check engine MITSUBISHI GALANT 1989 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 51 of 1273

11-I

CONTENTSM11AA-

ENGINE

........................

53

CAMSHAFT AND CAMSHAFT OIL

SEALS..........................................68

CYLINDER HEAD GASKET

.................73

ENGINE ASSEMBLY

.........................63

OIL PAN AND OIL SCREEN ...............71

SERVICE ADJUSTMENT

PROCEDURES................................

57

Basic

Idle Speed Adjustment

...........................

.

Refer to GROUP 13

Compression Pressure Check ..............

59

Curb- Idle Speed Adjustment_.___..__._____....___._....Refer to GROUP 13

Dash Pot Inspection and Adjustment 58

Drive Belts Tension Adjustment . 6

1

Engine Oil Check . . .

_. _. . . _. . . . . . . 57

Ignition Timing Adjustment

__..._.__...................Refer to GROUP 16

Lash Adjusters Check ......................

.

57

Manifold Vacuum Inspection

..............

.

60

SPECIAL TOOLS.............................56

SPECIFICATIONS

............................53

General Specifications .....................

.

53

Sealants and Adhesives ....................

56

Service Specifications......................

.

53

Torque Specifications

......................

.

54

TIMINGBELT.................................80

TROUBLESHOOTING

........................56

E,NGINE

CAMSHAFT AND CAMSHAFT OIL

SEAL. . . . . . . . . . . . . . . . . . . ..*............ . . . . . . . . . .19

CYLINDER HEAD GASKET..................25

ENGINE ASSEMBLY.........................14

OIL PAN AND OIL SCREEN. . . . . . . . . . . . . . . .23

SERVICE ADJUSTMENT

PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . ..*.......7

Basic Idle Speed Adjustment

. . . . . . . .._......... . Refer to GROUP 13

Compression Pressure Check . .

.

8

Curb Idle Speed Adjustment

.__................ _. . . . Refer to GROUP 13

Drive Belts Tension Adjustment .........

.

12

Engine Oil Check

..........................

.

7

Ignition Timing Adjustment

_...___............... . . . . . Refer to GROUP 16

Lash Adjusters Check . . . . . . . . . . . .

7

Manifold Vacuum Inspection . . . . . . . . . .9

Timing Belt Tension Adjustment . . . .10

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

.5

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Specifications _. _.2

Sealants and Adhesives

._ _. . . . . . . .5

Service Specifications . . . .2

Torque Specifications . . . . . . . . . . . . . . . .4

TIMING BELT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . m.. .6

Compression Too Low

Connecting Rod Noise/Main Bearing Noise Excessive Engine Rolling and Vibration

Noisy Valves

Oil Pressure Drop

Oil Pressure Too High

Timing Belt Noise

Page 56 of 1273

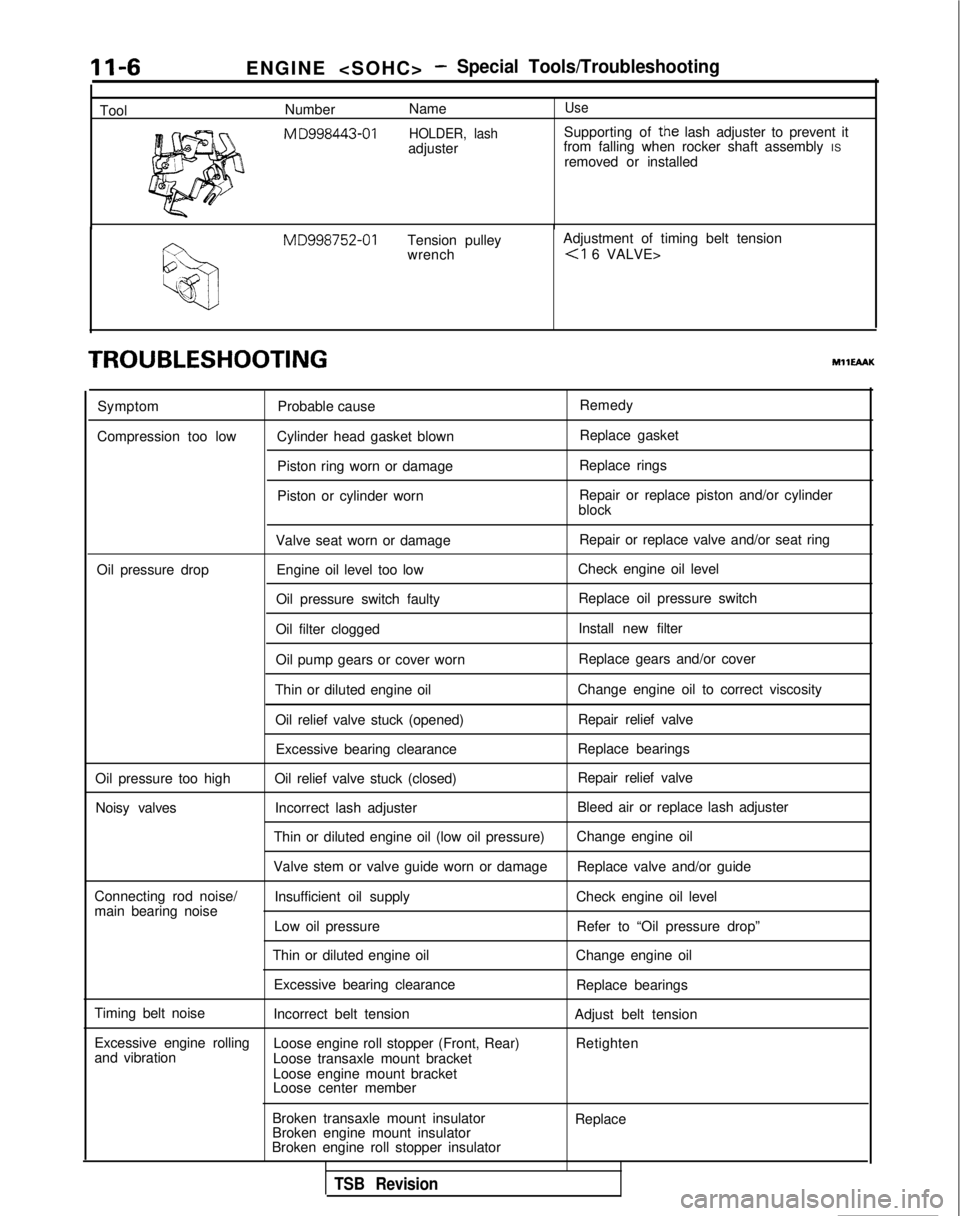

11-6

ToolENGINE

-Special Tools/Troubleshooting

Number

NameUse

M

D998443-01 HOLDER, lashSupporting of the lash adjuster to prevent it

adjuster from falling when rocker shaft assembly

IS

removed or installed MD998752-01

Tension pulley Adjustment of timing belt tension

wrench

TROUBLESHOOTINGMHEAAK

Symptom

Compression too low Probable cause

Cylinder head gasket blown Piston ring worn or damage

Piston or cylinder worn Remedy

Replace gasket

Replace rings

Repair or replace piston and/or cylinder

block

Valve seat worn or damage Repair or replace valve and/or seat ring

Oil pressure drop Engine oil level too low Check engine oil level

Oil pressure switch faulty Replace oil pressure switch

Oil filter clogged Install new filter

Oil pump gears or cover worn Replace gears and/or cover

Thin or diluted engine oil Change engine oil to correct viscosity

Oil relief valve stuck (opened) Repair relief valve

Excessive bearing clearance Replace bearings

Oil pressure too high Oil relief valve stuck (closed) Repair relief valve

Noisy valves Incorrect lash adjuster Bleed air or replace lash adjuster

Thin or diluted engine oil (low oil pressure) Change engine oil

Valve stem or valve guide worn or damage Replace valve and/or guide

Connecting rod noise/ Insufficient oil supply Check engine oil level

main bearing noise

Low oil pressure Refer to “Oil pressure drop”

Thin or diluted engine oil Change engine oil

Excessive bearing clearance Replace bearings

Timing belt noise Incorrect belt tension Adjust belt tension

Excessive engine rolling Loose engine roll stopper (Front, Rear)

and vibration Retighten

Loose transaxle mount bracket

Loose engine mount bracket

Loose center member

Broken transaxle mount insulator

Broken engine mount insulator

Broken engine roll stopper insulator Replace

TSB Revision

Page 57 of 1273

ENGINE

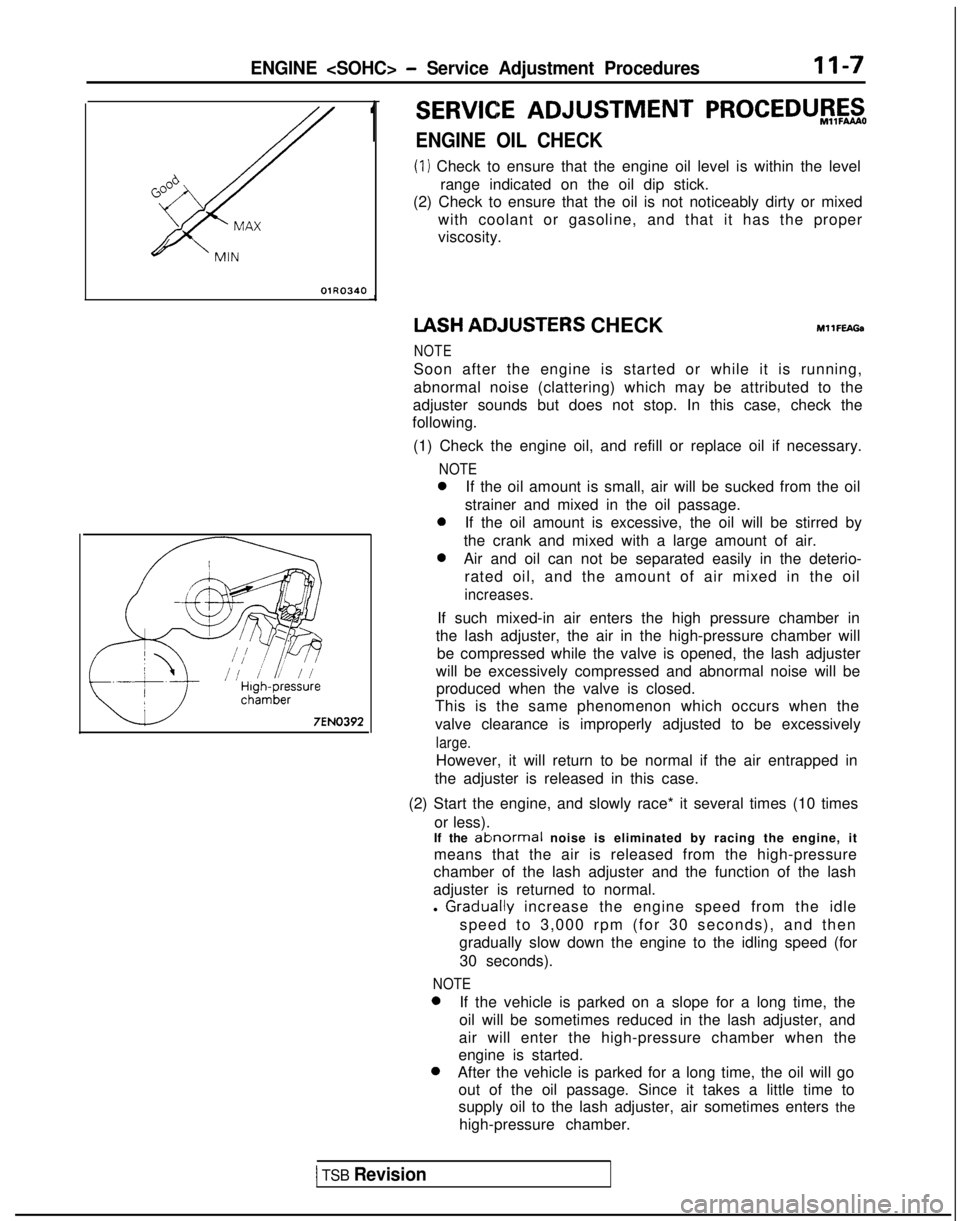

OlR0340

1

SERVICE ADJUSTMENT PROCEDU$$o

ENGINE OIL CHECK

(1) Check to ensure that the engine oil level is within the level

range indicated on the oil dip stick.

(2) Check to ensure that the oil is not noticeably dirty or mixed

with coolant or gasoline, and that it has the proper

viscosity. IASH

ACIJUSTERS CHECKMllFEAGa

NOTE

Soon after the engine is started or while it is running,

abnormal noise (clattering) which may be attributed to the

adjuster sounds but does not stop. In this case, check the

following.

(1) Check the engine oil, and refill or replace oil if necessary.

NOTE

0If the oil amount is small, air will be sucked from the oil

strainer and mixed in the oil passage.

0If the oil amount is excessive, the oil will be stirred by

the crank and mixed with a large amount of air.

0Air and oil can not be separated easily in the deterio- rated oil, and the amount of air mixed in the oil

increases.

If such mixed-in air enters the high pressure chamber in

the lash adjuster, the air in the high-pressure chamber will be compressed while the valve is opened, the lash adjuster

will be excessively compressed and abnormal noise will be produced when the valve is closed.

This is the same phenomenon which occurs when the

valve clearance is improperly adjusted to be excessively

large.

However, it will return to be normal if the air entrapped in

the adjuster is released in this case.

(2) Start the engine, and slowly race* it several times (10 times or less).

If the

ablnormal noise is eliminated by racing the engine, it

means that the air is released from the high-pressure

chamber of the lash adjuster and the function of the lash

adjuster is returned to normal.

l

Graclually increase the engine speed from the idle

speed to 3,000 rpm (for 30 seconds), and then

gradually slow down the engine to the idling speed (for

30 seconds).

NOTE 0

If the vehicle is parked on a slope for a long time, the

oil will be sometimes reduced in the lash adjuster, and

air will enter the high-pressure chamber when the

engine is started. 0

After the vehicle is parked for a long time, the oil will go

out of the oil passage. Since it takes a little time to

supply oil to the lash adjuster, air sometimes enters the

high-pressure chamber.

1 TSB Revision

Page 58 of 1273

II-8ENGINE

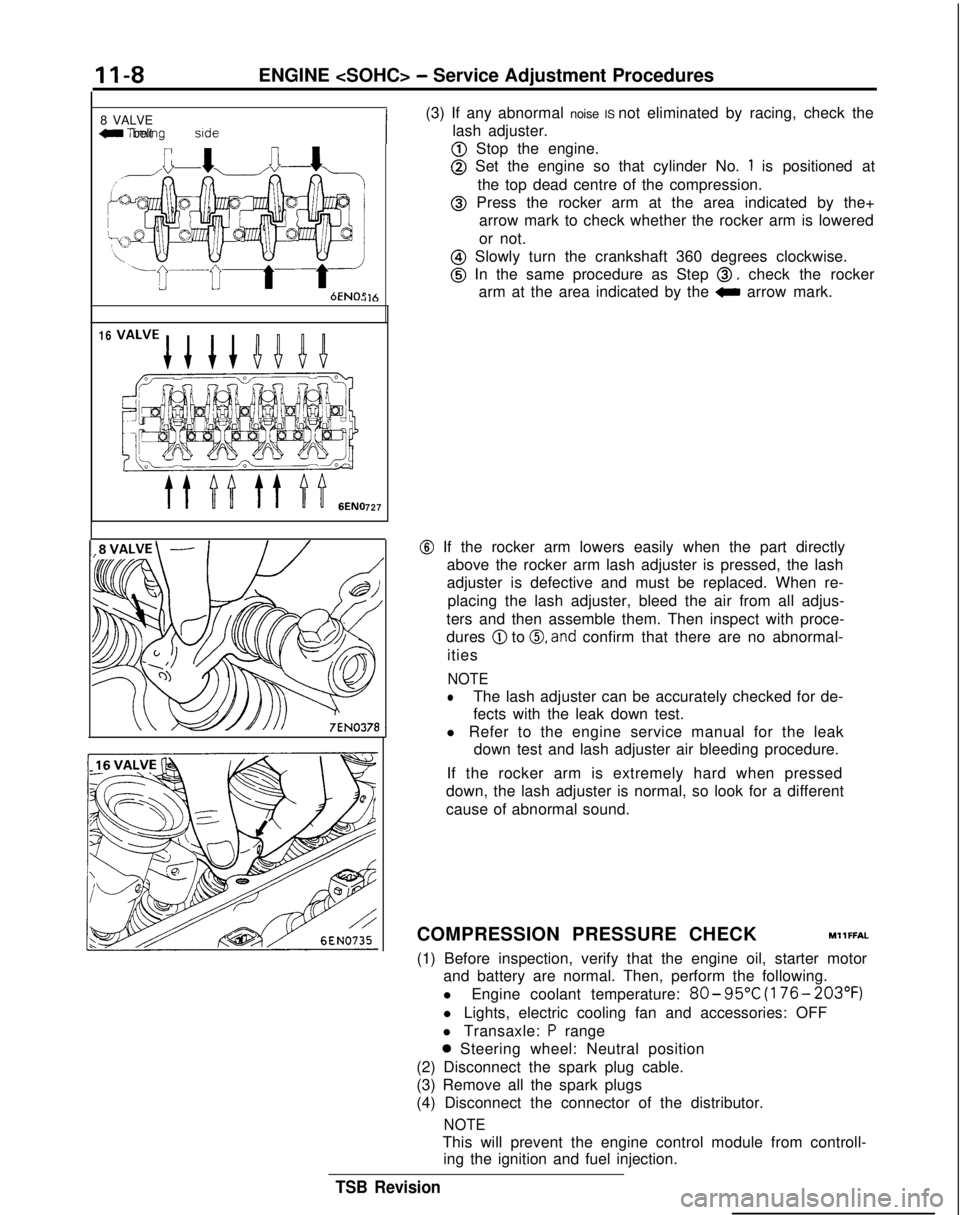

8 VALVE

W Tlmlng belt side

il6

16

727

(3) If any abnormal noise IS not eliminated by racing, check the

lash adjuster.

@ Stop the engine.

@ Set the engine so that cylinder No. 1 is positioned at

the top dead centre of the compression.

@ Press the rocker arm at the area indicated by the+ arrow mark to check whether the rocker arm is lowered

or not.

@ Slowly turn the crankshaft 360 degrees clockwise.

@ In the same procedure as Step 0, check the rocker

arm at the area indicated by the

0 arrow mark.

@ If the rocker arm lowers easily when the part directly

above the rocker arm lash adjuster is pressed, the lash

adjuster is defective and must be replaced. When re-

placing the lash adjuster, bleed the air from all adjus-

ters and then assemble them. Then inspect with proce-

dures

@ to 0, and confirm that there are no abnormal-

ities

NOTE

lThe lash adjuster can be accurately checked for de-

fects with the leak down test.

l Refer to the engine service manual for the leak down test and lash adjuster air bleeding procedure.

If the rocker arm is extremely hard when pressed

down, the lash adjuster is normal, so look for a different

cause of abnormal sound.

COMPRESSION PRESSURE CHECK

MllFFAL

(1) Before inspection, verify that the engine oil, starter motor and battery are normal. Then, perform the following.

l Engine coolant temperature:

80- 95°C

(176- 203°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle:

P range

0 Steering wheel: Neutral position

(2) Disconnect the spark plug cable.

(3) Remove all the spark plugs

(4) Disconnect the connector of the distributor.

NOTE

This will prevent the engine control module from controll- ing the ignition and fuel injection.

TSB Revision

Page 59 of 1273

ENGINE

(5) Cover the spark plug holes with a cloth, etc., and crank the engine. Then verify that no foreign material sticks to the

cloth, etc.

Caution

1. During cranking, be especially careful of the spark plug

installing hole.

2.Very hot water, oil, fuel, etc., which may have entered

the cylinder somehow, will violently spout through the spark plug hole if the compression is measured in the

entrapped state. This is very dangerous.

MANIFOILD VACUUM INSPECTIONMllFNAC

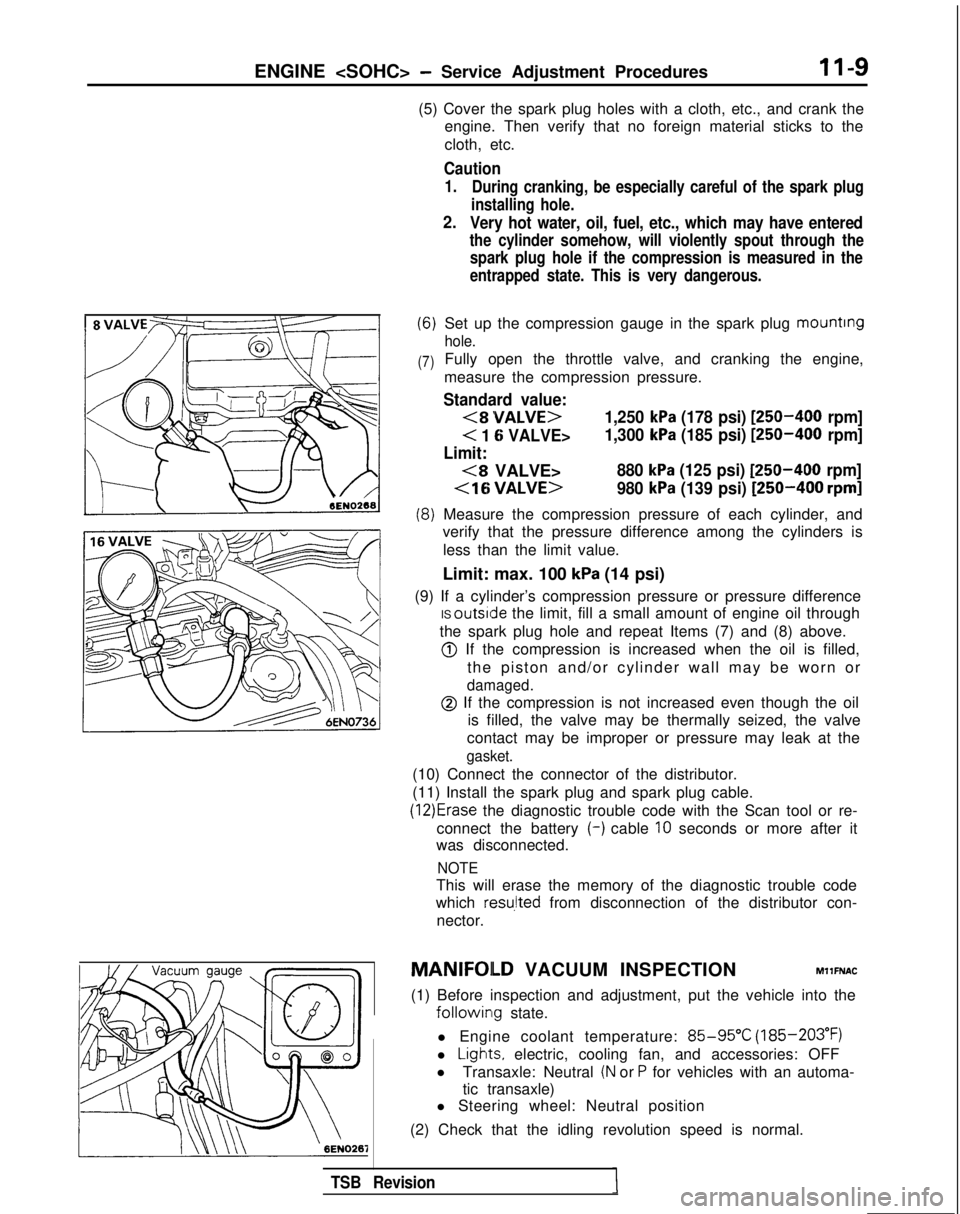

(6)

(7)

(8)

Set up the compression gauge in the spark plug mounting

hole.

Fully open the throttle valve, and cranking the engine,

measure the compression pressure.

Standard value:

<8VALVE>1,250 kPa (178 psi) [250-400 rpm]

< 1 Ei VALVE>

1,300 kPa (185 psi) [250-400 rpm]

Limit:

(8 VALVE>880 kPa (125 psi) [250-400 rpm]

[250-400 rpm]

Measure the compression pressure of each cylinder, and

verify that the pressure difference among the cylinders is

less than the limit value.

Limit: max. 100

kPa (14 psi)

(9) If a cylinder’s compression pressure or pressure difference IS outside

the limit, fill a small amount of engine oil through

the spark plug hole and repeat Items (7) and (8) above.

@ If the compression is increased when the oil is filled, the piston and/or cylinder wall may be worn or

damaged.

@ If the compression is not increased even though the oil is filled, the valve may be thermally seized, the valve

contact may be improper or pressure may leak at the

gasket.

(10) Connect the connector of the distributor.

(11) Install the spark plug and spark plug cable.

(12)Erase the diagnostic trouble code with the Scan tool or re-

connect the battery (-)

cable

10 seconds or more after it

was disconnected.

NOTE

This will erase the memory of the diagnostic trouble code

which

resu,lted from disconnection of the distributor con-

nector.

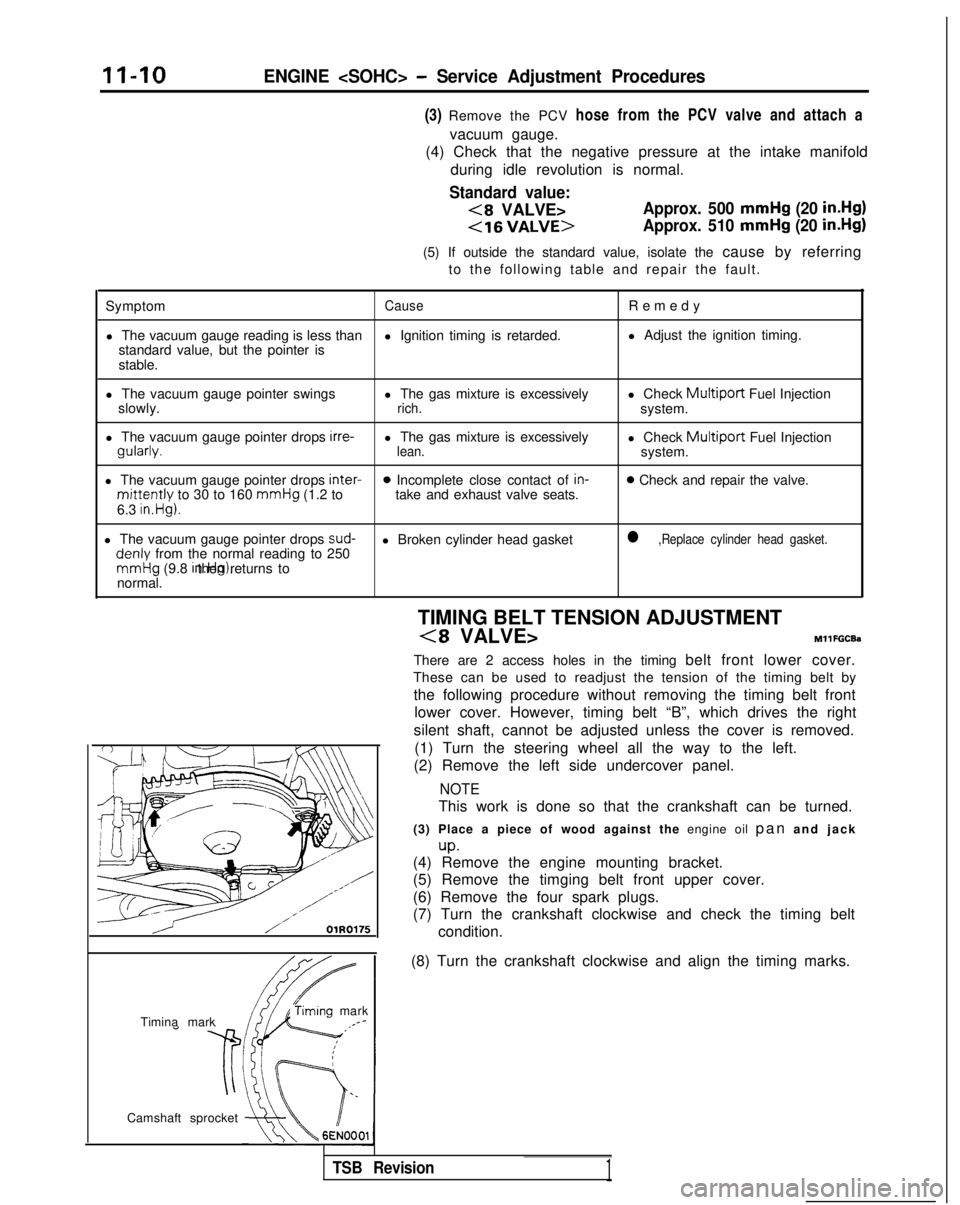

(1) Before inspection and adjustment, put the vehicle into the

followin~g state.

l Engine coolant temperature:

85-95°C (185-203°F)

l

Ligt-Its, electric, cooling fan, and accessories: OFF

l Transaxle: Neutral

(N or P for vehicles with an automa-

tic transaxle)

l Steering wheel: Neutral position

(2) Check that the idling revolution speed is normal.

TSB Revision

Page 60 of 1273

II-IOENGINE

(3) Remove the PCV hose from the PCV valve and attach a

vacuum gauge.

(4) Check that the negative pressure at the intake manifold

during idle revolution is normal.

Standard value:

(8 VALVE>Approx. 500 mmHg (20 in.Hg)

<16VALVE>Approx. 510 mmHg (20 in.Hg)

(5) If outside the standard value, isolate the cause by referring

to the following table and repair the fault.

Symptom

CauseRemed

y

l The vacuum gauge reading is less than l Ignition timing is retarded.l Adjust the ignition timing.

standard value, but the pointer is

stable.

l The vacuum gauge pointer swings l The gas mixture is excessivelyl Check

Multiport Fuel Injection

slowly.rich.system.

l The vacuum gauge pointer drops irre-

l The gas mixture is excessively

l Check

Multiport Fuel Injectiongularly.lean.system.

l The vacuum gauge pointer drops inter-

0 Incomplete close contact of in-0 Check and repair the valve.mittently to 30 to 160

mmHg

(1.2 to take and exhaust valve seats.

6.3 in.Hg).

l The vacuum gauge pointer drops sud-l Broken cylinder head gasketl ,Replace cylinder head gasket. denly

from the normal reading to 250 mmHg

(9.8 in.Hg). then returns to

normal.

/ OlR0175

condition.

Timina mark

‘timing mark._*-

Camshaft sprocket TIMING BELT TENSION ADJUSTMENT

(8 VALVE>MllFGCEa

There are 2 access holes in the timing belt front lower cover.

These can be used to readjust the tension of the timing belt by

the following procedure without removing the timing belt front lower cover. However, timing belt “B”, which drives the right

silent shaft, cannot be adjusted unless the cover is removed. (1) Turn the steering wheel all the way to the left.

(2) Remove the left side undercover panel.

NOTE

This work is done so that the crankshaft can be turned.

(3) Place a piece of wood against the engine oil pan and jac

k

up.(4) Remove the engine mounting bracket.

(5) Remove the timging belt front upper cover.

(6) Remove the four spark plugs.

(7) Turn the crankshaft clockwise and check the timing belt

(8) Turn the crankshaft clockwise and align the timing marks.

TSB Revision1

Page 62 of 1273

11-12ENGINE

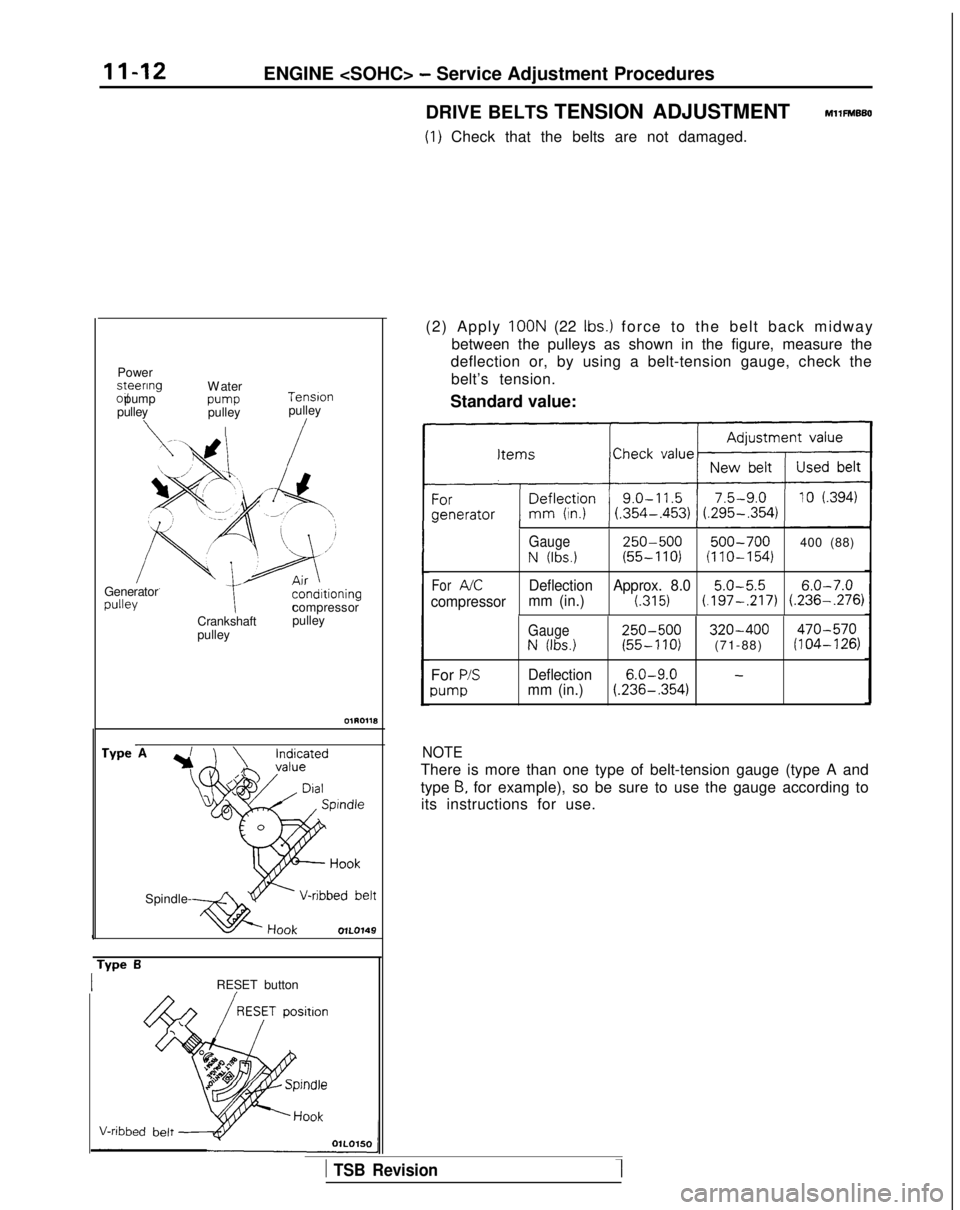

DRIVE BELTS TENSION ADJUSTMENT

MllFMBBO

(1) Check that the belts are not damaged.

Power steenng

oil pump

pulley

\

W

ater

pump

pulley

I Tension

pulley/

Generator

compressor

Crankshaft

pulley pulley

We

Spindle----As.

IRESET button (2) Apply

IOON (22 Ibs.) force to the belt back midwa

y

between the pulleys as shown in the figure, measure the

deflection or, by using a belt-tension gauge, check the

belt’s tension.

Standard value:

Gauge250-500500-700400 (88)

N (Ibs.)(55-110)(110-154)

ForAKDeflection Approx. 8.05.0-5.56.0-7.0

compressor mm (in.)(.315)(.197-,217) (.236-.276)

For P/S

pump Gauge

250-500320-400470-570

N (Ibs.)(55-110)(71-88)(104-126)

Deflection 6.0-9.0

-mm (in.)(.236-,354)

NOTE

There is more than one type of belt-tension gauge (type A and

type

8, for example), so be sure to use the gauge according to

its instructions for use.

1 TSB Revision

Page 63 of 1273

ENGINE

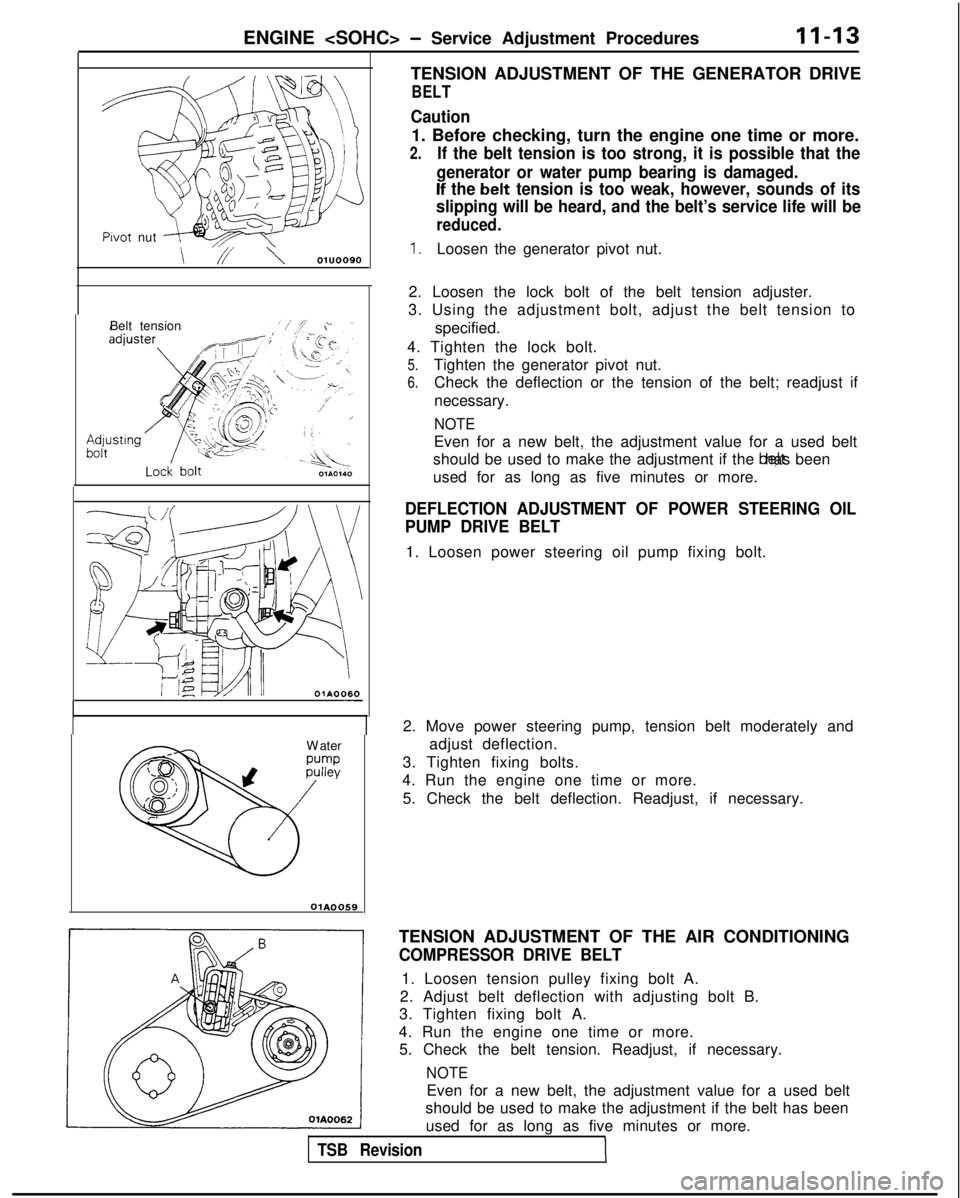

TENSION ADJUSTMENT OF THE GENERATOR DRIVE

BELT

Pwot

nut

,,,\

\ // \ 01u0090

Belt tension 01A0060

-

W

ater

OiA0059

Caution

1. Before checking, turn the engine one time or more.

2.If the belt tension is too strong, it is possible that the

generator or water pump bearing is damaged.

If the b’elt tension is too weak, however, sounds of its

slipping will be heard, and the belt’s service life will be

reduced.

1.Loosen the generator pivot nut.

2. Loosen the lock bolt of the belt tension adjuster.

3. Using the adjustment bolt, adjust the belt tension to

specified.

4. Tighten the lock bolt.

5.Tighten the generator pivot nut.

6.Check the deflection or the tension of the belt; readjust if

necessary.

NOTE

Even for a new belt, the adjustment value for a used belt

should be used to make the adjustment if the belt has been

used for as long as five minutes or more.

DEFLECTION ADJUSTMENT OF POWER STEERING OIL

PUMP DRIVE BELT

1. Loosen power steering oil pump fixing bolt.

2. Move power steering pump, tension belt moderately and adjust deflection.

3. Tighten fixing bolts.

4. Run the engine one time or more.

5. Check the belt deflection. Readjust, if necessary.

TENSION ADJUSTMENT OF THE AIR CONDITIONING

COMPRESSOR DRIVE BELT

1. Loosen tension pulley fixing bolt A.

2. Adjust belt deflection with adjusting bolt B.

3. Tighten fixing bolt A.

4. Run the engine one time or more. 5. Check the belt tension. Readjust, if necessary.

NOTE

Even for a new belt, the adjustment value for a used belt

should be used to make the adjustment if the belt has been

used for as long as five minutes or more.

TSB RevisionI

Page 66 of 1273

11-16ENGINE

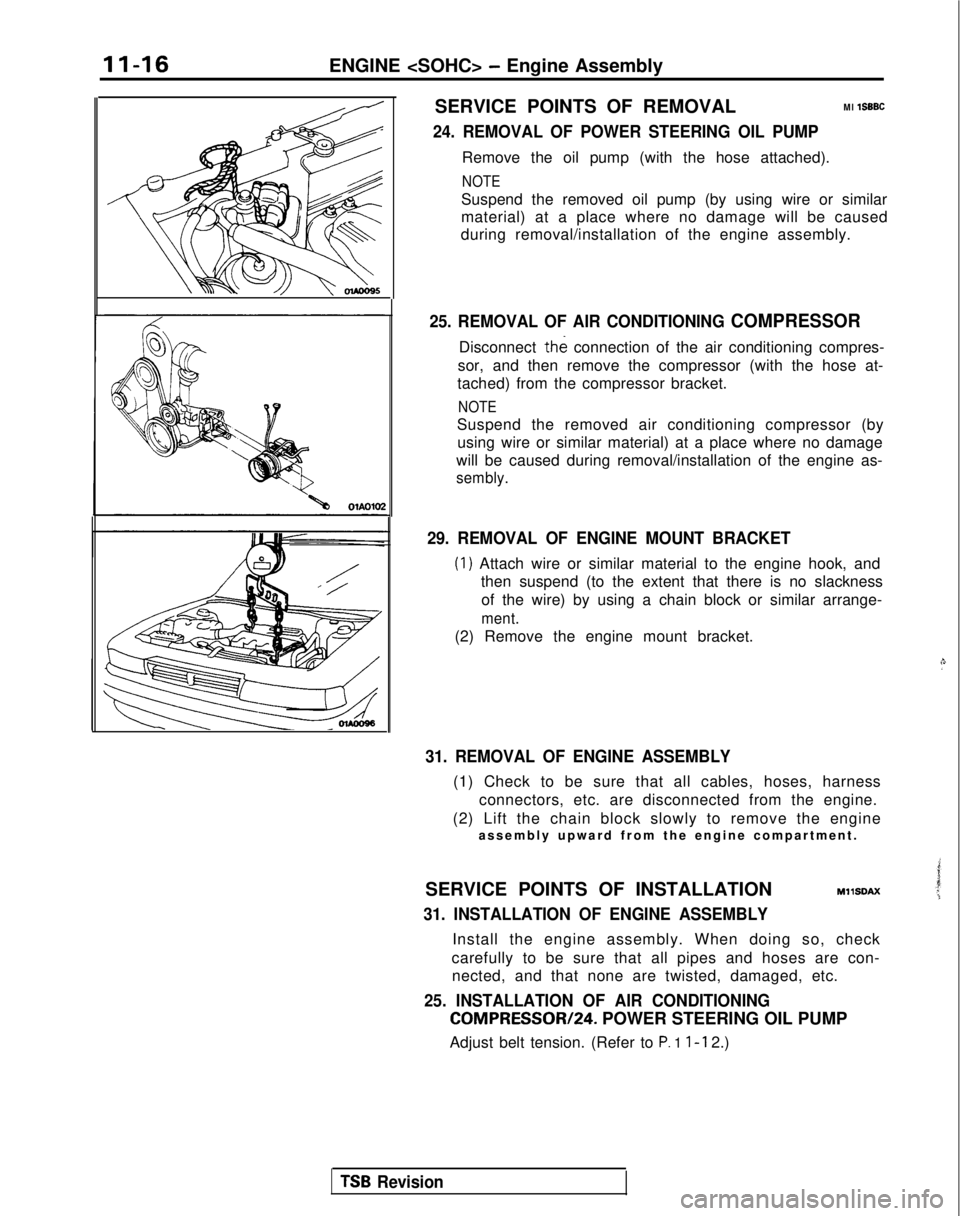

SERVICE POINTS OF REMOVAL

Ml 1SBBC

24. REMOVAL OF POWER STEERING OIL PUMP

Remove the oil pump (with the hose attached).

NOTE

Suspend the removed oil pump (by using wire or similar

material) at a place where no damage will be caused

during removal/installation of the engine assembly.

25. REMOVAL OF AIR CONDITIONING COMPRESSOR

Disconnect the

connection of the air conditioning compres-

sor, and then remove the compressor (with the hose at-

tached) from the compressor bracket.

NOTE

Suspend the removed air conditioning compressor (by using wire or similar material) at a place where no damage

will be caused during removal/installation of the engine as-

sembly.

29. REMOVAL OF ENGINE MOUNT BRACKET

(1) Attach wire or similar material to the engine hook, and then suspend (to the extent that there is no slackness

of the wire) by using a chain block or similar arrange-

ment.

(2) Remove the engine mount bracket.

31. REMOVAL OF ENGINE ASSEMBLY

(1) Check to be sure that all cables, hoses, harness connectors, etc. are disconnected from the engine.

(2) Lift the chain block slowly to remove the engine assembly upward from the engine compartment

.

SERVICE POINTS OF INSTALLATION

MllSDAX

31. INSTALLATION OF ENGINE ASSEMBLY

Install the engine assembly. When doing so, check

carefully to be sure that all pipes and hoses are con- nected, and that none are twisted, damaged, etc.

25. INSTALLATION OF AIR CONDITIONING

COMPRESSORI24. POWER STEERING OIL PUMP

Adjust belt tension. (Refer to

P. 1 1-l 2.)

TSB Revision

Page 73 of 1273

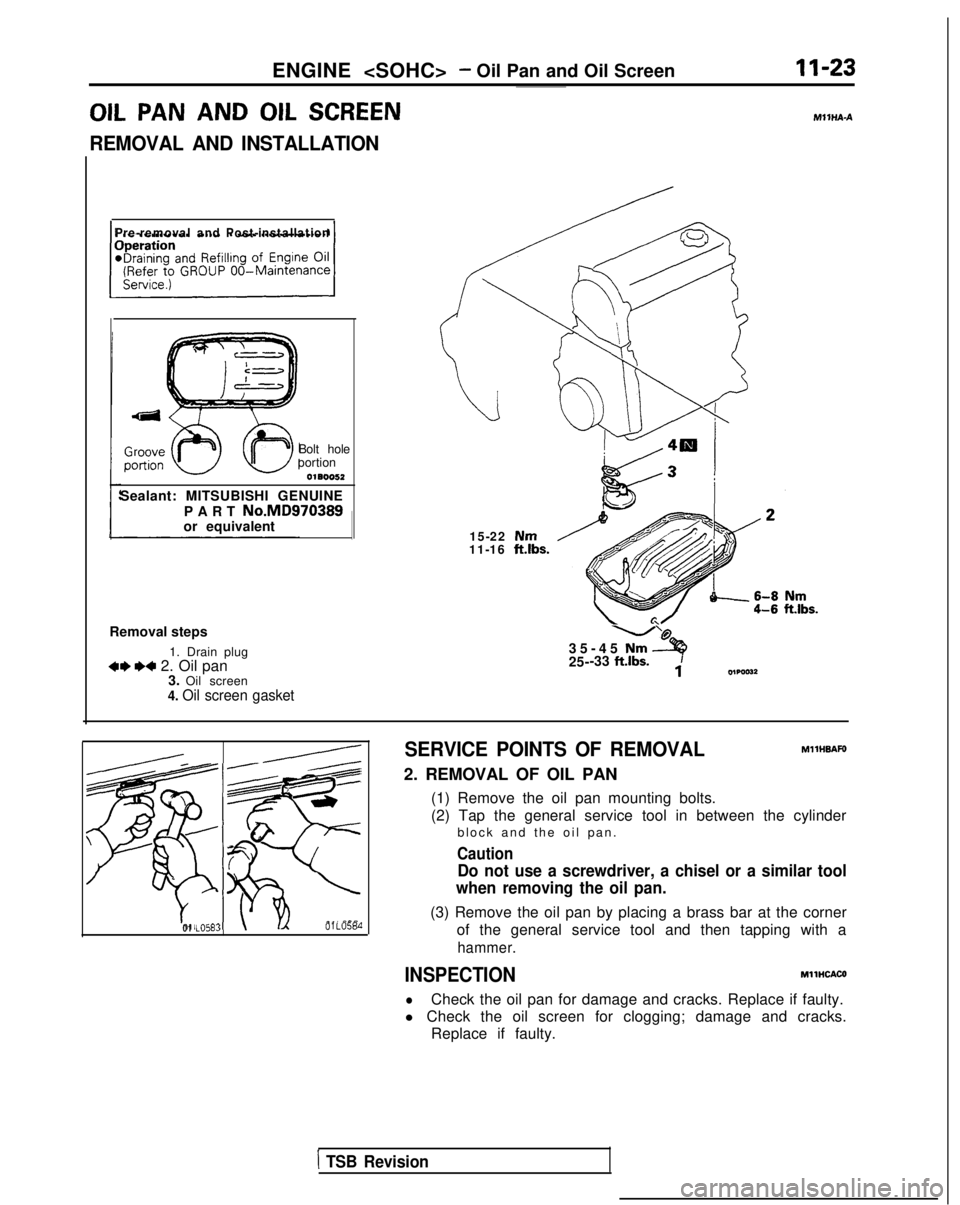

ENGINE

OIL PAN

AND

OIL SCREENMllHA-A

REMOVAL AND INSTALLATION

Pre-removal and Post-installation

Bolt hole

portion

0180052

Sealant: MITSUBISHI GENUINE

PART

No.MD970389or equivalent

Removal steps 1. Drain plug

4**4 2. Oil pan3. Oil screen

4. Oil screen gasket

15-22 Nm11-16 ft.lbs.

U’@

35-45 Nm a25- -33 ft.lbs.iowaI32

d- -<

--,\9 -

\’ 63

%e

;

01 LO583\01 LO584

SERVICE POINTS OF REMOVALMllHBAFO

2. REMOVAL OF OIL PAN

(1) Remove the oil pan mounting bolts.

(2) Tap the general service tool in between the cylinderblock and the oil pan

.

Caution

Do not use a screwdriver, a chisel or a similar tool

when removing the oil pan.

(3) Remove the oil pan by placing a brass bar at the corner

of the general service tool and then tapping with a

hammer.

INSPECTIONMllHCACO

lCheck the oil pan for damage and cracks. Replace if faulty.

l Check the oil screen for clogging; damage and cracks. Replace if faulty.

1 TSB Revision