glove box MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1124 of 1216

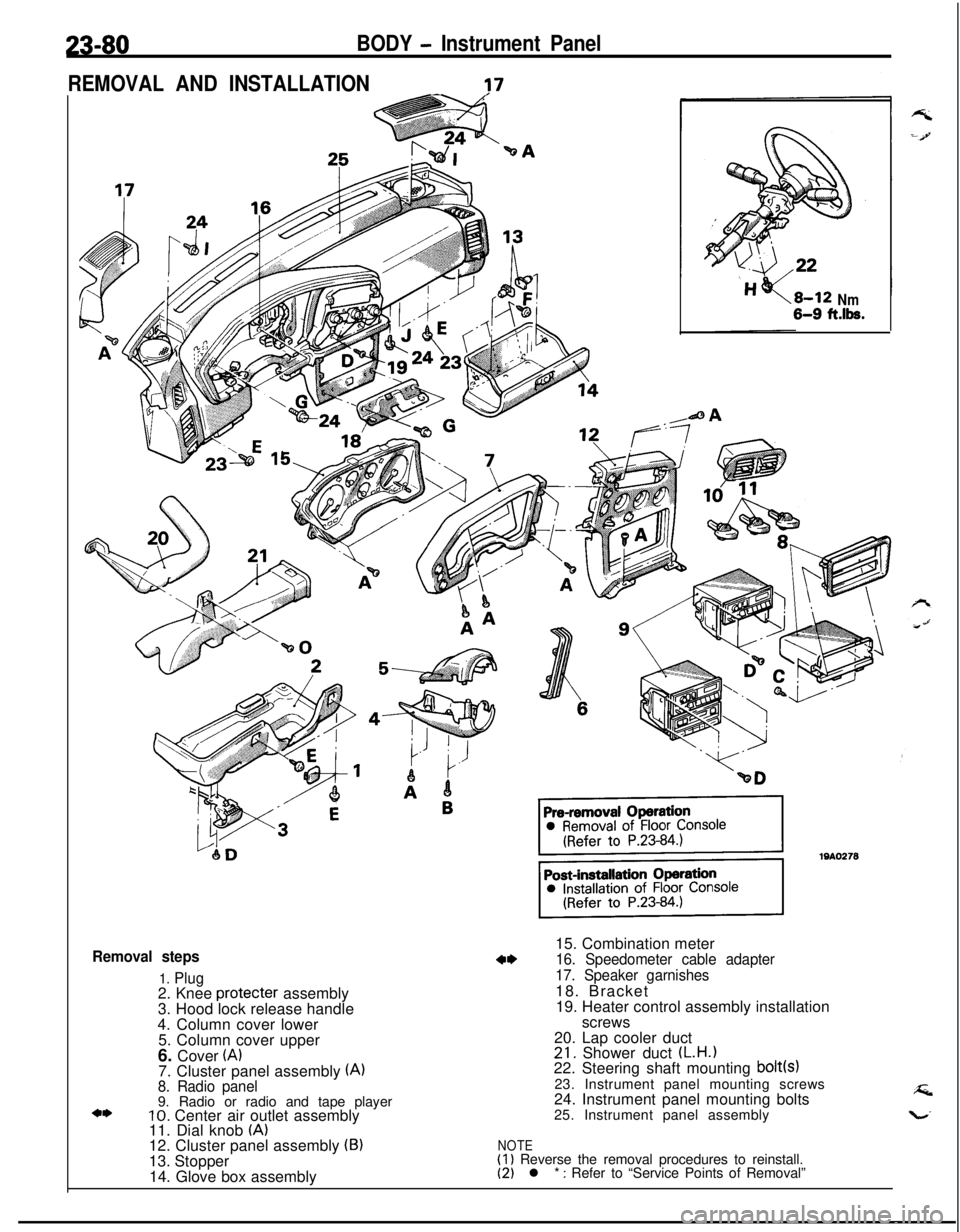

23-80BODY - Instrument Panel

REMOVAL AND INSTALLATION

-?7

Removal steps

1. Plug2. Knee protecter assembly

3. Hood lock release handle

4. Column cover lower

5. Column cover upper

6. Cover

(A)7. Cluster panel assembly (A)8. Radio panel9. Radio or radio and tape player

10. Center air outlet assembly

11. Dial knob (A)12. Cluster panel assembly (B)13. Stopper

14. Glove box assembly

Nm6-9 ft.lk.15. Combination meter

16. Speedometer cable adapter

17. Speaker garnishes18. Bracket

19. Heater control assembly installation

screws

20. Lap cooler duct

21. Shower duct (L.H.122. Steering shaft mounting bolt(s)23. Instrument panel mounting screws

24. Instrument panel mounting bolts

25. Instrument panel assembly

NOTE(1) Reverse the removal procedures to reinstall.(2) l * : Refer to “Service Points of Removal”

Page 1126 of 1216

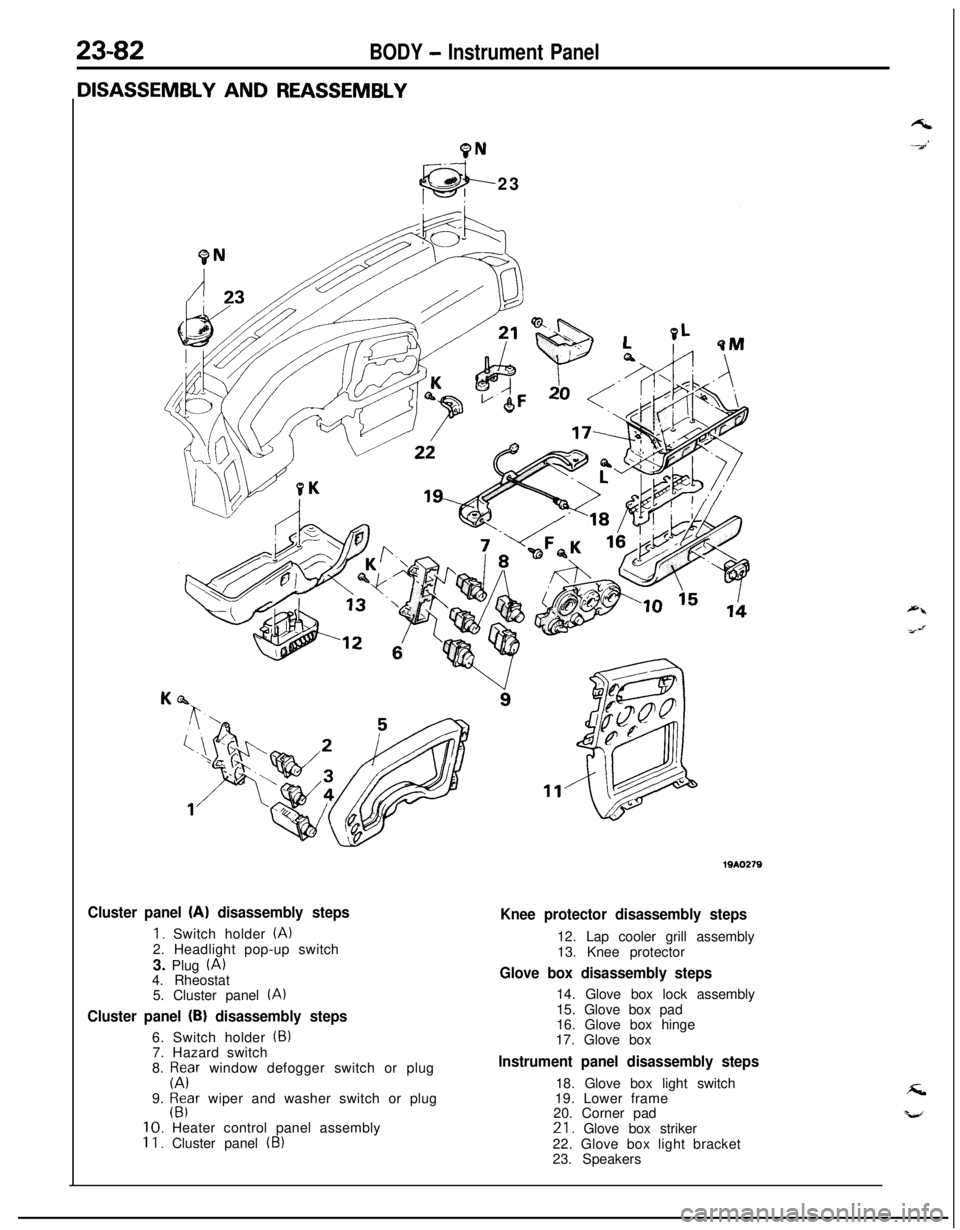

23-82BODY - Instrument Panel

9N23

Cluster panel (A) disassembly steps

1. Switch holder (A)2. Headlight pop-up switch

3. Plug

(A)4. Rheostat

5. Cluster panel

(A)

Cluster panel (B) disassembly steps6. Switch holder

(5)7. Hazard switch

8.

p;Fr window defogger switch or plug

9.

$far wiper and washer switch or plug10. Heater control panel assembly

II. Cluster panel (B)

Knee protector disassembly steps12. Lap cooler grill assembly

13. Knee protector

Glove box disassembly steps14. Glove box lock assembly

15. Glove box pad

16. Glove box hinge

17. Glove box

Instrument panel disassembly steps18. Glove box light switch

19. Lower frame

20. Corner pad21. Glove box striker

22. Glove box light bracket

23. Speakers

Page 1170 of 1216

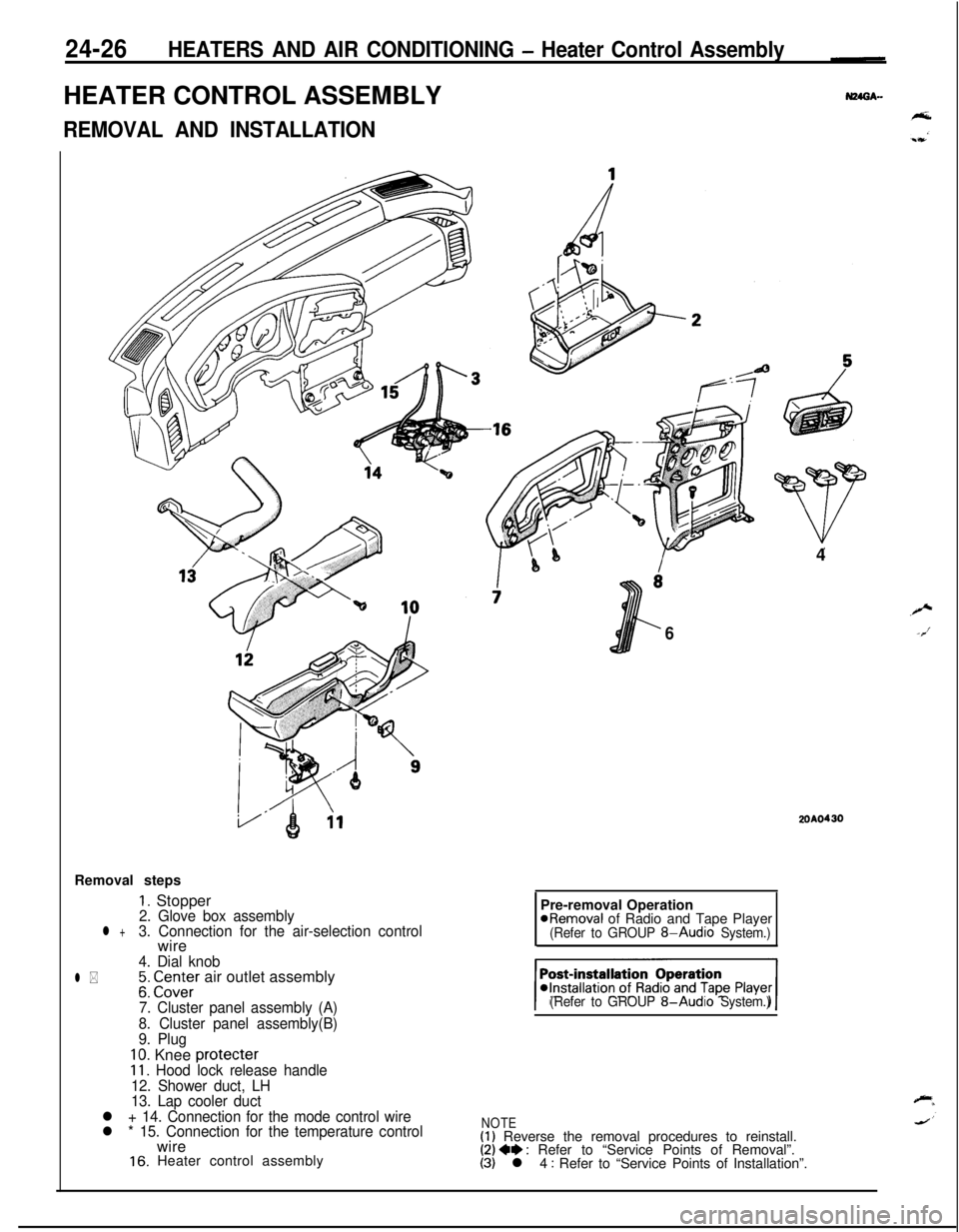

24-26HEATERS AND AIR CONDITIONING - Heater Control AssemblyHEATER CONTROL ASSEMBLY

REMOVAL AND INSTALLATIONRemoval steps

1. Stopper2. Glove box assemblyl +3. Connection for the air-selection controlwire

4. Dial knob

l *;: CI.Z;Er air outlet assembly

7. Cluster panel assembly (A)

8. Cluster panel assembly(B)

9. Plug

10. Knee protecter11. Hood lock release handle

12. Shower duct, LH

13. Lap cooler duct

l + 14. Connection for the mode control wire

l * 15. Connection for the temperature controlwire

16. Heater control assembly4

6

2OAO430Pre-removal Operation

@Removal of Radio and Tape Player(Refer to GROUP 8-Audio System.)

(Refer to GROUP

8-Audio System.)

NOTE(1) Reverse the removal procedures to reinstall.(2) 4e : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”.

Page 1173 of 1216

HEATERS AND AIR CONDITIONING - Resistor

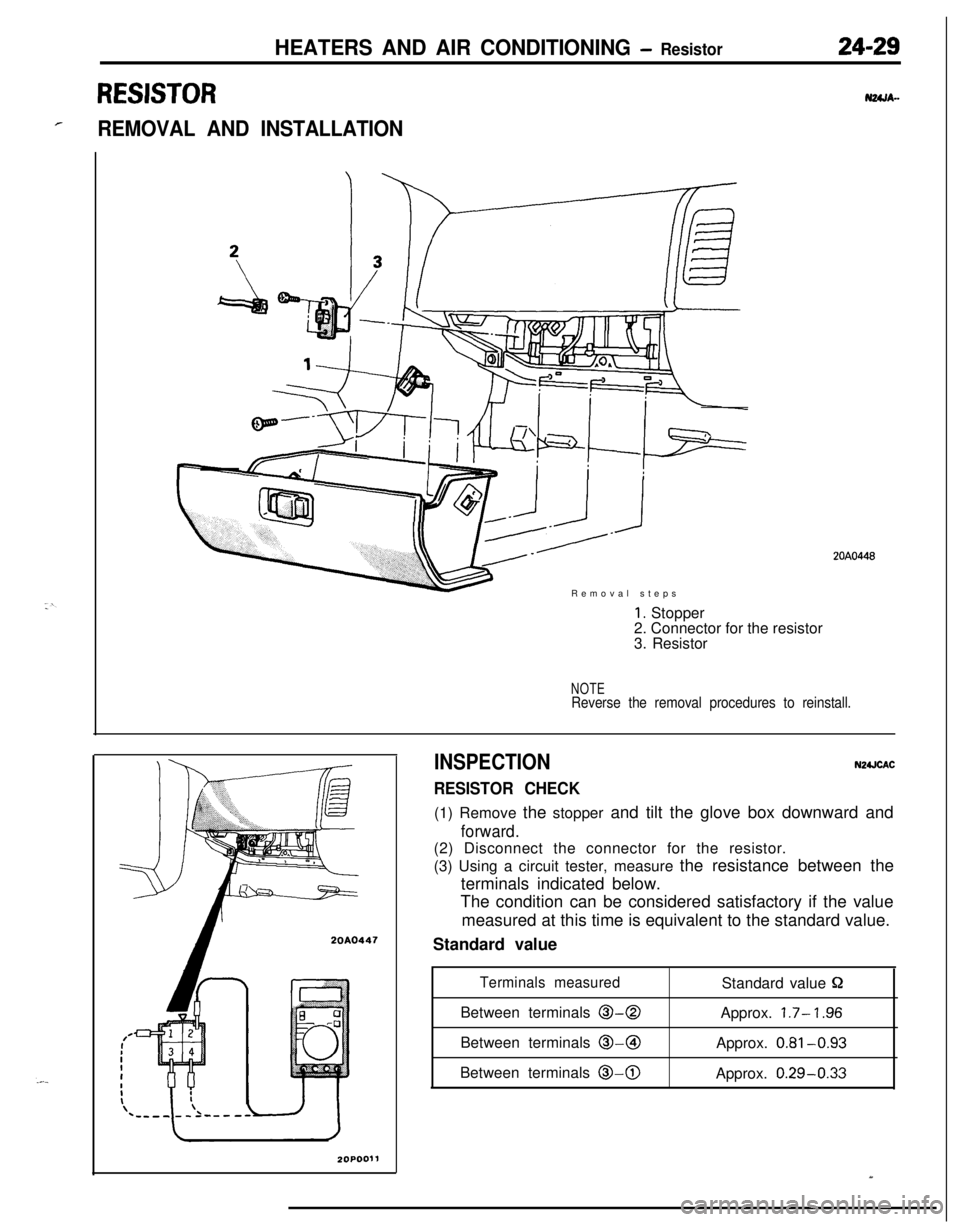

RESISTOR

rREMOVAL AND INSTALLATIONRemoval steps

20A0447

1. Stopper

2. Connector for the resistor

3. Resistor

NOTEReverse the removal procedures to reinstall.

INSPECTION

RESISTOR CHECK

N2UCAC(1) Remove the stopper and tilt the glove box downward and

forward.(2) Disconnect the connector for the resistor.

(3) Using a circuit tester, measure the resistance between the

terminals indicated below.

The condition can be considered satisfactory if the value

measured at this time is equivalent to the standard value.

Standard value

Terminals measuredStandard value PBetween terminals

O-0Approx. 1.7- ‘I .96Between terminals @-@I

Approx.

0.81-0.93Between terminals

0-0Approx. 0.29-0.33

20A0448

Page 1178 of 1216

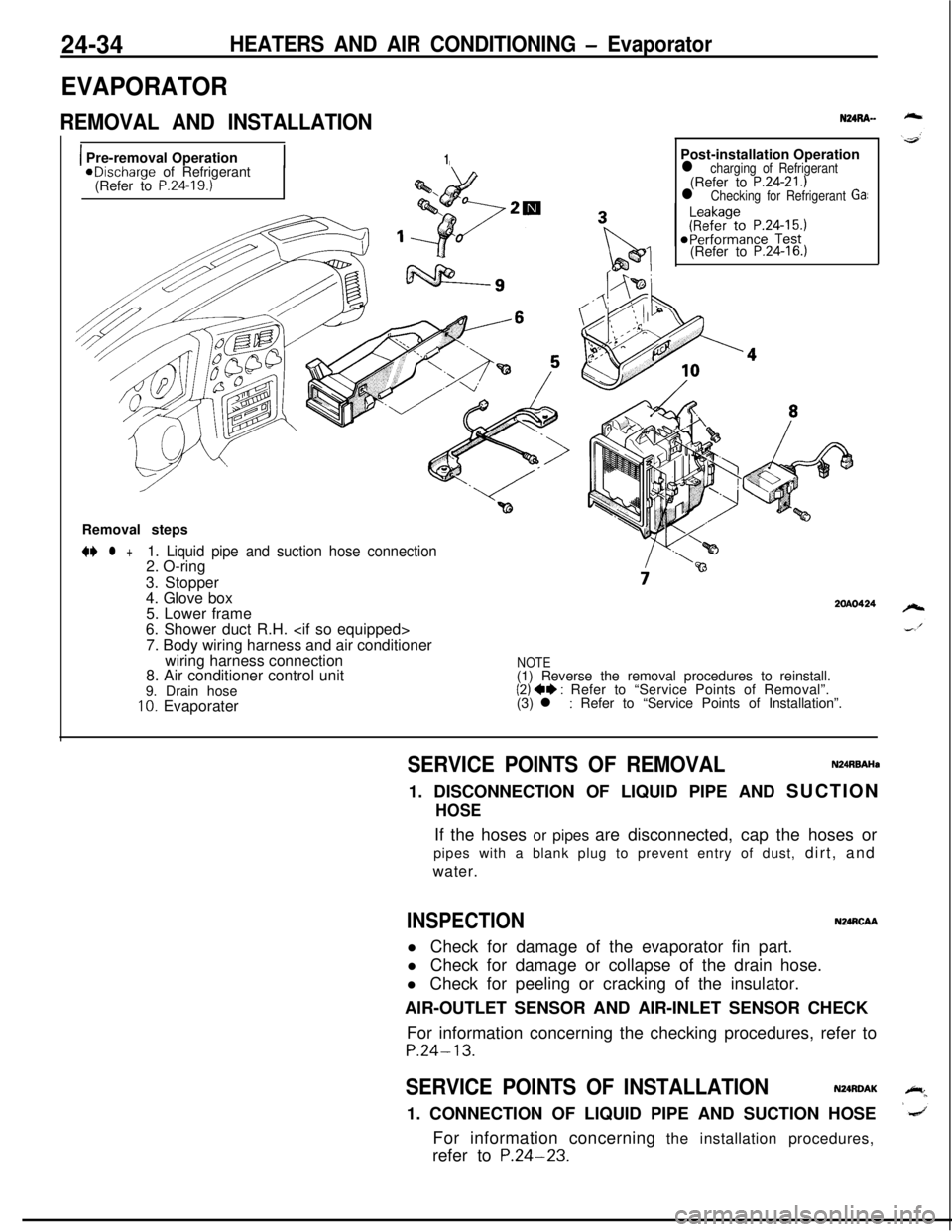

24-34HEATERS AND AIR CONDITIONING - Evaporator

EVAPORATOR

REMOVAL AND INSTALLATION

1 Pre-removal Operation1aDischarge of Refrigerant

(Refer to P.24.19.)Post-installation Operation

l charging of Refrigerant(Refer to P.24-21.)l Checking for Refrigerant Ga:(Refer to

P.24-16.)Removal steps

N l +1. Liquid pipe and suction hose connection2. O-ring

3. Stopper

4. Glove box

5. Lower frame

6. Shower duct R.H.

7. Body wiring harness and air conditioner

wiring harness connection

8. Air conditioner control unit

9. Drain hose

10. Evaporater

2OAO424

NOTE(1) Reverse the removal procedures to reinstall.

(2) ++ : Refer to “Service Points of Removal”.

(3) l : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVALN24RBAHa1. DISCONNECTION OF LIQUID PIPE AND SUCTION

HOSEIf the hoses or pipes are disconnected, cap the hoses or

pipes with a blank plug to prevent entry of dust, dirt, and

water.

INSPECTIONN24RCAAl Check for damage of the evaporator fin part.

l Check for damage or collapse of the drain hose.

l Check for peeling or cracking of the insulator.

AIR-OUTLET SENSOR AND AIR-INLET SENSOR CHECK

For information concerning the checking procedures, refer to

P.24-13.

SERVICE POINTS OF INSTALLATIONN24RDAK1. CONNECTION OF LIQUID PIPE AND SUCTION HOSE

For information concerning the installation procedures,

refer to

P.24-23.