check engine MITSUBISHI GALANT 1989 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 129 of 1273

ENGINE

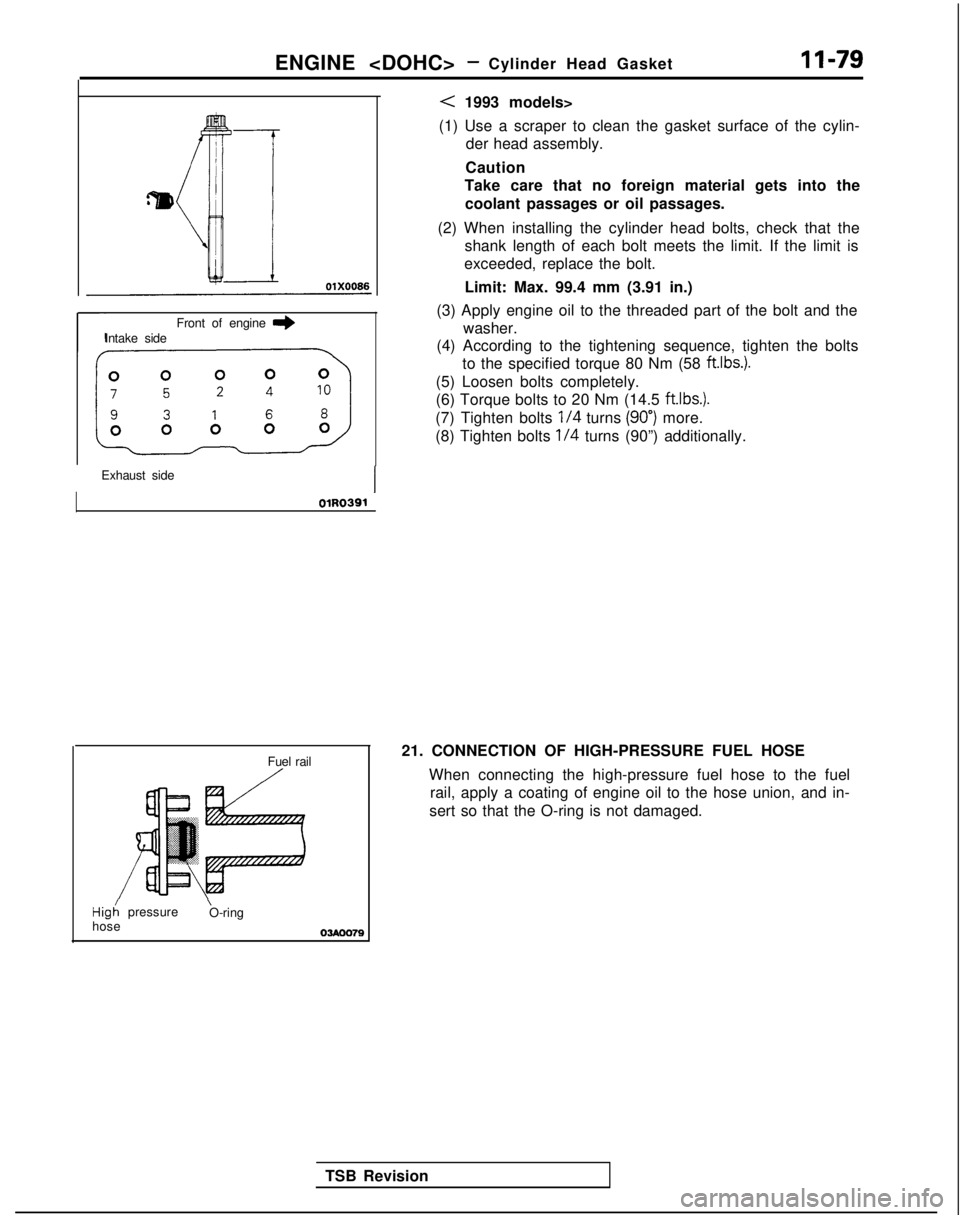

Front of engine I)Intake side

Exhaust side

OlR0391

Fuel rail/

Hig; pressure \

O-ring

hose

03Aoo79

< 1993 models>

(1) Use a scraper to clean the gasket surface of the cylin- der head assembly.

Caution

Take care that no foreign material gets into the

coolant passages or oil passages.

(2) When installing the cylinder head bolts, check that the shank length of each bolt meets the limit. If the limit is

exceeded, replace the bolt.

Limit: Max. 99.4 mm (3.91 in.)

(3) Apply engine oil to the threaded part of the bolt and the washer.

(4) According to the tightening sequence, tighten the bolts

to the specified torque 80 Nm (58 ftlbs.).

(5) Loosen bolts completely.

(6) Torque bolts to 20 Nm (14.5 ftlbs.).

(7) Tighten bolts

l/4 turns (90”) more.

(8) Tighten bolts

l/4 turns (90”) additionally.

TSB Revision 21. CONNECTION OF HIGH-PRESSURE FUEL HOSE

When connecting the high-pressure fuel hose to the fuelrail, apply a coating of engine oil to the hose union, and in-

sert so that the O-ring is not damaged.

Page 133 of 1273

ENGINE

1

r

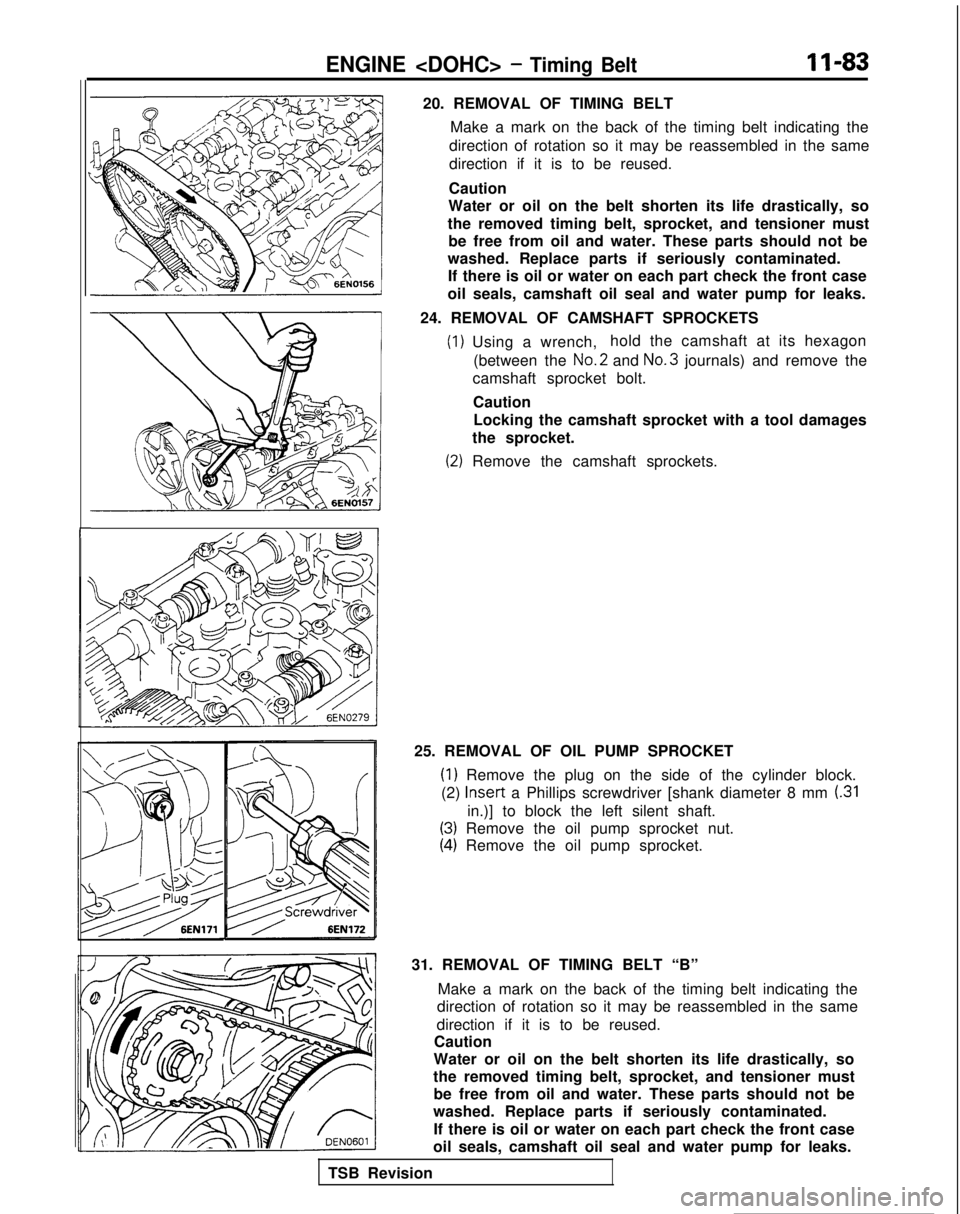

20. REMOVAL OF TIMING BELTMake a mark on the back of the timing belt indicating the

direction of rotation so it may be reassembled in the same

direction if it is to be reused.

Caution

Water or oil on the belt shorten its life drastically, so

the removed timing belt, sprocket, and tensioner must be free from oil and water. These parts should not be

washed. Replace parts if seriously contaminated. If there is oil or water on each part check the front case

oil seals, camshaft oil seal and water pump for leaks.

24. REMOVAL OF CAMSHAFT SPROCKETS

(1) Using a wrench, hold the camshaft at its hexagon

(between the No.2

and No.3

journals) and remove the

camshaft sprocket bolt.

CautionLocking the camshaft sprocket with a tool damages

the sprocket.

(2) Remove the camshaft sprockets.

25. REMOVAL OF OIL PUMP SPROCKET

(1) Remove the plug on the side of the cylinder block.

(2) Insert

a Phillips screwdriver [shank diameter 8 mm

(.31

in.)] to block the left silent shaft.

(3) Remove the oil pump sprocket nut.

(4) Remove the oil pump sprocket.

31. REMOVAL OF TIMING BELT “B” Make a mark on the back of the timing belt indicating the

direction of rotation so it may be reassembled in the same

direction if it is to be reused.

Caution

Water or oil on the belt shorten its life drastically, so

the removed timing belt, sprocket, and tensioner must be free from oil and water. These parts should not be

washed. Replace parts if seriously contaminated.

If there is oil or water on each part check the front case

oil seals, camshaft oil seal and water pump for leaks.

TSB Revision

Page 134 of 1273

11-84

ENGINE

QdiJ00°00B

rackCrack

Crack ’ 7EN207

Separation

Rounded belt side

Abnormal wear (fluffy canvas fiber)

7EN208

Rubber

exposed

Tooth

missing and

canvas fiber exposed

7EN209

6EN0159

Y

1

-

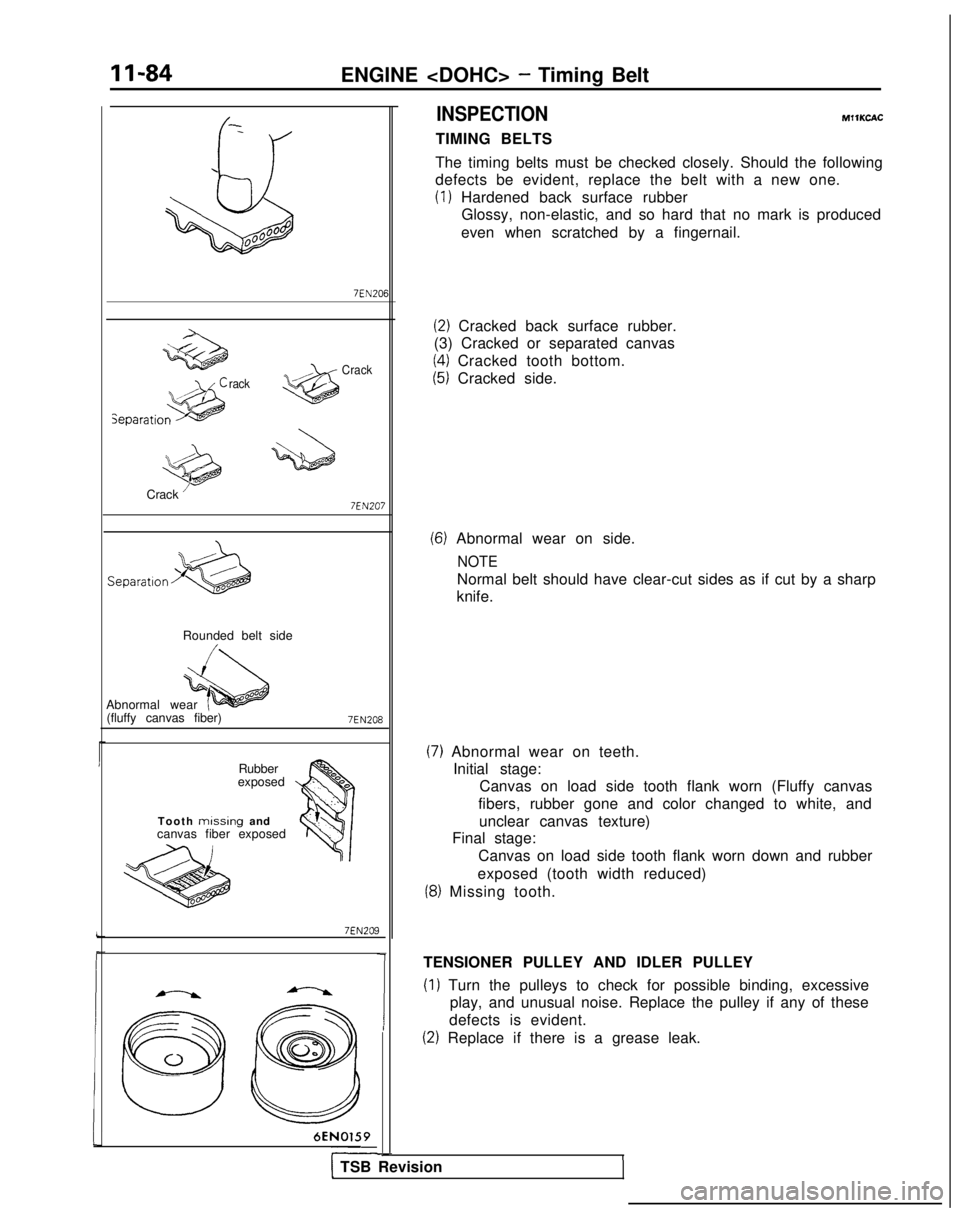

INSPECTION

TIMING BELTS MIlKCAC

The timing belts must be checked closely. Should the following

defects be evident, replace the belt with a new one.

(1) Hardened back surface rubber Glossy, non-elastic, and so hard that no mark is produced

even when scratched by a fingernail.

(2) Cracked back surface rubber.

(3) Cracked or separated canvas

(4) Cracked tooth bottom.

(5) Cracked side.

(6) Abnormal wear on side.

NOTE

Normal belt should have clear-cut sides as if cut by a sharp

knife.

(7) Abnormal wear on teeth. Initial stage: Canvas on load side tooth flank worn (Fluffy canvas

fibers, rubber gone and color changed to white, and unclear canvas texture)

Final stage:

Canvas on load side tooth flank worn down and rubber

exposed (tooth width reduced)

(8) Missing tooth.

TENSIONER PULLEY AND IDLER PULLEY

(1) Turn the pulleys to check for possible binding, excessive play, and unusual noise. Replace the pulley if any of these

defects is evident.

(2) Replace if there is a grease leak.

I1 TSB Revision

Page 135 of 1273

ENGINE

6EN0280

6EN0161

/6Ei40162

6

68

Plug

6EN0281 j

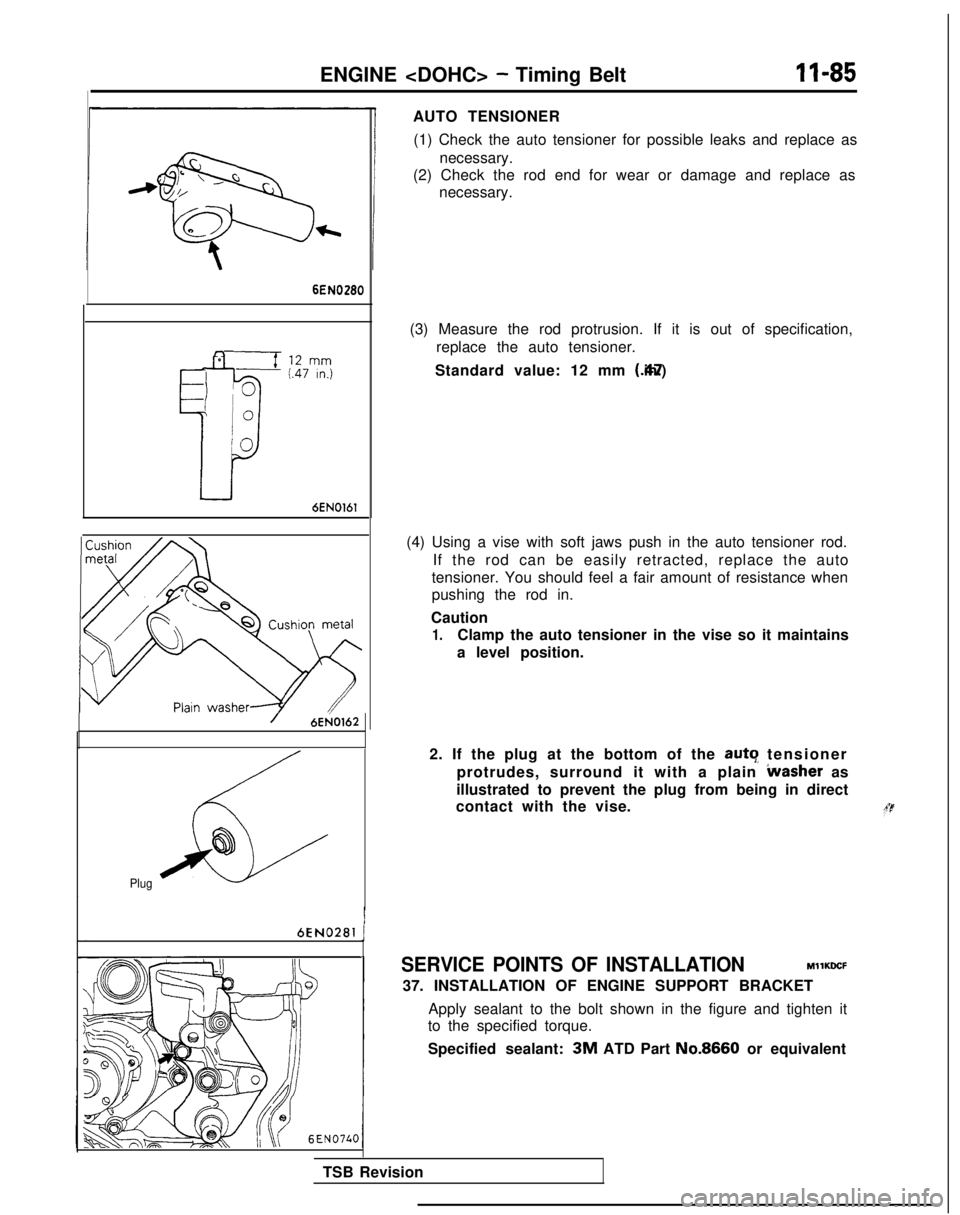

AUTO TENSIONER

(1) Check the auto tensioner for possible leaks and replace as necessary.

(2) Check the rod end for wear or damage and replace as necessary.

(3) Measure the rod protrusion. If it is out of specification, replace the auto tensioner.

Standard value: 12 mm (.47 in.)

(4) Using a vise with soft jaws push in the auto tensioner rod. If the rod can be easily retracted, replace the auto

tensioner. You should feel a fair amount of resistance when

pushing the rod in.

Caution

1.Clamp the auto tensioner in the vise so it maintains

a level position.

2. If the plug at the bottom of the auto

tensioner

protrudes, surround it with a plain

Lvasher as

illustrated to prevent the plug from being in direct

contact with the vise.

SERVICE POINTS OF INSTALLATION MllKDCF

37. INSTALLATION OF ENGINE SUPPORT BRACKET

Apply sealant to the bolt shown in the figure and tighten it

to the specified torque.

Specified sealant:

3M ATD Part No.8660 or equivalent

TSB Revision

Page 140 of 1273

II-90ENGINE

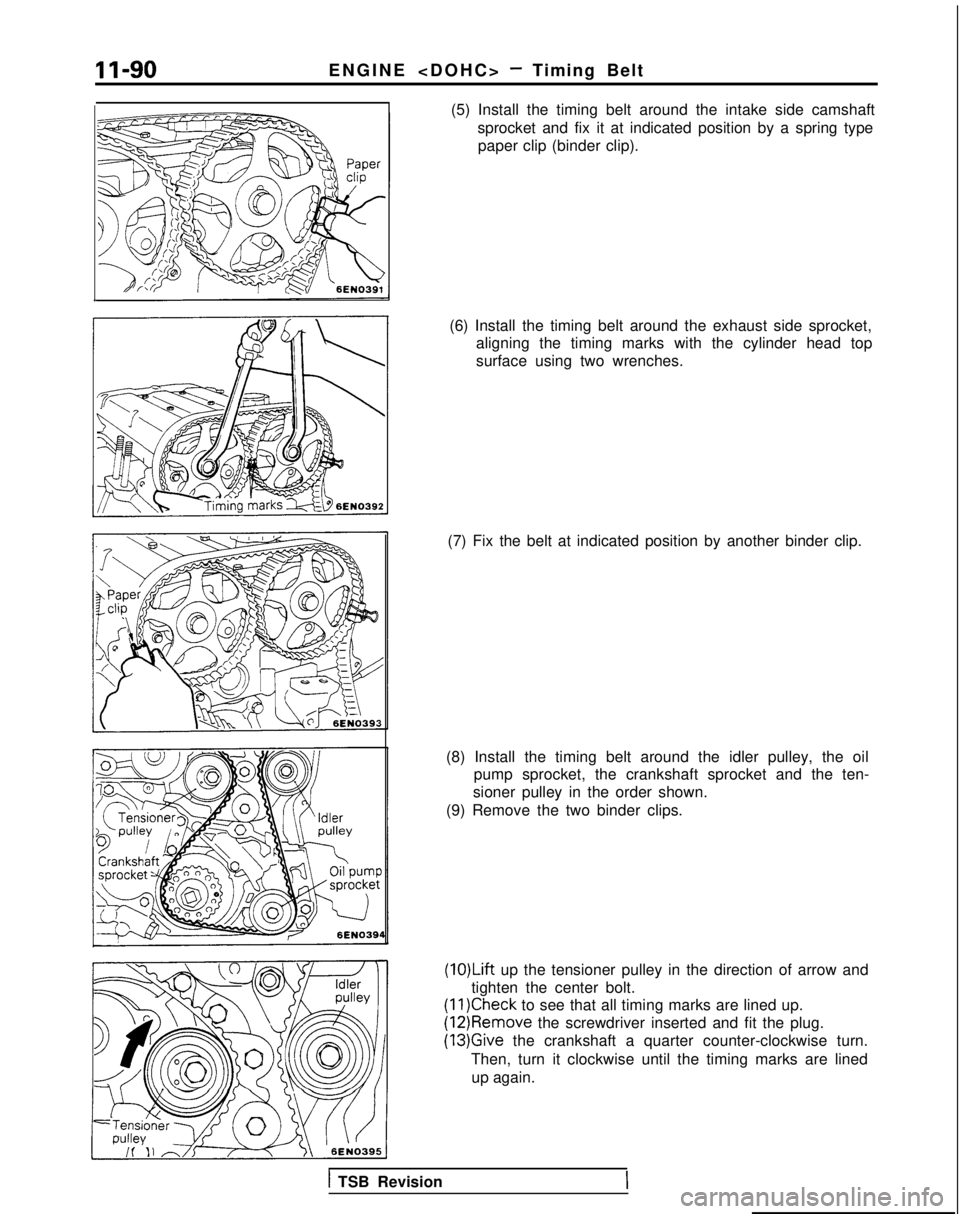

(5) Install the timing belt around the intake side camshaft sprocket and fix it at indicated position by a spring typepaper clip (binder clip).

(6) Install the timing belt around the exhaust side sprocket, aligning the timing marks with the cylinder head top

surface using two wrenches.

(7) Fix the belt at indicated position by another binder clip.

(8) Install the timing belt around the idler pulley, the oil pump sprocket, the crankshaft sprocket and the ten-

sioner pulley in the order shown.

(9) Remove the two binder clips.

(1O)Lift up the tensioner pulley in the direction of arrow and

tighten the center bolt.

(11)Check to see that all timing marks are lined up. (12)Remove

the screwdriver inserted and fit the plug.

(13)Give the crankshaft a quarter counter-clockwise turn.

Then, turn it clockwise until the timing marks are lined up again.

1 TSB Revision

Page 141 of 1273

ENGINE

J

Tensioner armTensioner arm

TSB Revision

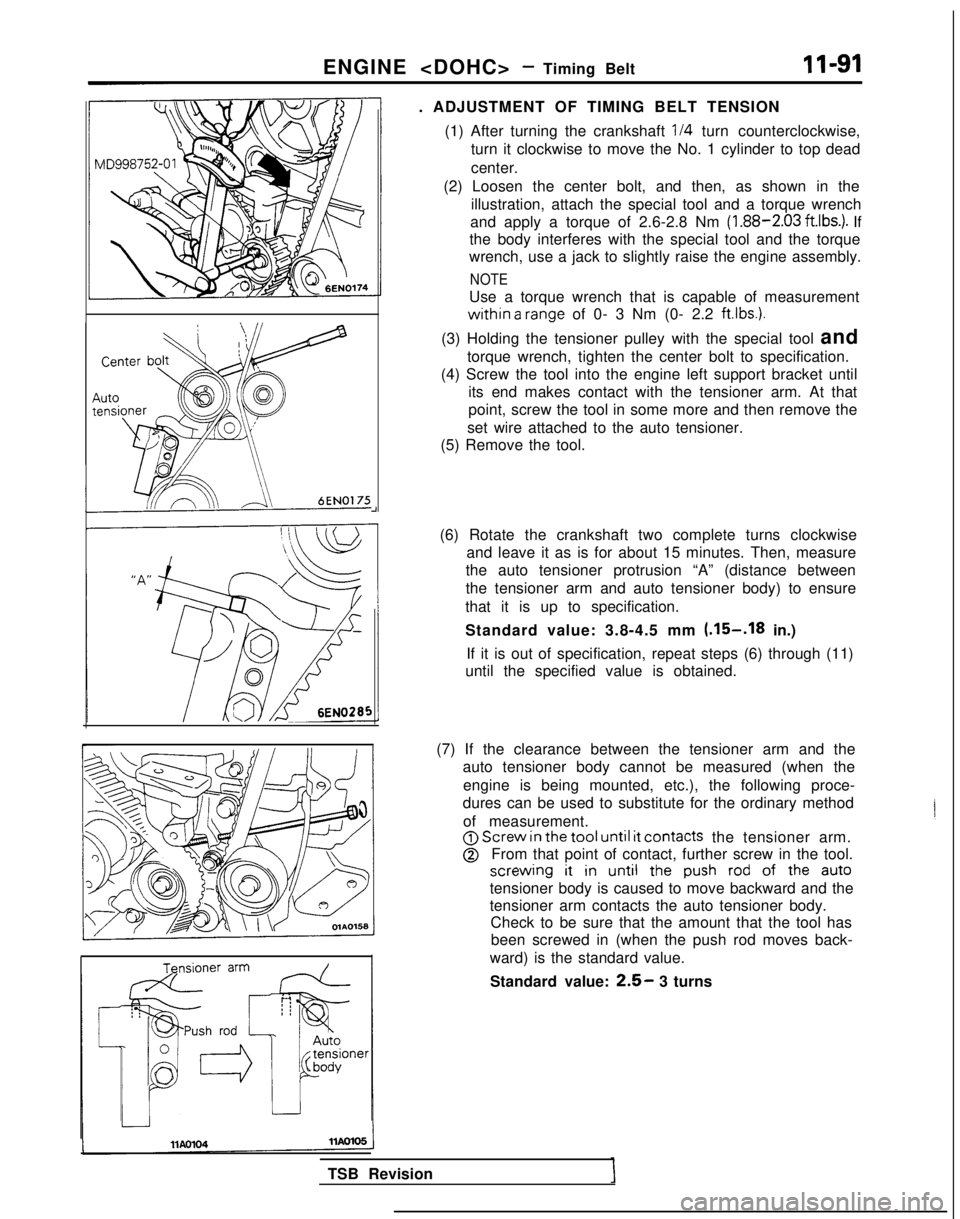

. ADJUSTMENT OF TIMING BELT TENSION

(1) After turning the crankshaft

l/4 turn counterclockwise,

turn it clockwise to move the No. 1 cylinder to top dead

center.

(2) Loosen the center bolt, and then, as shown in the illustration, attach the special tool and a torque wrench

and apply a torque of 2.6-2.8 Nm (1.88-2.03

ft.lbs.). If

the body interferes with the special tool and the torque

wrench, use a jack to slightly raise the engine assembly.

NOTE

Use a torque wrench that is capable of measurement

within a range of 0- 3 Nm (0- 2.2 ftlbs.).

(3) Holding the tensioner pulley with the special tool and torque wrench, tighten the center bolt to specification.

(4) Screw the tool into the engine left support bracket until its end makes contact with the tensioner arm. At that

point, screw the tool in some more and then remove the

set wire attached to the auto tensioner.

(5) Remove the tool.

(6) Rotate the crankshaft two complete turns clockwise and leave it as is for about 15 minutes. Then, measure

the auto tensioner protrusion “A” (distance between

the tensioner arm and auto tensioner body) to ensure

that it is up to specification.

Standard value: 3.8-4.5 mm

(.15-.I8 in.)

If it is out of specification, repeat steps (6) through (11)

until the specified value is obtained.

(7) If the clearance between the tensioner arm and the auto tensioner body cannot be measured (when the

engine is being mounted, etc.), the following proce-

dures can be used to substitute for the ordinary method

of measurement.

@j Screw in

the tool until it

contacts the tensioner arm.

@From that point of contact, further screw in the tool.

screwing it in

until the push

rod

of the auto

tensioner body is caused to move backward and the

tensioner arm contacts the auto tensioner body.

Check to be sure that the amount that the tool has

been screwed in (when the push rod moves back-

ward) is the standard value.

Standard value:

2.5- 3 turns

Page 143 of 1273

13-1

FUEL

CONTENTSM’ISAA--

AUTO-CRUISE CONTROL SYSTEM.............

.

332

AUTO-CRUISE CONTROL ............................. 408

SERVICE ADJUSTMENT PROCEDURES .................397

Accelerator Cables

inspectron and Adjustment ........

.

398 Auto-cruise

Control System Inspection

..............397

Individual Parts Inspection ......................

401SPECfAL

TOOLS

.....................................

333

SPECIFICATIONS .................................... 332

TROUBLESHOOTING ................................. 334

Auto-cruise Control Components Location ..........368

Auto-cruise Control

Related Harnesses

..........365

Check Chart

Check Chart

Circuit Diagram ................................

371input Checking................................

.

366

On-board Diagnostic Checking ......................

361Troubleshooting Quick-reference Chart

.

334

Troubleshooting Quick-reference Chart

ENGINE CONTROL...............................

.

328

ENGINE CONTROL ..................................

330

SERVICE ADJUSTMENT PROCEDURES .................329

Accelerator Cable inspectron and Adjustment

...........329

Accelerator Switch Inspection and Adjustment ..........329

SPECIFICATIONS ....................................

328

TROUBLESHOOTlNG................................

.

328

Accelerator

Cable and Accelerator Pedal .............

.

328

FUEL SYSTEM

FUEL FILTER .........................................

327

FUEL LINE AND VAPOR LINE

.

326

FUEL LINE AND VAPOR LINE

.

324

FUEL TANK

.

322

FUELTANK

.

318

GENERAL INFORMATION ............................ 196

ON-VEHICLE INSPECTION OF MFI

COMPONENTS

......251

Air Conditioning Switch and A/C Compressor Clutch Relay .....................................

285

Barometric Pressure Sensor .................... 266

Boost Meter

311Camshaft Position Sensor ........................

.

277Closed Throttle Position Switch

.....................

.

274

Component Location .............................

251Components Inspection Pocedure

................. 255

Crankshaft Position Sensor ..................... 280EGR

Solenord

...................

.

307EGR Temperature Sensor

.............

.

288Engrne Control Module Power Ground

................

.

257

Engine Coolant Temperature Sensor ..................

268Evaporative Emission Purge Solenoid .................

.

307

Fuel Pressure Solenoid

307Fuel Pressure Test...............................

.

312

Fuel Pump ...................................... 258

Heated Oxygen Sensor ............................ 290

Idle Air Control Motor (Stepper Motor) ................

238Ignition Coil and Ignition Power Transistor .............

.

302

Ignition Switch-ST .................................. 284

Ignition Switch-ST and Park/Neutral Position Switch .....284

Injectors .......................................

295Inspection of Engine Control Module Terminal

Voltage .......................................

.

315

Intake Air Temperature Sensor .......................263

Knock Sensor

Power Steering Pressure Switch ......................

284Power Supply and Ignition Switch ...................

.

255Resistor

..............................

.

298Terminal Voltage Check Chart

......................

.

315Throttle Position Sensor

..........................

.

270Turbocharger Waste Gate Solenoid

.........

.

309 Vehicle

Speed Sensor

............................... 284

Volume Air Flow Sensor ............................

261SERVICE ADJUSTMENT PROCEDURES ...............

.

245

Basic

idle Speed Adjustment .......................

.

245

Closed Throttle Position Switch (Fixed

SAS)Adjustment ......................................

.

250

Curb

Idle Speed Inspection

..........................245Throttle Body (Throttle Valve Area) Cleaning

...........

.

248Throttle Position Sensor Adjustment

..................

.

248

SPECIALTOOLS...................................

.

204

SPECIFICATIONS ...................................

201TROUBLESHOOTING ...............................

.

205

Check Engine/Malfunction Indicator Lamp ..............205

Circuit Diagram .................................... 214

Clear Memory of Diagnostic Trouble Code .............

211Explanation and Precaution Related to Harness

Checking ......................................

.

205Explanation of Troubleshooting Procedures

............

.

205Failsafe/Back-up Functions List

.....................

.

211Fuel tank and Fuel Line

............................

.

244

Read Out Diagnostic Trouble Code ...................

211Troubleshooting Table

.............................

.

208(CONTINUED ON NEXT PAGE)

Page 144 of 1273

13-2

FUEL SYSTEM

..........

FUEL FILTER ....................................

FUEL LINE AND VAPOR LINE .....................FUELTANK....................................

.

GENERAL INFORMATION ........................

ON-VEHICLE INSPECTION OF MFI

COMPONENTS . .

Air

Conditionrng Switch and A/C CompressorClutch Relay ......

.

.............

Barometric Pressure Sensor .........

Camshaft Position Sensor ...........

Closed Throttle Position Switch ...........

Component Location .............

Components

Inspectron Procedure .......

.

Crankshaft Positron Sensor ............

EGR Solenoid

. . .3. .

115..,.113

. 109

. . 3

. . . 38

83

536961384173101EGR Temperature Sensor

.

85

Enqine Control Module Power Ground ......

.

....

45

Engine Coolant Temperature Sensor ...............

55Evaporative Emission Purge Solenord..............

.

99

Fuel Pressure ...............................

102Fuel Pump

...................................

.

46

Idle Speed Control Motor (DC Motor) ................

.

93

Idle Speed Control Motor Positron Sensor ............

.

64

lgnitron Co11 and Ignition Power Transistor .........

.

96

Ignition Switch-ST ..........................

77Ignition Switch-ST and Park/Neutral Position Switch

...78

Injectors..................................

.

90

Inspection of

Engrne Control Module Terminal

Voltage .........

.

..........................

105Intake Air Temperature Sensor ..................

.

51Oxygen Sensor

............................

.

87Power Steering Pressure Switch

..................

.

81Power Supply

.........................

.

42

Terminal Voltage Check Chart ......................

106Throttle Positron Sensor.....................

.

57Vehicle Speed Sensor

.........................

.

80

Volume Air Flow Sensor .........................

49

SERVICE ADJUSTMENT PROCEDURES .................

32

Basic

Idle Speed Adjustment ...................

.

33

Curb Idle Speed Inspection ..........................

32Throttle Body (Throttle Valve Area) Cleaning........

.

35

Throttle Positron Sensor Adjustment ................

35

SPECIAL TOOLS 7

.................

...................

SPECIFICATIONS ....................................

5

TROUBLESHOOTING .................................

8

Check Engine/Malfunction Indicator Lamp ..............

10Crrcuit Diagram.................................

.

20

Clear Memory of Diagnostic Trouble Code ............

17Explanation and Precaution Related to HarnessChecking......................................

.

9Explanation of Troubleshooting Procedures

...........

.

8

Failsafe/Back-up Functions List ....................

16Fuel Tank and Fuel Lrne.........................

.

32Read Out of Diagnostic Trouble Code

...............

.

16Troubleshooting Table

.........................

.

13

FUEL SYSTEM

116

FUEL FILTER .......................................

195

FUEL LINE AND VAPOR LINE ........................

195

FUEL TANK ........................................ 195

GENERAL INFORMATION ............................

116

ON-VEHICLE INSPECTION OF MFI

COMPONENTS

Air Conditioning Switch and A/C Compressor Clutch Relay .............................

Barometric Pressure Sensor .................

Camshaft Position Sensor ....................

Closed Throttle Position Switch ................

Component Location .......................

Components Inspectron Pocedure

..............

Crankshaft Position Sensor .................

EGR Solenoid

EGR Temperature Sensor

Engine Control Module Power Ground ..........

Engine Coolant Temperature Sensor .............

Evaporative Emission Purge Solenoid ............

Fuel Pressure Test ...........................

Fuel Pump ..................................

IAC Valve Positon Sensor

......................

Idle Air Control Motor (DC Motor) ..............

lgnrtion Coil and Ignition Power Transistor

.......

.

Ignition Switch-ST ...........................

Ignition Switch-ST and Park/Neutral Position Switch

Injectors ....................................

Inspection of Engine Control Module Terminal

Voltage .....................................

Intake Air Temperature Sensor .................

Oxygen Sensor .............................

Power Steering Pressure

Swatch..............

.

Power Supply ...............................

Terminal Voltage Check Chart ..................

Throttle Position Sensor .......................

Vehicle Speed Sensor ......................... . . . . 139

176

154

165

16013914216

7

..,_ 191177146

155

189192

147

162

184

186

171172181

192152

179

175

143

192

157

173

Volume Air Flow Sensor ...........................

.

150

SERVICE ADJUSTMENT PROCEDURES

...............

.

133

Basic Idle Speed Adjustment 133

Closed Throttle Position Switch and Throttle Position

Sensor Adjustment .................................

136Curb Idle Speed Inspection

.........................

.

133Fixed SAS Adjustment

.............................

.

138Throttle Body (Throttle Valve Area) Cleaning

...........

.

136

SPECIAL TOOLS

...................................

.

119

SPECIFICATIONS 118

.... ..............................

TROUBLESHOOTING ..................

.............

119

Check Engine/Malfunction Indicator Lamp ..............

120Circuit Diagram...................................

.

128Clear Memory of Diagnostic Trouble Code

............

.

126Explanation and Precaution Related to Harness

Checking ........................................

.

119Explanation of Troubleshooting Procedures

............

.

119Failsafe/Back-up

Fuctions List

........................

126

Fuel Tank and Fuel Line .............................

133Read Out of Diagnostic Trouble Code ................

.

126

Troubleshooting Table ..............................

123

Page 145 of 1273

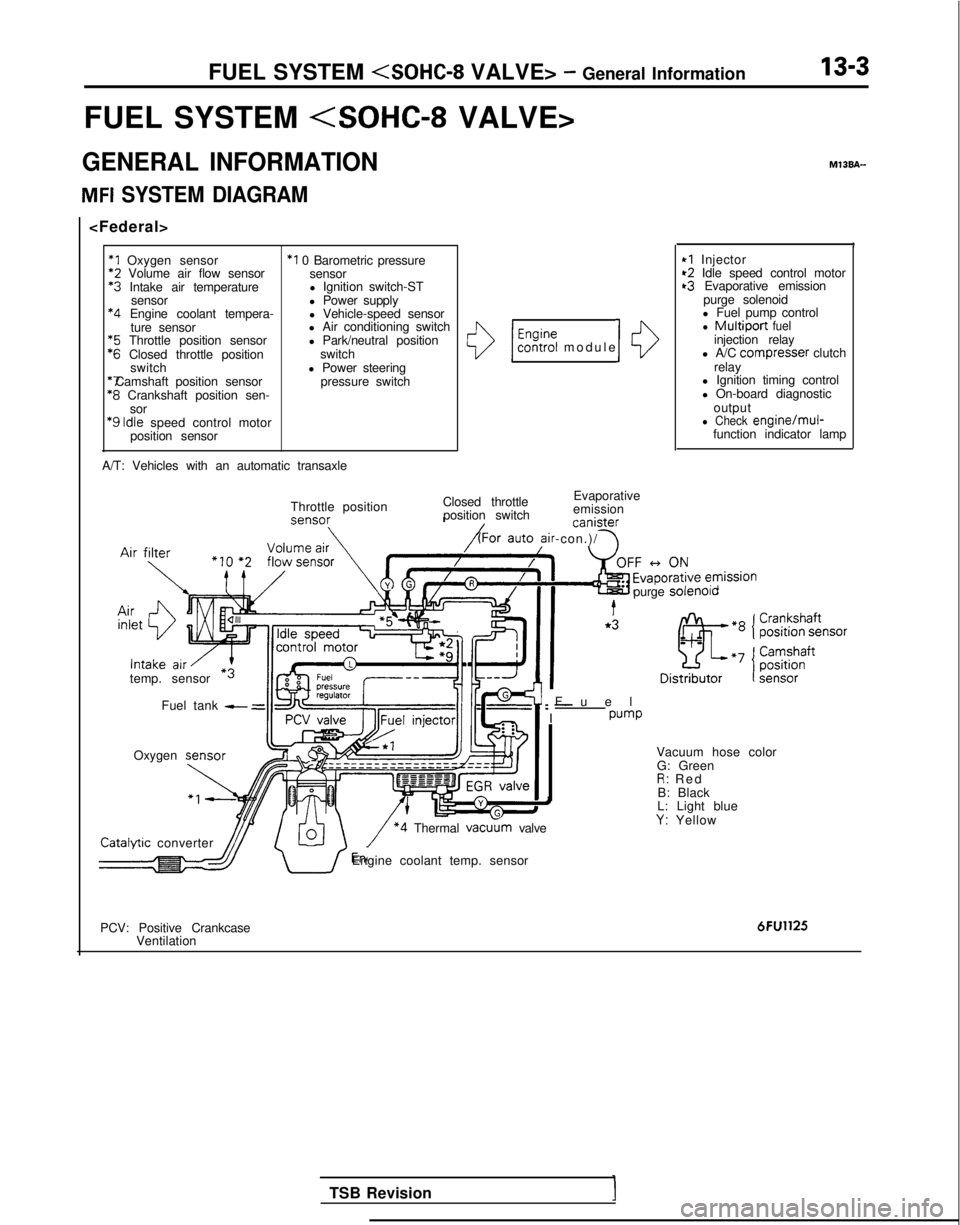

FUEL SYSTEM

FUEL SYSTEM

GENERAL INFORMATION

MFI SYSTEM DIAGRAM

*1 Oxygen sensor

*2

Volume air flow sensor *3

Intake air temperature

sensor *4

Engine coolant tempera-

ture sensor *5

Throttle position sensor *6

Closed throttle position

switch *7 Camshaft position sensor

*8

Crankshaft position sen-

sor

‘9 Idle

speed control motor

position sensor

*I 0 Barometric pressure sensor

l Ignition switch-ST

l Power supply

l Vehicle-speed sensor

l Air conditioning switch

l Park/neutral position

switch

l Power steering pressure switch

A/T: Vehicles with an automatic transaxle

()/ $%?i modul

e

Closed throttle Evaporative

position switch emission canister

ir-con.)/ \

10

Throttle position

temp. sensor Fuel tank

- =

Oxygen M13BA-

I

*I Injector~2 Idle speed control motort3 Evaporative emission

purge solenoid

l Fuel pump control

l Multiport fuelinjection relay

l A/C compresser clutch

relay

l Ignition timing control

l On-board diagnostic

output

l Check engine/mul-function indicator lamp

Fue

l

: -

I

pump

purge

solenolo Catalvtic

converter

\/ *4 Thermal vacu

G: Green

R: Re

d

B: Black

L: Light blue

Y: Yellow

dJJ/ U’Engine coolant temp. sensor

PCV: Positive Crankcase Ventilation

6FU1125

TSB Revision

Page 146 of 1273

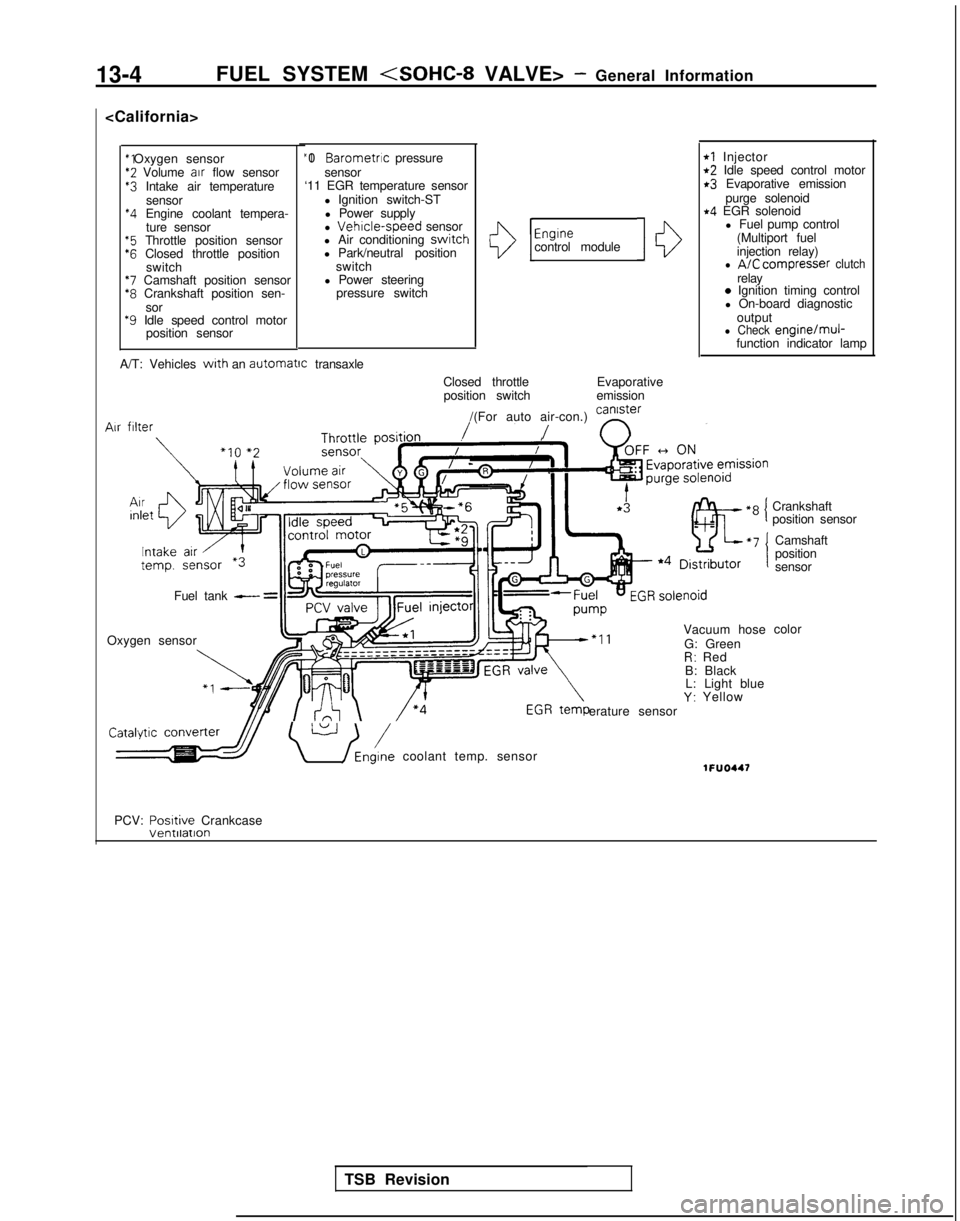

13-4FUEL SYSTEM

*2 Volume

air

flow sensor$3 Intake air temperature

sensor

*4 Engine coolant tempera-ture sensor

“5 Throttle position sensor‘6 Closed throttle position switch

*7 Camshaft position sensor*8 Crankshaft position sen-

sor

*9 Idle speed control motor position sensor “I 0

Barometric pressure

sensor

‘11 EGR temperature sensor

l Ignition switch-STl Power supply

l

Vehrcle-speed sensor

l Air conditioning switch

l Park/neutral position

switch

l Power steering pressure switchI13

Engrnecontrol module10

rl Injectort2 Idle speed control motorr3 Evaporative emission

purge solenoid

r4 EGR solenoidl Fuel pump control

(Multiport fuel

injection relay)

l A/C compresser clutchrelay0 Ignition timing control

l On-board diagnostic

output

l Check engine/muj-function indicator lamp

A/T: Vehicles

with an automatrc

transaxle

Closed throttleposition switch Evaporative

emission

/(For auto air-con.) can’ster

/ n

Vacuum hose

G: Green

R: Red

B: Black L: Light blue

Y: Yellow

erature sensor Air

filter

Fuel tank - =

Oxygen sensor

\ U /Eni coolant temp. sensor1FUO447

Crankshaft

position sensor

Camshaft

position

sensor

color

PCV: Posrtive

Crankcase

TSB Revision