checking oil MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 13 of 1216

INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions befdre Service‘1 S

OOV663OOY192

FOOO 1.

FOOO18

0

OOD511

J7

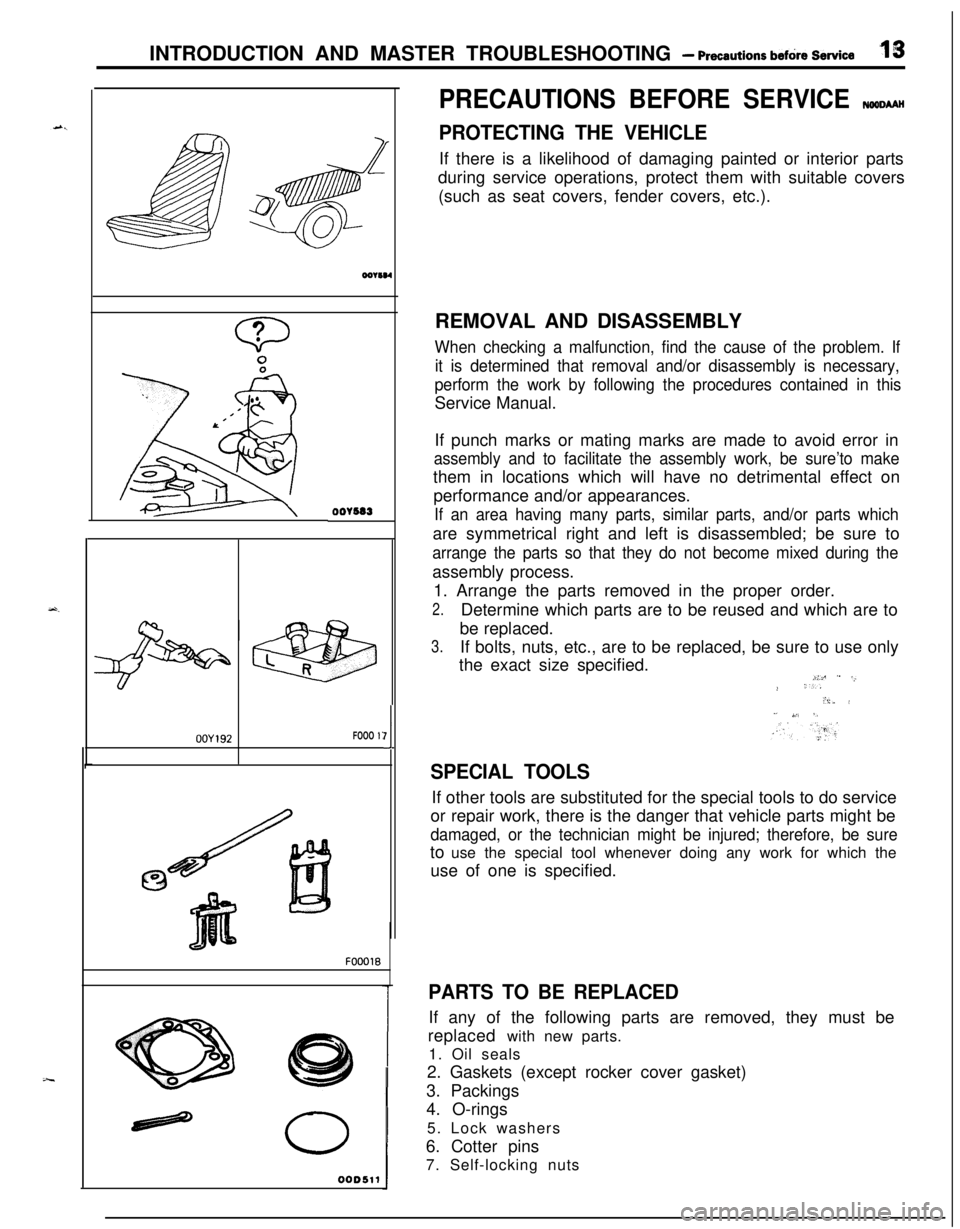

PRECAUTIONS BEFORE SERVICE wxww

PROTECTING THE VEHICLEIf there is a likelihood of damaging painted or interior parts

during service operations, protect them with suitable covers

(such as seat covers, fender covers, etc.).

REMOVAL AND DISASSEMBLY

When checking a malfunction, find the cause of the problem. If

it is determined that removal and/or disassembly is necessary,

perform the work by following the procedures contained in thisService Manual.

If punch marks or mating marks are made to avoid error in

assembly and to facilitate the assembly work, be sure’to makethem in locations which will have no detrimental effect on

performance and/or appearances.

If an area having many parts, similar parts, and/or parts whichare symmetrical right and left is disassembled; be sure to

arrange the parts so that they do not become mixed during theassembly process.

1. Arrange the parts removed in the proper order.

2.Determine which parts are to be reused and which are to

be replaced.

3.If bolts, nuts, etc., are to be replaced, be sure to use only

the exact size specified.

i:c ” -,.> ‘..“i,. i” ,,‘. 5,

SPECIAL TOOLSIf other tools are substituted for the special tools to do service

or repair work, there is the danger that vehicle parts might be

damaged, or the technician might be injured; therefore, be sureto use the special tool whenever doing any work for which the

use of one is specified.

PARTS TO BE REPLACEDIf any of the following parts are removed, they must be

replaced with new parts.

1. Oil seals

2. Gaskets (except rocker cover gasket)

3. Packings

4. O-rings

5. Lock washers

6. Cotter pins

7. Self-locking nuts

Page 129 of 1216

REAR AXLE - Differential Carrier3-27

llK010

71

llY181llY182

.MB990836(MB990835)

llrm3

V223

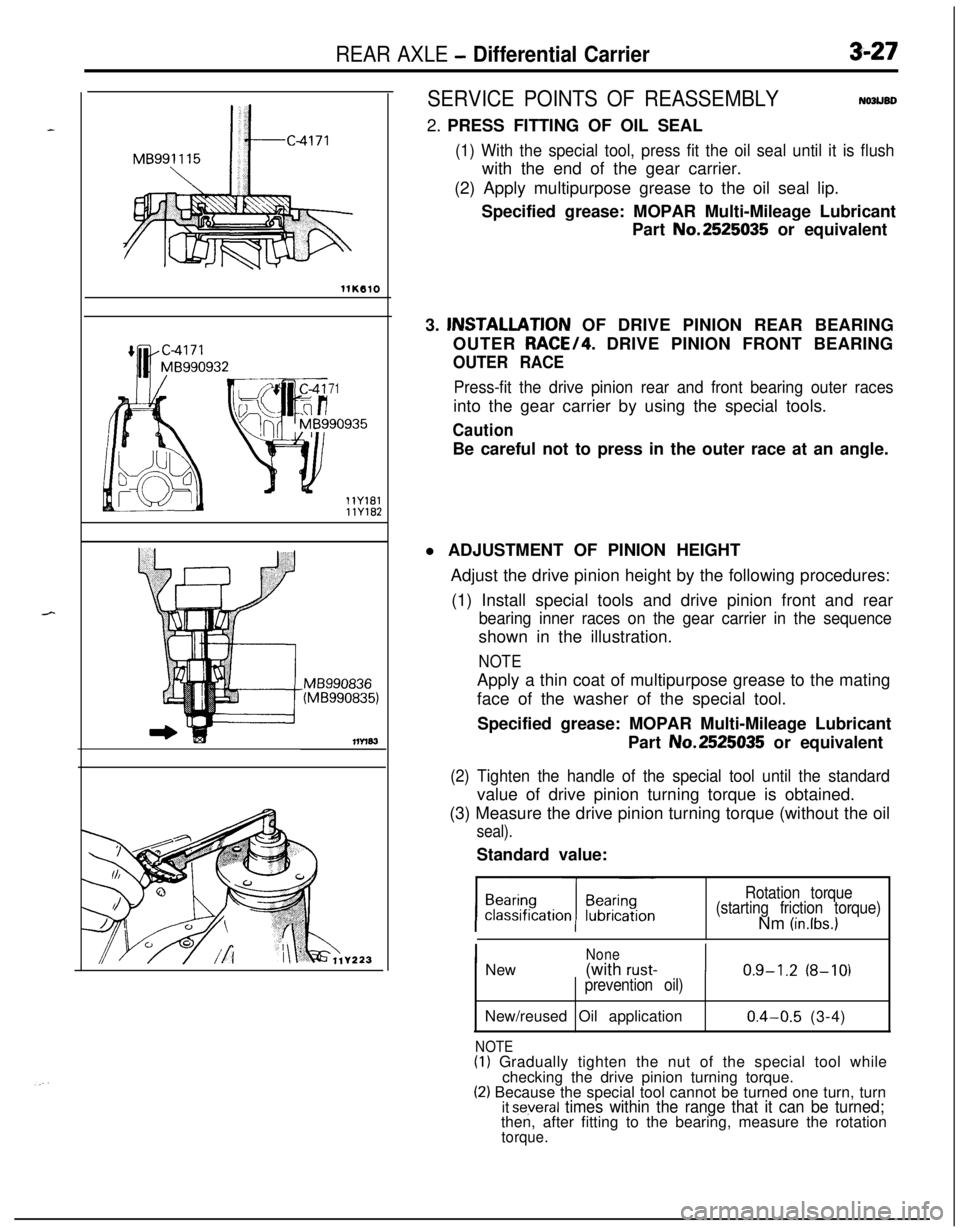

SERVICE POINTS OF REASSEMBLYNOJUBD2. PRESS FITTING OF OIL SEAL

(1) With the special tool, press fit the oil seal until it is flushwith the end of the gear carrier.

(2) Apply multipurpose grease to the oil seal lip.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

3. lNSTALLATlON OF DRIVE PINION REAR BEARING

OUTER RACE/4. DRIVE PINION FRONT BEARING

OUTER RACE

Press-fit the drive pinion rear and front bearing outer racesinto the gear carrier by using the special tools.

CautionBe careful not to press in the outer race at an angle.

l ADJUSTMENT OF PINION HEIGHT

Adjust the drive pinion height by the following procedures:

(1) Install special tools and drive pinion front and rear

bearing inner races on the gear carrier in the sequenceshown in the illustration.

NOTEApply a thin coat of multipurpose grease to the mating

face of the washer of the special tool.

Specified grease: MOPAR Multi-Mileage Lubricant

Part No.2525035 or equivalent

(2) Tighten the handle of the special tool until the standardvalue of drive pinion turning torque is obtained.

(3) Measure the drive pinion turning torque (without the oil

seal).Standard value:

Rotation torque

(starting friction torque)Nm

(in.lbs.)

I

NoneNew(with rust-I0.9-1.2 (8-10)prevention oil)New/reused Oil application

NOTE

0.4-0.5 (3-4)(I) Gradually tighten the nut of the special tool while

checking the drive pinion turning torque.

(2) Because the special tool cannot be turned one turn, turnit several times within the range that it can be turned;then, after fitting to the bearing, measure the rotation

torque.

Page 136 of 1216

3-34REAR AXLE - Differential Carrier (Limited Slip Differential)

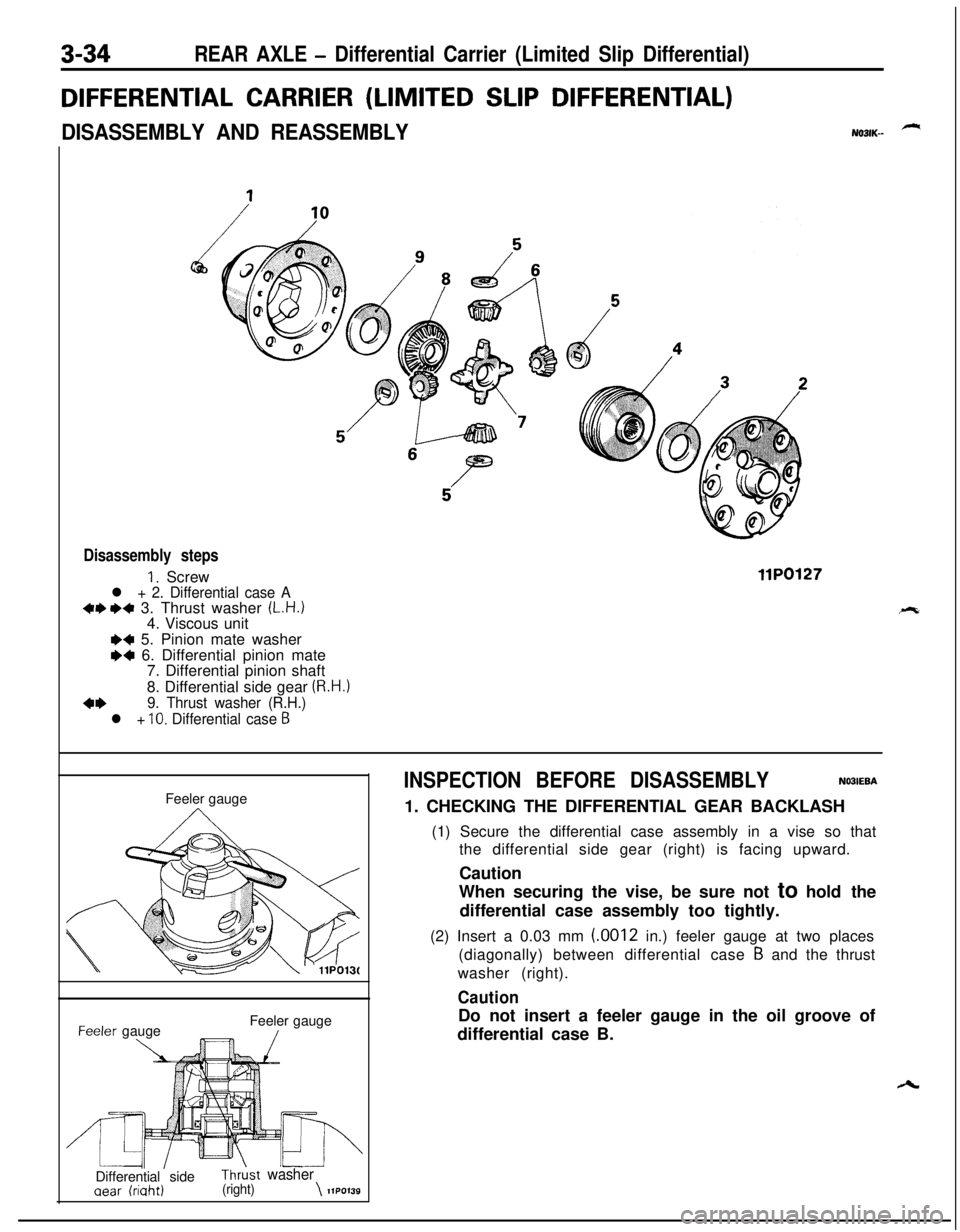

DIFFERENTIAL CARRIER (LIMITED SLIP DIFFERENTIAL)

DISASSEMBLY AND REASSEMBLYNO31K--

Disassembly steps

1. Screwl + 2. Differential case A+e I)+ 3. Thrust washer (L.H.)4. Viscous unit

llP0127

I)+ 5. Pinion mate washer

M 6. Differential pinion mate

7. Differential pinion shaft

8. Differential side gear

(R.H.)

4+9. Thrust washer (R.H.)

l +

10. Differential case 6Feeler gauge-eeler gauge

\Feeler gauge/

’ IL4l\’IIDifferential sideThrkt washer

aear (riaht)(right)\llPO139

INSPECTION BEFORE DISASSEMBLYNO3IEBA1. CHECKING THE DIFFERENTIAL GEAR BACKLASH

(1) Secure the differential case assembly in a vise so that

the differential side gear (right) is facing upward.

Caution

When securing the vise, be sure not to hold the

differential case assembly too tightly.

(2) Insert a 0.03 mm (.0012 in.) feeler gauge at two places

(diagonally) between differential case

B and the thrust

washer (right).

CautionDo not insert a feeler gauge in the oil groove of

differential case B.

Page 260 of 1216

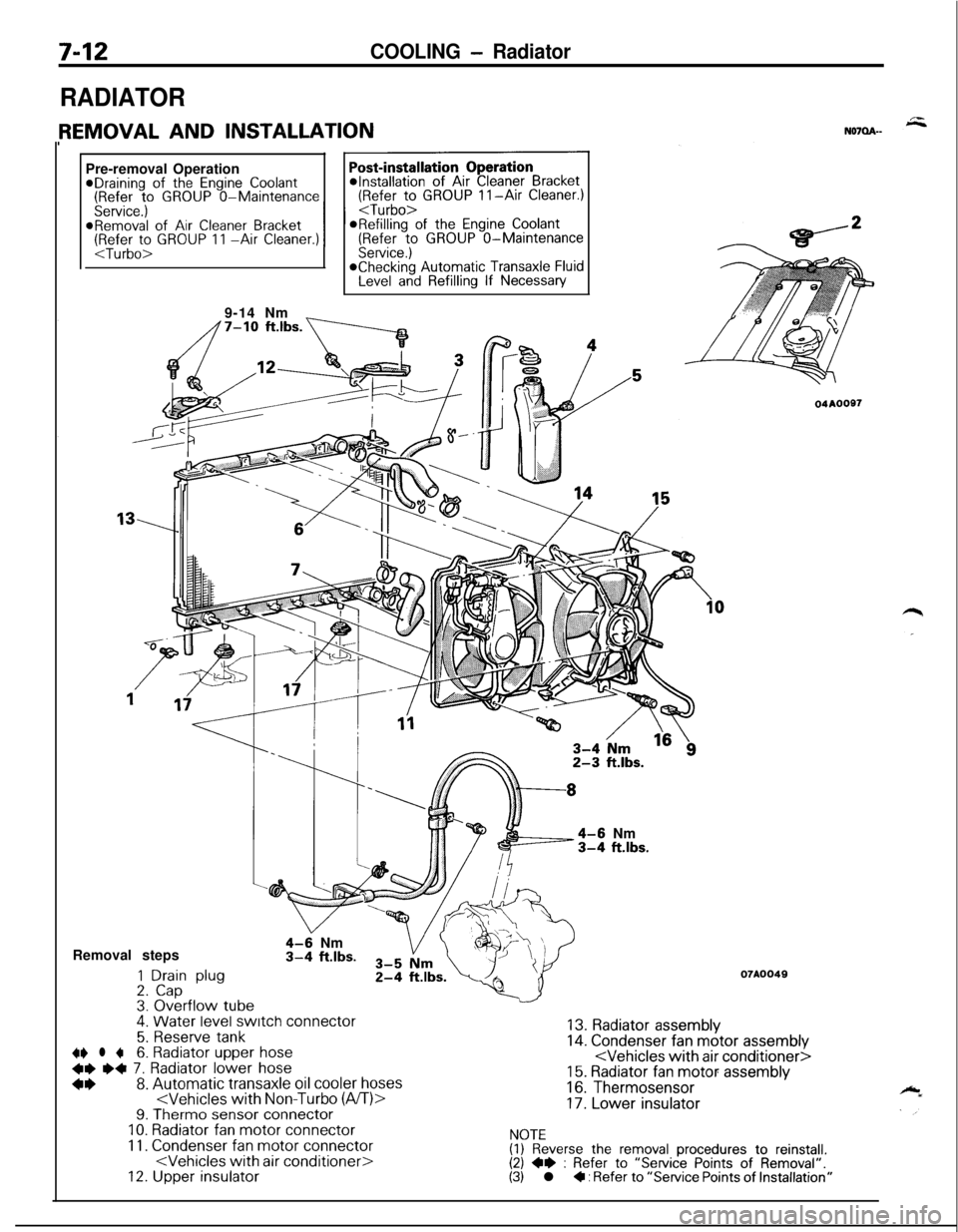

7-12COOLING - Radiator

RADIATORPre-removal Operation

@Draining of the Engine Coolant(Refer to GROUP O-Maintenance(Refer to GROUP II-Air Cleaner.)

Service.)

I I

9-14 Nm

_

4-6 Nm3-4 ft.lbs.Removal steps

1 Drain plug2. Cap3. Overflow tube.

4-9 Nm3-4 ft.lbs.

4. Water level switch connector

5. Reserve tank~~ l +6. Radiator upper hose

+e e+ 7. Radiator lower hose

*I)8. Automatic transaxle oil cooler hoses

11. Condenser fan motor connector

04AOOS7

07A0049

13. Radiator assembly14. Condenser fan motor assembly

16. Thermosensor

17. Lower insulator

NOTE(1) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”

Page 308 of 1216

9-24ENGINE - Service Adjustment Procedures

ENGINE 4.8L Engine>

SERVICE ADJUSTMENT PROCEDURES -

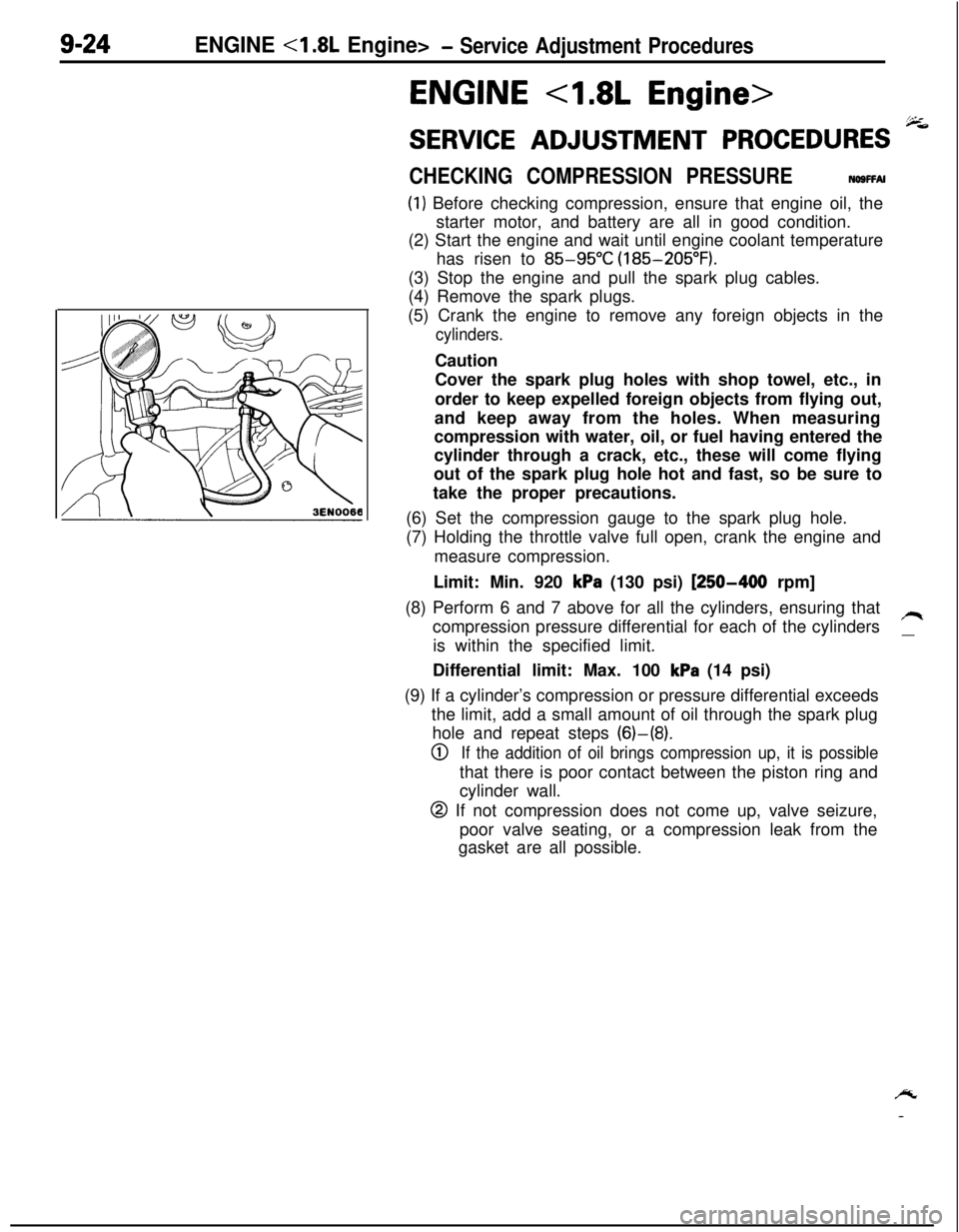

CHECKING COMPRESSION PRESSURENOSFFAI

(1) Before checking compression, ensure that engine oil, the

starter motor, and battery are all in good condition.

(2) Start the engine and wait until engine coolant temperature

has risen to

85-95°C (185-205°F).

(3) Stop the engine and pull the spark plug cables.

(4) Remove the spark plugs.

(5) Crank the engine to remove any foreign objects in the

cylinders.Caution

Cover the spark plug holes with shop towel, etc., in

order to keep expelled foreign objects from flying out,

and keep away from the holes. When measuring

compression with water, oil, or fuel having entered the

cylinder through a crack, etc., these will come flying

out of the spark plug hole hot and fast, so be sure to

take the proper precautions.

(6) Set the compression gauge to the spark plug hole.

(7) Holding the throttle valve full open, crank the engine and

measure compression.

Limit: Min. 920

kPa (130 psi) [250-400 rpm]

(8) Perform 6 and 7 above for all the cylinders, ensuring that

compression pressure differential for each of the cylinders

/Iis within the specified limit.

__Differential limit: Max. 100

kPa (14 psi)

(9) If a cylinder’s compression or pressure differential exceeds

the limit, add a small amount of oil through the spark plug

hole and repeat steps (6)-(8).

0If the addition of oil brings compression up, it is possiblethat there is poor contact between the piston ring and

cylinder wall.

@ If not compression does not come up, valve seizure,

poor valve seating, or a compression leak from the

gasket are all possible.

/y

-

Page 352 of 1216

9-68ENGINE <1.8L Engine> - Piston and Connecting Rod

r-Size and maker marks

No. 1Barrel

faced

1

1 Size and maker marks

L

INo.2

ti2zza

Tapered

Barrelfaced

1 EN064

-1 No. 1 rina aarGap of

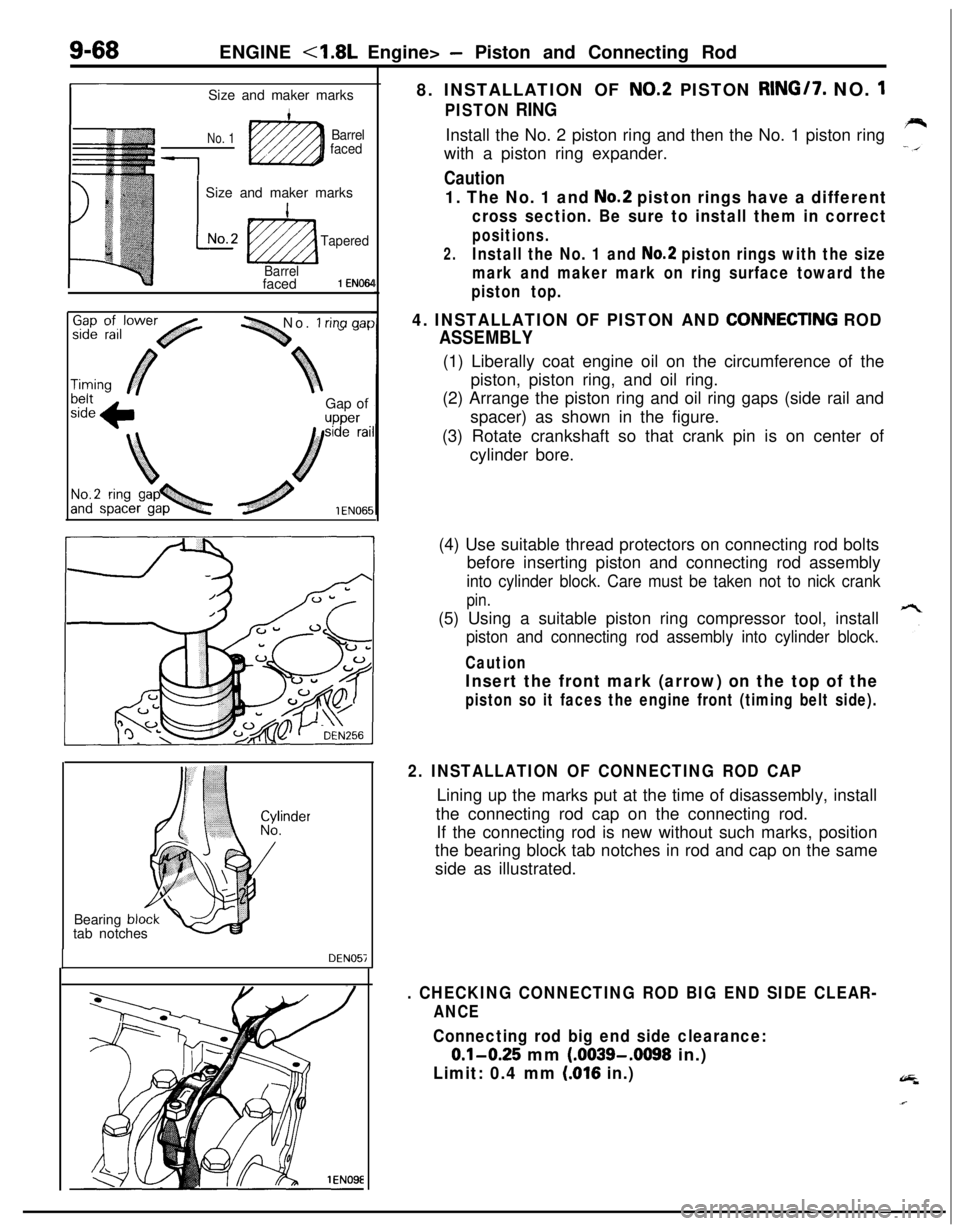

upper8. INSTALLATION OF

NO.2 PISTON RING/7. NO. 1

PISTON RINGInstall the No. 2 piston ring and then the No. 1 piston ring

with a piston ring expander.

Caution

1. The No. 1 and No.2 piston rings have a different

cross section. Be sure to install them in correct

positions.

2.Install the No. 1 and No.2 piston rings with the size

mark and maker mark on ring surface toward the

piston top.

4. INSTALLATION OF PISTON AND CONNECTlNG ROD

ASSEMBLY(1) Liberally coat engine oil on the circumference of the

piston, piston ring, and oil ring.

(2) Arrange the piston ring and oil ring gaps (side rail and

spacer) as shown in the figure.

(3) Rotate crankshaft so that crank pin is on center of

cylinder bore.

Bearing

bltab notches

DEN057(4) Use suitable thread protectors on connecting rod bolts

before inserting piston and connecting rod assembly

into cylinder block. Care must be taken not to nick crank

pin.(5) Using a suitable piston ring compressor tool, install

piston and connecting rod assembly into cylinder block.

Caution

Insert the front mark (arrow) on the top of the

piston so it faces the engine front (timing belt side).

2. INSTALLATION OF CONNECTING ROD CAPLining up the marks put at the time of disassembly, install

the connecting rod cap on the connecting rod.

If the connecting rod is new without such marks, position

the bearing block tab notches in rod and cap on the same

side as illustrated.

. CHECKING CONNECTING ROD BIG END SIDE CLEAR-

ANCE

Connecting rod big end side clearance:

0.1-0.25 mm (.0039-.0098 in.)

Limit: 0.4 mm (016 in.)

Page 355 of 1216

ENGINE - Crankshaft, Flwvheel and Drive Plate9-71

3EN30’lrrow mark toward

cap No,

I

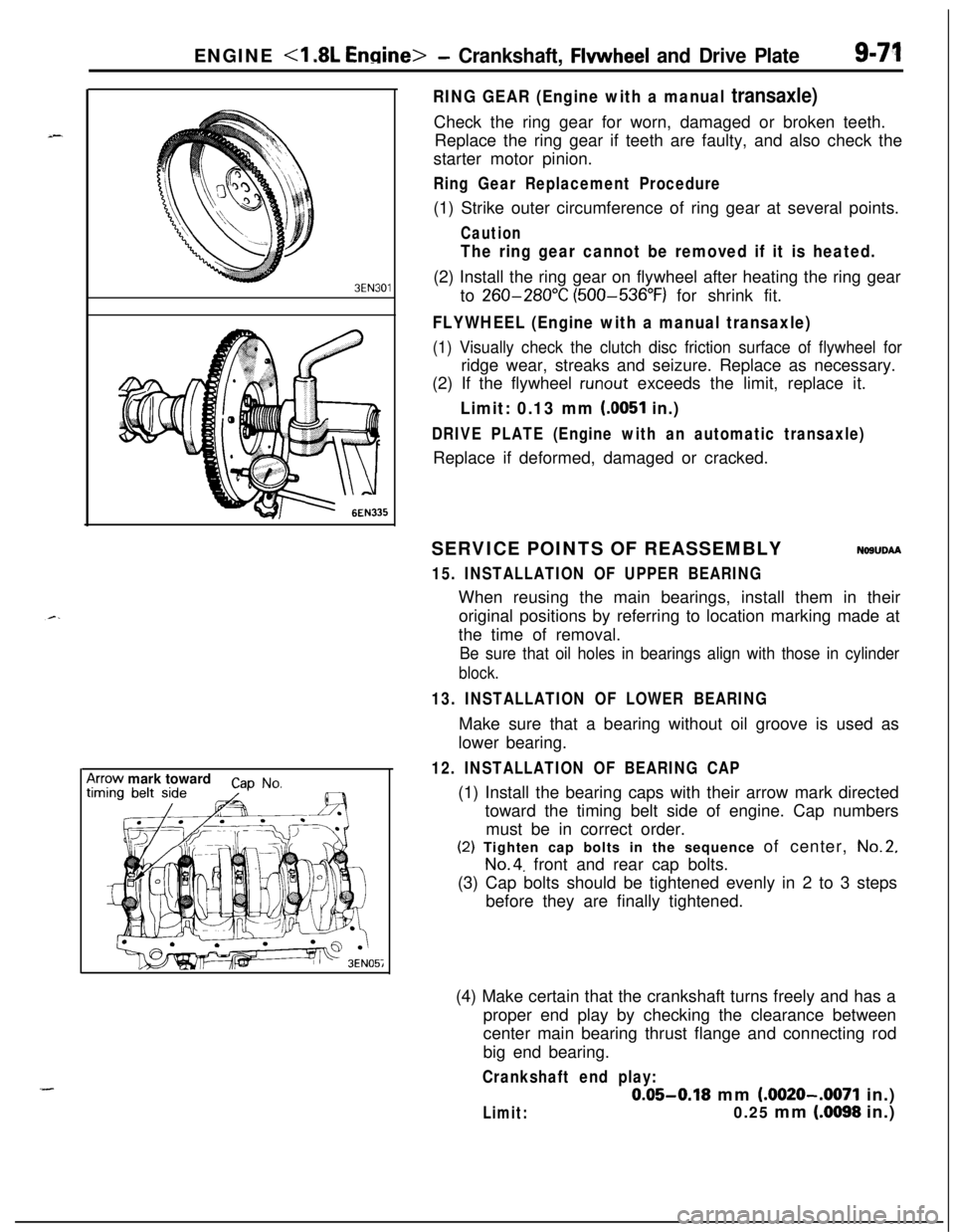

RING GEAR (Engine with a manual transaxle)Check the ring gear for worn, damaged or broken teeth.

Replace the ring gear if teeth are faulty, and also check the

starter motor pinion.

Ring Gear Replacement Procedure(1) Strike outer circumference of ring gear at several points.

Caution

The ring gear cannot be removed if it is heated.(2) Install the ring gear on flywheel after heating the ring gear

to

260-280°C (500-536°F) for shrink fit.

FLYWHEEL (Engine with a manual transaxle)

(1) Visually check the clutch disc friction surface of flywheel forridge wear, streaks and seizure. Replace as necessary.

(2) If the flywheel

runout exceeds the limit, replace it.

Limit: 0.13 mm (0051 in.)

DRIVE PLATE (Engine with an automatic transaxle)Replace if deformed, damaged or cracked.

SERVICE POINTS OF REASSEMBLY

NOSUDAA

15. INSTALLATION OF UPPER BEARINGWhen reusing the main bearings, install them in their

original positions by referring to location marking made at

the time of removal.

Be sure that oil holes in bearings align with those in cylinder

block.

13. INSTALLATION OF LOWER BEARINGMake sure that a bearing without oil groove is used as

lower bearing.

12. INSTALLATION OF BEARING CAP(1) Install the bearing caps with their arrow mark directed

toward the timing belt side of engine. Cap numbers

must be in correct order.(2) Tighten cap bolts in the sequence of center,

No.2,

No.4. front and rear cap bolts.

(3) Cap bolts should be tightened evenly in 2 to 3 steps

before they are finally tightened.

(4) Make certain that the crankshaft turns freely and has a

proper end play by checking the clearance between

center main bearing thrust flange and connecting rod

big end bearing.

Crankshaft end play:

0.05-0.18 mm (.0020-.0071 in.)

Limit:0.25 mm (.0098 in.)

Page 358 of 1216

9-74ENGINE <2.0L DOHC Engine>- Service Adjustment Procedures

ENGINE <2.0L DOHC Engine>

SERVICE ADJUSTMENT PROCEDURES pi

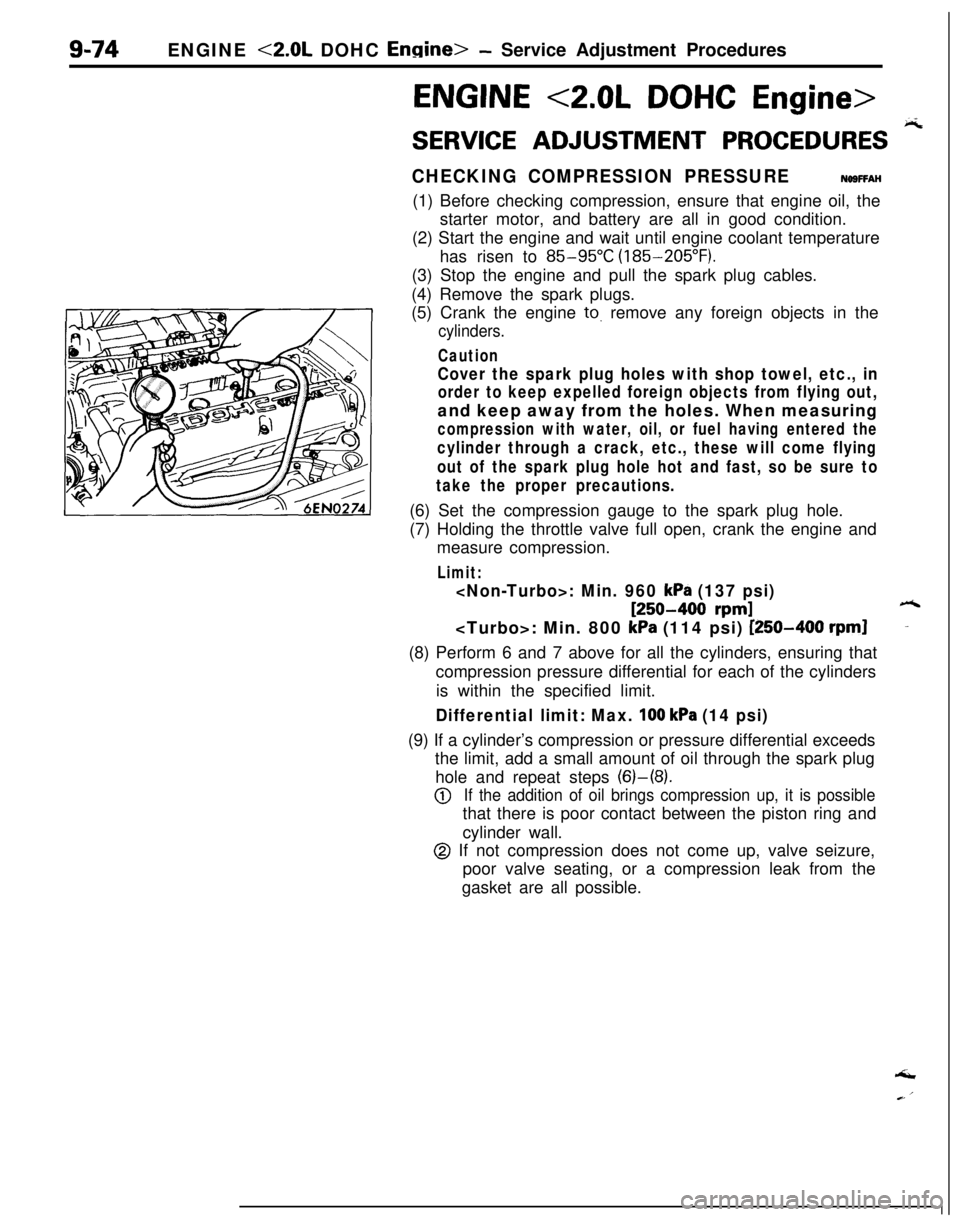

CHECKING COMPRESSION PRESSURENOSFFAH(1) Before checking compression, ensure that engine oil, the

starter motor, and battery are all in good condition.

(2) Start the engine and wait until engine coolant temperature

has risen to

85-95°C (185-205°F).

(3) Stop the engine and pull the spark plug cables.

(4) Remove the spark plugs.

(5) Crank the engine

to. remove any foreign objects in the

cylinders.

Caution

Cover the spark plug holes with shop towel, etc., in

order to keep expelled foreign objects from flying out,and keep away from the holes. When measuring

compression with water, oil, or fuel having entered the

cylinder through a crack, etc., these will come flying

out of the spark plug hole hot and fast, so be sure to

take the proper precautions.(6) Set the compression gauge to the spark plug hole.

(7) Holding the throttle valve full open, crank the engine and

measure compression.

Limit:

[250-400 rpm]6

kPa (114 psi) [250-400 rpml-(8) Perform 6 and 7 above for all the cylinders, ensuring that

compression pressure differential for each of the cylinders

is within the specified limit.

Differential limit: Max. 100 kPa (14 psi)(9) If a cylinder’s compression or pressure differential exceeds

the limit, add a small amount of oil through the spark plug

hole and repeat steps (6)-(8).

@If the addition of oil brings compression up, it is possiblethat there is poor contact between the piston ring and

cylinder wall.

@ If not compression does not come up, valve seizure,

poor valve seating, or a compression leak from the

gasket are all possible.‘I

Page 367 of 1216

r-.ENGINE <2.0L DOHC Engine>

- Engine AssemblyS-83

OlA0177

-mpp.-/- --OlA0553

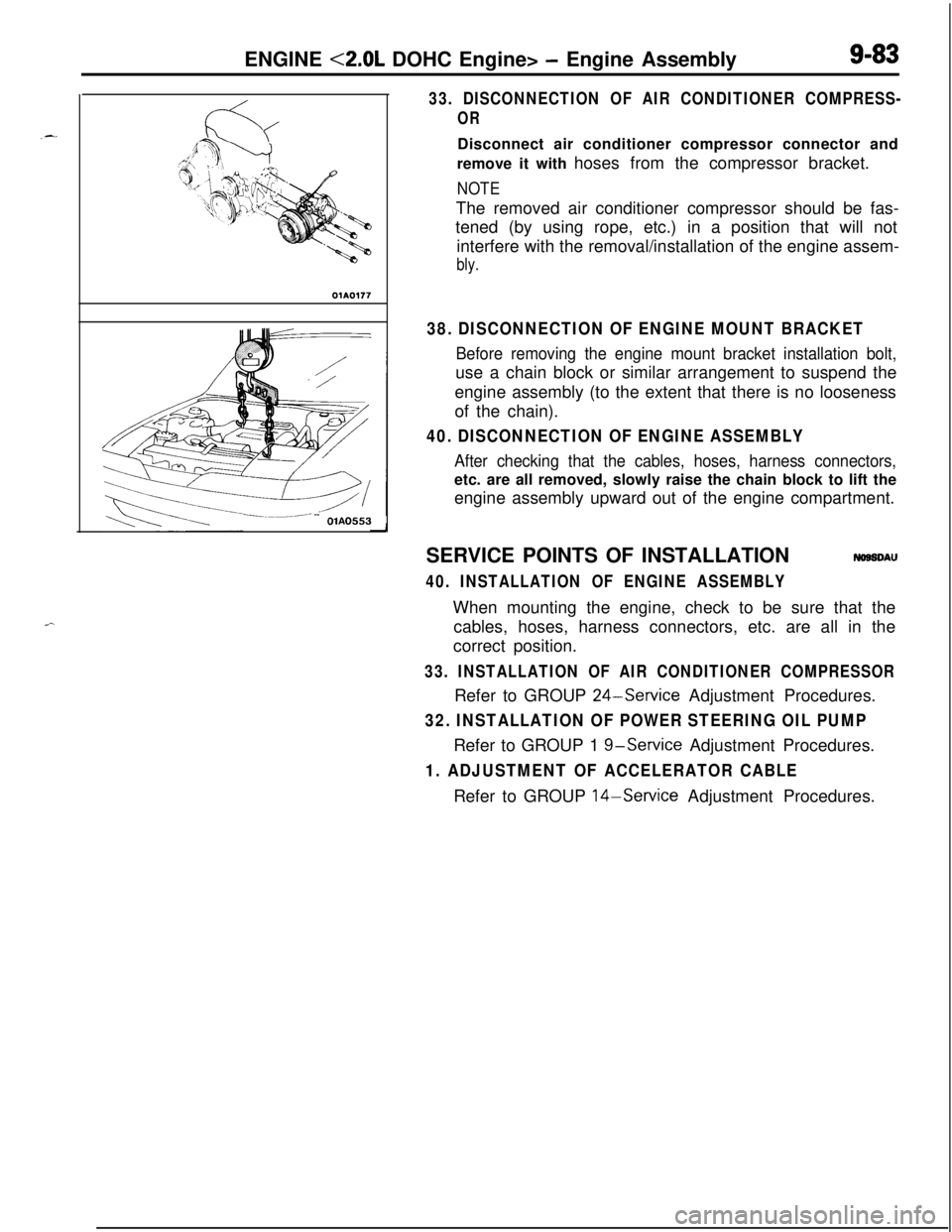

33. DISCONNECTION OF AIR CONDITIONER COMPRESS-

ORDisconnect air conditioner compressor connector and

remove it with hoses from the compressor bracket.

NOTEThe removed air conditioner compressor should be fas-

tened (by using rope, etc.) in a position that will not

interfere with the removal/installation of the engine assem-

bly.

38. DISCONNECTION OF ENGINE MOUNT BRACKET

Before removing the engine mount bracket installation bolt,use a chain block or similar arrangement to suspend the

engine assembly (to the extent that there is no looseness

of the chain).

40. DISCONNECTION OF ENGINE ASSEMBLY

After checking that the cables, hoses, harness connectors,etc. are all removed, slowly raise the chain block to lift the

engine assembly upward out of the engine compartment.

SERVICE POINTS OF INSTALLATION

NOSSDAU

40. INSTALLATION OF ENGINE ASSEMBLYWhen mounting the engine, check to be sure that the

cables, hoses, harness connectors, etc. are all in the

correct position.

33. INSTALLATION OF AIR CONDITIONER COMPRESSORRefer to GROUP

24-Service Adjustment Procedures.

32. INSTALLATION OF POWER STEERING OIL PUMPRefer to GROUP 1

g-service Adjustment Procedures.

1. ADJUSTMENT OF ACCELERATOR CABLERefer to GROUP 14-Service Adjustment Procedures.

Page 369 of 1216

ENGINE <2.0L DOHC Engine> -Camshafts and Camshaft Oil Seals9-85Plastic hammer

Intake side

Exhaust side

Jzzl

(22

Slits

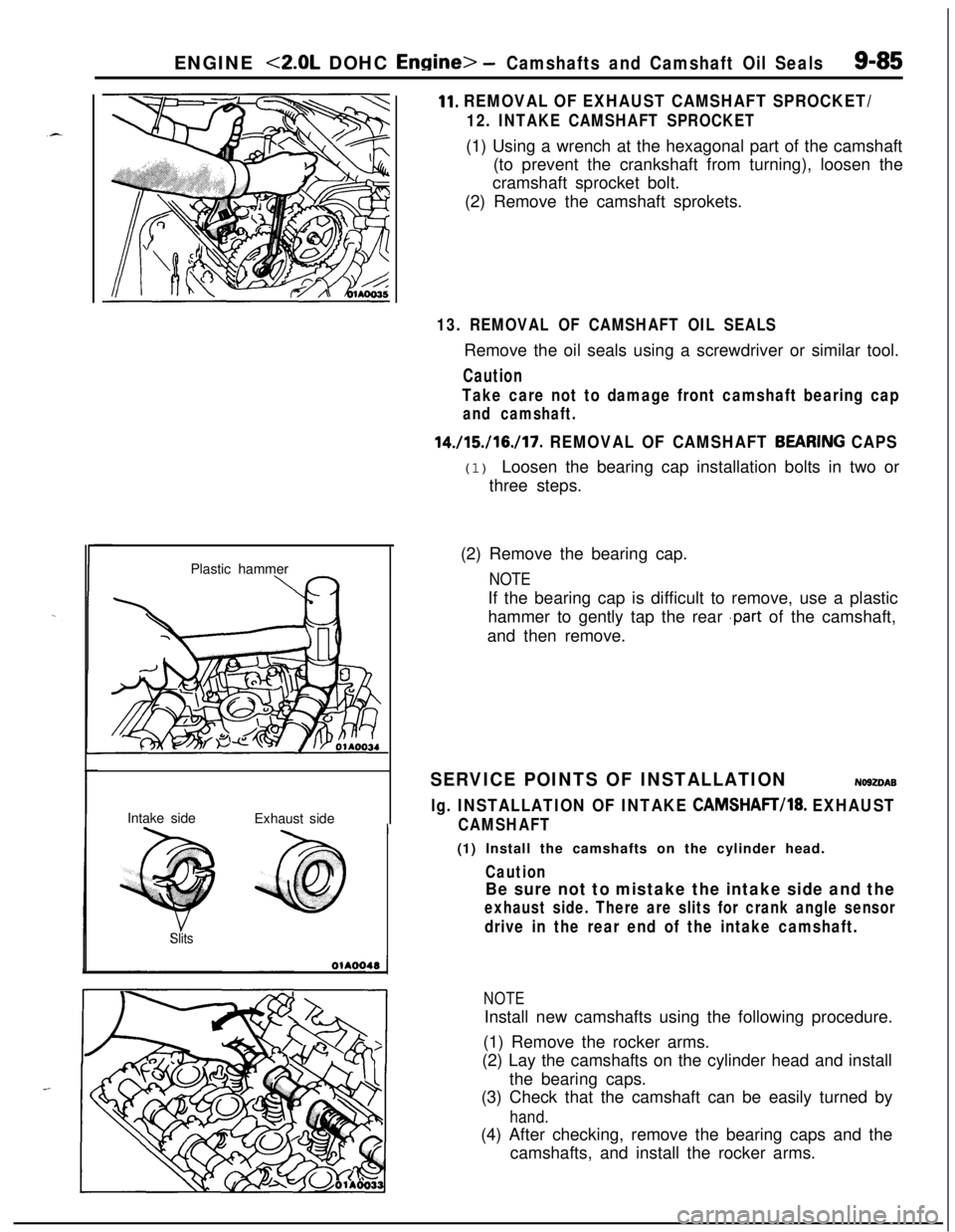

11. REMOVAL OF EXHAUST CAMSHAFT SPROCKET/

12. INTAKE CAMSHAFT SPROCKET(1) Using a wrench at the hexagonal part of the camshaft

(to prevent the crankshaft from turning), loosen the

cramshaft sprocket bolt.

(2) Remove the camshaft sprokets.

13. REMOVAL OF CAMSHAFT OIL SEALSRemove the oil seals using a screwdriver or similar tool.

Caution

Take care not to damage front camshaft bearing cap

and camshaft.

14./15./16./17. REMOVAL OF CAMSHAFT BEARfNG CAPS(1) Loosen the bearing cap installation bolts in two or

three steps.

(2) Remove the bearing cap.

NOTEIf the bearing cap is difficult to remove, use a plastic

hammer to gently tap the rear

.part of the camshaft,

and then remove.

SERVICE POINTS OF INSTALLATIONNO92DAB

lg. INSTALLATION OF INTAKE CAMSHAFT/18. EXHAUST

CAMSHAFT(1) Install the camshafts on the cylinder head.

Caution

Be sure not to mistake the intake side and the

exhaust side. There are slits for crank angle sensor

drive in the rear end of the intake camshaft.

NOTEInstall new camshafts using the following procedure.

(1) Remove the rocker arms.

(2) Lay the camshafts on the cylinder head and install

the bearing caps.

(3) Check that the camshaft can be easily turned by

hand.(4) After checking, remove the bearing caps and the

camshafts, and install the rocker arms.