control module MITSUBISHI ENDEAVOR 2004 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 2203 of 3870

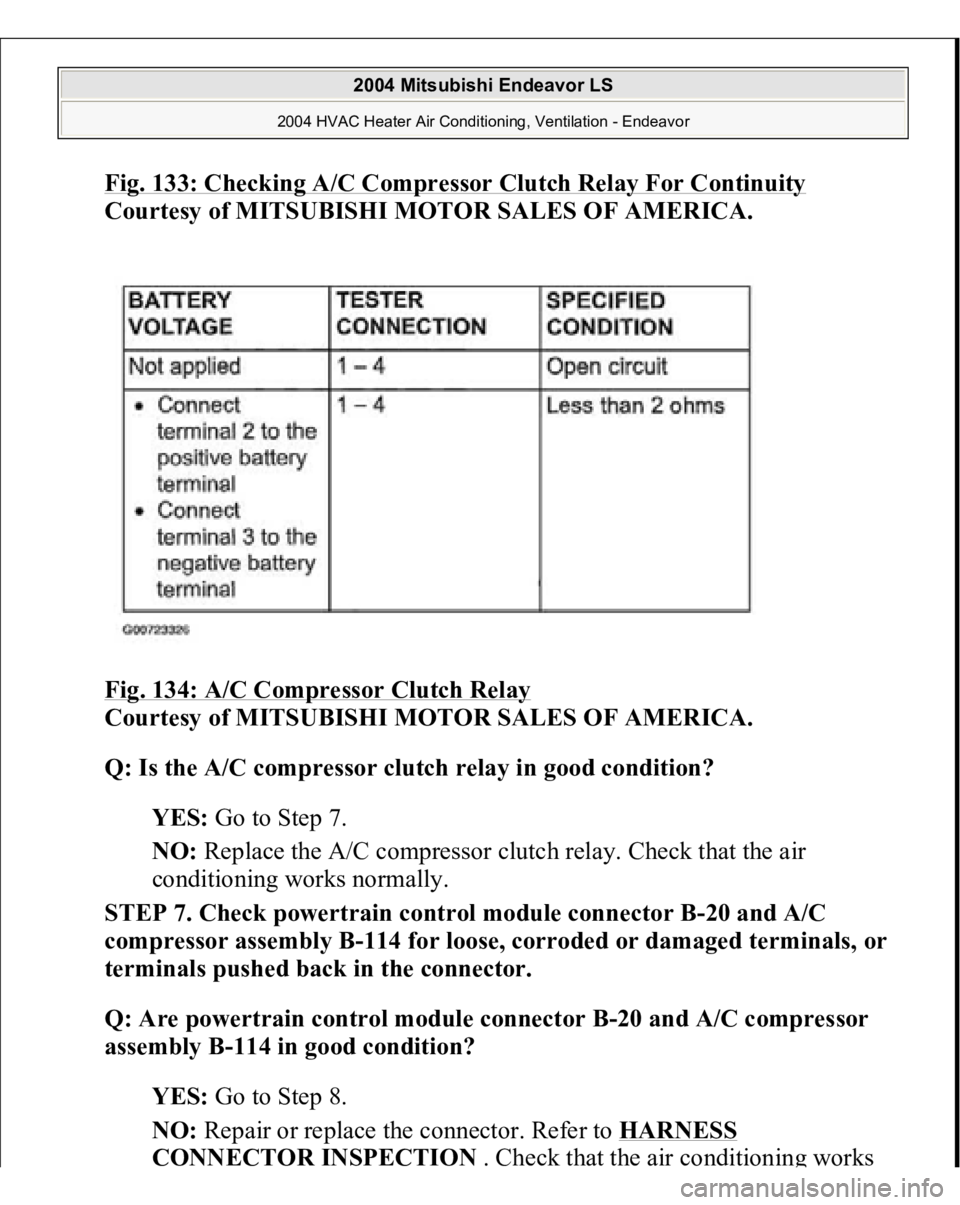

Fig. 133: Checking A/C Compressor Clutch Relay For Continuity

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Fig. 134: A/C Compressor Clutch Relay

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Q: Is the A/C compressor clutch relay in good condition?

YES:

Go to Step 7.

NO:

Replace the A/C compressor clutch relay. Check that the air

conditioning works normally.

STEP 7. Check powertrain control module connector B-20 and A/C

compressor assembly B-114 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Are powertrain control module connector B-20 and A/C compressor

assembly B-114 in good condition?

YES:

Go to Step 8.

NO:

Repair or replace the connector. Refer to

HARNESS

CONNECTOR INSPECTION

. Check that the air conditionin

g works

2004 Mitsubishi Endeavor LS

2004 HVAC Heater Air Conditioning, Ventilation - Endeavor

Page 2206 of 3870

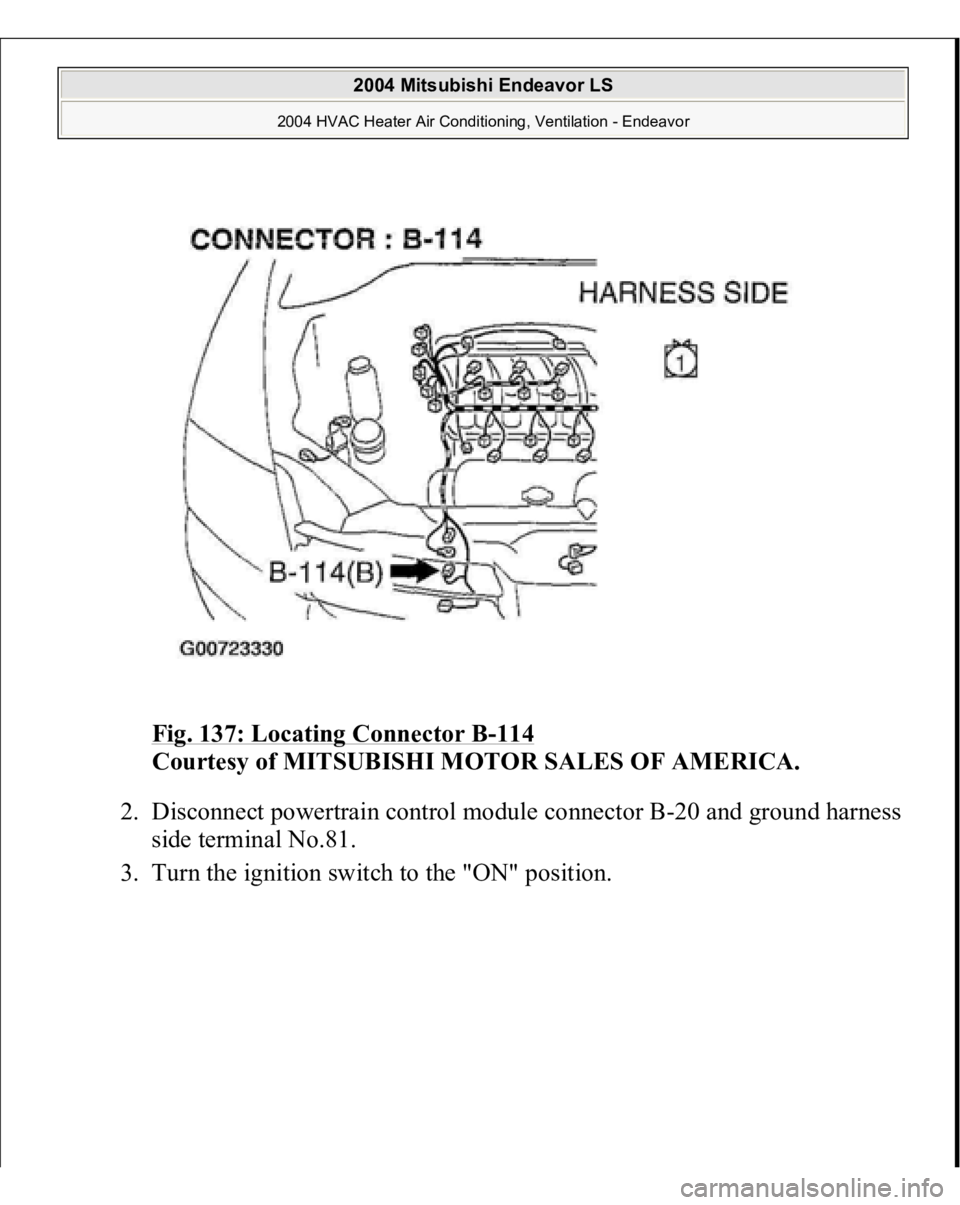

Fig. 137: Locating Connector B

-114

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Disconnect powertrain control module connector B-20 and ground harness

side terminal No.81.

3. Turn the i

gnition switch to the "ON"

position.

2004 Mitsubishi Endeavor LS

2004 HVAC Heater Air Conditioning, Ventilation - Endeavor

Page 2221 of 3870

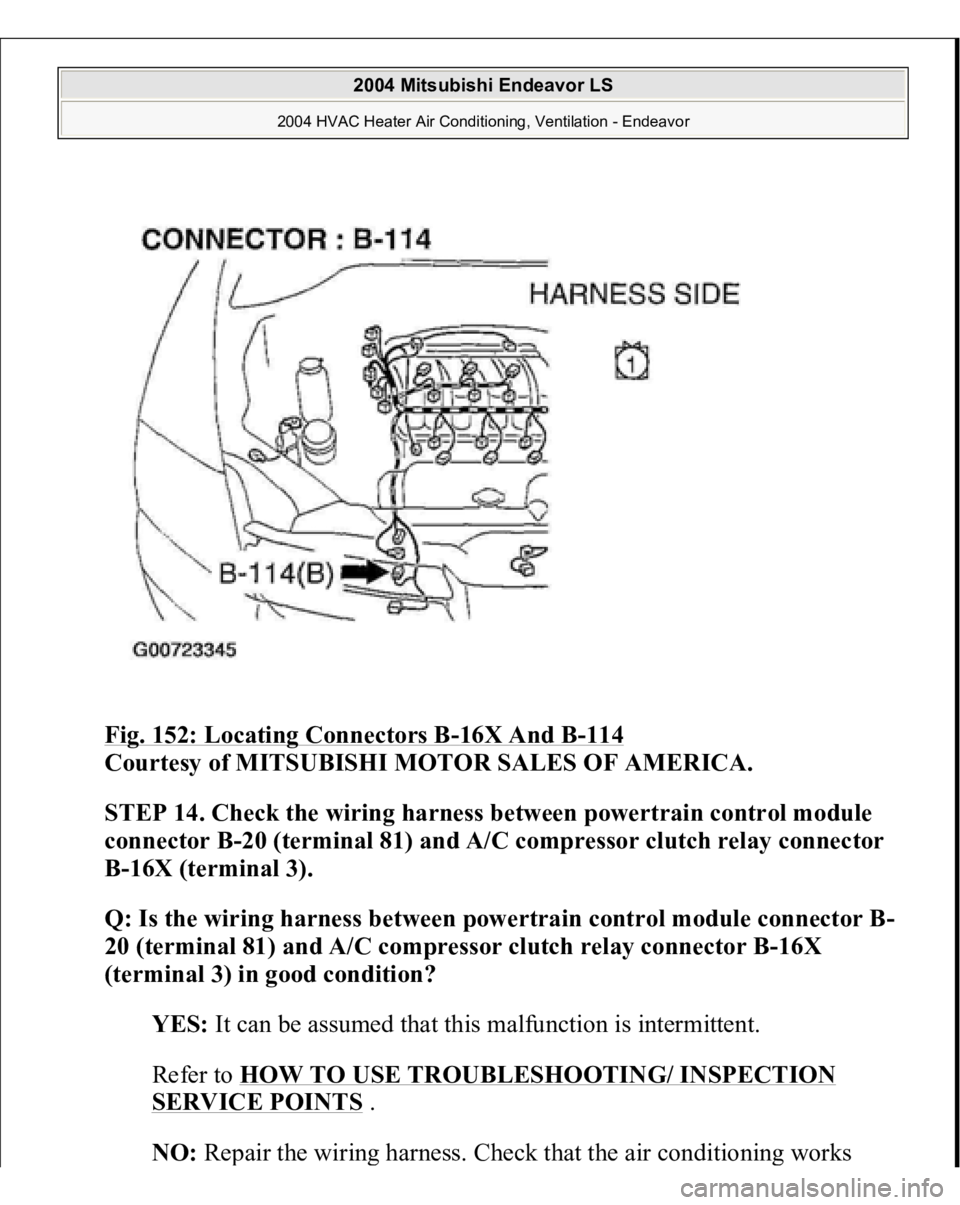

Fig. 152: Locating Connectors B

-16X And B

-114

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

STEP 14. Check the wiring harness between powertrain control module

connector B-20 (terminal 81) and A/C compressor clutch relay connector

B-16X (terminal 3).

Q: Is the wiring harness between powertrain control module connector B-

20 (terminal 81) and A/C compressor clutch relay connector B-16X

(terminal 3) in good condition?

YES:

It can be assumed that this malfunction is intermittent.

Refer to

HOW TO USE TROUBLESHOOTING/ INSPECTION

SERVICE POINTS

.

NO:

Re

pair the wirin

g harness. Check that the air con

ditionin

g works

2004 Mitsubishi Endeavor LS

2004 HVAC Heater Air Conditioning, Ventilation - Endeavor

Page 2225 of 3870

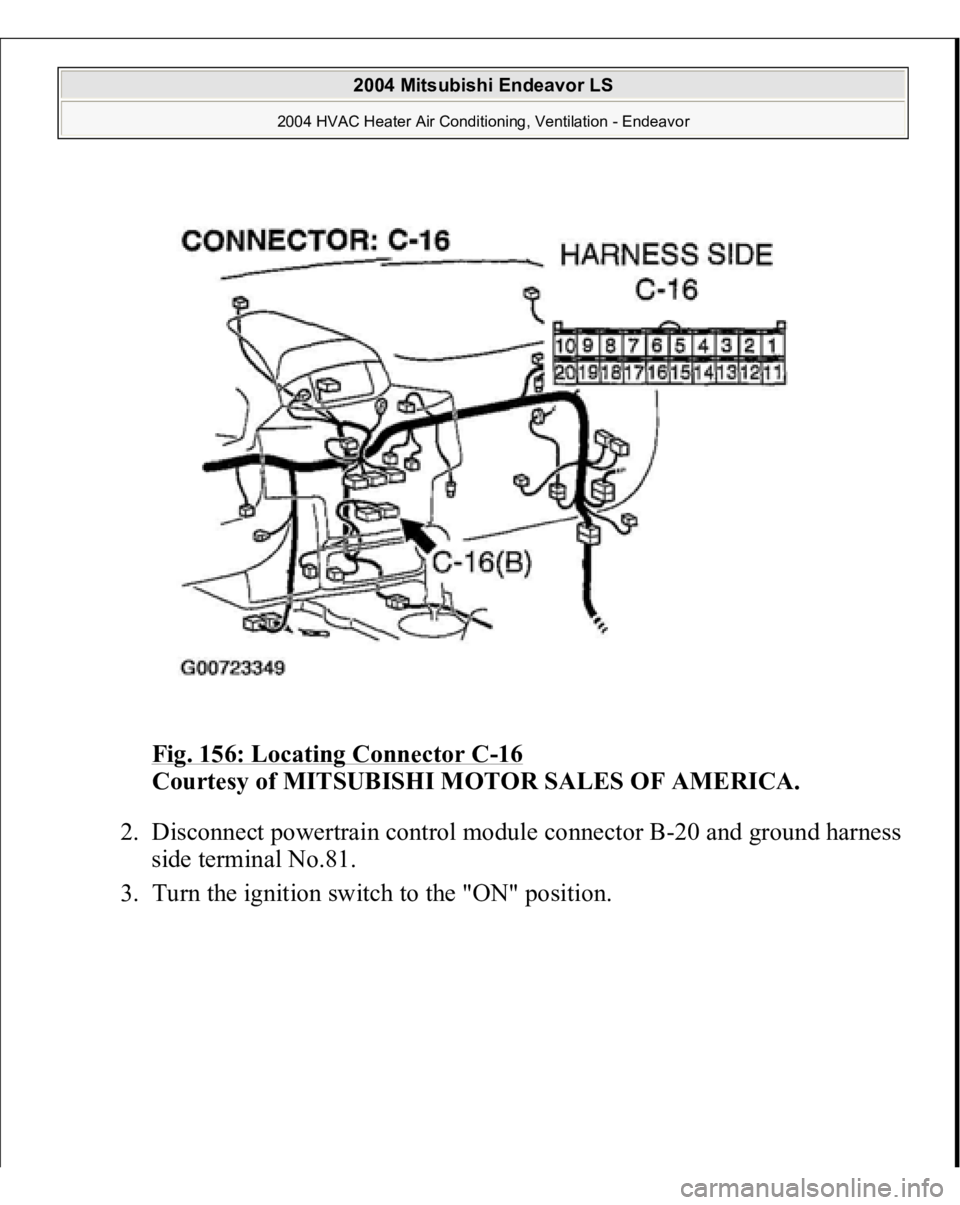

Fig. 156: Locating Connector C

-16

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Disconnect powertrain control module connector B-20 and ground harness

side terminal No.81.

3. Turn the ignition switch to the "ON" position.

2004 Mitsubishi Endeavor LS

2004 HVAC Heater Air Conditioning, Ventilation - Endeavor

Page 2242 of 3870

Q: Does the A/C operate normally?

YES:

No action is necessary and testing is complete.

NO:

Replace the powertrain control module. Check that the air

conditioning works normally.

INSPECTION PROCEDURE 5: FRONT BLOWER FAN AND MOTOR DO NOT TURN

2004 Mitsubishi Endeavor LS

2004 HVAC Heater Air Conditioning, Ventilation - Endeavor

Page 2378 of 3870

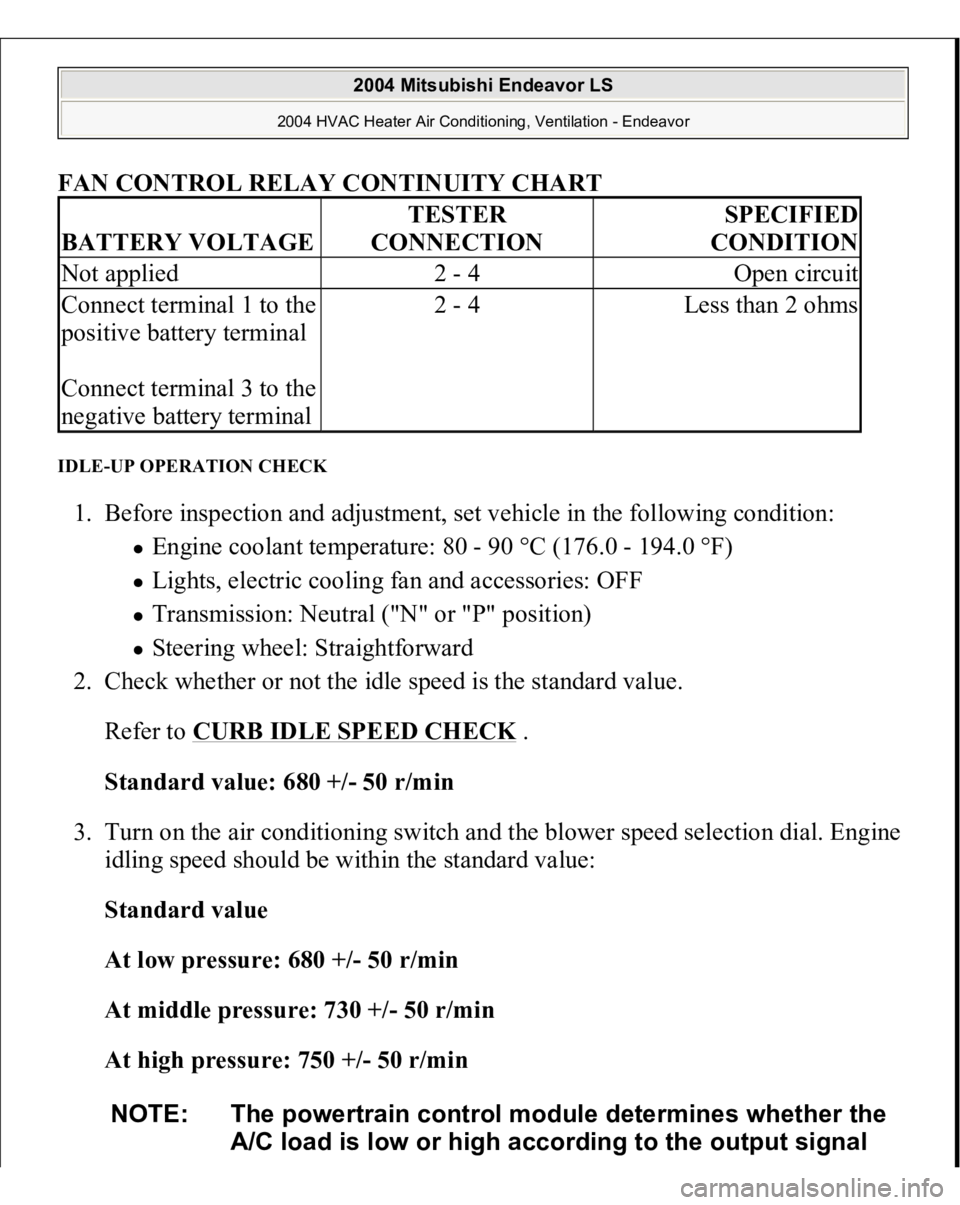

FAN CONTROL RELAY CONTINUITY CHART

IDLE-UP OPERATION CHECK 1. Before inspection and adjustment, set vehicle in the following condition:

Engine coolant temperature: 80 - 90 °C (176.0 - 194.0 °F) Lights, electric cooling fan and accessories: OFF Transmission: Neutral ("N" or "P" position) Steering wheel: Straightforward

2. Check whether or not the idle speed is the standard value.

Refer to

CURB IDLE SPEED CHECK

.

Standard value: 680 +/- 50 r/min

3. Turn on the air conditioning switch and the blower speed selection dial. Engine

idling speed should be within the standard value:

Standard value

At low pressure: 680 +/- 50 r/min

At middle pressure: 730 +/- 50 r/min

At high pressure: 750 +/- 50 r/min

BATTERY VOLTAGE

TESTER

CONNECTION

SPECIFIED

CONDITION

Not applied

2 - 4

Open circuit

Connect terminal 1 to the

positive battery terminal

Connect terminal 3 to the

negative battery terminal

2 - 4

Less than 2 ohms

NOTE: The powertrain control module determines whether the

A/C load is low or high according to the output signal

2004 Mitsubishi Endeavor LS

2004 HVAC Heater Air Conditioning, Ventilation - Endeavor

Page 2683 of 3870

2004 ENGINE

Ignition System - Endeavor

GENERAL DESCRIPTION This system is provided with six ignition coils with built-in ignition power

transistors for each of the cylinders.

Interruption of the primary current flowing in the primary side of ignition coil

generates a high voltage in the secondary side of ignition coil.

The powertrain control module (PCM) controls the three ignition power transistors

to turn them alternately ON and OFF. This causes the primary currents in the

ignition coils to be alternately interrupted and allowed to flow to fire the cylinders

in the order 1-2-3-4-5-6.

The PCM determines which ignition coil should be controlled by means of the

signals from the camshaft position sensor which is incorporated in the camshaft and

from the crankshaft position sensor which is incorporated in the crankshaft.

It also detects the crankshaft position to provide ignition at the most appropriate

timing in response to the engine operation conditions.

When the engine is cold or operated at high altitudes, the ignition timing is slightly

advanced to

provide o

ptimum

performance.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Ignition System - Endeavor

2004 Mitsubishi Endeavor Limited 2004 ENGINE Ignition System - Endeavor

Page 3419 of 3870

2. Turn the ignition switch to "ON" position.

3. Diagnose the CAN bus line.

Q: Is the check result satisfactory?

YES: Go to Step 2

NO: Repair the CAN bus lines (Refer to DIAGNOSTIC TROUBLE

CODE DIAGNOSIS

or DIAGNOSIS < VEHICLES WITHOUT

ADVANCED AIR BAG

). On completion, go to Step 6.

STEP 2. Using scan tool MB991958, read the steering wheel sensor

diagnostic trouble code.

Check if a steering wheel sensor DTC is set.

Q: Is the DTC set?

YES: Diagnose the steering wheel sensor by referring to DIAGNOSTIC

TROUBLE CODE CHART

.

NO: Go to Step 3.

STEP 3. Using scan tool MB991958 read any of the diagnostic trouble

code.

Check if a DTC, which relates to CAN communication-linked systems below,

is set.

Power train control module

DTC U1100: ABS-ECU time-out

Combination meter DTC 011: ABS-ECU time-out

Q: Is the DTC set?

YES: Go to Step 4. NO:

Go to Step

5.

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3425 of 3870

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

STEP 2. Using scan tool MB991958 read the diagnostic trouble code.

Check if a DTC, which relates to CAN communication-linked systems below,

is set.

Power train control module

DTC U1102: ABS-ECU time-out

Combination meter DTC 018: ABS-ECU time-out

Q: Is the DTC set?

YES: Go to Step 3.

NO: Go to Step 4.

STEP 3. Recheck for diagnostic trouble code.

Recheck if the DTC is set.

1. Erase the DTC.

2. Turn the ignition switch to "ON" position.

3. Check if the DTC is set.

Q: Is the check result satisfactory?

YES: A poor connection, open circuit or other intermittent malfunction is

present in the CAN bus lines between the G and yaw rate sensor and the

TCL/ASC-ECU (Refer to HOW TO COPE WITH INTERMITTENT MALFUNCTIONS

).

NO: Replace hydraulic unit (integrated with TCL/ASC-ECU) and then go

to Step 4.

STEP 4. Recheck for diagnostic trouble code.

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3430 of 3870

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

2. Turn the ignition switch to "ON" position.

3. Diagnose the CAN bus line.

Q: Is the check result satisfactory?

YES: Go to Step 2

NO: Repair the CAN bus lines (Refer to EXPLANATION ABOUT THE

MUT

-III CAN BUS DIAGNOSTICS

, or DIAGNOSIS < VEHICLES

WITHOUT ADVANCED AIR BAG

). On completion, go to Step 6.

STEP 2. Using scan tool MB991958, read the combination meter

diagnostic trouble code.

Check if a combination meter DTC is set.

Q: Is the DTC set?

YES: Diagnose the combination meter by referring to DIAGNOSTIC

TROUBLE CODE CHART

.

NO: Go to Step 3.

STEP 3. Using scan tool MB991958 read any of the diagnostic trouble

code.

Check if a DTC, which relates to CAN communication-linked systems below,

is set.

Power train control module

DTC U1108: Combination meter time-out

Multi-center display unit (middle-grade type) DTC 014: Combination meter time-out

ETACS-EC

U

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor