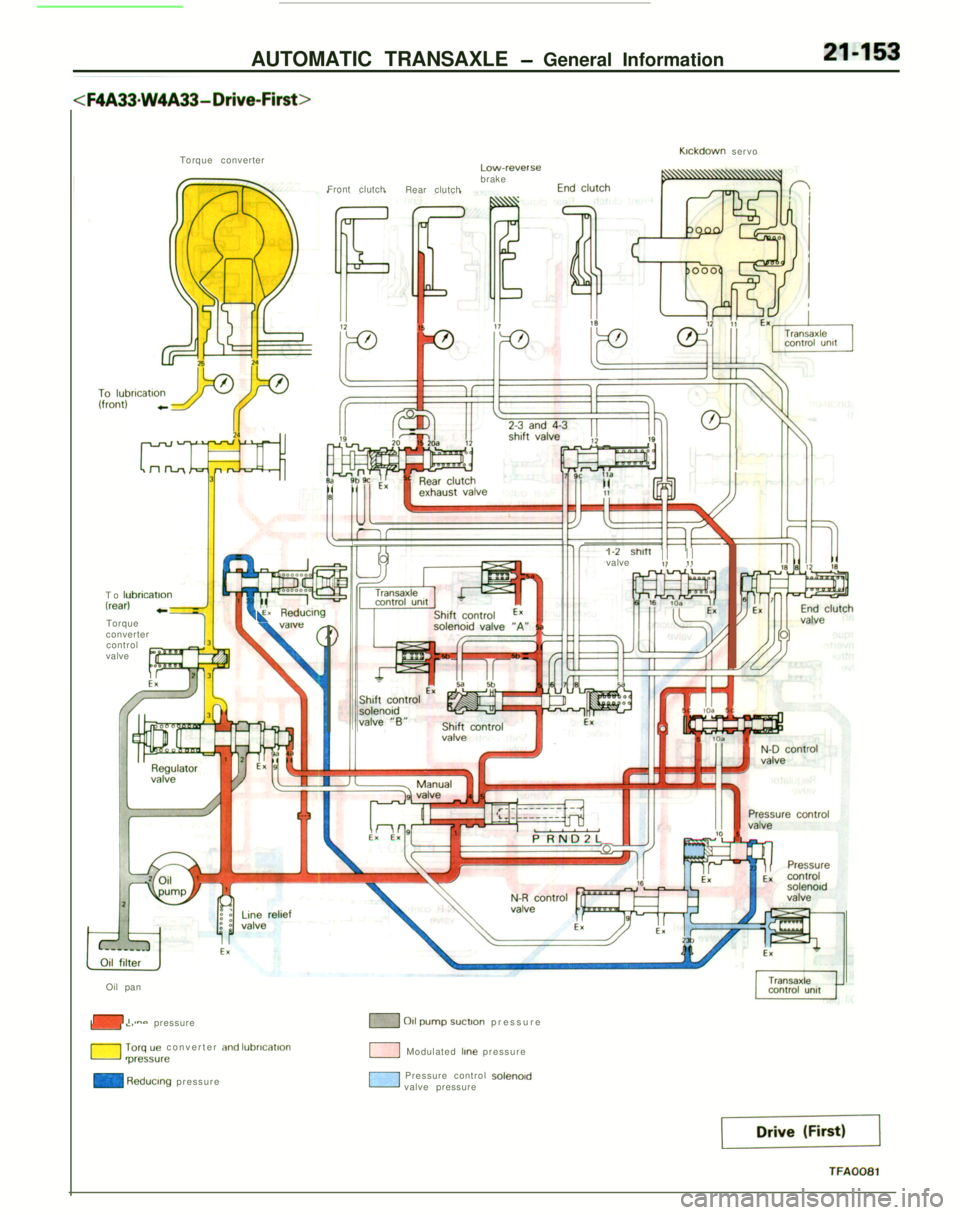

21-156AUTOMATIC TRANSAXLE - General Information

GTo

lubrvzatlon(front) czTo

lubnc

(rear)

Torqueconverter

control

valveFront clutch

Rear clutchLow reversebrakeP

\

L

IOil filter

Oil pan

mLone pressure

ue converter and lubncatlonsure

Kickdown servo

Y

control

Pressure control

valve

-a

m 011 pump swtlon pressure

n Modulated ltne pressure

1 Redumg pressurenPressure control solenoidvalve pressure

TFA0084

1 Drive (Fourth)

Page 851 of 1216

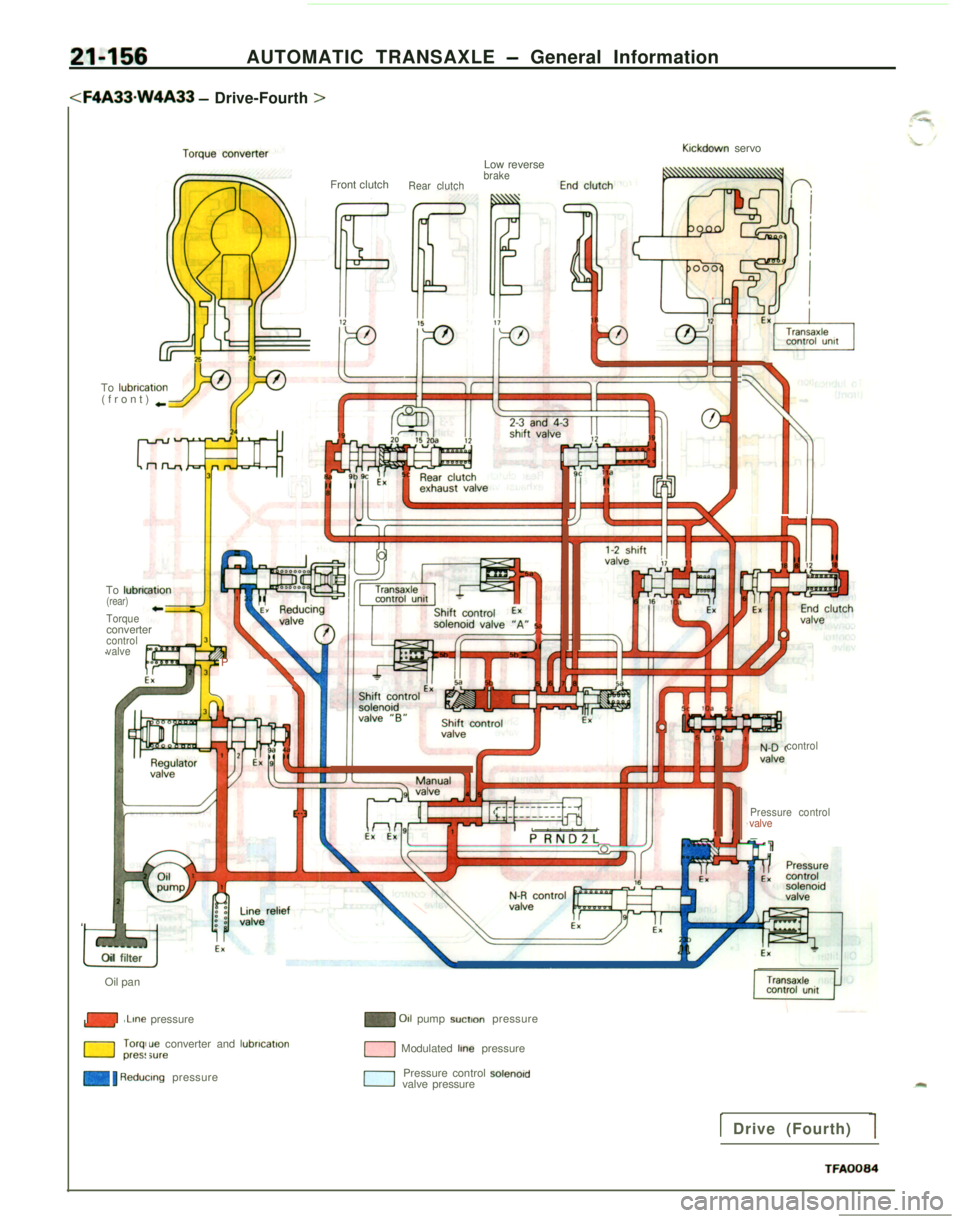

-______-_..AUTOMATIC TRANSAXLE

- General Information

21-157

Klckdown servo? converter

Low reverse

brakeFront clutchRear clutch

-PY

zrlutchTo

lubrlcatlon

7lo,,l;bricatlon-2iiiiiaTorqueconverterh--

control

valve

F*

Ex

IIIIt i

IIvalve tlShift control

IEX

valve

control

III. III valve

ure control

Pressure

control

solenoidI valve

\I

i i Lme relief”valve

ExOil

Dan

011 pump suction pressureLtne pressure

0Torque converter and lubrlcatloy

pressure

Reducmg pressure

n Modulated lme pressure

nPressure control solenoidvalve pressure

TFA0085

Page 860 of 1216

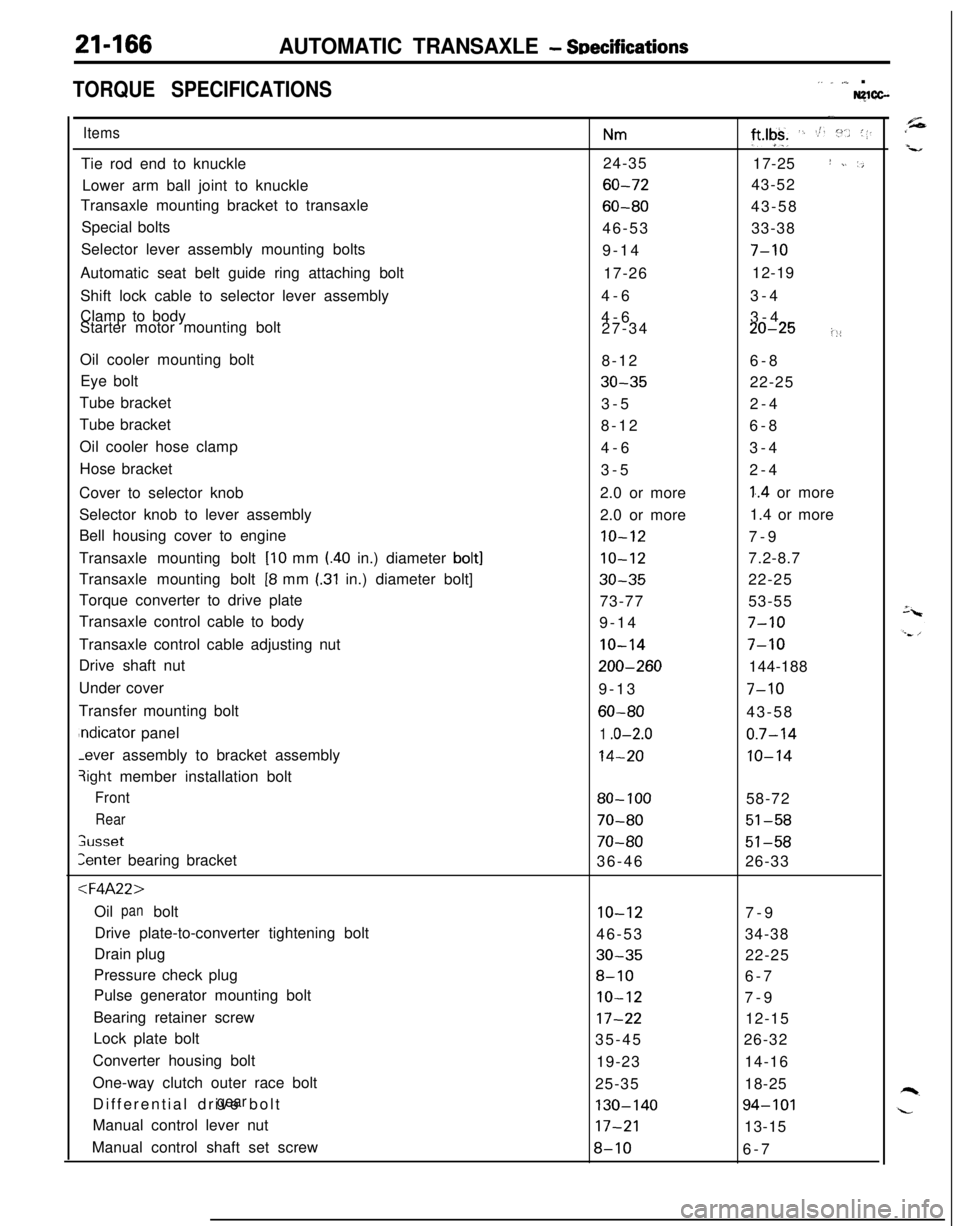

21-166AUTOMATIC TRANSAXLE - SDecifications

TORQUE SPECIFICATIONS,. _ ,,,_ .Nglcc-

ItemsTie rod end to knuckle

Lower arm ball joint to knuckle

Transaxle mounting bracket to transaxle

Special bolts

Selector lever assembly mounting bolts

Automatic seat belt guide ring attaching bolt

Shift lock cable to selector lever assembly

Clamp to body

Starter motor mounting bolt

Oil cooler mounting bolt

Eye bolt

Tube bracket

Tube bracket

Oil cooler hose clamp

Hose bracket

Cover to selector knob

Selector knob to lever assembly

Bell housing cover to engine

Transaxle mounting bolt

[lo mm l.40 in.) diameter bolt]Transaxle mounting bolt

[8 mm I.31 in.) diameter bolt]

Torque converter to drive plate

Transaxle control cable to body

Transaxle control cable adjusting nut

Drive shaft nut

Under cover

Transfer mounting boltndicator panel-ever assembly to bracket assembly

3ight member installation bolt

Front

Rear

;usset

Zenter bearing bracket

:l=4A22>Oil bolt

panDrive plate-to-converter tightening bolt

Drain plug

Pressure check plug

Pulse generator mounting bolt

Bearing retainer screw

Lock plate bolt

Converter housing bolt

One-way clutch outer race bolt

Differential drive bolt

gearManual control lever nut

Manual control shaft set screw

Nm24-35

60-72

60-8046-53

9-14

17-26

4-6

4-6

27-34

8-12

30-353-5

8-12

4-6

3-5

2.0 or more

2.0 or more

10-12

10-12

30-3573-77

9-14

IO-14

200-2609-13

60-80

1 .o-2.0

14-20

80- 100

70-80

70-8036-46

10-1246-53

30-35

8-10

IO-12

17-2235-45

19-23

25-35

130-14017-21

8-10

-.

ft*lgk+ ‘. St. :“.. (1.17-25

I ~. ‘,43-52

43-58

33-38

7-1012-19

3-4

3-4

20-25i::6-8

22-25

2-4

6-8

3-4

2-4

1..4 or more

1.4 or more

7-9

7.2-8.7

22-25

53-55

7-10

7-10144-188

7-1043-58

0.7-14

10-1458-72

51-58

51-5826-33

7-9

34-38

22-25

6-7

7-9

12-15

26-32

14-16

18-25

94-10113-15

6-7

Page 861 of 1216

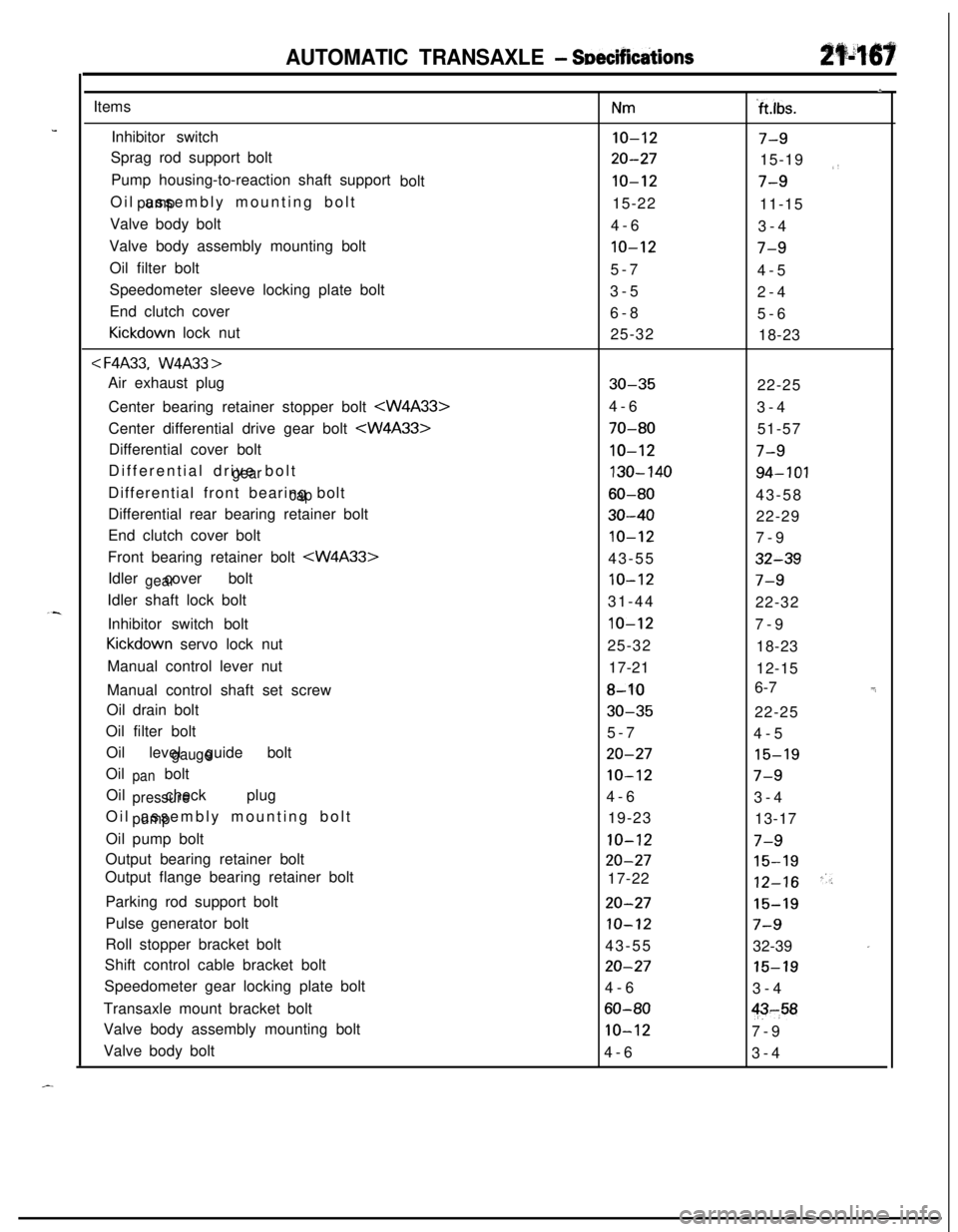

AUTOMATIC TRANSAXLE - SeecificdionsItems

Inhibitor switch

Sprag rod support bolt

Pump housing-to-reaction shaft support

bolt

Oil assembly mounting bolt

pumpValve body bolt

Valve body assembly mounting bolt

Oil filter bolt

Speedometer sleeve locking plate bolt

End clutch cover

Kickdown lock nut

< F4A33.W4A33 >Air exhaust plug

Center bearing retainer stopper bolt

Differential drive bolt

gearDifferential front bearing bolt

capDifferential rear bearing retainer bolt

End clutch cover bolt

Front bearing retainer bolt

gearIdler shaft lock bolt

Inhibitor switch bolt

Kickdown servo lock nut

Manual control lever nut

Manual control shaft set screw

Oil drain bolt

Oil filter bolt

Oil level guide bolt

gaugeOil bolt

panOil check plug

pressureOil assembly mounting bolt

pumpOil pump bolt

Output bearing retainer bolt

Output flange bearing retainer bolt

Nm

IO-12

20-27

10-1215-22

4-6

10-125-7

3-5

6-8

25-32

30-354-6

70-80

10-12

130-140

60-80

30-40

10-1243-55

10-1231-44

IO-1225-32

17-21

8-10

30-355-7

20-27

10-124-6

19-23

10-12

20-2717-22

,I

‘ft.lbs.

7-915-19

,,

7-911-15

3-4

7-94-5

2-4

5-6

18-23

22-25

3-4

51-57

7-9

94-10143-58

22-29

7-9

32-39

7-922-32

7-9

18-23

12-15

6-7

-_22-25

4-5

15-19

7-93-4

13-17

7-9

15-19

12-16"/Parking rod support bolt

20-2715-19Pulse generator bolt

IO-127-9Roll stopper bracket bolt

43-55

32-39

'Shift control cable bracket bolt

20-2715-19Speedometer gear locking plate bolt

4-6

3-4

Transaxle mount bracket bolt

60-80$-,58Valve body assembly mounting bolt

10-127-9

Valve body bolt

4-6

3-4

-.

Page 869 of 1216

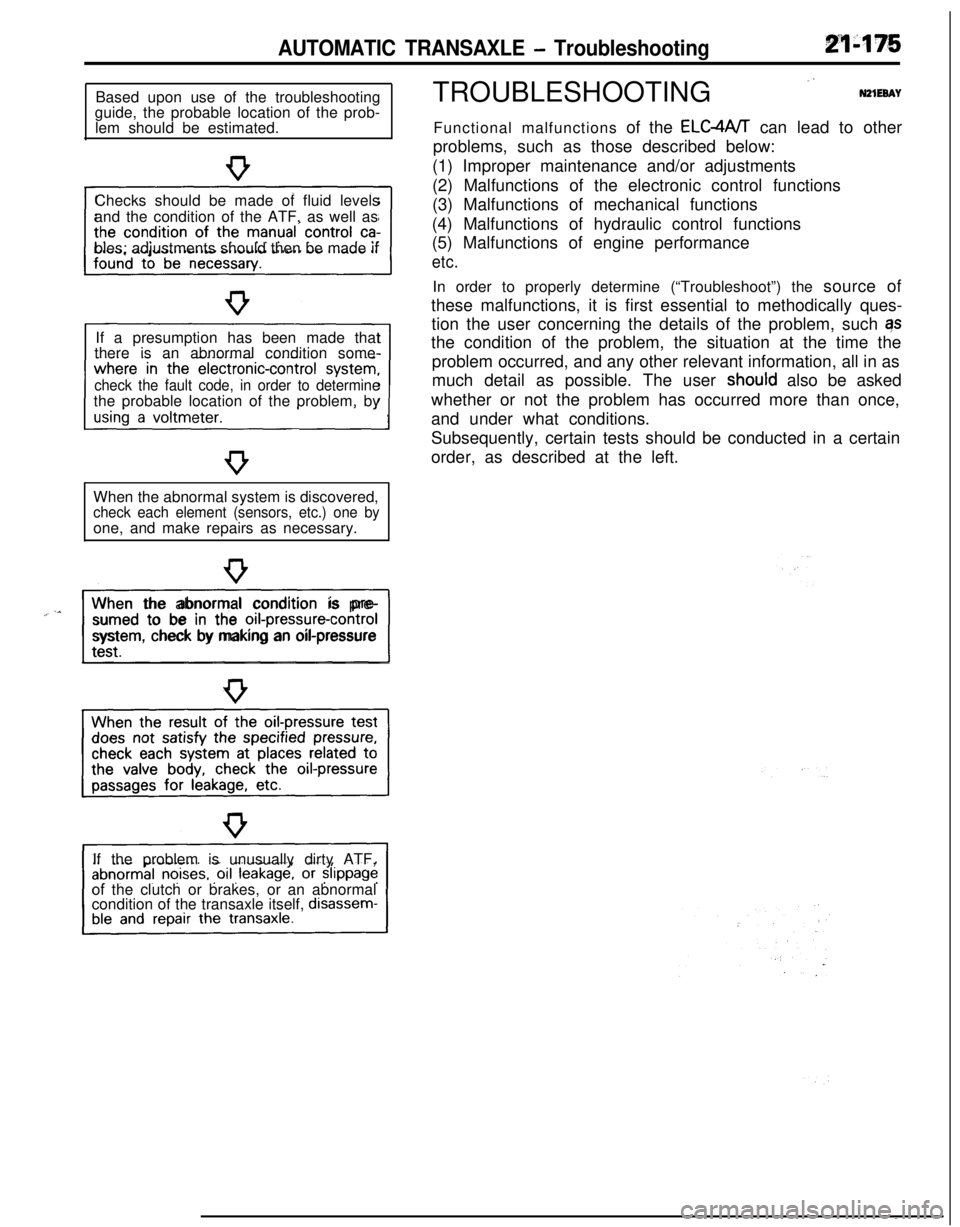

AUTOMATIC TRANSAXLE - TroubleshootingBased upon use of the troubleshooting

guide, the probable location of the prob-

lem should be estimated.

Checks should be made of fluid levels

and the condition of the ATF, as well as

bles; adjustments should then be made if

If a presumption has been made that

there is an abnormal condition some-

check the fault code, in order to determinethe probable location of the problem, by

When the abnormal system is discovered,

check each element (sensors, etc.) one byone, and make repairs as necessary.

“~^II_When the abnormal condition is pre-

sumed to be in the

orI-pressure-controlsystem, check by making an oil-pressure

If the problem is unusually dirty ATF,

of the clutch or brakes, or an abnormal

condition of the transaxle itself,

disassem-TROUBLESHOOTING

”N21EeAYFunctional malfunctions of the ELC4A/T can lead to other

problems, such as those described below:

(1) Improper maintenance and/or adjustments

(2) Malfunctions of the electronic control functions

(3) Malfunctions of mechanical functions

(4) Malfunctions of hydraulic control functions

(5) Malfunctions of engine performance

etc.In order to properly determine (“Troubleshoot”) the source of

these malfunctions, it is first essential to methodically ques-

tion the user concerning the details of the problem, such qs

the condition of the problem, the situation at the time the

problem occurred, and any other relevant information, all in as

much detail as possible. The user

shoutd also be asked

whether or not the problem has occurred more than once,

and under what conditions.

Subsequently, certain tests should be conducted in a certain

order, as described at the left.

Page 877 of 1216

AUTOMATIC TRANSAXLE - Troubleshooting214%3

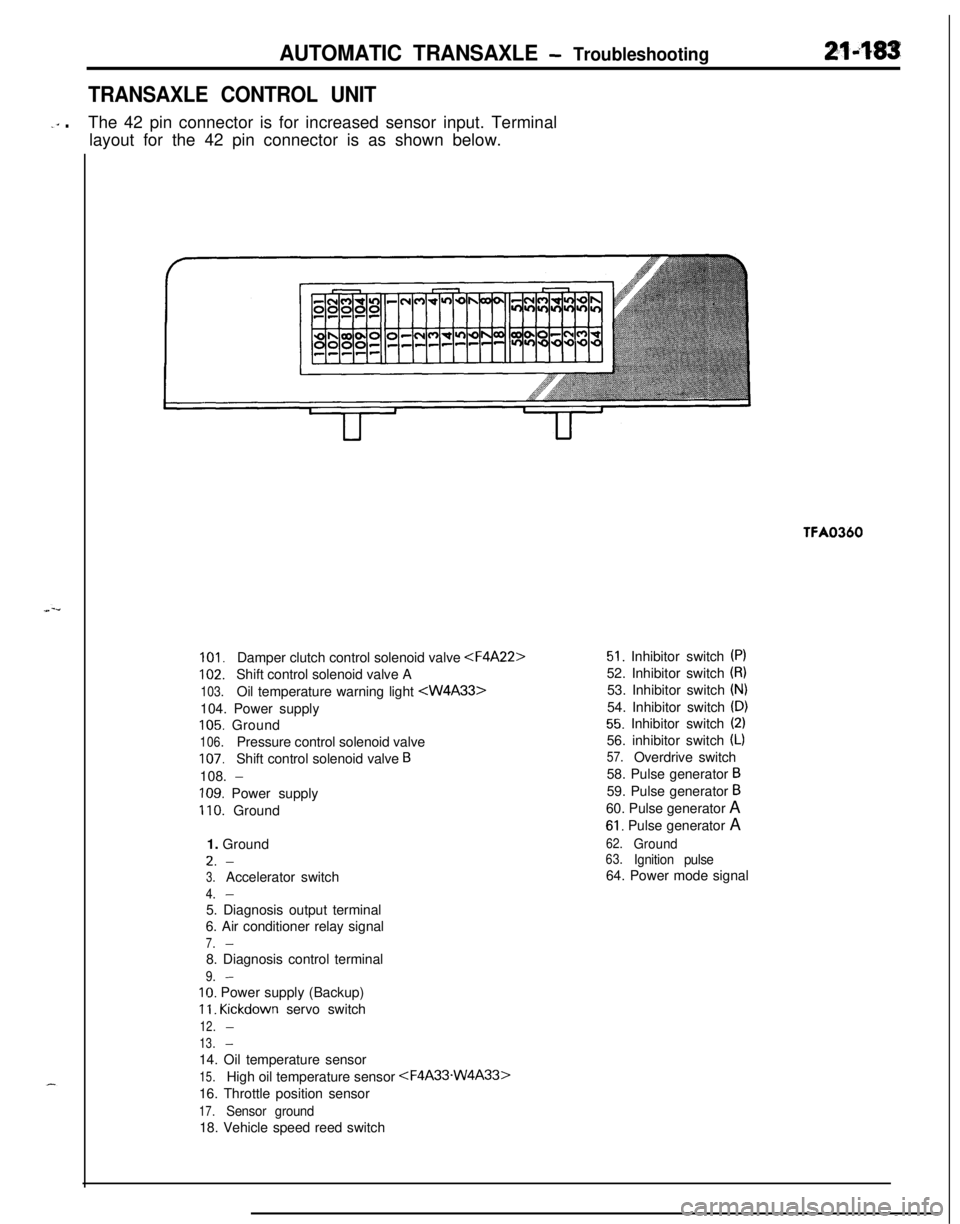

TRANSAXLE CONTROL UNIT

-‘” .The 42 pin connector is for increased sensor input. Terminal

layout for the 42 pin connector is as shown below.TFA0360

101.Damper clutch control solenoid valve

102.Shift control solenoid valve A

103.Oil temperature warning light

105. Ground

106.Pressure control solenoid valve

107.Shift control solenoid valve B108.

-

109. Power supply

110. Ground

1. GroundL.

-

3.Accelerator switch

4.-5. Diagnosis output terminal

6. Air conditioner relay signal

7.-8. Diagnosis control terminal

9.-

IO. Power supply (Backup)

11. Kickdown servo switch

12.-

13.-14. Oil temperature sensor

15.High oil temperature sensor

16. Throttle position sensor

17.Sensor ground18. Vehicle speed reed switch

51. Inhibitor switch (PI52. Inhibitor switch

(8)53. Inhibitor switch

(N)54. Inhibitor switch

(D)

55. Inhibitor switch (2)56. inhibitor switch

(L)

57.Overdrive switch

58. Pulse generator

B59. Pulse generator

B60. Pulse generator A

61. Pulse generator A

62.Ground63.Ignition pulse64. Power mode signal

Page 889 of 1216

AUTOMATIC TRANSAXLE - Troubleshooting21'495

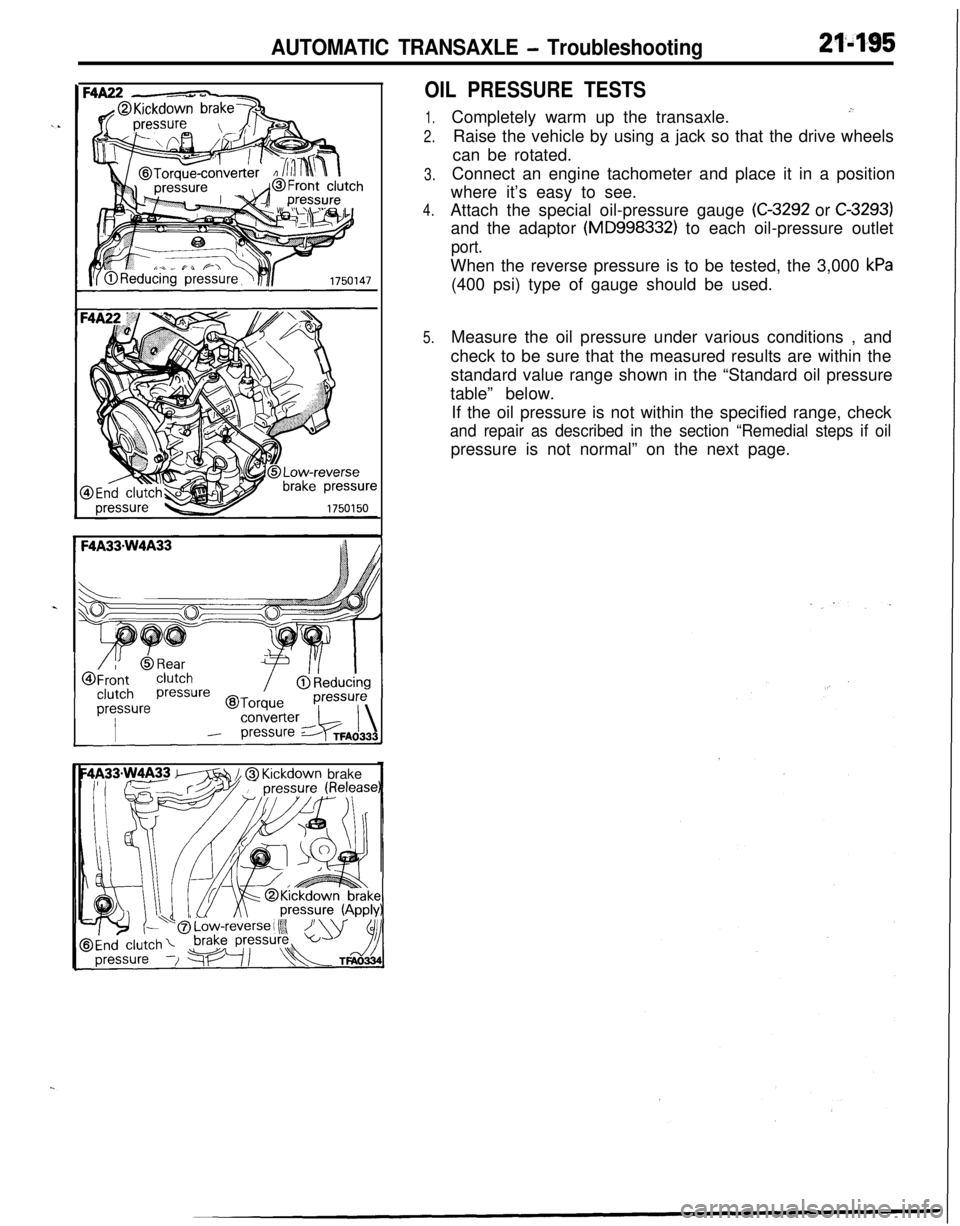

OIL PRESSURE TESTS

1.

2.

3.

4.

5.Completely warm up the transaxle.

.”Raise the vehicle by using a jack so that the drive wheels

can be rotated.

Connect an engine tachometer and place it in a position

where it’s easy to see.

Attach the special oil-pressure gauge

(C-3292 or C-3293)and the adaptor

(MD998332) to each oil-pressure outlet

port.When the reverse pressure is to be tested, the 3,000

kPa(400 psi) type of gauge should be used.

Measure the oil pressure under various conditions , and

check to be sure that the measured results are within the

standard value range shown in the “Standard oil pressure

table” below.

If the oil pressure is not within the specified range, check

and repair as described in the section “Remedial steps if oilpressure is not normal” on the next page.

m // @ Kickdown brake