ESP MITSUBISHI ECLIPSE 1993 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1993Pages: 57, PDF Size: 4.18 MB

Page 4 of 57

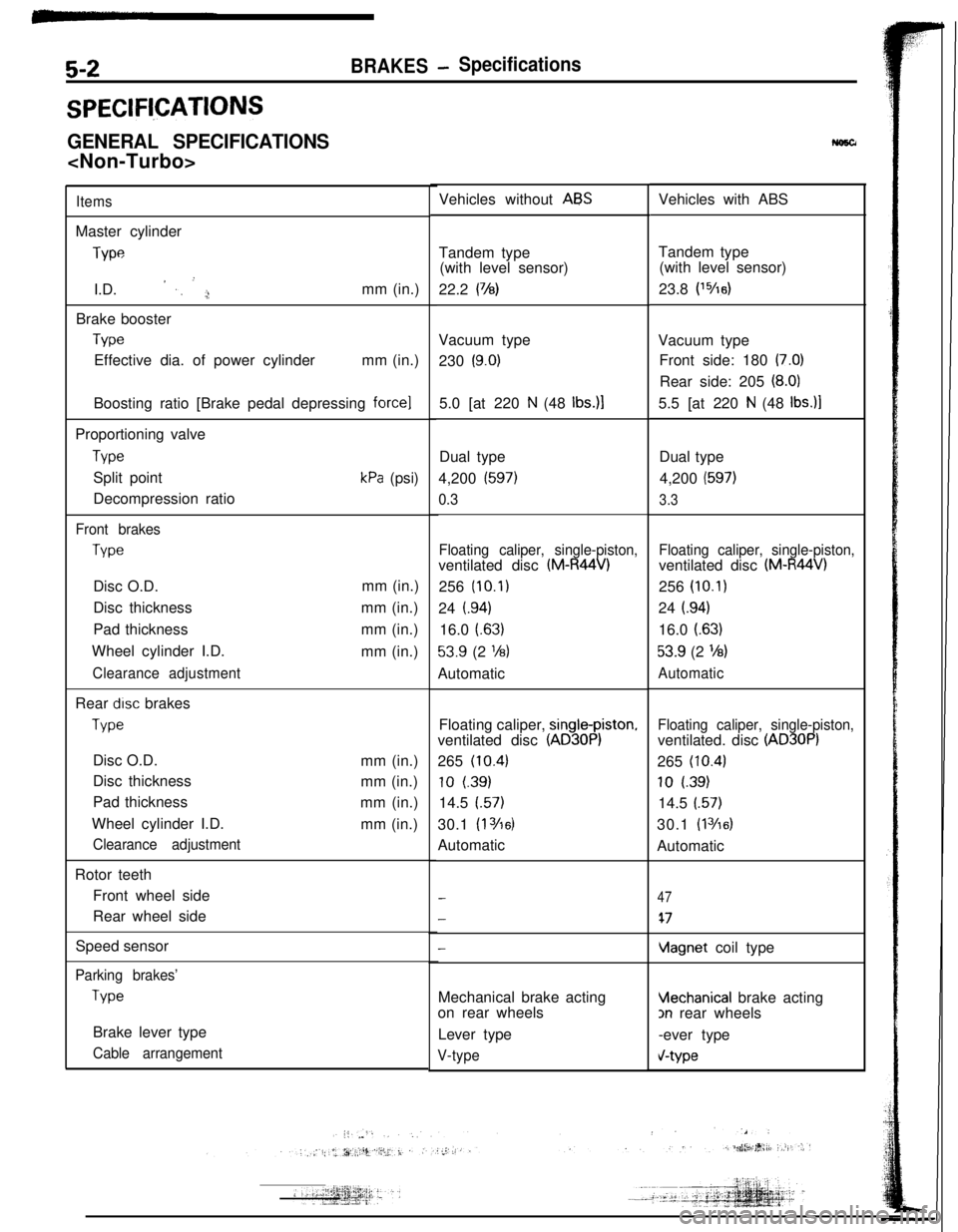

5-2BRAKES- Specifications

SPECIFl,CATIONS

GENERAL SPECIFICATIONS

ItemsMaster cylinder

J-wI.D.

’ ,, ’ ,;!mm (in.)

Brake booster

TvwEffective dia. of power cylindermm (in.)

Boosting ratio [Brake pedal depressing

force]5.0 [at 220 N (48 Ibs.)lProportioning valve

TypeSplit point

Decompression ratio

kPa (psi)

Front brakes

TypeDisc O.D.

Disc thickness

Pad thickness

Wheel cylinder I.D.

Clearance adjustmentmm (in.)

mm (in.)

mm (in.)

mm (in.)

Rear

drsc brakes

TypeDisc O.D.

Disc thickness

Pad thickness

Wheel cylinder I.D.

Clearance adjustmentmm (in.)

mm (in.)

mm (in.)

mm (in.)

Rotor teeth

Front wheel side

Rear wheel side

Speed sensor

-

Parking brakes’

TvwBrake lever type

Cable arrangementVehicles without

ABSVehicles with ABS

Tandem type

(with level sensor)

22.2

(78)Tandem type

(with level sensor)

23.8 P5/1dVacuum type

230

(9.0)Vacuum type

Front side: 180 (7.0)Rear side: 205

(8.0)5.5 [at 220

N (48 Ibs.)lDual type

4,200

(597)

0.3Dual type

4,200

(597)

3.3

Floating caliper, single-piston,ventilated disc

(M-R44V)256

(10.1)24

i.94)16.0

(.63)

53.9 (2 l/8)Automatic

Floating caliper, single-piston,ventilated disc

(M-R44V)256

(10.1)24

i.94)16.0

(.63)

53.9 (2 %)

AutomaticFloating caliper,

single-piston,ventilated disc

(AD30P)265

(10.43

10 (39)

14.5

(.57)30.1

(1 Yl6)Automatic

Floating caliper, single-piston,ventilated. disc

(AD30P)265

(10.4)

10 l.39)14.5

(.57)30.1

(1 3/6)Automatic

-

-

47

47

vlagnet coil type

Mechanical brake acting

Vlechanical brake acting

on rear wheels

3n rear wheels

Lever type

-ever type

V-typeV-type

Page 8 of 57

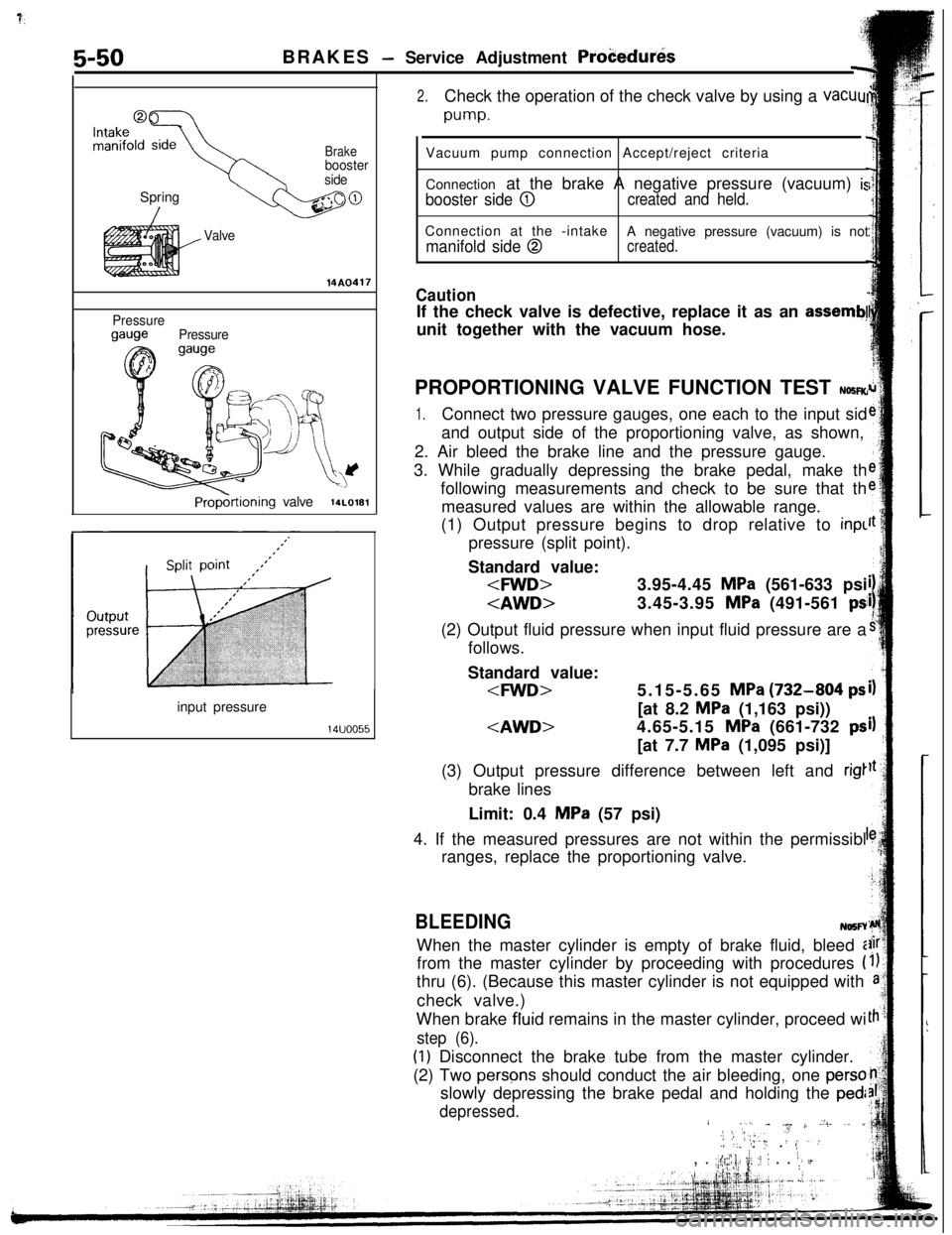

5-50BRAKES - Service Adjustment Proi?edur&

Brakebooster

sideSpring

’

/

Valve

Pressure

gaugePressure

PropGtioning valve14LO181input pressure

14uoo55

2.Check the operation of the check valve by using a vacuul

pump.Vacuum pump connection Accept/reject criteria

Connection at the brake A negative pressure (vacuum)

is

booster side @created and held.Connection at the -intake

manifold side @A negative pressure (vacuum) is notcreated.

CautionIf the check valve is defective, replace it as an

assemb!unit together with the vacuum hose.

PROPORTIONING VALVE FUNCTION TEST

NO!iR(r

1.Connect two pressure gauges, one each to the input sid

and output side of the proportioning valve, as shown,

2. Air bleed the brake line and the pressure gauge.

3. While gradually depressing the brake pedal, make th

following measurements and check to be sure that th

measured values are within the allowable range.

(1) Output pressure begins to drop relative to inpl

pressure (split point).

Standard value:

follows.

Standard value:

MPa (1,163 psi))

MPa (1,095 psi)]

(3) Output pressure difference between left and

rig1brake lines

Limit: 0.4

MPa (57 psi)

4. If the measured pressures are not within the permissibl

ranges, replace the proportioning valve.

BLEEDINGNo5FYWhen the master cylinder is empty of brake fluid, bleed i

from the master cylinder by proceeding with procedures

(thru (6). (Because this master cylinder is not equipped with

check valve.)

When brake fluid remains in the master cylinder, proceed wi

step (6).

(1) Disconnect the brake tube from the master cylinder.

(2) Two

persqs should conduct the air bleeding, one persoslowly depressing the brake pedal and holding the

ped:

depressed.i .I..[ j,‘I- .~ j, Z’:. ~. jl2;:‘,.Y .‘.:./ ‘:” ‘: ,, . 8,, .

.;$y; ii; :: 1 . . i;, d

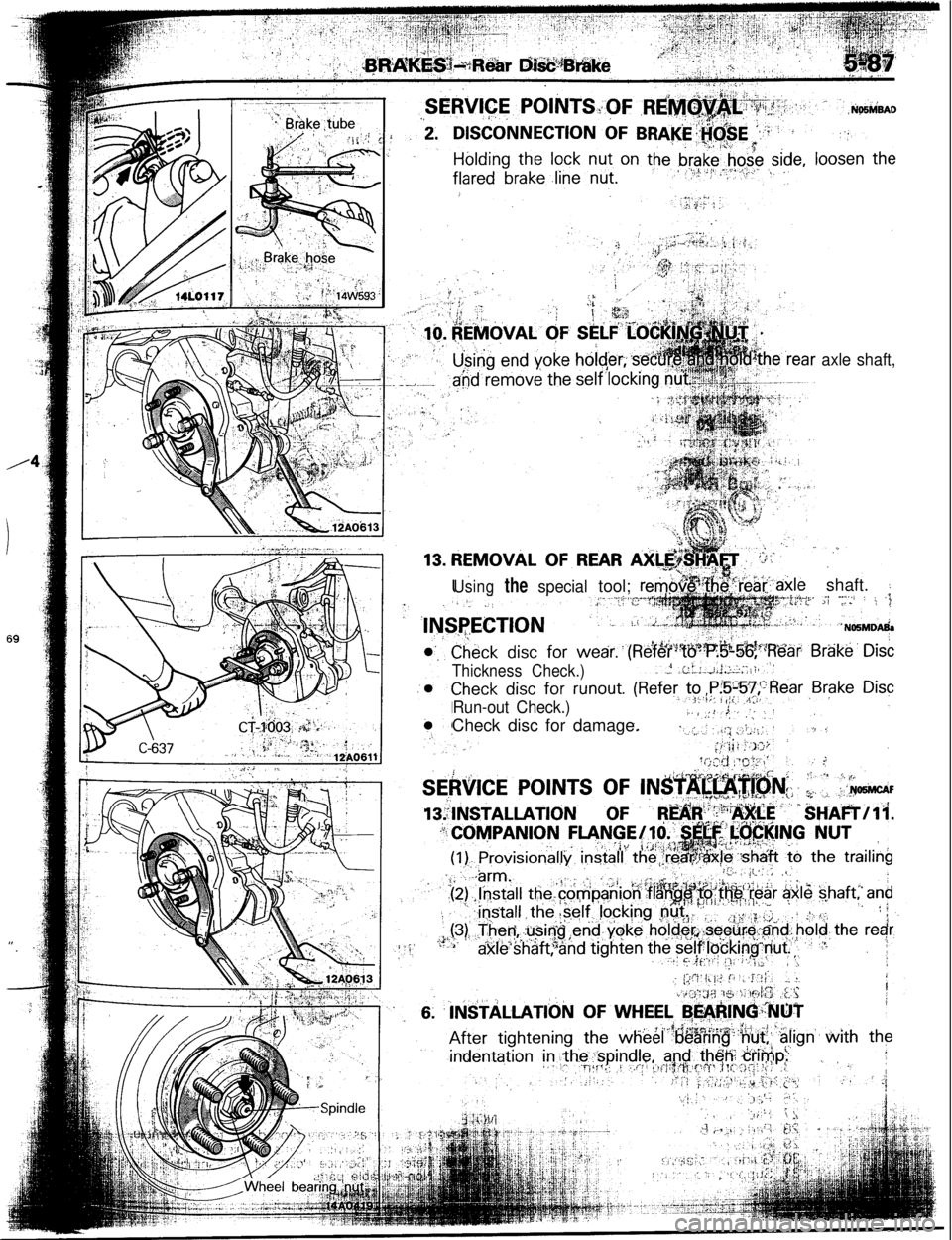

Page 30 of 57

axle shaft,

Usingthespecialtool; r:&.le shaft. :.;; -..s../ : i 3<.- Ef

Thickness Check.)

Run-out Check.)Check disc for damage.

Page 31 of 57

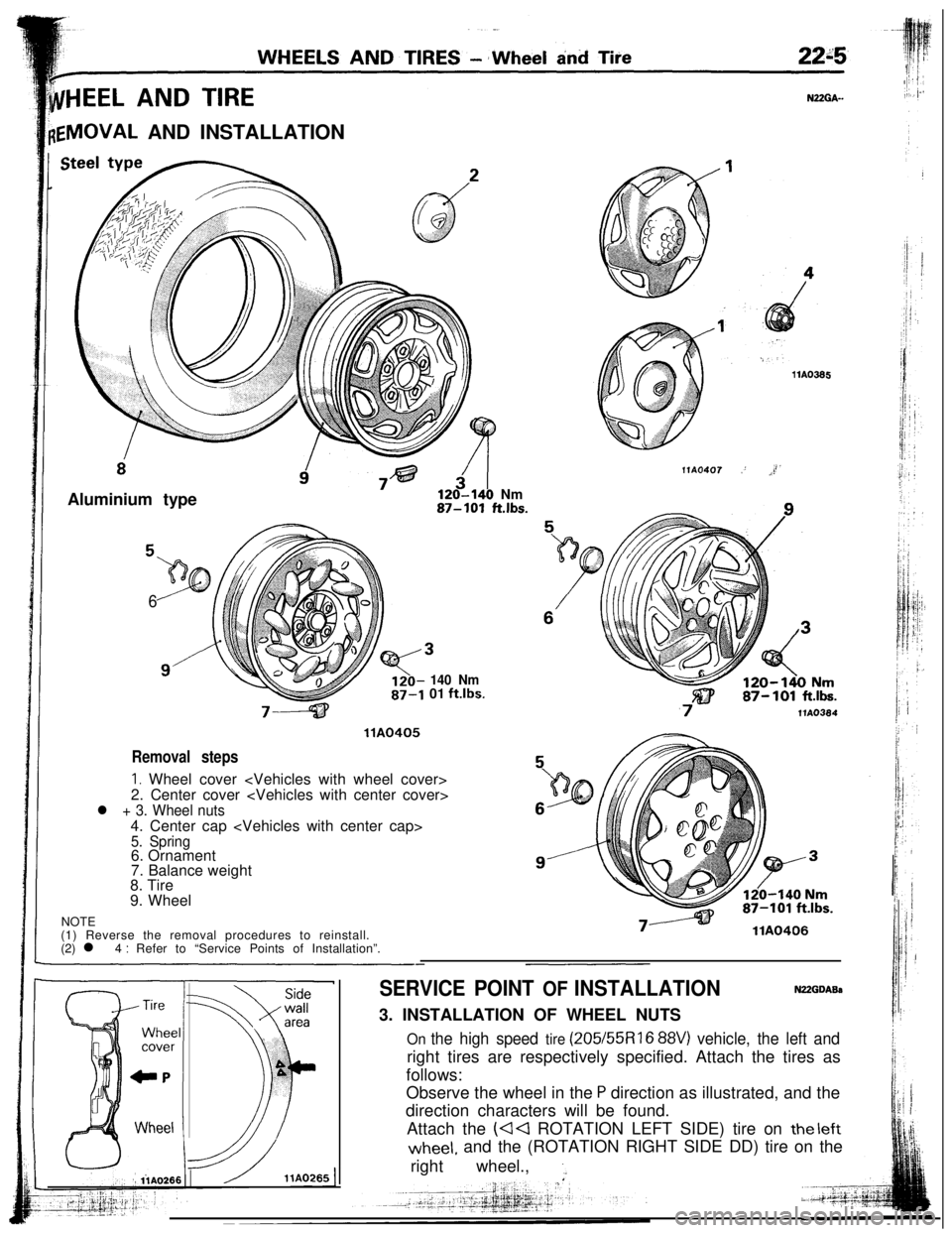

~~~HEEL AND TIREN22GA..

{EMOVAL AND INSTALLATION

Aluminium type

120-140 Nm87-101 ft.lbs.

6

140 Nm01 ft.lbs.

llA0405

Removal steps

I. Wheel cover

2. Center cover

l + 3. Wheel nuts4. Center cap

5. Spring6. Ornament

NOTE7. Balance weight

8. Tire

9. Wheel

(1) Reverse the removal procedures to reinstall.

(2) l 4

: Refer to “Service Points of Installation”.llA0366

llA0407,’ J’

7VA0364

llA0406

SERVICE POINT OF INSTALLATIONN22GDABs3. INSTALLATION OF WHEEL NUTS

On the high speed tire (205/55Rl6 88V) vehicle, the left andright tires are respectively specified. Attach the tires as

follows:

Observe the wheel in the

P direction as illustrated, and the

direction characters will be found.

Attach the

(44 ROTATION LEFT SIDE) tire on the leftwheel, and the (ROTATION RIGHT SIDE DD) tire on the

right wheel.,

1.