MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Page 1096 of 3870

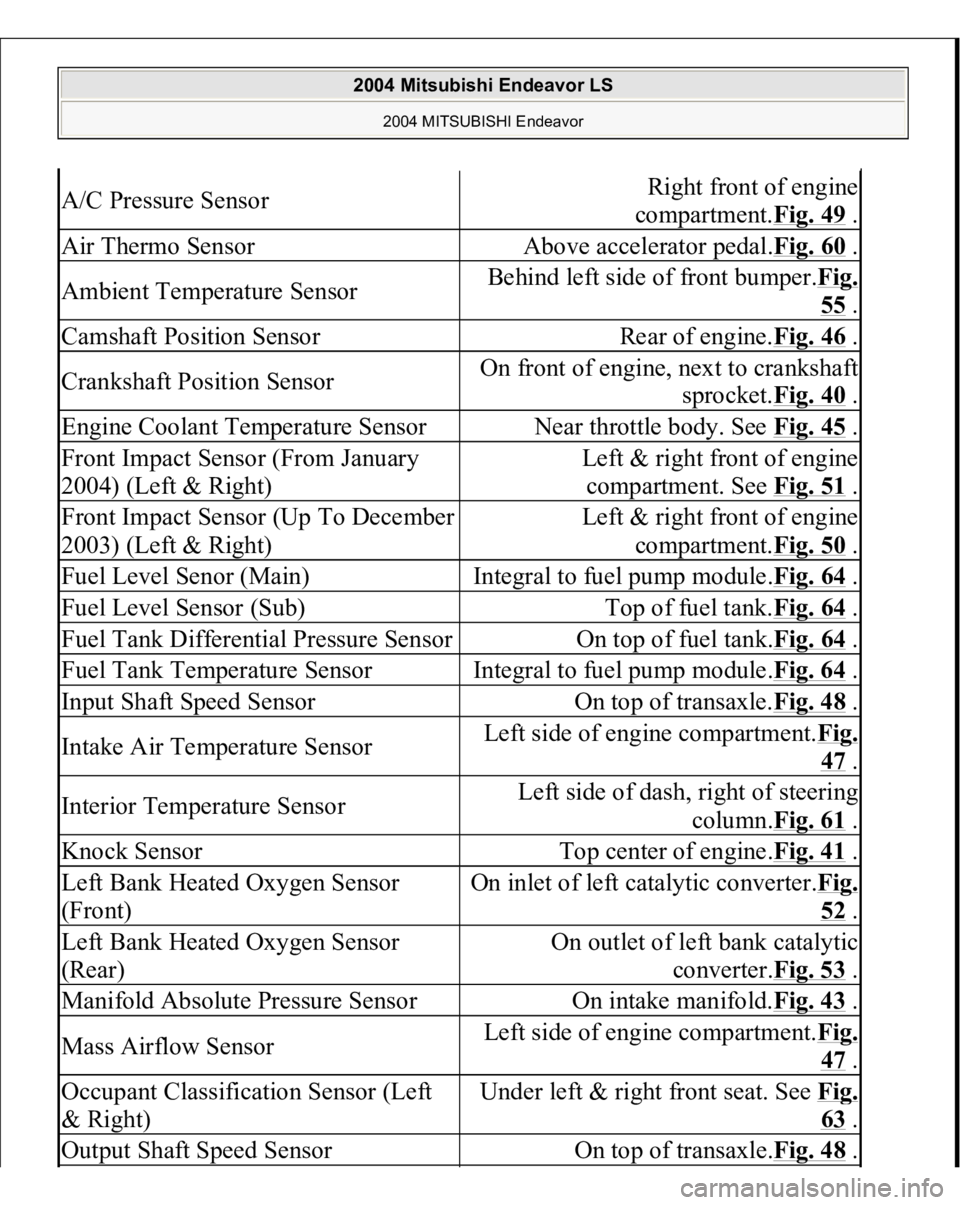

A/C Pressure Sensor

Right front of engine

compartment.Fig. 49

.

Air Thermo Sensor

Above accelerator pedal.Fig. 60

.

Ambient Temperature Sensor

Behind left side of front bumper.Fig.

55 .

Camshaft Position Sensor

Rear of engine.Fig. 46

.

Crankshaft Position Sensor

On front of engine, next to crankshaft

sprocket.Fig. 40

.

Engine Coolant Temperature Sensor

Near throttle body. See Fig. 45

.

Front Impact Sensor (From January

2004) (Left & Right)

Left & right front of engine

compartment. See Fig. 51

.

Front Impact Sensor (Up To December

2003) (Left & Right)

Left & right front of engine

compartment.Fig. 50

.

Fuel Level Senor (Main)

Integral to fuel pump module.Fig. 64

.

Fuel Level Sensor (Sub)

Top of fuel tank.Fig. 64

.

Fuel Tank Differential Pressure Sensor

On top of fuel tank.Fig. 64

.

Fuel Tank Temperature Sensor

Integral to fuel pump module.Fig. 64

.

Input Shaft Speed Sensor

On top of transaxle.Fig. 48

.

Intake Air Temperature Sensor

Left side of engine compartment.Fi

g.

47 .

Interior Temperature Sensor

Left side of dash, right of steering

column.Fig. 61

.

Knock Sensor

Top center of engine.Fig. 41

.

Left Bank Heated Oxygen Sensor

(Front)

On inlet of left catalytic converter.Fi

g.

52 .

Left Bank Heated Oxygen Sensor

(Rear)

On outlet of left bank catalytic

converter.Fig. 53

.

Manifold Absolute Pressure Sensor

On intake manifold.Fig. 43

.

Mass Airflow Sensor

Left side of engine compartment.Fi

g.

47 .

Occupant Classification Sensor (Left

& Right)

Under left & right front seat. See Fi

g.

63 .

Output Shaft Speed Sensor

On top of transaxle.Fig. 48

.

2004 Mitsubishi Endeavor LS

2004 MITSUBISHI Endeavor

Page 1331 of 3870

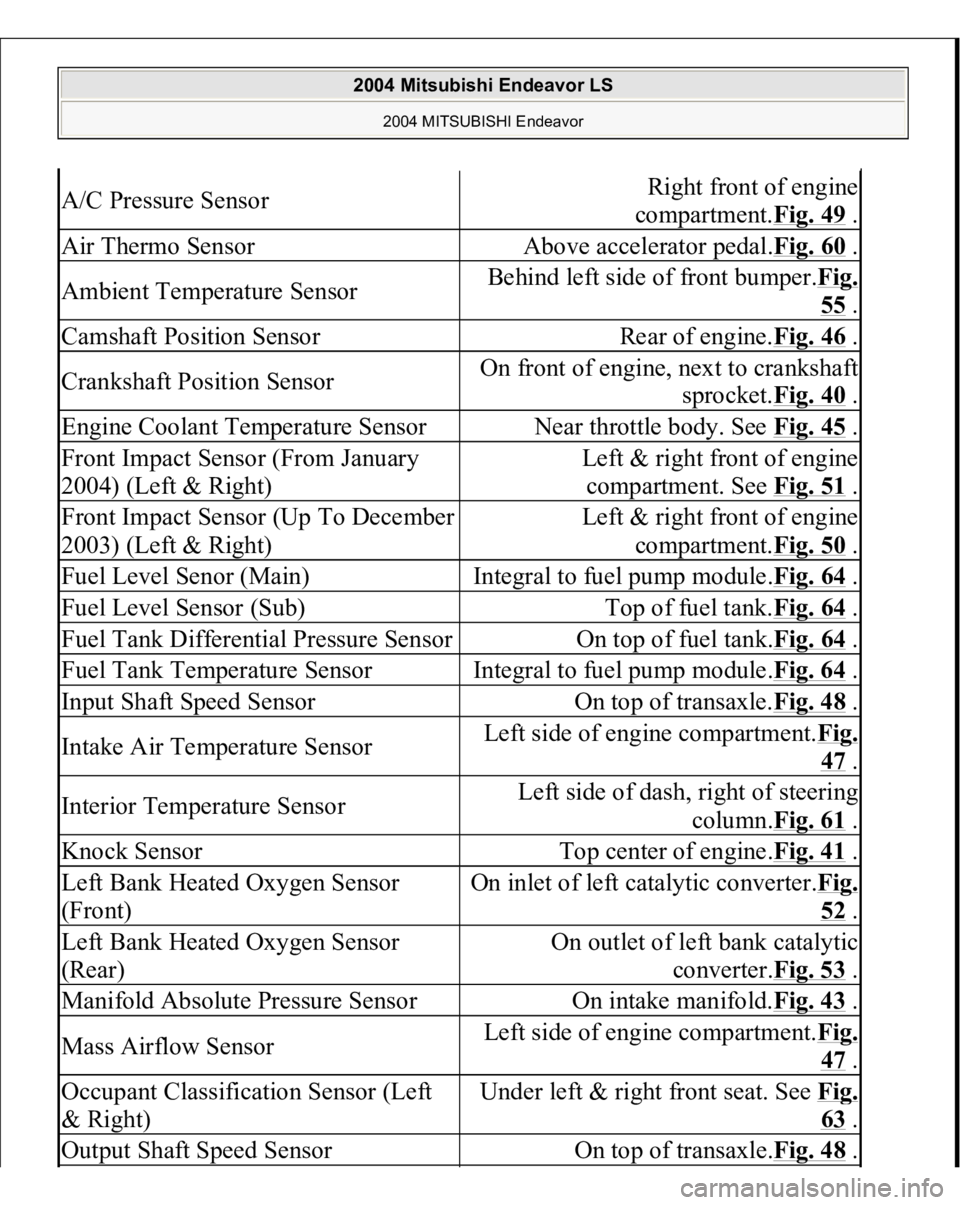

Fig. 13: Removing And Installing Ignition System

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

REQUIRED SPECIAL TOOLS:

MD998781: Flywheel Stopper

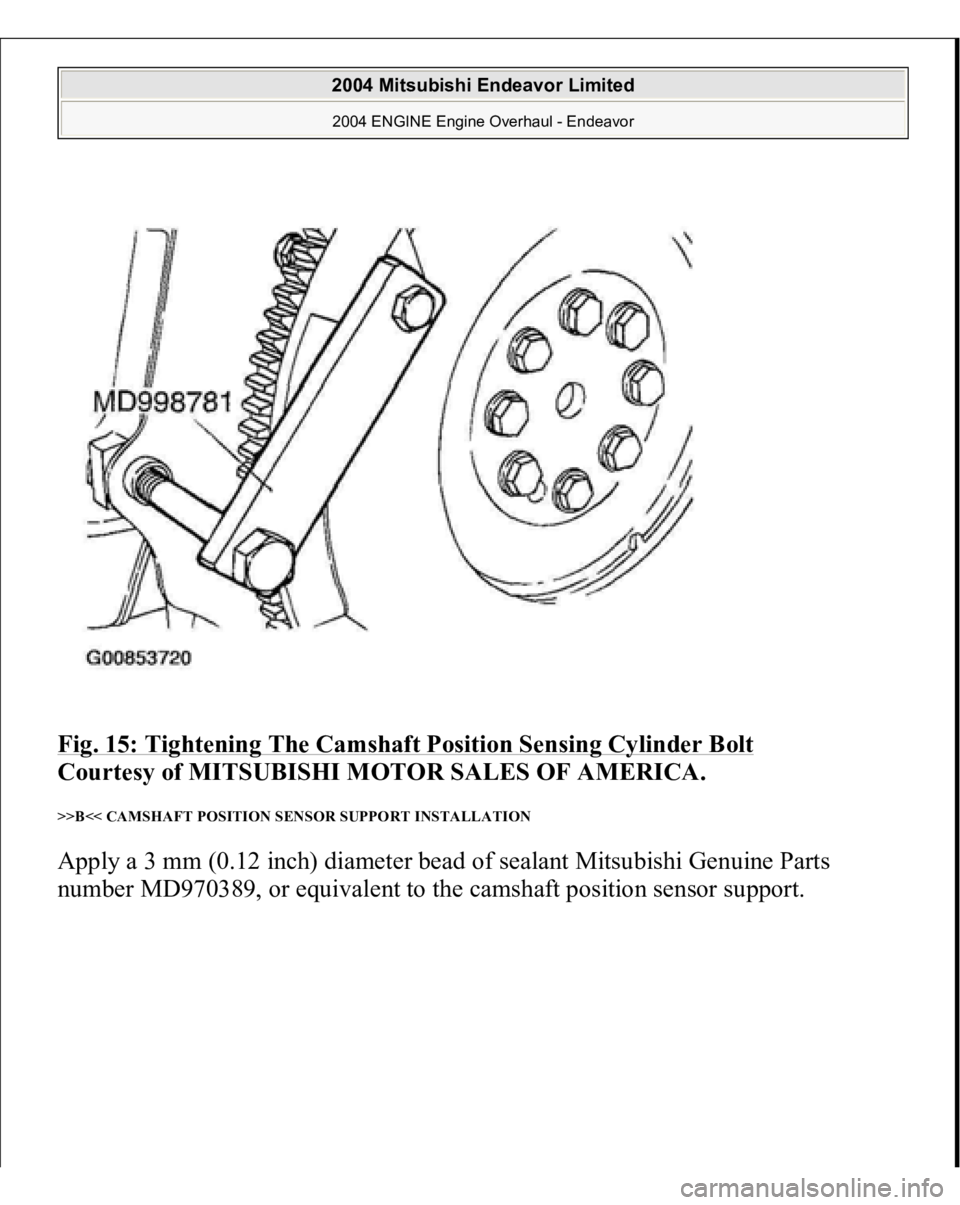

REMOVAL SERVICE POINT << A >> CAMSHAFT POSITION SENSING CYLINDER REMOVAL

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1332 of 3870

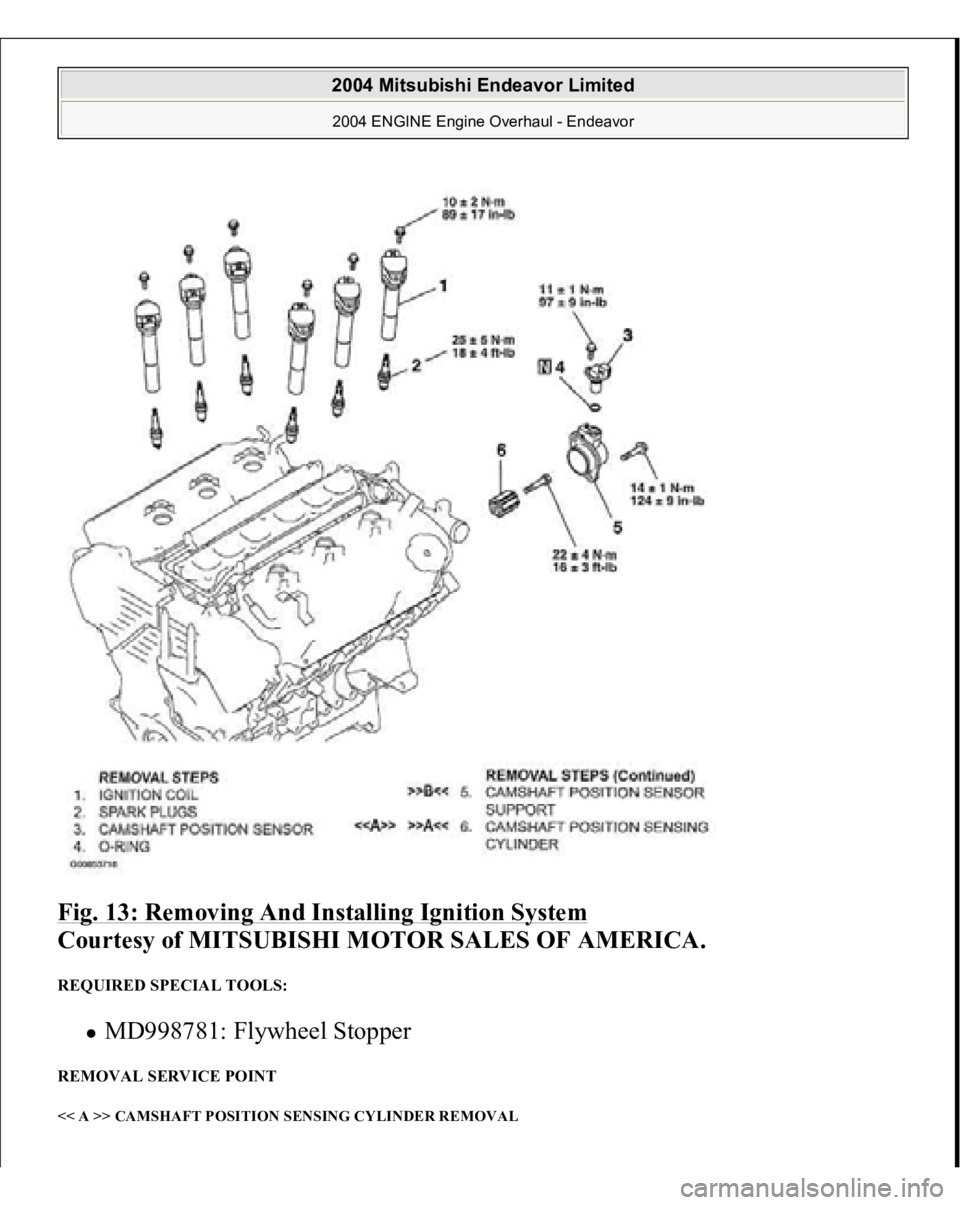

1. Using special tool MD998781, hold the drive plate or flywheel.

2. Loosen the camshaft position sensing cylinder bolt.

Fig. 14: Removing Camshaft Position Sensing Cylinder

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSTALLATION SERVICE POINT >>A<< CAMSHAFT POSITION SENSING CYLINDER INSTALLATION 1. Using special tool MD998781, hold the drive plate or flywheel.

2. Tighten the camshaft position sensing cylinder bolt to the specified torque.

Tightening torque: 22+/-4 N.m (16+/-3 ft-lb)

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1333 of 3870

Fig. 15: Tightening The Camshaft Position Sensing Cylinder Bolt

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

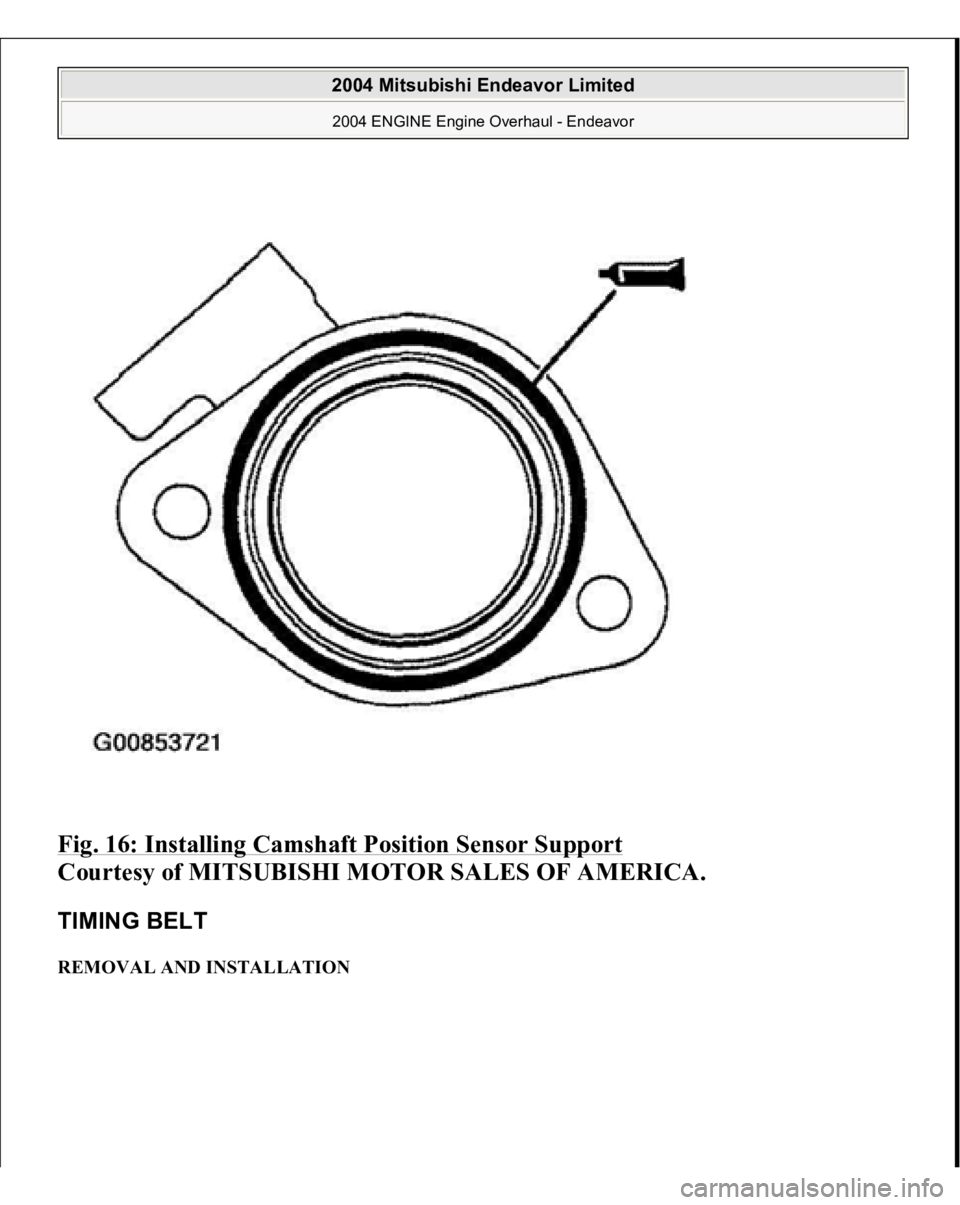

>>B<< CAMSHAFT POSITION SENSOR SUPPORT INSTALLATION Apply a 3 mm (0.12 inch) diameter bead of sealant Mitsubishi Genuine Parts

number MD970389, or e

quivalent to the camshaft

position sensor su

pport.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1334 of 3870

Fig. 16: Installing Camshaft Position Sensor Support

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

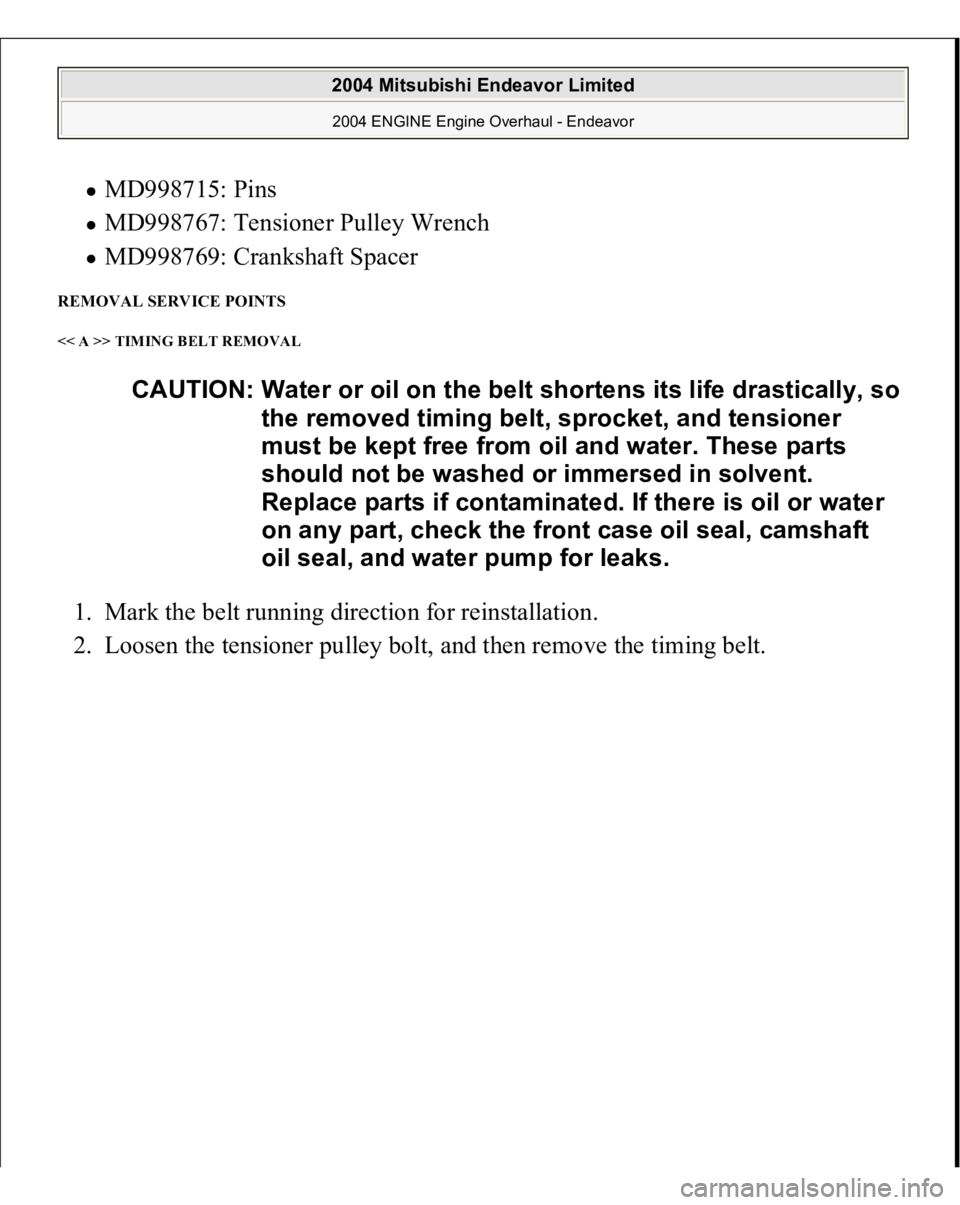

TIMING BELT REMOVAL AND INSTALLATION

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1336 of 3870

MD998715: Pins MD998767: Tensioner Pulley Wrench MD998769: Crankshaft Spacer

REMOVAL SERVICE POINTS << A >> TIMING BELT REMOVAL 1. Mark the belt running direction for reinstallation.

2. Loosen the tensioner pulley bolt, and then remove

the timing belt.

CAUTION: Water or oil on the belt shortens its life drasticall

y, so

the removed timing belt, sprocket, and tensioner

must be kept free from oil and water. These parts

should not be washed or immersed in solvent.

Replace parts if contaminated. If there is oil or water

on any part, check the front case oil seal, camshaft

oil seal, and water pump for leaks.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1337 of 3870

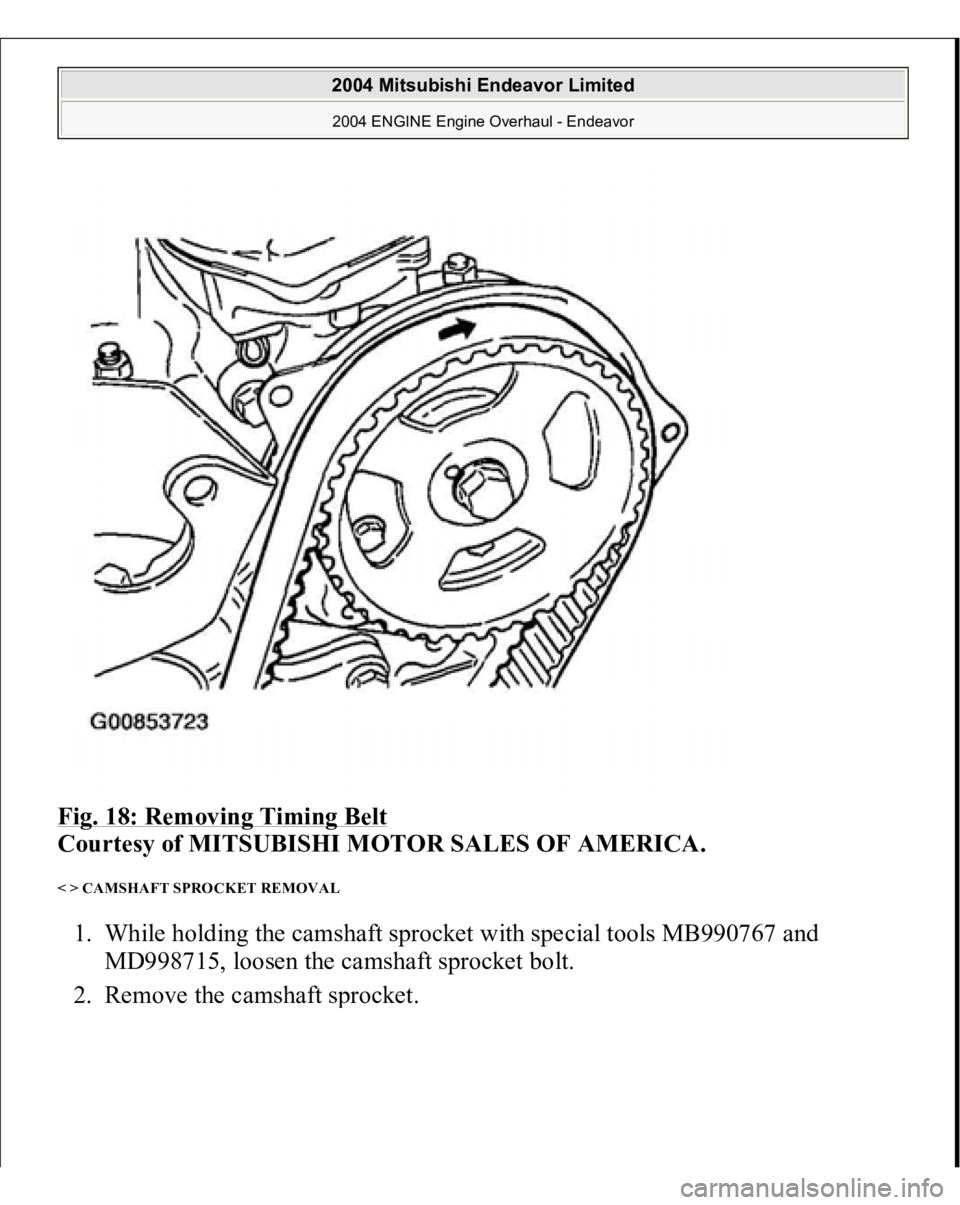

Fig. 18: Removing Timing Belt

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

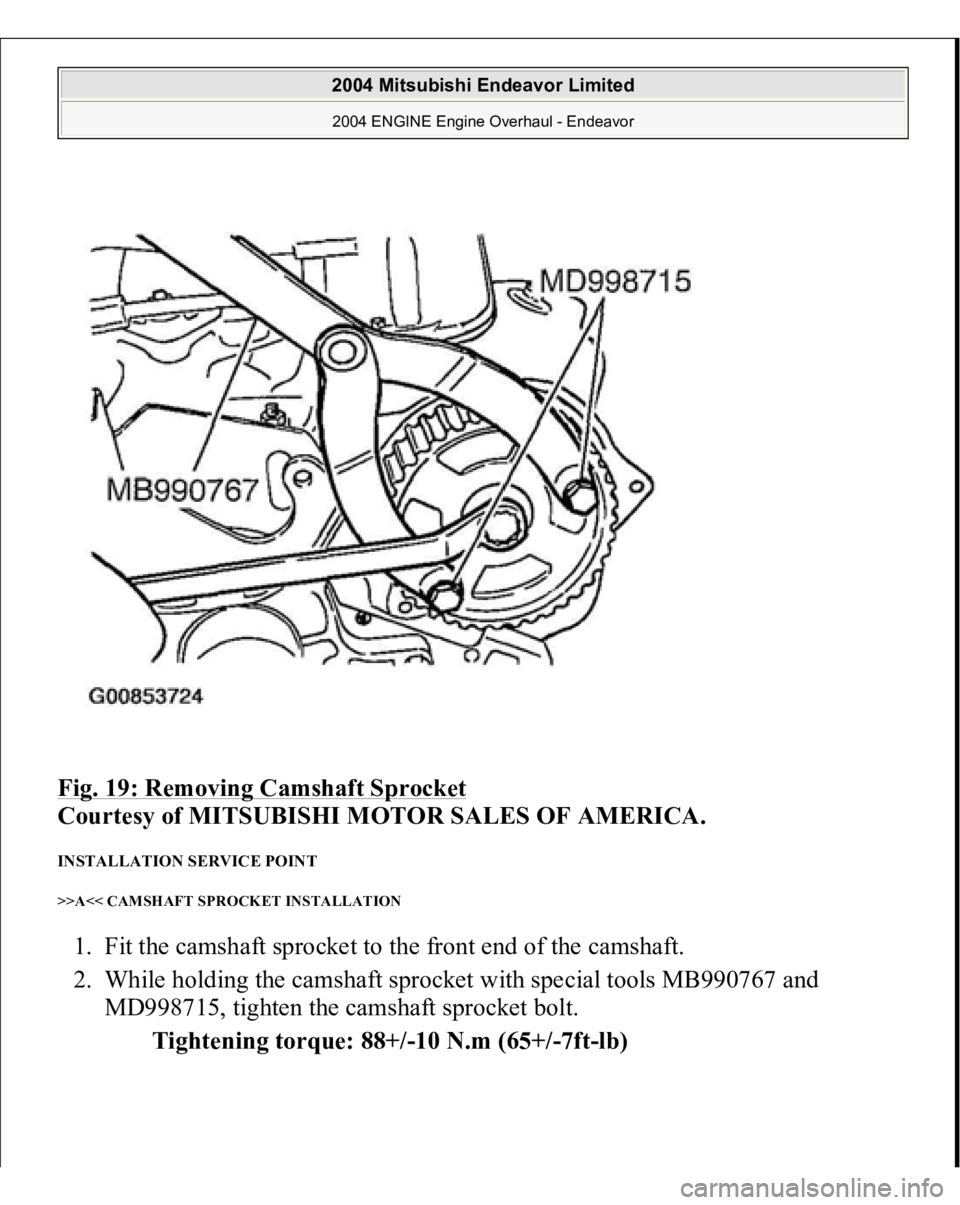

< > CAMSHAFT SPROCKET REMOVAL 1. While holding the camshaft sprocket with special tools MB990767 and

MD998715, loosen the camshaft sprocket bolt.

2. Remove the camshaft s

procket.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1338 of 3870

Fig. 19: Removing Camshaft Sprocket

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSTALLATION SERVICE POINT >>A<< CAMSHAFT SPROCKET INSTALLATION 1. Fit the camshaft sprocket to the front end of the camshaft.

2. While holding the camshaft sprocket with special tools MB990767 and

MD998715, tighten the camshaft sprocket bolt.

Tightening torque: 88+/-10 N.m (65+/-7ft-lb)

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1339 of 3870

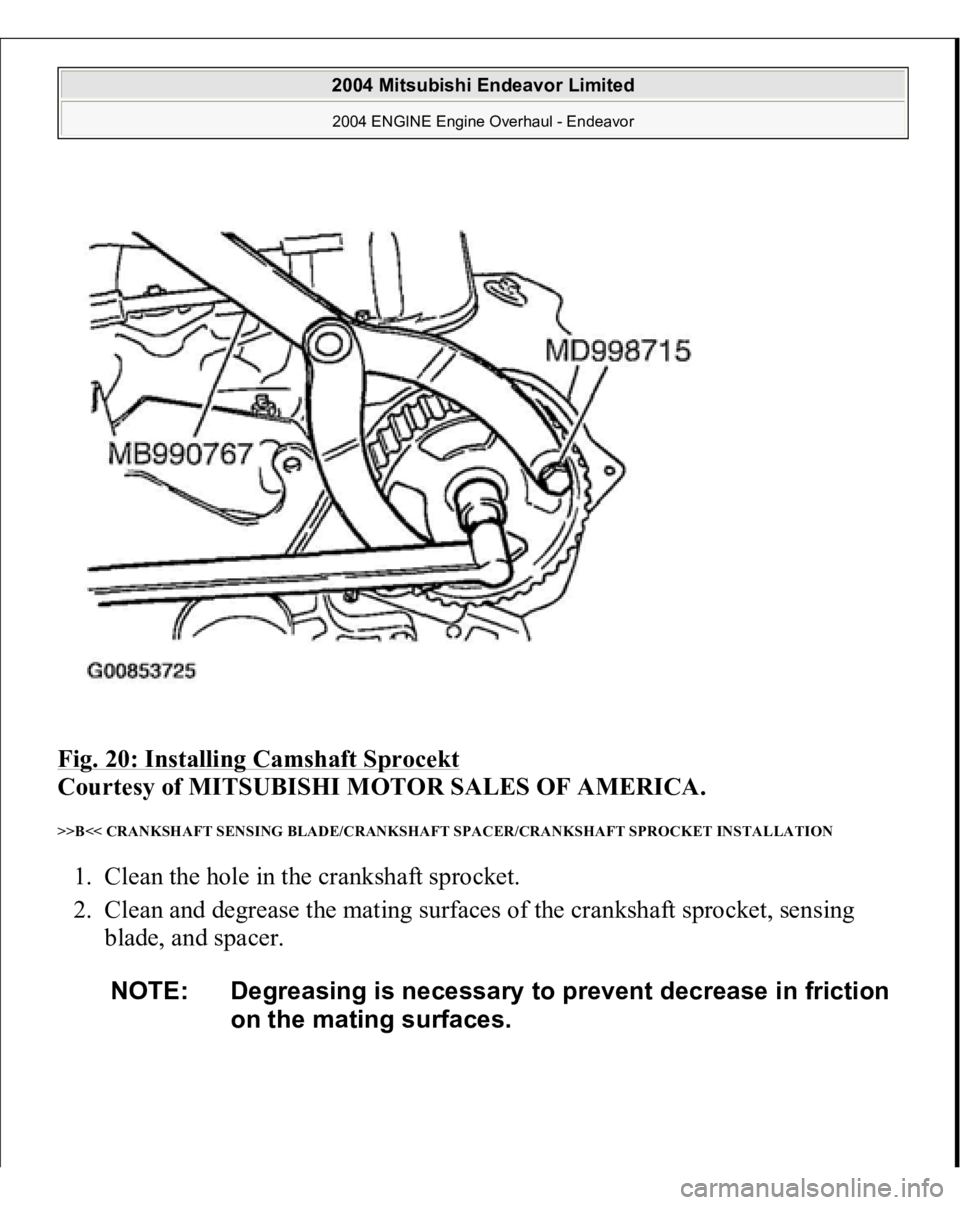

Fig. 20: Installing Camshaft Sprocekt

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

>>B<< CRANKSHAFT SENSING BLADE/CRANKSHAFT SPACER/CRANKSHAFT SPROCKET INSTALLATION 1. Clean the hole in the crankshaft sprocket.

2. Clean and degrease the mating surfaces of the crankshaft sprocket, sensing

blade, and spacer.

NOTE: Degreasing is necessary to prevent decrease in friction

on the mating surfaces.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1342 of 3870

with hole B in the cylinder.

Fig. 23: Installing Auto

-Tensioner

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Insert a wire [1.4 mm (0.055 inch) in diameter] into the set holes. This auto-

tensioner setting wire will be used during timing belt alignment.

4. Unclamp the auto-tensioner from the vise.

>>D<< TIMING BELT INSTALLATION

CAUTION: Do not turn the camshaft when the piston in No. 1

cylinder is at top dead center on the compression

stroke. Doing so can cause the lifted valve to hit

against the piston, damaging parts.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

![MITSUBISHI ENDEAVOR 2004 Service Repair Manual with hole B in the cylinder.

Fig. 23: Installing Auto

-Tensioner

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Insert a wire [1.4 mm (0.055 inch) in diameter] into the set holes. This auto-

t MITSUBISHI ENDEAVOR 2004 Service Repair Manual with hole B in the cylinder.

Fig. 23: Installing Auto

-Tensioner

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Insert a wire [1.4 mm (0.055 inch) in diameter] into the set holes. This auto-

t](/img/19/57105/w960_57105-1341.png)