oil level MITSUBISHI ENDEAVOR 2004 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2004, Model line: ENDEAVOR, Model: MITSUBISHI ENDEAVOR 2004Pages: 3870, PDF Size: 98.47 MB

Page 1269 of 3870

2004 STARTING & CHARGING SYSTEMS

Generators & Regulators - Endeavor

DESCRIPTION The charging system charges the battery with the generator output to keep the

battery charged at a constant level during varying electrical load. OPERATION Rotation of the excited field coil generates AC voltage in the stator. This alternating

current is rectified through diodes to DC voltage having a waveform. The average

output voltage fluctuates slightly with the generator load condition.

When the ignition switch is turned on, current flows in the field coil and initial

excitation of the field coil occurs. When the stator coil begins to generate power

after the engine is started, the field coil is excited by the output current of the stator

coil. The generator output voltage rises as the field current increases and it falls as

the field current decreases. When the battery positive voltage (generator S terminal

voltage) reaches a regulated voltage of approximately 14.4V, the field current is cut

off. When the battery positive voltage drops below the regulated voltage, the

voltage regulator regulates the output voltage to a constant level by controlling the

field current. In addition, when the field current is constant, the generator output

volta

ge rises as the en

gine s

peed increases. See Fig. 1

or Fig. 2

.

NOTE: See appropriate SELF DIAGNOSTICS article in ENGINE

PERFORMANCE to properly diagnose charging system.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Generators & Regulators - Endeavor

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Generators & Regulators - Endeavor

Page 1302 of 3870

cleaned regularly and kept separate from personal clothing. Where there is a risk of eye contact, eye protection should be worn i.e.

chemical goggles or face shields. In addition, an eye wash facility should be

provided. Obtain First Aid treatment immediately for open cuts and wounds. Wash regularly with soap and water to ensure all oil is removed, especially

before meals (skin cleansers and nail brushes will help). After cleaning, apply

lotion, etc., containing lanolin to replace natural skin oils is advised. Do not use gasoline, kerosene, diesel fuel, gas oil, thinner or solvents for

cleaning skin. Apply barrier creams before each work period to help clean the skin after

work. If skin disorders develop, obtain medical advice immediately.

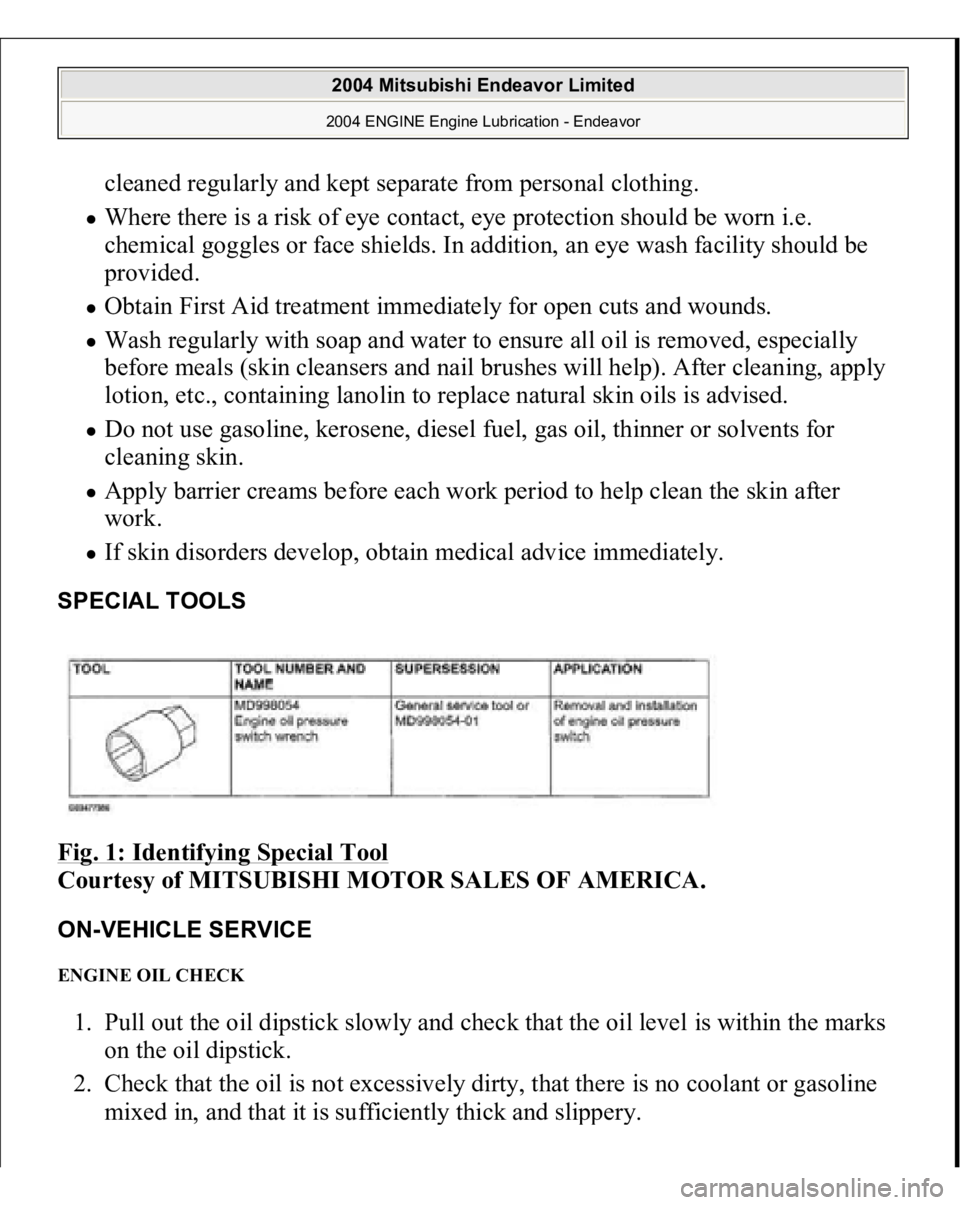

SPECIAL TOOLS Fig. 1: Identifying Special Tool

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

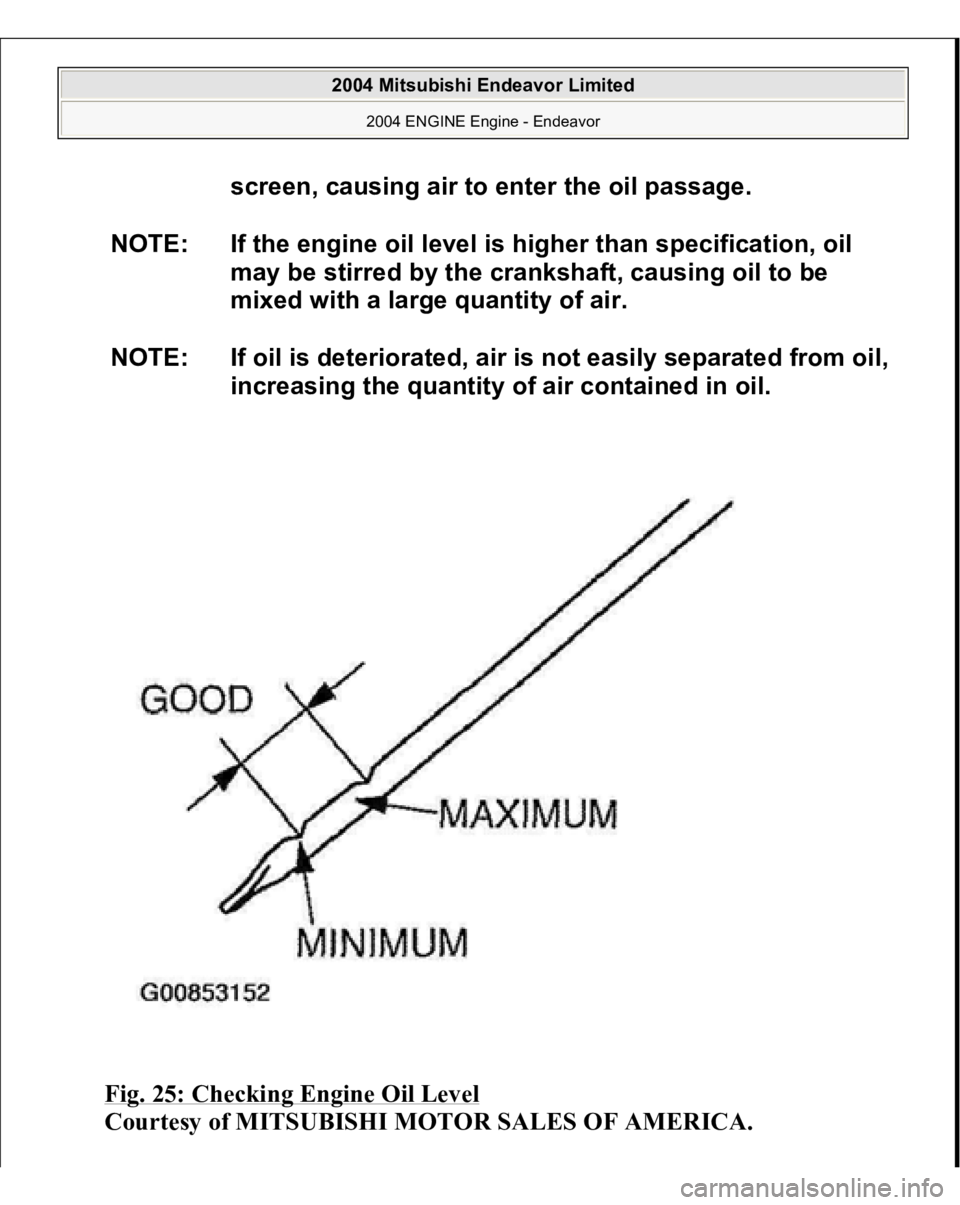

ON-VEHICLE SERVICE ENGINE OIL CHECK 1. Pull out the oil dipstick slowly and check that the oil level is within the marks

on the oil dipstick.

2. Check that the oil is not excessively dirty, that there is no coolant or gasoline

mixed in, and that it is sufficientl

y thick and sli

ppery.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Lubrication - Endeavor

Page 1303 of 3870

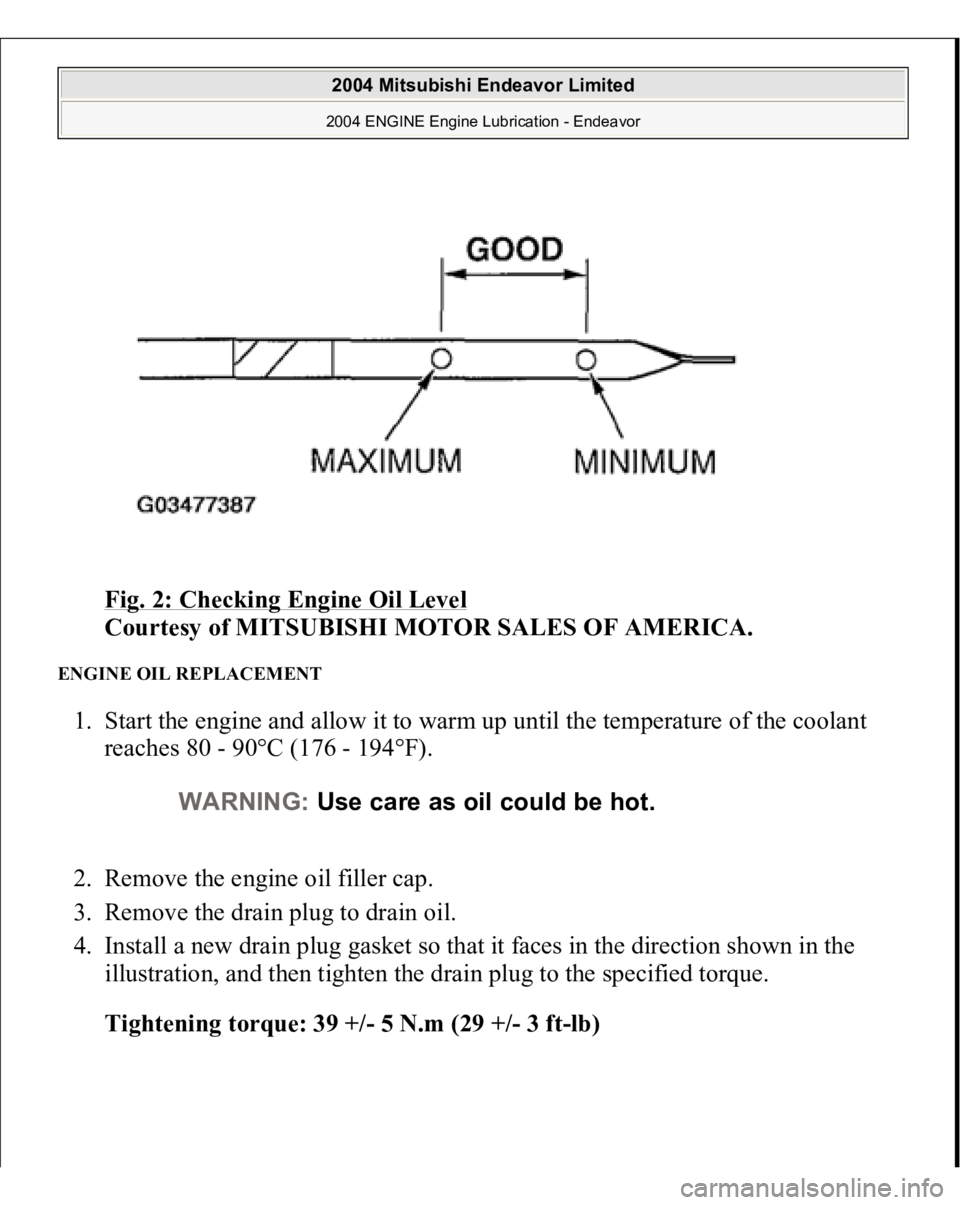

Fig. 2: Checking Engine Oil Level

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

ENGINE OIL REPLACEMENT 1. Start the engine and allow it to warm up until the temperature of the coolant

reaches 80 - 90°C (176 - 194°F).

2. Remove the engine oil filler cap.

3. Remove the drain plug to drain oil.

4. Install a new drain plug gasket so that it faces in the direction shown in the

illustration, and then tighten the drain plug to the specified torque.

Tightening torque: 39 +/- 5 N.m (29 +/- 3 ft-lb)

WARNING:Use care as oil could be hot.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Lubrication - Endeavor

Page 1305 of 3870

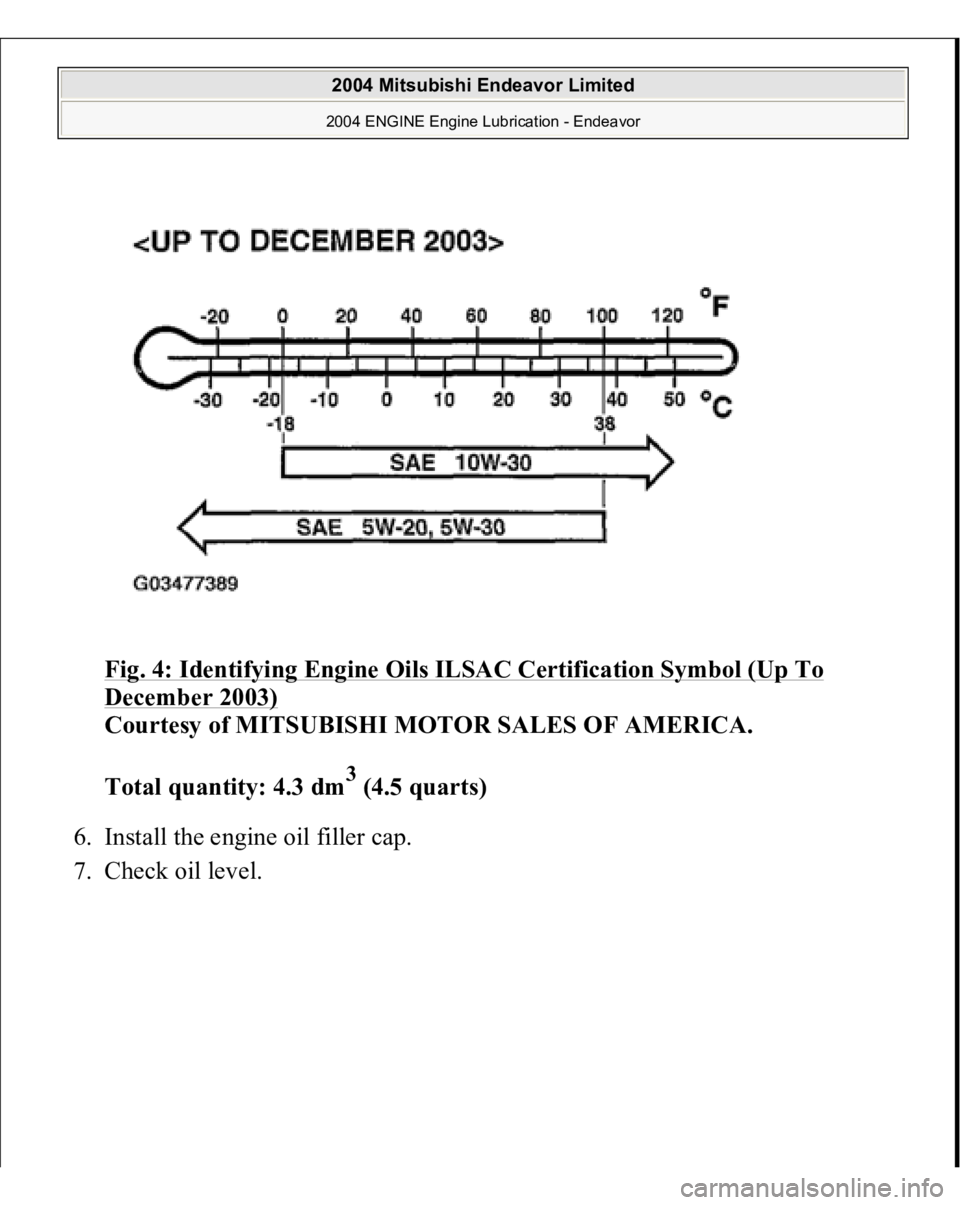

Fig. 4: Identifying Engine Oils ILSAC Certification Symbol (Up To December 2003)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Total quantity: 4.3 dm

3 (4.5 quarts)

6. Install the engine oil filler cap.

7. Check oil level.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Lubrication - Endeavor

Page 1532 of 3870

3. With the engine idling, change the engine load (shift from N to D range, for

example) to make sure that there is no change in the level of abnormal noise.

If there is a change in the level of abnormal noise, suspect a tapping noise due

to worn crankshaft bearing or connecting rod bearing (In this case, the lash

adjuster is in good condition.).

4. After completion of warm-up, run the engine at idle to check for abnormal

noise.

If the noise is reduced or disappears, clean the lash adjuster (Refer to

ROCKER ARMS AND CAMSHAFT

). As it is suspected that the noise is

due to seizure of the lash adjuster. If there is no change in the level of the

abnormal noise, proceed to step 5.

5. Run the engine to bleed the lash adjuster system (Refer to LASH ADJUSTER

CHECK

.).

6. If the abnormal noise does not disappear after air bleeding operation, clean the

lash adjuster (Refer to ROCKER ARMS AND CAMSHAFT

).

Bleeding lash adjuster system 1. Check engine oil and add or change oil if required. NOTE: Parkin

g the vehicle on a

grade for a lon

g time ma

y decrease

oil in the lash adjuster, causing air to enter the high

pressure chamber when starting the engine.

NOTE: After parking for many hours, oil may run out from the oil

passage and take time before oil is supplied to the lash

adjuster, causing air to enter the high pressure chamber.

NOTE: In the above cases, abnormal noise can be eliminated by

bleeding the lash adjuster system.

NOTE: If the engine oil level is low, air is sucked from the oil

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 1533 of 3870

Fig. 25: Checking Engine Oil Level

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

screen, causing air to enter the oil passage.

NOTE: If the engine oil level is higher than specification, oil

may be stirred by the crankshaft, causing oil to be

mixed with a large quantity of air.

NOTE: If oil is deteriorated, air is not easily separated from oil,

increasing the quantity of air contained in oil.

2004 Mitsubishi Endeavor Limited

2004 ENGINE Engine - Endeavor

Page 2815 of 3870

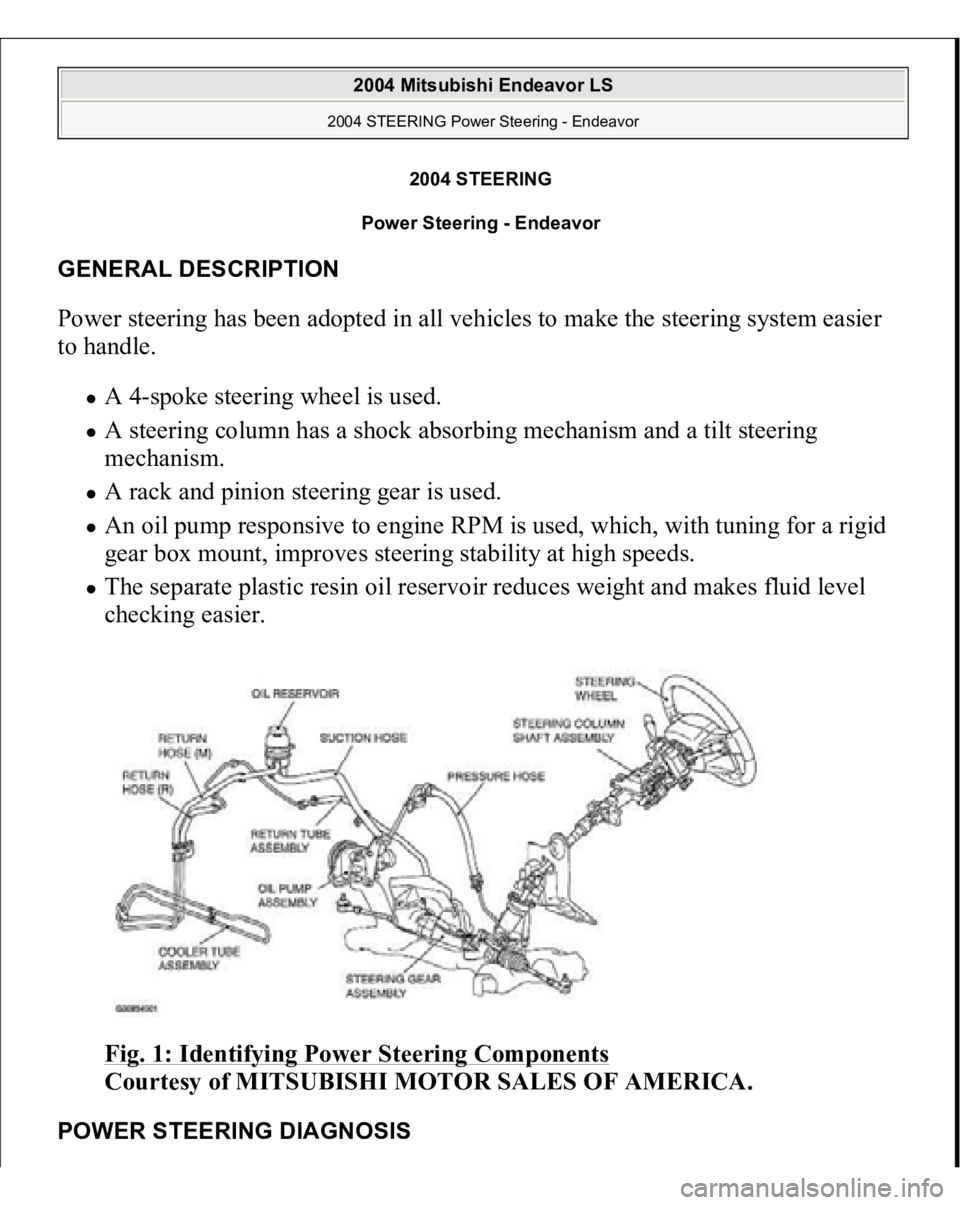

2004 STEERING

Power Steering - Endeavor

GENERAL DESCRIPTION Power steering has been adopted in all vehicles to make the steering system easier

to handle.

A 4-spoke steering wheel is used. A steering column has a shock absorbing mechanism and a tilt steering

mechanism. A rack and pinion steering gear is used. An oil pump responsive to engine RPM is used, which, with tuning for a rigid

gear box mount, improves steering stability at high speeds. The separate plastic resin oil reservoir reduces weight and makes fluid level

checking easier.

Fig. 1: Identifying Power Steering Components

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

POWER STEERING DIAGNOSIS

2004 Mitsubishi Endeavor LS

2004 STEERING Power Steering - Endeavor

2004 Mitsubishi Endeavor LS

2004 STEERING Power Steering - Endeavor

Page 2820 of 3870

YES: Repeat from Step 1 .

NO: The procedure is complete.

INSPECTION PROCEDURE 2: DIFFICULT STEERING WHEEL OPERATION (INSUFFICIENT POWER ASSIST) DIAGNOSIS

STEP 1. Check the drive belt for damage.

Q: Is the drive belt damaged?

YES: Replace the drive belt. Then go to Step 9 .

NO: Go to Step 2.

STEP 2. Check the power steering oil pump drive belt tension.

Refer to 7. DRIVE BELTS (FOR GENERATOR, POWER STEERING OIL PUMP AND AIR CONDITIONING) (CHECK)

.

Q: Is the power steering oil pump drive belt tension within the standard

value?

YES: Go to Step 3.

NO: Adjust the tension. (Refer to 7. DRIVE BELTS (FOR

GENERATOR, POWER STEERING OIL PUMP AND AIR CONDITIONING) (CHECK)

). Then go to Step 9 .

STEP 3. Check the fluid level.

1. Park the vehicle on a flat, level surface, and then start the engine.

2. Turn the steering wheel several times to raise the temperature of the fluid

to approximately 50 - 60°C (122 - 140°F).

3. With the engine running, turn the wheel all the way to the left and right

several times.

4. Check the fluid in the oil reservoir for foaming or milkiness. Check the

difference of the fluid level when the engine is stopped, and while it is

running.

Q: Is the check result OK?

2004 Mitsubishi Endeavor LS

2004 STEERING Power Steering - Endeavor

Page 2824 of 3870

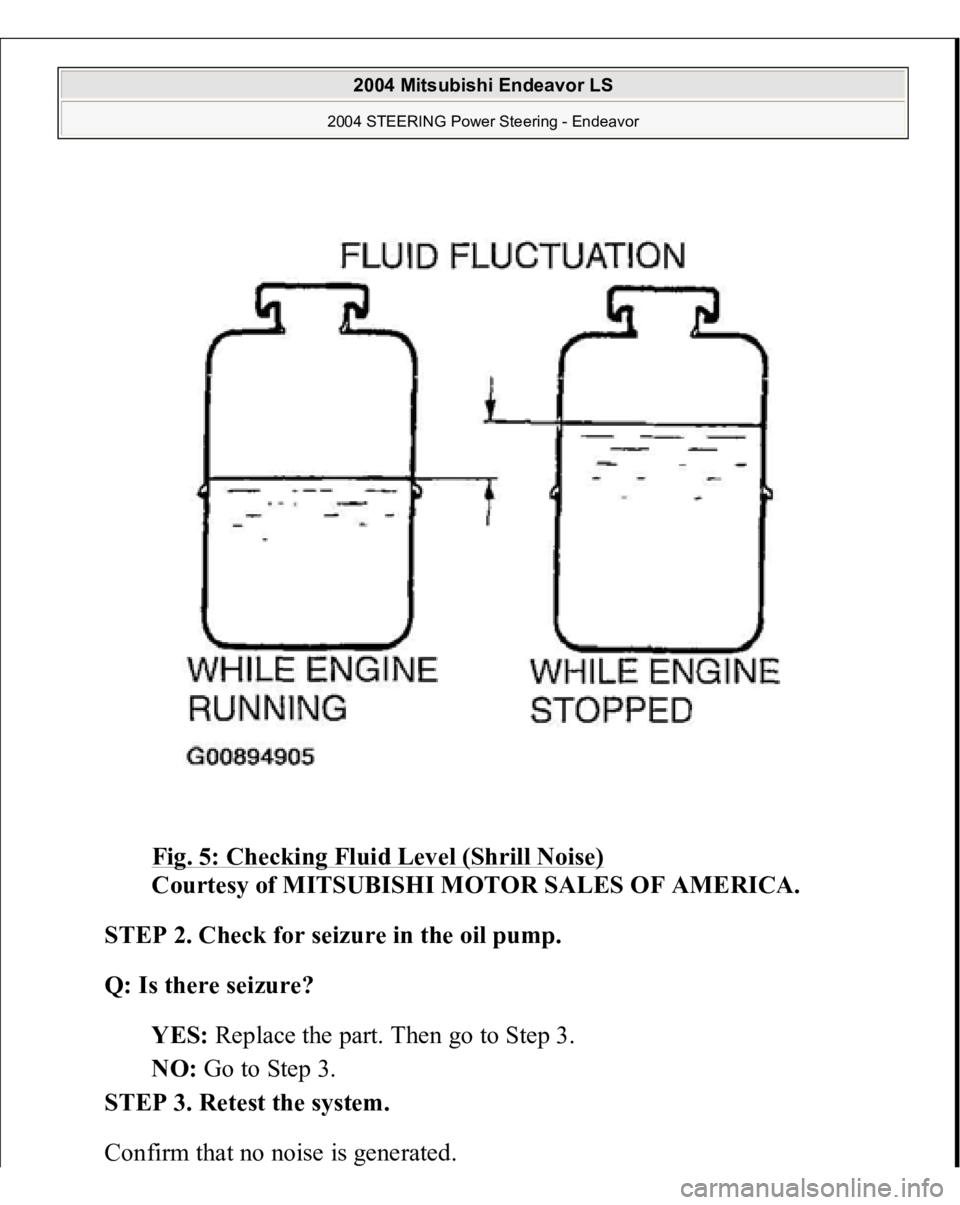

STEP 1. Check the fluid level.

1. Park the vehicle on a flat, level surface, and then start the engine.

2. Turn the steering wheel several times to raise the temperature of the fluid

to approximately 50 - 60°C (122 - 140°F).

3. With the engine running, turn the wheel all the way to the left and right

several times.

4. Check the fluid in the oil reservoir for foaming or milkiness. Check the

difference of the fluid level when the engine is stopped, and while it is

running.

Q: Is the check result OK?

YES: Go to Step 2.

NO: Bleed the air (Refer to POWER STEERING SYSTEM AIR

BLEEDING

). Then

go to Ste

p 3.

2004 Mitsubishi Endeavor LS

2004 STEERING Power Steering - Endeavor

Page 2825 of 3870

Fig. 5: Checking Fluid Level (Shrill Noise)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

STEP 2. Check for seizure in the oil pump.

Q: Is there seizure?

YES: Replace the part. Then go to Step 3.

NO: Go to Step 3.

STEP 3. Retest the system.

Confirm that no noise is generated.

2004 Mitsubishi Endeavor LS

2004 STEERING Power Steering - Endeavor