MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Page 1534 of 3870

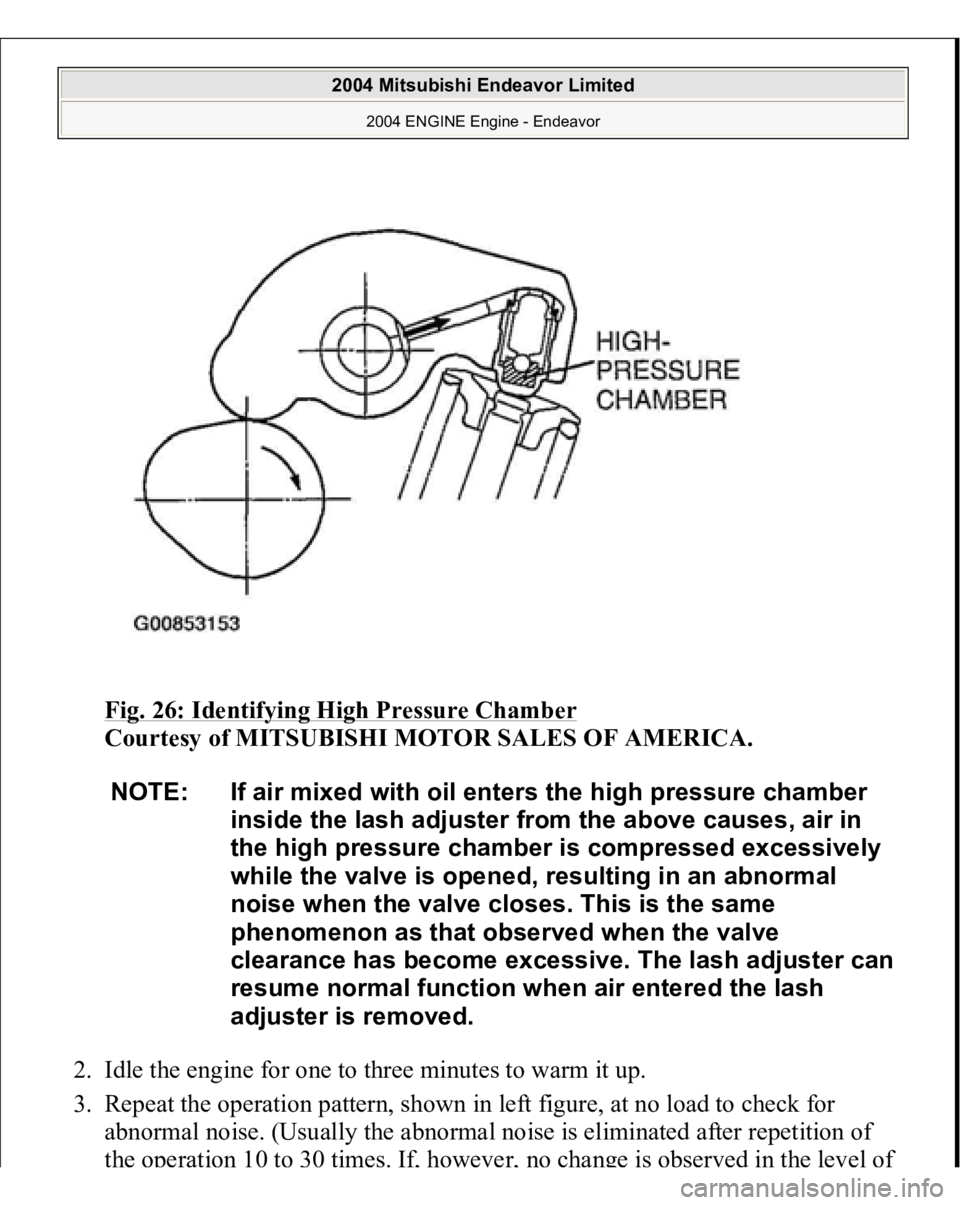

Fig. 26: Identifying High Pressure Chamber

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Idle the engine for one to three minutes to warm it up.

3. Repeat the operation pattern, shown in left figure, at no load to check for

abnormal noise. (Usually the abnormal noise is eliminated after repetition of

the ope

ration 1

0 to 30 tim

es.

If, howeve

r, no change is obse

rved

in

the leve

l of

NOTE: If air mixed with oil enters the high pressure chamber

inside the lash adjuster from the above causes, air in

the high pressure chamber is compressed excessively

while the valve is opened, resulting in an abnormal

noise when the valve closes. This is the same

phenomenon as that observed when the valve

clearance has become excessive. The lash adjuster can

resume normal function when air entered the lash

adjuster is removed.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1543 of 3870

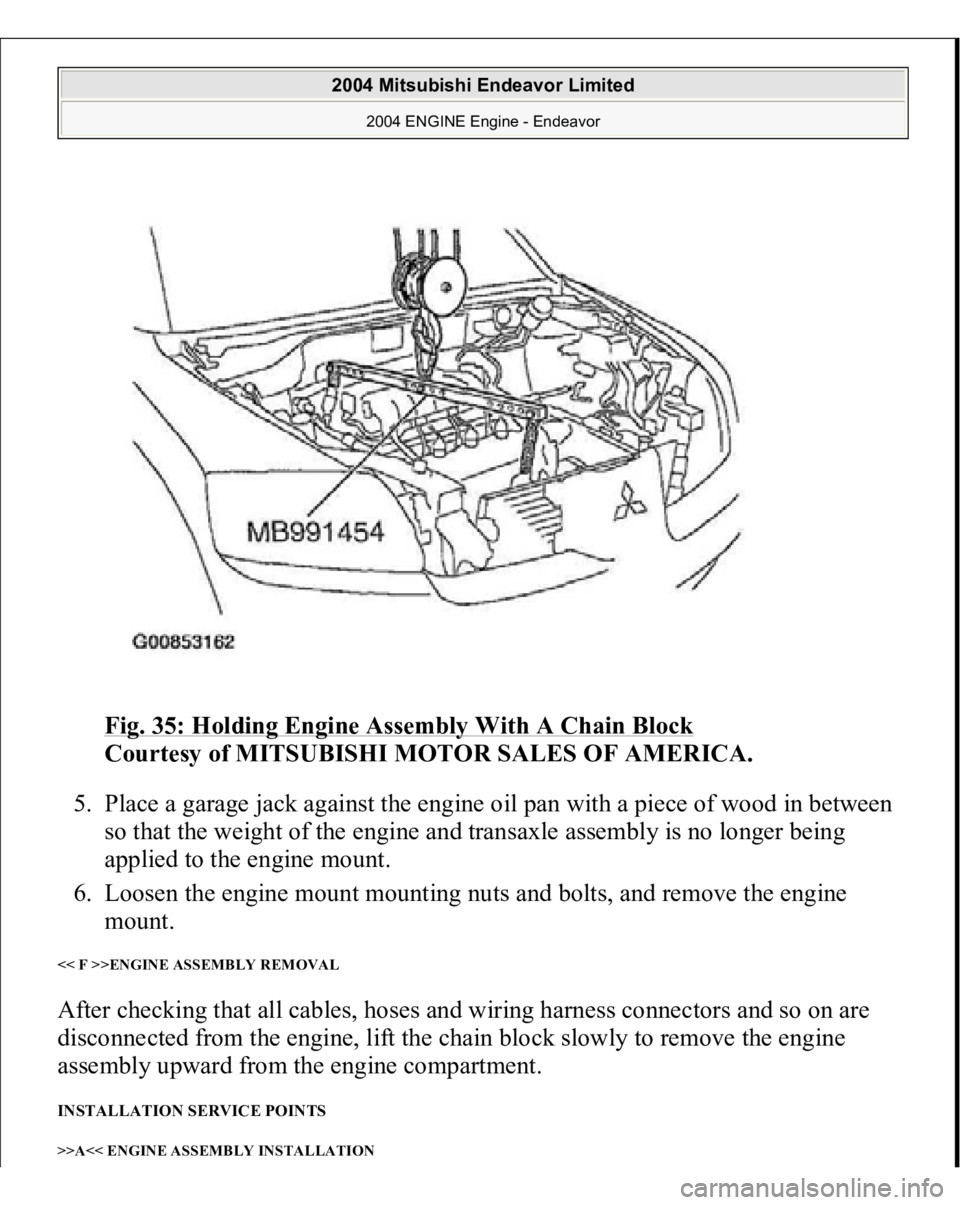

Fig. 35: Holding Engine Assembly With A Chain Block

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

5. Place a garage jack against the engine oil pan with a piece of wood in between

so that the weight of the engine and transaxle assembly is no longer being

applied to the engine mount.

6. Loosen the engine mount mounting nuts and bolts, and remove the engine

mount.

<< F >>ENGINE ASSEMBLY REMOVAL After checking that all cables, hoses and wiring harness connectors and so on are

disconnected from the engine, lift the chain block slowly to remove the engine

assembly upward from the engine compartment. INSTALLATION SERVICE POINTS >>A<< ENGINE ASSEMBLY INSTALLATION

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1574 of 3870

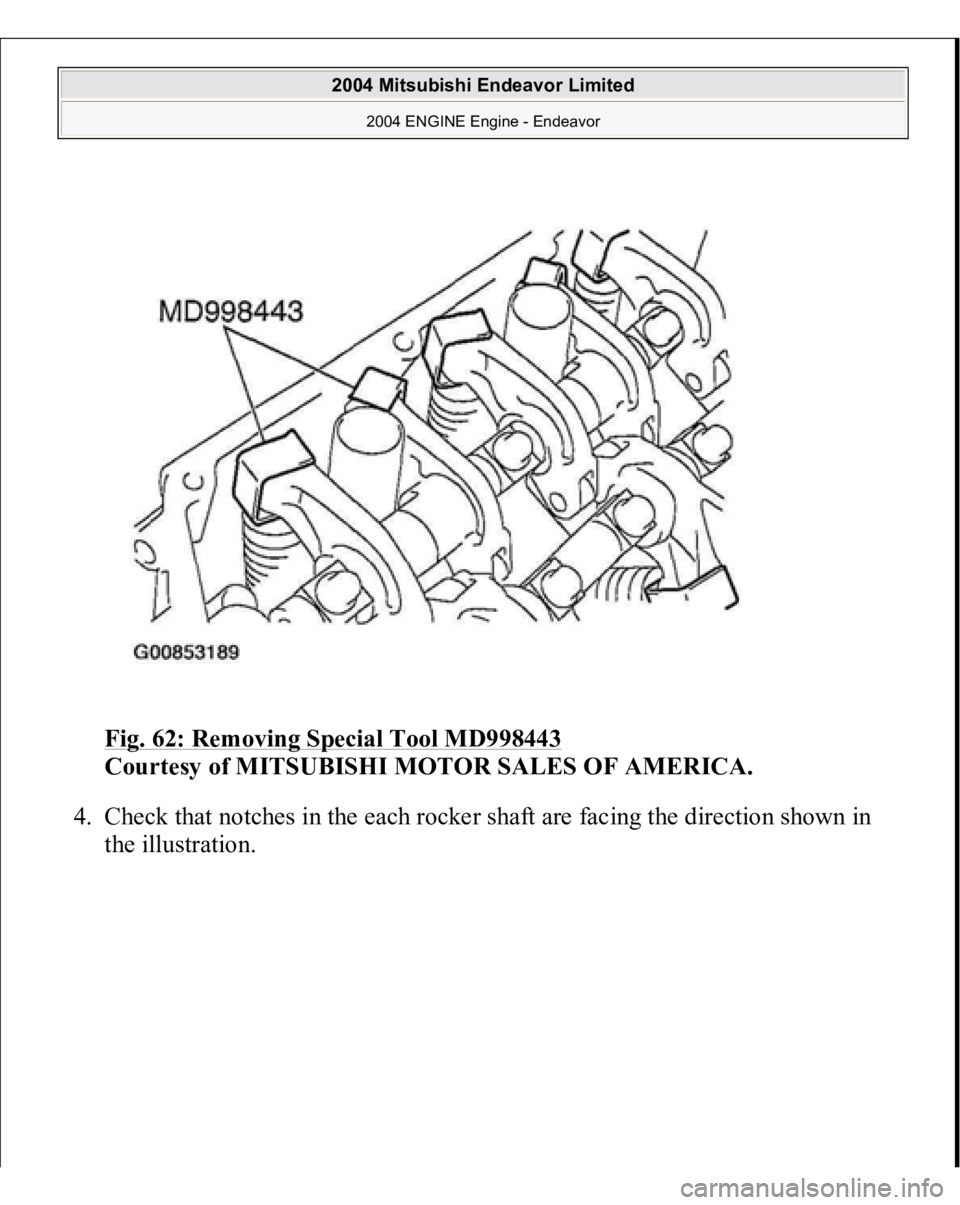

Fig. 62: Removing Special Tool MD998443

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

4. Check that notches in the each rocker shaft are facing the direction shown in

the illustration.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1576 of 3870

Fig. 63: Checking Notches In Each Rocker Shaft Are Facing Directio

n

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

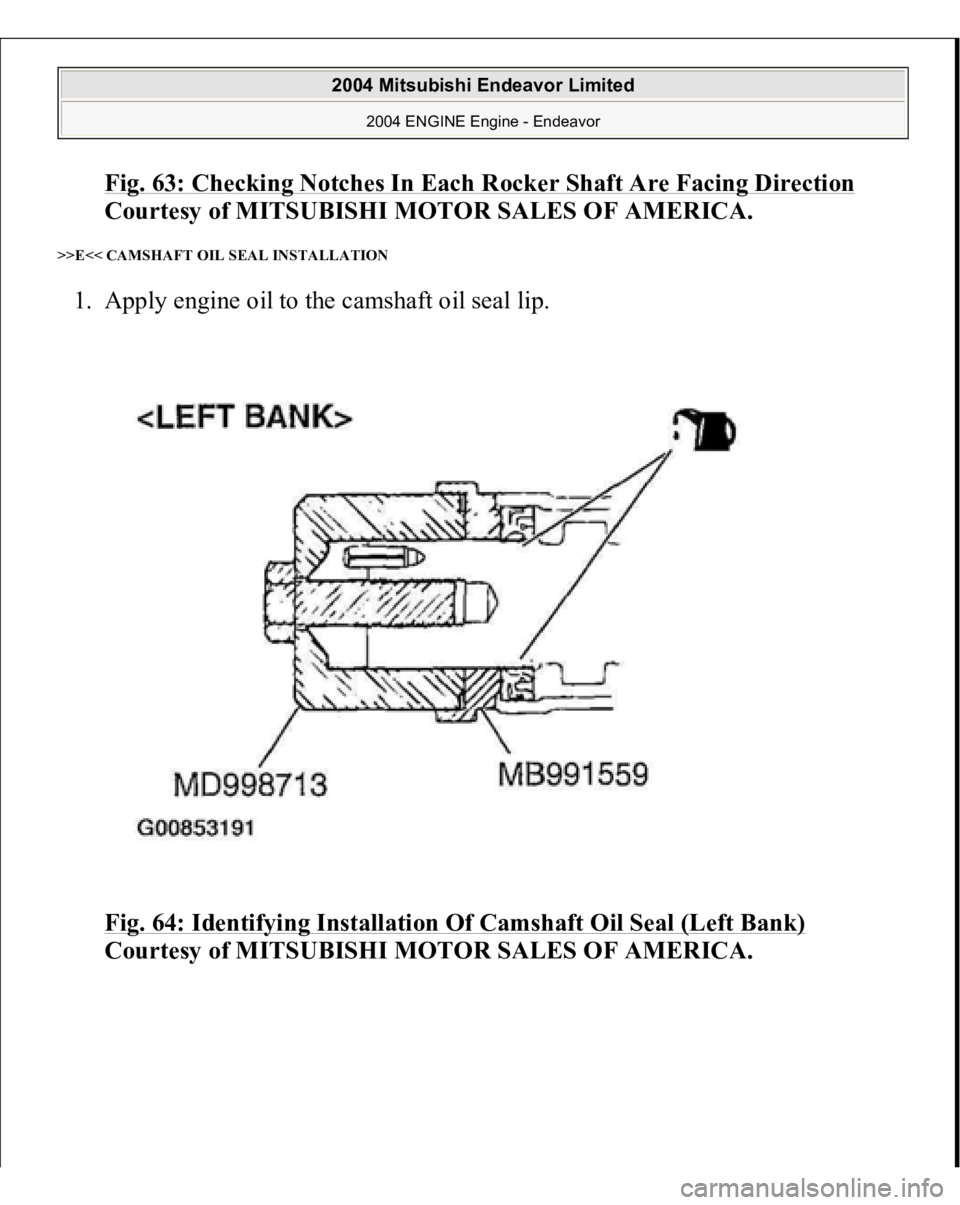

>>E<< CAMSHAFT OIL SEAL INSTALLATION 1. Apply engine oil to the camshaft oil seal lip.

Fig. 64: Identifying Installation Of Camshaft Oil Seal (Left Bank)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1588 of 3870

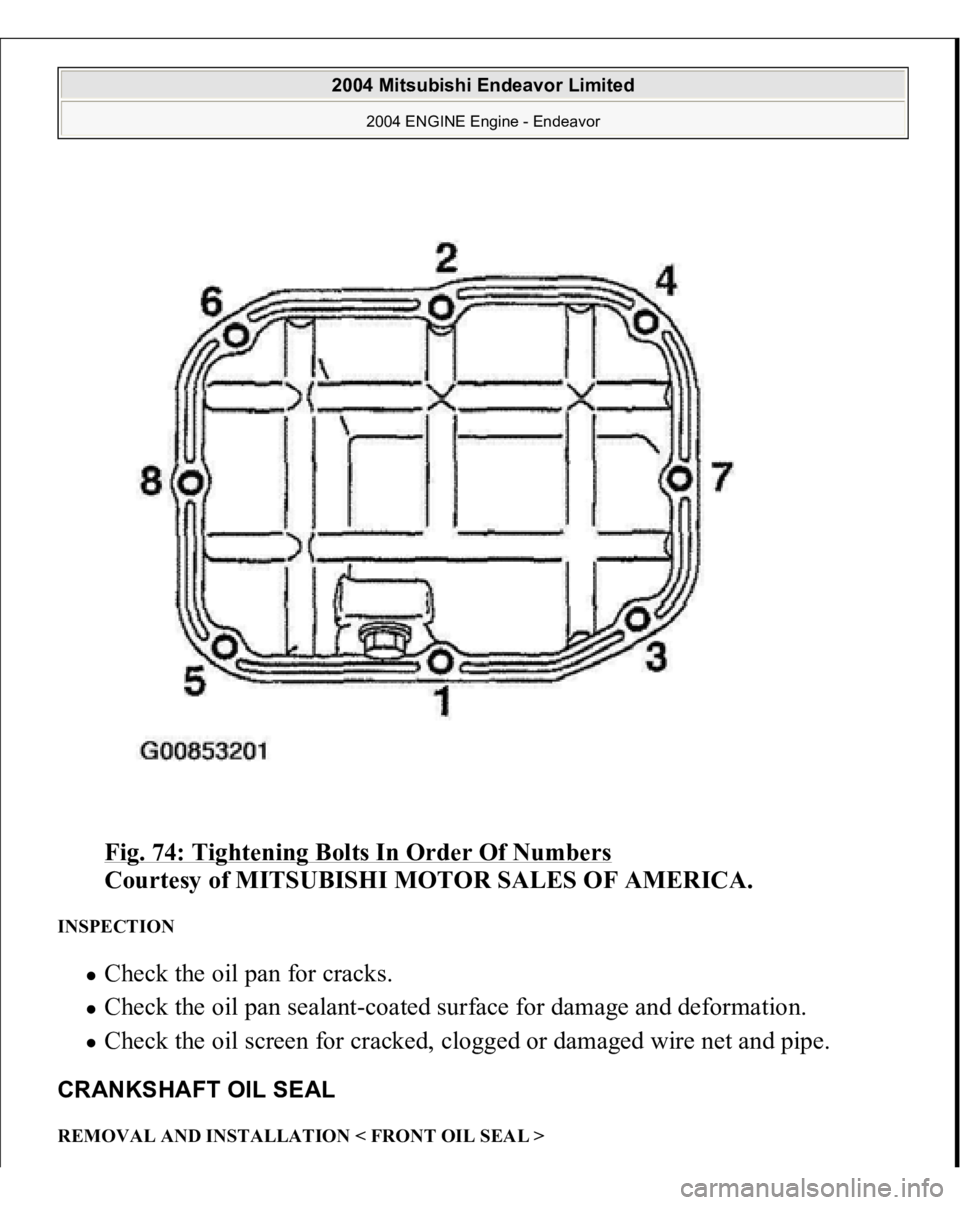

Fig. 74: Tightening Bolts In Order Of Numbers

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSPECTION

Check the oil pan for cracks. Check the oil pan sealant-coated surface for damage and deformation. Check the oil screen for cracked, clogged or damaged wire net and pipe.

CRANKSHAFT OIL SEAL REMOVAL AND INSTALLATION < FRONT OIL SEAL >

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1612 of 3870

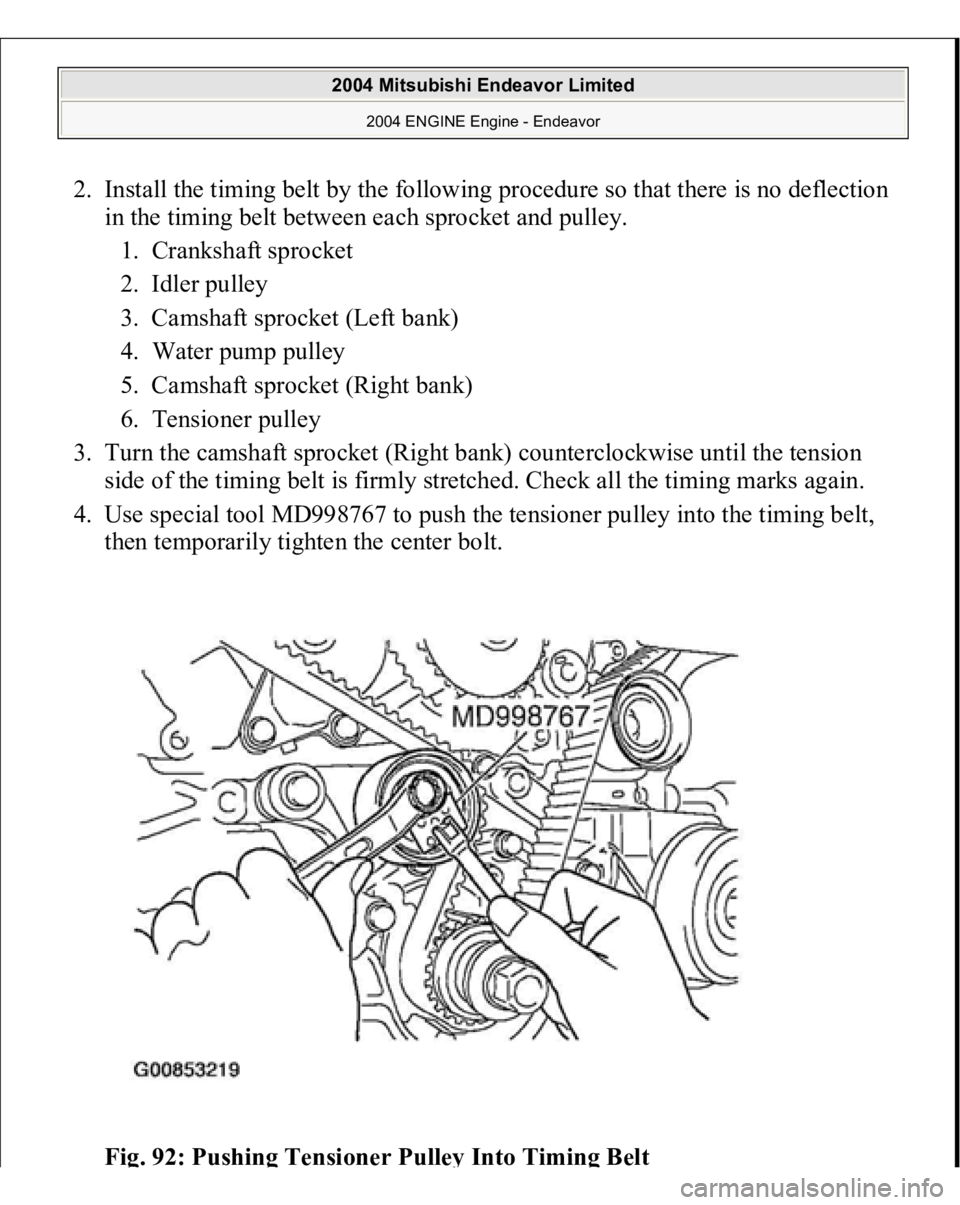

2. Install the timing belt by the following procedure so that there is no deflection

in the timing belt between each sprocket and pulley.

1. Crankshaft sprocket

2. Idler pulley

3. Camshaft sprocket (Left bank)

4. Water pump pulley

5. Camshaft sprocket (Right bank)

6. Tensioner pulley

3. Turn the camshaft sprocket (Right bank) counterclockwise until the tension

side of the timing belt is firmly stretched. Check all the timing marks again.

4. Use special tool MD998767 to push the tensioner pulley into the timing belt,

then temporarily tighten the center bolt.

Fi

g. 92: Pushin

g Tensioner Pulle

y Into Timin

g Bel

t

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1615 of 3870

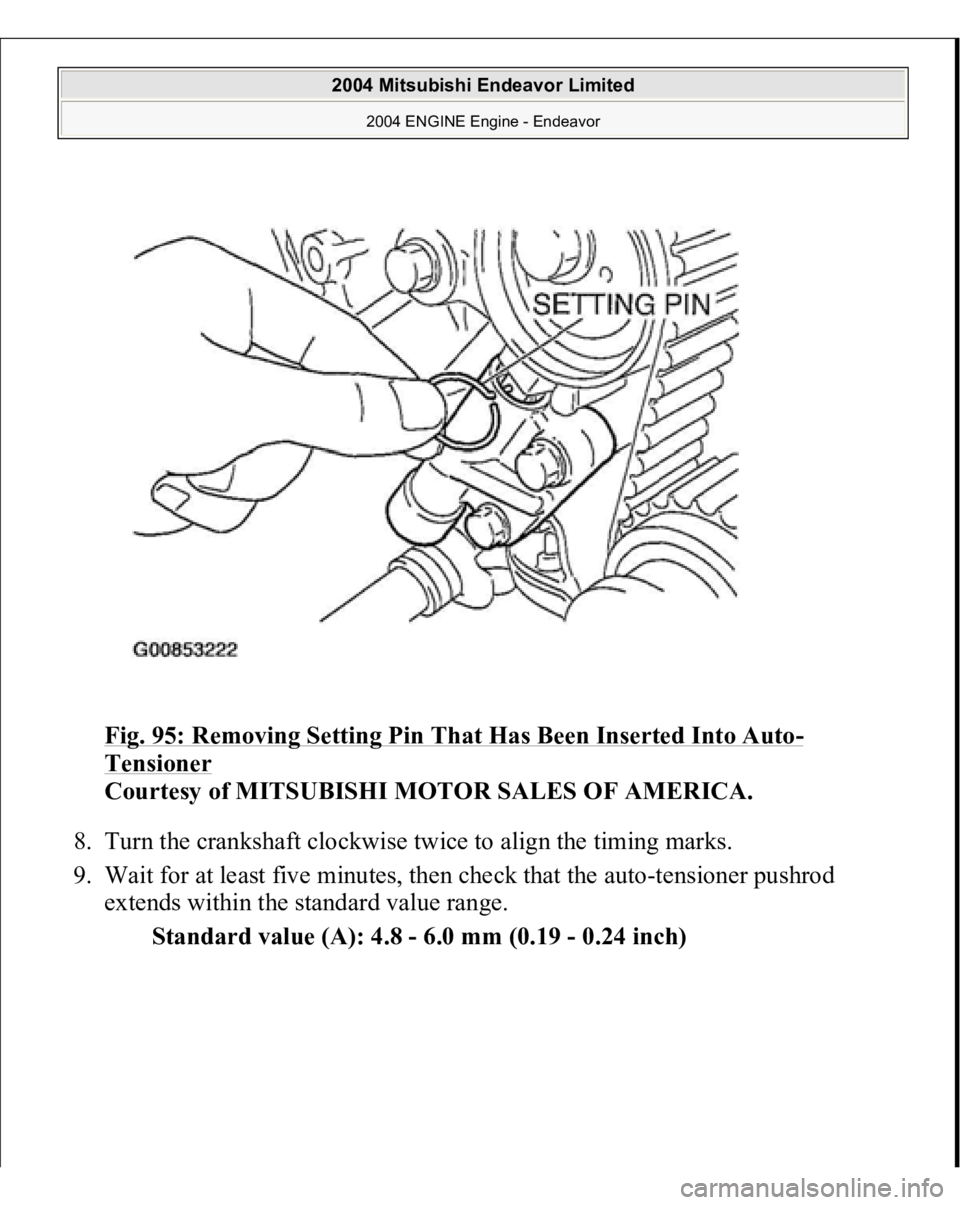

Fig. 95: Removing Setting Pin That Has Been Inserted Into Auto

-

Tensioner

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

8. Turn the crankshaft clockwise twice to align the timing marks.

9. Wait for at least five minutes, then check that the auto-tensioner pushrod

extends within the standard value range.

Standard value (A): 4.8 - 6.0 mm (0.19 - 0.24 inch)

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1616 of 3870

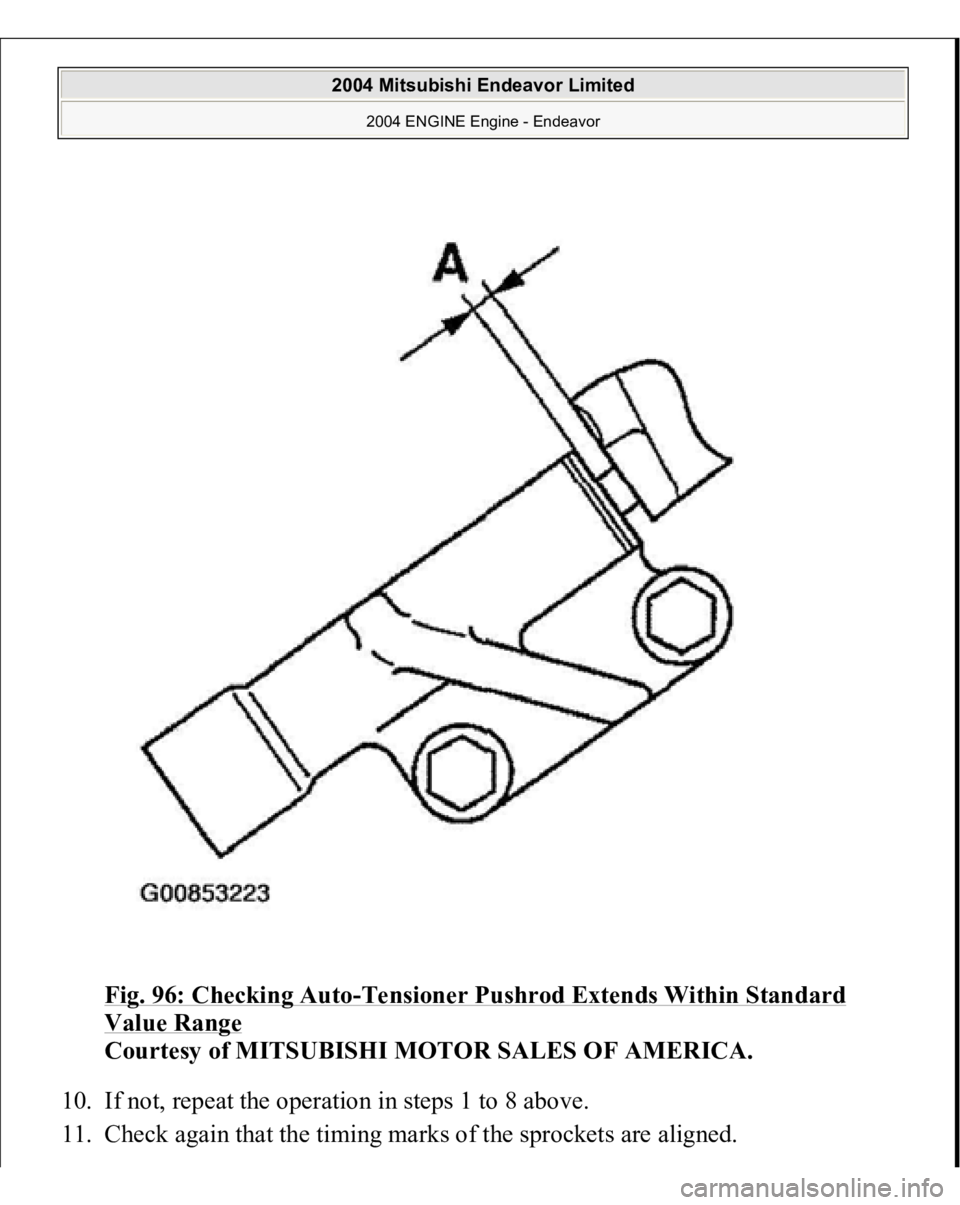

Fig. 96: Checking Auto

-Tensioner Pushrod Extends Within Standard

Value Range

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

10. If not, repeat the operation in steps 1 to 8 above.

11. Check a

gain that the timin

g marks of the s

prockets are ali

gned.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1617 of 3870

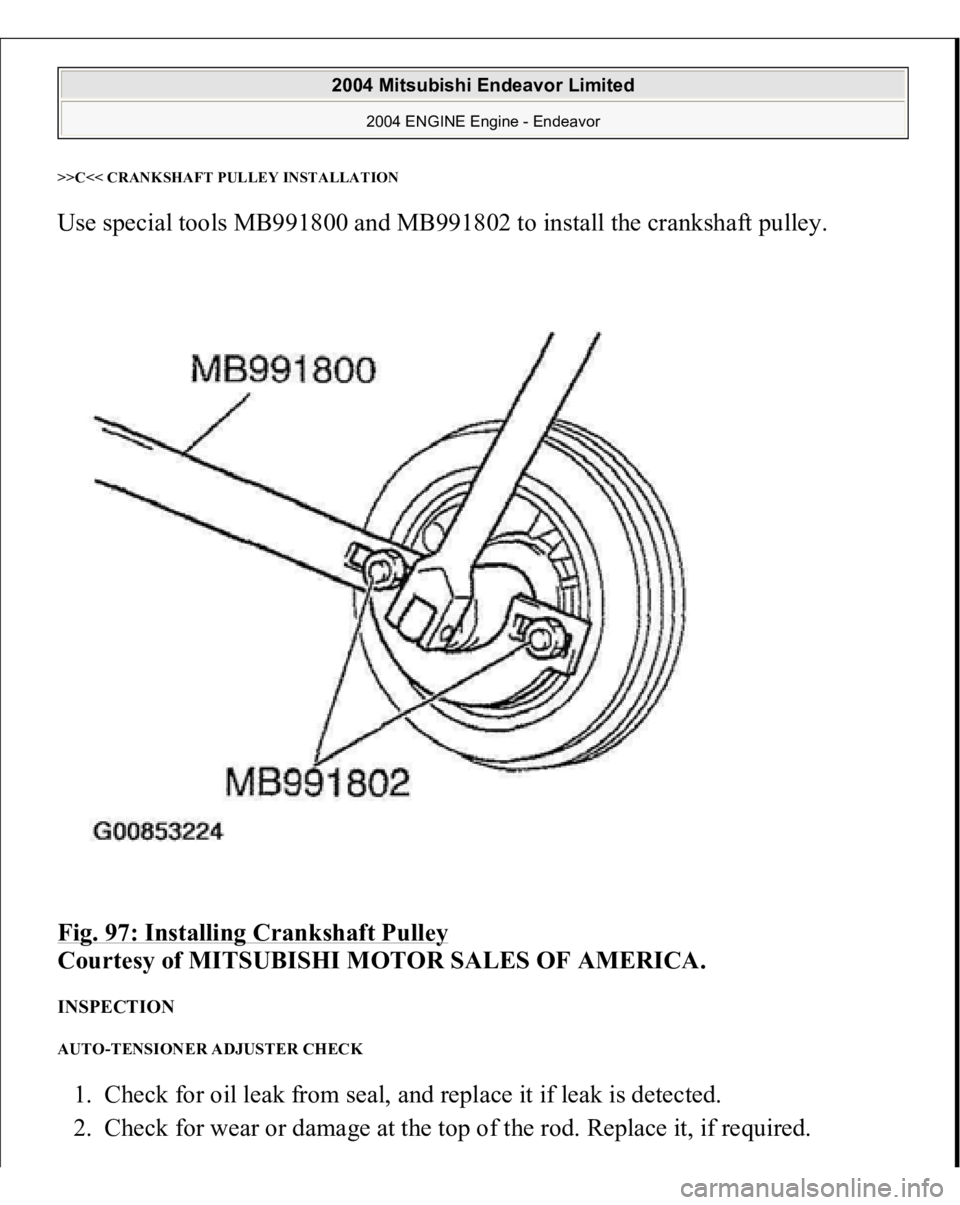

>>C<< CRANKSHAFT PULLEY INSTALLATIONUse special tools MB991800 and MB991802 to install the crankshaft pulley.

Fig. 97: Installing Crankshaft Pulley

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

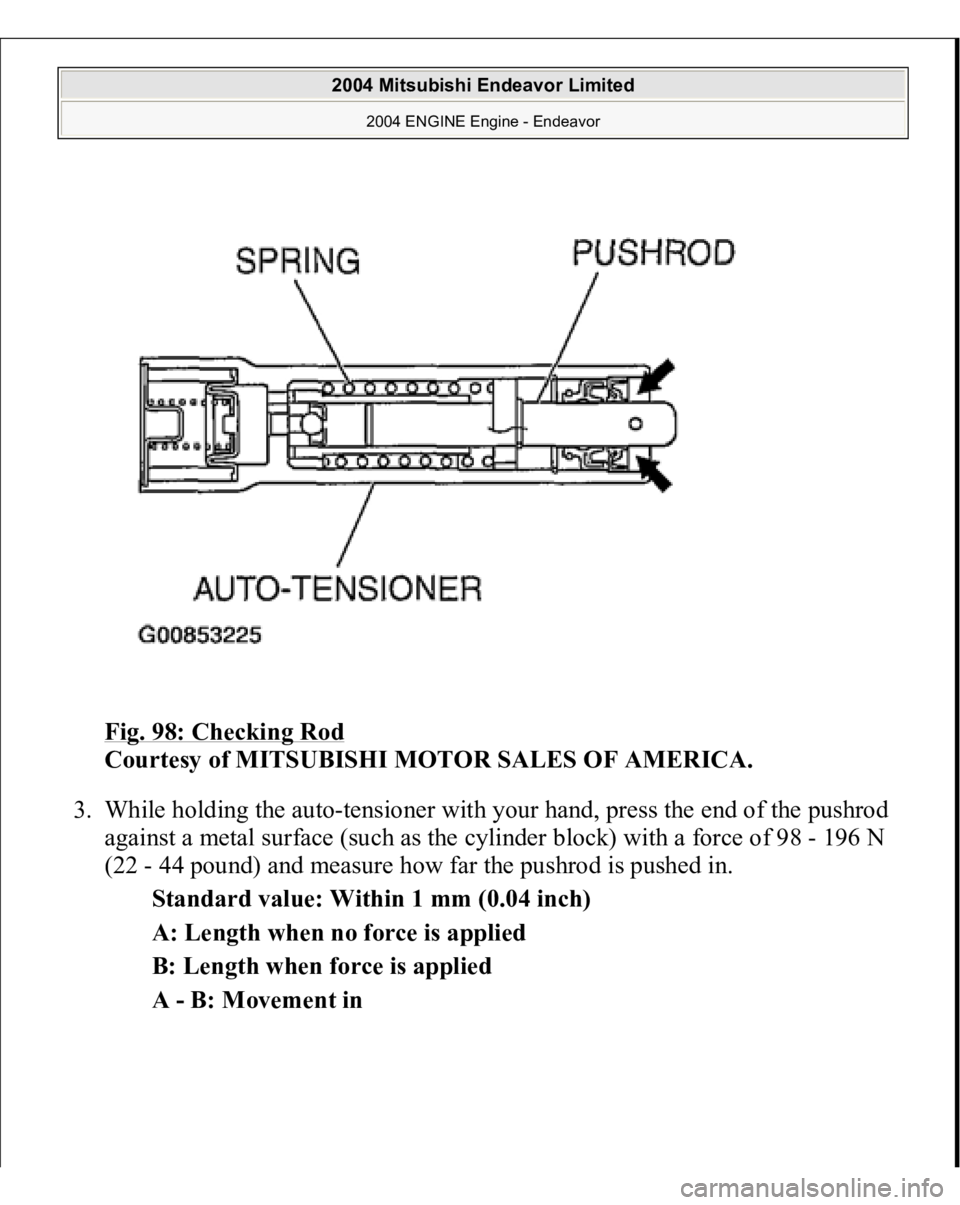

INSPECTION AUTO-TENSIONER ADJUSTER CHECK 1. Check for oil leak from seal, and replace it if leak is detected.

2. Check for wear or dama

ge at the to

p of the rod. Re

place it, if re

quired.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1618 of 3870

Fig. 98: Checking Rod

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. While holding the auto-tensioner with your hand, press the end of the pushrod

against a metal surface (such as the cylinder block) with a force of 98 - 196 N

(22 - 44 pound) and measure how far the pushrod is pushed in.

Standard value: Within 1 mm (0.04 inch)

A: Length when no force is applied

B: Length when force is applied

A - B: Movement in

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor