brake fluid MITSUBISHI ECLIPSE 1993 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1993, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1993Pages: 57, PDF Size: 4.18 MB

Page 3 of 57

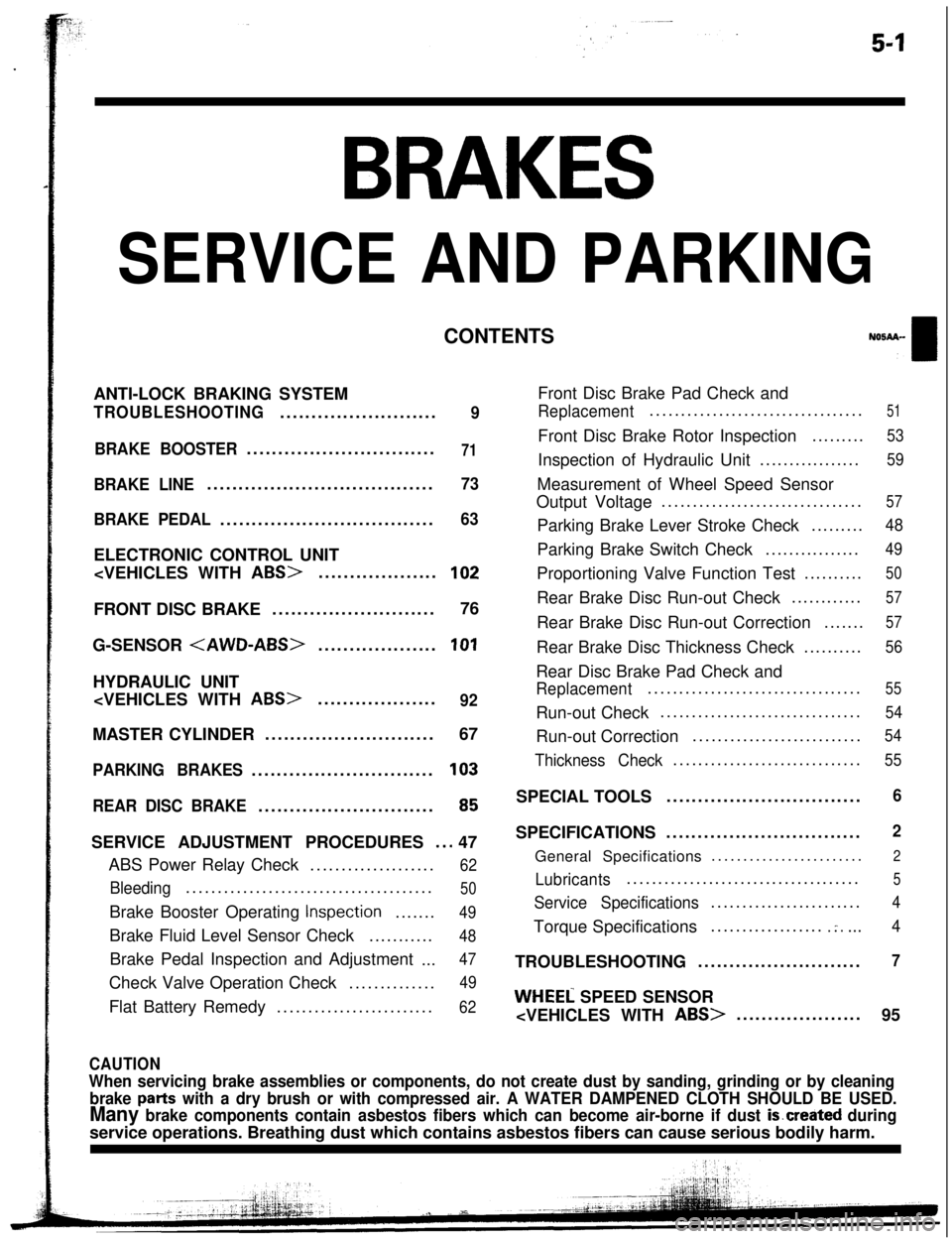

BRAKES

SERVICE AND PARKINGCONTENTS

ANTI-LOCK BRAKING SYSTEM

TROUBLESHOOTING.........................9

BRAKE BOOSTER..............................

71

BRAKE LINE....................................73

BRAKE PEDAL..................................

63ELECTRONIC CONTROL UNIT

G-SENSOR

PARKING BRAKES.............................103

REAR DISC BRAKE............................

65SERVICE ADJUSTMENT PROCEDURES

..a 47

ABS Power Relay Check....................

62

Bleeding.......................................50Brake Booster Operating

Inspection.......49Brake Fluid Level Sensor Check...........

48Brake Pedal Inspection and Adjustment

...

47Check Valve Operation Check..............

49Flat Battery Remedy.........................

62Front Disc Brake Pad Check and

Replacement..................................51Front Disc Brake Rotor Inspection.........

53Inspection of Hydraulic Unit.................

59Measurement of Wheel Speed Sensor

Output Voltage................................

57Parking Brake Lever Stroke Check.........

48Parking Brake Switch Check................

49Proportioning Valve Function Test..........

50Rear Brake Disc Run-out Check............

57Rear Brake Disc Run-out Correction.......

57Rear Brake Disc Thickness Check..........

56Rear Disc Brake Pad Check and

Replacement..................................55Run-out Check................................

54Run-out Correction...........................

54

Thickness Check..............................55SPECIAL TOOLS...............................

6SPECIFICATIONS...............................

2General Specifications........................

2

Lubricants.....................................5

Service Specifications........................4Torque Specifications..................

.:....4TROUBLESHOOTING..........................

7

WHEEL SPEED SENSOR

95

CAUTION

When servicing brake assemblies or components, do not create dust by sanding, grinding or by cleaning

brake

parts with a dry brush or with compressed air. A WATER DAMPENED CLOTH SHOULD BE USED.

Many brake components contain asbestos fibers which can become air-borne if dust is.created duringservice operations. Breathing dust which contains asbestos fibers can cause serious bodily harm.

Page 7 of 57

-

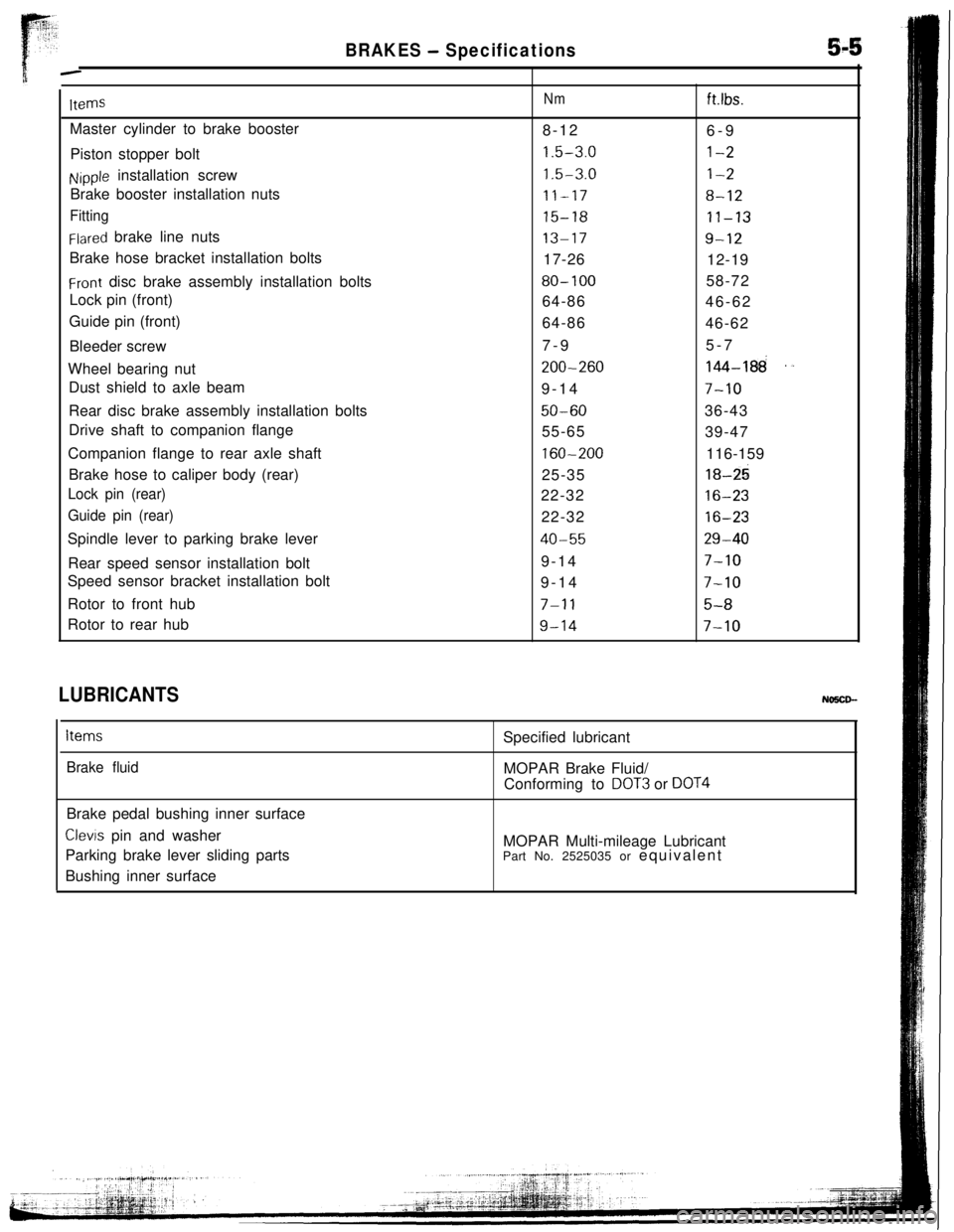

BRAKES - Specifications

ItemsMaster cylinder to brake booster

Piston stopper bolt

Nipple installation screw

Brake booster installation nuts

Fitting

Flared brake line nuts

Brake hose bracket installation bolts

Front disc brake assembly installation bolts

Lock pin (front)

Guide pin (front)

Bleeder screw

Wheel bearing nut

Dust shield to axle beam

Rear disc brake assembly installation bolts

Drive shaft to companion flange

Companion flange to rear axle shaft

Brake hose to caliper body (rear)

Lock pin (rear)

Guide pin (rear)Spindle lever to parking brake lever

Rear speed sensor installation bolt

Speed sensor bracket installation bolt

Rotor to front hub

Rotor to rear hub

Nm8-12

1.5-3.0

1.5-3.0

11-17

15-18

13-1717-26

80-10064-86

64-86

7-9

200-2609-14

50-6055-65

160-20025-35

22-32

22-32

40-559-14

9-14

7-l 1

9-14

ft.lbs.6-9

l-2

l-2

8-12

11-13

9-1212-19

58-72

46-62

46-62

5-7

144-188”

7-1036-43

39-47

116-159

18-25

16-23

16-23

29-40

7-10

7-10

5-a

7-10

LUBRICANTSNo!xD-

Items

Brake fluidSpecified lubricant

MOPAR Brake Fluid/

Conforming to

DOT3 or DOT4Brake pedal bushing inner surface

Clevls pin and washer

Parking brake lever sliding parts

Bushing inner surfaceMOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

Page 8 of 57

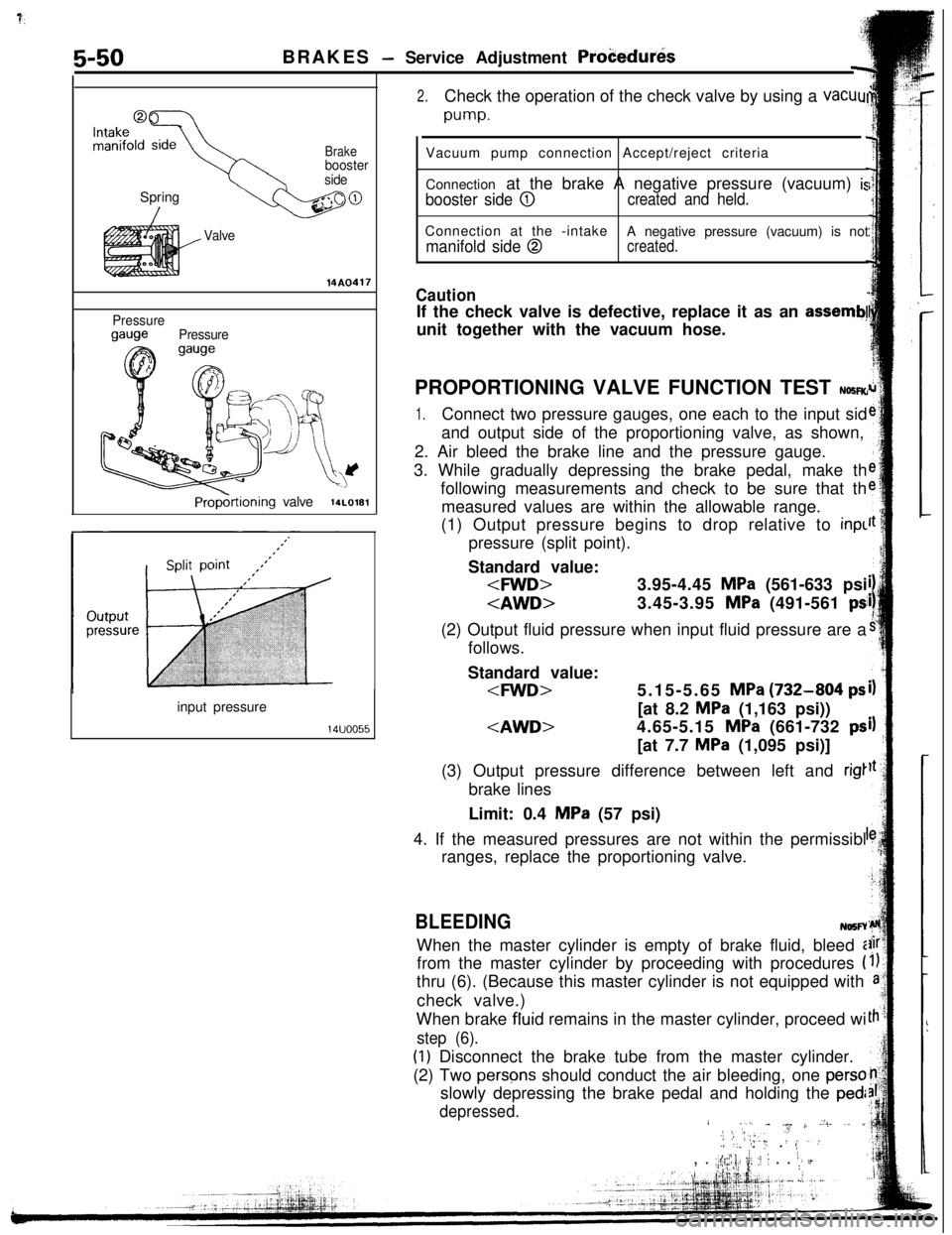

5-50BRAKES - Service Adjustment Proi?edur&

Brakebooster

sideSpring

’

/

Valve

Pressure

gaugePressure

PropGtioning valve14LO181input pressure

14uoo55

2.Check the operation of the check valve by using a vacuul

pump.Vacuum pump connection Accept/reject criteria

Connection at the brake A negative pressure (vacuum)

is

booster side @created and held.Connection at the -intake

manifold side @A negative pressure (vacuum) is notcreated.

CautionIf the check valve is defective, replace it as an

assemb!unit together with the vacuum hose.

PROPORTIONING VALVE FUNCTION TEST

NO!iR(r

1.Connect two pressure gauges, one each to the input sid

and output side of the proportioning valve, as shown,

2. Air bleed the brake line and the pressure gauge.

3. While gradually depressing the brake pedal, make th

following measurements and check to be sure that th

measured values are within the allowable range.

(1) Output pressure begins to drop relative to inpl

pressure (split point).

Standard value:

follows.

Standard value:

MPa (1,163 psi))

MPa (1,095 psi)]

(3) Output pressure difference between left and

rig1brake lines

Limit: 0.4

MPa (57 psi)

4. If the measured pressures are not within the permissibl

ranges, replace the proportioning valve.

BLEEDINGNo5FYWhen the master cylinder is empty of brake fluid, bleed i

from the master cylinder by proceeding with procedures

(thru (6). (Because this master cylinder is not equipped with

check valve.)

When brake fluid remains in the master cylinder, proceed wi

step (6).

(1) Disconnect the brake tube from the master cylinder.

(2) Two

persqs should conduct the air bleeding, one persoslowly depressing the brake pedal and holding the

ped:

depressed.i .I..[ j,‘I- .~ j, Z’:. ~. jl2;:‘,.Y .‘.:./ ‘:” ‘: ,, . 8,, .

.;$y; ii; :: 1 . . i;, d

Page 9 of 57

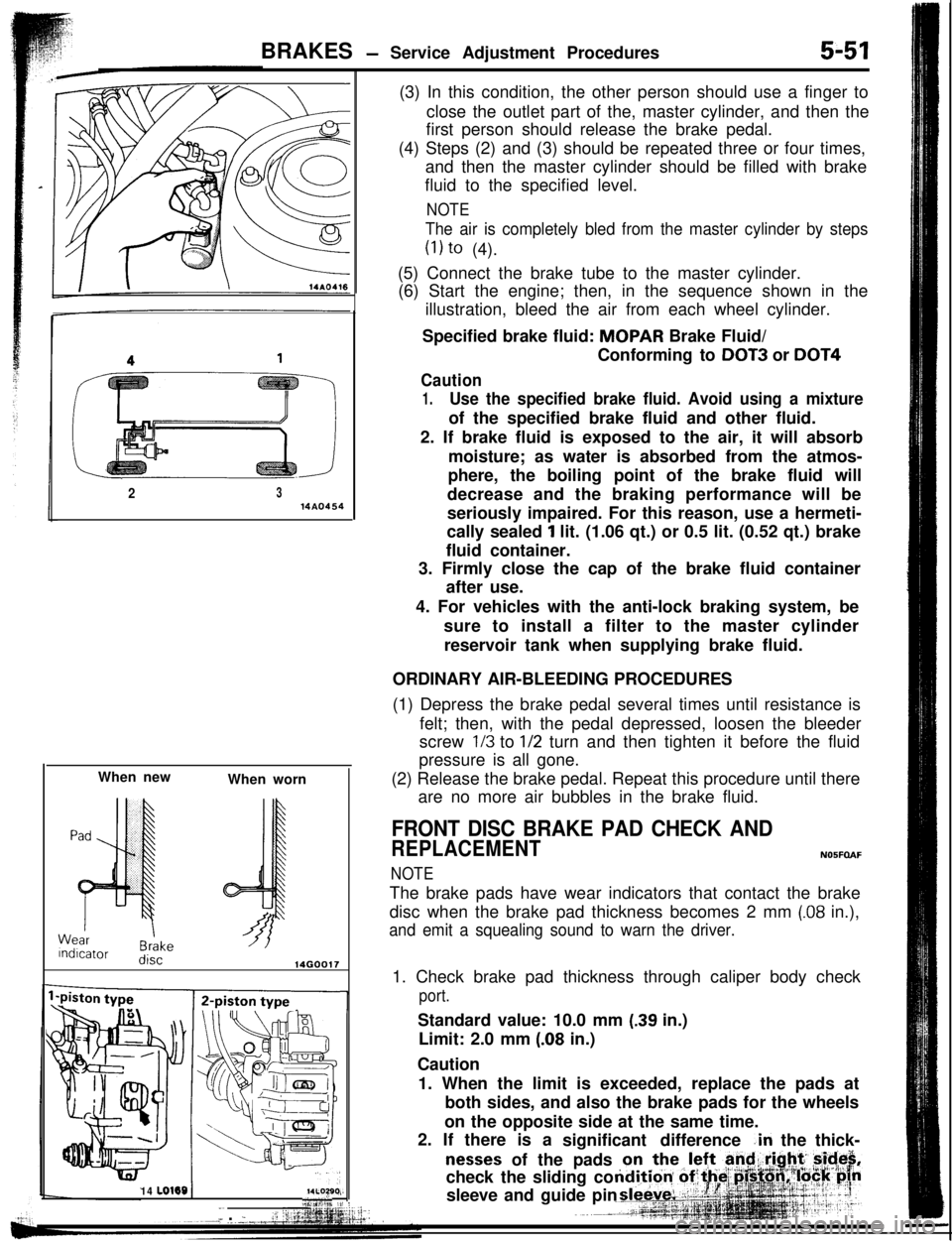

BRAKES - Service Adjustment Procedures5-51

2314A0454When new

When worn14G0017

1

14 LO169check the sliding coWsTm~3..“.W% ,Y :sleeve and guide pin-~I ._. ;;:i ‘.(3) In this condition, the other person should use a finger to

close the outlet part of the, master cylinder, and then the

first person should release the brake pedal.

(4) Steps (2) and (3) should be repeated three or four times,

and then the master cylinder should be filled with brake

fluid to the specified level.

NOTE

The air is completely bled from the master cylinder by steps

(1) to (4).

(5) Connect the brake tube to the master cylinder.

(6) Start the engine; then, in the sequence shown in the

illustration, bleed the air from each wheel cylinder.

Specified brake fluid: MOPAR Brake Fluid/

Conforming to

DOT3 or DOT4

Caution

1.Use the specified brake fluid. Avoid using a mixtureof the specified brake fluid and other fluid.

2. If brake fluid is exposed to the air, it will absorb

moisture; as water is absorbed from the atmos-

phere, the boiling point of the brake fluid will

decrease and the braking performance will be

seriously impaired. For this reason, use a hermeti-

cally sealed

1 lit. (1.06 qt.) or 0.5 lit. (0.52 qt.) brake

fluid container.

3. Firmly close the cap of the brake fluid container

after use.

4. For vehicles with the anti-lock braking system, be

sure to install a filter to the master cylinder

reservoir tank when supplying brake fluid.

ORDINARY AIR-BLEEDING PROCEDURES

(1) Depress the brake pedal several times until resistance is

felt; then, with the pedal depressed, loosen the bleeder

screw

l/3 to l/2 turn and then tighten it before the fluid

pressure is all gone.

(2) Release the brake pedal. Repeat this procedure until there

are no more air bubbles in the brake fluid.

FRONT DISC BRAKE PAD CHECK AND

REPLACEMENTN05FOAF

NOTEThe brake pads have wear indicators that contact the brake

disc when the brake pad thickness becomes 2 mm

(.08 in.),

and emit a squealing sound to warn the driver.1. Check brake pad thickness through caliper body check

port.Standard value: 10.0 mm

(.39 in.)

Limit: 2.0 mm

(.08 in.)

Caution

1. When the limit is exceeded, replace the pads at

both sides, and also the brake pads for the wheels

on the opposite side at the same time.

2. If there is a

significant difference

.in the thick-

nesses of the pads

Page 15 of 57

N0sJa

4LVI

:e the

cuu<

‘=JD4\

;HER

and

!htly.

Wg

CK3a

nd

3ly

he

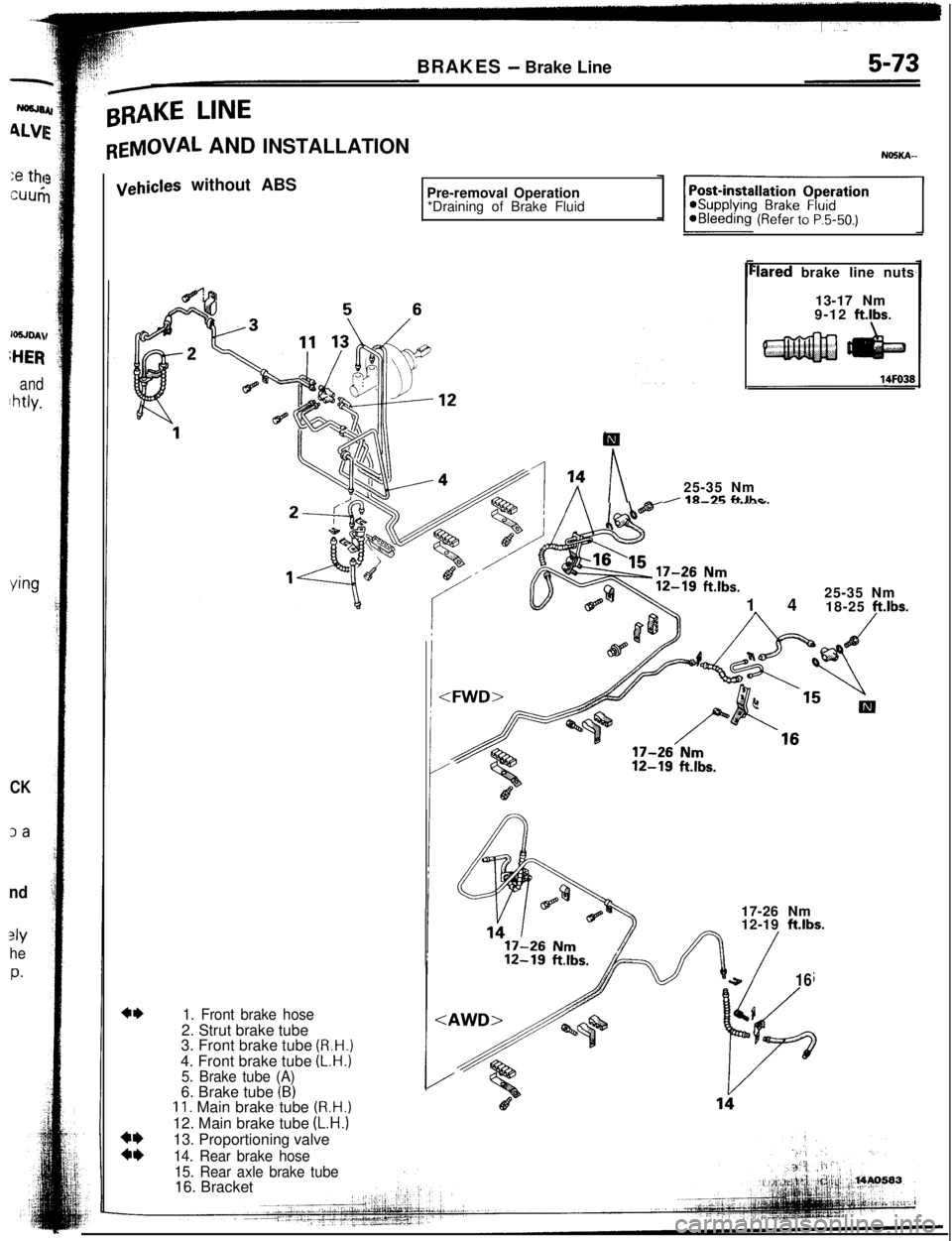

P.BRAKES

- Brake Line

BRAKE LINE

REMOVAL AND INSTALLATIONNOSKA--

1. Front brake hose2. Strut brake tube

3. Front brake tube

(R.H.)4. Front brake tube

(L.H.)5. Brake tube (A)6. Brake tube (B)11. Main brake tube (R.H.)12. Main brake tube

(L.H.)13. Proportioning valve

14. Rear brake hose

15. Rear axle brake tube

._-

Ill

n25-35 NmI 111-7G f-t Ihr:lared brake line nuts

13-17 Nm

9-12

ftlbs.

vehicles without ABS

Pre-removal Operation

*Draining of Brake Fluid

1425-35 Nm

18-25

ft.lbs.17-26 Nm

12-19

ft.lbs.

+1616. Bracket

Page 16 of 57

a-.

i.-J

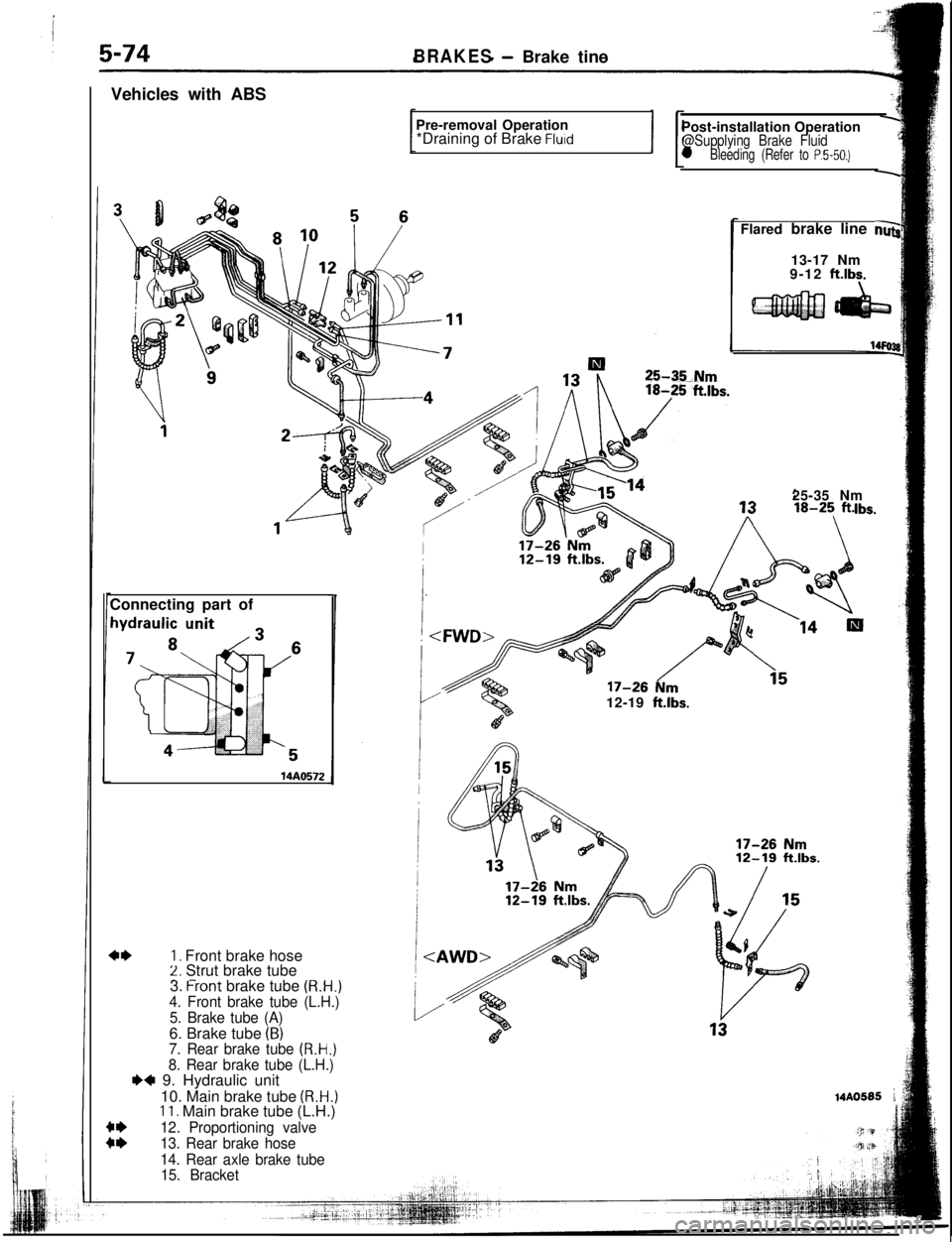

5-74BRAKES- Brake tine

Vehicles with ABS

Pre-removal Operation

*Draining of Brake

Fluid

,“iPost-installation OperationA

@Supplying Brake Fluid1

l Bleeding (Refer to P.5-50.)

-Connecting part of

14AO572

I. Front brake hose2. Strut brake tube- -25-35 Nm

Ibs.12-19

ft.lbs.Flared brake line

ns13-17 Nm

9-12

ftlbs.

15. Bracket3.

f-ront brake tube (R.H.)

4. Front brake tube (L.H.)

5. Brake tube (A)6. Brake tube

(B)7. Rear brake tube (R.H.)

8. Rear brake tube (L.H.)I)+ 9. Hydraulic unit

10. Main brake tube

(R.H.)11. Main brake tube (L.H.)

::

12. Proportioning valve

13. Rear brake hose

14. Rear axle brake tube

14AO585 ;

Page 18 of 57

! -;-596

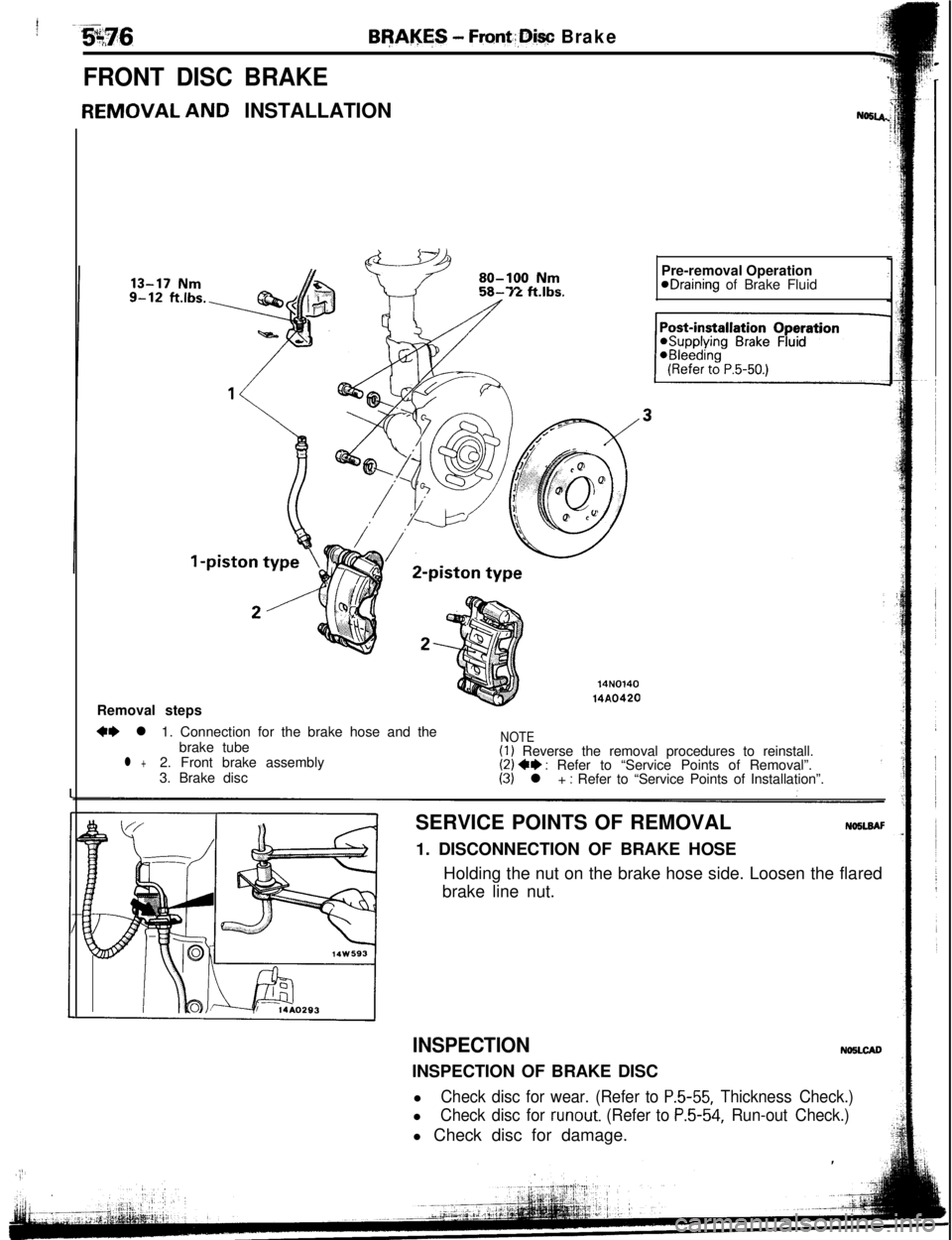

FRONT DISC BRAKE

Bf?Al$ES - Front.:,Diw Brake

REMOVAL AND INSTALLATIONN=U.

3U- IL l-LIDS.Y-i A

14N014014A0420Pre-removal Operation

eDraining of Brake Fluid

Removal steps

+e l1. Connection for the brake hose and the

brake tubeNOTE

l +2. Front brake assembly(1) Reverse the removal procedures to reinstall.

3. Brake disc(2) ++ : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL

No5LsAF1. DISCONNECTION OF BRAKE HOSE

Holding the nut on the brake hose side. Loosen the flared

brake line nut.

INSPECTIONNNiLCIDINSPECTION OF BRAKE DISC

l

Check disc for wear. (Refer to P.5-55, Thickness Check.)l

Check disc for runout. (Refer to P.5-54, Run-out Check.)l Check disc for damage.

Page 21 of 57

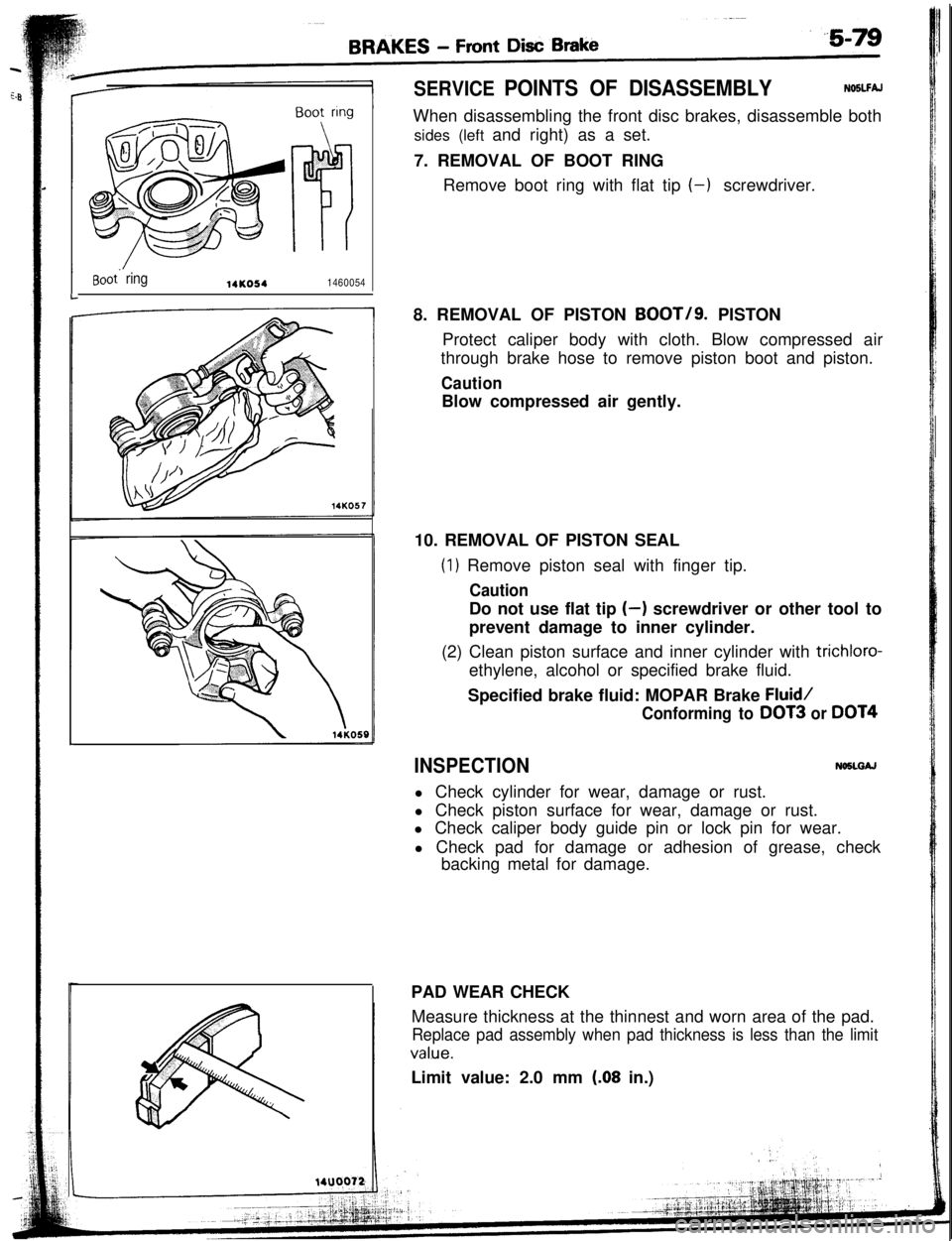

Boot. ring14KO541460054L

SERVICE POINTS OF DISASSEMBLYNOSLFAJWhen disassembling the front disc brakes, disassemble both

sides (left and right) as a set.

7. REMOVAL OF BOOT RING

Remove boot ring with flat tip (-1 screwdriver.

8. REMOVAL OF PISTON BOOT/g. PISTON

Protect caliper body with cloth. Blow compressed air

through brake hose to remove piston boot and piston.

CautionBlow compressed air gently.

10. REMOVAL OF PISTON SEAL

(1) Remove piston seal with finger tip.

CautionDo not use flat tip

(-) screwdriver or other tool to

prevent damage to inner cylinder.

(2) Clean piston surface and inner cylinder with

trichloro-ethylene, alcohol or specified brake fluid.

Specified brake fluid: MOPAR Brake

Fluid/

Conforming to DOT3 or DOT4

INSPECTIONNOXGAJ

l Check cylinder for wear, damage or rust.

l Check piston surface for wear, damage or rust.

l Check caliper body guide pin or lock pin for wear.

l Check pad for damage or adhesion of grease, check

backing metal for damage.

PAD WEAR CHECK

Measure thickness at the thinnest and worn area of the pad.

Replace pad assembly when pad thickness is less than the limit

value.Limit value: 2.0 mm

(.08 in.)

Page 22 of 57

----aI’-I

5-80BRAKES - Front Disc Brake

I-

Pad and wear

indicator assemblyPad assembly

Grease14FOO97

14KOIQPiston boot

’14KO70

Grease

L

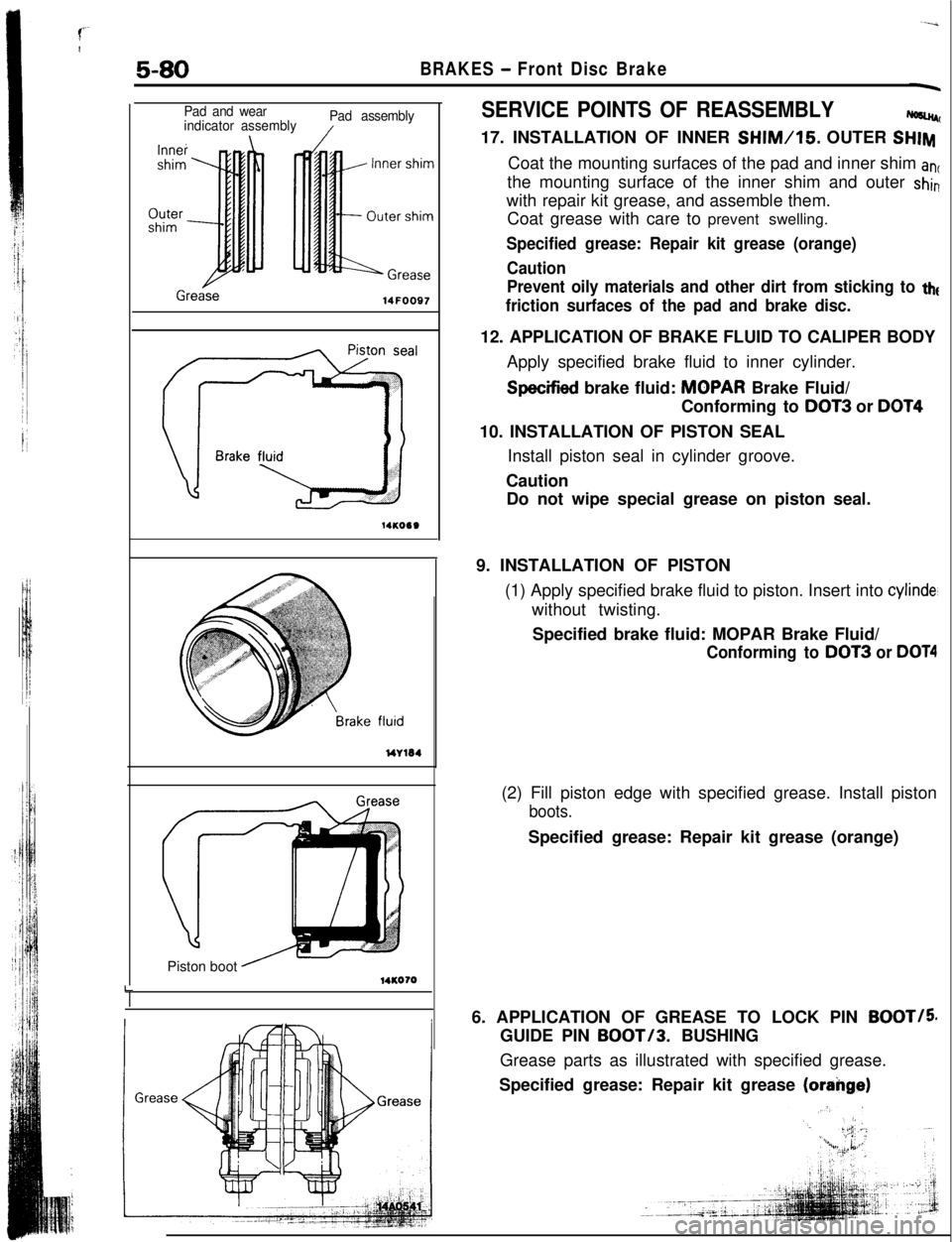

SERVICE POINTS OF REASSEMBLYWC17. INSTALLATION OF INNER

SHIM/15. OUTER SHIMCoat the mounting surfaces of the pad and inner shim

antthe mounting surface of the inner shim and outer

shinwith repair kit grease, and assemble them.

Coat grease with care to prevent swelling.

Specified grease: Repair kit grease (orange)

Caution

Prevent oily materials and other dirt from sticking to

tht

friction surfaces of the pad and brake disc.12. APPLICATION OF BRAKE FLUID TO CALIPER BODY

Apply specified brake fluid to inner cylinder.

Specified brake fluid: MDPAR Brake Fluid/

Conforming to DOT3 or

DOT410. INSTALLATION OF PISTON SEAL

Install piston seal in cylinder groove.

Caution

Do not wipe special grease on piston seal.

9. INSTALLATION OF PISTON

(1) Apply specified brake fluid to piston. Insert into

cylinde’without twisting.

Specified brake fluid: MOPAR Brake Fluid/

Conforming to DOT3 or DOT4(2) Fill piston edge with specified grease. Install piston

boots.Specified grease: Repair kit grease (orange)

6. APPLICATION OF GREASE TO LOCK PIN

BOOT/5GUIDE PIN BOOT/3. BUSHING

Grease parts as illustrated with specified grease.

Specified grease: Repair kit grease

(orange)

Page 25 of 57

BRAKES 7 Front Disc Brake5-83

14AO55314A0552

\Piston seal\

14AO551

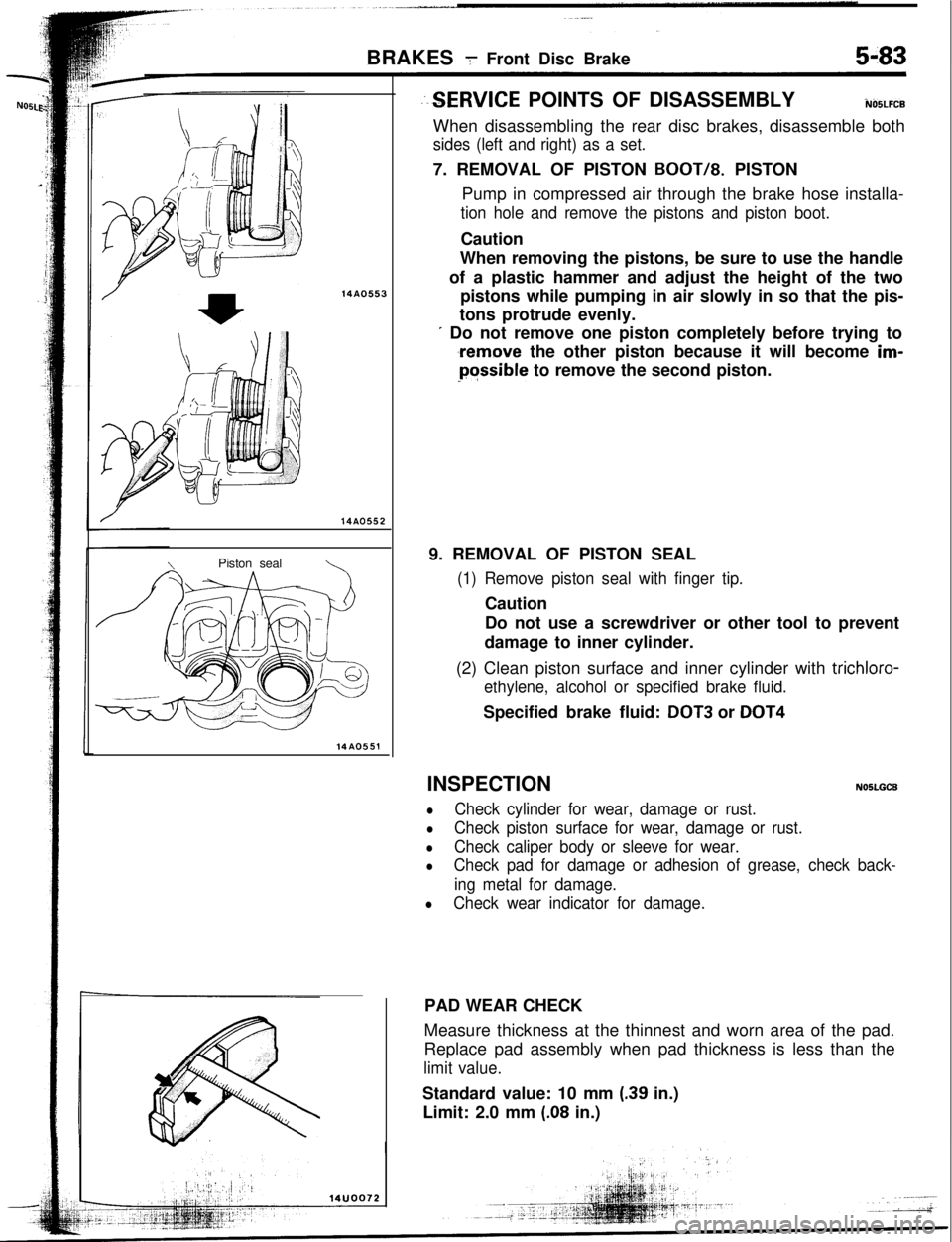

--SERVICE POINTS OF DISASSEMBLYiUO5LFCBWhen disassembling the rear disc brakes, disassemble both

sides (left and right) as a set.7. REMOVAL OF PISTON

BOOT/8. PISTON

Pump in compressed air through the brake hose installa-

tion hole and remove the pistons and piston boot.Caution

When removing the pistons, be sure to use the handle

of a plastic hammer and adjust the height of the two

pistons while pumping in air slowly in so that the pis-

tons protrude evenly.

I Do not remove one piston completely before trying to

,remove the other piston because it will become im-Possible to remove the second piston.

9. REMOVAL OF PISTON SEAL

(1) Remove piston seal with finger tip.Caution

Do not use a screwdriver or other tool to prevent

damage to inner cylinder.

(2) Clean piston surface and inner cylinder with trichloro-

ethylene, alcohol or specified brake fluid.Specified brake fluid:

DOT3 or DOT4INSPECTION

NOSLGCB

lCheck cylinder for wear, damage or rust.

lCheck piston surface for wear, damage or rust.

lCheck caliper body or sleeve for wear.

lCheck pad for damage or adhesion of grease, check back-

ing metal for damage.

lCheck wear indicator for damage.PAD WEAR CHECK

Measure thickness at the thinnest and worn area of the pad.

Replace pad assembly when pad thickness is less than the

limit value.Standard value: 10 mm

(.39 in.)

Limit: 2.0 mm

(.08 in.)