check engine MITSUBISHI ENDEAVOR 2004 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 2861 of 3870

C (122 - 140°F).

3. The engine should be idling.

4. Disconnect the connector for the oil pressure switch, and place an ohmmeter at

the switch.

5. Gradually close the shut-off valve of the pressure gauge and increase the

hydraulic pressure, then check whether or not the hydraulic pressure that

activates the switch is the standard value.

Standard value: 18 - 2.4 MPa (261 - 348 psi)

6. Gradually open the shut-off valve and reduce the hydraulic pressure; then

check whether or not the hydraulic pressure that deactivates the switch is the

standard value.

Standard value: 0.8 - 2.4 MPa (116 - 348 psi)

7. Remove the special tools MB991548, MB990662 and MB991549, and then

tighten the pressure tube flare nut to the specified torque.

Tightening torque: 15 +/- 3 N.m (11 +/- 2 ft-lb)

8. Bleed the system. (Refer to POWER STEERING SYSTEM AIR BLEEDING

).

2004 Mitsubishi Endeavor LS

2004 STEERING Power Steering - Endeavor

Page 3111 of 3870

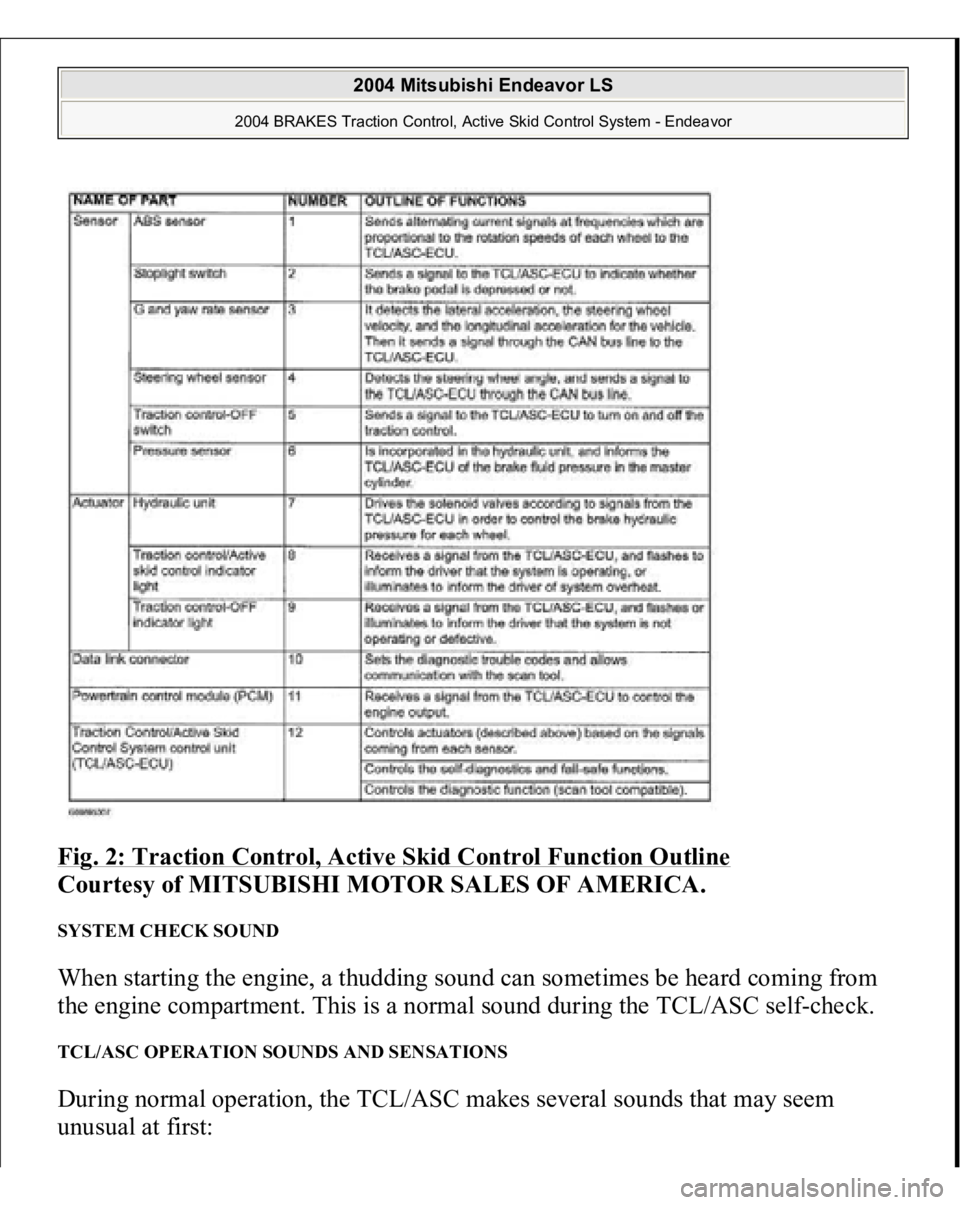

Fig. 2: Traction Control, Active Skid Control Function Outline

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

SYSTEM CHECK SOUND When starting the engine, a thudding sound can sometimes be heard coming from

the engine compartment. This is a normal sound during the TCL/ASC self-check. TCL/ASC OPERATION SOUNDS AND SENSATIONS During normal operation, the TCL/ASC makes several sounds that may seem

unusual at first:

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3134 of 3870

Fig. 30: Status Of Operation Valve Specificatio

n

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

TRACTION CONTROL SYSTEM OPERATION The TCL/ASC-ECU receives information from the PCM, the G and yaw-rate

sensor, and the wheel speed sensor. If the ECU determines that a road wheel is

spinning, it will control the fluid pressure to the spinning wheel to apply torque to

the other road wheels. The operations of the ABS solenoid valves and the active

skid control system valves are the same as for the active skid control system.

Furthermore, the system also controls the engine if the accelerator pedal is

depressed excessively. TCL/ASC DIAGNOSIS INTRODUCTION TO TRACTION CONTROL/ACTIVE SKID CONTROL SYSTEM DIAGNOSIS The traction control/active skid control system (TCL/ASC) is a system that has

added the cut valve and suction valve to the conventional ABS system. These

valves are used to control each of the road wheels independently. These differences

include sounds, sensations, and vehicle performance that owners and service

technicians who are not familiar with TCL/ASC may not be used to.

Some operational characteristics may seem to be malfunctions, but they are simply

signs of normal TCL/ASC operation. When diagnosing the TCL/ASC system, keep

these operational characteristics in mind. Inform the owner of the kind of

performance characteristics to expect from an TCL/ASC-equipped vehicle. TCL/ASC Diagnostic Trouble Code Detection Conditions TCL/ASC diagnostic trouble codes (TCL/ASC DTCs) are set under different

conditions, depending on the malfunction detected. Most TCL/ASC DTCs will only

be set during vehicle operation. Some TCL/ASC DTCs will also be set during the

TCL/ASC self-check immediatel

y after the en

gine is started.

NOTE: *: When the ASC is operating while the brake pedal is

depressed, the suction valve turns on and off according to

the brake fluid amount supplied to the buffer chamber.

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3135 of 3870

When you check if an TCL/ASC DTC will be displayed again after the DTC has

been erased, you should duplicate the TCL/ASC DTC set conditions. Depending on

the detection timing and set conditions for the specific TCL/ASC DTC, you must

either drive the vehicle or turn the engine off and restart it. To set the proper

conditions for that DTC again, refer to "TCL/ASC DTC SET CONDITIONS

" for

each TCL/ASC DTC that you are trying to reset.

TCL/ASC DIAGNOSTIC TROUBLESHOOTING STRATEGY Use these steps to plan your diagnostic strategy. If you follow them carefully, you

will be sure that you have exhausted most of the possible ways to find an TCL/ASC

fault.

1. Gather information about the problem from the customer.

2. Verify that the condition described by the customer exists.

3. Check the vehicle for any TCL/ASC DTC.

4. If you cannot verify the condition and there are no TCL/ASC DTCs, the

malfunction is intermittent. Refer to HOW TO COPE WITH

INTERMITTENT MALFUNCTIONS

.

5. If you can verify the condition but there are no TCL/ASC DTCs, or the system

cannot communicate with the scan tool, check that the basic brake system is

operating properly.

If the basic brake system is not operating properly, refer to the BASIC BRAKE SYSTEM DIAGNOSIS

, .

If the basic brake system is operating properly, refer to SYMPTOM CHART

.

6. If there is an TCL/ASC DTC, record the number of the DTC, then erase the

DTC from the memory using the scan tool.

7. Duplicate the TCL/ASC DTC set conditions to see if the same TCL/ASC DTC

will set again.

If the same TCL/ASC DTC sets again or the TCL/ASC DTC cannot be

erased, perform the diagnostic procedures for the DTC. Refer to

DIAGNOSTIC TROUBLE CODE CHART

.

If you cannot

get the same TCL/ASC DTC to set a

gain, the malfunction is

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3163 of 3870

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

2. Start the engine.

3. Set scan tool MB991958 to the data reading mode, and check the data list

items by driving the vehicle.

Item 01 (DTC C1200 is set): Front right ABS sensor Item 02 (DTC C1205 is set): Front left ABS sensor Item 03 (DTC C1210 is set): Rear right ABS sensor Item 04 (DTC C1215 is set): Rear left ABS sensor

4. Turn the ignition switch to the "LOCK" (OFF) position.

Q: Does the speedometer indication match the scan tool indication?

YES: It can be assumed that this malfunction is intermittent.

Refer to HOW TO COPE WITH INTERMITTENT

MALFUNCTIONS

.

NO: Go to Step 4.

STEP 4. Measure the voltage at TCL/ASC-ECU connector A-32.

1. Disconnect the connector A-32, and connect special tool ABS Check

Harness (MB991952) to the wiring harness-side connector.

2. Turn the ignition switch to the "ON" position.

3. Measure the voltage between the relevant signal and ground terminals in

the ABS sensor circuit and body ground. It should be less than 1V.

DTC C1200 is set: Between signal terminal 30 and body ground, and

between ground terminal 21 and body ground DTC C1205 is set: Between signal terminal 22 and body ground, and

between ground terminal 31 and body ground DTC C1210 is set: Between si

gnal terminal 8 and bo

dy ground, and

NOTE: Do not connect special tool ABS Check Harness

(MB991952) to the TCL/ASC-ECU.

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3516 of 3870

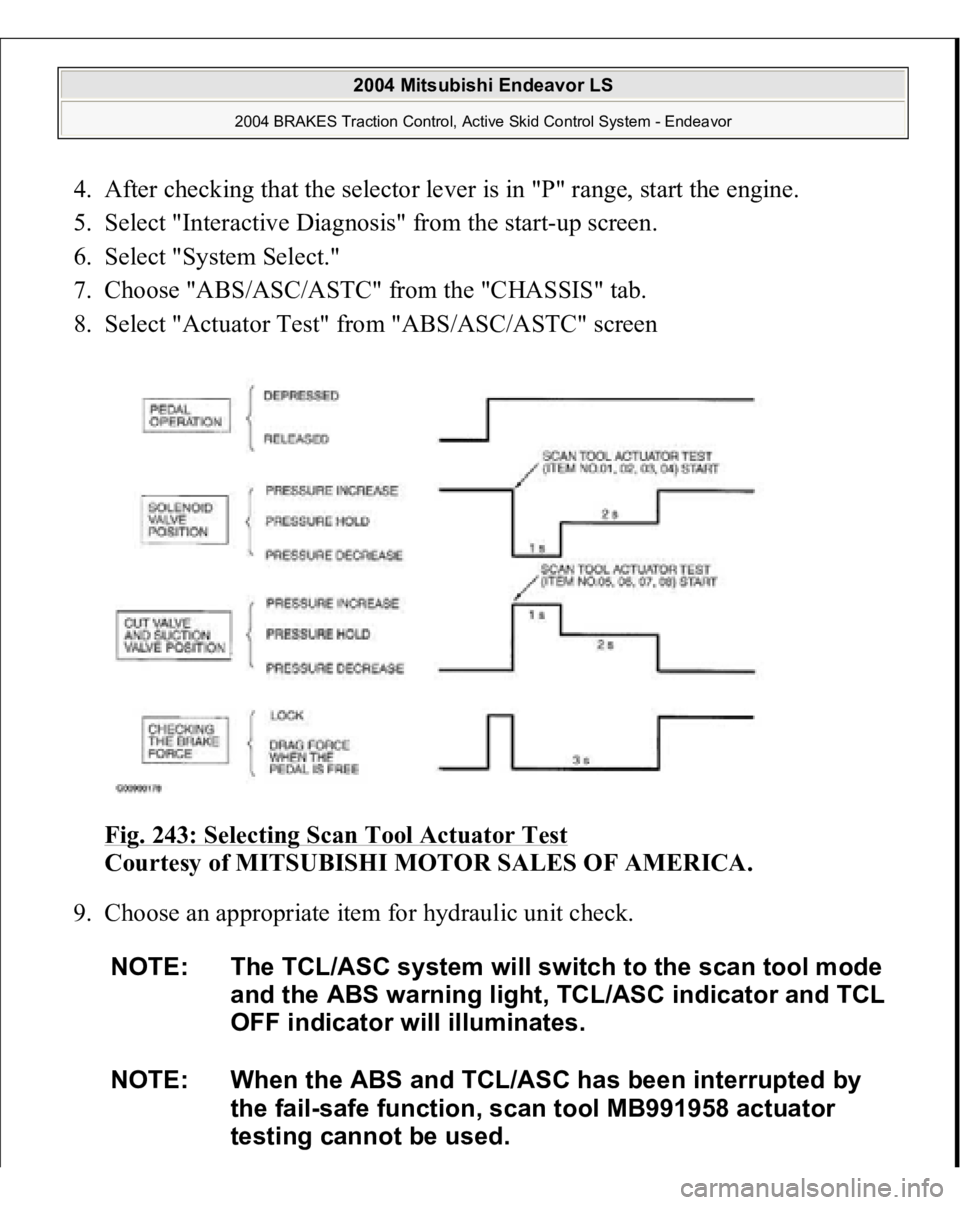

4. After checking that the selector lever is in "P" range, start the engine.

5. Select "Interactive Diagnosis" from the start-up screen.

6. Select "System Select."

7. Choose "ABS/ASC/ASTC" from the "CHASSIS" tab.

8. Select "Actuator Test" from "ABS/ASC/ASTC" screen

Fig. 243: Selecting Scan Tool Actuator Test

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

9. Choose an appropriate item for hydraulic unit check.

NOTE: The TCL/ASC system will switch to the scan tool mode

and the ABS warning light, TCL/ASC indicator and TCL

OFF indicator will illuminates.

NOTE: When the ABS and TCL/ASC has been interrupted by

the fail-safe function, scan tool MB991958 actuator

testing cannot be used.

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3518 of 3870

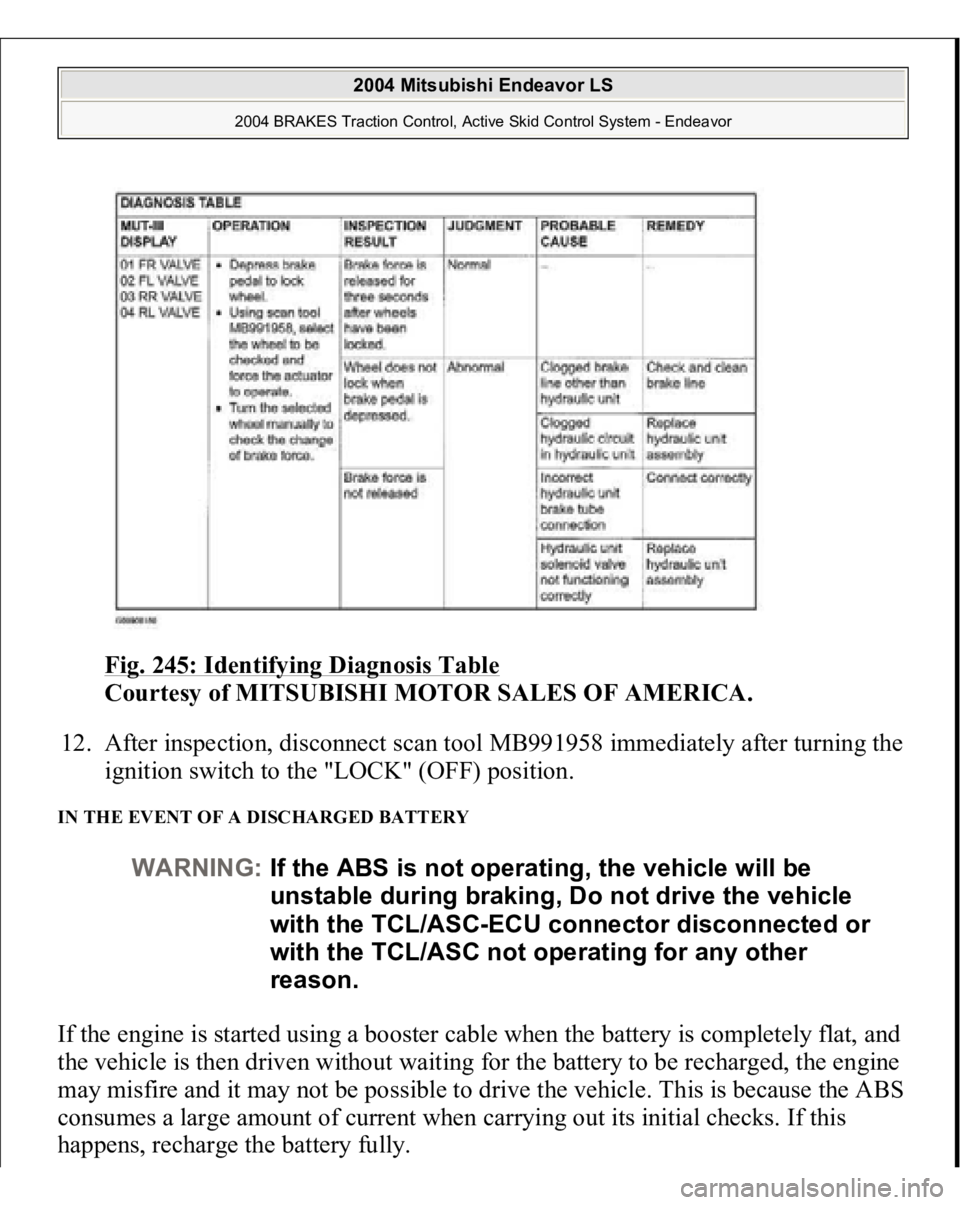

Fig. 245: Identifying Diagnosis Table

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

12. After inspection, disconnect scan tool MB991958 immediately after turning the

ignition switch to the "LOCK" (OFF) position.

IN THE EVENT OF A DISCHARGED BATTERY If the engine is started using a booster cable when the battery is completely flat, and

the vehicle is then driven without waiting for the battery to be recharged, the engine

may misfire and it may not be possible to drive the vehicle. This is because the ABS

consumes a large amount of current when carrying out its initial checks. If this

happens, recharge the battery fully.

WARNING:If the ABS is not operating, the vehicle will be

unstable during braking, Do not drive the vehicle

with the TCL/ASC-ECU connector disconnected or

with the TCL/ASC not operating for any other

reason.

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3534 of 3870

2004 STARTING & CHARGING SYSTEMS

Starters - Endeavor

DESCRIPTION & OPERATION If the ignition switch is turned to START position, current flows in the coil

provided inside magnetic switch, attracting the plunger. When plunger is attracted,

the lever connected to plunger is actuated to engage starter clutch. On the other

hand, attracting plunger will turn on magnetic switch, allowing "B" terminal and

"M" terminal to conduct. Thus, current flows to engage starter motor. When

ignition switch is returned to ON position after starting engine, starter clutch is

disengaged from ring gear.

An overrunning clutch is provided between pinion and armature shaft to prevent

damage to starter.

When the ignition switch is switched to the START position while the selector leve

r

is at the "P" or "N" range, the contact (magnetic switch) of the starter is switched

ON and the starter motor is activated.

ADJUSTMENT PINION GAP 1. Disconnect the field coil wire from the "M" terminal of magnetic switch.

2. Connect a 12V battery between "S" terminal and "M" terminal. See Fig. 1

.

3. Set switch to ON and pinion will move out.

4. Check the pinion to stopper clearance (pinion gap) with a feeler gauge. See

Fig. 2

.

5. If the pinion gap is out of specification, adjust by adding or removing gasket(s)

between the ma

gnetic switch and front bracket. CAUTION: To prevent coil from burning, DO NOT apply voltage

to starter assembly for more than 10 seconds.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Page 3537 of 3870

STARTER MOTOR DOES NOT STOPCheck the magnetic switch. ON-VEHICLE TESTING STARTER MOTOR DOES NOT OPERATE 1. Is the battery in good condition? If Yes, go to the next step. If No, then charge

or replace battery.

2. Disconnect the starter motor "S" (solenoid) terminal connector. Using a jumper

wire, apply battery positive voltage to starter motor "S" (solenoid) terminal.

Does starter motor operate normally? If Yes, then check ignition switch,

transmission range switch and the line between the battery and starter motor

"S" (solenoid) terminal. If No, then go to the next step.

3. Check if the cable between starter "B" (battery) terminal and battery positive

terminal for connection and continuity. Is the starter cable in good condition? I

f

Yes, then go to the next step. If No, then repair or replace the cable.

4. Check the connection and continuity of the cable between starter motor body

and the negative battery terminal. Is the ground line in good condition? If Yes,

then go to the next step. If No, then repair or replace cable.

5. Is the starter motor in good condition? If Yes, problem is excessive rotational

resistance of the engine. If No, then replace the starter motor.

BENCH TESTING MAGNETIC SWITCH PULL-IN TEST 1. Disconnect field coil wire from "M" terminal of the magnetic switch. See Fig.

3 . WARNING:Battery posts, terminals and related accessories

contain lead and lead compounds. Wash hands after

handling.

CAUTION: To prevent coil from burning, DO NOT apply voltage

to starter assembly for more than 10 seconds.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Page 3577 of 3870

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

Installation 1. Place auto-tensioner in soft-jawed vise to SLOWLY compress the push rod. If

there is a plug at the base of the auto-tensioner body, place flat washer around

plug so it will not contact vise jaw.

2. Slowly compress auto-tensioner push rod until holes in push rod and auto-

tensioner housing are aligned. Insert a locking pin into the alignment holes.

Install auto-tensioner on engine.

3. Ensure all timing marks are still aligned. See Fig. 3

. Install timing belt on

crankshaft sprocket, idler pulley, left bank camshaft sprocket, water pump

pulley, right bank camshaft sprocket, and tensioner pulley. Take all slack out o

f

timing belt.

4. Loosen the tensioner pulley center bolt. Rotate tensioner pulley against timing

belt. Temporarily tighten tensioner pulley center bolt. Turn crankshaft 1/4 turn

counterclockwise. Turn crankshaft 1/4 turn clockwise. Ensure all timing belt

marks are still aligned.

5. Loosen tensioner pulley center bolt. Position tensioner pin holes at bottom of

tensioner. Install Adapter (MD998767) on tensioner pulley. See Fig. 5

. Using

torque wrench, apply 39 INCH lbs. (4.4 N.m) of torque (counterclockwise

direction) to tensioner pulley. Tighten tensioner center bolt to specification

while holding tensioner pulley stationary. See TORQUE

SPECIFICATIONS

.

6. Remove locking pin from auto-tensioner. Turn crankshaft 2 revolutions

clockwise and align all timing marks. DO NOT rotate counterclockwise.

7. Wait for at least 5 minutes, then check auto-tensioner push rod protrusion. To

check push rod protrusion, measure clearance between body of auto-tensioner

and bottom of tensioner pulley bracket arm. Clearance should be 0.19-

0.24" (4.8-6.0 mm). If protrusion is not correct, repeat timing belt tensioning

procedure. CAUTION: Never compress the auto-tensioner too fast, or

the push rod will be damaged.

2004 Mitsubishi Endeavor Limited MITSUBISHI 3.8L V6 - SOHC - Endeavor & Galant